Page 1

APG

Thank You

Automation Products Group, Inc.

Automation Products Group, Inc.

Thanks for purchasing a Hammer Union Pressure Transmitter from us! We appreciate your

business and your trust. Please take a moment to familiarize yourself with the product and this

manual before installation. If you have any questions, at any time, don’t hesitate to call us at 888525-7300.

NOTE: Scan the QR code to the right to see the full

user manual on your tablet or smartphone. Or visit

www.apgsensors.com/support to nd it on our website.

Table of Contents

Hammer Union Pressure Transmitters

Installation Guide

For The HU-L24 & HU-L27

1.Description

2. How To Read Your Label

3. Warranty

4. Dimensions

Description

1

5. Mounting Instructions

6. Wiring Information

7. Calibration Shunt Procedure

8. General Care

9. Repair & Return Information

10. Removal Instructions

11. Hazardous Location Wiring

APG’s Hammer Union Pressure Transmitter is extremely rugged and designed for the environments

of land-based and oshore drilling installations. It is certied intrinsically safe for hazardous areas in

the US, Canada, Europe and internationally by CSA, ATEX, and IECEx for Class I, Zone 0, and Class II,

Division 1, Groups C and D environments.

How To Read Your Label

2

Each label comes with a full model number, a part number, and a serial number. The model

number for your Hammer Union Pressure Transmitter will look something like this:

SAMPLE: HU-L24-10K-E2-P34-K0

The model number correlates with all the congurable options and tells you exactly what you have.

Compare the model number to the options on the datasheet to identify your exact conguration.

You can also call us with the model, part, or the serial number and we can help you.

The label also includes the pinout.

You will also nd all hazardous certication information on the label.

R

Automation Products Group, Inc.

1025 W 1700 N Logan, UT 84321

www.apgsensors.com | phone: 888-525-7300 | email: sales@apgsensors.com

Mounting Instructions

5

Doc #9004050 Rev B

Part #122950-0002

Mounting your pressure transducer is easy if you follow a few simple steps:

• Ensure mating union faces are clean, dry, and free of debris.

• Place Hammer Union Pressure Transmitter in socket.

• Place Hammer Union wing nut on transmitter and tighten into place.

• Hammer wing nut until tight.

DANGER: Mismatched unions and nuts can result in dangerous or hazardous equipment

failures. Always check identications on both union pieces and nuts prior to installation. Only

use pieces with matching union gure numbers, sizes, and pressure ratings.

Wiring Information

6

The label on your Hammer Union Pressure Transmitter includes the pinout table for your device.

Check that your electrical system wiring matches the pinout table on your device prior to electrical

installation.

Warranty

3

This product is covered by APG’s waranty to be free from defects in material and workmanship

under normal use and service of the product for 24 months. For a full explanation of our Warranty,

please visit https://www.apgsensors.com/about-us/terms-conditions. Contact Technical Support to

recieve a Return Material Authorization before shipping your product back.

Scan the QR code below to read the full explanation of our Warranty on your tablet or smartphone.

IMPORTANT: Refer to section 11 for Hazardous Location Wiring.

IMPORTANT: Hammer Union Pressure Transmitter MUST be installed according to drawing

9002460 (Intrinsically Safe Wiring Diagram) to meet listed approvals. Faulty installation will

invalidate all safety approvals and ratings.

Calibration Shunt Procedure

7

APG’s Hammer Union Pressure Transmitters provide a true 20.0 mA calibration shunt output when

10 to 28 VDC is applied to the designated + Shunt Cal pin. See the pinout chart on your Hammer

Union Pressure Transmitter’s label.

General Care

8

Your Hammer Union Pressure Transmitter is designed to be maintenance free. As such, there are

no customer servicable parts on or in the device. However, in general, you should:

• Avoid touching the diaphragm. Contact with the diaphragm, especially with a tool, could

permanently shift the output and ruin accuracy.

• Clean the diaphragm or the diaphragm bore only with extreme care. If using a tool is

required, make sure it does not touch the diaphram.

