Page 1

DC POWER PLANT

PRODUCT MANUAL

MODEL MX28B-1200/2400

APC DC Network Solutions Inc. Division

11035 Switzer Avenue

Dallas, TX 75238 Part Number PML-0218

800-800-4APC Revision (B)

Page 2

MX28B-1200 PRODUCT MANUAL Revision B

ii MX28B-1200/2400

Page 3

Revision B MX28B-1200 PRODUCT MANUAL

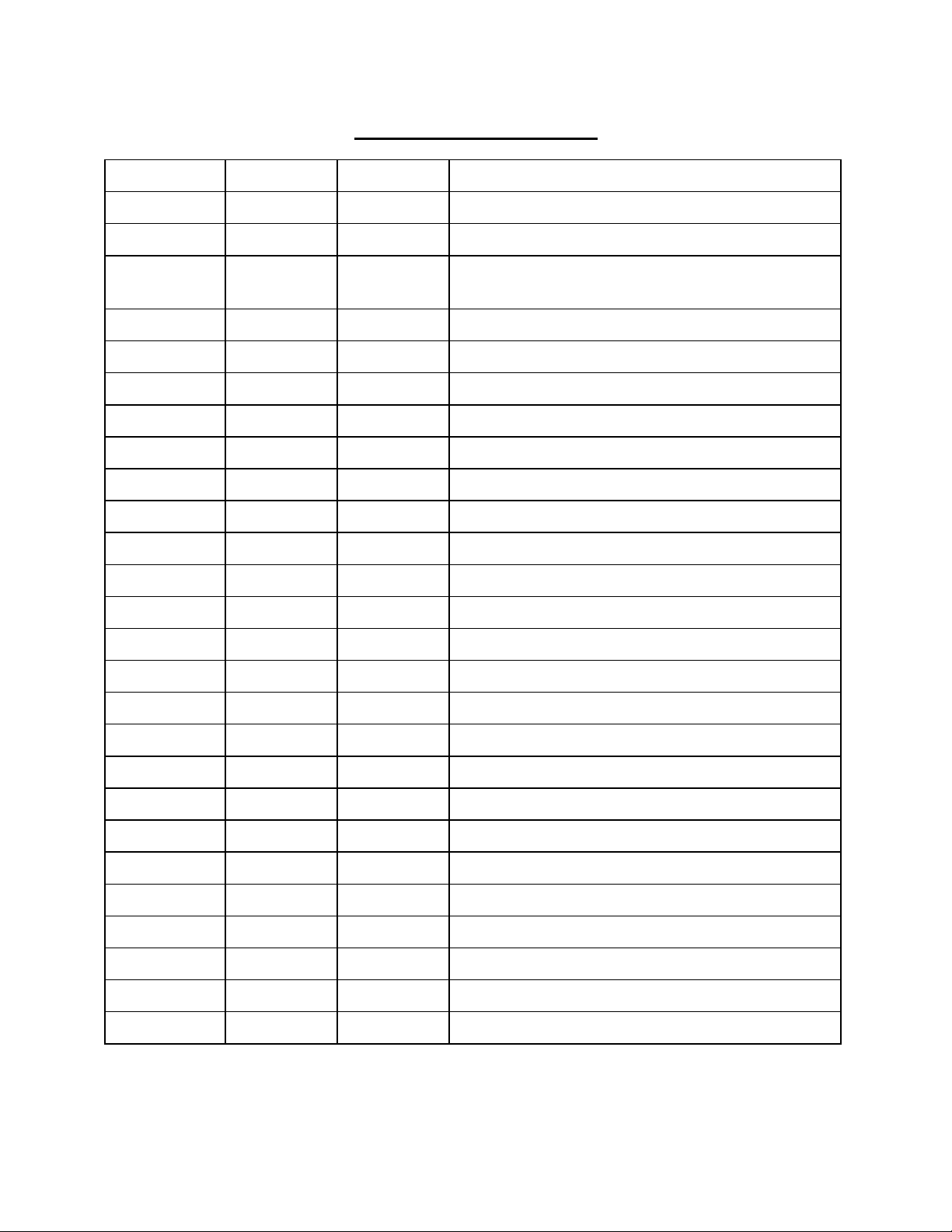

REVISION HISTORY

Revision Date By Description

Preliminary 05/19/2000 SCG Preliminary release.

A 06/30/2000 SCG Various corrections and typos.

B 01-16-01 JNF Replaced Advance with APC. Changed 1-800

number. Added ESD caution

MX28B-1200/2400 iii

Page 4

MX28B-1200 PRODUCT MANUAL Revision B

TABLE OF CONTENTS

1. GENERAL INFORMATION........................................................................................................................... 1

NTRODUCTION................................................................................................................................................ 1

1.1 I

1.2 P

RECAUTIONS.................................................................................................................................................. 1

1.3 I

NSPECTION UPON RECEIPT OF GOODS ............................................................................................................ 1

1.3.1 General.................................................................................................................................................. 1

1.3.2 Visible External Damage ...................................................................................................................... 1

1.3.3 Concealed Damage ............................................................................................................................... 2

1.3.4 Return of Damaged Goods.................................................................................................................... 2

2. CUSTOMER SERVICE AND SUPPORT ...................................................................................................... 3

3. WARRANTY PROVISIONS ........................................................................................................................... 5

3.1 G

ENERAL PROVISIONS..................................................................................................................................... 5

3.1.1 Warranty Returns .................................................................................................................................. 5

3.1.2 Warranty Repair or Replacement.......................................................................................................... 5

3.2 E

XCLUSIONS AND LIMITATIONS ...................................................................................................................... 5

4. PRODUCT OVERVIEW AND TECHNICAL DESCRIPTION................................................................... 7

4.1 D

4.2 P

4.3 R

4.4 C

4.5 AC I

4.6 B

4.7 DC D

4.8 E

4.9 M

4.10 C

ESCRIPTION................................................................................................................................................... 7

OWER OUTPUT CAPACITY ............................................................................................................................. 9

ECTIFIERS...................................................................................................................................................... 9

ONTROL UNIT................................................................................................................................................ 9

NPUT POWER.......................................................................................................................................... 10

ATTERY CONNECTIONS................................................................................................................................ 10

ISTRIBUT ION ......................................................................................................................................... 10

NVIRONMENTAL .......................................................................................................................................... 11

ECHANICAL ................................................................................................................................................ 11

OMPLIANCE ........................................................................................... ERROR! BOOKMARK NOT DEFINED.

5. INSTALLATION PROCEDURES ................................................................................................................ 13

5.1 P

REPARATION................................................................................................................................................ 13

5.1.1 Recommended Tools............................................................................................................................ 13

5.1.2 Recommended Test Equipment............................................................................................................ 13

5.1.3 Equipment Inspection.......................................................................................................................... 13

5.1.4 Safety Precautions............................................................................................................................... 13

5.1.5 Room/Locations................................................................................................................................... 14

5.1.6 Mounting ............................................................................................................................................. 14

5.1.7 Ventilation........................................................................................................................................... 15

5.2 AC S

5.3 B

ERVICE AND GROUND CONNECTIONS.................................................................................................... 15

ATTERY CONNECTIONS ............................................................................................................................... 17

5.3.1 Battery Disconnect .............................................................................................................................. 17

5.3.2 Cable Sizing Considerations ............................................................................................................... 17

5.3.3 Connecting the Cables ........................................................................................................................ 17

5.4 DC SYSTEM GROUNDING....................................................................................................................... 17

5.5 R

5.6 M

ECTIFIER INSTALLATION ............................................................................................................................. 18

ULTIPLE FRAME ASSEMBLY ....................................................................................................................... 18

5.6.1 Power Bus Connections ...................................................................................................................... 18

5.6.2 Control Wiring .................................................................................................................................... 19

5.7 A

LARM CONNECTIONS .................................................................................................................................. 23

5.7.1 External Alarm Inputs ......................................................................................................................... 24

5.7.2 Alarm Outputs ..................................................................................................................................... 24

5.8 C

ONNECTING THE LOADS.............................................................................................................................. 25

5.8.1 DC Circuit Breakers and Fuses .......................................................................................................... 25

iv MX28B-1200/2400

Page 5

Revision B MX28B-1200 PRODUCT MANUAL

5.8.2 Installation of Circuit Breakers and Fuses ......................................................................................... 26

5.8.2.1 Plug-in Circuit Breakers ..................................................................................................................................26

5.8.2.2 Circuit Breaker Load Connections...................................................................................................................27

5.8.2.3 Power Distribution Fuse Load Connections ..................................................................................................... 27

5.9 BATTERY TEMPERATURE PROBE INSTALLATION........................................................................................... 28

OWER-UP AND CHECKOUT .......................................................................................................................... 28

5.10 P

5.10.1 Apply AC Power.................................................................................................................................. 28

5.10.2 System Parameters Verification/Adjustment ....................................................................................... 29

5.10.3 Full System Power Up......................................................................................................................... 29

6. SETUP, ADJUSTMENTS, AND OPERATION ........................................................................................... 31

6.1 U

6.2 E

6.3 A

6.4 P

SER INTERFACE ........................................................................................................................................... 31

XTERNAL ALARM INPUTS ............................................................................................................................ 32

LARM OUTPUT RELAYS .............................................................................................................................. 32

ARAMETER LOCATIONS, DESCRIPTIONS, AND DEFAULT VALUES................................................................ 32

MX28B-1200/2400 v

Page 6

Page 7

Revision B MX28B-1200 PRODUCT MANUAL

1. GENERAL INFORMATION

1.1 Introduction

DC Power Plants from APC have unique features that make them easy to install, maintain, and

upgrade. The rectifier units are modular and truly “hot-pluggable” into the shelf assembly

without any separate ac wiring.

