Page 1

www.mgeups.com

40 – 130KVA

MGE Galaxy 5000

Critical Power and Cooling Services Division

Installation and User Manual

Page 2

Page 3

Installation and User Manual

i86-174010-00 B00

MGE Galaxy 5000

40 – 130KVA

Uninterruptible Power Systems

Installation and User Manual

Schneider Electric

1660 Scenic Avenue, Costa Mesa, CA 92626, (714) 557-1636

Service Solutions Team:

1-800-438-7373

(Hours: 24/7)

Revision History: A00 ECN-005986 5/28/08

B00 ECN-006020 6/20/08

Copyright © 2008 American Power Conversion Corporation. All rights reserved.

Printed in U.S.A.

Page 4

MGE Galaxy 5000

Important Safety Instructionsii 86-174010-00 B00

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS – This manual contains important instructions for Galaxy

5000 that must be followed during operation and maintenance of the equipment.

WARNING

Opening enclosures expose hazardous voltages. Always refer service to qualified

personnel only.

ATTENTION

L'ouverture des cellules expose à des tensions dangereuses. Assurez-vous

toujours que le service ne soit fait que par des personnes qualifiees.

WARNUNG!

Das öffnen der Gehäuse legen gefährliche Spannungen bloss. Service sollte

immer nur von qualifizierten Personal durchgeführt werden.

WARNING

As standards, specifications, and designs are subject to change, please ask for

confirmation of the information given in this publication.

ATTENTION

Comme les normes, spécifications et produits peuvent changer, veuillez

demander confirmation des informations contenues dans cette publication.

WARNUNG!

Normen, Spezifizierungen und Pläne unterliegen Anderungen. Bitte verlangen

Sie eine Bestätigung über alle Informationen, die in dieser Ausgabe gemacht

wurden.

NOTE

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at user's own expense.

WARNING

To reduce the risk of fire or electric shock, install in a controlled indoor

environment free of conductive contaminants.

This equipment is intended only for installations in a RESTRICTED ACCESS

LOCATION.

ATTENTION

Pour réduire le riske d'inccendie ou d'électrocution, installer dans une enciente

intérieure contrôlée en température et humidité et sans contaminants conducteurs.

Ce matériel est destiné seulement pour des installations dans un EMPLACEMENT RESTREINT D'ACCES.

WARNUNG!

Um die Gefahr von Feuer und elektrischem Schock zu reduzieren, muss das

Gerät in einem temperatur – und feuchtigkeitskontrollierten Raum, frei von

leitungsfähigen Verunreinigungen, installiert werden. Dieses Gerät ist nur für

die Installation an einem Ort mit qeingeschränkter Zugangserlaubnis vorgesehen.

Diese Ausrüstung ist nur für Anlagen in einem EINGESCHRäNKTEN ZUGRIFF

STANDORT bestimmti.

Page 5

Installation and User Manual

iii86-174010-00 B00

WARNING HIGH LEAKAGE CURRENT. Ground connection essential before connecting

supply.

ATTENTION COURANT DE FUITE ELEVE. Raccordement a la terre indispensable

avant le raccordement au reseau.

WARNUNG! Hoher Ableitstrom Vor Inbetriebnahme Schutzleiterverbindung herstellen.

Certification Standards – Three Phase UPS

◗ IEC1004/ANSI C62.41 Standards for Surge Withstand Ability.

◗ FCC Part 15, Subpart J, Class A.

◗ UL/CUL 1778, Standards for Uninterruptible Power Supply Equipment.

◗ NEMA PE 1 - Uninterruptible Power Systems.

◗ NFPA 70 – National Electrical Code.

◗ ISO 9001.

Environment

This product has been designed to respect the environment. It does not contain any Chlorofluorocarbon (CFC) or

Hydrochlorofluorocarbon (HCFC).

UPS recycling at the end of service life: Schneider Electric undertakes to recycle, by certified companies and in

compliance with all applicable regulations, all UPS products recovered at the end of their service life (contact your

Schneider Electric branch office).

Packing: UPS packing materials must be recycled in compliance with all applicable regulations.

WARNING: This product may be supplied with lead-acid batteries. Lead is a dangerous substance for the environment

if it is not properly recycled by specialized companies.

Certification Standards, Three Phase UPS, Environment

Page 6

(This page left blank intentionally)

MGE Galaxy 5000

iv 86-174010-00 B00

Page 7

Contents

Contents

I86-174010-00 B00

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Certification Standards – Three Phase UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Contents

CAUTION: Record All Serial Numbers! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IV

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .V

Symbol Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VI

Section Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VII

Introduction

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1.2 Inside the UPS Cabinet, Access to Connections . . . . . . . . . . . . . . . . . . . .1 — 3

1.3 UPS Cabinet Bottom View Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1.4 User-Machine Interface Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 5

