Page 1

English User's Manual

Page 2

Main Tech Support:

Phone ......................... +353 91 702020

Fax .............................. +353 91 755275

E-Mail......................... apceurtech@apcc.com

Toll-Free Numbers:

Ireland ........................ 1-800-702000 x2045

Austria ........................ 0660 6480

Belgium ...................... 0800 15063

Czech Republic .......... 0800 102063

Denmark .................... 800 18 153

France ......................... 0800 906 483

Finland ....................... 9800 13 374

Germany .................... 0130 818907

Holland ...................... 0800 0224655

Hungary ..................... 00800 12221

Israel ........................... 177 353 2206

Italy............................. 1678 74731

Luxembourg............... 0800 2091

Norway ....................... 800 11 632

Poland ........................ 00800 353 1202

Portugal ...................... 050 553182

South Africa ............... 0800 994206

Spain........................... 900 95 35 33

Sweden ....................... 020 795 419

Switzerland................. 0800 556177

Turkey ........................ 0800 353 90275

United Kingdom ........ 0800 132990

Not Toll-Free Numbers:

Russia ......................... +7 095 916 7166

Page 3

Important Safety Instructions!Important Safety Instructions!

Important Safety Instructions!

Important Safety Instructions!Important Safety Instructions!

Please read this manual!

Veuillez lire ce manuel!

Bitte lesen Sie dieses Anleitungshandbuch!

¡Se ruega leer este manual de instrucciones!

This User's Manual provides safety, installation and operating instructions that will help you derive the fullest performance and

service life that the SymmetraTM Power Array has to offer.

PLEASE SAVE THIS USER'S MANUAL! It includes important instructions for the safe use of the SymmetraTM Power Array, and

for obtaining factory service should the proper operation of the system or the components come into question. Service or storage

issues may arise at a later date, and may require reference to this User's Manual, or to the technical support information that is

included in it.

CONSERVER CES INSTRUCTIONS! Cette notice contient des instructions importantes concernant la sécurité.

Radio Frequency Interference

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules and the Class A limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of

the Canadian Department of Communications. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with the Class A FCC limits.

WARNING: Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the

users authority to operate the equipment.

Part #: 990-7779 Rev. 1

Revised 3/98

Page 4

Limited Warranty

American Power Conversion (APC) warrants its products to be free from defects in materials and workmanship for a period of one

year from the date of purchase. Its obligation under this warranty is limited to repairing or replacing, at its own sole option, any

such defective products. To obtain service under warranty you must obtain a Returned Material Authorization (RMA) number

from APC or an APC service center. Products must be returned to APC or an APC service center with transportation charges

prepaid and must be accompanied by a brief description of the problem encountered and proof of date and place of purchase.

This warranty does not apply to equipment which has been damaged by accident, negligence, or mis-application or has been

altered or modified in any way. This warranty applies only to the original purchaser who must have properly registered the

product within 10 days of purchase.

EXCEPT AS PROVIDED HEREIN, AMERICAN POWER CONVERSION MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Some states do not

permit limitation or exclusion of implied warranties; therefore, the aforesaid limitation(s) or exclusion(s) may not apply to the

purchaser.

EXCEPT AS PROVIDED ABOVE, IN NO EVENT WILL APC BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF THIS PRODUCT, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. Specifically, APC is not liable for any costs, such as lost profits or revenue, loss of equipment, loss of use

of equipment, loss of software, loss of data, costs of substitutes, claims by third parties, or otherwise. This warranty gives you

specific legal rights and you may also have other rights which vary from state to state.

Life Support Policy

As a general policy, American Power Conversion (APC) does not recommend the use of any of its products in life support applications where failure or malfunction of the APC product can be reasonably expected to cause failure of the life support device or

to significantly affect its safety or effectiveness. APC does not recommend the use of any of its products in direct patient care. APC

will not knowingly sell its products for use in such applications unless it receives in writing assurances satisfactory to APC that (a)

the risks of injury or damage have been minimized, (b) the customer assumes all such risks, and (c) the liability of American Power

Conversion is adequately protected under the circumstances.

Examples of devices considered to be life support devices are neonatal oxygen analyzers, nerve stimulators (whether used for

anesthesia, pain relief, or other purposes), autotransfusion devices, blood pumps, defibrillators, arrhythmia detectors and alarms,

pacemakers, hemodialysis systems, peritoneal dialysis systems, neonatal ventilator incubators, ventilators for both adults and infants, anesthesia ventilators, infusion pumps, and any other device designated as critical by the U.S.F.D.A.

Hospital grade wiring devices and leakage current may be ordered as options on many APC UPS systems. APC does not claim that

units with this modification are certified or listed as Hospital Grade by APC or any other organization. Therefore these units do

not meet the requirements for use in direct patient care.

Entire contents copyright © 1998 American Power Conversion. All rights reserved; reproduction in whole or in part without

permission is prohibited. Symmetra, Power Array, SmartSlot, SmartCell and SNMP Adapter are trademarks of APC. Power-

Chute and PowerDoctor are registered trademarks of APC. All other trademarks are the property of their respective owners.

Page 5

TT

able of Contentsable of Contents

T

able of Contents

TT

able of Contentsable of Contents

INTRODUCTION

SAFETY INFORMATION

1. PHYSICAL REPRESENTATION

Theory of Operation ................................................................................................................. i

Modes of Operation .................................................................................................................. iii

Symbols Used In This Manual ......................................................................................... safety-1

Important Safety Instructions .......................................................................................... safety-1

The Power Array Frame ............................................................................................................ 1-1

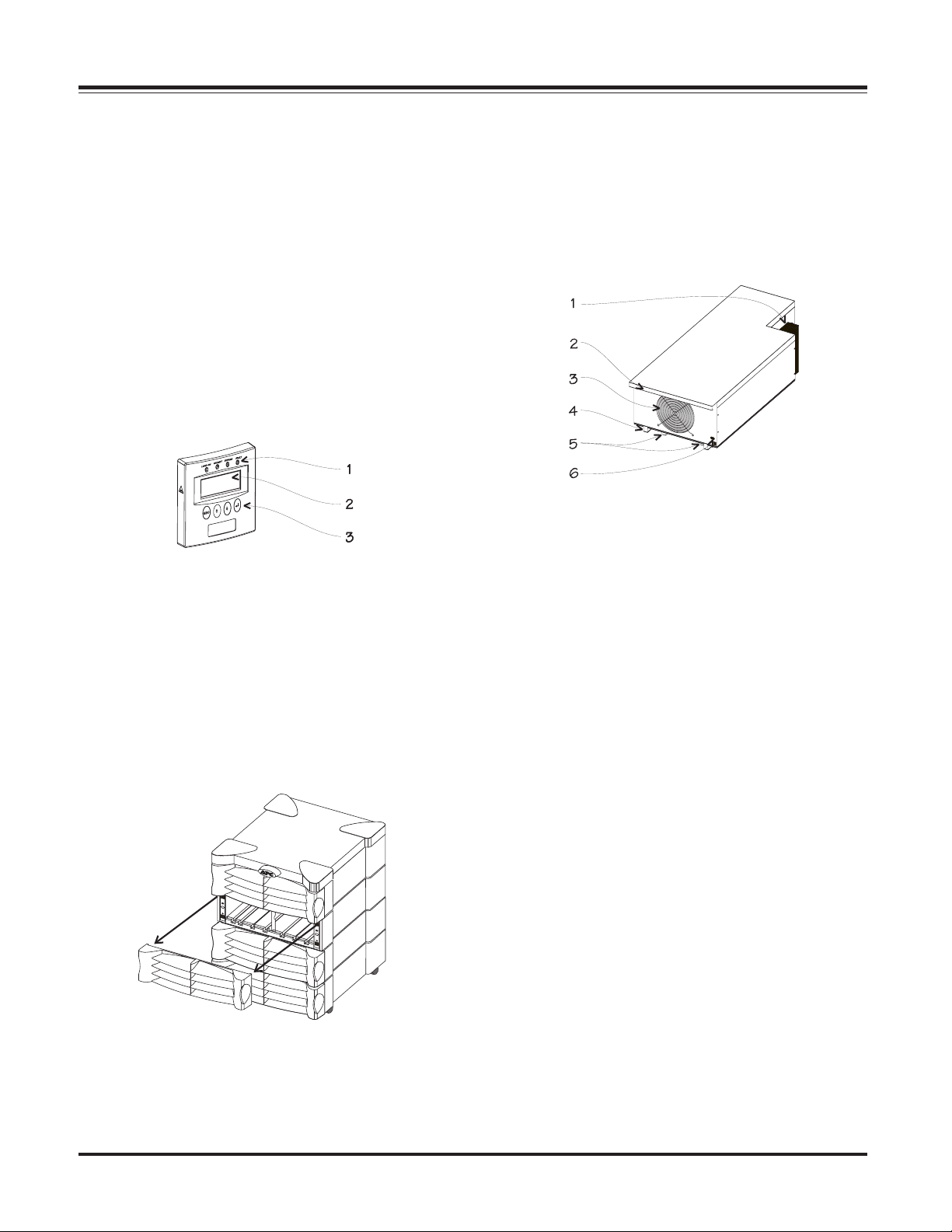

PowerView User Interface ......................................................................................................... 1-2

Grill Covers ................................................................................................................................ 1-2

Power Module............................................................................................................................ 1-2

Battery Module .......................................................................................................................... 1-2

Main Intelligence Module (MIM) ........................................................................................... 1-3

Redundant Intelligence Module (RIM) ................................................................................... 1-3

Input Circuit Breaker ................................................................................................................ 1-3

Maintenance Bypass Switch ..................................................................................................... 1-3

Rear View of Power Array ......................................................................................................... 1-4

System Enable Switch ................................................................................................................ 1-4

Communication Interface Ports .............................................................................................. 1-4

SmartSlotTM Accessory Ports ..................................................................................................... 1-4

REPO/Input/Output Wiring Panels ........................................................................................ 1-4

Convenience Power Panel ......................................................................................................... 1-4

Extended Run Battery Frame Connector ................................................................................ 1-4

2. SITE PREPARATION

Space and Weight Considerations ........................................................................................... 2-1

Transporting Power Array to Installation Site ........................................................................ 2-1

Operating Conditions ............................................................................................................... 2-1

BTU Output ............................................................................................................................... 2-1

3. UNPACKING AND INSTALLING FRAME

Initial Inspection ....................................................................................................................... 3-1

Check For Damage .................................................................................................................... 3-1

Handling Considerations ......................................................................................................... 3-1

Move the Frame ......................................................................................................................... 3-1

Remove Packing Materials........................................................................................................ 3-2

Remove the Frame from the Pallet .......................................................................................... 3-2

Moving Battery & Power Modules .......................................................................................... 3-2

4. WIRING REQUIRMENTS & PROCEDURES

Wiring Overview ....................................................................................................................... 4-1

Input Wiring .............................................................................................................................. 4-2

Output Wiring ........................................................................................................................... 4-4

Remote Emergency Power Off Wiring .................................................................................... 4-5

Electrical Wiring Test/Checklist ............................................................................................... 4-6

Page 6

5. SETTING UP THE POWER ARRAY

Overview of Setup ..................................................................................................................... 5-1

Frame Leveling Procedure ........................................................................................................ 5-1

Installing the Battery Modules ................................................................................................. 5-2

Installing the Power Modules ................................................................................................... 5-3

Installing the Main Intelligence Module (MIM) .................................................................... 5-4

Installing the Redundant Intelligence Module (RIM) ........................................................... 5-4

Installing the PowerView Interface .......................................................................................... 5-5

SmartSlotTM Interface Accessories ............................................................................................. 5-6

Installation Test/Checklist ........................................................................................................ 5-7

6. THE POWERVIEW USER INTERFACE

Overview .................................................................................................................................... 6-1

PowerView Functions ............................................................................................................... 6-1

PowerView LED Indicators ...................................................................................................... 6-2

Navigation Keys ......................................................................................................................... 6-2

Startup Screen ........................................................................................................................... 6-3

Top-Level Menu Screen ............................................................................................................ 6-3

Language Configuration ........................................................................................................... 6-4

7. CONFIGURING & OPERATING THE SYMMETRA

Introduction .............................................................................................................................. 7-1