All system settings are made from the system control unit that provides monitoring and control

functions for each component of the system as well as alarm listings for system diagnosis and

maintenance.

The APC international network of sales and service offices and qualified representatives

provides sales assistance for proposals, purchases, and after-sales support.

APC provides nationwide 24-hour, 7-day service response by dialing:

(800) 800-4APC

This service will answer your call, gather specific service information, and have a qualified APC

service representative contact you as quickly as possible (refer to section on customer service

and support).

1.2 Precautions

It is extremely important to read, understand, and strictly follow the instructions in

sections on installation and setup. Also, please note the special SAFETY PRECAUTIONS

outlined in Section 5.1.4 before beginning actual installation of the power system.

If any precautions are not clearly understood, or local conditions are not covered, contact the

nearest APC representative or APC at (214) 342-5000 for clarification.

Also, refer to all applicable federal, state, and local regulations, and industry guidelines for

correct installation of this power system.

1.3 Inspection upon Receipt of Goods

1.3.1 General

APC has taken precautions in packing the power equipment for shipment to ensure its safe

arrival; however, the entire shipment including any boxes or crates should be inspected upon

receipt for evidence of damage that may have occurred during transit.

1.3.2 Visible External Damage

It is the responsibility of the person receiving the shipment to inventory and inspect all materials

against the bill of lading or waybill provided IMMEDIATELY

carrier representative is STILL ON SITE

including the correct number of pallets and the quantity of accessory and/or component boxes.

Also, note any visible external damage that may have occurred during transit.

. Please be sure that all items are accounted for,

upon taking delivery while the

If damage has occurred or the quantity of items is not correct, then:

1) Make a descriptive notation on the delivery receipt before signing.

MX28B-1200/2400 1

Page 8

MX28B-1200 PRODUCT MANUAL Revision B

2) File a damage or shortage report with the carrier that delivered the shipment.

1.3.3 Concealed Damage

It is the customer’s responsibility to unpack the power system and equipment received from

APC and check for concealed damage. Within 15 days of receipt, check the materials received

against the detailed packing list to verify that the quantity and condition are complete and

satisfactory.

Again, note any damage to the internal packing material and/or material shortages. If damage or

shortage is noted, then:

1) Request an inspection by the carrier;

2) File a concealed damage claim; and/or

3) File a material shortage claim with your APC representative.

DELAY IN NOTIFYING THE CARRIER MAY RESULT IN LOSS OF RIGHT TO

REIMBURSEMENT FOR DAMAGES OR LOSS.

If you are unsure about the appearance of a part while conducting the materials inventory and

inspection, refer to the manual or contact the Customer Service Department of APC

Should you have any questions concerning potential damages or should you experience a

lack of cooperation from your carrier, please contact your APC representative, or call

APC

1.3.4 Return of Damaged Goods

Should equipment be damaged and require return to APC for repair, the APC service

representative will provide instructions along with a valid returned material authorization

(RMA) number to facilitate return of the damaged goods to the APC repair center.

It is important that the steps outlined in Section 1.3.2 and Section 1.3.3 above are followed

carefully. Your APC representative will assist you, if required, in obtaining proper disposition

of an initial delivery return issue; however, a valid RMA number must be obtained before

returning any equipment to APC.

2 MX28B-1200/2400

Page 9

Revision B MX28B-1200 PRODUCT MANUAL

2. CUSTOMER SERVICE AND SUPPORT

APC manufactures a line power plants and provides customers with complete product and

systems support and service. APC has an international network of factory trained service

technicians. The service organization is on call 24 hours a day, 365 days a year.

If there is a problem with the power system, contact APC at

(800) 800-4APC

Units returned for repair can be turned around within 24 to 48 hours of receipt at the

factory location. Shipment should be sent pre-paid. The unit will be returned pre-paid

provided it was received that way.

An RMA must be obtained for all equipment returned to APC. It is important that correct

procedures be followed in filing an RMA, including providing an accurate written description of

the problem. An accurate written problem description will help ensure that the unit will be

properly repaired.

If a unit is returned and a “No Fault Found” results, APC reserves the right to bill the customer

for labor and assess a service charge to cover extra costs incurred.

MX28B-1200/2400 3

Page 10

Page 11

Revision B MX28B-1200 PRODUCT MANUAL

3. WARRANTY PROVISIONS

3.1 General Provisions

APC warrants the power equipment and components it manufactures or sells against defective

materials and workmanship for a period of TWO (2) YEARS from the date of shipment.

3.1.1 Warranty Returns

If initial physical inspection results in identification of a material or workmanship flaw(s) that

could impair product performance as defined by APC’s electrical and physical specification in

effect at the time of shipment, and if this flaw(s) is not due to transportation damage or

installation abuse, contact APC or call the 24-hour emergency number, (800) 800-4APC, to

request assistance.

You will be provided either a) an RMA number with instructions for return of the equipment or

component(s) to the APC factory service center, FOB destination, freight pre-paid, for

examination, or b) for non-returnable systems and equipment, notice to wait until an APC

authorized service representative arrives at the site to inspect the equipment. Repaired or

advance replacement modules or circuit components will normally be available within 24 to 48

hours of receipt of equipment or RMA.

3.1.2 Warranty Repair or Replacement

If, during the warranty period, the supplied equipment is found to be physically or electrically

faulty due to defective materials or workmanship on the part of APC, the defective product(s) or

component(s) will be repaired or replaced at the sole option of APC without charge to the user

for replacement materials or repair labor. (The procedure outlined above for contacting APC

must be followed.) Costs incurred for replacement installation including, but not limited to,

installation equipment, travel expenses of an APC representative(s), and costs of installation

material transportation expenses are not the responsibility of APC Any replacement product(s)

or component(s) shall only complete the remaining unused portion of the original warranty of

the replaced product(s) or component(s).

3.2 Exclusions and Limitations

1. This warranty applies only to the original US domestic purchaser (user) and is not

transferable internationally, except with expressed written consent from APC facility in

Dallas, Texas.

2. APC reserves the right to void the warranty if identification marks or serial numbers have

been removed or tampered with, or the defect is determined to have been caused by misuse,

neglect, improper installation, environmental conditions, non-authorized repair, alteration, or

accident.

3. This warranty does not cover physical damage due to the acts of nature or man that stress the

equipment or component(s) beyond design limits and exert undesirable influence aside from

normal wear and tear.

4. APC assumes no responsibility for any work accomplished or expenses incurred except with

expressed written consent from APC

MX28B-1200/2400 5

Page 12

MX28B-1200 PRODUCT MANUAL Revision B

5. APC shall not be liable to the user (purchaser) or any third party for indirect, incidental, or

consequential damages such as, but not limited to, loss of use, loss of profits, costs

associated with removal/installation of a defective product(s) or component(s) arising out of

the sale or relating to the use of this product, and the user (purchaser) assumes responsibility

for all personal injury and property damage resulting from the handling, possession, or use

of the product. In no event shall the liability of APC for any and all claims, including claims

of breach of warranty or negligence, exceed the purchase price of the product that gave rise

to the claim.

The above warranty is in lieu of all other remedies, including actions for contract or negligence.

All other warranties, expressed or implied, including but not limited to the implied

warranties of merchantability and fitness for a particular purpose, are hereby excluded.

6 MX28B-1200/2400

Page 13

Revision B MX28B-1200 PRODUCT MANUAL

4. PRODUCT OVERVIEW AND TECHNICAL DESCRIPTION

4.1 Description

The APC Models MX28B-1200/2400 represents a family of stand-alone -48V dc power plants.

Through the use of modular power and distribution box frames, a system is configurable in such

a manner that it will support most typical applications within the specified current range of up to

3600 amps without special application engineering or assistance.

The system is designed to start as a base unit capable of supplying 1200 amps of –48V dc power

in a single box frame with integrated power distribution breakers and an advanced control and

monitoring module. Standard distribution for a power bay includes up to 48 plug-in circuit

breakers (1 to 100 amps), or large panel-mounted circuit breakers (250 to 700 amps).

Expansion of the base unit is accomplished by adding power frames and distribution frames on

either side of the base unit The distribution box frames come with a variety of circuit breaker

and fuse options. Power expansion of the 1200 amp plant to a 2400 amp plant only requires the

addition of splice plates to the existing bus structure.