1.5 Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 6

1.6 Relay Communication Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 7

Setup and Installation

2.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

2.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

2.1.1 Layout of Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 2

2.2 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 2

2.3 Connection of Power Cables in a Single UPS . . . . . . . . . . . . . . . . . . . . . .2 — 3

2.4 Redundant Parallel Configuration (Maximum Two UPS Units for Pn) . . . .2 — 4

2.5 Auxiliary Interconnections Between UPSs in Parallel Configurations . . . .2 — 5

2.6 Connection of General Shutdown or Remote Emergency Power Off

(REPO) Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 7

2.7 Adding Communication Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 8

2.8 Connection of the Relay Communications Card . . . . . . . . . . . . . . . . . . . .2 — 9

2.8.1 Characteristics of the Contacts on the Relay Communications Card . . . .2 — 10

2.9 Routing the Control/Communications Cables . . . . . . . . . . . . . . . . . . . . . .2 — 11

Operation

3.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1

3.1 Shutting Down a Single UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1

3.2 Restarting a Single UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 2

3.3 Shutting Down a Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 2

3.4 Restarting a Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 3

3.5 Operation of Mimic-Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 4

Page 8

MGE Galaxy 5000

ContentsII 86-174010-00 B00

3.6 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 5

3.7 Load on Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 5

3.8 UPS Personalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 6

3.9 Display Messages List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 7

3.10 Operation of the Relay Communication Card (Dry Contacts) . . . . . . . . . .3 — 8

3.10.1 Standard Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 8

3.10.2 Programmable Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 8

3.10.3 List of Operating Status Conditions That May be Assigned to an

SECI Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 9

Maintenance

4.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.1 Identification of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.2 Life Cycle Monitoring (LCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.3 UPS Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 2

4.3.1 UPS Isolation Single UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 2

4.3.2 UPS Isolation Parallel UPS Without External Bypass Cabinet . . . . . . . . .4 — 3

4.3.3 UPS Isolation Parallel UPS With External Bypass Cabinet . . . . . . . . . . . .4 — 4

4.4 Return to the Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 5

4.4.1 Return to Normal Single UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 5

4.4.2 Return to Normal Parallel UPS Without External Bypass Cabinet . . . . . .4 — 6

4.4.3 Return to Normal Parallel UPS With External Bypass Cabinet . . . . . . . . .4 — 8

4.5 Servicing Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 9

4.6 Training Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 9

Appendices

A1 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 1

A2 Maximum Allowable Power for Parallel UPS Units . . . . . . . . . . . . . . . . . .A — 5

A3 UPS Cabinet Major Internal Components . . . . . . . . . . . . . . . . . . . . . . . . .A — 6

A4 Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 7

A5 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 8

MGE Warranty & Proprietary Rights Statement for Three Phase Products

MGE Standard Three Phase Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W — 1

Proprietary Rights Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W — 1

Warranty and Product Registration

User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W — 2

Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W — 2

Warranty Extension (Warranty+) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W — 2

Service Solutions Team — Three Phase Products

Technical Support and Product Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .S — 1

Who To Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .S — 1

Scheduling Field Service Engineer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .S — 1

Return Policy for Repair of Three Phase Products (RGA) . . . . . . . . . . . . . . . . . . .S — 1

Glossary

Reorder Form

Page 9

Installation and User Manual

Contents III86-174010-00 B00

Figures

1-1 MGE Galaxy 5000 UPS Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2

1-2 Single Line Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2

1-3 Inside MGE Galaxy 5000 UPS Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 3

1-4 Power Connection Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1-5 INTN PCA for Auxiliary Interconnections of Parallel UPSs . . . . . . . . . . . .1 — 4

1-6 MGE Galaxy 5000 Cabinet Bottom View Layout . . . . . . . . . . . . . . . . . . . .1 — 4

1-7 User-Machine Interface Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 5

1-8 Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 6

1-9 Relay Communication Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 7

2-1 Space Allowance for Installation of UPS . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

2-2 Layout of Cabinets (typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 2

2-3 Single UPS With Common Normal and Bypass AC Inputs . . . . . . . . . . . .2 — 3

2-4 Single UPS With Separate Normal and Bypass AC Inputs . . . . . . . . . . . .2 — 3

2-5 Parallel UPS With Common Normal and Bypass AC Inputs . . . . . . . . . . .2 — 4

2-6 Parallel UPS With Separate Normal and Bypass AC Inputs . . . . . . . . . .2 — 4

2-7 Redundant Parallel Configuration (Maximum Two UPS) . . . . . . . . . . . . . .2 — 5

2-8 Parallel Configuration for Increased Capacity (Four UPSs) . . . . . . . . . . .2 — 6

2-9 Fitting the Protection Cover for the Auxiliary Interconnection Cables . . . .2 — 7

2-10 Connection of General Shutdown or Remote Emergency Power Off

(REPO) Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 7

2-11 Adding Communication Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 8

2-12 Connection of Relay Communication Card . . . . . . . . . . . . . . . . . . . . . . . .2 — 9

2-13 Characteristics of the Contacts on the Relay Communications Card . . . .2 — 10

2-14 Routing the Control/Communications Cables for Single UPS . . . . . . . . . .2 — 11

2-15 Routing the Control/Communications Cables for Parallel UPS . . . . . . . . .2 — 12

3-1 Shutting Down a Single UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1

