Page 1

APG

True Echo

™

Guided Wave Radar Level Transmitter

User Manual

For the GWR200

R

Doc #9004784

Rev A, 05/2016

Page 2

Table of Contents

Introduction ................................................................................................................ iii

Warranty and Warranty Restrictions .................................................................... iv

Chapter 1: Specications and Options ....................................................................1

Dimensions ........................................................................................................................................1

Specications ...................................................................................................................................2

Model Number Congurator ......................................................................................................... 3

Wiring Diagram ................................................................................................................................ 4

Chapter 2: Installation and Removal Procedure and Notes ................................5

Tools Needed ....................................................................................................................................5

Installation Notes ............................................................................................................................ 5

Tensile Forces .................................................................................................................................. 5

Mounting Instructions .................................................................................................................. 6

Electrical Installation ....................................................................................................................6

Powering on the True Echo™ ......................................................................................................... 6

Software Installation ...................................................................................................................... 6

Removal Instrustions ..................................................................................................................... 7

Chapter 3: Communications and Programming .................................................... 7

True Echo™ Communication Tool ................................................................................................. 7

Setup ................................................................................................................................................... 7

Navigation Window Options ..........................................................................................................8

True Echo™ Communication Software Overview .................................................................9-12

Chapter 4: Maintenance ...........................................................................................13

General Care .................................................................................................................................... 13

Repair and Returns ........................................................................................................................ 13

ii

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Introduction

Thank you for purchasing a True Echo™ Guided Wave Radar level transmitter from APG. We appreciate your

business and your trust. Please take a few minutes to familiarize yourself with your True Echo™ and this

manual.

The True Echo™ GWR200 takes the mystery and frustration out of level measurement. With programmable

4-20 mA or RS-485 Modbus outputs, and innovative signal analysis, the True Echo™ can accurately measure

solids, liquids, and slurries at depths up to 80 feet. NEMA 6 housing is standard, and 316 SS or PFTE-coated

316 SS probes operate in process temperatures from -40° to 398° F. Robust and reliable, the True Echo™

makes dicult level measurements easy.

Reading your label

Every APG sensor comes with a label that includes the instrument’s model number, part number, and serial

number. Please ensure that the part number on your label matches your order.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

iii

Page 4

Warranty and Warranty Restrictions

This product is covered by APG’s waranty to be free from defects in material and workmanship under

normal use and service of the product for 24 months. For a full explanation of our Warranty, please visit

https://www.apgsensors.com/about-us/terms-conditions. Contact Technical Support to recieve a Return

Material Authorization before shipping your product back.

Scan the QR code below to read the full explanation of our Warranty on your tablet or smartphone.

