Page 1

Din Mounted Digital Display

Instruction Manual

®

Digital Panel Meter

• 0-20 mA, 4-20 mA, 0-5 V, 1-5 V, and ±10 V Inputs

• Multi-Pump Alternation Control

• Display One Input in Two Different Scales (e.g. Height & Volume)

• Signal Input Conditioning for Flow & Round Horizontal Tank

• 32-Point, Square Root, or Exponential Linearization

• Dual-Line Display

• NEMA 4X and IP65 Rated Front Panel

• UL Listed & CE Marked

• Display Features 0.6" & 0.46" Digits

• Six Full Digits on Each Line

• Optional Superluminous Sunlight Readable Display

• Free USB Programming Software & Cable

• 2 or 4 Relays + Isolated 4-20 mA Output Options

• USB, RS-232, & RS-485 Serial Communication Options

• External 4-Relay & Digital I/O Expansion Modules

• Input Power Options Include 85-265 VAC or 12-24 VDC

• Isolated 24 VDC @ 200 mA Transmitter Power Supply

• Modbus® RTU Communication Protocol Standard

Automation Products Group

1025 W 1700 N • Logan UT 84321 USA

Tel (435) 753-7300 • Fax (435) 753-7490

www.apgsensors.com

Page 2

Din Mounted Digital Display Instruction Manual

CAUTION: Read complete

instructions prior to

installation and operation

of the meter.

WARNING: Risk of

electric shock or

personal injury.

Warning!

This product is not recommended for life support

applications or applications where malfunctioning could

result in personal injury or property loss. Anyone using this

product for such applications does so at his/her own risk.

Automation Products Group, Inc. shall not be held liable for

damages resulting from such improper use.

!

Disclaimer

The information contained in this document is subject to change without notice.

Automation Products Group makes no representations or warranties with respect to

the contents hereof and specifically disclaims any implied warranties of

merchantability or fitness for a particular purpose.

Limited Warranty

Automation Products Group, Inc. warrants this product against defects in material or

workmanship for the specified period under “Specifications” from the date of

shipment from the factory. Automation Products Group’s liability under this limited

warranty shall not exceed the purchase value, repair, or replacement of the defective

unit.

Registered Trademarks

Modbus® is a Registered Trademark of Schneider Automation Inc. All other

trademarks mentioned in this document are the property of their respective owners.

© 2018 Automation Products Group, Inc. All rights reserved.

www.apgsensors.com

2

Page 3

Din Mounted Digital Display Instruction Manual

Table of Contents

Table of Contents ----------------------------------------- 3

Table of Figures ------------------------------------------- 4

Introduction ------------------------------------------------- 4

Ordering Information ------------------------------------ 5

Specifications ---------------------------------------------- 6

General --------------------------------------------------------------- 6

Process Input ------------------------------------------------------- 6

Relays ----------------------------------------------------------------- 7

Isolated 4-20 mA Transmitter Output ----------------------- 7

Modbus® RTU Serial Communications -------------------- 7

MeterView Pro ------------------------------------------------------ 7

Compliance Information -------------------------------- 8

Safety------------------------------------------------------------------ 8

Electromagnetic Compatibility ------------------------------- 8

Safety Information ---------------------------------------- 9

Installation -------------------------------------------------- 9

Unpacking ----------------------------------------------------------- 9

Panel Mounting Instructions ---------------------------------- 9

Mounting Dimensions ----------------------------------------- 10

Transmitter Supply Voltage Selection (P+, P-) -------- 10

Connections ------------------------------------------------------ 11

Connectors Labeling ------------------------------------------ 11

Power Connections-------------------------------------------- 11

Signal Connections -------------------------------------------- 12

Modbus RTU Serial Communications -------------------- 13

Relay Connections -------------------------------------------- 13

Switching Inductive Loads ----------------------------------- 13

F4 Digital Input Connections -------------------------------- 14

4-20 mA Output Connections ------------------------------- 14

Analog Output Transmitter Power Supply --------------- 14

External Relays & Digital I/O Connections -------------- 15

Interlock Relay Feature--------------------------------------- 15

Setup and Programming------------------------------ 16

Overview ----------------------------------------------------------- 16

Front Panel Buttons and Status LED Indicators ------ 16

MeterView® Pro Software ------------------------------------- 17

MeterView Pro Installation ----------------------------------- 17

Display Functions & Messages----------------------------- 18

Main Menu --------------------------------------------------------- 19

Setting Numeric Values --------------------------------------- 19

Setting Up the Meter (setup) -------------------------------- 20

Setting the Input Signal (Input) --------------------------- 20

Setting the Input Units or Custom Tags (units) ------- 21

Setting the Decimal Point (dEc pt) ----------------------- 21

Programming the Meter (prog) ----------------------------- 22

Setting the Display Parameter & Intensity (dsplay) -- 25

Setting the Relay Operation (relay) ---------------------- 26

Setting the Relay Action ------------------------------------- 26

Programming Set and Reset Points----------------------- 26

Setting Fail-Safe Operation --------------------------------- 27

Programming Time Delay------------------------------------ 27

Relay Action for Loss of 4-20 mA Input (Loop Break) 27

Relay and Alarm Operation Diagrams ------------------- 27

High Alarm Operation (Set > Reset) ---------------------- 27

Low Alarm Operation (Set < Reset)----------------------- 27

High Alarm with Fail-Safe Operation (Set > Reset) --- 28

Low Alarm with Fail-Safe Operation (Set < Reset) ---- 28

Pump Alternation Control Operation ---------------------- 29

Relay Sampling Operation ---------------------------------- 29

Signal Loss or Loop Break Relay Operation ------------ 30

Time Delay Operation ---------------------------------------- 30

Relay Operation Details --------------------------------------- 31

Overview --------------------------------------------------------- 31

Relays Auto Initialization ------------------------------------- 31

Fail-Safe Operation ------------------------------------------- 31

Front Panel LEDs ---------------------------------------------- 31

Latching and Non-Latching Relay Operation ----------- 32

Non-Latching Relay (Auto)---------------------------------- 32

Non-Latching Relay (A-man) ----------------------------- 32

Latching Relay (LatcH) -------------------------------------- 32

Latching Relay (Lt-Clr) ------------------------------------- 32

Acknowledging Relays --------------------------------------- 33

Pump Alternation Control Applications (Altern) ------ 33

Setting Up the Interlock Relay (Force On) Feature --- 35

Scaling the 4-20 mA Analog Output (Aout) ------------- 35

Reset Menu (reset) -------------------------------------------- 36

Control Menu (Contrl) ---------------------------------------- 36

Setting Up the Password (pass)---------------------------- 36

Protecting or Locking the Meter ---------------------------- 36

Making Changes to a Password Protected Meter ----- 37

Disabling Password Protection ----------------------------- 37

Advanced Features Menu ------------------------------------ 38

Advanced Features Menu & Display Messages ------- 38

Noise Filter (filter) ----------------------------------------- 39

Noise Filter Bypass (bypass) ------------------------------- 39

Rounding Feature (round) ---------------------------------- 39

Modbus RTU Serial Communications (serial) ------- 40

Select Menu (SElect) ---------------------------------------- 40

Signal Input Conditioning (Functn) ----------------------- 41

Low-Flow Cutoff (CutofF) ----------------------------------- 42

Analog Output Programming (AoutPr) ------------------- 42

Programmable Function Keys User Menu (user) ----- 42

Tare (tare) ------------------------------------------------------ 43

Internal Source Calibration (ICAL) ------------------------ 44

Meter Operation ------------------------------------------ 45

Front Panel Buttons Operation ----------------------------- 45

Function Keys Operation ------------------------------------- 45

F4 Operation ------------------------------------------------------ 45

Maximum/Minimum Readings ------------------------------ 45

Troubleshooting ----------------------------------------- 46

Diagnostics Menu (diag) ------------------------------------- 46

Determining Software Version ----------------------------- 46

Reset Meter to Factory Defaults --------------------------- 46

Factory Defaults & User Settings -------------------------- 47

Troubleshooting Tips ------------------------------------------ 48

EU Declaration of Conformity ----------------------- 49

3

Page 4

Din Mounted Digital Display Instruction Manual

Table of Figures

Figure 1. 1/8 DIN Panel Cutout Dimensions ................... 9

Figure 2. Panel Mounting Details .................................... 9

Figure 3. Meter Dimensions - Side View ....................... 10

Figure 4. Meter Dimensions - Top View ........................ 10

Figure 5. Transmitter Supply Voltage Selection ............ 10

Figure 6. Connector Labeling for Fully Loaded Meter ... 11

Figure 7. Power Connections ........................................ 11

Figure 8. Transmitters Powered by Internal Supply ...... 12

Figure 9. Transmitter Powered by Ext. Supply or Self-

Powered ................................................................ 12

Figure 10. Voltage Input Connections ........................... 12

Figure 11. Relay Connections ........................................ 13

Figure 12. AC and DC Loads Protection ........................ 13

Figure 13. Low Voltage DC Loads Protection ................ 13

Figure 14. F4 Digital Input Connections ......................... 14

Figure 15. 4-20 mA Output Connections........................ 14

Figure 16. Expansion Modules & DIN Rail Mounting Kit 15

Figure 17. External Relays Module Connections ........... 15

Figure 18. Digital I/O Module Connections .................... 15

Figure 19. Interlock Connections ................................... 15

Figure 20. Acknowledge Relays w/Function Key or Digital

Input ....................................................................... 33

Introduction

This analog input process meter is a multi-purpose, easy-to-use digital process meter ideal for

level, flow rate, temperature, or pressure transmitter applications. Its superluminous LED digits

make it easily readable in smoke, dust, fog, and, with the optional sunlight readable display,

even direct sunlight. It accepts current and voltage signals (e.g. 4-20 mA, 0-10 V). Three of the

front panel buttons can be custom-programmed for a specific operation. The analog input can

be scaled to display the process in two different scales; for example, the main display could

indicate level in feet and the second display could indicate the volume in gallons.

The basic model includes an isolated 24 VDC transmitter power supply that can be used to

power the input transmitter or other devices. An additional isolated 24 VDC power supply is

included with the 4-20 mA output option. A digital input is standard.

A fully loaded meter has the following: four SPDT relays, 4-20 mA output, and two 24 VDC power

supplies. The meter’s capabilities may be enhanced by adding the following external expansion

modules: four SPST relays (creating an eight-relay process meter), two digital I/O modules with

four inputs and four outputs each, and USB, RS-232 or RS-485 communication adapters.

The eight relays can be used for alarm indication or process control applications such as pump

alternation control. The 4-20 mA isolated output, Modbus RTU serial communications, and digital

I/O options make this meter an excellent addition to any system.

