Page 1

AUTOMATION

Operator’s Manual

PRODUCTS

GROUP, INC.

ACF-10 Series

Acoustical Flow Sensor for Solids

Rev. 1a, 2/03

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • E-mail: sales@apgsensors.com

Page 2

Rev. 1a, 2/03 ACF-10 Series

Table of Contents

Warranty ......................................................................................... 2

Introduction .................................................................................... 3

Specifications .................................................................................. 4

Principle of Operation .................................................................... 5

Installation ...................................................................................... 6

Wiring ............................................................................................. 7

Adjustment ...................................................................................... 8

Cautions on Handling ................................................................... 11

Check Up ...................................................................................... 12

Dimensions ................................................................................... 13

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

1

Page 3

ACF-10 Series Rev. 1a, 2/03

• Warranty and Warranty Restrictions

APG warrants its products to be free from defects of material and

workmanship and will, without charge, replace or repair any equipment found

defective upon inspection at its factory, provided the equipment has been

returned, transportation prepaid, within 18 months from date of shipment from

factory.

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES NOT EXPRESSLY SET FORTH HEREIN, WHETHER

EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

No representation or warranty, express or implied, made by any sales

representative, distributor, or other agent or representative of APG which is

not specifically set forth herein shall be binding upon APG. APG shall not be

liable for any incidental or consequential damages, losses or expenses directly

or indirectly arising from the sale, handling, improper application or use of the

goods or from any other cause relating thereto and APG’s liability hereunder,

in any case, is expressly limited to the repair or replacement (at APG’s option)

of goods.

Warranty is specifically at the factory. Any on site service will be provided at

the sole expense of the Purchaser at standard field service rates.

All associated equipment must be protected by properly rated electronic/

electrical protection devices. APG shall not be liable for any damage due to

improper engineering or installation by the purchaser or third parties. Proper

installation, operation and maintenance of the product becomes the

responsibility of the user upon receipt of the product.

Returns and allowances must be authorized by APG in advance. APG will

assign a Return Material Authorization (RMA) number which must appear on

all related papers and the outside of the shipping carton. All returns are

subject to the final review by APG. Returns are subject to restocking charges

as determined by APG’s “Credit Return Policy”.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

2

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 4

Rev. 1a, 2/03 ACF-10 Series

• Introduction

The ACF-10 Acoustical Flow Sensor is a compact unit that detects audible

noise made by powders and grains which is converted to a relay output.

In addition, since the ACF-10 is attached to the outside of the pipe or chute

and does not contact directly with the grains to be detected, the ACF-10 will

not have critical problems of flow fluctuations caused by conventional contacttype sensor inside the pipes and chutes, and with abrasion and corrosion

problems of the contact-type sensor. The ACF-10 can be easily attached to

existing pipes with straps.

The ACF-10 is easily adjusted with the use of four LED.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

3

Page 5

ACF-10 Series Rev. 1a, 2/03

• Specifications

Operating Characteristics

On Indication ................... Red LED (4)

Output Capacity:

Relay Contact ............... 240 V 2 A AC

30 V 2 A DC (resistive load)

Sensitivity Adjustment..... Adjusting by offset and gain trimmers

Output Functions ............. Detect switch

On Delay adjusting trimmer (approx. 0.1 to 7 sec.)

Off Delay adjusting trimmer (approx. 0.1 to 7 sec.)

Ambient Temperature ...... -10 to 70°C (14 to 158°F) without dewing

Ambient Humidity ........... Max. 85% RH

Electrical Characteristics

Power Supply Voltage ..... 22~264 VDC AC (50/60 Hz)

Withstand Voltage ............ 1,500 VAC 1 minute (between line terminals and

output terminals)

Insulation Resistance ....... 500 VDC 100 MΩ (between line terminals and

output terminals)

Power Consumption ........ Approx. 2.5 VA (at 100 VAC)

Mechanical Characteristics

Vibration Proof ................ 60~2000 Hz 10 G

Others

Material ............................ ABS, PC

Construction ..................... Drip-proof (IP54)

Installation ....................... Attaching band or metal fixtures (option)

Wire Inlet ......................... PF1/2 (cable gland method, gasket I.D. ø10 and ø8)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

4

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 6

Rev. 1a, 2/03 ACF-10 Series

• Principle of Operation

When grains flow within a distributed tube such as a pipe or a chute, by

collision and friction between grains themselves or between grains and the wall

of the distributed tube, various sounds and vibrations will be generated.