iv

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 5

Chapter 1: Specications and Options

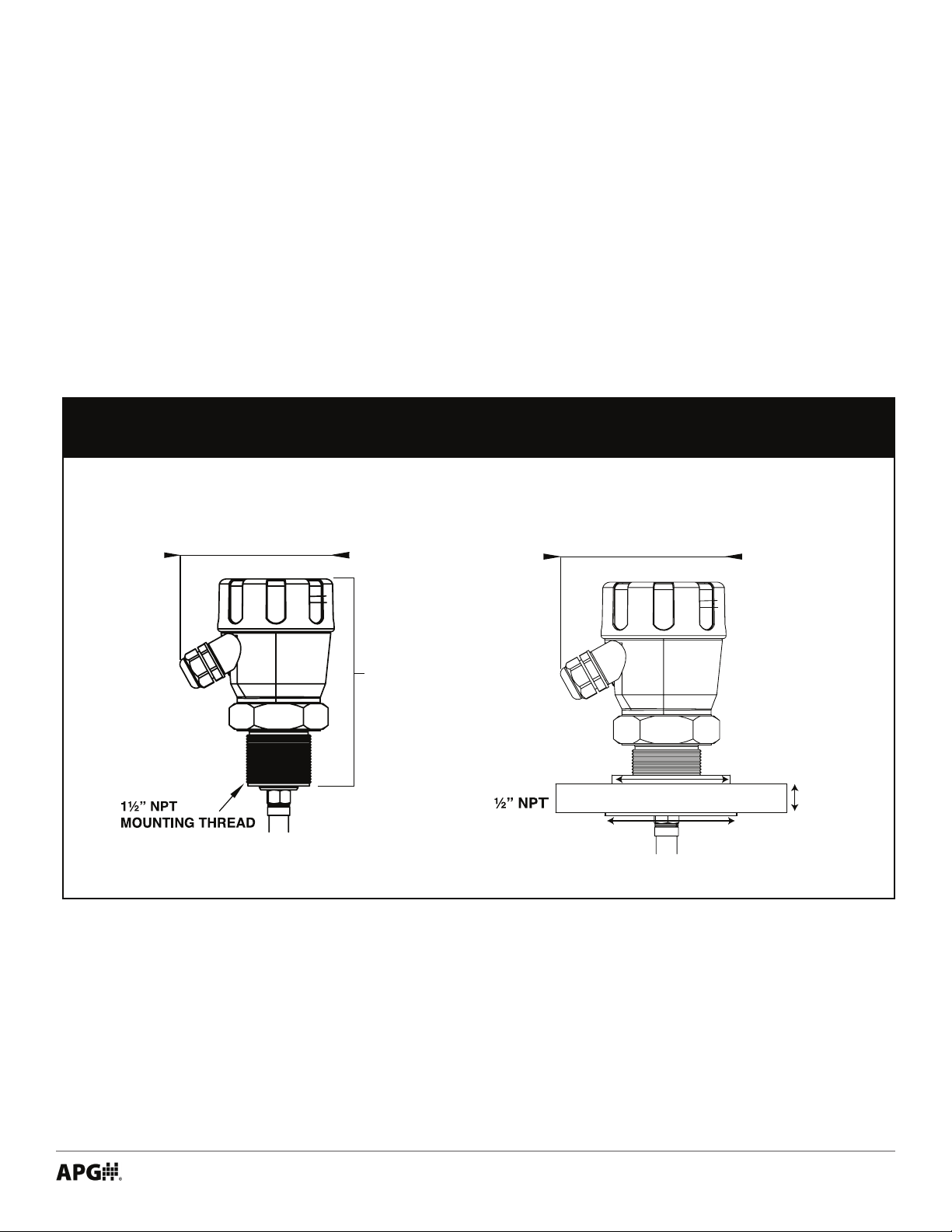

• Dimensions

NEMA 6 ENCLOSURE

Standard

4.3” (110mm) 4.3” (110mm)

6” (154mm)

Flange Option

2-9/16” (65mm)

7/8”

(22mm)

2-7/8” (73mm)

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

1

Page 6

• Specications

Performance

Measurement Range 1.25’ to 80’ with minimum dielectric constant of 0.3

Communications

Communications RS485 Modbus

Response Time 100 samples/sec/updated <100 millisec.

Electrical

Output 4-20mA, Isolated 4-20 mA

Loop Resistance 750 ohms (current loop 24VDC supply)

250 ohms (isolated 24 VDC supply)

Operating Voltage 12-30 VDC

Power Consumption <3W @ 24 VDC

Accuracy

Accuracy +/- 0.039” ( 1 mm) or 0.02% of measured distance,

whichever is greatest.

Repeatability +/- 0.02” (0.5mm)

Ambient Temp. Eect +/- 0.005”/K of measured value

Environmental

Maximum Operating Temperature Electronics: -40º to 158ºF (-40° to 70ºC)

Process/Probe: -40º to 398ºF (-40° to 203ºC)

Maximum Operating Pressure -14.50 PSI to 580 PS

Enclosure NEMA 6: Coated Epoxy Aluminum with IP67 Sealing

Materials of Construction

PFTE-coated 316 SS, 0.395” ø

Wire Cable Probe: 316 SS, 0.195” ø

PFTE-coated 316 SS, 0.34” ø

Weighted Assembly: 0.75” diameter

Tensile Load 4,270 lbs max

Probe Type/Diameter Rod Probe: 316 SS, 0.25” ø

Mounting

Process Connection/Type Standard: 1.50” MNPT

Option: 1.50” ANSI 150lb. Flange

Cable Entries (2) 1/2” NPT Conduit Entries

2

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

• Model Number Congurator

Model Number: GWR200 - ____ - _____ - _____ - _____ - _____ - _____ - _____

A B C D E F G

A. Wiring Option

□ 4 4-wire

B. Probe Type

□ R 316 SS Rod (120” max)

□ T 316 SS PTFE Coated Rod (120” max)

□ W Wire Cable (960” max)

□ X PTFE Coated Wire Cable (960” max)

C. Enclosure Rating

□ N6 NEMA 6

D. Process Connection

▲

□ 0

1.5” NPT

□ 1 1.5” ANSI 150# Flange

▲

This option is standard

E. Conduit Entries

▲

□ 1

Two 1/2” NPT

□ 2 Two Cable Glands

□ 3 One 1/2” NPT, One Cable Gland

F. Probe Length

□ ___ Probe Length in Inches (15” to 120” or 960”)

G. Options

▲

□ NN

None

□ 04 PTFE Isolation Gasket

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 8

• Wiring Diagram

Isolated 4-20 mA Circuit

True Echo

Terminals

4-20mA-

4-20mA+

IS+

4

Comm A

Comm B

DC In +

DC In -

9

10

Isolated 4-20mA Output

TX A-

TX B+

Modbus

Network Node

TX A-

TX B+

4-20 mA

CURRENT

LOOP

Supply Voltage

Note: Modbus Network connection

is seperate from supply voltage and

4-20 mA output.