Step #1: Powering the System ................................................................................................... 7-1

Step #2: Powering the Loads ..................................................................................................... 7-2

Step #3: Review Status Conditions .......................................................................................... 7-2

Step #4: Perform a Self Test ...................................................................................................... 7-4

Step #5: Configure Shutdown Parameters .............................................................................. 7-5

Step #6: Configure Alarms ........................................................................................................ 7-5

Step #7: Review Diagnostics Menu .......................................................................................... 7-6

Step #8: Review Logging Menu ................................................................................................ 7-6

8. MODULE REPLACEMENT

Module Failure Alarm Indicators .......................................................................................... 8-1

Technical Support and Obtaining a Replacement Module ................................................. 8-1

Battery Module Replacement Procedure .............................................................................. 8-2

Power Module Replacement Procedure ................................................................................ 8-3

Main Intelligence Module Replacement Procedure ............................................................. 8-4

Redundant Intelligence Module Replacement Procedure ................................................... 8-4

9. POWERVIEW INTERFACE MESSAGES

Start-Up Messages ................................................................................................................... 9-1

General Status Messages ......................................................................................................... 9-2

Module Failure Messages ........................................................................................................ 9-3

Threshold Alarm Messages ..................................................................................................... 9-3

Bypass Messages ...................................................................................................................... 9-3

General Fault Messages ........................................................................................................... 9-4

INDEX

Page 7

Introduction

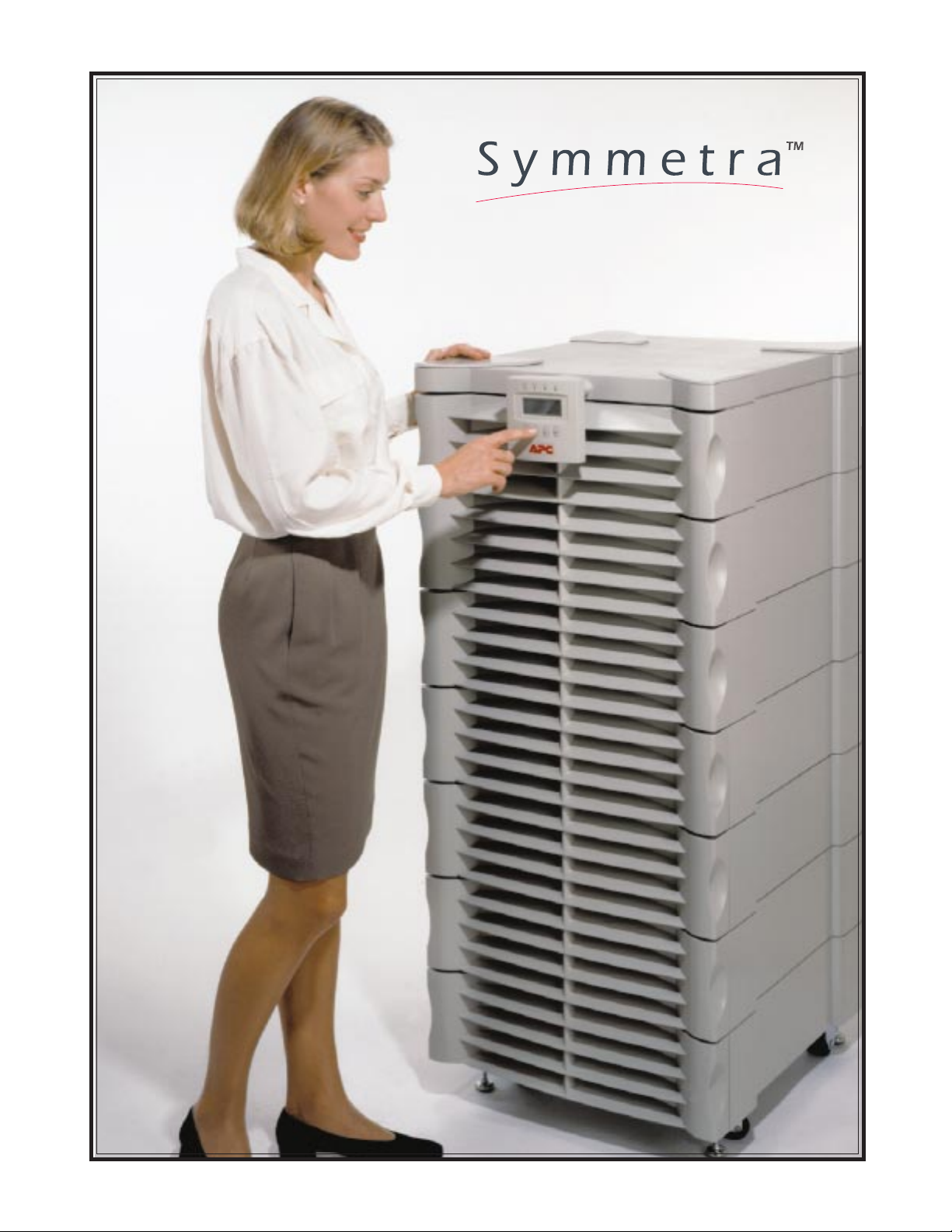

The APC SymmetraTM Power Array is a

scalable, redundant power protection sys-

tem for multiple servers and business

critical applications. This is an introduction

to the SymmetraTM Power Array.

MiniFrame

MasterFrame

Page 8

Thank YThank Y

Thank Y

Thank YThank Y

ou!ou!

ou!

ou!ou!

Theory of OperationTheory of Operation

Theory of Operation

Theory of OperationTheory of Operation

Thank you for investing in the SymmetraTM Power Array. Please

read this User's Manual thoroughly before installing the system. It provides important information for using the

SymmetraTM safely and effectively.

TMTM

TM

SymmetraSymmetra

Symmetra

SymmetraSymmetra

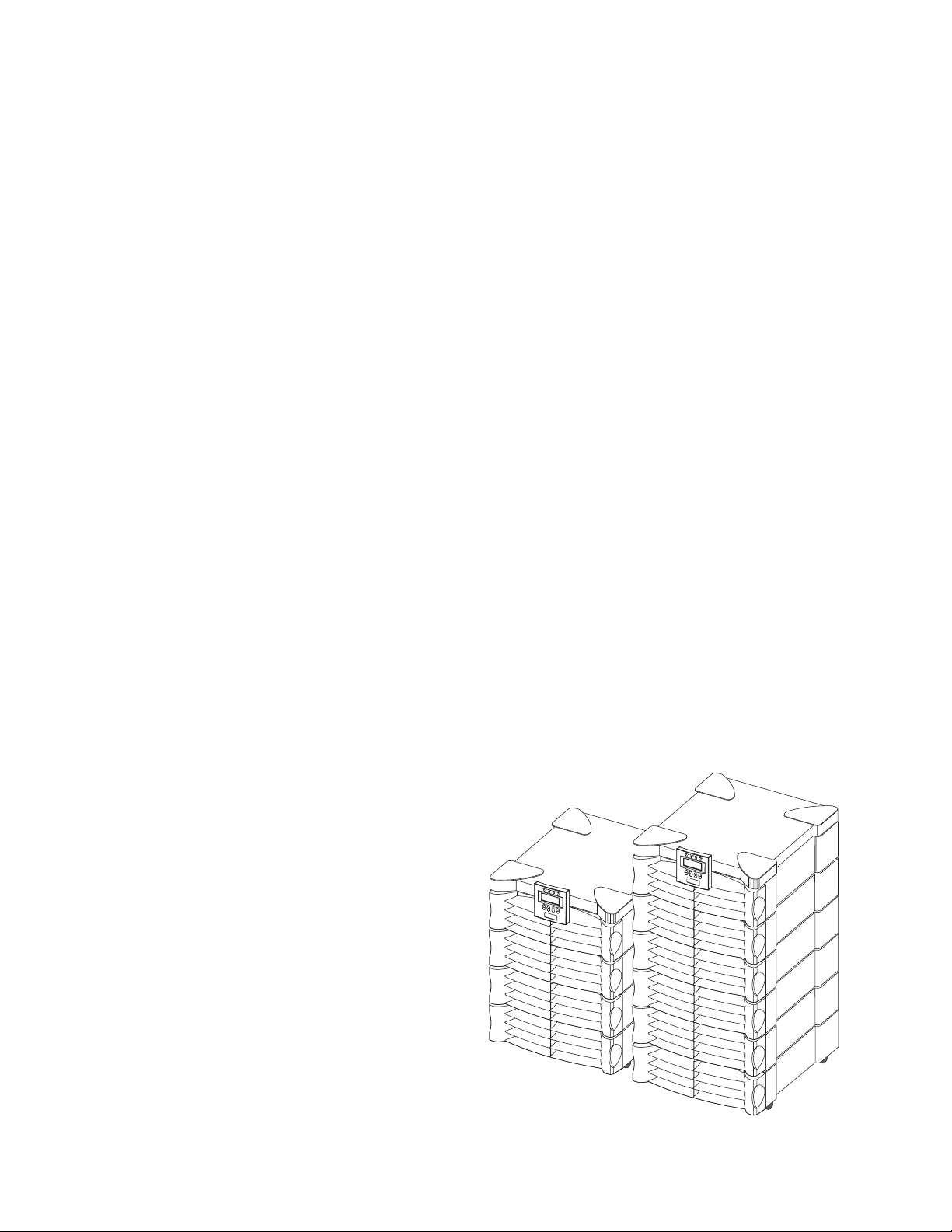

The SymmetraTM is a high-performance, uninterruptible

power array system, designed for large-scale loads. It provides conditioned, reliable AC power to load equipment, and

provides protection from power blackouts, brownouts, swells,

sags, surges and interference. The SymmetraTM Power Array

system is comprised of either a MiniFrame, or a MasterFrame,

and a variable set of modules. A MiniFrame system can be

configured to deliver a maximum output of 8kVA, and a

MasterFrame system can deliver a maximum of 16kVA.

TMTM

Overview Overview

Overview

Overview Overview

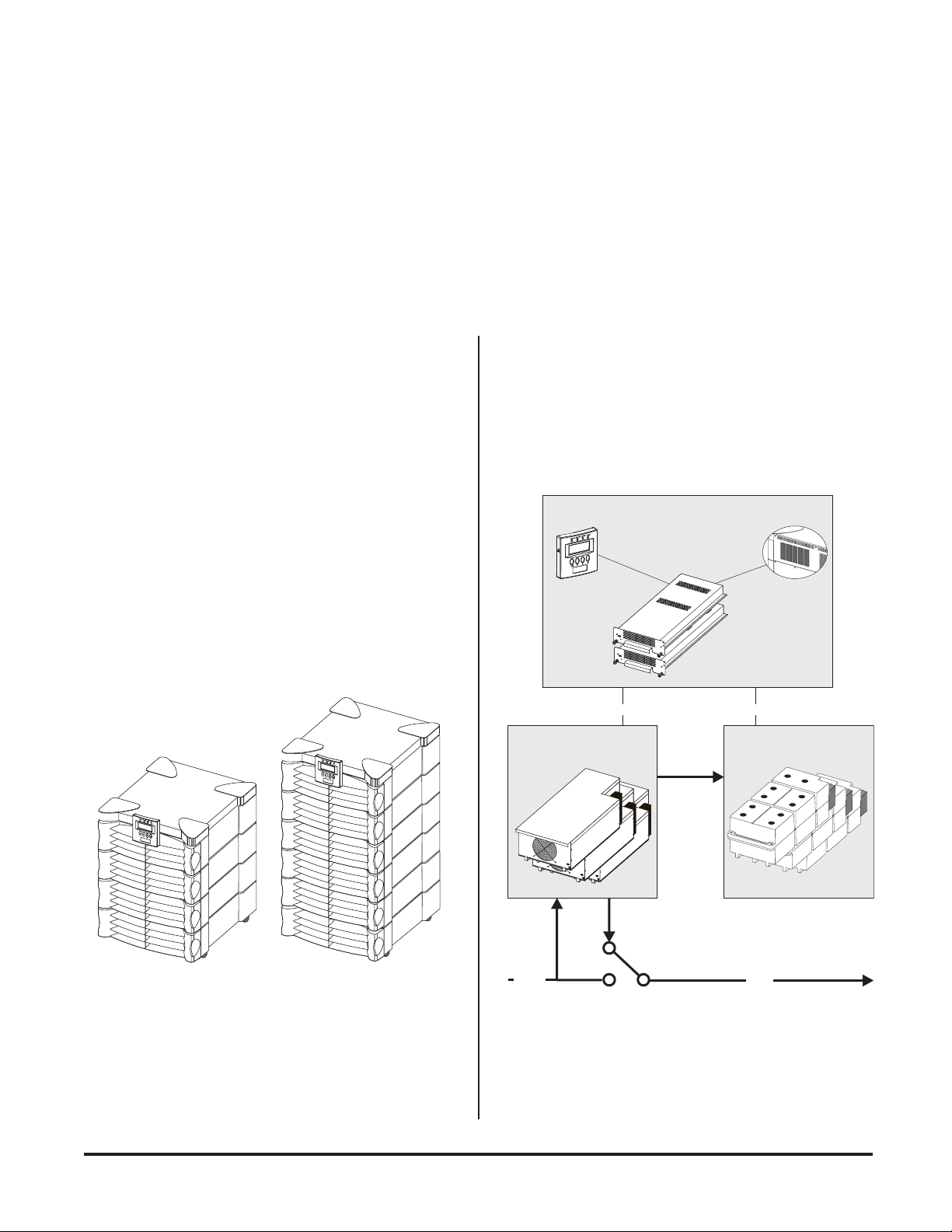

The SymmetraTM Power Array is comprised of three functional components: A power processing system, a battery

source, and a control/user interface system. The relationship

of these functional components is illustrated in figure I-2.

