Page 1

PRODUCTS

AUTOMATION

Operator’s Manual

GROUP, INC.

FLE

Series

Magnetic Float Sensors

Rev. A3, 10/08

Doc. 9002273

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • E-mail: sales@apgsensors.com

Automation Products Group, Inc.

Page 2

FLE Series Rev. A3, 10/08

Table of Contents

Warranty ......................................................................................... 3

Description...................................................................................... 4

Installation ................................................................................... 5-6

Wiring.............................................................................................. 7

Circuit Protection ........................................................................... 8

Inspection & Maintenance .............................................................. 9

Technical Notes............................................................................... 9

Specifications ................................................................................ 10

Automation Products Group, Inc.

2

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 3

Rev. A3, 10/08 FLE Series

• Warranty and Warranty Restrictions

APG warrants its products to be free from defects of material and workmanship

and will, without charge, replace or repair any equipment found defective upon

inspection at its factory, provided the equipment has been returned,

transportation prepaid, within 24 months from date of shipment from factory .

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER

EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHER WISE

INCLUDING BUT NOT LIMITED T O ANY IMPLIED WARRANTIES OF

MERCHANT ABILITY OR FITNESS FOR A P AR TICULAR PURPOSE.

No representation or warranty, express or implied, made by any sales

representative, distributor, or other agent or representative of APG which is not

specifically set forth herein shall be binding upon APG. APG shall not be liable

for any incidental or consequential damages, losses or expenses directly or

indirectly arising from the sale, handling, improper application or use of the

goods or from any other cause relating thereto and APG’s liability hereunder, in

any case, is expressly limited to the repair or replacement (at APG’s option) of

goods.

Warranty is specifically at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard field service rates.

All associated equipment must be protected by properly rated electronic/

electrical protection devices. APG shall not be liable for any damage due to

improper engineering or installation by the purchaser or third parties. Proper

installation, operation and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authorization (RMA) number which must appear on

all related papers and the outside of the shipping carton. All returns are subject