4

Page 5

Din Mounted Digital Display Instruction Manual

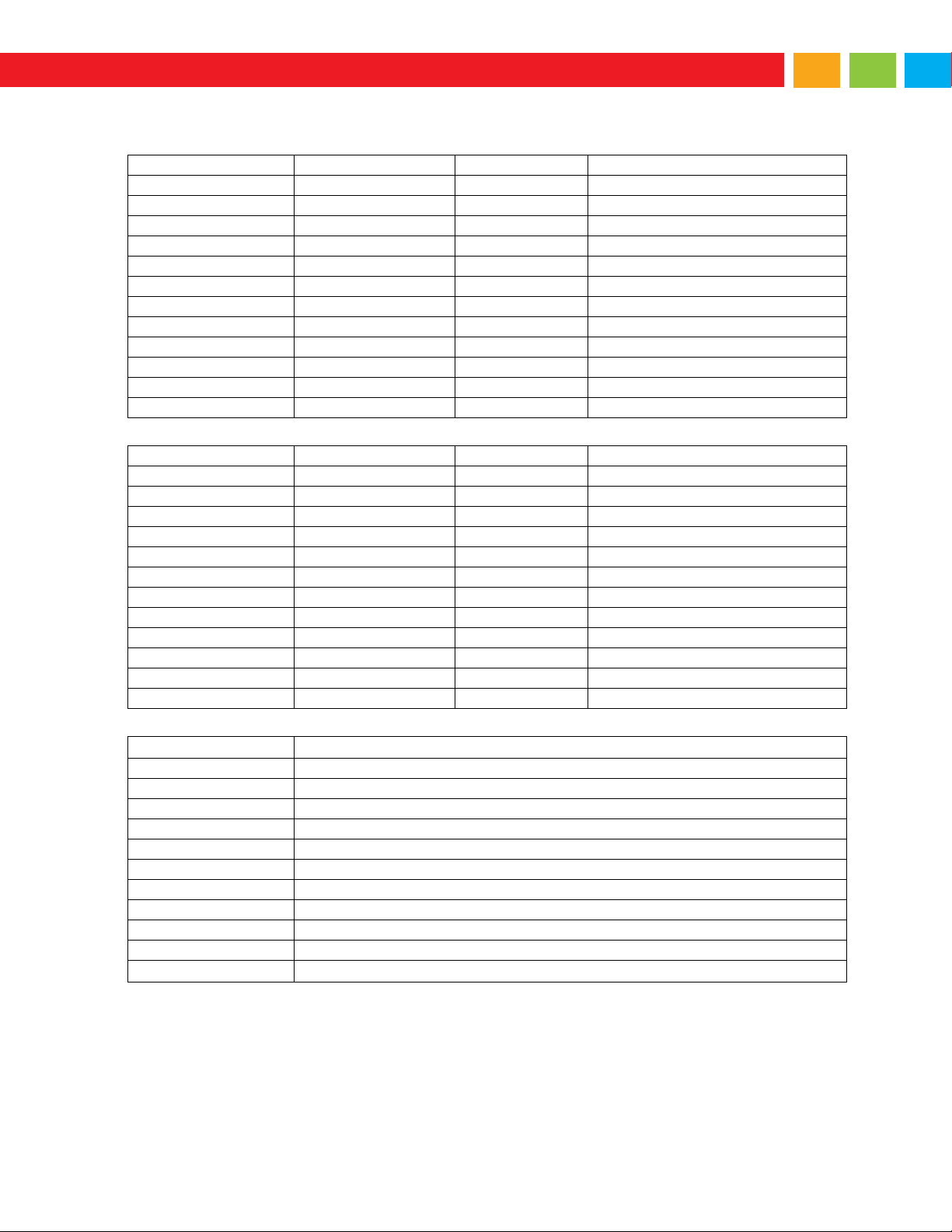

Model Number

Reorder Number

Power

Options

PD6000-6R0-AP

DDD-A00

85-265 VAC

No options

PD6000-6R2-AP

DDD-A02

85-265 VAC

2 relays

PD6000-6R3-AP

DDD-A10

85-265 VAC

4-20 mA output

PD6000-6R4-AP

DDD-A04

85-265 VAC

4 relays

PD6000-6R5-AP

DDD-A12

85-265 VAC

2 relays & 4-20 mA output

PD6000-6R7-AP

DDD-A14

85-265 VAC

4 relays & 4-20 mA output

PD6000-7R0-AP

DDD-D00

12-24 VDC

No options

PD6000-7R2-AP

DDD-D02

12-24 VDC

2 relays

PD6000-7R3-AP

DDD-D10

12-24 VDC

4-20 mA output

PD6000-7R4-AP

DDD-D04

12-24 VDC

4 relays

PD6000-7R5-AP

DDD-D12

12-24 VDC

2 relays & 4-20 mA output

PD6000-7R7-AP

DDD-D14

12-24 VDC

4 relays & 4-20 mA output

Model Number

Reorder Number

Power

Options

PD6000-6H0-AP

DBD-A00

85-265 VAC

No options

PD6000-6H2-AP

DBD-A02

85-265 VAC

2 relays

PD6000-6H3-AP

DBD-A10

85-265 VAC

4-20 mA output

PD6000-6H4-AP

DBD-A04

85-265 VAC

4 relays

PD6000-6H5-AP

DBD-A12

85-265 VAC

2 relays & 4-20 mA output

PD6000-6H7-AP

DBD-A14

85-265 VAC

4 relays & 4-20 mA output

PD6000-7H0-AP

DBD-D00

12-24 VDC

No options

PD6000-7H2-AP

DBD-D02

12-24 VDC

2 relays

PD6000-7H3-AP

DBD-D10

12-24 VDC

4-20 mA output

PD6000-7H4-AP

DBD-D04

12-24 VDC

4 relays

PD6000-7H5-AP

DBD-D12

12-24 VDC

2 relays & 4-20 mA output

PD6000-7H7-AP

DBD-D14

12-24 VDC

4 relays & 4-20 mA output

Model Number

Description

PDA1002

DIN rail mounting kit for two expansion modules

PDA1004

4 SPST (Form A) relays

PDA1044

4 digital inputs & 4 digital outputs (2 may be connected)

PDA1232

RS-232 serial adapter

PDA1485

RS-485 serial adapter

PDA7485-I

RS-232 to RS-422/485 isolated converter

PDA7485-N

RS-232 to RS-422/485 non-isolated converter

PDA8232-N

USB to RS-232 non-isolated converter

PDA8485-I

USB to RS-422/485 isolated converter

PDA8485-N

USB to RS-422/485 non-isolated converter

PDX6901

Suppressor (snubber): 0.01 µF/470 , 250 VAC

Ordering Information

Standard Models

Sunlight Readable Display Models

Accessories

Manufactured by Precision Digital Corporation, 233 South St, Hopkinton MA 01748 USA

5

Page 6

Din Mounted Digital Display Instruction Manual

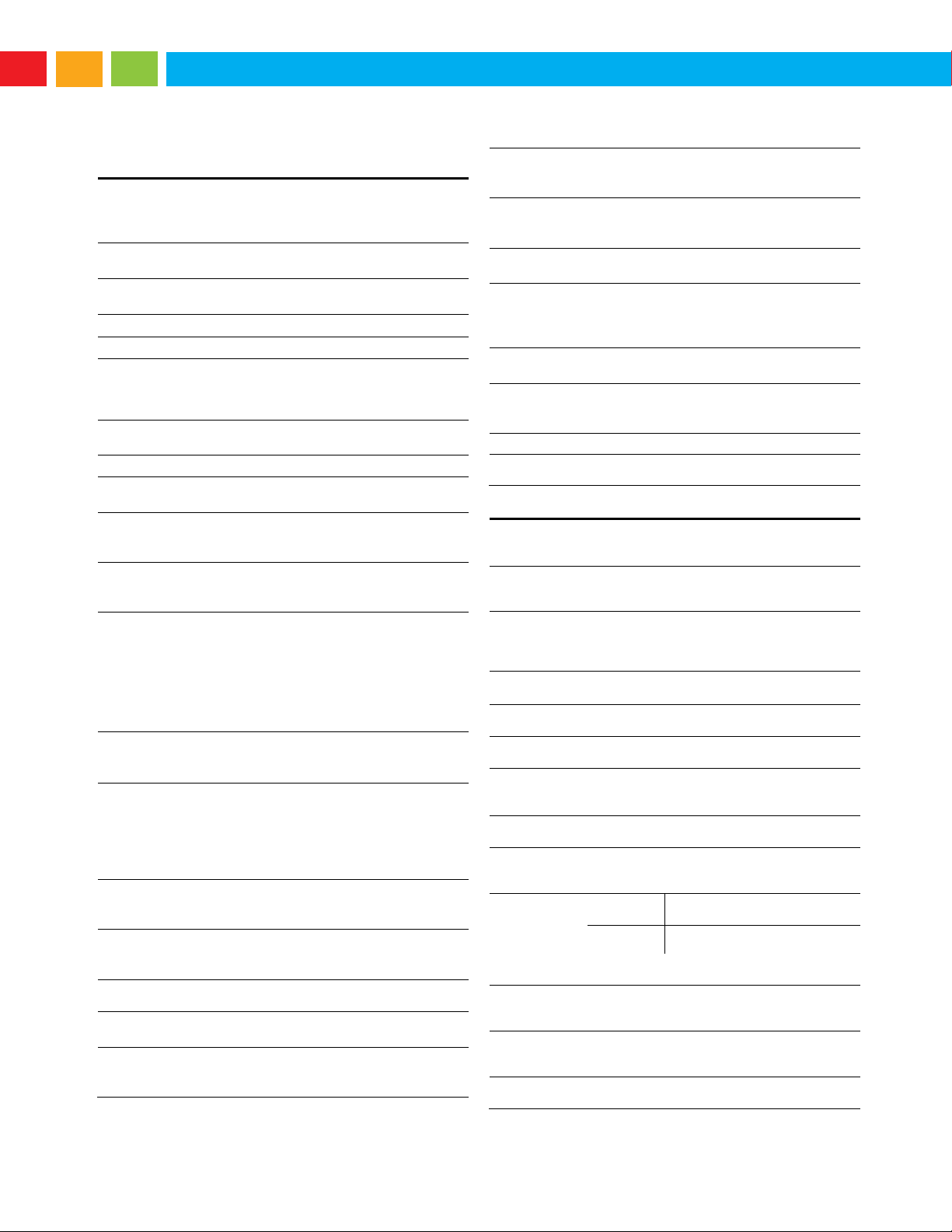

Display

Line 1: 0.60" (15 mm) high, red LEDs

Line 2: 0.46" (12 mm) high, red LEDs

6 digits each (-99999 to 999999), with lead zero

blanking

Display

Intensity

Eight user selectable intensity levels

Display

Update Rate

5/second (200 ms)

Overrange

Display flashes 999999

Underrange

Display flashes -99999

Display

Assignment

Display lines 1 and 2 may be assigned to PV1,

PV2, PCT, d r-u, d gross, d nt-g, max/min, max

& min, set points, units (display line 2 only), or

Modbus input.

Programming

Methods

Four front panel buttons, digital inputs, PC and

MeterView Pro software, or Modbus registers.

Noise Filter

Programmable from 2 to 199 (0 will disable filter)

Filter Bypass

Programmable from 0.1 to 99.9% of calibrated

span

Recalibration

All ranges are calibrated at the factory.

Recalibration is recommended at least every

12 months.

Max/Min

Display

Max/min readings reached by the process are

stored until reset by the user or until power to the

meter is turned off.

Password

Three programmable passwords restrict

modification of programmed settings.

Pass 1: Allows use of function keys and digital

inputs

Pass 2: Allows use of function keys, digital

inputs and editing set/reset points

Pass 3: Restricts all programming, function keys,

and digital inputs.

Power

Options

85-265 VAC 50/60 Hz, 90-265 VDC, 20 W max

or 12-24 VDC 10%, 15 W max

Powered over USB for configuration only.

Isolated

Transmitter

Power Supply

Terminals P+ & P-: 24 VDC 10%. 12-24 VDC

powered models selectable for 24, 10, or 5 VDC

supply (internal jumper J4).

85-265 VAC models rated @ 200 mA max, 12-24

VDC powered models rated @ 100 mA max, @ 50

mA max for 5 or 10 VDC supply.

Non-Volatile

Memory

All programmed settings are stored in nonvolatile memory for a minimum of ten years if

power is lost.

Fuse

Required external fuse: UL Recognized, 5 A

max, slow blow; up to 6 meters may share one 5

A fuse

Normal Mode

Rejection

Greater than 60 dB at 50/60 Hz

Isolation

4 kV input/output-to-power line

500 V input-to-output or output-to-P+ supply

Overvoltage

Category

Installation Overvoltage Category II:

Local level with smaller transient overvoltages

than Installation Overvoltage Category III.

Environmental

Operating temperature range: -40 to 65°C

Storage temperature range: -40 to 85°C

Relative humidity: 0 to 90% non-condensing

Connections

Removable screw terminal blocks accept 12 to

22 AWG wire, RJ45 for external relays, digital

I/O, and serial communication adapters.

Enclosure

1/8 DIN, high impact plastic, UL 94V-0, color:

black

Mounting

1/8 DIN panel cutout required:

3.622" x 1.772" (92 mm x 45 mm)

Two panel mounting bracket assemblies are

provided.

Tightening

Torque

Screw terminal connectors: 5 lb-in (0.56 Nm)

Overall

Dimensions

4.68" x 2.45" x 5.64" (119 mm x 62 mm x 143

mm)

(W x H x D)

Weight

9.5 oz (269 g)

Warranty

Please see https://www.apgsensors.com/aboutus/terms-conditions for full warranty statement.

Inputs

Field selectable:

0-20, 4-20 mA, 10 V (0-5, 1-5, 0-10 V), Modbus

PV (Slave)

Accuracy

±0.03% of calibrated span ±1 count,

square root & programmable exponent accuracy

range: 10-100% of calibrated span

Temperature

Drift

0.005% of calibrated span/C max from 0 to

65C ambient,

0.01% of calibrated span/C max from -40 to

0C ambient

Signal Input

Conditioning

Linear, square root, programmable exponent, or

round horizontal tank volume calculation

Multi-Point

Linearization

2 to 32 points for PV or PV1

2 to 8 points for PV2 (Dual-scale Level feature)

Programmable

Exponent

1.0001 to 2.9999

Round H Tank

Diameter & Length: 999.999 inch or cm

calculates volume in gallons or liters

respectively.

Low-Flow

Cutoff

0-999999 (0 disables cutoff function)

Decimal Point

Up to five decimal places or none:

d.ddddd, d.dddd, d.ddd, d.dd, d.d, or

dddddd

Calibration

Range

Input Range

Minimum Span

Input 1 & Input 2

4-20 mA

0.15 mA

10 V

0.01 V

An error message will appear if the input 1 and

input 2 signals are too close together.