System Control

and Interface

Powerview User

Interface

Communication Communication

Power Processing

Charge

Communication

Card and

SmartSlots

TM

Battery Source

Fig I-1 MiniFrame and MasterFrame

Bypass

Switch

AC

IN

Fig I-2 Functional Diagram of a Symmetra

AC

OUT

TM

i

Page 9

Power PrPower Pr

Power Pr

Power PrPower Pr

ocessing Systemocessing System

ocessing System

ocessing Systemocessing System

ContrContr

Contr

ContrContr

ol/User Interol/User Inter

ol/User Inter

ol/User Interol/User Inter

faceface

face

faceface

The power processing system delivers conditioned AC output

power with a low distortion sinewave. Under normal operating conditions, power is received from the AC mains (utility)

power source, conditioned by the power processing system,

and delivered to the load equipment. In the event of an AC

mains power source failure, the power processing system receives power from the battery source (battery modules), converts it to conditioned AC, and delivers it to the load equipment. When AC mains power is present, the power processing

system also maintains the battery source at full charge.

The power processing system in SymmetraTM is comprised of

one or more power modules. Each power module contains

the electronic components for a complete 4kVA UPS, including

the rectifier, charger and inverter. When two or more power

modules are present, they operate in parallel, sharing the load

equally.

By configuring the system with at least one more power module than is required to power the load (a redundant power

module), SymmetraTM can sustain a power module failure

and still deliver full power to the load equipment. The failed

module is identified by the control/user interface system, an

alarm is initiated to notify the user of the module failure, and

the hot-swappable module can be replaced by the user, without the need to power down the load equipment.

A SymmetraTM MiniFrame provides bays for up to three power

modules, and a MasterFrame provides bays for up to five.

This provides the full system capacity (8kVA and 16kVA respectively), plus one redundant power module.

The control/user interface system coordinates the operation

of the SymmetraTM and reports status conditions via several

user interface options. Functions performed by the control/

user interface component include module coordination and

state control, analysis and reporting of system status, and

reporting of alarm conditions.

Module Coordination & State Control - The Symmetra

incorporates a main intelligence module (MIM) that continuously monitors the system, and delivers data to both the

PowerView user interface, and to the communication ports.

The MIM coordinates the initial power up of the system, transfers it into and out of bypass mode, transfers the power source

between the mains AC power, and the battery source, and

coordinates shutdown operations.

System Status Monitoring - The MIM gathers data about the

system components and delivers it to both the PowerView

interface, and to the computer interface ports. System status

monitoring and reporting data include the current predicted

run time, the status of individual battery and power modules,

the input & output voltage, input & output voltage frequency,

and the size and status of the output load.

Alarm Condition Detection - The control/user interface system monitors the SymmetraTM for alarm conditions. If an

alarm condition is detected, the PowerView user interface initiates an audible and visual alarm. Alarm conditions include

on-battery, low battery, module faults, overloads, loss of redundancy and a variety of other default and user defined events.

All possible alarm messages and the appropriate user responses

are provided in Chapter 9.

TM

BatterBatter

Batter

BatterBatter

The battery source is comprised of parallel, hot-swappable,

120V battery modules. These are housed in the Symmetra

frame, and in an optional XR Extension Battery frame.

A SymmetraTM MiniFrame provides bays for up to two battery modules, and a MasterFrame provides bays for up to

four. Both of these frames can be connected to an XR Extension Battery frame. Additional battery modules increase onbattery run time.

ii

y Soury Sour

y Sour

y Soury Sour

cece

ce

cece

TM

Page 10

Modes of OperationModes of Operation

Modes of Operation

Modes of OperationModes of Operation

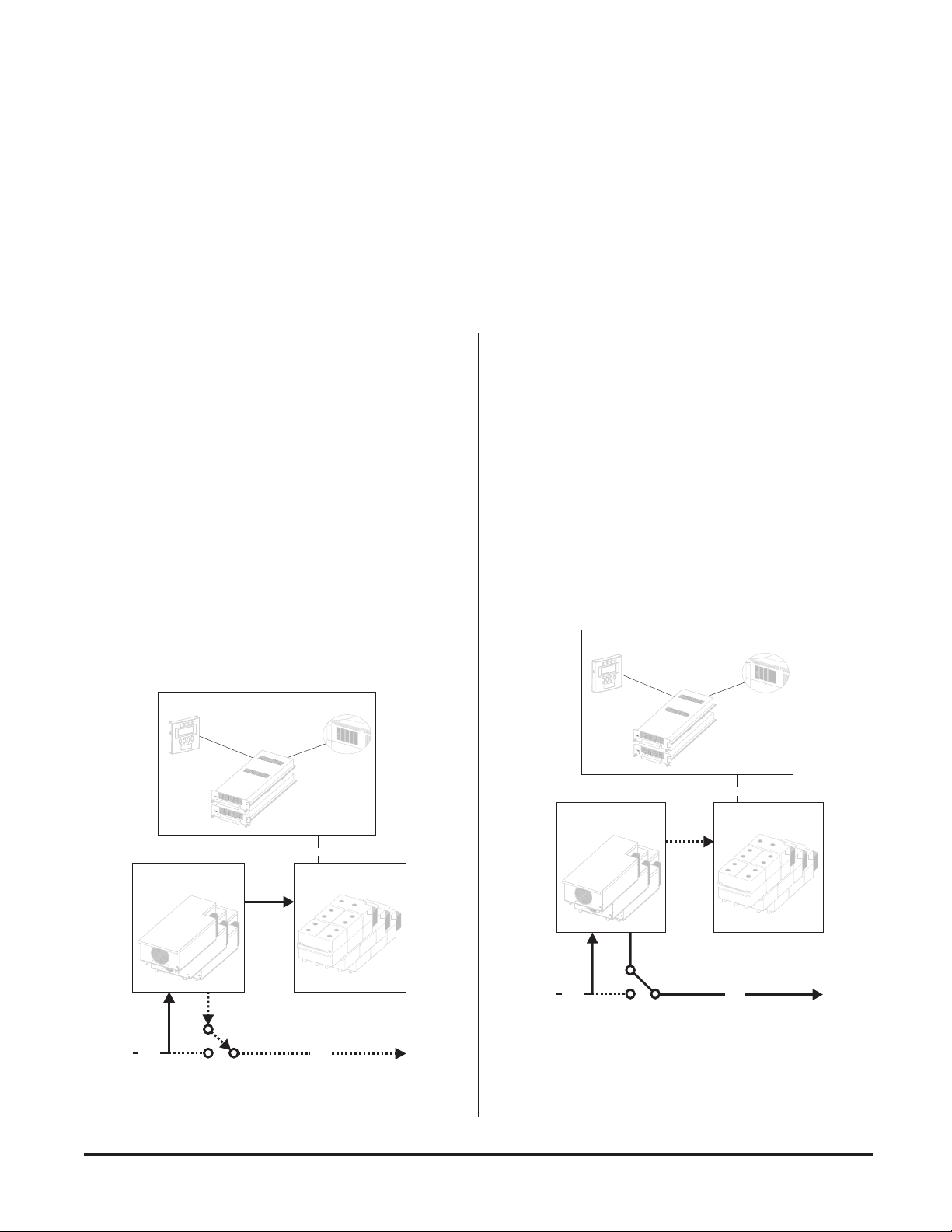

The Power Array functions in one of four modes of operation

depending on user commands, the status of the AC mains

(utility) voltage, and the condition of the SymmetraTM itself.

The four modes are Load-Disconnect, On-Line, On-Battery,

and Bypass. The PowerView reports the operating mode.

Load-Disconnect Mode

In the load-disconnect mode, incoming mains (utility) power

is present and the system is internally powered, but no output

power is delivered to the load equipment. The Symmetra

enters the load-disconnect mode at the initial power up when

the system enable switch is switched to the on position. When

the system is operating on-line, and the load off command

is entered in the PowerView interface, it returns to the loaddisconnect mode. Figure I-3 illustrates power flow when the

system is operating in the load-disconnect mode.

TM

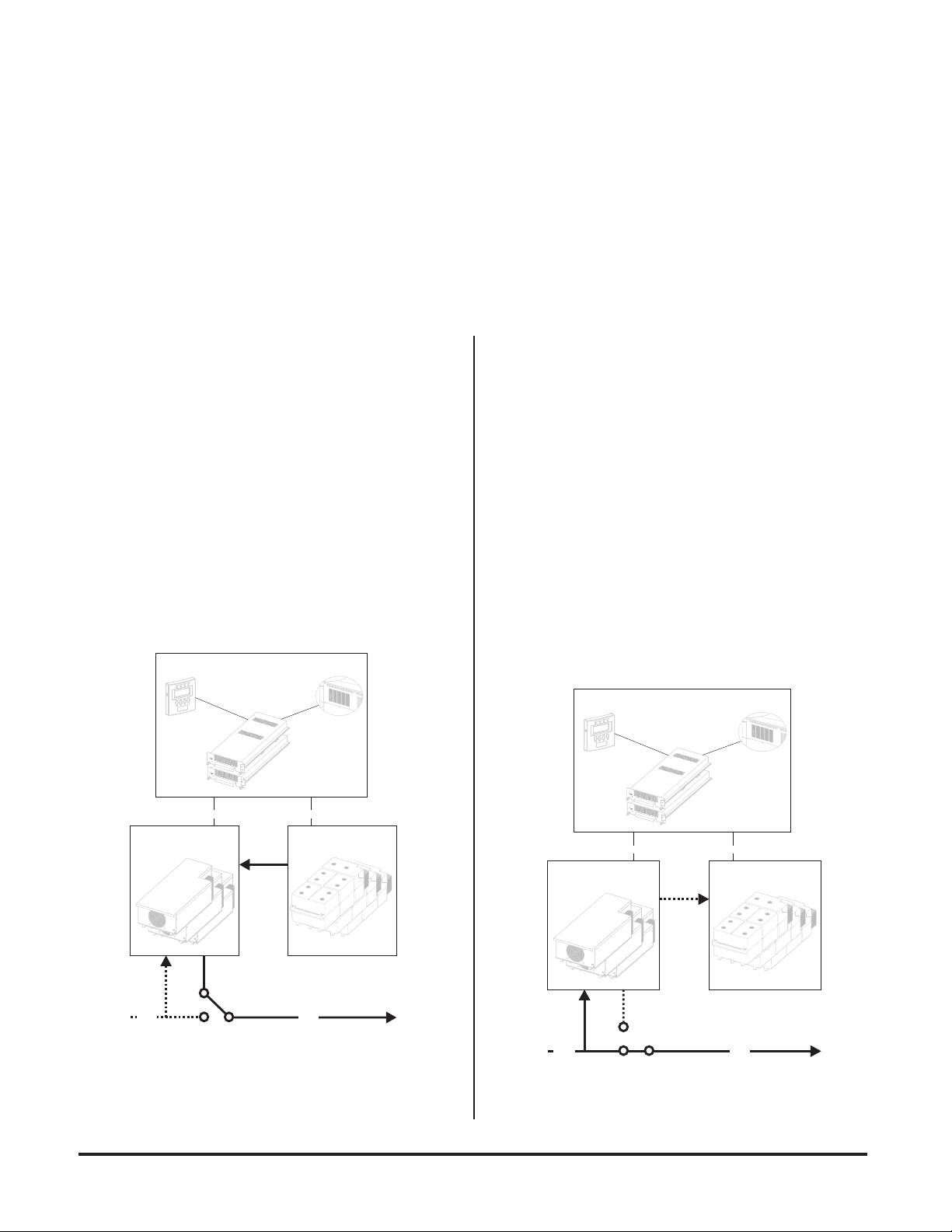

On-Line Operating Mode

The on-line operating mode is the normal operating mode.