to the final review by APG. Returns are subject to restocking charges as

determined by APG’s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

3

Page 4

FLE Series Rev. A3, 10/08

• Description

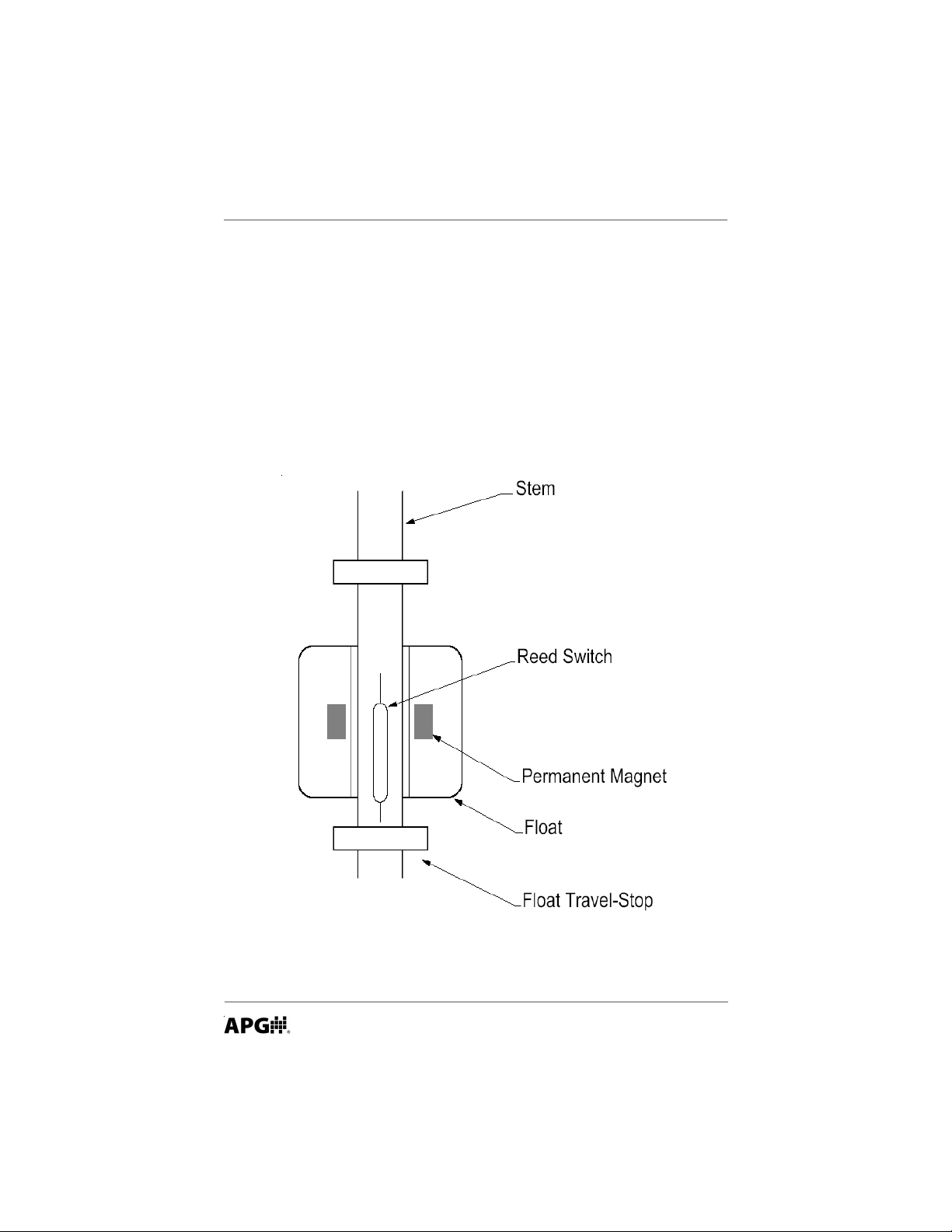

The FLE series instruments contain reed switches in the stem and permanent

magnets in the floats. As the float rises or falls with the level of the liquid, the

magnet inside the float act on the reed switch inside the stem to provide the

SPST switching action.

Automation Products Group, Inc.

4

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 5

Rev. A3, 10/08 FLE Series

• Installation

- Unpacking -

When unpacking the instrument, exercise care not to subject the instrument to

mechanical shock. After unpacking, visually inspect the instrument for

damage.

- Environment -

The FLE series sensors should be installed in an area which meets the following

conditions:

1. Non-hazardous area.

2. The medium temperature does not exceed -140F to 1850F (-100C to 850C).

3. Locate the sensor away from strong magnetic fields such as those produced

by motors, transformers, solenoid valves, etc.

4. The medium is free from metallic substances and other foreign matter .

5. No corrosive gases such as NH3, SO2, Cl2, etc.

6. No excessive vibration

7. Ample space for maintenance and inspection.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

5

Page 6

FLE Series Rev. A3, 10/08

• Installation

- Location -

Do not locate the FLE series sensor near inlets/outlets.

If there is surface wave action, then use a time-delay relay or stilling tube. If a

stilling tube is used, drill vent holes in the tube and use a centering spacer on

the bottom of the stem to assure the float has free travel inside the tube.

Wave action may cause switch to chatter. Use a stilling tube or time-delay

relay to prevent switch chatter.

- Mounting -

The FLE can be mounted up to 300 from vertical.

1. Flange Mounting

Provide the compatible mating flange on the tank and install using a suitable

gasket.

2. Plug Mounting

Provide the compatible female boss on the tank and install the FLE with a

suitable gasket, O-ring, or thread tape.

Automation Products Group, Inc.

6

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 7

Rev. A3, 10/08 FLE Series

• Wiring

- Wiring for 1 to 3 switches

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

7

Page 8

FLE Series Rev. A3, 10/08

L

C

R

E

C = I

R = Approx.

10 x I (I + 50/E)

E

Protecting Circuit Using CRProtecting Circuit Using Varistor

Protecting Circuit Using Diode

2

/10 (uF)