An optional low voltage disconnect (LVD) can be provided on either the battery or the load side

in each power bay. Systems incorporating power distribution frames need an external LVD unit

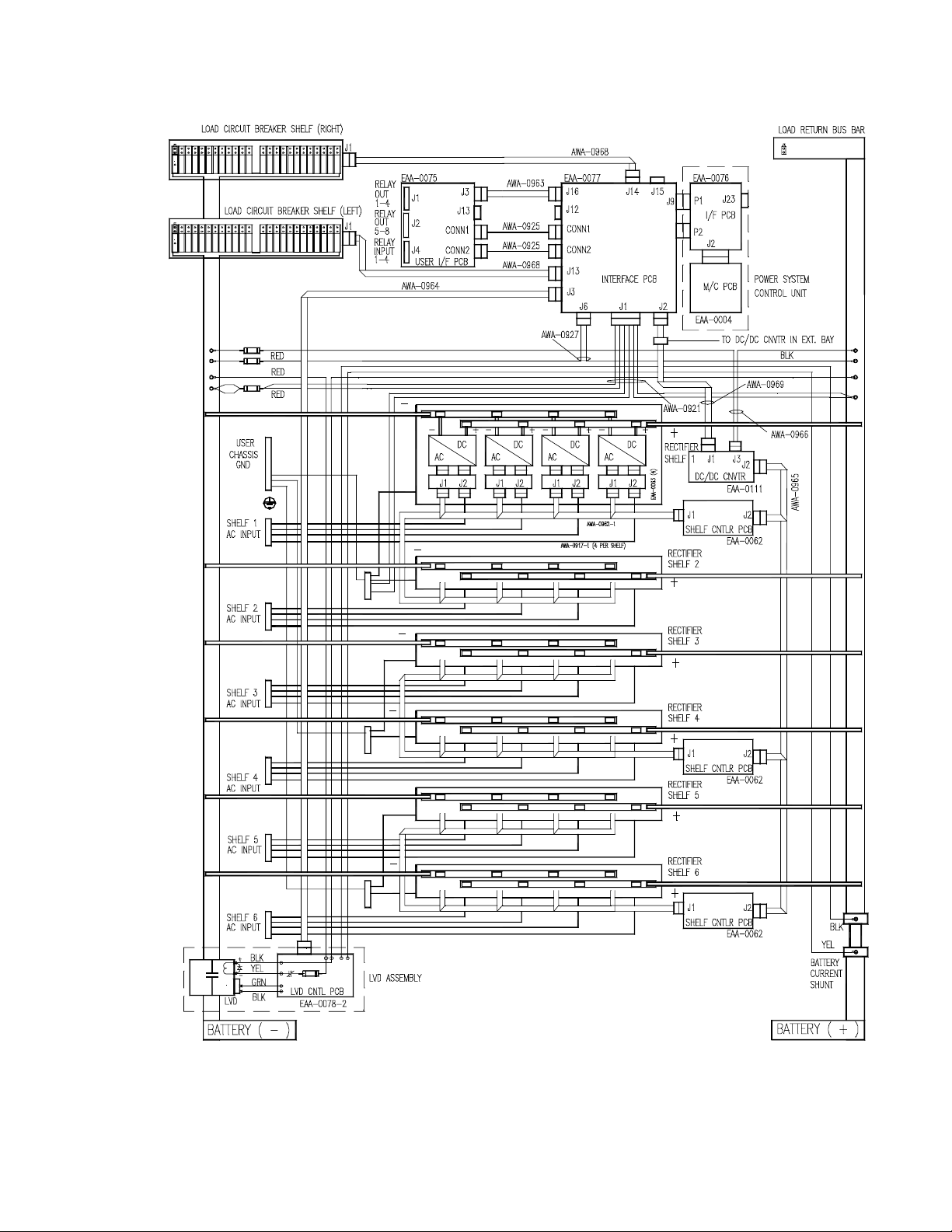

A 1200 amp MX28B is shown in. Figure 4-1. A block diagram is shown in Figure 4–2.

Figure 4-1 MX28B-1200

MX28B-1200/2400 7

Page 14

MX28B-1200 PRODUCT MANUAL Revision B

Figure 4-2 MX28B-1200 System Diagram

8 MX28B-1200/2400

Page 15

Revision B MX28B-1200 PRODUCT MANUAL

4.2 Power Output Capacity

A single power box frame consists of six rectifier shelves, each shelf accommodating up to four

hot-plug, 50 amp rectifiers. A completely configured power frame with 24 rectifiers is rated at

1200 amps. Each additional power frame will add up to 1200 amps for a maximum total of

2400 amps using 48 rectifiers. A single master control unit in the first power frame provides

control and monitoring for the entire system.

4.3 Rectifiers

The rectifiers are APC Model MRF28H54BV with specifications as follows:

•= Input Voltage: 176-264V ac (230V ac nominal) @ 45-66 Hz

•= Input Current per Rectifier: 13.9 Amps @ 230V ac

•= Apparent Power Factor: 99% Typical, 98% Minimum

•= Output Voltage: 54.5V dc

•= Overvoltage Protection: Set at 59.5V dc

•= Output Current per Rectifier: 50 Amps Minimum Continuous

•= Power Output per Rectifier: 2800W Continuous, Vin > 198V ac

•= Efficiency: 91% Typical

•= Cooling: Fan cooled, front to rear airflow

•= Ambient Temperature: -25°C to 65°C Operational

4.4 Control Unit

The microprocessor-based power system control unit is 1U high (1.75”) and provides control

and monitoring functions. Features implemented are:

•= 32-character alphanumeric display (2 lines by 16 characters)

•= LED alarm and status indicators

•= Standard voltage and battery charging control

•= Battery temperature compensation (optional temperature probe)

•= Monitoring of up to 18 shelves of four rectifiers each

•= Individual alarm monitoring of 72 breakers

•= Individual alarm monitoring of ten power distribution fuses

•= Eight alarm / annunciation relays (Major, Minor, and six user defined) with form C

contact outputs

•= Four external alarm inputs (either N.O. or N.C. contacts)

•= Control for two independent Low Voltage Disconnects (LVD’s)

MX28B-1200/2400 9

Page 16

MX28B-1200 PRODUCT MANUAL Revision B

+

)

4.5 AC Input Power

Each rectifier requires 208/220/240V ac, singlephase, 50/60 Hz, supplied through an external 20amp two-pole breaker. A vertical wire channel at

the rear of the box frame provides terminal strips

for ac input power connection of each shelf.

Separate “Earth Ground” terminal bars are

provided for the connection of the safety ground

wires. A power entry box is provided at the top

and rear of the box frame where AC wiring

conduit can be attached. Refer to Figure 4-3.

4.6 Battery connections

-

Battery connections are made at the top rear of the

unit. The -48V and Battery Return buses each

provide four sets of threaded 3/8”-16 holes on 1

inch or 1 ¾ inch centers for connecting two-hole

battery cable lugs. Refer to Figure 4-3.

A battery disconnect breaker is required external

to this equipment. The power plant can monitor

auxiliary contacts from this breaker. Battery

temperature compensation is available. APC’s

master control unit, in conjunction with the

optional temperature monitor sensor cable, is used

to implement this function.

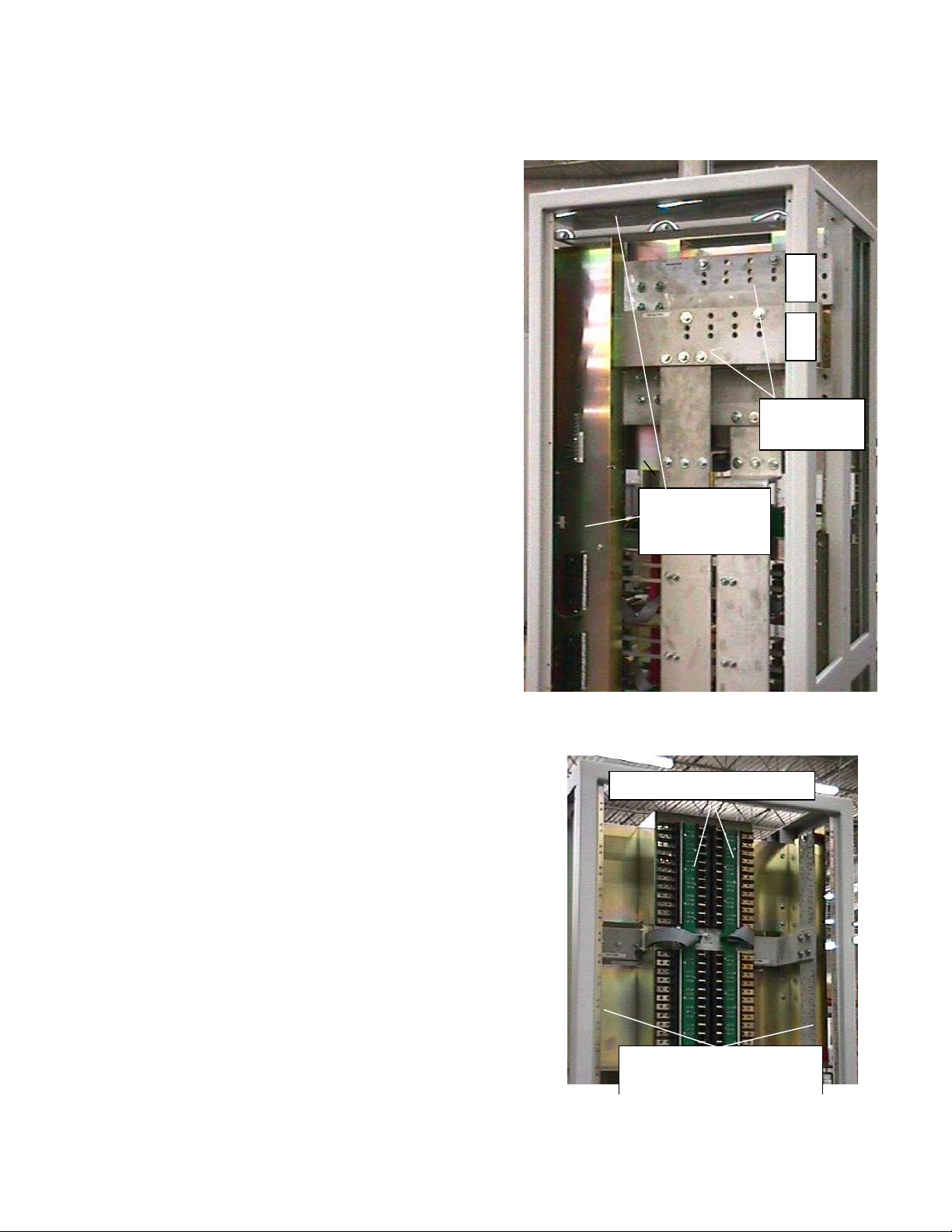

4.7 DC Distribution

A standard power distribution module within the power

box frame contains two 24-position plug-in circuit

breaker columns, providing -48V power for customer

loads. Each breaker column is connected at its center to

the -48V dc bus, with each side having an ampacity of

300A. Connections for the -48V dc loads are located

directly to the side of the corresponding breaker. A

typical load connection would utilize a #6 AWG wire

with a two-hole lug on 5/8-inch centers, attached with

standard #10-32 mounting screws.