Input

Impedance

Voltage ranges: greater than 500 k

Current ranges: 50 - 100 (depending on resettable

fuse impedance)

Input

Overload

Current input protected by resettable fuse, 30

VDC max.

Fuse resets automatically after fault is removed.

F4 Digital Input

Contacts

3.3 VDC on contact. Connect normally open

contacts across F4 to COM.

Specifications

Except where noted all specifications apply to operation at +25°C.

General

Process Input

6

Page 7

Din Mounted Digital Display Instruction Manual

F4 Digital Input

Logic Levels

Logic High: 3 to 5 VDC

Logic Low: 0 to 1.25 VDC

Rating

2 or 4 SPDT (Form C) internal and/or 4 SPST

(Form A) external; rated 3 A @ 30 VDC and

125/250 VAC resistive load; 1/14 HP (≈ 50 W)

@ 125/250 VAC for inductive loads

Noise

Suppression

Noise suppression is recommended for each

relay contact switching inductive loads; see

page 13 for details.

Deadband

0-100% of span, user programmable

High or Low

Alarm

User may program any alarm for high or low trip

point.

Unused alarm LEDs and relays may be disabled

(turn off).

Relay

Operation

Automatic (non-latching) and/or manual reset

Latching (requires manual acknowledge)

with/without clear

Pump alternation control (2 to 8 relays)

Sampling (based on time)

Off (disable unused relays and enable Interlock

feature)

Manual on/off control mode

Relay Reset

User selectable via front panel buttons or digital

inputs

1. Automatic reset only (non-latching), when

the input passes the reset point.

2. Automatic + manual reset at any time (nonlatching)

3. Manual reset only, at any time (latching)

4. Manual reset only after alarm condition has

cleared (latching)

Note: Front panel button or digital input may be

assigned to acknowledge relays

programmed for manual reset.

Time Delay

0 to 999.9 seconds, on & off relay time delays

Programmable and independent for each relay

Fail-Safe

Operation

Programmable and independent for each relay.

Note: Relay coil is energized in non-alarm

condition.

In case of power failure, relay will go to

alarm state.

Auto

Initialization

When power is applied to the meter, relays will

reflect the state of the input to the meter.

Output Source

Process variable (PV), max, min, set points 1-8,

Modbus input, or manual control mode

Scaling Range

1.000 to 23.000 mA for any display range

Calibration

Factory calibrated: 4.000 to 20.000 = 4-20 mA

output

Analog Out

Programming

23.000 mA maximum for all parameters:

Overrange, underrange, max, min, and break

Accuracy

± 0.1% of span ± 0.004 mA

Temperature

Drift

0.4 µA/C max from 0 to 65C ambient,

0.8 µA/C max from -40 to 0C ambient

Note: Analog output drift is separate from input drift.

Isolated

Transmitter

Power Supply

Terminals I+ & R: 24 VDC 10%. May be used to

power the 4-20 mA output or other devices.

Refer to Transmitter Supply Voltage Selection

(P+, P-) on page 10. All models rated @ 40 mA

max.

External Loop

Power Supply

35 VDC maximum

Output Loop

Resistance

Power supply

Minimum

Maximum

24 VDC

10

700

35 VDC

(external)

100

1200

Slave Id

1 – 247 (Meter address)

Baud Rate

300 – 19,200 bps

Transmit

Time Delay

Programmable between 0 and 199 ms

Data

8 bit (1 start bit, 1 or 2 stop bits)

Parity

Even, Odd, or None with 1 or 2 stop bits

Byte-To-Byte

Timeout

0.01 – 2.54 second

Turn Around

Delay

Less than 2 ms (fixed)

Note: Refer to the Modbus Register Tables located at

www.apgsensors.com for details.

System

Requirements

Microsoft® Windows® XP/Vista/7/8/10

Communications

USB 2.0 (Standard USB A to Micro USB B)

Configuration

Configure meters one at a time

Relays

Isolated 4-20 mA Transmitter Output

Modbus® RTU Serial Communications

MeterView Pro

7

Page 8

Din Mounted Digital Display Instruction Manual

UL & C-UL Listed

USA & Canada

UL 508 Industrial Control Equipment

UL File Number

E160849

Front Panel

UL Type 4X, NEMA 4X, IP65; panel gasket provided

Low Voltage Directive

EN 61010-1:2010

Safety requirements for measurement, control, and laboratory use

Emissions

EN 55022:2010

Class A ITE emissions requirements

Radiated Emissions

Class A

AC Mains Conducted

Emissions

Class A

Immunity

EN 61326-1:2013

Measurement, control, and laboratory equipment

EN 61000-6-2:2005

EMC heavy industrial generic immunity standard

RFI - Amplitude

Modulated

80 -1000 MHz 10 V/m 80% AM (1 kHz)

1.4 - 2.0 GHz 3 V/m 80% AM (1 kHz)

2.0 - 2.7 GHz 1 V/m 80% AM (1 kHz)

Electrical Fast

Transients

±2kV AC mains, ±1kV other

Electrostatic

Discharge

±4kV contact, ±8kV air

RFI - Conducted

10V, 0.15-80 MHz, 1kHz 80% AM

AC Surge

±2kV Common, ±1kV Differential

Surge

1KV (CM)

Power-Frequency

Magnetic Field

30 A/m 70%V for 0.5 period

Voltage Dips

40%V for 5 & 50 periods

70%V for 25 periods

Voltage Interruptions

<5%V for 250 periods

Compliance Information

Safety

Electromagnetic Compatibility

Note:

Testing was conducted on meters installed through the covers of grounded metal enclosures with

cable shields grounded at the point of entry representing installations designed to optimize EMC

performance.

Declaration of Conformity available at www.apgsensors.com

8

Page 9

Din Mounted Digital Display Instruction Manual

CAUTION: Read complete

instructions prior to installation

and operation of the meter.

WARNING: Risk of electric

shock or personal injury.

Warning!

Hazardous voltages exist within enclosure.

Installation and service should be performed

only by trained service personnel.

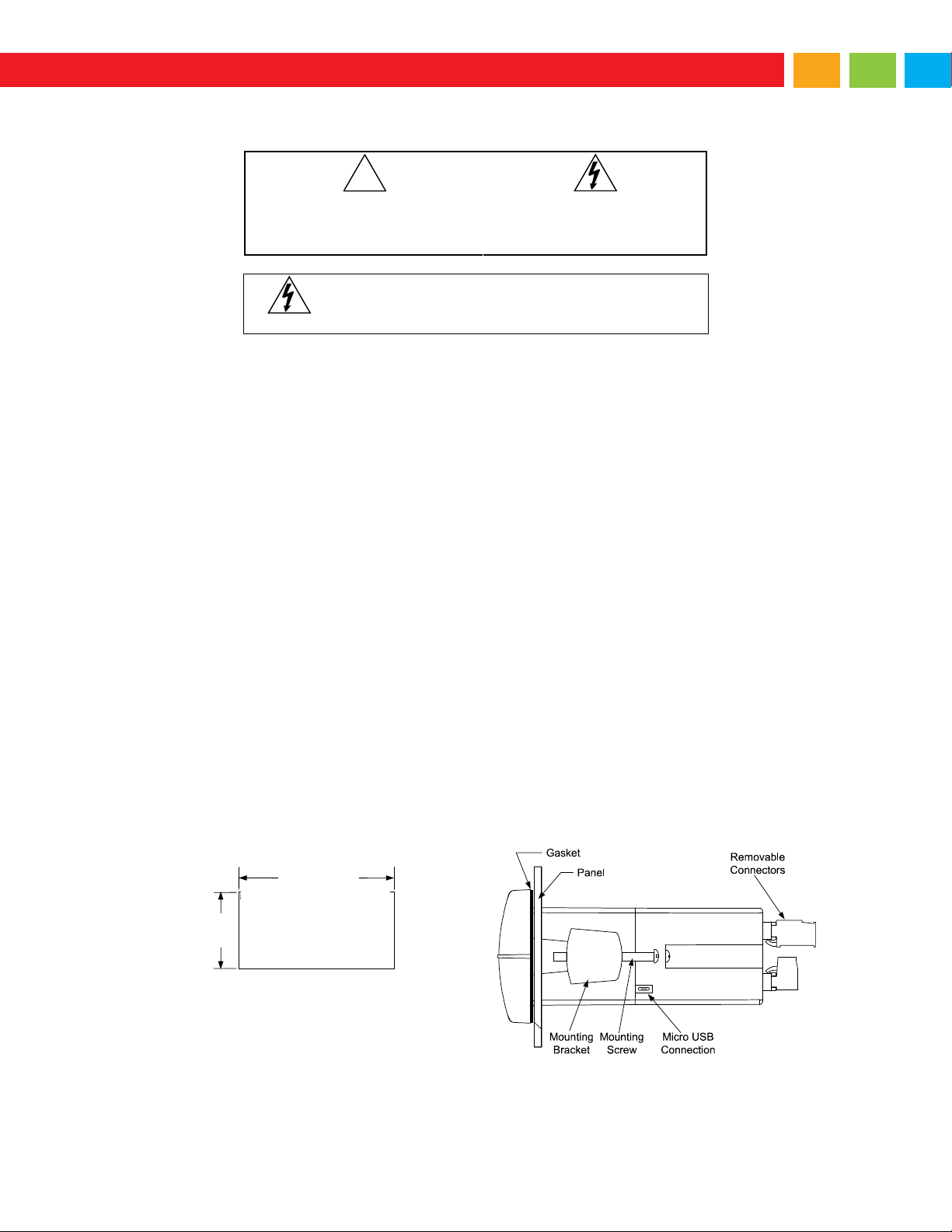

Figure 1. 1/8 DIN Panel Cutout Dimensions

Figure 2. Panel Mounting Details

!

3.622" (92 mm)

1.772"

(45mm)

Panel Cutout

to DIN 43700

Square Corners to 0.060"

(1.5mm) Max Radius

A

B

Tolerances:

A: +0.032 (+0.8mm)

-0.000 (-0.0mm)

B: +0.024 (+0.6mm)

-0.000 (-0.0mm)

Safety Information

Installation

There is no need to remove the meter from its case to complete the installation, wiring, and setup of

the meter for most applications.

Instructions are provided for changing the transmitter power supply to output 5 or 10 VDC instead of

24 VDC, see page 10.

Unpacking

Remove the meter from box. Inspect the packaging and contents for damage. Report damages, if

any, to the carrier.

If any part is missing or the meter malfunctions, please contact your supplier or the factory for

assistance.

Panel Mounting Instructions

• Prepare a standard 1/8 DIN panel cutout – 3.622" x 1.772" (92 mm x 45 mm). Refer to Figure 1

below, for more details.

• Clearance: allow at least 6.0" (152 mm) behind the panel for wiring.

• Panel thickness: 0.04" - 0.25" (1.0 mm - 6.4 mm).

Recommended minimum panel thickness to maintain Type 4X

rating: 0.06" (1.5 mm) steel panel, 0.16" (4.1 mm) plastic panel.

• Remove the two mounting brackets provided with the meter (back-off the two screws so that there is ¼"

(6.4 mm) or less through the bracket. Slide the bracket toward the front of the case and remove).

• Insert meter into the panel cutout.

• Install mounting brackets and tighten the screws against the panel. To achieve a proper seal, tighten

the mounting bracket screws evenly until meter is snug to the panel along its short side. DO NOT

OVER TIGHTEN, as the rear of the panel may be damaged.