Process

Controller

DC Gnd

R

L

+

DC Gnd

4

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 9

Chapter 2: Installation and Removal Procedures and Notes

• Tools Needed

• Appropriately sized wrenches for sensor installation and for probe connection

• Flathead screwdriver for wire connections

• Installation Notes

The True Echo™ GWR200 should be installed in an area--indoors or outdoors--which meets the following

conditions:

• Ambient temperature between -40º to 158ºF (-40° to 70ºC)

• Ample space for maintenance and inspection

Additional care must be taken to ensure:

• The probe is securely fastened to the sensor prior to installing the sensor on the tank or vessel

• The sensor is mounted away from tank or vessel walls and inlets

• The probe is free from obstructions such as inows and agitators

• The sensor threading is started by hand to avoid cross-threading

NOTE: Do not mount the sensor where the probe will interact with objects such as ll

streams, pipes, ladder rungs, outlet ow, or agitators.

• Tensile Forces

Tensile forces are heavily dependent on the viscosity and abrasive characteristics of the product in the

vessel. Ensure the tensile loading is appropriate for the silo cover and mounting structure. The maximum

tensile load of the cable probe is 4,275 pounds.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

5

Page 10

• Mounting Instructions

Mounting your True Echo™ GWR200 is easy if you follow a few simple steps:

• Securely connect probe to sensor head prior to mounting sensor.

• Carefully feed probe through mounting hole

• Ensure that probe hangs free from obstructions

• Begin threading sensor NPT connection by hand

• Finish with wrench as necessary

• Electrical Installation

• Remove the screw-on lid of the True Echo™.

• Feed the cable(s) into the True Echo™ via the 1/2” NPT or cable glands.

• Attach the wires of your control system to the True Echo™ terminal block according to the pinout table

on page 4.

• Replace the screw-on lid.

• Powering the True Echo™ for the First Time

1) Conrm the True Echo™ is mounted within the recommended specications.

2) Conrm the wiring is correct and all connections are as shown in page 4.

3) Apply power to the True Echo™.

4) The True Echo™ will take up to 30 seconds to warm up and stabilize upon initial startup. It will then perform a scan to locate the level which will take approximately 1 second or less. Once the load sequence is

complete and the True Echo™ has taken the rst measurement scan, the analog output should indicate the

material level (factory default) or distance measurement. If the proper analog output is not achieved please

contact the factory for further instructions.

• Software Installation

• Download True Echo™ Software and windows driver ziple from https://www.apgsensors.com/support.

• Open the zip le.

• Choose “Install” from the options at the top of the zip le window.

• The software will create True Echo.exe which will run from a folder in your Start Menu titled “APG”.

6

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 11

• Removal Instructions

• Ensure that power to the sensor is o.

• Remove screw-on lid, disconnect wires and remove cable(s). Replace lid.

• Carefully unscrew sensor from mounting.

• Lift sensor from tank and carefully back probe out of tank.

• Remove the sensor and store it in a dry place, at a temperature between -40° F and 158° F.

Chapter 3: Communications and Programming

• True Echo™ Communication Tool

The True Echo™ Communication Tool can be used in tandem with the APG True

Echo™ Software to program and control your True Echo™ Level Transmitter.

Through the True Echo™ Software, you can monitor the raw readings from the

sensor, or congure multiple sensors.

• Setup

Connect the True Echo™ Communication Tool to the Modbus Network Terminals shown on page 4. Connect

A on the True Echo™ Communication Tool to Comm A (TX A-) and B to Comm B (TX B+).

Connect the USB side of the True Echo™ Communication Tool to a USB port on your PC.

Double click the True Echo™ icon on your desktop or in your Start Menu.

The Navigation Window

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

7

Page 12

• Navigation Window Options

MENU SELECTION DESCRIPTION OPTIONS

File Load and save custom application settings Load / Save current setting

Load Application setting

View Adjust view settings, access options menu Toolbar

Status Bar

Options

™

Help Access Help le & display True Echo

version info Help

About

Connect Attempts to open communication or terminate

communication with unit

DeviceID Select DeviceID (if using comms networked units with

unique IDs assigned)

Setup When connected the setup menus will be listed under

the arrow button to the right

Diag When connected this opens the Diagnostic window

where you can view live echo proles and operational

diagnostics and measurements.