When the system is in the on-line operating mode, the Power

Array receives AC mains (utility) power and delivers conditioned power to the load equipment. The Power Array maintains proper battery charge, regulates the output voltage and

frequency, and protects the load from surges and electrical

noise. SymmetraTM will operate in this mode if it has been

commanded to turn the load on, the incoming utility voltage

is present and functioning properly, and there are no preventing abnormal conditions such as an overload. See figure I-4

for a diagram of the power flow when the system is in the online operating mode.

System Control

and Interface

System Control

and Interface

Powerview User

Interface

Communication Communication

Power Processing Battery Source

Charge

Bypass

AC

IN

Switch

Communication

Card and

SmartSlots

AC

OUT

TM

Fig I-3 Load-Disconnect Operating Mode

Powerview User

Interface

Communication Communication

Power Processing Battery Source

Charge

Bypass

AC

IN

Switch

Communication

Card and

SmartSlots

AC

OUT

TM

Fig I-4 On-Line Operating Mode

iii

Page 11

On-Battery Operating Mode

Bypass Operating Mode

When in the on-battery mode, the Power Array draws DC

power from the battery source, converts it to conditioned AC

power and delivers it to the load equipment. Symmetra

TM

typically enters this mode in the event of a mains (utility) power

failure. It will also operate in the on-battery mode during a

user initiated battery self test.

On-battery operation is limited in duration and is dependent

on the number of battery modules, their state of charge, and

the size of the load. SymmetraTM will remain in the on-battery

state until either the incoming utility power is restored or the

batteries are depleted. See figure I-5 for a diagram of power

flow when the system is in the on-battery mode.

System Control

and Interface

Powerview User

Interface

Communication Communication

Power Processing Battery Source

Discharge

Communication

Card and

SmartSlots

TM

When the SymmetraTM is in the bypass operating mode, the

system is bypassed and utility power is delivered directly to the

load. SymmetraTM is equipped with an automatic bypass function to allow the system to automatically go into bypass mode,

and a manual maintenance bypass switch to allow a user to

manually bypass the system. Either can be used to place the

Power Array into bypass operating mode.

The SymmetraTM will automatically transfer to the bypass

operating mode when AC mains power is present, but the

load cannot be powered by the inverter. Events which may

cause this include overloads and failed non-redundant power

modules. The SymmetraTM will automatically return to the

on-line mode when the triggering event clears. Figure I-6 illustrates power flow when the system is in the bypass mode.

System Control

and Interface

Powerview User

Interface

Communication Communication

Power Processing Battery Source

Communication

Card and

SmartSlots

TM

Charge

Bypass

AC

Switch

IN

Fig I-5 On-Battery Operating Mode

AC

OUT

AC

IN

Bypass

Switch

AC

OUT

Fig I-6 Bypass Operating Mode

iv

Page 12

DefinitionsDefinitions

Definitions

DefinitionsDefinitions

Important InformationImportant Information

Important Information

Important InformationImportant Information

The following terms are used in this manual. Review these

definitions for a better understanding of the SymmetraTM:

Redundancy - Indicates the presence of one or more extra

power modules which allow the system to sustain a fault and

still provide protection to the load. To be fully redundant, the

system should be configured with a redundant intelligence

module, and at least one redundant power module.

Note: The number of battery modules determines the length of

the run time. While it is prudent to use the maximum number

of battery modules possible, they are not considered redundant.

N+1 Redundancy - Refers to the level of power module redundancy. N represents the number of power modules required to power the load, and +1, +2, etc. represents the

number of extra power modules that are present.

For example, a 7.3 kVA load requires two power modules for

adequate protection. If the SymmetraTM is configured with

only two modules, it has an N+0, level of redundancy. (No

redundancy). If the system is configured with three power

modules, it has an N+1 redundancy. Depending on the size

of the load, SymmetraTM can be configured with 2, 3 or even 4

extra power modules. Respectively, it would have an N+2,

N+3, or N+4 level of redundancy.

Please read this User's Manual thoroughly before proceeding

with the installation of the SymmetraTM Power Array system.

It provides important information about installing and using

the SymmetraTM safely and effectively. Pay close attention to

text that is accompanied by a danger, or caution symbol. For

technical support, see the inside front cover of this manual.

Capacity - The maximum amount of output power that a

SymmetraTM system can deliver. The capacity is limited by the

lesser of the frame size, or the capacity of the installed power

modules.

For example, a MiniFrame (8kVA) with one power module

installed (4kVA) has a system capacity of 4kVA. A MasterFrame

(16kVA) with five power modules (20kVA) has a system capacity of 16kVA.

Hot-swappable - The modules are hot-swappable means

they can be replaced safely by a user or service provider while

the load is still powered and fully protected.

v

Page 13

vi

Page 14

Safety Information

Important Safety Information

Read this safety information com-

pletely before installing or using the

SymmetraTM Power Array.

MiniFrame

MasterFrame

Page 15

Safety

Symbols Used In This ManualSymbols Used In This Manual

Symbols Used In This Manual

Symbols Used In This ManualSymbols Used In This Manual

The following symbols appear in this User's Manual:

CAUTION/DANGER - Caution indicates risk of

bodily harm. Danger indicates that a risk of electrical shock is present and the associated procedures should be followed carefully.

STAND BY MODE - The system enable switch,

and the input circuit breaker use the stand by

mode. When either of these are switched to stand

by, the Power Array is disconnected from mains

(utility) input voltage. In this mode, the system

appears to be off, although the mains (utility)

power is still connected to the system. For this

reason, the standby mode is unsafe for servicing

the system. Always follow the five step Total Power

Off procedure before servicing the Power Array.

(See procedure at right.)

OFF POSITION - The maintenance bypass

switch is the only switch that can be placed in the

off position. When switched to the off position, the Power Array functions normally, receiving mains (utility) power, and delivering conditioned power to the load equipment.

ON POSITION - All three switches (The system enable switch, the maintenance bypass switch

and the input circuit breaker) can be placed in the

on position. See the description for each of these

switches in Chapter 1.

SAFETY EARTH GROUND - Indicates the primary safety ground.

IMPORIMPOR

IMPOR

IMPORIMPOR

n SAVE THIS USER MANUAL - This manual contains im-

CONSERVER CES INSTRUCTIONS. CETTE NOTICE

CONCERNANT LA SÉCURITÉ.

n Connection to the branch circuit (mains utility power

n Installation of the power and battery modules can be per-

n Operation of the SymmetraTM can be performed by any

n The protective earth conductor for the SymmetraTM car-

n FIVE STEP TOTAL POWER OFF PROCEDURE

TT

ANT SAFETY INSTRUCTIONSANT SAFETY INSTRUCTIONS

T

ANT SAFETY INSTRUCTIONS

TT

ANT SAFETY INSTRUCTIONSANT SAFETY INSTRUCTIONS

portant instructions that should be followed during installation and maintenance of the Power Array, and for

installation or replacement of the battery and power modules.

CONTIENT DES INSTUCTIONS IMPORTANTES

source) must be performed by a licensed electician.

formed by any individual with no previous technical experience.

individual with no previous technical experience.

ries the leakage current from the load devices (computer

equipment). Therefore, the size of the conductor must be

at least as large as the wire required by IEC 950. IEC 950

states the following nominal cross-sectional areas:

- 2.5 mm2 for rated current between 17 & 25 A

- 6 mm2 for rated current between 33 & 40 A

- 10 mm2 for rated current between 41 & 63 A

- 16 mm2 for rated current between 64 & 80 A

To remove all power from the Power Array (Total Power

Off), the following events must occur in the order listed:

1. Set system enable switch to the stand by position.

2. Set input circuit breaker to the stand by position.

3. Remove all battery modules from the Power Array.

4. Disconnect XR external battery cabinet (if present).

5. Disconnect the mains/branch circuit breaker.

Safety-1

Page 16

Safety

n CAUTION: Risk of Electrical Shock and Energy Hazard,

120V, 7.2 Ah battery module. Before replacing battery

modules, remove conductive jewelry such as chains, wrist

watches and rings. High short circuit current through

conductive materials could cause severe burns.

n CAUTION: Do not dispose of batteries or battery mod-

ules in a fire. The batteries may explode.

n CAUTION: Do not open or mutilate battery modules or

batteries. Released electrolyte is harmful to the skin and

eyes. It may be toxic.

n While battery modules are user replaceable, servicing of

the battery modules themselves should be performed or

supervised by personnel knowledgeable of batteries and

the required precautions. Keep unauthorized personnel

away from batteries.

n When replacing or adding battery modules to the Power

Array system, use only the SYBATT SymmetraTM Battery Module. See the APC telephone numbers listed on

the inside cover of this manual for technical support, or

to obtain replacement modules.

Safety-2

Page 17

Chapter One

Physical Representation

This chapter provides an illustrated descrip-

tion of the SymmetraTM Power Array system

and each of the modular components.

Before proceeding, examine the illustration

below. It depicts a MiniFrame (8kVA) and a

MasterFrame (16kVA) Power Array as they

appear during normal operating conditions.