9

Page 10

Din Mounted Digital Display Instruction Manual

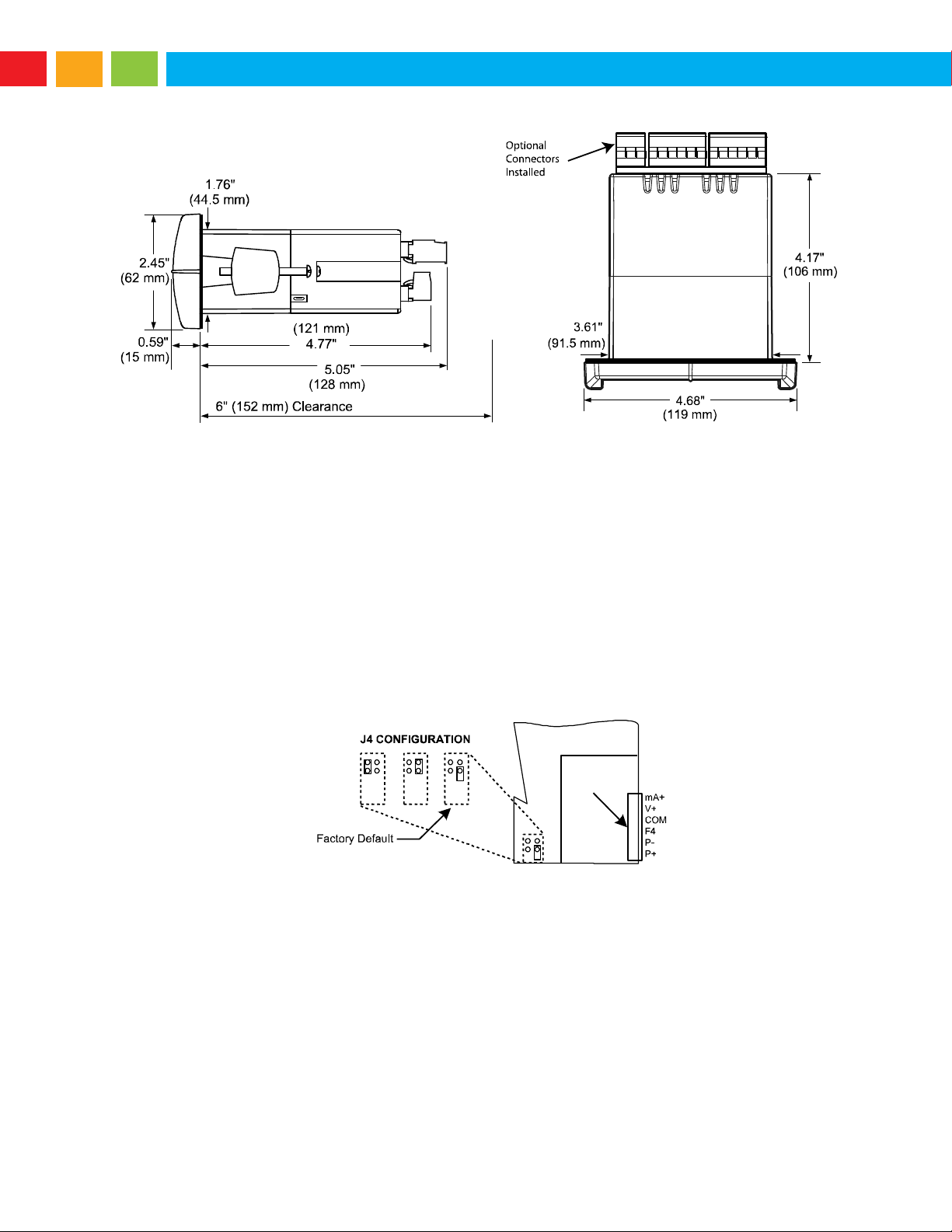

Figure 3. Meter Dimensions - Side View

Figure 4. Meter Dimensions - Top View

NO

NC

NC

C

NO

C

NO

NC

NC

C

NO

C

+

-

R

Mounting Dimensions

Transmitter Supply Voltage Selection (P+, P-)

All meters, including models equipped with the 12-24 VDC power option, are shipped from the factory

configured to provide 24 VDC power for the transmitter or sensor.

If the transmitter requires 5 or 10 VDC excitation, the internal jumper J4 must be configured

accordingly.

To access the voltage selection jumper:

1. Remove all the wiring connectors.

2. Unscrew the back cover.

3. Slide out the back cover by about 1 inch.

4. Configure the J4 jumper, located behind the input signal connector, for the desired excitation

voltage as shown.

Figure 5. Transmitter Supply Voltage Selection

10

Page 11

Din Mounted Digital Display Instruction Manual

Use copper wire with 60°C or 60/75°C insulation for all line

voltage connections. Observe all safety regulations. Electrical

wiring should be performed in accordance with all applicable

national, state, and local codes to prevent damage to the

meter and ensure personnel safety.

Warning!

Do not connect any equipment other than Automation

Products Group’s expansion modules, cables, or meters

to the RJ45 M-LINK connector. Otherwise damage will

occur to the equipment and the meter.

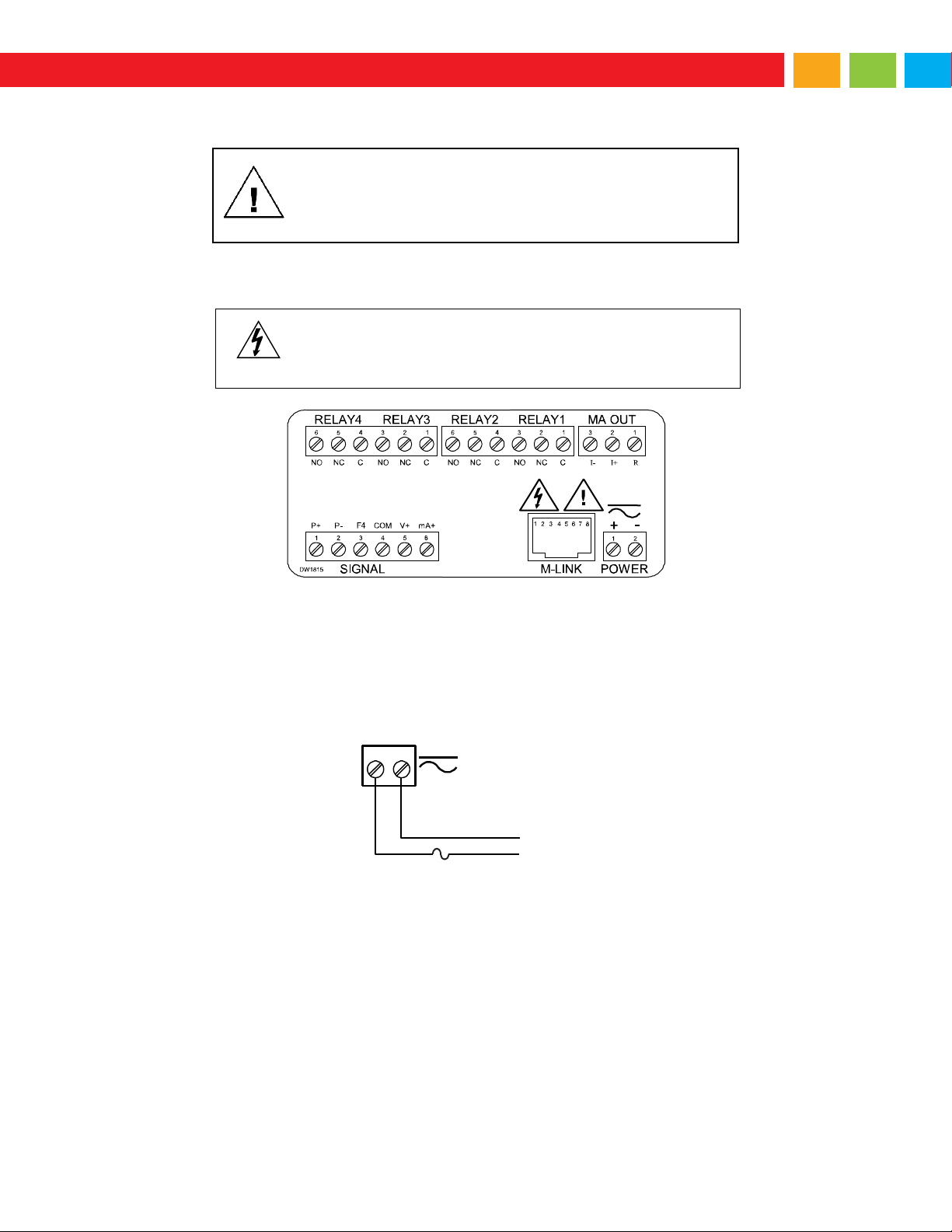

Figure 7. Power Connections

AC or DC

POWER

Required External Fuse:

5 A max, 250 V Slow Blow

POWER

+

-

Connections

All connections are made to removable screw terminal connectors located at the rear of the meter.

Connectors Labeling

The connectors’ label, affixed to the meter, shows the location of all connectors available with requested

configuration.

Figure 6. Connector Labeling for Fully Loaded Meter

Power Connections

Power connections are made to a two-terminal connector labeled POWER on Figure 6 on page 11. The

meter will operate regardless of DC polarity connection. The + and - symbols are only a suggested wiring

convention.

11

Page 12

Din Mounted Digital Display Instruction Manual

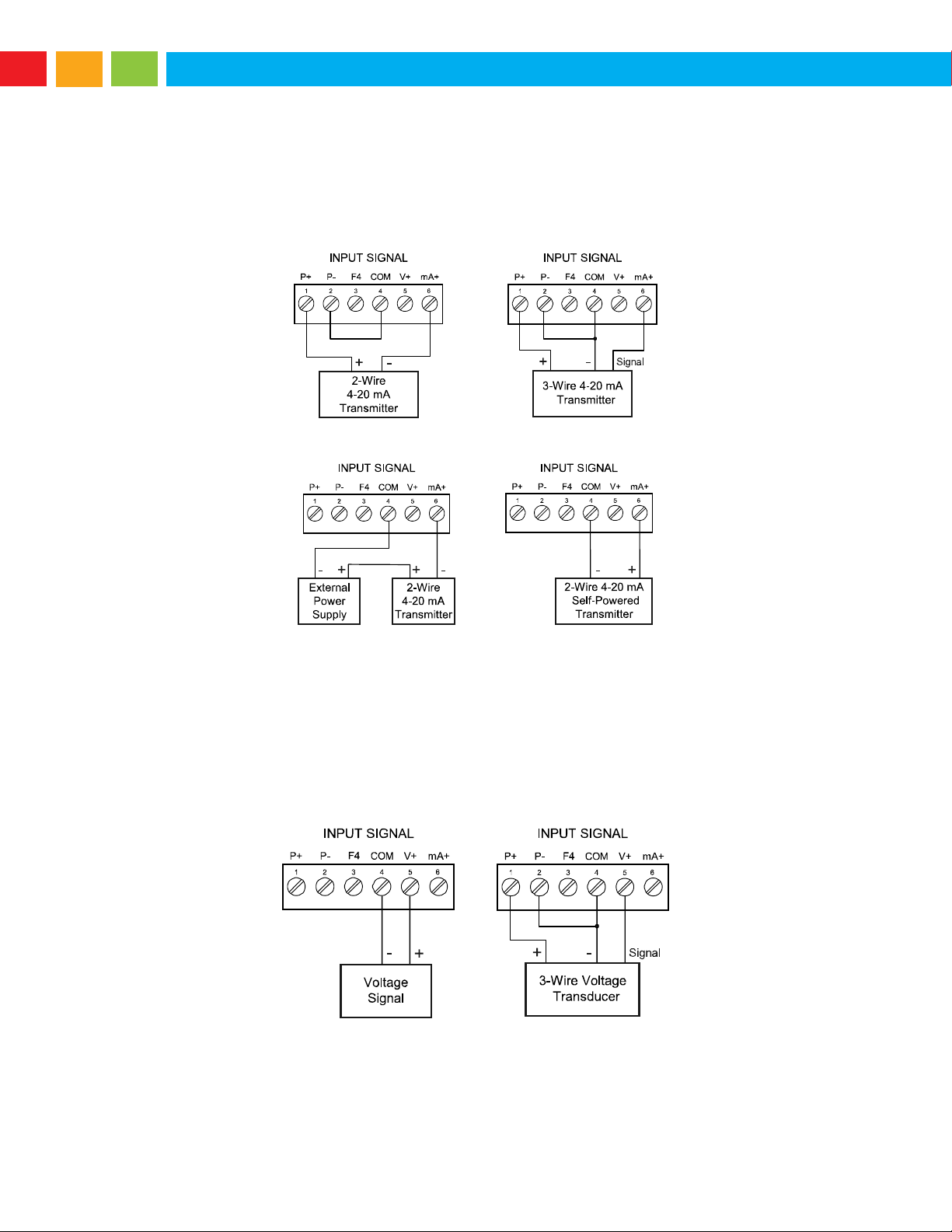

Signal Connections

Signal connections are made to a six-terminal connector labeled SIGNAL on Figure 6. The COM

(common) terminal is the return for the 4-20 mA and the 10 V input signals.

Current (mA) Connections

The following figures show examples of current connections.

There are no switches or jumpers to set up for current inputs. Setup and programming is performed

through the front panel buttons.

Figure 8. Transmitters Powered by Internal Supply

Figure 9. Transmitter Powered by Ext. Supply or Self-Powered

The current input is protected against current overload by a resettable fuse. The display may or may not

show a fault condition depending on the nature of the overload.

The fuse limits the current to a safe level when it detects a fault condition, and automatically resets itself

when the fault condition is removed.

Voltage (V) Connections

The following figures show examples of voltage connections.