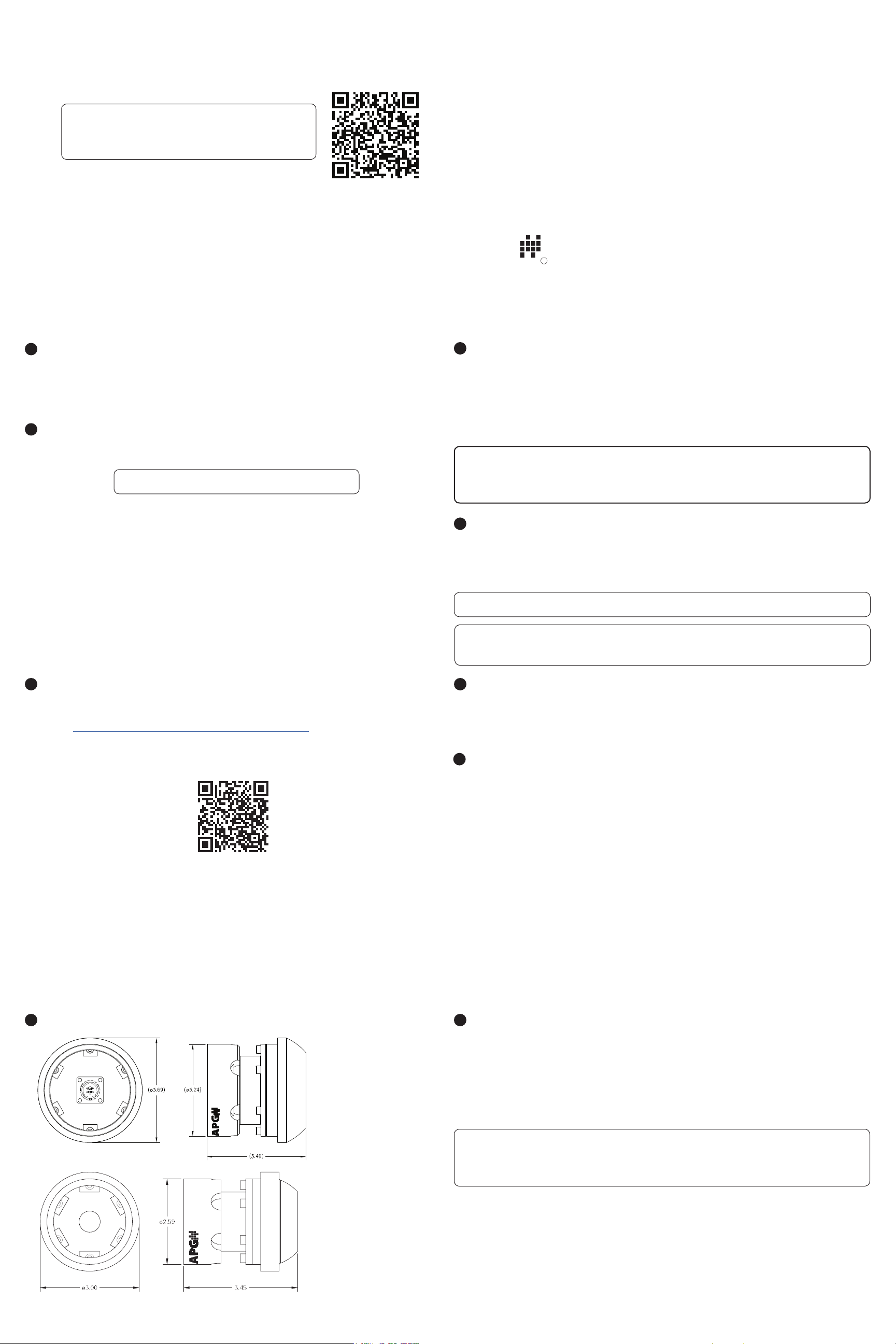

Dimensions

4

Repair & Return Information

9

If your pressure transmitter needs repair, contact us via email, phone, or online chat on our

website. We will issue you an RMA number with instructions.