MiniFrame

MasterFrame

Page 18

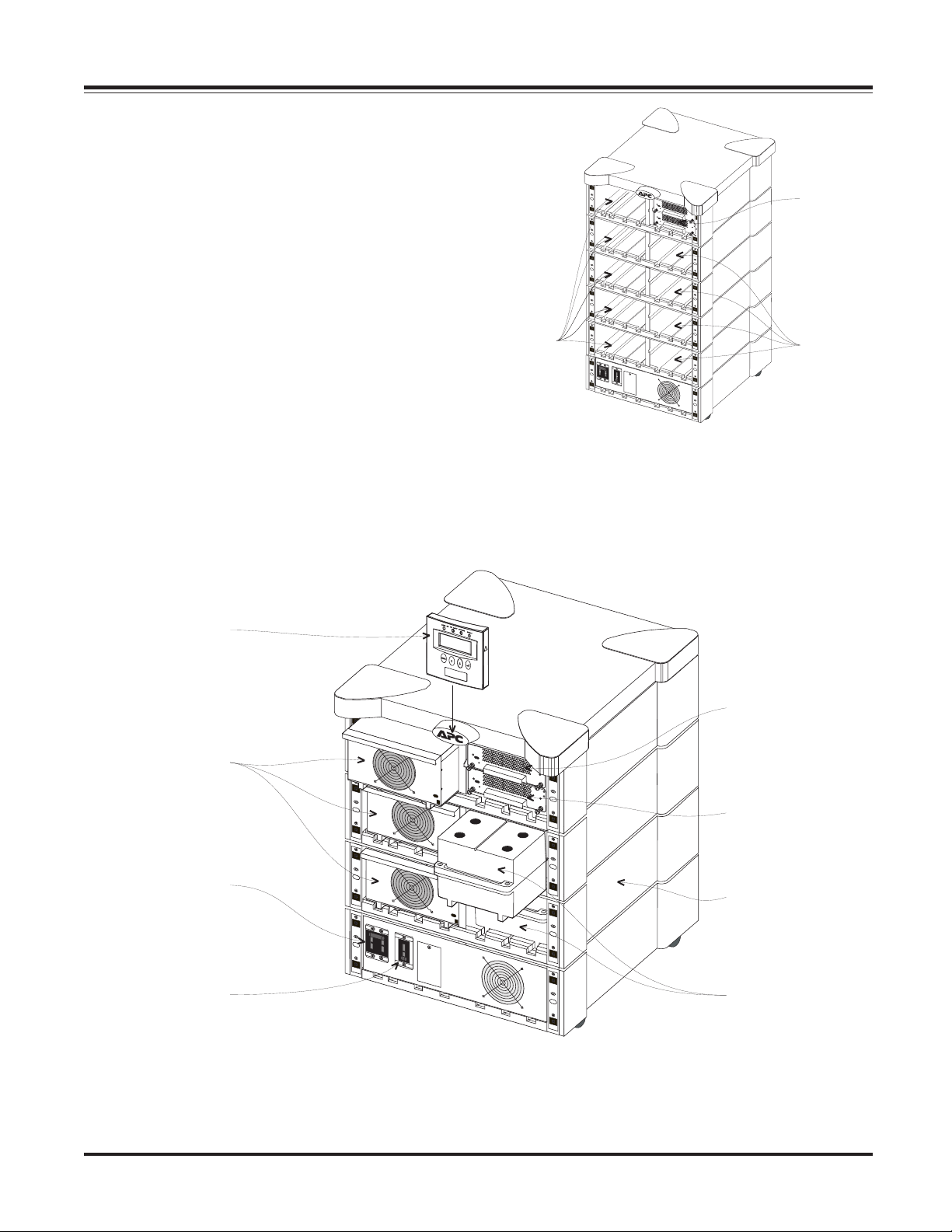

The Power Array FrameThe Power Array Frame

The Power Array Frame

The Power Array FrameThe Power Array Frame

The SymmetraTM Power Array frame serves as the base for

the modular components of the system. The MiniFrame provides bays for three power modules and two battery modules. The MasterFrame provides bays for five power modules and four battery modules. The bay at the top right houses

the main intelligence module (MIM) and redundant intelligence module (RIM).

Wiring input/output access panels and terminal blocks, a system enable switch, an input circuit breaker and a maintenance bypass switch are located near the bottom of the frame.

A MiniFrame with all battery and power module bays loaded

is depicted in figure 1-1. A MasterFrame with factory installed MIM and RIM, and empty power and battery module

bays is depicted in figure 1-2.

Chapter 1 - Physical Representation

Five

Power

Module

Bays

Fig 1-2 An Empty MasterFrame (grill covers removed)

Main

Intelligence

and

Redundant

Intelligence

Modules

Four

Battery

Module

Bays

PowerView

Interface

Power

Modules

Input

Circuit

Breaker

Maintenance

Bypass

Switch

Redundant

Intelligence

Module

Main

Intelligence

Module

MiniFrame

Battery

Modules

Fig 1-1 A Fully Loaded MiniFrame (grill covers removed)

1-1

Page 19

Chapter 1 - Physical Representation

PowerPower

Power

PowerPower

The PowerView incorporates a 4 x 20 alphanumeric LCD

screen with four navigation keys, four LED status indicators,

and an audible alarm. The display communicates with the

Power Array via a short RJ45 connector cable that is hardwired

into the intelligence modules bay. The PowerView can be

mounted on the front of the frame, stand on top of the frame,

or it can be installed at a remote location. A 6.1m (20') RJ45

cable is provided for remote installation.

The alphanumeric LCD screen displays system status, fault

reporting, and module diagnostics information. The navigation keys scroll through an elaborate menu. Chapter 6 provides detailed information about the PowerView.

Alarm thresholds and parameters are set with the PowerView.

In the event of an alarm condition, the PowerView emits both

audible and visual alarm indicators.

view User Interview User Inter

view User Inter

view User Interview User Inter

faceface

face

faceface

Power ModulePower Module

Power Module

Power ModulePower Module

The power module is a self-contained, 4kVA UPS (without

batteries) housed inside a metal enclosure. A blind mating

connector at the rear of the module engages with a connector inside the frame. Power modules are installed in the vertical column of bays at the left of the frame. These bays are

labeled L1, L2, L3, etc.

1-Blind Mating Connector, 2-Positioning Handle,

3-Cooling Fan Grill, 4-Alignment Runners,

5-Seating Tabs, 6-Flip Latch Micro Switch

1-LED Status Indicators, 2-LCD Screen, 3-Navigation Keys

Fig 1-3 PowerView User Interface

Grill CoversGrill Covers

Grill Covers

Grill CoversGrill Covers

Each level of the frame is equipped with a grill cover. These

covers are interchangeable, and snap securely onto the frame.

When removing, temporarily storing, and replacing grill covers, use care to prevent them from being marred or scratched.

Fig 1-5 Power Module

In the event of a power module failure, the PowerView initiates an audible alarm and displays an error message. The

power module is hot-swappable. Instructions for module

replacement are provided in Chapter 8.

BatterBatter

Batter

BatterBatter

The battery module is comprised of a series of ten 12V batteries housed inside a plastic enclosure. A blind mating connector at the rear of the module engages with a connector

inside the frame.

Battery modules are installed in the vertical column of bays

at the right of the frame. These are labeled R2, R3, R4, etc.

(R1 houses the intelligence modules.) The condition and

charge of each battery module is reported on the PowerView.

If a battery module fails, an alarm is initiated. Battery modules are hot-swappable and user replaceable.

y Moduley Module

y Module

y Moduley Module

Fig 1-4 Front Grill Cover Removal and Replacement

1-2

Page 20

Chapter 1 - Physical Representation

Redundant Intelligence Module (RIM)Redundant Intelligence Module (RIM)

Redundant Intelligence Module (RIM)

Redundant Intelligence Module (RIM)Redundant Intelligence Module (RIM)

The redundant intelligence module is a backup version of

the main intelligence module. It provides redundancy in the

event of a MIM failure or while a MIM is being replaced. If a

functioning MIM is present, the RIM can be removed and

replaced without placing the load at risk. The condition of

the RIM can be determined with the PowerView display.

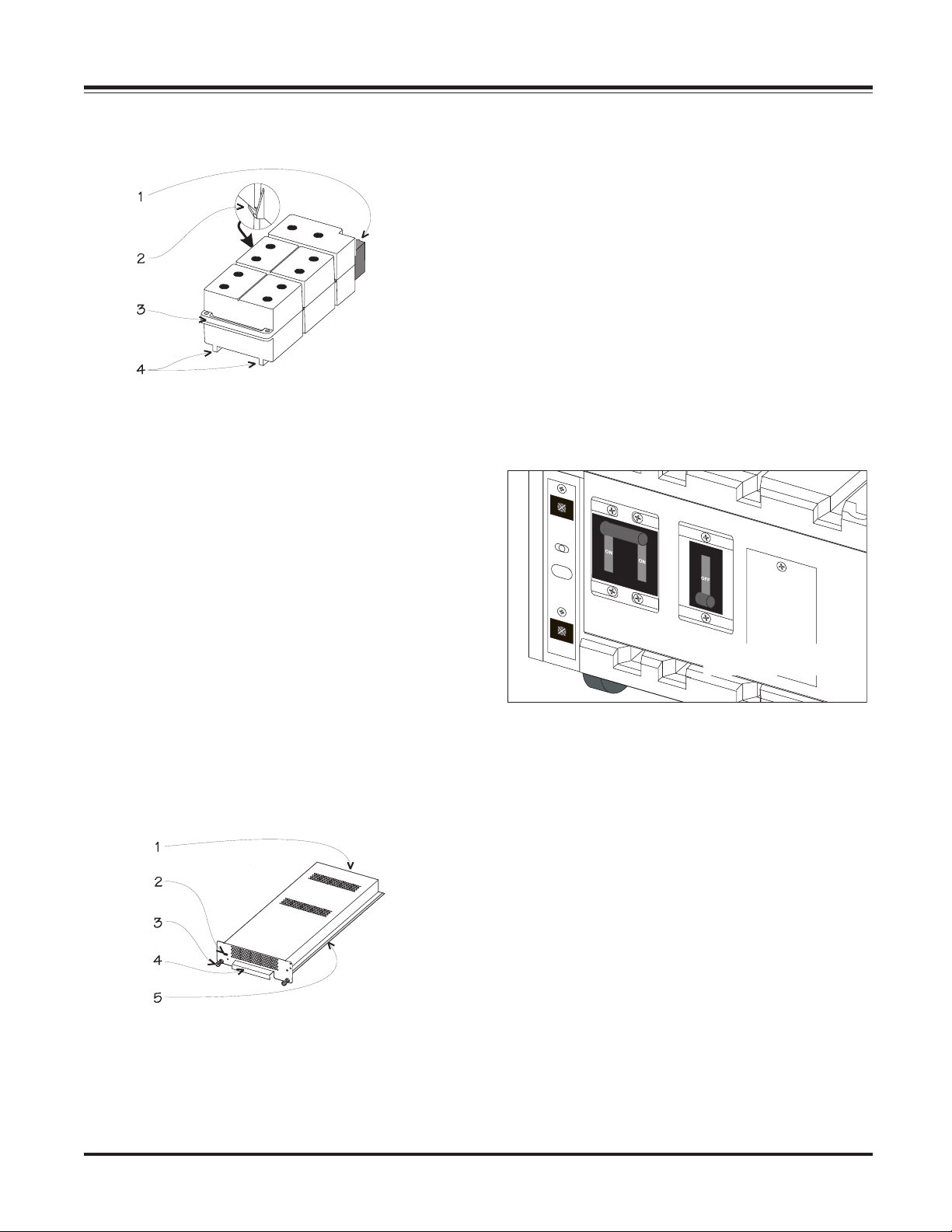

1-Blind Mating Connector, 2-Retaining Flange,

3-Positioning Handle, 4-Runners

Fig 1-6 Battery Module

Main Intelligence Module (MIM)Main Intelligence Module (MIM)

Main Intelligence Module (MIM)

Main Intelligence Module (MIM)Main Intelligence Module (MIM)

The MIM is the computer for the Power Array system. It

gathers and processes data, including monitoring the condition of each of the modules.

The PowerView functions as the user interface for the MIM,

and is used to access data, and to configure the system. When

a redundant intelligence module is installed and functioning, the main intelligence module can be replaced without

placing the load at risk. The main intelligence module also

communicates with an external battery frame (if present).

The main intelligence and the redundant intelligence module are factory installed in the upper right bay of the frame.

Important: The MIM is always installed in the bottom rack,

and the RIM is always installed in the top rack in this bay.

Input CirInput Cir

Input Cir

Input CirInput Cir

The input circuit breaker protects the Power Array from extreme overloads. When switched to stand by, the Power

Array is disconnected from incoming (mains) voltage. When

switched to the on position, power flows from the mains

power source into the Power Array. Under normal operating

conditions, the input circuit breaker always remains in the

on position.

cuit Brcuit Br

cuit Br

cuit Brcuit Br

eakereaker

eaker

eakereaker

(Front of Frame)

Fig 1-9 Input Circuit Breaker & Maintenance Bypass Switch

Maintenance Bypass SwitchMaintenance Bypass Switch

Maintenance Bypass Switch

Maintenance Bypass SwitchMaintenance Bypass Switch

When switched to the on position, the maintenance bypass

switch bypasses the Power Array and causes the load equipment to be powered directly from the mains power source.

When it is switched to the off position, mains power flows

into the Power Array, and conditioned power is delivered to

the load equipment. The load equipment is unprotected when

the maintenance bypass switch is in the on position. Under

normal operating conditions, the maintenance bypass switch

remains in the off position.