There are no switches or jumpers to set up for voltage inputs. Setup and programming is performed

through the front panel buttons.

Figure 10. Voltage Input Connections

The meter is capable of accepting any voltage from -10 VDC to +10 VDC.

12

Page 13

Din Mounted Digital Display Instruction Manual

C NONO NC NC C

RELAY4 RELAY3

4 36 5 2 1

C NONO NC NC C

RELAY2 RELAY1

4 36 5 2 1

C

R

C

R

Use a diode with a reverse

breakdown voltage two to

three times the circuit voltage

and forward current at least as

large as the load current.

Modbus RTU Serial Communications

Serial communications connection is made to an RJ45 connector labeled M-LINK on Figure 6. For

interfacing to the meter, use the PDA1232 for RS-232 or the PDA1485 for RS-485. The same port is used

for interfacing with all expansion modules (e.g. external relays, digital I/O).

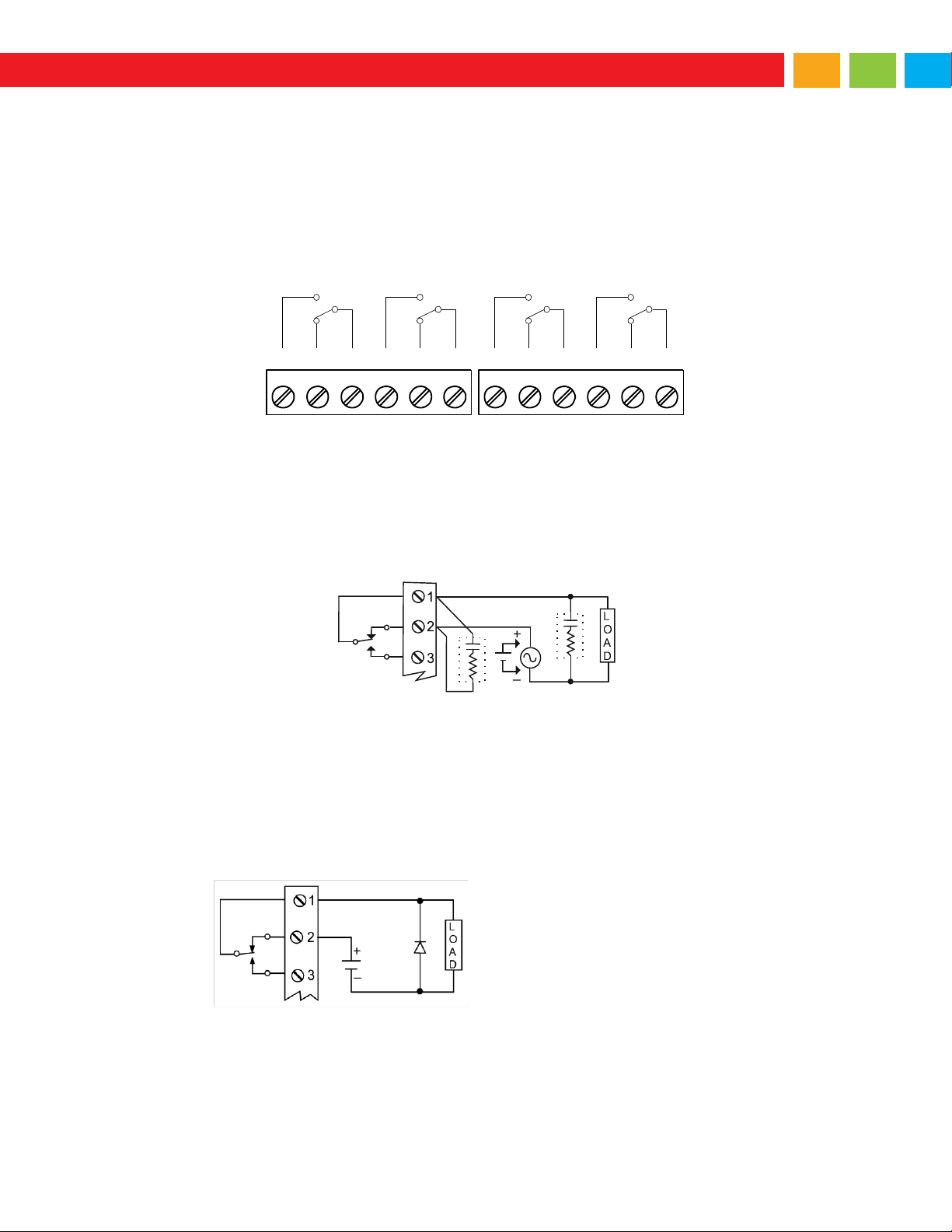

Relay Connections

Relay connections are made to two six-terminal connectors labeled RELAY1 – RELAY4 on Figure 6.

Each relay’s C terminal is common only to the normally open (NO) and normally closed (NC) contacts of

the corresponding relay. The relays’ C terminals should not be confused with the COM (common) terminal

of the INPUT SIGNAL connector.

Figure 11. Relay Connections

Switching Inductive Loads

The use of suppressors (snubbers) is strongly recommended when switching inductive loads to prevent

disrupting the microprocessor’s operation. The suppressors also prolong the life of the relay contacts.

Suppression can be obtained with resistor-capacitor (RC) networks assembled by the user or purchased

as complete assemblies. Refer to the following circuits for RC network assembly and installation:

Figure 12. AC and DC Loads Protection

Choose R and C as follows:

R: 0.5 to 1 Ω for each volt across the contacts

C: 0.5 to 1 µF for each amp through closed contacts

Notes:

1. Use capacitors rated for 250 VAC.

2. RC networks may affect load release time of solenoid loads. Check to confirm proper operation.

3. Install the RC network at the meter's relay screw terminals. An RC network may also be installed across the load.

Experiment for best results.

Figure 13. Low Voltage DC Loads Protection

RC Networks Available from Automation Products Group

RC networks are available from Automation Products Group and should be applied to each relay contact switching an

inductive load. Part number: PDX6901.

Note: Relays are de-rated to 1/14th HP (50 watts) with an inductive load.

13

Page 14

Din Mounted Digital Display Instruction Manual

12-35 VDC

Power

Supply

+

4-20 mA

Input Meter

-

+

RI- I+

13 2

RELAY1

3 2 1

24 V

-

4-20 mA Input

Remote Display,

Chart Recorder, Etc.

-

+

RI- I+

MA OUT

13 2

RELAY1

3 2 1

24 V

MA OUT

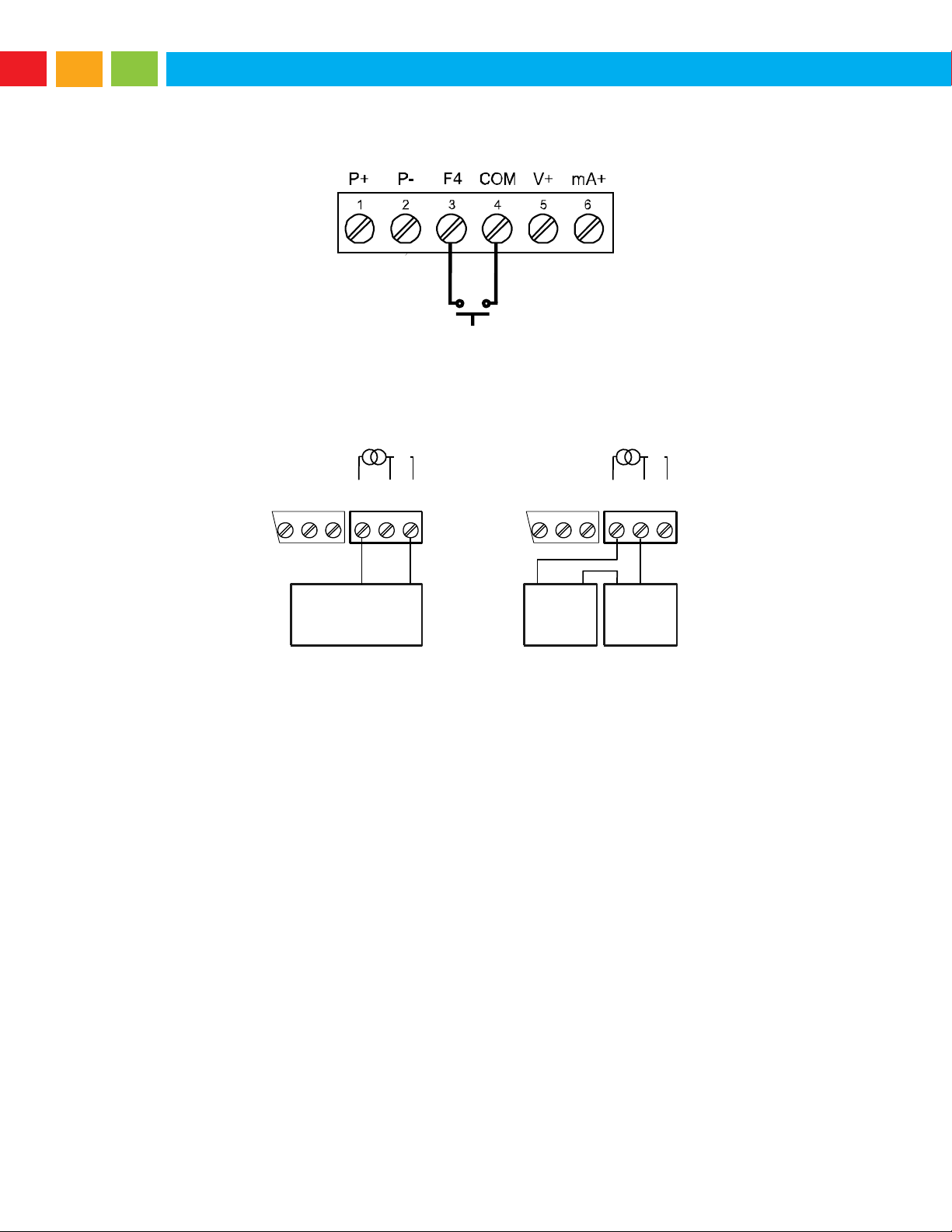

F4 Digital Input Connections

A digital input, F4, is standard on the meter. This digital input is connected with a normally open contact

across F4 and COM, or with an active low signal applied to F4.

Figure 14. F4 Digital Input Connections

4-20 mA Output Connections

Connections for the 4-20 mA transmitter output are made to the connector terminals labeled MA OUT.

The 4-20 mA output may be powered internally or from an external power supply.

Figure 15. 4-20 mA Output Connections

Analog Output Transmitter Power Supply

The internal 24 VDC power supply powering the analog output may be used to power other devices, if the

analog output is not used. The I+ terminal is the +24 V and the R terminal is the return.

14

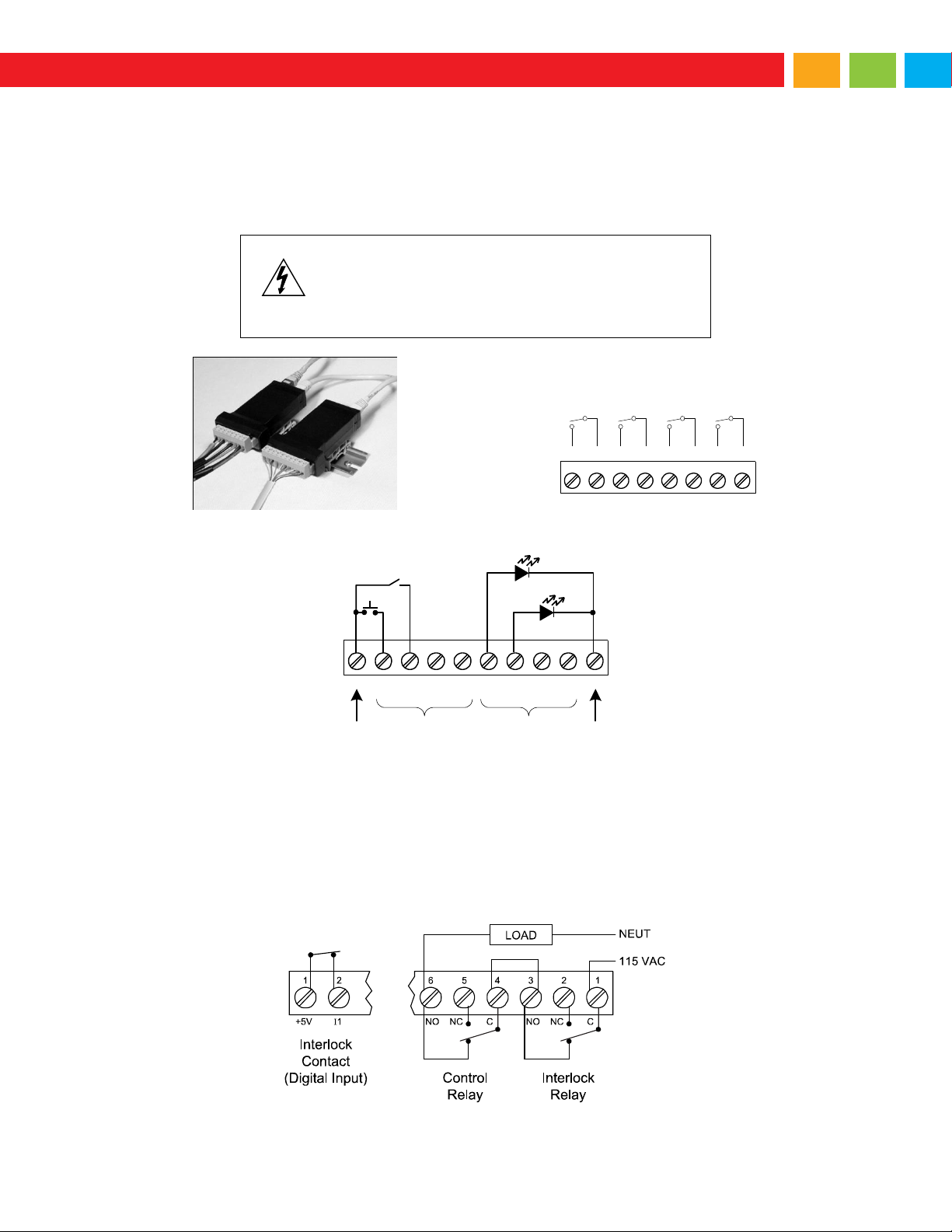

Page 15

Din Mounted Digital Display Instruction Manual

Warning!