NewView If you have multiple True Echo

™

units connected to a

single network you can view the basic measurement

Flash For updating unit software. This button is locked

Connect

Disconnect

Adjustable via Client

Information in ‘Options’ menu

Info Screen

Quick Set

Output Adjust

Advanced

Report This button can generate a PDF report of the current

settings & serial numbers of the unit or view the settings

of a stored report

8

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Preview current setup

Preview stored setup

Page 13

• True Echo™ Communication Software Overview

The True Echo™ Software is included with the Communication Tool for easy setup and diagnostics of

the True Echo™. This tool will allow the user interface into the programming, setup and diagnostics tools

imbedded within the True Echo™ program. The True Echo™ GWR Level Transmitter has advanced auto-tuning

parameters that adjust the unit’ s sensitivity (to changing dielectric, mounting and obstructions) and gain

settings so the user does not have to preform any initial startup settings. Please contact the factory if there

is a requirement or question regarding the True Echo™ Communication Software.

Fig. 1) The Diagnostics Menu allows the user to see how the return echo is preforming and make

adjustments to the measurement signal.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

9

Page 14

Fig. 2) The Tank View Menu allows the user to view their application activity.

The Quickset menu (g 3) is found on the dropdown arrow

of the Setup button. The Quickset menu contains the basic

parameters required to get the unit up and running. It is one

of the three main menu options in the internal software. The

menu will provide elds which the user can edit by clicking in

the eld and re-entering the correct value.

Low Level (ft): Enter the distance in feet between the

connection point of the True Echo™ and the end of the probe.

Hi Level (ft): Enter the distance in feet between the

connection point of the True Echo™ and the highest point of

level (must be at least 1.1ft)

Fail Safe: Enter a set failsafe output from the dropdown box.

Fail Safe Time: Enter the amount of time (in seconds) the

unit will wait in a fail mode (set countdown clock) before

outputting a fail mode set milliamp value.

Fig. 3) The Quick Setup Menu sets the

application base parameters.

Fill Speed: Select the applications ll speed

Read All Parameters

Green Cell

Red Cell

10

To refresh any menu

Damp Fill: Select the amount of dampening upon tank lling

for stable reading

Read / write successful

Read / write failed

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 15

Empty Speed: Select the applications empty speed

Damp Empty: Select the amount of dampening upon tank empty for stable reading

DispMode: Select the default display mode in; Space, Material Level or % of Material

Lock Code: Enter in a pass code number from 0 to 200

Fig. 4) Info Screen with device information

Advanced parameters are for adjusting primary sensitivity,

echo controls and lters and executing the auto

calibration routines as well as factory resets.

Digital Bias (%): Sets the amount of digital signal and

sensitivity to mapping range. The higher the percentage

increases the digital bias or lter. This parameter is auto

set and typically does not require adjustment, but can be

manually set.

Gain (%): Increase or decrease the amplication of

the signal detected by the Sensitivity routines and

adjustments. This parameter is auto set and typically does

not require adjustment.

Sens Max (%): Adjust the peak Sensitivity cap. This value

will be auto set by the Digitize calibration routine.

Sensitivity: The primary adjustment for the unit to detect

level accurately. This value is auto set by the Digitize

calibration routine but can be manually adjusted.

Fig. 5) The Advanced Setup Menu allows the user to

ne tune the measurement signal and preform a

Digitze TDR command for auto tuning in the aplication

Echo Size (V): Sets the target echo size that the unit is

attempting to maintain. Any signal which is detected by the Sensitivity setting will be either full signal (2.5V)

or less. If the signal detected by Sensitivity is less than Echo Size, than the unit uses gain to amplify the signal

to the Echo Size.

Threshold (V): Adjust the amount of lter which tells the unit to ignore any echoes of a signal size less than

this value (in Volts). This can be used a part of troubleshooting (see Troubleshooting false echo elimination).

Blanking (ft): Blanking is the non-measurable zone closest to the process connection. This can be increased

to “Blank” out high false echoes caused by mounting.

Digitize TDR: Perform auto-Digitization of sensitivity based on mounting, tank obstructions and dielectric of

material touching the probe.

Probe Reset: Restores probe settings back to factory default. Most probe settings are in the Advanced Setup

Menu.

Cal. Mount: Performs a digital mapping routine of a user selected span. Used when there is signal

interference at high level or mounting.

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

11

Page 16

Fig. 4) Factory Menu

12

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 17

Chapter 4: Maintenance

• General Care

Your level sensor is very low maintenance and will need little care as long as it was installed correctly.

However, in general, you should periodically inspect your True Echo™ GWR200 sensor to ensure the probe is

free of any buildup that might impede the function of the sensor. If sediment or other foreign matter builds

up on the probe, detection errors can occur.

If you need to remove the sensor, be sure to store it in a dry place at a temperature between -40° and 158°

F.

• Repair and Returns

If your True Echo™ GWR200 needs repair, contact us via email, phone, or online chat on our website. We will

issue you an RMA number with instructions.

• Phone: 888-525-7300

• Email: sales@apgsensors.com

• Online chat at www.apgsensors.com

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

13

Page 18

APG

R

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Automation Products Group, Inc.

Loading...

Loading...