1-Blind Mating Connector, 2-Flip Latch Micro Switch,

3-Retaining Screw, 4-Positioning Handle, 5-Installation Rail

Fig 1-7 Main & Redundant Intelligence Module

1-3

Page 21

Chapter 1 - Physical Representation

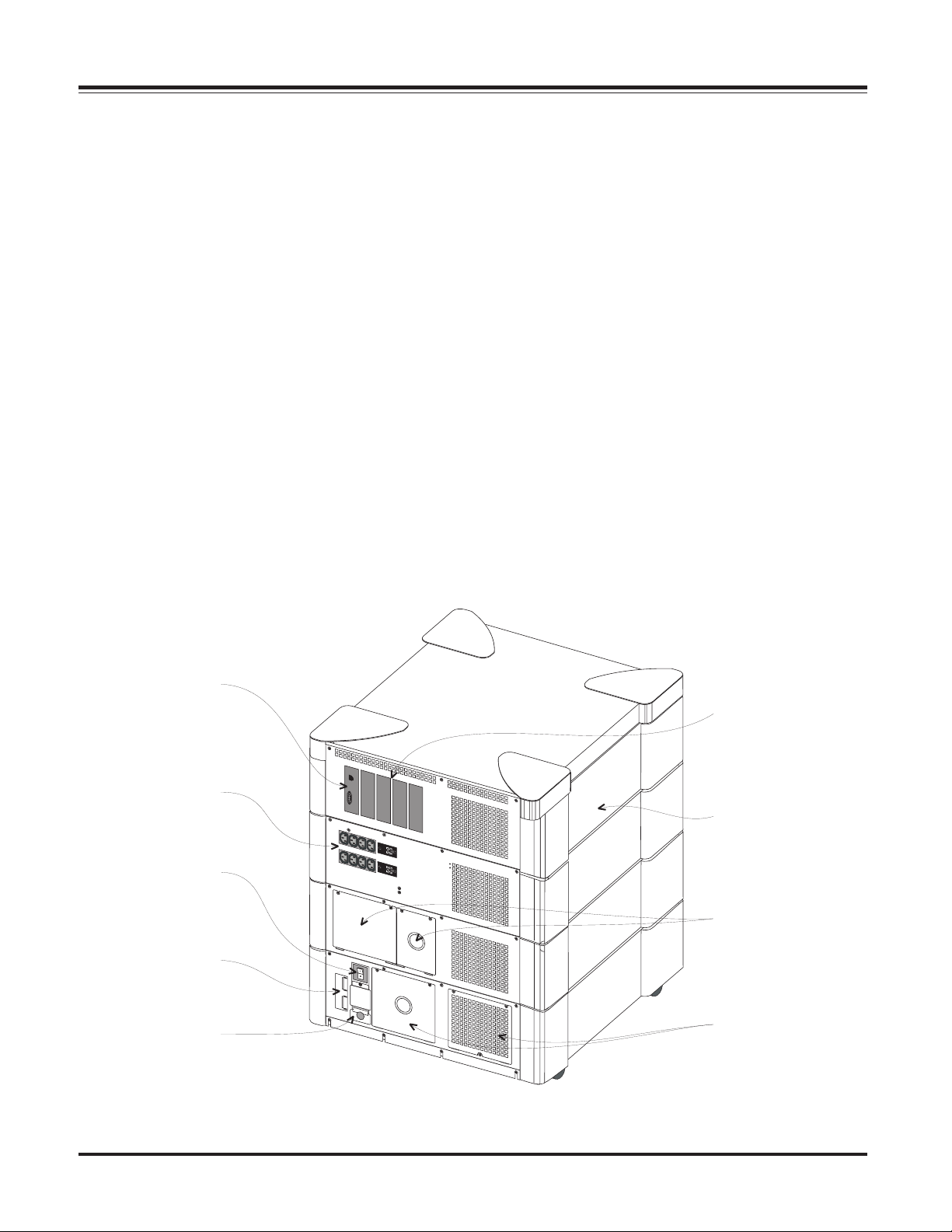

Rear VRear V

Rear V

Rear VRear V

The rear of a MiniFrame Power Array system is shown below. (The rear of a MasterFrame is identical.) Each of the

components is described in a section that follows:

iew of a Power Ariew of a Power Ar

iew of a Power Ar

iew of a Power Ariew of a Power Ar

rayray

ray

rayray

System Enable Switch

The system enable switch regulates power to the intelligence

modules. It does not power the load. When switched to the

on position, the Power Array enters the load-disconnect

operating mode. When switched to stand by, the intelligence modules are disconnected from the mains voltage, and

the system shuts down.

Note : The load is not powered until the power the load command is entered into the PowerView user interface.

Communication Interface Ports

There are three interface ports: A Remote PowerView port

for the 6.1 m (20') RJ45 PowerView cable, a 9-pin computer

interface port for APC PowerChute Plus software, and a battery communication port for an XR Extended Run Frame.

Smart Slots

APC manufactures a set of auxiliary user interface accessories, called SmartSlot

TM

Accessory Ports

TM

devices. Four SmartSlotTM installa-

tion ports are provided. SmartSlotTM interface options include

the following:

n Protection and safe shutdown of multiple servers

n SNMP adaptor for accessing data via a network

n CallUPSTM - telephone notification of power event

n MeasureUPSTM - monitor environmental conditions

n Control and monitor Power Array via modem

Note: Use only SmartSlot

Compatible.

TM

devices labeled Symmetra

TM

REPO/Input/Output Wiring Access Panels

Wiring terminal blocks for input and output wiring and for

remote emergency power off (REPO) switch installations are

accessed through these panels.

Note: Wiring is to be installed by a qualified electrician only.

Convenience Power Panel

Eight IEC 320 C13 type power outlets are provided. The outlets are arranged in two sets of four. Each set is equipped with

a circuit breaker.

Extended Run Battery Frame Connector

An optional XR Extended Run Battery Frame can be connected

to the Power Array via this connector. See the Users Manual

included with the XR Extended Run Battery Frame.

Communication

Interface

Ports

Convenience Power

Panel

System

Enable

Switch

XR Extended Run

Battery Frame

Connector

REPO Wiring

Access Panels

SmartSlot

Accessory

Ports

MiniFrame

Output

Wiring

Access

Panels

Input

Wiring

Access

Panels

TM

1-4

Fig 1-10 Rear View of a Mini Frame SymmetraTM Power Array System

Page 22

Chapter Two

Site Preparation

This chapter provides the environmental and

structural requirements for a SymmetraTM Power

Array system. Included are the weights, dimen-

sions, and heat output of a functioning system.

MiniFrame

MasterFrame

Page 23

Chapter 2 - Site Preparation

Space and WSpace and W

Space and W

Space and WSpace and W

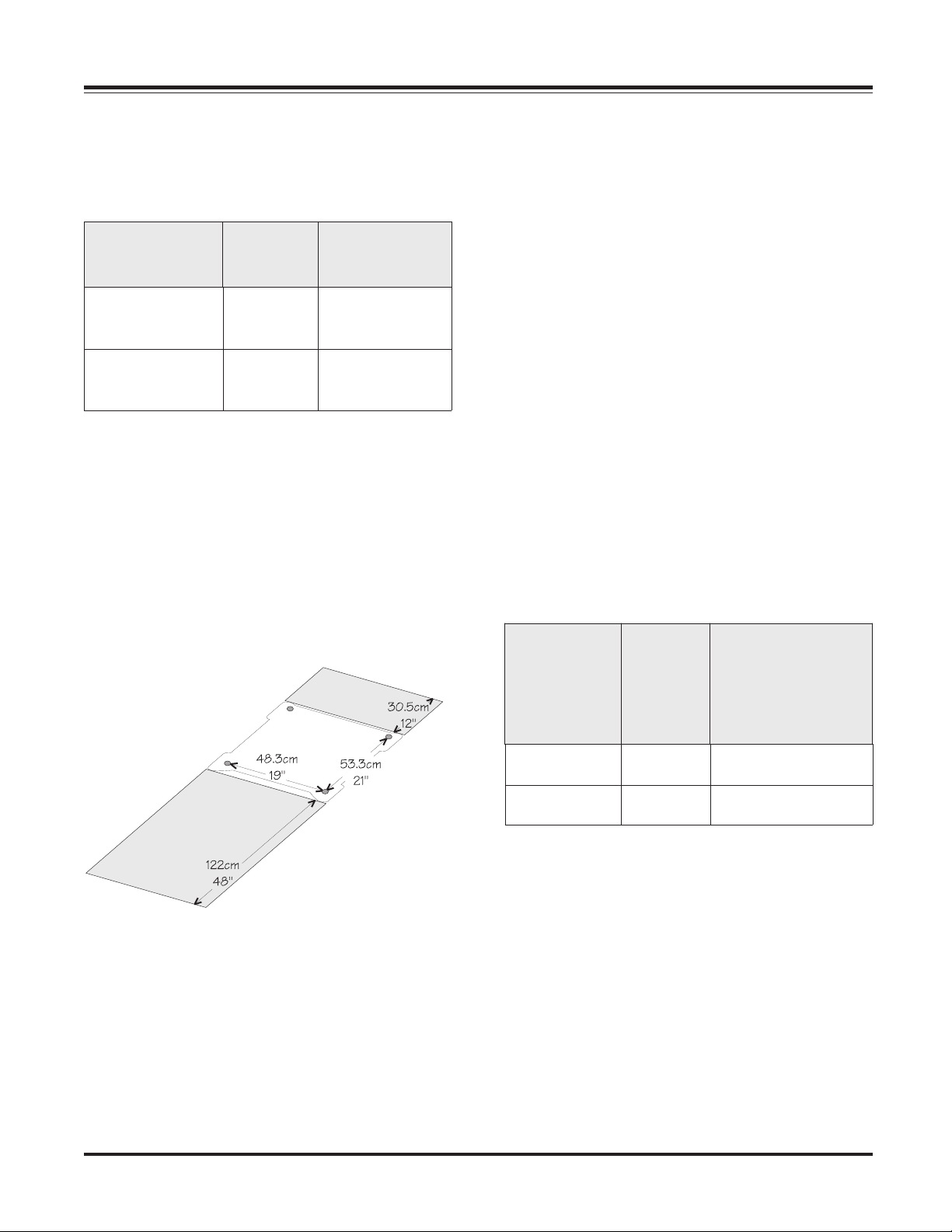

The Power Array frame is 61cm (24") wide and 68.6cm (27")

deep. Refer to table 4-1 for the height and weight of fully

loaded systems.

Table 2-1 Height & Weight (Loaded w/ Modules)

Make sure there is adequate space and structural integrity to

support the fully loaded frame. Refer to figure 2-1. The weight

of the Power Array rests on four 3.8cm (1.5") diameter leveling

feet. Positions of the leveling feet are shown. When installing

the frame, allow 30.5cm (12") of clearance behind the frame

for adequate airflow. (Air flows in through the front of the

frame and out the back.) Allow 122cm (48") of clearance in

the front of the SymmetraTM to access the PowerView and to

install modules.

eight Considerationseight Considerations

eight Considerations

eight Considerationseight Considerations

eziSemarFeziSemarF

eziSemarFeziSemarF thgieHthgieH

eziSemarF

emarFiniM

emarFretsaM

mc7.87

"13

"25

thgieHthgieH

thgieH

mc1.231

Rear

Clearance

thgieWthgieW

thgieWthgieW

thgieW

dedaoLylluFdedaoLylluF

dedaoLylluFdedaoLylluF

dedaoLylluF

gk832

bl525

gk914

bl529

Operating Conditions

The Power Array is intended for installation in a temperature

controlled indoor area that is free of conductive contaminants.

The operating evironment must be clean, dry, and protected.

The atmosphere must be free of dust and corrosive fumes.

Adequate airflow must be provided for the operation of the

system. Make sure environmental conditions are within the

following parameters:

n Relative Humidity: 0 to 95%, non-condensing.

n Temperature: 0°C to 40°C (32°F to 104°F).

n Elevation: 0m to 3,048m (0ft to 10,000ft).

n Electro-Static Discharge (ESD) Susceptibility: The Power

Array and all modules are capable of withstanding

through air electro-static discharges up to an amplitude of +/-15kV and direct discharge electro-static discharges up to an amplitude of +/-8kV without failure,

abnormal operation, or degradation in performance. ESD

test methods conform to IEC 801-2.