Battery

Connections

AC entry and

vertical wiring

channel

Figure 4-3 Power Entry Box and Battery

Connections

Circuit Breaker Positions (-

The load return cables for each circuit breaker section

connect to a return bus directly opposite the circuit

breakers. These return buses contain patterns for 28

two-hole #10-32 lugs on 5/8-inch centers, and 14 twohole ¼”-20 lugs on a double-pattern of either 5/8-inch

or 1-inch centers. Figure 4-4 shows the power plant’s dc

Load Returns (+) and

Facility Main Ground Bus

Figure 4-4 DC Distribution

10 MX28B-1200/2400

Page 17

Revision B MX28B-1200 PRODUCT MANUAL

distribution section with the front cover removed.

Alternate circuit breaker configurations are available in order for the power frames to provide

support for larger individual load connections. Six circuit breakers in the 100 amp to 400 amp

range or four circuit breakers in the 225 to 700 amp range in a panel-mount arrangement can be

specified instead of the distribution module with 48 plug-in breakers.

Optional power distribution box frames can be added to a power system to support additional

circuit breakers or telecom fuses. Auxiliary alarm contacts from circuit breakers can be brought

back to the control unit through the use of an alarm extension printed circuit board in each bay.

Ten fuses outputs can also be directly monitored by the control unit.

4.8 Environmental

•= Ambient Temperature: -20°C to +65°C operating

-40°C to +85°C storage

•= Humidity: 0% to 85% RH non-condensing operating

0% to 95% RH non-condensing storage

•= Altitude: Up to 3000m, operating

Up to 10,000m, storage

4.9 Mechanical

•= Weight: Base Power Frame – 400 to 600 lbs. (181 to 272 kg)

•= Dimensions Box Frame: 84” high x 26” wide x 26” deep

•= Color: Dawn Gray (fronts)

4.10 Compliance

•= Safety UL 1950

Extension Power Frame – 400 to 600 lbs. (181 to 272 kg)

Rectifier - 11 lbs. (5 kg.)

(2134 mm x 660 mm x 660 mm)

MX28B-1200/2400 11

Page 18

Page 19

Revision B MX28B-1200 PRODUCT MANUAL

5. INSTALLATION PROCEDURES

5.1 Preparation

5.1.1 Recommended Tools

•= Standard selection of insulated hand tools.

•= Proper tools for crimping the selected cable lugs.

5.1.2 Recommended Test Equipment

•= Digital Multimeter

5.1.3 Equipment Inspection

Remove equipment from packing material and inspect for shipping damage to verify the safety

and operational suitability for the installation site. [Refer to Section 1.3]

5.1.4 Safety Precautions

***** WARNING *****

The MX28B dc power plant is supplied from a nominal 220V ac, 60 Hz source. Keep the ac

input enclosure cover in place when the system is operational or energized.

***** CAUTION *****

Handling or touching the controller boards located inside this unit without being electro

statically discharged (grounded to the frame) may cause extensive damage to the electronics.

Before touching or handling the controller boards, it is recommended that an ESD wrist

strap be utilized.

***** WARNING *****

Hazardous energy levels are present on bare conductors in the -48V dc distribution

connection area of the plant. Accidental shorting of distribution conductors can cause

arcing and high currents that can cause serious burns or other physical harm.

It is recommended that:

•= Any jewelry, rings or watches be removed while working on this equipment.

•= Handles of all wrenches, screwdrivers, cutters and pliers be insulated.

•= Shafts of screwdrivers be wrapped in electrical tape or otherwise insulated.

MX28B-1200/2400 13

Page 20

MX28B-1200 PRODUCT MANUAL Revision B

5.1.5 Room/Locations

NOTE: The APC Model MX28B dc power plant is to be installed in a room, vault, or

similar enclosure that is accessible only to qualified persons in accordance with

the NEC or the authority having jurisdiction.

Prior to installation, drawings, floor loading requirements, external alarm points, ac service

entrance, and grounding schemes should all be checked and confirmed. If batteries are to be

mounted in a room separate from the power plant, careful attention should be paid to battery

cable voltage drop effects. Environmental operating temperatures and ventilation/cooling

considerations should also be noted, not just for the power system but for all other equipment

that may reside in the power room area.

5.1.6 Mounting

The box frame housing the MX28B components is self-supporting, but designed to be bolted to

the floor of the housing structure. Figure 5-1 shows the footprint of the box frame and the

mounting points with dimensions (shown in inches). Consult the system design specifications to

see if it is necessary to electrically isolate the frame from the floor structure. This is required in

many installations.

FRONT

23.00

1.50

Figure 5-1 Floor Mounting Dimensions

11.50

11.50

Systems with multiple box frames are mounted with each frame touching, side by side. The side

cover panels where two frames touch are removed so that bus work and control cables can pass

between the frames. Three holes are provided in center vertical rail of each side to allow the

frames to be mechanically secured to each other if desired.

14 MX28B-1200/2400

Page 21

Revision B MX28B-1200 PRODUCT MANUAL

5.1.7 Ventilation

The rectifiers have fans that provide front to rear airflow for internal cooling. The MX28B

housing should mounted such that there is free airflow to the front and top of the unit. [Refer to

Section 4.8 for environmental characteristics.]

5.2 AC Service and Ground Connections

*****

WARNING *****

Ensure that all of the dc and external ac circuit breakers are in the OFF position prior to

connecting service to the power plant. Confirm that all voltages have been removed

including any battery sources before proceeding.

The MX28B dc power plant requires the

supply of 208/220/240V ac, singlephase, 50/60 Hz power through

individual external 20-amp two-pole

circuit breakers to the ac input terminal

block connections for each rectifier in

the system. The ac wiring, from the ac

input terminal block connections to the

hot-pluggable ac input connector for

each rectifier, is factory installed.

AC Input

Enclosure

Access

Opening

The ac input enclosure, located at the top

rear of the MX28B housing, is provided

with nine ¼ -inch conduit pilot holes in

the top plate (Figure 5-2). Remove the

ac input enclosure from the box frame in

Vertical channel

for AC wiring

order to punch or drill the appropriate

number of conduit openings for the

conduit size(s) desired. Do not leave the

ac input enclosure in place when punching

Figure 5-2 AC Wiring Access

or drilling holes in order to prevent metal

pieces from falling into the power system.

AC wiring passing through the conduit will be routed through

the access opening in the ac input enclosure into the vertical

wiring channel where safety ground bar and rectifier input

terminal blocks are located. The terminal block(s) is labeled

as Rectifier 1 through Rectifier 4 with each position having

inputs designated “L1” and “L2” for connection of the two ac

wires (Figure 5-3). Each terminal block represents

connections for one shelf, with positions 1 through 4

corresponding to the rectifier shelf positions numbered from

left to right as view from the front.

The suggested wire size is #10 AWG rated at 90°C or higher;

however, the ambient temperature and number of wires in a

Figure 5-3 AC

Terminal Block

MX28B-1200/2400 15

Page 22

MX28B-1200 PRODUCT MANUAL Revision B

conduit must also be considered in accordance with NEC requirements. It is suggested that

feeds for four rectifiers (8 wires) and one safety ground wire be run in a one-inch conduit;

however, be sure to follow any local electrical wiring codes.

If the ac input power is provided from a three-phase distribution panel, the circuit breaker

positions should be selected such that the load is balanced as much as possible.

16 MX28B-1200/2400

Page 23

Revision B MX28B-1200 PRODUCT MANUAL

+

5.3 Battery Connections

5.3.1 Battery Disconnect

An external circuit breaker (not supplied) is required in the negative line (located at the battery

end) to protect the cables from the battery to the MX28B dc power plant. The power plant can

monitor auxiliary contacts from this breaker. Selection of a circuit breaker for a battery string

should take into account maximum battery short circuit current and cable sizing.

5.3.2 Cable Sizing Considerations

The battery cable(s) should be sized

sufficiently large to limit the voltage drop from

the MX28B dc power plant to the battery

during charging per system design

requirements. The cable(s) must also carry the

full load current during battery operation. If

assistance is required to determine the

necessary cables for the application, contact

your sales representative or APC.

5.3.3 Connecting the Cables

The battery cable connections are located at the

top rear of the unit as shown in Figure 5-4.

The battery positive (return bus) and battery

negative (-48V bus) buses each provide four

sets of 3/8”-16 holes on a double pattern oneinch and 1 ¾-inch centers for connecting twohole battery cable lugs. Connect the battery

cables as applicable using 3/8”-16 bolts (not

provided) and tighten them with a torque

wrench to 200 in-lbs.

Battery Positive (+)

-

Battery Negative (-)

Figure 5-4 Battery Connections

***** CAUTION *****

Make certain that the battery polarity is correct when making connections to the Model

MX28B dc power plant. Incorrect connection could cause severe equipment damage.

5.4 DC SYSTEM GROUNDING

THE POSITIVE LOAD CONNECTION (RETURN BUS) FOR THE POWER PLANT

MUST BE CONNECTED TO THE FACILITY MASTER STATION GROUND. THE

CONNECTION SHOULD BE MADE ON THE RETURN BUS IN THE BASE UNIT

DISTRIBUTION AREA. DETAILS FOR THIS CONNECTION SHOULD BE

PROVIDED IN THE SITE ELECTRICAL GROUNDING PLANS.

MX28B-1200/2400 17

Page 24

MX28B-1200 PRODUCT MANUAL Revision B

5.5 Rectifier Installation

The APC Model MRF28H54BV rectifiers are shipped in separate containers. Follow the

procedure below to install a rectifier.