Do not connect or disconnect the expansion

modules with the power on!

More detailed instructions are provided with each

optional expansion module.

Figure 16. Expansion Modules & DIN Rail

Mounting Kit

Figure 17. External Relays Module

Connections

1 2

RLY5 RLY6 RLY7 RLY8

3 4 5 6 7 8

NO C NO C NO C NO C

1 2 3 4 5 6

+5 I1 I2 I3 I4 O1

7 8

O2 O3

9 10

O4 G

DI 1-4 DO 1-4

5 VDC GND

External Relays & Digital I/O Connections

The relay and the digital I/O expansion modules PDA1004 & PDA1044 are connected to the meter using

a CAT5 cable provided with each module. The two RJ45 connectors on the expansion modules are

identical and interchangeable; they are used to connect additional modules to the system.

Note: The jumper located between the RJ45 connectors of the PDA1044 must be removed on the second

digital I/O module in order for the system to recognize it as module #2.

Figure 18. Digital I/O Module Connections

Interlock Relay Feature

As the name implies, the interlock relay feature reassigns one, or more, alarm/control relays for use as

interlock relay(s). Interlock contact(s) are wired to digital input(s) and trigger the interlock relay. This

feature is enabled by configuring the relay, and relative digital input(s) (see page 35).

In one example, dry interlock contacts are connected in series to one digital input which will be used to

force on (energize) the assigned interlock power relay when all interlock contacts are closed (safe). The

interlock relay front panel LED flashes when locked out. The interlock relay would be wired in-series with

the load (N/O contact). See below.

Figure 19. Interlock Connections

15

Page 16

Din Mounted Digital Display Instruction Manual

The meter is factory calibrated prior to shipment to read

in milliamps and volts depending on the input selection.

The calibration equipment is certified to NIST standards.

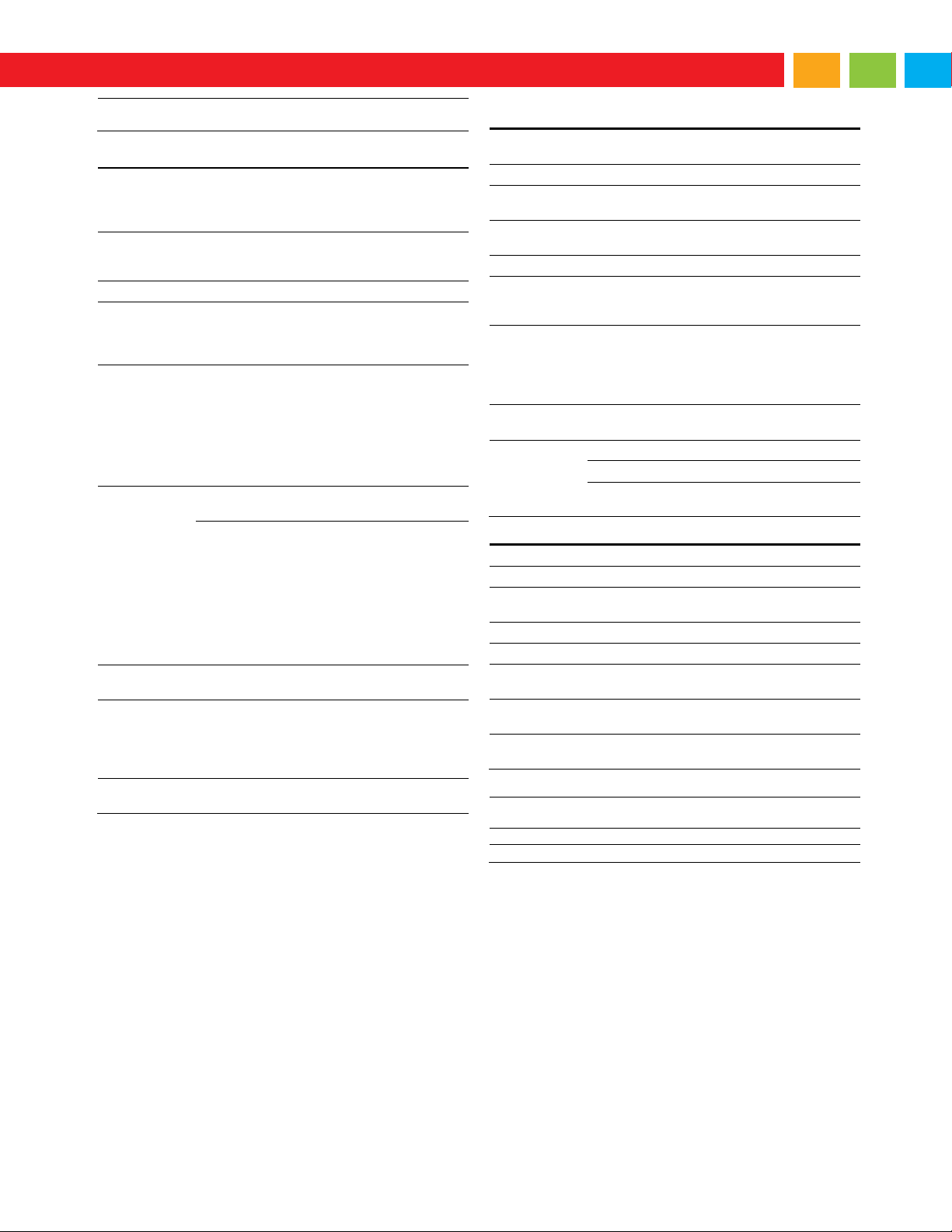

Button

Symbol

Description

LED

Status

Menu

1-8

Alarm 1-8 indicator

Right arrow/F1

1-8

M

Flashing: Relay in

manual control mode

Up arrow/F2

T Flashing: Tare

Enter/F3

1-8

Flashing: Relay

interlock switch open

Note:

F4 is a digital input. Alarms 5-

8 are enabled when relay

expansion module is installed.

Note:

LEDs for relays in manual

mode flash with the “M” LED

every 10 seconds. “M” flashing

by itself indicates Aout –

manual control is used.

Setup and Programming

Overview

There are no jumpers to set for the meter input selection.

Setup and programming is done through the front panel buttons.

After power and input signal connections have been completed and verified, apply power to the meter.

Front Panel Buttons and Status LED Indicators

• Press the Menu button to enter or exit the Programming Mode at any time.

• Press the Right arrow button to move to the next digit during digit or decimal point programming.

• Press or hold the Up-arrow button to scroll through the menus, decimal point, or to increment the

value of a digit.

• Press the Enter button to access a menu or to accept a setting.

• Press and hold the Menu button for three seconds to access the advanced features of the meter.

16

Page 17

Din Mounted Digital Display Instruction Manual

Note: If you decide to update your MeterView Pro software, once the installation has completed, you

will be asked if you want to update the setup files located on the meter itself. This way, you will always

have the most current version on the meter for future installs.

Warning!

Do not unplug the meter while the new installation files are being written to it. The

meter will display

uwrite

during the process and you will receive an onscreen

notification once the process is complete.

MeterView® Pro Software

The meter can also be programmed using the PC-based MeterView Pro software included with the meter.

This software can be installed on any Microsoft® Windows® (XP/Vista/7/8/10) computer by connecting

the meter’s onboard USB. The meter is powered by the USB connection, so there is no need to wire

anything prior to programming the meter, though USB is intended only for meter configuration.

MeterView Pro Installation

1. Connect one end of the provided USB cable to the meter and the other end to the computer.

The computer will automatically install the driver software it needs to talk to the meter.

Only one meter may be connected at a time.

Attaching multiple meters will cause a

conflict with the meter software.

2. Once the driver is installed, an AutoPlay dialog should appear

for the drive “MAINSTAL.” Click “Open folder to view files.”

If the computer does not display an AutoPlay dialog for the

drive “MAINSTAL,” you should open My Computer and doubleclick on the drive labeled “MAINSTAL.”

3. Double-click on the file named “MAStart.” The program will

open a few windows and install two programs on your

computer. Simply follow the onscreen instructions until you see

one of the dialogs below. If you receive a “User Account

Control” warning, click “Yes.”

4. If there is an update available, click the “Update” button to

install the new version. Otherwise, click “Configure” to begin

programming your meter.

Data logging for one meter at a time is available with MeterView Pro software. More advanced data

acquisition may be accomplished by using any Modbus RTU compliant software. Additional information

regarding configuration and monitoring of the meter using MeterView Pro software is available online.

17

Page 18

Din Mounted Digital Display Instruction Manual

Display

Parameter

Action/Setting Description

setup

Setup

Enter Setup menu

Input

Input

Enter Input selection menu

nmA

4-20 mA

Set meter for 4-20 mA input

volt

0-10 VDC

Set meter for 10 VDC input

d-SCAL

Dual-scale

Press Enter to select dualscale display for some level

applications (Select Yes or

No)

units

Units

Select the display units/tags

Dec pt

Decimal

point

Set decimal point

PV 1

PV1

PV1 decimal point (Level)

PV 2

PV2

PV2 decimal point (Level)

prog

Program

Enter the Program menu

SCALE

Scale

Enter the Scale menu

SCAL 1

Scale 1

Enter the Scale menu for

PV1

SCAL 2

Scale 2

Enter the Scale menu for

PV2

Cal

Calibrate

Enter the Calibration menu

Inp 1

Input 1

Calibrate input 1 signal or

program input 1 value

Dis 1

Display 1

Program display 1 value

Inp 2

Input 2

Calibrate input 2 signal or

program input 2 value (up to

32 points)

Dis 2

Display 2

Program display 2 value (up

to 32 points)

Error

Error

Error, calibration not

successful, check signal or

programmed value

dsplay

Display

Enter the Display menu

Line 1

Display

Line 1

Press Enter to assign the

Main display parameter

(default: PV)

Line 2

Display

Line 2

Press Enter to assign the

small display parameter

(default: engineering units)

d-Inty

Display

intensity

Set display intensity level

from 1 to 8

RELaY

Relay

Enter the Relay menu

RLY 1

Relay 1

Relay 1 setup

Act 1

Action 1

Set relay 1 action

Auto

Automatic

Set relay for automatic reset

A-nman

Automanual

Set relay for automatic &

manual reset any time

LatCH

Latching

Set relay for latching

operation

Display

Parameter

Action/Setting Description

Lt-CLr

Latchingcleared

Set relay for latching

operation with manual reset

only after alarm condition

has cleared

Altern

Alternate

Set relay for pump

alternation control

Sanmpl

Sampling

Set relay for sampling

operation

OFF

Off

Disable relay and front

panel status LED (Select Off

to enable Interlock feature)

Set 1

Set 1

Program set point 1

RSt 1

Reset 1

Program reset point 1

RLY 2

Relay 2

Relays 2-8 setup

Note: Relays 5-8 are shown,

only if expansion relay

module is installed.