Model: HU-Lnn-IS-nnK-PSIS

Serial #: .

Mfg Date: .

PN: nnnnnn-nnnn

PN: nnnnnn-nnnn

Hammer Union with

1502 Fitting

888-525-7300

• Phone: 888-525-7300

• Email: sales@apgsensors.com

• Online chat at www.apgsensors.com

IMPORTANT: All repairs and adjustments of the Hammer Union Pressure Transmitter must

be made by the factory. Modifying, disassembling, or altering the Hammer Union Pressure

Transmitter on site is strictly prohibited.

Model: HU-Lnn-IS-nnK-PSIS

Serial #: .

Mfg Date: .

PN: nnnnnn-nnnn

PN: nnnnnn-nnnn

Hammer Union with

2002 / 2202 Fitting

888-525-7300

Page 2

Removal Instructions

10

Removing your Hammer Union Pressure Transmitter from service must be done with care. It’s easy

to create an unsafe situation if you are not careful to follow these guidelines:

• Make sure the pressure is completely removed from the line where your sensor is installed.

Follow any and all procedures for safely isolating any media contained inside the line.

• Remove the Hammer Union wing nut.

• Remove your Hammer Union Pressure Transmitter.

• Clean the sensor’s tting and diaphragm of any debris (see instructions in Section 8 above)

and inspect for damage.

• Store your sensor in a dry place, at a temperature between -40° F and 180° F.

DANGER: Removing your Hammer Union Pressure Transmitter while there is still pressure

in the line could result in injury or death.