1) Remove the rectifier from its shipping container.

2) Remove the rectifier retaining screw from the shelf position where the rectifier is to be

installed.

3) Slide the rectifier into the shelf between the guides until it is fully seated.

4) Fasten the rectifier in place with the rectifier retaining screw.

Since all adjustments are made from the system control unit, no rectifier adjustments are

necessary.

NOTE: All “FLOAT” – “BOOST/EQUALISE” switches (one is located on the front of

each rectifier in the system) must be set to “FLOAT” to allow the MX28B to

control the output voltage properly.

5.6 Multiple Frame Assembly

5.6.1 Power Bus Connections

Installations with multiple box frames requires splicing of the power buses. The MX28B-1200 /

2400 family of power systems and distribution bays are designed so that the power buses can be

connected from bay to bay through the use of simple splice plates. Figure 5-5 shows the

connection between two box frames for the normal 2500 amp bus work.

Splice Plates

Figure 5-5 Multi-Bay Splice Plates

18 MX28B-1200/2400

Page 25

Revision B MX28B-1200 PRODUCT MANUAL

5.6.2 Control Wiring

Cables for controlling and monitoring the rectifiers and circuit breakers/fuses must be run from

expansion frames to the control unit in the base frame. There are three basic cables used for

these functions:

•= The AWA-0970 ten-pin ribbon cable connector handles serial communications for rectifier

reporting and control. This cable connects to the J1 connector of the DC/DC converter

PCB’s (EAA-0111) in each power box frame.

•= Circuit breaker reporting in extension power and distribution bays is communicated back to

the control unit through the AWA-0972 cable. This cable is connected to J15 on the control

unit interface PCB in the base unit and runs to connector J2 on the Alarm Extension PCB

(EAA-0072) in the remote bay. Additional bays are connected via the same cable, which

connects up to four Alarm Extension PCB’s.

•= Fuse reporting is routed from the Fuse Sense PCB (ADV-1204) to the control unit via cable

AWA-0967.

Refer to Figure 5-6 for a pictorial representation of multi-bay cable connection. Figure 5-7

shows the information as a wiring diagram.

MX28B-1200/2400 19

Page 26

MX28B-1200 PRODUCT MANUAL Revision B

EXTENSION

DC/DC CONVERTER

POWER

BAY

AWA-0970

DC/DC CONVERTER

AWA-0969

AWA-0967

BASE

POWER

BAY

AWA-0972

CONTROL UNIT

FUSE BAY

FUSE SENSE PCB

Figure 5-6 Typical Connection of Cables in Multi-Bay System

20 MX28B-1200/2400

Page 27

MX28B-1200/2400 21

Figure 5-7 Multi-Bay Wiring Diagram

Revision B MX28B-1200 PRODUCT MANUAL

Page 28

22 MX28B-1200/2400

MX28B-1200 PRODUCT MANUAL Revision B

Page 29

Revision B MX28B-1200 PRODUCT MANUAL

5.7 Alarm Connections

The alarm connections for all rectifiers, breakers, and fuses are factory pre-wired. The MX28B

dc power plant, however, permits the user to program the system alarms in various ways. A

Printed Circuit (PC) board designated “EAA-0075” is mounted in the space above the master

control unit and provides terminal block connection points for alarm outputs and alarm inputs

(Figure 5-8). These cage-clamp terminal blocks are operated by pushing back the lever,

inserting the wire and then releasing the lever to clinch the connection. Recommended wire size

is #28 AWG to #20 AWG.

Alarm Outputs Alarm Inputs

Figure 5-8 Alarm Interface PC Board

MX28B-1200/2400 23

Page 30

MX28B-1200 PRODUCT MANUAL Revision B

5.7.1 External Alarm Inputs

Four external alarm inputs with assignable priority levels are available. These alarm inputs

respond to external dry contact closures between normally open (NO) and common (C) or

contact openings between normally closed (NC) and C (see Table 5-1).

External Alarm Source

(non-alarm state)

OPEN

CLOSED

Table 5-1. External Alarm Input Definition

Table 5-2 shows the external alarm input connection designations. Connector J4 is located on

the alarm interface board mounted in the space above the control unit. Systems are shipped with

jumper wires connecting each NC and corresponding C contact. A jumper wire should be

removed only if the corresponding NC-C contacts are going to be used.

EXTERNAL

ALARM

INPUT

#1

#2

#3

#4

Table 5-2. External Alarm Input Connections

J4 TERMINAL

DESIGNATION

(NO-NC-C)

NO1-NC1-C1

NO2-NC2-C2

NO3-NC3-C3

NO4-NC4-C4

Connect To Input

Alarm Terminals

NO-C

NC-C

USER ALARM NOTES

___________________________

___________________________

___________________________

___________________________

5.7.2 Alarm Outputs

There are eight alarms available that provide outputs via Form “C” relay contacts. The last two

of these are pre-assigned as the Minor and Major alarm outputs. The Major relay is energized

(NO-C contacts closed) during normal (non-alarm) operating conditions; all the other relays

energize when an alarm condition occurs. The other six outputs are initially designated as

“Relay 1” through “Relay 6” (the user may assign more meaningful names if desired). The

various system alarm conditions can be assigned to any of the eight alarm outputs.

Table 5-3 shows the alarm output connection designations. Connectors J1 and J2 are located on

the alarm interface board mounted in the space above the control unit. The relay contacts should

only be used to switch resistive loads of 0.5 amperes or less at 60 volts or less.

24 MX28B-1200/2400

Page 31

Revision B MX28B-1200 PRODUCT MANUAL

ALARM

OUTPUT

RELAY #1

RELAY #2

RELAY #3

RELAY #4

RELAY #5

RELAY #6

MINOR

MAJOR

Table 5-3. Alarm Output Connections

5.8 Connecting The Loads

5.8.1 DC Circuit Breakers and Fuses

Both plug-in circuit breakers and Telecom fuses can be installed in the MX28B power plant for

dc distribution circuit protection. Available plug-in circuit breakers are shown in Table 5-4.

Plug-in circuit breakers rated at 60A or more require two mounting positions and require a

breaker adapter kit, which is included (see kit selection information below the table). The

breaker adapter kit includes all necessary mounting hardware.

TERMINAL

DESIGNATION

NO-NC-C

J1

NO1-NC1-C1

NO2-NC2-C2

NO3-NC3-C3

NO4-NC4-C4

J2

NO5-NC5-C5

NO6-NC6-C6

NO7-NC7-C7

NO8-NC8-C8

USER ALARM NOTES

________________________

________________________

________________________

________________________

________________________

________________________

________________________

________________________

BREAKER

RATING

1 A FFA-0014 40 A FFA-0020

3 A FFA-0015 50 A FFA-0025

5 A FFA-0016 60 A FFA-0021-X *

10 A FFA-0017 70 A FFA-0022-X *

15 A FFA-0028 80 A FFA-0023-X *

20 A FFA-0018 100 A FFA-0024-X *

30 A FFA-0019

* -1: adapter has #10 studs on 5/8” centers for two-hole cable lug

-2: adapter has #10 studs on ¾” centers for two-hole cable lug

-3: adapter has ¼” studs on 1” centers for two-hole cable lug

PART NUMBER BREAKER

RATING

Table 5-4. Plug-in Circuit Breakers

PART NUMBER

MX28B-1200/2400 25

Page 32

MX28B-1200 PRODUCT MANUAL Revision B

Fuse holders that accommodate telecom fuses are located in a separate fuse power distribution

box frame. The fuse holders are designed to hold Bussmann® (or equivalent) TPL-series fuses

in sizes of 70 amps to 600 amps. The following stock sizes are available from APC:

FUSE

RATING

200 A FFA-0106

300 A FFA-0093

600 A FFA-0099

Table 5-5 Telecom Power Fuses

5.8.2 Installation of Circuit Breakers and Fuses

5.8.2.1 Plug-in Circuit Breakers

1) Remove the circuit breaker cover panel and the plastic cover(s) from the desired

location(s).

2) Install the circuit breaker(s) by snapping the top terminal onto the upper bus bar and

rotating the unit down until the second terminal snaps onto the breaker termination post

as shown in Figure 5-9. The breaker alarm terminals are designed to make contact with

the alarm terminal board as the breaker is snapped into place.

NOTE: Circuit breaker alarm contacts close when the circuit breaker is tripped but

not when it is turned OFF.

APC PART

NUMBER

***** CAUTION *****

During circuit breaker installation, carefully align the breaker alarm terminals with the alarm

terminal board to avoid breaker terminal damage.

3) Reattach the circuit breaker cover panel.

26 MX28B-1200/2400

Page 33

Revision B MX28B-1200 PRODUCT MANUAL

Figure 5-9 Plug-in Circuit Breaker Insertion

5.8.2.2 Circuit Breaker Load Connections

Connections for the -48V dc loads are located directly to the side of the corresponding breaker.

A typical load connection would utilize a #6 AWG wire with a two-hole lug on 5/8-inch centers,

attached with standard #10-32 mounting screws.

The load return cables for each circuit breaker section connect to a return bus directly opposite

the circuit breakers. These return buses contain patterns for 28 two-hole #10-32 lugs on 5/8inch centers, and 14 two-hole ¼”-20 lugs on a double-pattern of either 5/8-inch or 1-inch

centers.

5.8.2.3 Power Distribution Fuse Load Connections

Connection for the –48V dc loads are made to L-shaped

landing pads connected to the distribution side of the

fuse. All the fuses within a given box frame have a

common bus connection to –48V dc. Load side

connections utilize a double-hole lug on 1 ¾ -inch

centers and return connections are made to the common

Fuse Connections

return bus bar at the top of the cabinet using 1-inch or 1

¾ -inch lugs (Figure 5-10).