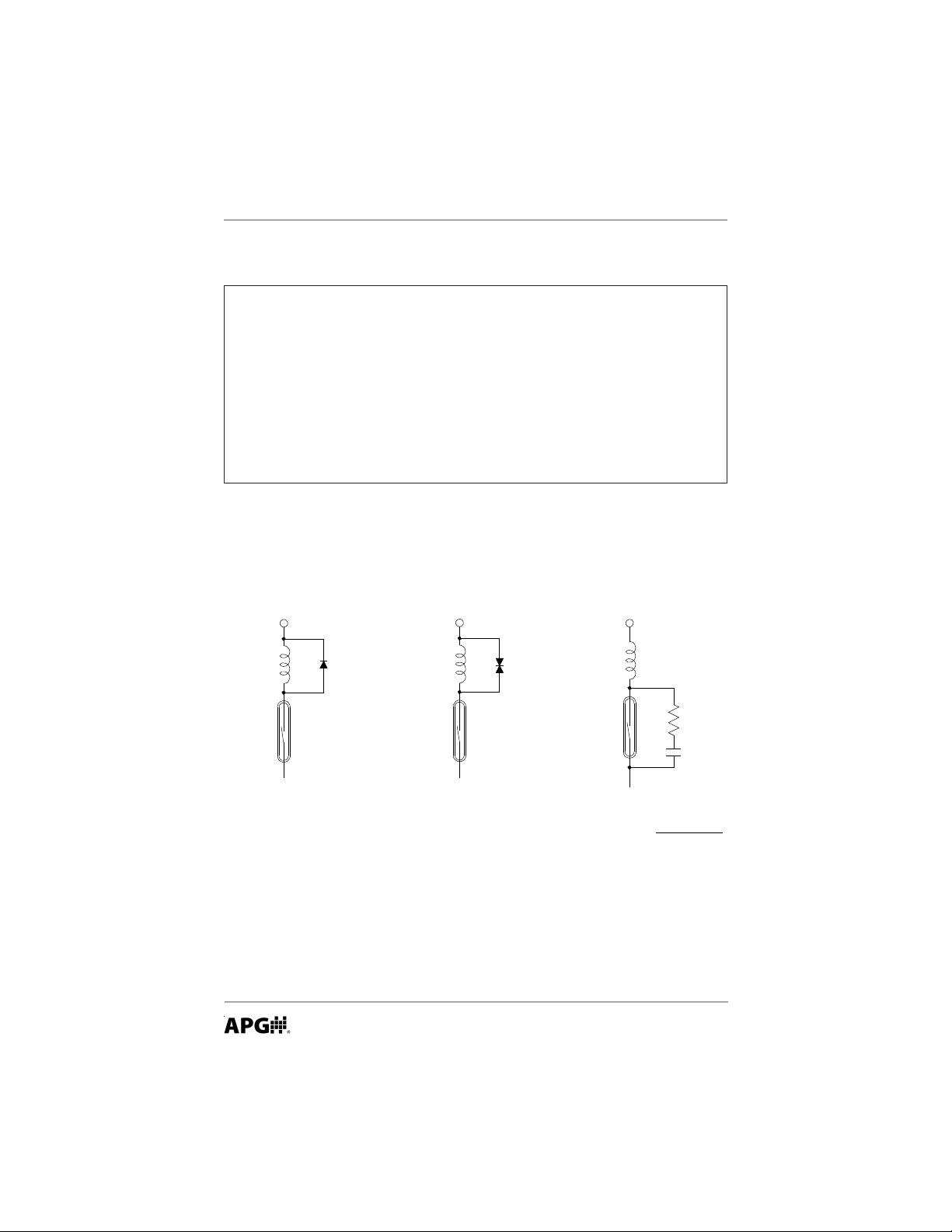

• Circuit Protection

W ARNING!

DO NOT EXCEED CONT ACT RA TINGS! When an inductive load is

used (e.g. a motor, a coil, or an electromagnetic relay), a back

electromotive force of several hundred volts (energy stored in the

inductance) arises when the contacts are opened. This results in

considerable decrease in contact life. The same result arises even

when a resistive load is used with a high voltage or a large current. The

figures below show circuits for protecting the reed switch(s) from the

back electromotive force.

Switch Code A Code B

Max. contact capacity 20 VA 50 VA

Max. switching current 0.5A AC 0.5 A AC

Max. Voltage 220 VAC 220 VAC

Automation Products Group, Inc.

8

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 9

Rev. A3, 10/08 FLE Series

• Inspection and Maintenance

Periodic inspection is necessary to keep your FLE unit in good working

order.

CAUTION! Do not remove the housing cover until the power

supplied to the unit is turned off.

Keep the sensor clean.

Never leave the housing cover off (for units equipted with a housing).

If the cover becomes damaged or is misplaced, order a replacement

immediately .

If sediment or other foreign matter is trapped between the stem

and the float, detection errors may be caused. Keep the float and

stem clean.

• Technical Notes

1. The float travel stop settings are based on how the magnetic field

influences the reed switch. Normally it is not necessary to move the

stop. If the stops are moved, check the switch action for float overrun.

2. Normally Open (NO) (switch closes as level rises) and Normally Closed

(NC) (switch closes as level falls).

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

9

Page 10

FLE Series Rev. A3, 10/08

• FLE Specifications

Maximum Number Switching Points 3

Resolution +/- 1/16” (2mm)

Field Adjustable Actuation Levels No

Maximum Length 48 in.

Maximum Process Temperature -140 to 1850 F

(-100 to 850 C)

Housing Material (optional)

Aluminium (IP68, NEMA 4X),

St ainless S teel ((NEMA 4X)

Nylon (IP 65)

Hazardous Rating None

Contact Rating:

Switch Code A Code B

Max. contact capacity 20 VA 50 VA

Max. switching current 0.5A AC 0.5 A AC

Max. Voltage 220 VAC 220 VAC

Automation Products Group, Inc.

10

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 11

Rev. A3, 10/08 FLE Series

Notes

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www .apgsensors.com • sales@apgsensors.com

11

Page 12

AUTOMATION

APG...Providing tailored solutions

for measurement applications

Automation Products Group, Inc.

T el: 1/888/525-7300

Fax: 1/435/753-7490

e-mail: sales@apgsensors.com

www.apgsensors.com

GROUP, INC.

1/435/753-7300

PRODUCTS

Automation Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

Loading...

Loading...