FaiLSF

Fail-safe

Enter Fail-safe menu

FLS 1

Fail-safe 1

Set relay 1 fail-safe

operation

on

On

Enable fail-safe operation

off

Off

Disable fail-safe operation

FLS 2

Fail-safe 2

Set relays 2-8 fail-safe

operation

DeLAY

Delay

Enter relay Time Delay

menu

DLY 1

Delay 1

Enter relay 1 time delay

setup

On 1

On 1

Set relay 1 On time delay

OFF 1

Off 1

Set relay 1 Off time delay

DLY 2

Delay 2

Enter relays 2-8 time delay

setup

break

Loop break

Set relay condition if loop

break detected

ignore

Ignore

Ignore loop break condition

(Processed as a low signal

condition)

On

On

Relay goes to alarm

condition when loop break is

detected

Off

Off

Relay goes to non-alarm

condition when loop break is

detected

Aout

Analog

output

Enter the Analog output

scaling menu

Dis 1

Display 1

Program display 1 value

Out 1

Output 1

Program output 1 value (e.g.

4.000 mA)

Dis 2

Display 2

Program display 2 value

Out 2

Output 2

Program output 2 value (e.g.

20.000 mA)

reset

Reset

Press Enter to access the

Reset menu

Display Functions & Messages

The meter displays various functions and messages during setup, programming, and operation. The following table

shows the main menu functions and messages in the order they appear in the menu.

18

Page 19

Din Mounted Digital Display Instruction Manual

Display

Parameter

Action/Setting Description

Rst Hi

Reset high

Press Enter to reset max

display

Rst Lo

Reset low

Press Enter to reset min

display

Rst HL

Reset

high & low

Press Enter to reset max &

min displays

Rst tr

Reset tare

Reset tare

Contrl

Control

Enter Control menu

Auto

Automatic

Press Enter to set meter for

automatic operation

nmAn

Manual

Press Enter to manually

control relays or analog

output operation

Display

Parameter

Action/Setting Description

pass

Password

Enter the Password menu

Pass 1

Password 1

Set or enter Password 1

Pass 2

Password 2

Set or enter Password 2

Pass 3

Password 3

Set or enter Password 3

unloc

Unlocked

Program password to lock

meter

locd

Locked

Enter password to unlock

meter

999999

-99999

Flashing

Over/under range condition

004.000

004.000

005.000

dis 1 dis 1 dis 1

Next

Setting

Select

Next

Digit

Increment

Digital

Value

Accept

Setting

Main Menu

The main menu consists of the most commonly

used functions: Setup, Reset, Control, and

Password.

• Press Menu button to enter Programming

Mode then press the Up-arrow button to scroll

main menu.

• Press Menu, at any time, to exit and return to

Run Mode. Changes made to settings prior to

pressing Enter are not saved.

• Changes to the settings are saved to memory

only after pressing Enter/F3.

• The display moves to the next menu every

time a setting is accepted by pressing

Enter/F3.

Setting Numeric Values

The numeric values are set using the Right and Up arrow buttons. Press Right arrow to select next digit

and Up arrow to increment digit value. The digit being changed is displayed brighter than the rest. Press

and hold Up to auto-increment the display value. If negative numbers are allowed, the first digit position

will include a negative symbol (-) after the 9.

Press the Enter button, at any time, to accept a setting or Menu button to exit without saving changes.

19

Page 20

Din Mounted Digital Display Instruction Manual

Note:

Scal 1 & Scal 2 are

displayed instead of

Scale if d-SCAL is

selected under the

Setup Input menu.

They correspond to

the PV1 & PV2

scales.

Enter custom

units here

Note:

Use the d-SCAL selection

to activate the dual-scale

level feature - PV1 & PV2

(see introduction on page 6).

Set d-SCAL to no if both

displays are to be used for

anything other than PV1 & PV2.

Setting Up the Meter (setup)

The Setup menu is used to select:

1. Input signal the meter will

accept

2. Dual-scale feature for

some level applications

3. Select the display

units/tags

4. Decimal point position

5. Programming Menu

6. Display parameter and

intensity

7. Relay operation

8. 4-20 mA analog output

scaling

Press the Enter button to access

any menu or press Up arrow

button to scroll through choices.

Press the Menu button to exit at

any time.

Setting the Input Signal (Input)

Enter the Input menu to set up the meter to display current (mA) or voltage (volt) inputs.

The current input is capable of accepting any signal from 0 to 20 mA. Select current input to accept 0-20

mA or 4-20 mA signals.

The voltage input is capable of accepting any signal from -10 to +10 VDC. Select voltage input to accept 05, 1-5, 0-10, or 10 VDC signals.

After selecting mA or Volt input, d-SCAL is displayed; press Enter to select “Yes” or “No”. Selecting “Yes”

enables the dual-scale feature, which allows for the Scale (SCALE) and Units (units) menus to be used to

scale the same input in two different scales for PV1 & PV2.

Set d-SCAL to no if both displays are to be used for anything other than PV1 & PV2.

20

Page 21

Din Mounted Digital Display Instruction Manual

Display

Character

Display

Character

Display

Character

Display

Character

0

0

C

C

k

K

v V 1

1

c

c

l

L

uw

w

2

2

d

d

n m

m

x X 3

3

e

E

n

n

y Y 4

4

f

F

O

O

z Z 5

5

g

G

o

o

- - 6

6

9

g

p

P

/

/

7

7

H

H

q

q

[

]

8

8

h

h

r

r

] [ 9

9

I

I

s

S

=

=

A

A

I

i

t

t

!

Degree(<)

b

b

j

J

u

u

Space

Setting the Input Units or Custom Tags (units)

Enter the input unit or custom tag that will be displayed if d unit is selected as the line 2 parameter. See

the flow chart on page 25 to access the display menu to show the unit or tag on display line 2. The

engineering units or custom legends can be set using the following 7-segment character set:

Notes:

Degree symbol represented by (<) if programming with MeterView® Pro.

The letters “m” and “w” use two 7-segment LEDs each; when selected the characters to the right are shifted

one position.

Press and hold up arrow to auto-scroll the characters in the display.

Setting the Decimal Point (dEc pt)

The decimal point may be set with up to five decimal places or with no decimal point at all.

Pressing the Right arrow moves the decimal point one place to the right until no decimal point is

displayed, and then it moves to the leftmost position. Pressing the Up arrow moves the decimal point one

place to the left.

If the dual-scale level feature is selected, the decimal point selections for PV1 & PV2 are enabled.

21

Page 22

Din Mounted Digital Display Instruction Manual

Programming the Meter (prog)

It is very important to read the following information, before proceeding to program the meter:

• The meter is factory calibrated prior to shipment to read in milliamps and volts depending on the input

selection. The calibration equipment is certified to NIST standards.

• Use the Scale menu to scale the process input (e.g. 4-20 mA). A calibrated signal source is not

needed to scale the meter.

• Use the Calibrate menu to apply a signal from a calibrator or a flowmeter.

• The meter is a single input meter with dual-scale capability.

The Program menu contains the Scale and the Calibrate menus.

Note: The Scale and Calibrate functions are exclusive of each other. The meter uses the last function

programmed. Only one of these methods can be employed at a time. The Scale and Calibrate functions

can use up to 32 points (default is 2). The number of points should be set in the Advanced menu under

the Multi-Point Linearization (Linear) menu selection prior to scaling and calibration of the meter, see

page 41 for details.

If the dual-scale level feature is selected in the Setup menu, the Scale 1 and Scale 2 menus are enabled

for PV1 & PV2 respectively.

The process input may be calibrated or scaled to any display value within the range of the meter.

Program Menu for Single Scale Process

Program Menu for Dual-Scale Level Applications

Additional parameters, not needed for most applications, are programmed in the Advanced Features

menu; see Advanced Features Menu, page 38.

Multi-Point Calibration & Scaling

The meter is set up at the factory for 2-point linear calibration. The number of points for multi-point

calibration/scaling is set up in the Advanced Features menu. Up to 32 linearization points may be

selected for PV1 and up to 8 linearization points may be selected for PV2. See page 41 for details.

22

Page 23

Din Mounted Digital Display Instruction Manual

Scaling the Input for PV1 (SCAL 1)

Scaling the Input for PV2 (SCAL 2)

For instructions on how to

program numeric values see

Setting Numeric Values, page 19.

Input Range

Input 1 & Input 2 Span

4-20 mA

0.15 mA

10 VDC

0.01 VDC

Scaling the Meter (SCALE)

The process input (4-20 mA, 10 VDC) can be scaled to display the process variable in engineering units.

A signal source is not needed to scale the meter; simply program the inputs and corresponding display

values.

Dual-Scale for Level Application

The analog input can be displayed in two different scales, by enabling the dual-scale feature (d-SCAL) in

the Setup-Input menu, see page 20.

To enable the dual-scale feature for some level applications you must select d-SCAL in the Input

selection menu.

Error Message (Error)

An error message indicates that the calibration or scaling process was not successful.

After the error message is displayed, the meter reverts to the input prior to the failure during calibration or

scaling and to input 1 during internal calibration, allowing the appropriate input signal to be applied or

programmed.

The error message might be caused by any of the following conditions:

1. Input signal is not connected to the proper terminals or it is connected backwards.

2. Wrong signal selection in Setup menu.

3. Minimum input span requirements not maintained.

4. Input 1 signal inadvertently applied to calibrate input 2.

Minimum Input Span

The minimum input span is the minimum difference between

input 1 and input 2 signals required to complete the calibration

or scaling of the meter.

23

Page 24

Din Mounted Digital Display Instruction Manual

Note: To scale the meter without a signal source refer to

Scaling the Meter (SCALE), page 23.

Warm up the meter for at least 15 minutes before

performing calibration to ensure specified accuracy.

Calibrating the Meter with External Source (Cal)

The meter can be calibrated to display the process variable in engineering units by applying the

appropriate input signal and following the calibration procedure.

The use of a calibrated signal source is strongly recommended to calibrate the meter.

24

Page 25

Din Mounted Digital Display Instruction Manual

Setting the Display Parameter & Intensity (dsplay)

The main display (Line 1) can be programmed to

display:

1. Process value 1 (PV1)

2. Process value 2 (PV2)

3. Percent of PV1 (PCT)

4. Relay set points

5. Max & min values

6. Modbus input

7. Display reading and units

8. Display gross

9. Toggle net & gross

The secondary display (Line 2) can be programmed

to display:

1. Unit

2. Process value 1 (PV1)

3. Process value 2 (PV2)

4. Percent of PV1 (PCT)

5. Relay set points

6. Max & min values

7. Engineering units or custom legends

8. Modbus input

9. Off (no display)

10. Toggle reading and units

11. Display gross

12. Toggle net/gross

Display Intensity: The meter has eight display

intensity levels to give the best performance under

various lighting conditions. Select intensity 8 for

outdoor applications. The default intensity setting is 8.

After setting up the input and display, press the Menu button to exit programming and skip the rest of the

setup menu. Press the Menu button again and the Up arrow to reach the Program menu and complete

the scaling or calibration of the meter.

25

Page 26

Din Mounted Digital Display Instruction Manual

Caution!

During setup, the relays do not follow the input and they will

remain in the state found prior to entering the Relay menu.

!

From

Relay 1

Menu

Latch

Act 1

S am pl

Act 1

Act 1

rly 1

A -m An

Act 1

Auto

Act 1

Lt-Clr

Act 1

Altern

Act 1

OFF

Act 1

set 1

rly 1

rst 1

rly 1

Program

Set Point

Program

Reset Point

Setting the Relay Operation (relay)

This menu is used to set up the operation of the relays.

1. Relay action

a. Automatic reset only (non-latching)

b. Automatic + manual reset at any time (non-latching)

c. Latching (manual reset only)

d. Latching with Clear (manual reset only after alarm condition has cleared)

e. Pump alternation control (automatic reset only)

f. Sampling (the relay

is activated for a

user-specified time)

g. Off (relay state

controlled by Interlock feature)

2. Set point

3. Reset point

4. Fail-safe operation

a. On (enabled)

b. Off (disabled)

5. Time delay

a. On delay (0-999.9 seconds)

b. Off delay (0-999.9 seconds)

6. Relay action for loss (break) of 4-20

mA input (ignore, on, off)

Setting the Relay Action

Operation of the relays is programmed in the Action menu.

The relays may be set up for any of the following modes of

operation:

1. Automatic reset (non-latching)

2. Automatic + manual reset at any time (non-latching)

3. Latching (manual reset only, at any time)

4. Latching with Clear (manual reset only after alarm condition has cleared)

5. Pump alternation control (automatic reset only)

6. Sampling (the relay is activated for a user-specified time)

7. Off (relay state controlled by Interlock feature)

The following graphic shows relay 1 action setup; relay 2-8 are set up in a similar fashion.

Programming Set and Reset Points

High alarm indication: program set point above reset point.

Low alarm indication: program set point below reset point.