Figure 5-10 Fuse Bay Connections

MX28B-1200/2400 27

Page 34

MX28B-1200 PRODUCT MANUAL Revision B

5.9 Battery Temperature Probe Installation

The optional temperature probe is used to monitor the battery string temperature. To get the

most representative temperature measurement, the probe should be placed in contact with a

battery cell that is centrally located. The probe should be placed directly in contact with the cell

(not the frame surrounding the cell). Generally, the cell cover can be used; be careful not to

allow the probe body to touch the terminals.

1) Plug the connector end of the temperature probe into J5 the control unit interface card in

the base power bay.

2) Route the cable as required to position the probe on the selected battery cell

3) Remove the adhesive protection strip from the probe body and press the adhesive side of

the probe on the battery cell cover.

BATTERY

TEMPERATURE

PROBE CABLE

15 ft. (4.6m) FFA-0013-1

50 ft. (15.2m) FFA-0013-2

Table 5-6 Temperature Probe Cables

5.10 Power-Up and Checkout

Before initiating power-up and checkout, ensure that the following conditions exist:

1) Make sure that the external circuit breaker protecting the cables from the battery to the

power plant is turned OFF (the battery cables should be connected to the power plant, but

the battery should not

2) Make sure that all load circuit breakers are turned OFF and all load distribution fuses are

removed.

3) Verify that all rectifiers have been installed.

5.10.1 Apply AC Power

be connected).

APC PART

NUMBER

Turn on the circuit breakers that supply ac power to the rectifiers in the MX28B dc power plant.

The main screen should appear on the control unit display (see Figure 5-11). The display on the

control unit is a 2-lines by 16-characters display. The cursor cycles below the characters of the

active selection on the display. Information shown in the second line of Figure 5-11 that extends

beyond 16 characters (to the right of the “S” in “ALARMS”) can viewed on the control unit

display by using the scrolling controls (refer to Section 6 for operation of the control unit).

NOTE: When ac power is initially applied, there is a 60-second period during which no

alarms are reported.

28 MX28B-1200/2400

Page 35

Revision B MX28B-1200 PRODUCT MANUAL

MX28B-1200 +

STATUS ALARMS SYSTEM MODULES BATT PIN OEM

Figure 5-11 Control Unit Display

5.10.2 System Parameters Verification/Adjustment

The MX28B system control unit is delivered with pre-programmed parameter default settings.

A complete listing and description of all system configuration parameters as well as displayable

system status and information is provided in Section 6. Read Section 6 to gain an understanding

of and how to use the operational features provided by the MX28B dc power plant. As a

minimum, the following parameters should be verified and adjusted, if required, before

connecting batteries or loads to the power plant:

1) Battery Float Voltage - default = -54.00V dc (Check the manufacturer’s

recommendation for the batteries being used in the system.)

2) Battery Maximum Recharge Rate - default = 50A. (Bellcore specifications

recommend a maximum charging rate of battery capacity (in Ampere-hours) divided by

20 hours; check the manufacturer’s recommendation.)

3) System Voltage - measurement ≅ -54.00V dc (This is a measurement by the system of

the dc output bus voltage.)

4) LVD Option - default = “Enable” (If the MX28B does not have an LVD installed, this

should be changed to “Disable”.)

5) Rectifier Information - Check the rectifier information displays to verify that all

rectifiers installed can be viewed on the control unit display and that no rectifier alarms

are active.

Section 6 provides location information for these parameters and how to make changes if

required.

5.10.3 Full System Power Up

To complete a full system power up, perform the following steps

1) Turn OFF all the circuit breakers that supply ac power to the rectifiers in the MX28B dc

power plant.

2) Turn on the external circuit breaker from the battery to the power plant.

3) Turn on all the circuit breakers that supply ac power to the rectifiers in the MX28B dc

power plant.

4) Load circuit breakers and distribution fusses may now be turned on and inserted as

required.

MX28B-1200/2400 29

Page 36

Page 37

Revision B MX28B-1200 PRODUCT MANUAL

6. SETUP, ADJUSTMENTS, AND OPERATION

6.1 User Interface

The MX28B control unit provides a user interface designed with a hierarchical menu that can be

viewed on the 32-character display by “navigating” with the “ ” (left), “ ” (right), “ ” (up),

and “ ” (down) arrow keys located on the front panel. The selected item on the display is

identified by the cursor cycling beneath its characters.

MX28B +

STATUS ALARMS SYSTEM MODULES BATT PIN OEM

Arrow Keys move Display Window across main

menu items and down into additional menu

selections

Figure 6-1 Navigating the Menu

The “M” (Modify) key and the arrow keys are used to set parameters and text to customize the

system operation for a specific application. Items that can be modified have "m+" in the upper

right corner of the display. If a security level higher than the one presently set is required to

modify the parameter, "s+" is displayed instead of “m+”. Status, alarms, and information

screens have "+" in the upper right corner of the display (or “#” in the case of rectifier

information screens) and cannot be modified. When ac power is initially applied, there is a 60second period during which no alarms are reported.

Pressing the "M" key on the front panel will change the "m+" to "M+", indicating that the

parameter can now be changed using the arrow keys. Some parameters can be changed to other

predefined selections by pressing the up or down arrow keys to display an alternative selection.

These parameters can be recognized after the “M” key is pressed by the cursor cycling beneath

the characters of the selection. For other parameters, such as text and most numeric values, after

the “M” key is pressed the cursor will be displayed under an individual character. The right or

left arrow key is used to position the cursor below the character to be changed and the up or

down arrow key is used to "spin" the digit or letter to the desired value. When the desired

changes have been made to an individual parameter screen, the “M” key is pressed again; the

“M+” changes back to “m+” and the new entry is stored in memory.

If the user plans to make any changes to system parameters, the first item that should be verified

or entered is the appropriate password for the security level required for the parameters to be

modified. Security level 2 enables modification of all variable system parameters, level 1

MX28B-1200/2400 31

Page 38

MX28B-1200 PRODUCT MANUAL Revision B

permits modification of some parameters; no security is required for viewing status items. The

security level password is entered through the “PIN” screen. If no front panel keys are pressed

for 60 minutes, the active password reverts to “0000” and “█APC█” begins to move about the

display. Pressing any key returns the display to normal; the password must be re-entered if

system parameters require changes. The default passwords for level 1 and level 2 are “1111”

and “2222”, respectively. There are no alternate passwords or “backdoors” for accessing the

system. A forgotten password may require a new master controller board, at customer expense.

System control parameters are stored in non-volatile memory and will not be erased when power

is removed for the master control unit. However, if a new program EPROM is installed or a

different device model selected, the system control parameters will be re-initialized to the

factory default settings.

Eleven LEDs are provided on the front panel of the control unit to indicate system status. Three

LEDs grouped together vertically provide overall system status; they are “MAJOR”, “MINOR”,

and “NORMAL”, indicating the presence of a major alarm, a minor alarm, or normal operation.

The other eight LEDs correspond to the active state of each of the alarm output relays and are

labeled “ALM1”∙∙∙“ALM6”, “MIN”, and “MAJ”.

6.2 External Alarm Inputs

The four external alarm inputs (also referred to as “Input Relay Alarms”) can be assigned a

priority and routed or “mapped” to alarm output relays. Available assignments are “Ignore”,

“Major”, “Minor”, and “Relay 1” ∙∙∙ “Relay 6”. Screens for making the assignments are

located at [SYSTEM/IN-RLY/RLY-MAP]. This special menu notation is explained with an

example in section 6.4

A user defined name or “alias” may also be assigned to each of these input alarms. Screens for

making these assignments are located at [SYSTEM/IN-RLY/ALIAS]. For information on

wiring connections to these inputs refer to Section 5.7.1.

6.3 Alarm Output Relays

There are eight alarm output relays designated Relay 1 through Relay 6, Minor, and Major,

respectively. Various system parameters may be programmed to activate any of these alarm

relays when set thresholds are exceeded or specific conditions occur. The first six relays can

also be assigned a priority and routed or “mapped” to other output alarm relays. Available

assignments are “Ignore”, “Major”, “Minor”, and “Relay 1” ∙∙∙ “Relay 6”. Screens for making

these assignments are located at [SYSTEM/OUT-RLY/RLY-MAP]. This feature makes it

possible for a single alarm condition to activate multiple alarm output relays including the Minor

or Major alarm relay. A user defined name or “alias” may also be assigned to each of the eight

output relay alarms. Screens for making these assignments are located at [SYSTEM/OUT-

RLY/ALIAS]. For information on making wiring connections to the alarm output relays refer

to Section 5.7.2.

6.4 Parameter Locations, Descriptions, and Default Values

The location, description, and factory programmed default value for each of the MX28B system

parameters is found in Table 6-1. The table also shows all of the status and information screens

with typical displays. The location of a parameter screen is shown in brackets, for example:

[SYSTEM/IN-RLY/RLY-MAP]. To find the parameters that can be accessed in this category,

starting from the main menu screen, do the following:

32 MX28B-1200/2400

Page 39

Revision B MX28B-1200 PRODUCT MANUAL

1) Use the right or left arrow keys to position the cycling cursor below “SYSTEM”.

2) Press the down arrow key once.

3) Use the right arrow key to position the cycling cursor below “IN-RLY”.

4) Press the down arrow key once; the cursor will be cycling below “RLY-MAP”.

5) Press the down arrow key (repeatedly if necessary) until the desired parameter screen is

displayed (there are eight parameter screens in this category).

6) After making any desired changes (refer to Section 6.1 for the procedure), to return to the

main menu press the up arrow key repeatedly.

If a parameter requires a level 1 or level 2 security access to permit changes to it, the security

level will be found in braces, i.e. {2}, in the “PARAMETER” column of Table 6-1.