The sound pickup of the ACF-10 attached outside the distributed tube

receives the generated sounds and vibrations and converts the signal to a relay

output.

Explanation of Functions

Offset Adjustment

By adjusting the signals (noise: sounds and vibrations generating during the

operation of the surrounding equipment) from the sound pickup when the

grains are not flowing, the component of noise can be cancelled.

Gain Adjustment

When the grains flows, by adjusting to amplify only the component of

signals, the signals can be increased to a desired voltage.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

5

Page 7

ACF-10 Series Rev. 1a, 2/03

• Installation

The ACF-10 can be attached by fastening the band or the metal fixtures with

two bolts.

Cautions in Selecting a Place to be Attached

Select a place where a lot of sounds and vibrations are generating to install

the ACF-10. Be sure to install the receiving part so that it can contact firmly

with the wall of a distributed tube. If the receiving part does not contact firmly

due the rugged surface of the wall, paint the surface with silicon grease etc. to

increase the contact efficiency. Unless the receiving part is in contact firmly

with the wall, the sensor will be insensitive.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

6

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 8

Rev. 1a, 2/03 ACF-10 Series

• Wiring

1

23NO4

Line

Supply Voltage: 24-264V AC/DC

Relay Contact Output: 240V 2A AC

(resistive load)

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

7

Page 9

ACF-10 Series Rev. 1a, 2/03

• Adjustment

1

NON

DETECT

ZERO RY ON

6

DETECT

OFFON

DELAYDELAYGAINOFFSET

5432

1. DETECT Switch For shifting the magnetizing state of the

output relay. The magnetizing state of the

output relay is as follows:

At Non-Detection At Detection

Detect On OFF ON

Non Detect ON OFF

2. OFFSET Adjusting Trimmer An offset adjusting trimmer for noise

component

left ... larger right ... smaller

3. GAIN Adjustment Trimmer An adjusting trimmer for amplifying only

input signals

left ... smaller right ... larger

4. ON DELAY Adjusting Trimmer A time adjusting trimmer for ON DELAY

Max. setting time is approx. 7 seconds

5. OFF DELAY Adjusting Trimmer A time adjusting trimmer for OFF

DELAY. Max. setting time is approx. 7

seconds

6. LED Display The red LED (4 pieces) indicate the

intensity of input signals. When the LED

illuminate, the relay will be switched on.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

8

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 10

Rev. 1a, 2/03 ACF-10 Series

Preparations

Attach the ACF-10 to a distributed tube to check up again the wiring before switching

on. After switching on, the ACF-10 starts operating in an initial time of some 2 seconds

by the initial time circuit. Within the initial delay time, the relay will not operate.

(1) Flow Detection

Set the OFFSET trimmer to center, the GAIN trimmer to extreme left (min.)

and the DETECT switch to DETECT position before starting the following

procedures.

Operation Indication

1 ★ Stop the flow grains ZERO RY ON

(The magnitude of noise ❍ ❍ ❍ ❍

component is indicated)

2 Rotate the OFFSET trimmer to ZERO RY ON

illuminate the ZERO LED ❍ ❍ ❍ ❍

3 ★ Start flowing grains. ZERO RY ON

Rotate the GAIN trimmer to ad- ❍ ❍ ❍ ❍

just to illuminate RY ON LED

❊

❊

❊

(2) Plugged Detection

Set the OFFSET trimmer to center, the GAIN trimmer to extreme left (min.)

and the DETECT switch to DETECT position before starting the following

procedures.

Operation Indication

1 ★ Grains flowing. ZERO RY ON

(Rotate the GAIN trimmer 3-4 ❍ ❍ ❍ ❍

readings to the right)

2 Rotate the OFFSET trimmer to ZERO RY ON

a position where the RY ON ❍ ❍ ❍ ❍

LED is put out.

3 Rotate the GAIN trimmer to ad- ZERO RY ON

just to illuminate RY ON LED ❍ ❍ ❍ ❍

4 ★ Stop the flow of grains. ZERO RY ON

❍ ❍ ❍ ❍

❊

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

❊

❊

❊

9

Page 11

ACF-10 Series Rev. 1a, 2/03

Other Functions

(1) Setting of DETECT switch

• Depending upon position of DETECT switch, the relay will operate as

follows:

Relay Contact

Detect Side OFF OPEN

Non Detect Side ON CLOSE

Relay Contact

Detect Side ON CLOSE

Non Detect Side OFF OPEN

(2) Setting of DELAY TIME

ON DELAY OFF DELAY

0.1 to 7 seconds 0.1 to 7 seconds

ON DELAY: Delay in output for change from non-detection to detection.