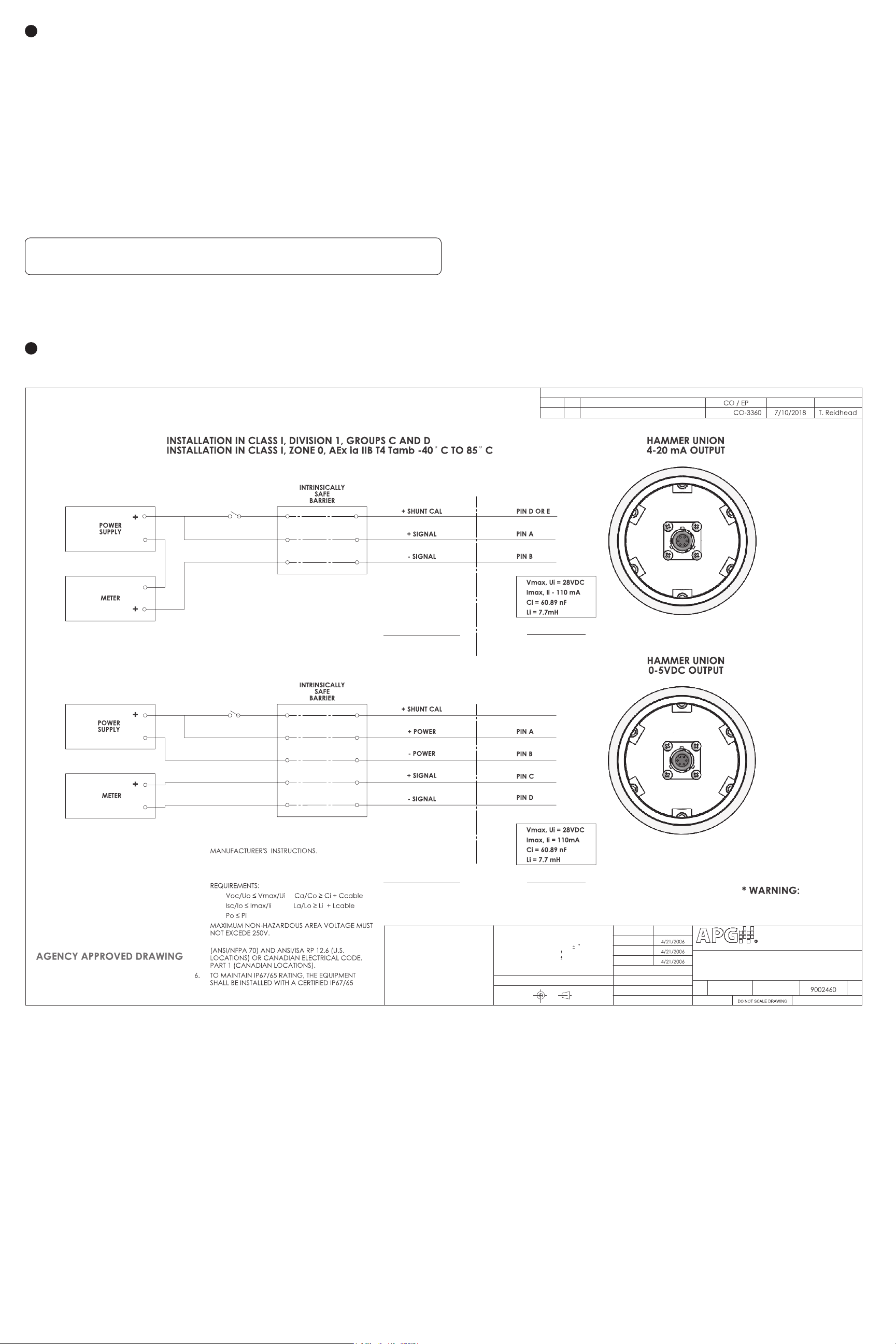

Hazardous Location Wiring

11

Intrinsically Safe Wiring (4-20mA / 0-5VDC Output)

-

-

NON-HAZARDOUS AREA

REV

ZONE

--

D

HAZARDOUS AREA

SEE CHANGE ORDER.

DESCRIPTION

REVISIONS

DATE

APPROVED

-

-

DO NOT ALTER WITHOUT PROPER APPROVAL

FROM THE CONTROLLING AGENCY

AUTHORIZED PERSON AND THE NOTIFIED BODY.

1.

BARRIERS MUST BE NRTL APPROVED AND MUST BE

INSTALLED IN ACCORDANCE WITH

THIS DEVICE MUST BE CONNECTED TO AN

2.

APPROVED SAFETY BARRIER.

BARRIER PARAMETERS MUST MEET THE FOLLOWING

3.

A.

B.

C.

4.

INSTALL IN ACCORDANCE WITH THE NEC

5.

MATING CONNECTOR.

NON-HAZARDOUS AREA

PROPRIETARY AND CONFIDENTIAL

THIS DRAWING IS THE PROPERTY OF

AUTOMATION PRODUCTS GROUP, INC.

LOGAN, UTAH AND MAY NOT BE

USED, REPRODUCED, PUBLISHED, OR

DISCLOSED TO OTHERS WITHOUT

WRITTEN CONSENT OF THE COMPANY.

IF LOANED, IT IS SUBJECT TO RETURN

UPON DEMAND AND MAY NOT BE USED

IN ANY WAY DIRECTLY OR INDIRECTLY

DETRIMENTAL TO THE COMPANY.

HAZARDOUS AREA

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

AND TOLERANCES ARE AS FOLLOWS:

TOLERANCE ON ANGLES:

2 PLACES:

3 PLACES:

INTERPRET DIMENSIONS AND TOLERANCES

PER ASME Y14.5-2009

THIRD ANGLE PROJECTION

.01

.005

1

APPROVALS

DRWN

R. OBORN

CHKD

E. TOLMAN

APVD

M. HARVEY

CONTRACT

MATL

FINISH

DATE

AUTOMATION PRODUCTS GROUP, INC.

CSA INTRINSICALLY SAFE HAZARDOUS

INSTALLATION DRAWING HAMMER

SIZE

CAGE CODE

C

52797

SCALE

1:1

ACTUAL PINOUT PER LABEL ON UNIT.

SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY.

1025 West 1700 North

Logan, Utah USA

888.525.7300

UNION PRESSURE TRANSMITTER

PART NO

PER ORDER

DOCUMENT NO

SHEET

1 OF 1

REV

D

Loading...

Loading...