BTU Output

Refer to table 2-2 for BTU output of a fully loaded Power

Array system. The BTU output is significantly higher while

the batteries are charging. Under normal operating conditions, battery recharge periods are relatively infrequent.

rH/UTBrH/UTB

rH/UTBrH/UTB

rH/UTBrH/UTB

rH/UTBrH/UTB

rH/UTB

emarFemarF

emarFemarF

emarF

eziSeziS

eziSeziS

eziS

(((((

yllufylluf

yllufylluf

ylluf

(((((

seirettabseirettab

seirettabseirettab

seirettab

)degrahc)degrahc

)degrahc)degrahc

)degrahc

rH/UTB

,gnigrahcseirettab,gnigrahcseirettab

,gnigrahcseirettab,gnigrahcseirettab

,gnigrahcseirettab

yticapacemarfllufyticapacemarflluf

yticapacemarfllufyticapacemarflluf

yticapacemarflluf

eludom1+Nhtiweludom1+Nhtiw

eludom1+Nhtiweludom1+Nhtiw

eludom1+Nhtiw

)noitarugifnoc)noitarugifnoc

)noitarugifnoc)noitarugifnoc

)noitarugifnoc

Front Clearance

Fig 2-1 System Footprint and Required Clearance

Transporting Power Array to Installation Site

When it is shipped, the Power Array frame is bolted to a custom-designed pallet. The modules are stacked on either one

or two additional pallets. It is recommended that these pallets

be moved from the receiving dock to the installation area with

a pallet jack. Make sure there is enough space and structural

integrity to move these pallets.

emarFiniM314,3076,8

emarFretsaM628,6046,51

Table 2-2 BTU Output

Temporary Storage of Modules

The battery and power modules must be temporarily stored

until the frame is permanently installed. To preserve battery

life, always store batteries in a cool, dry place.

2-1

Page 24

Chapter 2 - Site Preparation

2-2

Page 25

Chapter Three

Unpacking and Installing Frame

This chapter provides the procedures for inspect-

ing the SymmetraTM frame and modules when

they arrive. It includes procedures for moving the

frame and modules to the installation site and

for removing them from the pallet.

MiniFrame

MasterFrame

Page 26

Chapter 3 - Unpacking and Installing Frame

Initial InspectionInitial Inspection

Initial Inspection

Initial InspectionInitial Inspection

The SymmetraTM Power Array system is shipped on pallets.

The system frame is bolted to one pallet, and the modules are

boxed and stacked on one or two additional pallets.

Check For Damage

1. Inspect the Packaging - for damage or signs of mishandling before moving the pallets. If damage is detected, note it

on the Bill of Lading.

2. If Any Damage Is Detected - file a damage claim with the

shipping agency within 24 hours. Inform APC of the damage

claim and the condition of the equipment.

3. System Administrator- make sure the system administrator participates in the initial inspection.

snoisnemiDsnoisnemiD

snoisnemiDsnoisnemiD

MTMTMTMTMT

artemmySartemmyS

artemmySartemmyS

artemmyS

tnenopmoCtnenopmoC

tnenopmoCtnenopmoC

tnenopmoC

6

emarFiniM

emarFretsaM

x1

16

6x

(

snoisnemiD

mcHxDxW

)sehcni(

6.86

x

7.87

)"13x"72x"42(

6.8

x

1.231

)"25x"72x"42

thgieWthgieW

thgieWthgieW

thgieW

)bl(gk

gk631

(

bl003

)

gk632

(

bl025

)

Move the FrameMove the Frame

Move the Frame

Move the FrameMove the Frame

1. Plan the Route - Make sure all passages are large enough to

accommodate the frame and the pallet jack. Check to see that

the floor has sufficient strength. See Table 3-1 for weights and

dimensions. Check doorways, elevators, ramps, etc, to insure

there are no non-negotiable corners, step-ups, or offsets. Select a route that provides the smoothest possible floor surface.

2. Staging Area - A smooth, level floor surface is required to

position the frame pallet, to remove the packaging materials,

and to install the ramp. It must provide adequate space for

two people to carefully roll the frame down the ramp and onto

the floor. See Figure 3-1 below for staging area dimensions.

3. Using the Pallet Jack - Carefully move the frame to the

staging area.

Pallet Jack

Frame

on Pallet

Ramp

Floor

Staging

Area

yrettaB

eludoM

eludoMrewoP

Table 3-1 Dimensions and Weights

9.22

5x

.0

(

4.52

x

8.05

(

2.51x8

)"6x"02x"9

x

2.51

"6x"02x"01

)

gk82

(

bl06

)

gk61

(

bl53

)

Handling Considerations

1. The Frame Pallet - See Table 3-1 for frame weight and

dimensions. Before removing shipping materials, the frame

and pallet should be positioned as closely as possible to the

installation site. The frame is bolted to the pallet. It is removed from the pallet using a ramp that is included. Use a

pallet jack to position the frame pallet.

Note: Do not attempt to move the frame with a hand dolley.

2. The Modules Pallet - Position the modules pallet(s) as

closely as possible to the final installation site with the pallet

jack. If this is not possible, remove the outer packaging materials and carry each individual, boxed module to the installation site.

Fig 3-1 Staging Area

3-1

Page 27

Chapter 3 - Unpacking and Installing Frame

Remove Packing MaterialsRemove Packing Materials

Remove Packing Materials

Remove Packing MaterialsRemove Packing Materials

Note: Temporarily store all packaging materials in case any of

the system components must be returned to APC.

1. Remove the Shipping Bands - Using appropriate precautions, cut the plastic shipping bands.

2. Remove the Cardboard - Using care not to damage the

surface of the Power Array, remove the cardboard from the

frame. Save the electrical installation instructions that are

printed on the packaging material.

3. The Pallet Ramp - The pallet ramp is shipped under the

cardboard cap on top of the frame. Cautiously remove the

ramp from the top of the frame.

4. Remove the Cover Grills - Remove the grill covers from the

frame. Grasp a grill cover by the side finger hold, and pull

straight forward. Set the covers to one side. Do not scratch

them.

5. Leveling Feet - Fully retract each of the four leveling feet

located near the casters on the bottom of the frame.

Frame

Restraint

Remove the Frame frRemove the Frame fr

Remove the Frame fr

Remove the Frame frRemove the Frame fr

1. Loosen Rear Bracket Screws - Loosen the two phillipshead screws securing the brackets at the rear of the frame.

2. Remove Two Frame Restraint Screws - See Figure 3-2.

Remove the frame restraint screws. Use the cloth handle to

remove the frame restraint from the pallet. Place the frame

restraint and two screws aside.

3. Install the Ramp - Position the ramp so that the installation

bolts line up with the ramp bolt holes on the pallet. Install the

ramp onto the pallet as shown in Figure 3-3.

om the Palletom the Pallet

om the Pallet

om the Palletom the Pallet

Ramp

Holes

Fig 3-2 Frame Restraint and Ramp Holes

Fig 3-3 Frame Pallet Ramp

4. Roll the Frame from the Pallet - The following operation

requires two people. Holding the frame near the center, care-

fully roll it down the ramp and onto the floor. (The frame is

equipped with casters.)

5. Roll the Frame to the Installation Site - Carefully roll the

frame from the staging area to the final installation site.

6. Shipping Material Storage - Gather and store all shipping

materials.

Moving Battery & Power ModulesMoving Battery & Power Modules

Moving Battery & Power Modules

Moving Battery & Power ModulesMoving Battery & Power Modules

1. Move Battery and Power Modules On Pallet - Use the

pallet jack to move the modules pallet(s) to the installation

site. Remove the outer packaging materials.

2. Stack Modules - Carefully stack the boxed battery and

power modules near the installation site. Leave adequate space

for the electrican to install wiring to the frame.

3-2

Page 28

Chapter Four

Wiring Requirements & Procedures

This chapter is addressed to the qualified

electrican who will install the input, output

and remote emergency power off hardwiring

connections. Circuit requirements and

minimum wire gauges are included.

MiniFrame

MasterFrame

Page 29

SymmetraTM Wiring

n All power and control wiring must be installed by a

qualified electrician only. All input, output, and

emergency power off wiring must comply with applicable local and country codes.

n Use flexible metal conduit when hardwiring the Power

Array. This will provide for ease of service and maintenance of the system.

There are three categories of hardwiring installation procedures for the SymmetraTM Power Array:

n Input Wiring

n Output Wiring

n Remote Emergency Power Off Switch Wiring

Input Wiring

Chapter 4 - Electrical Requirements and Procedures

The Power Array requires a single phase 220V, 230V, or 240V

incoming AC mains (utility) power source. Incoming power

is wired directly to a terminal block inside the Power Array.

Input wiring specifications and installation procedures are

provided.

Output Wiring

Power is distributed to the load equipment via hardwired connections from an output terminal block inside the Power Array frame and/or by plugging the load equipment into the

convenience power panel. With the PowerView user interface, the Power Array can be configured to deliver either 220V,

230V, or 240V. Output wiring specifications and installation

procedures are provided.

REPO Switch Wiring

The SymmetraTM Power Array can be connected to either a

dry contact or a 24Vdc remote emergency power off (REPO)

switch. The wiring terminal connections for the REPO are

physically isolated from the primary circuitry of the Power

Array. Wiring specifications and installation procedures for

REPO wiring are provided.

4-1

Page 30

Chapter 4 - Electrical Requirements and Procedures

Input Wiring

n Read this chapter completely before installing wiring.

n Verify that all incoming line voltage (mains power)

and low voltage (control) circuits are de-energized and

locked out before installing cables or making connections, whether in the junction box or to the

SymmetraTM Power Array.

n Always verify that all battery modules are removed

and all battery extension frames are disconnected from

the Power Array before installing wiring.

Input Wiring SpecificationsInput Wiring Specifications

Input Wiring Specifications

Input Wiring SpecificationsInput Wiring Specifications

The Power Array requires a single phase 220V, 230V, or 240V

50 or 60Hz incoming utility (mains) power source. A 3-conductor cable (2 live, 1 ground) is to be brought to two input

wiring terminal blocks inside an adequate length of flexible

metal conduit. To minimize disturbances caused by other

loads in the building, input wiring should be supplied directly from the service entrance (a dedicated power feeder).

All electrical service, both input and output, must be sized in

accordance with local building codes. The circuit for input

power must be adequate to carry the full load of the system

and the load equipment. The 3-conductor input cable should

be sized for no more than 3% voltage drop.

A 20 mm (3/4") knockout in the input wiring access panel

provides access to the terminal blocks.

See table 4-1 for input wiring specifications.

Input WInput W

Input W

Input WInput W

1. Refer to figure 4-1. Locate the input wiring entry and

input wiring inspection panels at the rear of the frame.

2. Remove the four screws securing the panels to the frame.

Remove only the screws indicated in the illustration. Place

the screws and panels aside.

3. Pull the input wires through an adequate length of 20 mm

(3/4") flexible metal conduit, leaving about 51.3 cm (20") of

wiring extending from the end. Install a flexible metal conduit connector to the end of the conduit. Using appropriate

tools, remove the knockout in the entry panel. Feed the wires

through the entry panel, and attach the flexible metal conduit connector to the panel.

4. Strip 13mm (1/2") of insulation from the end of each of

the incoming wires.

5. Note the positions of the ground wiring terminal block

and the input wiring terminal block. See figure 4-2.

iring Priring Pr

iring Pr

iring Priring Pr

Fig 4-1 Removal of Input Hardwiring Panels

ocedurocedur

ocedur

ocedurocedur

Entry Panel

eses

es

eses

4-2

emarFemarF

emarFemarF

tupnItupnI

tupnItupnI

tupnI

egatloVegatloV

egatloVegatloV

egatloV

sulperiw-2(sulperiw-2(

sulperiw-2(sulperiw-2(

sulperiw-2(

)dnuorg)dnuorg

)dnuorg)dnuorg

)dnuorg

caV032,caV022

caV042ro

emarF

eziSeziS

eziSeziS

eziS

AVk.xaM(AVk.xaM(

AVk.xaM(AVk.xaM(

AVk.xaM(

)gnitaR)gnitaR

)gnitaR)gnitaR

)gnitaR

)AVk8(iniM

)AVk61(retsaM

Table 4-1 Input Wiring Specifications

lluFtupnIlluFtupnI

lluFtupnIlluFtupnI

lluFtupnI

daoLdaoL

daoLdaoL

daoL

egarepmAegarepmA

egarepmAegarepmA

egarepmA

pmA53

pmA07

tupnItupnI

tupnItupnI

tupnI

&tupnImuminiM&tupnImuminiM

tnerrucrevOtnerrucrevO

tnerrucrevOtnerrucrevO

tnerrucrevO

noitcetorPnoitcetorP

noitcetorPnoitcetorP

noitcetorP

)lanretxE()lanretxE(

)lanretxE()lanretxE(

)lanretxE(

pmA05

pmA001

&tupnImuminiM&tupnImuminiM

&tupnImuminiM

eguaGeriWdnuorGeguaGeriWdnuorG

eguaGeriWdnuorGeguaGeriWdnuorG

eguaGeriWdnuorG

)mm462,3(eguaG8#

)mm981,5(eguaG4#

Page 31

Ground Wiring Terminal Block

Chapter 4 - Electrical Requirements and Procedures

Fig

Input Wiring Terminal Block

Fig 4-2 Ground Wiring and Input Wiring Terminal Blocks

6. Connect the ground wire to the ground wiring terminal

block. See figure 4-3. Make sure there are no loose strands

and the terminal connection screw is sufficiently tightened.