The complete menu structure shown in the order in which it is accessed from the control unit

display is presented in outline form in Figure 6.2. Each indentation to the right represents a

menu level below the indicated title.

MX28B-1200/2400 33

Page 40

MX28B-1200 PRODUCT MANUAL Revision B

Figure 6-2. Control Unit Menu Structure

MX28B-1200 +

STATUS

Sys Voltage

Sys Current

Sys Temp

Batt Current

Batt Temp

ALARMS

Alarm Item 1

Alarm Item 2

Alarm Item 3

Alarm Item 4

Alarm Item 5

Alarm Item 6

Alarm Item 7

Alarm Item 8

Alarm Item 9

Alarm Item 10

Alarm Item 11

Alarm Item 12

Alarm Item 13

Alarm Item 14

Alarm Item 15

Alarm Item 16

SYSTEM

SET-ALM

Sys HV Thr

Sys HV Alm

Sys LV Thr

Sys LV Alm

Rect Cfg Alm

Rect 1ofN Alm

Rect 2ofN Alm

Sys HT Thr

Sys HT Alm

Sys LT Thr

Sys LT Alm

Hw Sys V Alm

Hw Batt C Alm

Hw Batt T Alm

Hw Sys T Alm

Hw LVD1 Alm

Hw LVD2 Alm

SETUP

PIN 1

PIN 2

Address 1

34 MX28B-1200/2400

Page 41

Revision B MX28B-1200 PRODUCT MANUAL

(Figure 6-2. Control Unit Menu Structure)

Address 2

Address 3

Model

Fahrenheit

Cntrl Rev

FW Version

Display Type

DATE

Date

Time

OUT-RLY

RLY-MAP

Out-Rly 1 Alm

Out-Rly 2 Alm

Out-Rly 3 Alm

Out-Rly 4 Alm

Out-Rly 5 Alm

Out-Rly 6 Alm

Out-Rly 1 Dly

Out-Rly 2 Dly

Out-Rly 3 Dly

Out-Rly 4 Dly

Out-Rly 5 Dly

Out-Rly 6 Dly

ALIAS

Out-Rly 1

Out-Rly 2

Out-Rly 3

Out-Rly 4

Out-Rly 5

Out-Rly 6

Relay Minor

Relay Major

IN-RLY

RLY-MAP

In-Rly 1 Alm

In-Rly 2 Alm

In-Rly 3 Alm

In-Rly 4 Alm

ALIAS

In-Rly 1

In-Rly 2

In-Rly 3

In-Rly 4

DIAG

Store Cfg

Lamp Test

MX28B-1200/2400 35

Page 42

MX28B-1200 PRODUCT MANUAL Revision B

(Figure 6-2. Control Unit Menu Structure)

Test Relay En

Test Relay 1

Test Relay 2

Test Relay 3

Test Relay 4

Test Relay 5

Test Relay 6

Test Min Rly

Test Maj Rly

MODULES

RECT

SET-ALM

Rect CL Alm

Rect Stdby Alm

Rect FF Alm

Rect RFA Alm

PARAM

Rect Fail Safe

Rect Fail Comm

INFO

Rect # Desc

Rect # Curr

Rect # CL

Rect # Stdby

Rect # FF

Rect # RFA

CIRBKR

SET-ALM

Cir Bkr 1 Alm

Cir Bkr 2 Alm

Cir Bkr 3 Alm

Cir Bkr 4 Alm

Cir Bkr 5 Alm

Cir Bkr 6 Alm

••••

••••

••••

Cir Bkr 70 Alm

Cir Bkr 71 Alm

Cir Bkr 72 Alm

ALIAS

Cir Bkr 1

Cir Bkr 2

Cir Bkr 3

Cir Bkr 4

Cir Bkr 5

Cir Bkr 6

36 MX28B-1200/2400

Page 43

Revision B MX28B-1200 PRODUCT MANUAL

(Figure 6-2. Control Unit Menu Structure)

Cir Bkr 7

Cir Bkr 8

••••

••••

••••

Cir Bkr 70

Cir Bkr 71

Cir Bkr 72

FUSE

SET-ALM

FUSE 1 Alm

FUSE 2 Alm

FUSE 3 Alm

FUSE 4 Alm

FUSE 5 Alm

FUSE 6 Alm

FUSE 7 Alm

FUSE 8 Alm

FUSE 9 Alm

FUSE 10 Alm

FUSE 11 Alm

FUSE 12 Alm

FUSE 13 Alm

FUSE 14 Alm

FUSE 15 Alm

FUSE 16 Alm

ALIAS

FUSE 1

FUSE 2

FUSE 3

FUSE 4

FUSE 5

FUSE 6

FUSE 7

FUSE 8

FUSE 9

FUSE 10

FUSE 11

FUSE 12

FUSE 13

FUSE 14

FUSE 15

FUSE 16

MX28B-1200/2400 37

Page 44

MX28B-1200 PRODUCT MANUAL Revision B

(Figure 6-2. Control Unit Menu Structure)

LVD

SET-ALM

LVD1 Option

LVD1 Open Alm

LVD2 Option

LVD2 Open Alm

PARAM

LVD1 Trip

LVD1 Reset

LVD2 Trip

LVD2 Reset

BATT

SET-ALM

Batt Disc Thr

Batt Disc Alm

Batt HV Thr

Batt HV Alm

Batt LV Thr

Batt LV Alm

Batt HT Thr

Batt HT Alm

Batt LT Thr

Batt LT Alm

PARAM

Batt Float

Batt Max Rech

COMP

Comp Method

Comp TC

Comp HKnee

Comp LKnee

PIN

PIN

OEM

OEM R Offset

OEM R Gain

OEM S Offset

OEM S Gain

38 MX28B-1200/2400

Page 45

Revision B MX28B-1200 PRODUCT MANUAL

Table 6-1. Parameter Locations, Descriptions, and Default Values

PARAMETER DESCRIPTION DISPLAY SCREENS /

DEFAULT SETTINGS

SYSTEM SETUP

Password Entry

PIN Entry

[PIN]

Password Setup

Level 1 PIN {2}

[SYSTEM/SETUP]

Level 2 Password {2}

[SYSTEM/SETUP]

OEM Calibration

OEM R Offset {2}

[OEM]

OEM R Gain {2}

[OEM]

OEM S Offset {2}

[OEM]

OEM S Gain {2}

[OEM]

Site Address/Identification

Screen for entry of the active password (PIN).

Password (PIN) that permits security Level 1 parameter

changes - limited access.

Password (PIN) that permits security Level 2 parameter

changes - unlimited access.

Voltage offset adjustment for factory calibration of voltage

readings/settings.

Voltage gain adjustment for factory calibration of voltage

readings/settings.

Current offset adjustment for factory calibration of battery

current readings/settings.

Current gain adjustment for factory calibration of battery

current readings/settings.

PIN m+

0000

PIN 1 m+

1111

PIN 2 m+

2222

OEM R Offset m+

0.000 V

OEM R Gain m+

1.000 V

OEM S Offset m+

0.0 A

OEM S Gain m+

1.000 A

Address 1 {1}

[SYSTEM/SETUP]

Address 2 {1}

[SYSTEM/SETUP]

Address 3 {1}

[SYSTEM/SETUP]

Control Unit Setup & Info.

Model Type {2}

[SYSTEM/SETUP]

Temperature Scale {1}

[SYSTEM/SETUP]

Control Unit Revision

[SYSTEM/SETUP]

Firmware Version

[SYSTEM/SETUP]

Power plant address or identification - first line.

Power plant address or identification - second line.

Power plant address or identification - third line.

Model type number for the MX28B dc power plant

NOTE: Changing the model number causes the system to

reinitialize.

Enables selection of Fahrenheit or Celsius temperature scale

(Fahrenheit “OFF” displays readings in °C).

Hardware revision level of the control unit.

Version number of the control unit firmware.

NOTE: Actual firmware version number displayed is the

current version as of the date of manufacture.

Address 1 m+

APC

Address 2 m+

11035 Switzer Av

Address 3 m+

Dallas, TX.

Model m+

0001

Fahrenheit m+

OFF

Cntrl Rev +

000002

FW Version +

000131

MX28B-1200/2400 39

Page 46

MX28B-1200 PRODUCT MANUAL Revision B

(Table 6.1 Parameter Locations, Descriptions, and Default Values)

PARAMETER DESCRIPTION DISPLAY SCREENS /

DEFAULT SETTINGS

Display Type

[SYSTEM/SETUP]

Type number for the control unit display.

Display Type +

000255

Date/Time Setup

Date {1}

[SYSTEM/DATE]

Time {1}

[SYSTEM/DATE]

Alarm Threshold Setup

High Voltage Threshold {1}

[SYSTEM/SET-ALM]

Low Voltage Threshold {1}

[SYSTEM/SET-ALM]

High Temperature Threshold {1}

[SYSTEM/SET-ALM]

Low Temperature Threshold {1}

[SYSTEM/SET-ALM]

System Status

System Voltage

[STATUS]

System Current

[STATUS]

Internal system calendar date.

Internal system clock time (24-hour format).

System High voltage alarm threshold.

System Low voltage alarm threshold.

Over temperature alarm threshold.

Under temperature alarm threshold.

System output voltage measured between the MX28B dc

power plant -48V and return buses.

The total system output current (calculated as the sum of the

individual rectifier output currents).

