APCOM UT1 Installation Manual

Effective: 6/11/18

Kit: 100306289

Instruction Sheet: APCOM Model # UT1 Point of Use Hot Water Recirculation System (For use with Tank Systems)

THANK YOU for purchasing a new APCOM Hot water Recirculation System! For optimum reliability and performance please follow the installation instructions outlined below.

NOTE: Please note that this is not an anti-scald unit. There may be some warm water in the cold water line under the sink where the circulator is installed. Once the cold water line is opened, the warm water will disappear in a short time. (Longer hot water lines may result in longer time for hot water to reach the sink.)

APPLICATION

The APCOM circulators are designed to deliver hot water instantly at the point of use (under sink). Water savings can be as great as 12,000 – 15,000 gallons per year with 4-5 taps in a home. The UT1 circulator together with the APCOM “On Call™” accessories are designed to be user friendly, reliable and to produce a professional installation.

Contact with the electrical parts can result in severe injury or death from electrical shock. To reduce the risk of shock, follow these instructions:

•Turn off power to your water heater at the circuit breaker before installing.

•Turn off power to water heater and recirculation system before servicing.

•Use a non-contact circuit tester to confirm that power is off before working on or near any electrical parts.

•Do not plug in circulation pump until installation is complete and insure that it is plugged into a grounding type receptacle.

•Use only in proper applications and do not install outdoors or in pool or marine areas.

•Observe all applicable electric and plumbing codes.

NOTICE: The UT1 has been evaluated for use with water only. The suitability of The UT1 for use with liquids other than water is the responsibility of the end user.

SYSTEM REQUIREMENTS

Minimum water pressure 20 psi, Maximum water pressure 125 psi, Maximum water temperature 176F (80 C)

•Both commercial and residential water heaters can make water hot enough to cause severe burns instantly, resulting in severe injury or death.

•Higher temperatures increase the risk of scalding, but even at 120°F, hot water can scald.

•Always feel water before bathing or showering. Water heaters can generate water hotter than its temperature setting in certain circumstances.

•To reduce the risk of scalding, Thermostatic Mixing Valves (temperature limiting valves) should be installed at each point-of-use. These valves automatically mix hot and cold water to limit the temperature at the tap. Mixing valves are available from your local plumbing supplier. Follow manufacturer’s instructions for installation and adjustment of the valves.

•THIS PRODUCT IS NOT AN ANTI-SCALD DEVICE

SHIPMENT INSPECTION

Examine all components carefully to ensure they are all present and they have not been damaged in transit to you. Care should be taken to avoid dropping or mishandling the UT1. Damage to the UT1 may occur if it is dropped.

KIT CONTENTS

The UT1 Hot Water Recirculation kit includes:

(1) Pump, model AM7-SU1LAM complete with mounting bracket, prewired 10 foot flexible cord, and built-in Aquastat

(1)Union tail piece without red marking.

(1)Union tail piece with red marking.

(2)Union nuts.

(2) Union gaskets.

(2) Flex hoses 1/2” NPS x 1/2” NPS 24 inches long.

(2) Tee, 3/8” compression x 1/2” NPS x 3/8” compression.

REQUIRED TOOLS

(2) - Pipe wrenches which open to at least 1 1/2”

(1) - Adjustable wrench which opens to at least 1”