OFF DELAY: Delay in output for change from detection to non-detection.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

10

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 12

Rev. 1a, 2/03 ACF-10 Series

• Cautions on Handling

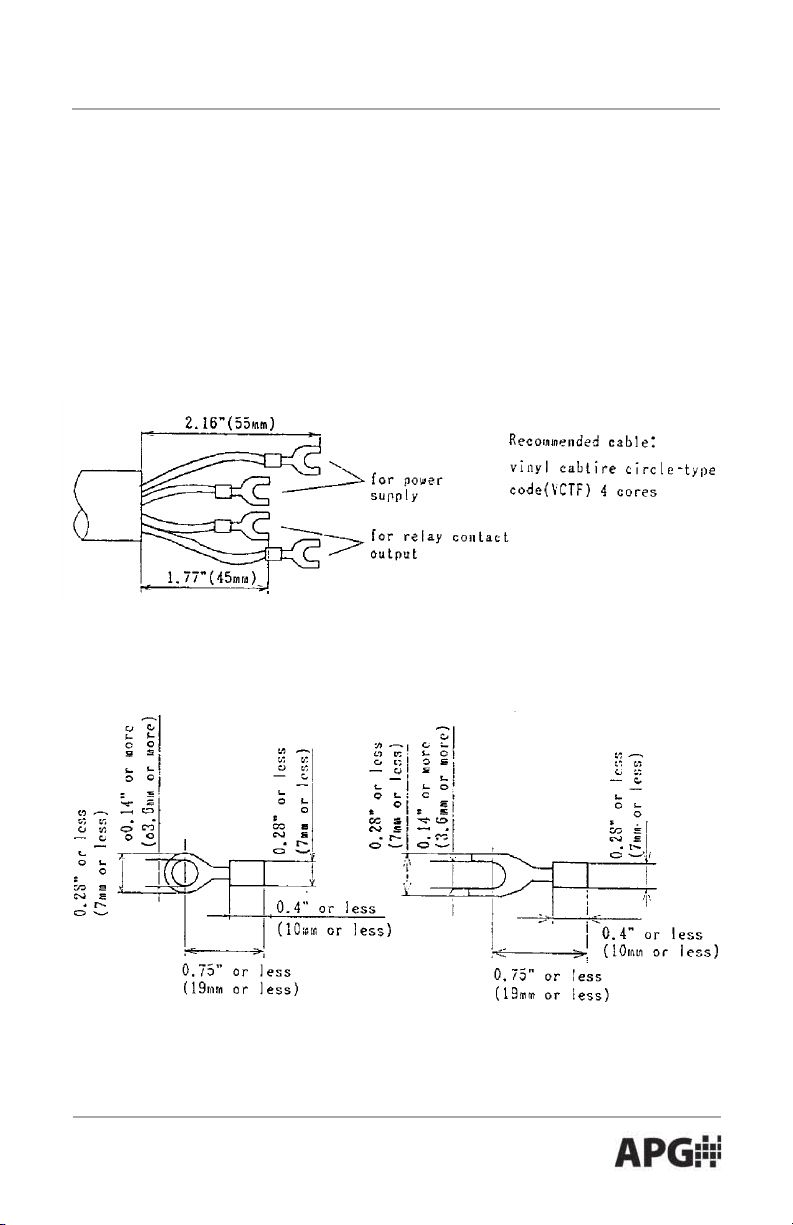

Wiring

Use the connection cables of ø5 to ø10 mm cross section.

If using cables other than specified diameter and strained cables, drip-proof

must be maintained.

Treat the cable as shown in the following figure.

After passing the cable through the cable gland, making press-fit is

recommended for easy-to-work.

Shape of solderless terminals for cable

Use the solderless terminal with the size as shown in the figure below.

Recommended press-fit terminal: nominal 1.25-3.5

Use the terminal with insulating tube.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

11

Page 13

ACF-10 Series Rev. 1a, 2/03

Other Cautions

• If the ACF-10 is dropped or receive a strong shock, it may be damaged.

Handle with care.

• Do not use the ACF-10 in a vapor and corrosive gases or misty

environments.

• Be sure to check up the terminal numbers before wiring. Be sure to fasten

the cable gland and the cover. If the fastening is loose, this may damage the

drip-proof.