Date m+

DEC 16 1999

Time m+

9:00:25

Sys HV Thr m+

-58.00 V

Sys LV Thr m+

-50.00 V

Sys HT Thr m+

70.0 C

Sys LT Thr m+

0.0 C

Sys Voltage +

-54.00 V

Sys Current +

145.8 A

System Temperature

[STATUS]

Battery Current

[STATUS]

Battery Temperature

[STATUS]

System Alarms

System High Voltage {1}

[SYSTEM/SET-ALM]

System Low Voltage {1}

[SYSTEM/SET-ALM]

System High Temperature {1}

[SYSTEM/SET-ALM]

System temperature measured within the control unit.

Battery current measured at the current shunt.

Battery temperature measured by the optional battery

temperature sensor probe.

System voltage is above the high voltage threshold.

System voltage is below the low-voltage threshold.

The control unit temperature is above the high temperature

threshold.

Sys Temp +

26.7 C

Batt Current +

-15.0 A

Batt Temp +

25.2 C

Sys HV Alm m+

Minor

Sys LV Alm m+

Minor

Sys HT Alm m+

Minor

40 MX28B-1200/2400

Page 47

Revision B MX28B-1200 PRODUCT MANUAL

(Table 6-1. Parameter Locations, Descriptions, and Default Values)

PARAMETER DESCRIPTION DISPLAY SCREENS /

DEFAULT SETTINGS

System Low Temperature {1}

[SYSTEM/SET-ALM]

The control unit temperature is below the low temperature

threshold.

Sys LT Alm m+

Minor

Rectifier Configuration {1}

[SYSTEM/SET-ALM]

Rectifier Fail 1-of-N {1}

[SYSTEM/SET-ALM]

Rectifier Fail 2-of-N {1}

[SYSTEM/SET-ALM]

Hardware System Voltage {2}

[SYSTEM/SET-ALM]

Hardware Battery Current {2}

[SYSTEM/SET-ALM]

Hardware Battery Temperature {2}

[SYSTEM/SET-ALM]

Hardware System Temperature {2}

[SYSTEM/SET-ALM]

Hardware LVD1 {2}

[SYSTEM/SET-ALM]

Hardware LVD2 {2}

[SYSTEM/SET-ALM]

The rectifier configuration differs from its stored

configuration.

Rectifier Fail 1-of-N alarm - one rectifier has at least one

alarm condition.

Rectifier Fail 2-of-N alarm – two or more rectifiers have at

least one alarm condition each.

This alarm indicates there is a hardware failure in the system

voltage monitoring function.

This alarm indicates there is a hardware failure in the battery

current monitoring function.

This alarm indicates there is a hardware failure in the battery

temperature monitoring function.

This alarm indicates there is a hardware failure in the system

temperature monitoring function.

This alarm indicates there is a conflict between the

commanded and sensed positions of the LVD1.

This alarm indicates there is a conflict between the

commanded and sensed positions of the LVD2.

Rect Cfg Alm m+

Minor

Rect 1ofN Alm m+

Minor

Rect 2ofN Alm m+

Major

Hw Sys V Alm m+

Minor

Hw Batt C Alm m+

Minor

Hw Batt T Alm m+

Minor

Hw Sys T Alm m+

Minor

Hw LVD1 Alm m+

Minor

Hw LVD2 Alm m+

Minor

SYSTEM ALARMS DISPLAY

Alarms Item 1

[ALARMS]

•

•

•

Alarms Item 16

[ALARMS]

SYSTEM DIAGNOSTICS

Store Configuration {1}

[SYSTEM/DIAG]

Lamp Test {1}

[SYSTEM/DIAG]

Test Relay Enable {1}

[SYSTEM/DIAG]

Display of up to 16 active alarms (a typical alarm screen is

shown).

•

•

•

Display of up to 16 active alarms (a typical alarm screen is

shown).

Setting this parameter to “Enable” will cause the current

rectifier configuration to be stored (the display toggles back

to “Disable” after entry).

Setting Lamp Test to “ON” will turn on the “MAJOR”,

“MINOR”, “NORMAL”, “MAJ”, and “MIN” LEDs on the

control unit front panel.

This parameter must be set to “Enable” to permit the eight

output relays to be manually tested; otherwise, the state of the

relays will be per system conditions.

Alarm Item 1 +

Batt LV Alm On m

•

•

•

Alarm Item 16 +

Store Cfg m+

Disable

Lamp Test m+

OFF

Test Relay En m+

Disable

MX28B-1200/2400 41

Page 48

MX28B-1200 PRODUCT MANUAL Revision B

(Table 6-1. Parameter Locations, Descriptions, and Default Values)

PARAMETER DESCRIPTION DISPLAY SCREENS /

DEFAULT SETTINGS

Test Relay 1 {1}

[SYSTEM/DIAG]

Setting this parameter to “ON” energizes Relay 1 and turns

on the “ALM1” LED on the control unit front panel.

Test Relay 1 m+

OFF

•

•

•

Test Relay 6 {1}

[SYSTEM/DIAG]

Test Minor Relay {1}

[SYSTEM/DIAG]

Test Major Relay {1}

[SYSTEM/DIAG]

BATTERY SETUP

Float Voltage {1}

[BATT/PARAM]

Maximum Recharge Current {1}

[BATT/PARAM]

Compensation Method {1}

[BATT/COMP]

Temperature Compensation {1}

[BATT/COMP]

•

•

•

Setting this parameter to “ON” energizes Relay 6 and turns

on the “ALM6” LED on the control unit front panel.

Setting this parameter to “ON” energizes the Minor Relay

and turns on the “MIN” LED on the control unit front panel.

Setting this parameter to “ON” de-energizes the Major Relay

and turns on the “MAJ” LED on the control unit front panel.

Float voltage at 25°C battery temperature.

Maximum battery recharge current (the system limits the

charging current to this programmable value).

Activate “000001” or de-activate “000000” battery

temperature compensation.

Temperature compensation between low knee and high knee

in mV/cell/°C. (Compensation equals zero at 25°C.)

•

•

•

Test Relay 6 m+

OFF

Test Min Rly m+

OFF

Test Maj Rly m+

OFF

Batt Float m+

-54.00 V

Batt Max Rech m+

12 A

Comp Method m+

000000

Comp TC m+

- 3.00mV

Compensation High Knee {1}

[BATT/COMP]

Compensation Low Knee {1}

[BATT/COMP]

Discharge Threshold {1}

[BATT/SET-ALM]

High Voltage Threshold {1}

[BATT/SET-ALM]

Low Voltage Threshold {1}

[BATT/SET-ALM]

High Temperature Threshold {1}

[BATT/SET-ALM]

Low Temperature Threshold {1}

[BATT/SET-ALM]

The temperature compensation high knee is the point above

which there is no additional battery voltage compensation for

further increases in temperature.

The temperature compensation low knee is the point below

which there is no additional battery voltage compensation for

further decreases in temperature.

An alarm is generated if the battery discharge current exceeds

this value.

An alarm is generated if the magnitude of the battery voltage

rises above this value.

An alarm is generated if the magnitude of the battery voltage

drops below this value.

An alarm is generated if the battery temperature exceeds this

value.

An alarm is generated if the battery temperature drops below

this value.

Comp Hknee m+

40.0 C

Comp Lknee m+

0.0 C

Batt Disc Thr m+

10 A

Batt HV Thr m+

-58.00 V

Batt LV Thr m+

-44.00 V

Batt HT Thr m+

70.0 C

Batt LT Thr m+

0.0 C

42 MX28B-1200/2400

Page 49

Revision B MX28B-1200 PRODUCT MANUAL

(Table 6-1. Parameter Locations, Descriptions, and Default Values)

PARAMETER DESCRIPTION DISPLAY SCREENS /

DEFAULT SETTINGS

Battery Alarms

Discharge Alarm {1}

[BATT/SET-ALM]

High Voltage Alarm {1}

[BATT/SET-ALM]

Low Voltage Alarm {1}

[BATT/SET-ALM]

High Temperature Alarm {1}

[BATT/SET-ALM]

Low Temperature Alarm {1}

[BATT/SET-ALM]

RECTIFIER SETUP

Fail Safe Voltage {1}

[MODULES/RECT/PARAM]

Communications Timeout {1}

[MODULES/RECT/PARAM]

Rectifier Information NOTE: This information can be viewed for each rectifier

Rectifier Description

[MODULES/RECT/INFO]

An alarm that is generated if the battery discharge current

exceeds the programmed battery discharge threshold.

An alarm that is generated if the magnitude of the battery

voltage rises above the high voltage threshold.

An alarm that is generated if the magnitude of the battery

voltage drops below the low voltage threshold.

An alarm that is generated if the battery temperature exceeds

the high temperature threshold.

An alarm that is generated if the battery temperature drops

below the low temperature threshold.

Rectifier default output voltage if communication with the

control unit fails.

The maximum rectifier communications response time

allowed before a communications failure is declared.

installed by using the horizontal arrow keys.

Displays the model number of the installed rectifier.

Batt Disc Alm m+

Minor

Batt HV Alm m+

Minor

Batt LV Alm m+

Minor

Batt HT Alm m+

Minor

Batt LT Alm m+

Minor

Rect Fail Safem+

-54.00 V

Rect Fail Commm+

1 min

Rect 1 Desc #

MRF28H54

Rectifier Current

[MODULES/RECT/INFO]

Current Limit Alarm

[MODULES/RECT/INFO]

Standby Alarm

[MODULES/RECT/INFO]

Fan Fail Alarm

[MODULES/RECT/INFO]

Rectifier Fault Alarm (RFA)

[MODULES/RECT/INFO]

Rectifier Alarms

Current Limit Alarm {1}

[MODULES/RECT/SET-ALM]

A display of the dc output current for the individual rectifier.

The status will be “ON” if the rectifier has been forced into

its current limited mode.

The status will be “ON” if the control unit is holding the

rectifier in the standby mode.

The status will be “ON” if the rectifier fan has failed.

The status will be on if the rectifier output has failed.