The deadband is determined by the difference between set and reset points. Minimum deadband is

one display count. If the set and reset points are programmed with the same value, the relay will reset

one count below the set point.

Note: Changes are not saved until the reset point has been

accepted.

26

Page 27

Din Mounted Digital Display Instruction Manual

High Alarm Operation (Set > Reset)

For Manual reset mode, ACK can be pressed anytime

to turn "off" relay. To detect a new alarm condition, the

signal must go below the set point, and then go above

it.

Low Alarm Operation (Set < Reset)

For Manual reset mode, ACK can be pressed anytime

to turn "off" relay. For relay to turn back “on”, signal

must go above set point and then go below it.

Setting Fail-Safe Operation

In fail-safe mode of operation, the relay coil is energized when the process variable is within safe limits

and the relay coil is de-energized when the alarm condition exists. The fail-safe operation is set

independently for each relay. Select on to enable or select off to disable fail-safe operation.

Programming Time Delay

The On and Off time delays may be programmed for each relay between 0 and 999.9 seconds. The

relays will transfer only after the condition has been maintained for the corresponding time delay.

The On time delay is associated with the set point.

The Off time delay is associated with the reset point.

Relay Action for Loss of 4-20 mA Input (Loop Break)

The loop break feature is associated with the 4-20 mA input. Each relay may be programmed to go to one

of the following conditions when the meter detects the loss of the input signal (i.e. < 0.005 mA):

1. Turn On (Go to alarm condition)

2. Turn Off (Go to non-alarm condition)

3. Ignore (Processed as a low signal condition)

Note: This is not a true loop break condition; if the signal drops below 0.005 mA, it is interpreted as a

“loop break” condition.

Relay and Alarm Operation Diagrams

The following graphs illustrate the operation of the relays, status LEDs, and ACK button.

27

Page 28

Din Mounted Digital Display Instruction Manual

High Alarm with Fail-Safe

Operation (Set > Reset)

Note: Relay coil is energized in non-alarm

condition. In case of power failure, relay will

go to alarm state.

Low Alarm with Fail-Safe Operation

(Set < Reset)

Note: Relay coil is energized in non-alarm

condition. In case of power failure, relay will

go to alarm state.

28

Page 29

Din Mounted Digital Display Instruction Manual

Set

Reset

Relay

LED

Input

Sample

Time

Sample

Time

Sample

Time

Pump Alternation Control Operation

Relay Sampling Operation

When the signal crosses the set point, the relay trips and the sample time starts. After the sample time

has elapsed, the relay resets. The cycle repeats every time the set point is crossed, going up for high

alarms and going down for low alarms.

The sample time can be programmed between 0.1 and 5999.9 seconds.

29

Page 30

Din Mounted Digital Display Instruction Manual

Relay

LED

Input

Loop Break = Ignore

de-energized energized

off on

Relay

LED

Loop Break = Off

Relay

LED

Loop Break = On

Set

Reset

Signal Loss or Loop Break Relay Operation

The following graph shows the loop break relay operation for a high alarm relay.

When the meter detects a break in the 4-20 mA loop, the relay will go to one of the following selected

actions:

1. Turn On (Go to alarm condition)

2. Turn Off (Go to non-alarm condition)

3. Ignore (Processed as a low signal condition)

Time Delay Operation

The following graphs show the operation of the time delay function.

When the signal crosses the set point, the On time delay timer starts and the relay trips when the time

delay has elapsed. If the signal drops below the set point (high alarm) before the time delay has elapsed,

the On time delay timer resets and the relay does not change state. The same principle applies to the Off

time delay.

Note: If “Automatic or Manual (A-mAn)” reset mode is selected, the LED follows the reset point and not

the relay state when the relay is acknowledged.

30

Page 31

Din Mounted Digital Display Instruction Manual

Alarm #

HI or LO

Alarm

Set

Point

Reset

Point

Power-Up

Reading

Relay &

LED

1

HI

1000

500

499

Off 2 LO

700

900

499

On

3

LO

250

400

499

Off

4

HI

450

200

499

On

Fail-Safe

Selection

Non-Alarm State

Alarm State

Power Failure

NO

NC

NO

NC

Off

Open

Closed

Closed

Open

Relays go to

non-alarm state

On

Closed

Open

Open

Closed

Relays go to

alarm state

LED

Status

LED

Status

1

Alarm 1

5 Alarm 5

2

Alarm 2

6 Alarm 6

3

Alarm 3

7 Alarm 7

4

Alarm 4

8 Alarm 8

Relay Operation Details

Overview

The relay capabilities of the meter expand its usefulness beyond simple indication to provide users with

alarm and control functions. These capabilities include front panel alarm status LEDs as well as either 2

or 4 optional internal relays and/or 4 external relays expansion module. Typical applications include high

or low temperature, level, pressure or flow alarms, control applications such as simple on/off pump

control, and pump alternation control for up to 8 pumps. There are four basic ways the relays can be

used:

1. High or Low Alarms with Latching or Non-Latching Relays

2. Simple On/Off Control with 100% Adjustable Deadband

3. Sampling (Based on Time)

4. Pump Alternation Control for up to 8 Pumps

Relays Auto Initialization

When power is applied to the

meter, the front panel LEDs and

alarm relays will reflect the state

of the input to the meter. The

following table indicates how the

alarm LEDs and relays will react

on power-up based on the set

and reset points:

Fail-Safe Operation

The following table indicates

how the relays behave based

on the fail-safe selection for

each relay:

Note: NO = Normally Open,

NC = Normally Closed.

This refers to the

condition of the relay

contacts when the power to the meter is off.

Front Panel LEDs

The LEDs on the front panel provide status indication for the

following:

The meter is supplied with four alarm points that include front

panel LEDs to indicate alarm conditions. This standard feature

is particularly useful for alarm applications that require visualonly indication. The LEDs are controlled by the set and reset

points programmed by the user. When the display reaches a set point for a high or low alarm, the

corresponding alarm LED will turn on. When the display returns to the reset point the LED will go off. The

front panel LEDs respond differently for latching and non-latching relays.

For non-latching relays, the LED is always off during normal condition and always on during alarm

condition, regardless of the state of the relay (e.g. Relay acknowledged after alarm condition).

For latching relays, the alarm LEDs reflect the status of the relays, regardless of the alarm condition. The

following tables illustrate how the alarm LEDs function in relation to the relays and the acknowledge

button (Default: F3 key assigned to ACK).

31

Page 32

Din Mounted Digital Display Instruction Manual

Warning!

In latching relay mode, latched relays will

reset (unlatch) when power is cycled.

Relay terminology for following tables

Terminology

Relay Condition

On

Alarm (Tripped)

Off

Normal (Reset)

Ack

Acknowledged

Automatic reset only

Condition

LED

Relay

Normal

Off

Off

Alarm

On

On

Ack (No effect)

On

On

Normal

Off

Off

Automatic + manual reset at any time

Condition

LED

Relay

Normal

Off

Off

Alarm

On

On

Normal

Off

Off

Next Alarm

On

On

Ack

On

Off

Normal

Off

Off

Manual reset any time

Condition

LED

Relay

Normal

Off

Off

Alarm

On

On

Ack

Off

Off

Manual reset only after alarm

condition has cleared

Condition

LED

Relay

Normal

Off

Off

Alarm

On

On

Ack (No effect)

On

On

Normal

On

On

Ack

Off

Off

Latching and Non-Latching Relay Operation

The relays can be set up for latching (manual reset) or

non-latching (automatic reset) operation.

The On and Off terminology does not refer to the status of

the relay’s coil, which depends on the fail-safe mode

selected.

Non-Latching Relay (Auto)

In this application, the meter is set up for automatic reset

(non-latching relay). Acknowledging the alarm while it is still

present has no effect on either the LED or the relay. When

the alarm finally goes away the relay automatically resets

and the LED also goes off.

Non-Latching Relay (A-man)

In this application, the meter is set up for automatic and

manual reset at any time (non-latching relay). The LED and

the relay automatically reset when the meter returns to the

normal condition.

The next time an alarm occurs, the operator acknowledges

the alarm manually while the alarm condition still exists.

This causes the relay to reset, but the LED stays on until

the meter returns to the normal condition.

Latching Relay (LatcH)

In this application, the meter is set up for manual reset at any

time. Acknowledging the alarm even if the alarm condition is

still present resets the relay and turns off the LED.

Latching Relay (Lt-Clr)

In this application, the meter is set up for manual reset only

after the signal passes the reset point (alarm condition has

cleared). Acknowledging the alarm while it is still present has

no effect on either the LED or the relay. When the alarm is

acknowledged after it returns to the normal state, the LED

and the relay go off. Notice that the LED remains on, even

after the meter returns to the normal condition. This is

because, for latching relays, the alarm LED reflects the

status of the relay, regardless of the alarm condition.

32

Page 33

Din Mounted Digital Display Instruction Manual

Set and Reset Point Programming

Relay

Set Point

Reset Point

Function

1

30.000

10.000

Controls pump #1

2

35.000

5.000

Controls pump #2

3

4.000

9.000

Controls low alarm

4

40.000

29.000

Controls high alarm

+5 I1 I2 I3 I4 O1 O2 O3 O4 G

DO 1-4

GND

ACK

PDA1044 Digital I/O Module

1 2 3 4 5 6 7 8 9 10

DI 1-4

Acknowledging Relays

There are two ways to acknowledge relays programmed for manual reset:

1. Via the programmable front panel function keys F1-F3 (Default:

F3 assigned to ACK).

2. Remotely via a normally open pushbutton wired across one of the digital inputs and the +5 V

terminals on the digital I/O modules, or using the F4 digital input, which is triggered with a contact

closure to COM, or with an active low signal (see page 14).

When the ACK button or the assigned digital input is closed, all relays programmed for manual reset are

acknowledged.

Figure 20. Acknowledge Relays w/Function Key or Digital Input

Pump Alternation Control Applications (Altern)

For pump control applications where two or more similar pumps are used to control the level of a tank or a

well, it is desirable to have all the pumps operate alternately. This prevents excessive wear and

overheating of one pump over the lack of use of the other pumps.

Up to 8 relays can be set up to alternate every time an on/off pump cycle is completed. The set points

and reset points can be programmed, so that the first pump on is the first pump off.

Application #1: Pump Alternation Using Relays 1 & 2

1. Relays 1 and 2 are set up for pump alternation.

2. Relays 3 and 4 are set up for low and high alarm indication.

Pump Alternation Operation

1. Pump #1 turns on when level reaches 30.000, when level drops below 10.000, pump #1 turns off.

2. The next time level reaches 30.000, pump #2 turns on, when level drops below 10.000, pump #2

turns off.

3. If the level doesn’t reach 35.000, pump #1 and pump #2 will be operating alternately.

4. If pump #1 cannot keep the level below 35.000, pump #2 will turn on at 35.000, then as the level

drops to10.000, pump #1 turns off, pump #2 is still running and shuts off below 5.000.

5. Notice that with the set and reset points of pump #2 outside the range of pump #1, the first pump on

is the first pump to go off. This is true for up to 8 alternating pumps, if setup accordingly.

6. Relay #3 will go into alarm if the level drops below 4.000 and relay #4 will go into alarm if the level

exceeds 40.000.

7. Adding the 4 external relays, expansion module allows using the 4 SPDT internal relays for pump

alternation and the 4 SPST external relays for high, high-high, low, and low-low alarm indication.

33

Page 34

Din Mounted Digital Display Instruction Manual

Set and Reset Point Programming

Relay

Set Point

Reset Point

Function

1

495

750

Controls low alarm

2

7500

6900

Controls high alarm

3

7000

900

Controls backup pump

4

6000

1000

Controls main pump

Application #2: Pump Alternation Using Relays 3 & 4

1. Relays 1 and 2 are set up for low and high alarm indication.

2. Relays 3 and 4 are set up for pump alternation.

The following graphics provide a visual representation of a typical pump alternation application with high

and low alarm monitoring:

1. Relay #4 turns the main pump on at 6000

gallons and turns it off at 1000 gallons.

2. With the Pump Alternation feature

activated, the next time the level reaches

6000 gallons, relay #3 transfers and starts

the backup pump.

3. If the backup pump is not able to keep up,

and the level reaches 7000 gallons, relay

#4 transfers and starts the main pump as

well.

4. Relay #2 trips the High Level Alarm at

7500 gallons and resets at 6900 gallons.

5. Relay #1 trips the Low Level Alarm at 495

gallons and resets at 750 gallons.

34

Page 35

Din Mounted Digital Display Instruction Manual

For instructions on how to program

numeric values see Setting Numeric

Values, page 19.

1 2 3 4 5

6

+5

I1

I2

I3

I4

O1

7

8

O2

O3

9

10

O4

G