Input Ground Wire

Existing Wiring

Fig 4-3 Ground Hardwiring Connection

7. Feed the L1 and Neutral wires through the wiring pathway

hole to the input wiring terminal block. See figure 4-4 for

the input wiring pathway.

4-4 Input Wiring Pathway

8. Connect input wires to the input terminal block connections labeled L1 and N as shown in figure 4-5. Make sure

there are no loose strands and that the terminal connection

screws are sufficiently tightened.

L1 Wire

Neutral Wire

Existing Wiring

Fig 4-5 Input Hardwiring Connections

9. Carefully fold the excess wiring into the entry compartment. After the electrical wiring test/checklist at the end of

this chapter is completed, replace the input wiring panels.

4-3

Page 32

Chapter 4 - Electrical Requirements and Procedures

Output Wiring

n Read this chapter completely before installing wiring.

n Verify that all incoming line voltage (mains power)

and low voltage (control) circuits are de-energized and

locked out before installing cables or making connections, whether in the junction box or to the

SymmetraTM Power Array.

n Always verify that all battery modules are removed

and all battery extension frames are disconnected from

the Power Array before installing wiring.

Output voltage is delivered to the load equipment via

hardwired connections and/or via eight IEC 320 C13 power

outlets at the rear of the Power Array. To facilitate maintenance and service of the Power Array, use flexible metal conduit for all hardwiring connections.

See table 4-2 for output wiring specifications.

Output Wiring InstallationOutput Wiring Installation

Output Wiring Installation

Output Wiring InstallationOutput Wiring Installation

1. Refer to Fig 4-6. Remove the four screws holding the output wiring entry panels to the rear of the Power Array. Remove only the screws indicated in the illustration. Set the

screws and both panels aside temporarily.

2. Pull the L1, Neutral, and Ground wires through conduit,

leaving about 51.3 cm (20") of wiring extending from the

end. Install a flexible metal conduit connector to the end of

the conduit. Using appropriate tools, remove the knockout

in the entry panel. Feed the wires through the entry panel,

and attach the flexible metal conduit connector to the panel.

Strip 13 mm (1/2") of insulation from the end of each of the

incoming wires.

3. Connect output wiring to the output terminal connections as shown in figure 4-7. Make sure there are no loose

strands and that the terminal connection screws are sufficiently tightened.

L1 Wire Connection

Fig. 4-6 Removal of Output Hardwiring Panels

emarFemarF

emarFemarF

tuptuOtuptuO

tuptuOtuptuO

tuptuO

egatloVegatloV

egatloVegatloV

egatloV

)dnuorg+seriw-2(

emarF

eziSeziS

eziSeziS

eziS

AVk.xaM(AVk.xaM(

AVk.xaM(AVk.xaM(

AVk.xaM(

)gnitaR)gnitaR

)gnitaR)gnitaR

)gnitaR

Neutral Wire

Connection

Ground Wire

Connection

Fig. 4-7 Output Hardwiring Connections

4. Carefully fold the excess wiring into the entry compartment. After the electrical wiring test/checklist at the end of

this chapter is completed, replace the input wiring panels.

tuptuOtuptuO

tuptuOtuptuO

mumixaMmumixaM

mumixaMmumixaM

mumixaM

rePtuptuOrePtuptuO

rePtuptuOrePtuptuO

rePtuptuO

rotcudnoCrotcudnoC

rotcudnoCrotcudnoC

rotcudnoC

tuptuO

tnerrucrevOtnerrucrevO

tnerrucrevOtnerrucrevO

tnerrucrevO

noitcetorPnoitcetorP

noitcetorPnoitcetorP

noitcetorP

)lanretxE()lanretxE(

)lanretxE()lanretxE(

)lanretxE(

&tuptuOmuminiM&tuptuOmuminiM

&tuptuOmuminiM&tuptuOmuminiM

&tuptuOmuminiM

eguaGeriWdnuorGeguaGeriWdnuorG

eguaGeriWdnuorGeguaGeriWdnuorG

eguaGeriWdnuorG

4-4

,caV032,caV022

caV042ro

)AVk8(iniM

)AVk61(retsaM

Table 4-2 Output Wiring Specifications

pmA04

pmA08

)elop-2(pmA05

)elop-2(pmA09

)mm462,3(eguaG8#

)mm981,5(eguaG4#

Page 33

Remote Emergency Power

Off Switch

Chapter 4 - Electrical Requirements and Procedures

REPO Switch InstallationREPO Switch Installation

REPO Switch Installation

REPO Switch InstallationREPO Switch Installation

The Power Array can be de-energized with a remote emergency power off (REPO) switch. REPO switches are common in computer rooms where, for safety reasons, power to

the loads must be quickly disconnected. The REPO switch

physically flips the system enable switch to stand by mode.

This cuts power to the main intelligence module, which in

turn cuts power to the Power Array and to the load equipment. The system enable switch must be physically reset.

IMPORTANT: The system enable switch cuts power to the intelligence module only. All internal circuitry that is connected

to incoming utility (mains) voltage is still powered if incoming

utility power is still present.

The REPO can be connected to either a switched, 24Vdc circuit, or a simple contact closure.

REPO SpecificationsREPO Specifications

REPO Specifications

REPO SpecificationsREPO Specifications

The REPO circuit is considered a Class 2 and SELV circuit.

SELV is an acronym for Safety Extra Low Voltage. SELV is a

common term in Europe and IEC standards. A SELV circuit

is isolated from primary circuitry through an isolating transformer and designed so that under normal conditions, the

voltage is limited to 42.4 Vpeak or 60 Vdc.

A Class 2 Circuit is a common term in North America and in

UL and CSA standards. It is defined in the Canadian Electrical Code (C22.1, Section 16) and in the National Electrical

Code (NFPA 70, Article 725).

SELV and Class 2 circuits must be isolated from all primary

circuitry. Do not connect any circuit to the EPO terminal

block unless it can be confirmed that the circuit is SELV or

Class 2. If there is a question, use a contact closure switch.

n Verify that all incoming line voltage (mains power)

and low voltage (control) circuits are de-energized and

locked out before installing cables or making connections, whether in the junction box or to the

SymmetraTM Power Array.

n Always verify that all battery modules are removed

and all battery extension frames are disconnected from

the Power Array before installing any wiring to the

Power Array.

REPO Wiring Procedures

1. Refer to figure 4-8. Remove the screw holding the twopiece access panel at the rear of the Power Array. Remove the

panel. Set the screw and the panel pieces aside.

Cable Specifications

The cable that connects SymmetraTM to the Emergency Power

Off switch should be one of the following UL Listed types:

CL2 - Class 2 cable for general purpose use; or

CL2P - Plenum cable for use in ducts, plenums, and other

space used for environmental air; or

CL2R - Riser cable for use in a vertical run in a shaft or from

floor to floor; or

CL2X - Limited Use cable for use in dwellings and for use in

raceway.

For installation in Canada, the cable should be CSA Certi-

fied, type ELC (Extra-Low-Voltage Control Cable).

Fig 4-8 Removal of REPO Wiring Panels

2. Refer to figures 4-9 and 4-10. Select the configuration that

matches the type of REPO switch that is to be installed.

Note: An existing jumper must be removed from the terminal

block if a 24Vdc REPO switch (figure 4-10) is to be installed.

3. Extend the wiring from the switch to the Power Array. Strip

13 mm (1/2") of insulation from the end of each of the incoming wires.

4. Feed the wires through the knockout in the access panel,

and install a strain relief (Romex) connector.

5. Make sure there are no loose strands and that the terminal

connection screws are sufficiently tightened.

6. After the electrical wiring test/checklist at the end of this

chapter is completed, replace the REPO access panel.

4-5

Page 34

Chapter 4 - Electrical Requirements and Procedures

Contact Closure REPO Switch Connection

Connect the contact closure REPO wiring to the terminal

block as illustrated in figure 4-9 below.

Note : The factory installed jumper remains as shown.

Jumper Installed

Fig 4-9 Dry Contact Switch

24 Vdc REPO Switch Connection

Connect the 24Vdc REPO wiring to the terminal block as

illustrated in figure 4-10 below.

Note : The factory installed jumper must be removed.

Electrical Wiring Test

The following test procedure will ensure that the Power Array has been correctly hardwired. The qualified electrician

who installed the Power Array should perform this test. A

true RMS voltmeter and a ground ohmmeter are required.

Before this test can be conducted, the main intelligence module (MIM) must be installed, and the PowerView display must

be connected to the Power Array. Refer to Chapter 5 for procedures to install the MIM and the PowerView.

IMPORTANT: Make sure the power modules and the battery

modules ARE NOT installed for this test.

Note: This test is intended to verify the electrical connection to

the Power Array, not to verify its operation or explain its usage.

In this procedure, you will be instructed to ignore PowerView

messages, etc. Refer to Chapters 6 & 7 for detailed information

about the operation of the Power Array.

Electrical WElectrical W

Electrical W

Electrical WElectrical W

q 1. Make sure all three switches -- system enable, mainte-

nance bypass, and input circuit breaker -- are in the off

or stand by position.

IMPORTANT: Make sure all load equipment is either

turned off or is unplugged from the Power Array.

q 2. Use a true RMS voltmeter to measure the input AC

utility (mains) voltagte to the terminal connections at

the rear of the frame (bottom level).

Note: If input voltage is less than 156Vrms or greater than

276Vrms, check input wiring for errors. DO NOT PROCEED UNTIL THE INPUT VOLTAGE IS WITHIN THIS

RANGE.

iring Tiring T

iring T

iring Tiring T

est/Checklistest/Checklist

est/Checklist

est/Checklistest/Checklist

4-6

Fig 4-10 24Vdc EPO Switch

24Vdc

Power

Source

Record the input voltage here: ____________________

q 3. Check for proper ground installation with a ground

ohmmeter. Check for continuity to building ground.

q 4. Switch the input circuit breaker to the on position.

q 5. Switch the system enable switch to the on position.

Note: The Power Array may make a series of clicking sounds

as it runs through an initial self test.

Page 35

Chapter 4 - Electrical Requirements and Procedures

q 6. Using the PowerView display, read and record the re-

ported input voltage from the startup screen. (220Vin

in figure 4-11 indicates that the input voltage is 220V.)

Note: The PowerView may display one or more messages

such as Number of Battery Modules Changed. Press the

ESC key until the startup screen appears.

Record the PowerView reported

input voltage here: ______________________________

Fig 4-11 Startup Screen

q 7. Compare the RMS input voltage measurement (Step

#2) with the input voltage as reported by the PowerView.

If the two measurements are significantly different, contact APC SymmetraTM technical support.

q 9. Measure the output AC voltage at the output wiring

terminal block. If the measured output voltage varies

significantly from the actual input voltage, or from the

output voltage reported by the PowerView, contact

SymmetraTM technical support.

q 10. Successful completion of steps 1 through 9 indicates

the Power Array is correctly wired to the utility power

source and that the correct output voltage is available at

the output terminal block. Load equipment voltage requirements and external wiring voltages should be

checked and verified at this time.