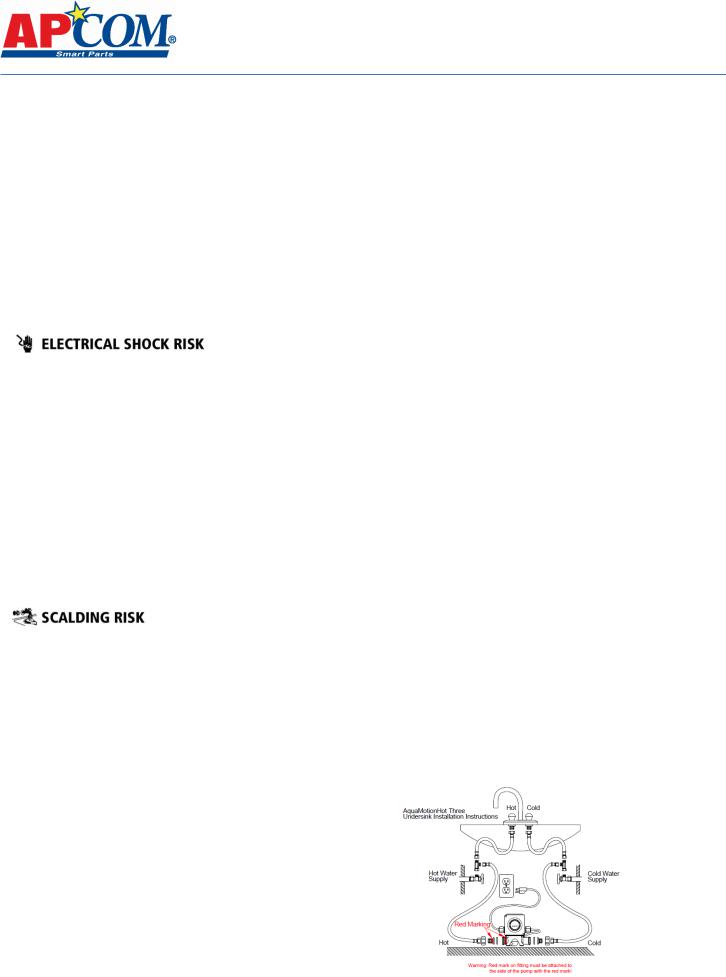

INSTRUCTIONS for Model #UT1 (see Fig. 1)

1.Locate the hot and cold shut off valves (angle stops) typically located near the faucet(s) under the counter.

2.Close both shut off valves and disconnect the flexible hoses attached to each valve by turning the nut at the end of the hoses counter-clockwise.

3.Install one Tee at each valve. Connect female port of the Tee to the port on the valves from which you have just disconnected the hoses.

4.Connect the hoses which you had disconnected from the valves to the top port of the Tee. MAKE SURE TO CONNECT THE HOSES TO THE SAME VALVE TO WHICH THEY HAD ORIGINALLY BEEN CONNECTED.

5.Attach the unions (gaskets, nuts and tail pieces) to the pump casing. The gaskets must be located between pump casing and tail piece. MAKE SURE THE TAIL PIECE MARKED RED IS MATCHED UP WITH THE RED MARKING ON THE INLET SIDE (THAT IS OPPOSITE DIRECTION OF ARROW) OF THE PUMP.

You will need two pipe wrenches that open to at least 1 1/2” inches.

Firmly tighten the two union nuts to avoid leaks. Do not install the pump upside down.

6.Place the pump into its intended location with the bracket on the floor and fasten with screws if necessary. It is also possible to install the pump horizontally but make sure that the wall to which it is fastened is sturdy enough to support the pump. NOTE: Be sure the arrows on the pump point to the cold water side.

7.Install the flex hoses by attaching one end to the remaining port of the Tee and the other end to the pump. MAKE SURE THE HOSE ATTACHED TO THE HOT VALVE IS CONNECTED TO THE INLET SIDE (THAT IS THE OPPOSITE DIRECTION OF THE ARROW) OF THE PUMP. MAKE SURE THE HOSE ATTACHED TO THE COLD VALVE IS CONNECTED TO THE DISCHARGE SIDE (THAT IS THE SIDE THE ARROW IS POINTING TO) OF THE PUMP.

8.Open the valves. Check for leaks.

9.Plug in the cord to any convenient grounded, 115 volt outlet. Your kit contains a circulator with a built-in timer. Follow the step by step directions on the timer instruction sheet to program the timer to meet your hot water needs.

10.The system will settle in 2 to 3 hours. Opening faucets will help release any trapped air.

(Figure 1) APCOM

Model #UT1 (Under

Sink Installation

Instructions)

100316132

Loading...

Loading...