• When using the ACF-10 outside, install to avoid direct sunlight or attach a

sunshading cover to avoid the temperature rise and the effect of ultraviolet

rays.

• Check Up

Check up the ACF-10’s operational functions with the following procedures.

Be sure to wire the ACF-10 before switching on. In approximately 2 seconds,

set the OFFSET trimmer in the center to tap lightly the receiving part by a

finger nail. When the illumination of the LED moves rightward from the zero

point, the operations are regarded as normal.

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

12

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

Page 14

Rev. 1a, 2/03 ACF-10 Series

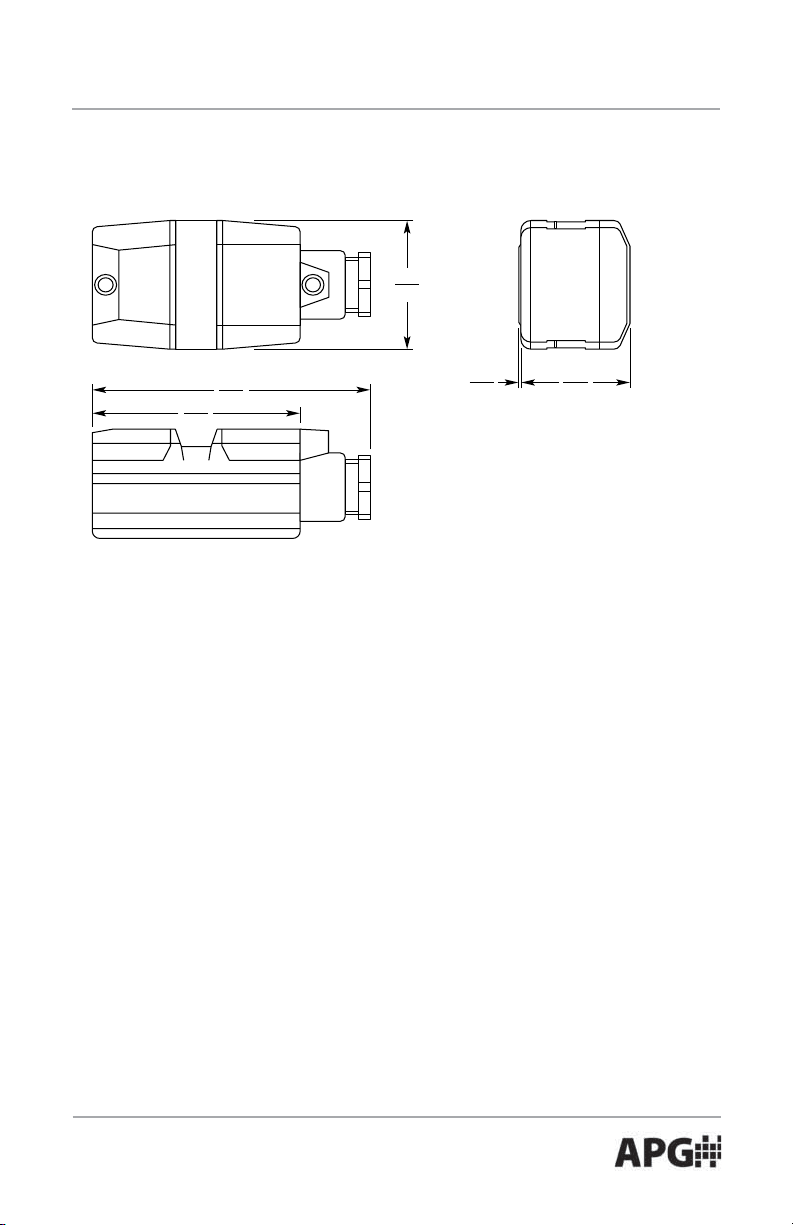

• Dimensions — in./mm

1.97

50

3.15

80

4.21

107

0.02

0.5

1.65

42

Automation Products Group, Inc.

APG...Providing tailored solutions for measurement applications

Tel: 1/888/525-7300 • Fax: 1/435/753-7490 • www.apgsensors.com • sales@apgsensors.com

13

Page 15

AUTOMATION

APG...Providing tailored solutions

for measurement applications

Automation Products Group, Inc.

Tel: 1/888/525-7300

Fax: 1/435/753-7490

GROUP, INC.

1/435/753-7300

PRODUCTS

e-mail: sales@apgsensors.com

www.apgsensors.com

Automation Products Group, Inc.

1025 W. 1700 N.

Logan, UT 84321

Loading...

Loading...