3-2 Restarting a Single UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 2

3-3 Shutting Down a Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 2

3-4 Restarting a Parallel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 3

3-5 Operation of Mimic-Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 4

3-6 Normal (Double Conversion) Operating Mode . . . . . . . . . . . . . . . . . . . . .3 — 5

3-7 Load on Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 5

3-8 UPS Personalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 6

4-1 Life Cycle Monitoring (LCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4-2 UPS Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 2

4-3 Parallel UPS Configuration Without External Bypass Cabinet . . . . . . . . .4 — 3

4-4 Parallel UPS Configuration With External Bypass Cabinet . . . . . . . . . . . .4 — 4

4-5 Shutdown and Isolation of all the UPSs . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 4

4-6 Return to the Normal Operation for Single UPS . . . . . . . . . . . . . . . . . . . .4 — 5

4-7 Parallel UPS Configuration Without External Bypass Cabinet . . . . . . . . .4 — 6

4-8 Parallel UPS Configuration With External Bypass Cabinet . . . . . . . . . . . .4 — 8

Tables

2-1 Electrical Specifications for the MGE Galaxy 5000 . . . . . . . . . . . . . . . . . .2 — 2

4-1 Identification of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

Page 10

MGE Galaxy 5000

Record All Serial NumbersIV 86-174010-00 B00

CAUTION: Record All Serial Numbers!

RECORD ALL SERIAL NUMBERS FOR THE MGE GALAXY 5000 AND ACCESSORIES.

THESE SERIAL NUMBERS WILL BE REQUIRED IF YOUR SYSTEM NEEDS SERVICE.

KEEP THIS MANUAL IN A PLACE WHERE YOU CAN REFERENCE THE SERIAL NUMBERS

IF SERVICE IS REQUIRED!

UPS SERIAL NUMBER: ____________________________________________________________

BATTERY SERIAL NUMBER: _______________________________________________________

AUXILIARY SERIAL NUMBER: ______________________________________________________

ADDITIONAL SERIAL NUMBERS:

____________________________________ ____________________________________

____________________________________ ____________________________________

____________________________________ ____________________________________

____________________________________ ____________________________________

____________________________________ ____________________________________

____________________________________ ____________________________________

____________________________________ ____________________________________

NOTES:

Page 11

Safety Rules

Safety of persons

The UPS must be installed in a room with restricted access (qualified personnel only). A UPS has its own external

power source (the battery). Consequently, the power outlets may be energized even if the UPS is disconnected from

the AC-power source.

Dangerous voltage levels are present within the UPS. It should be opened exclusively by qualified service

personnel.

The UPS must be properly grounded.

The battery supplied with the UPS contains small amounts of toxic materials.

To avoid accidents, the instructions below must be observed.

◗ Never operate the UPS if the ambient temperature and relative humidity are higher than the levels specified

in the documentation.

◗ Never burn the battery (risk of explosion).

◗ Do not attempt to open the battery (the electrolyte is dangerous for the eyes and skin).

◗ Comply with all applicable regulations for the disposal of the battery.

◗ Caution, wait five minutes before opening the UPS to allow the capacitors to discharge.

◗ Caution, there is high leakage current, the grounding conductor must be connected first.

◗ The product must be installed on a non-inflammable surface (e.g. concrete).

◗ Caution, battery replacement must be carried out by qualified personnel.

Product safety

A protection circuit breaker must be installed upstream and downstream, and be easily accessible.

◗ Never install the UPS near liquids or in an excessively damp environment.

◗ Never let a liquid or foreign body penetrate inside the UPS.

◗ Never block the ventilation grates of the UPS.

◗ Never expose the UPS to direct sunlight or a source of heat.

◗ When replacing battery cells, use the same type and number of cells.

Special precautions

◗ The UPS connection instructions contained in this manual must be followed in the indicated order.

◗ Check that the indications on the rating plate correspond to your AC-power system and to the actual electrical

consumption of all the equipment to be connected to the UPS.

◗ If the UPS must be stored prior to installation, storage must be in a dry place.

◗ The admissible storage temperature range is -25°C to +45°C.

◗ If the UPS remains de-energized for a long period, we recommend that you energize the UPS for a period of 24

hours, at least every three months. This charges the battery, thus avoiding possible irreversible damage.

◗ The UPS is designed for normal climatic and environmental operating conditions concerning the altitude, ambient

operating temperature, relative humidity and ambient transport and storage conditions.

◗ Using the UPS within the given limits guarantees its operation, but may affect the service life of certain components, particularly that of the battery and its autonomy. The maximum storage time of the UPS is limited due to the

need to recharge the battery.

◗ Unusual operating conditions may justify special design or protection measures:

- harmful smoke, dust, abrasive dust,

- humidity, vapor, salt air, bad weather or dripping,

- explosive dust and gas mixture,

- extreme temperature variations,

- bad ventilation,

- conductive or radiant heat from other sources,

- strong electromagnetic fields,

- radioactive levels higher than those of the natural environment,

- fungus, insects, vermin, etc.,

- battery operating conditions.

Installation and User Manual

Safety Rules V86-174010-00 B00

Page 12

MGE Galaxy 5000

Symbol UsageVI 86-174010-00 B00

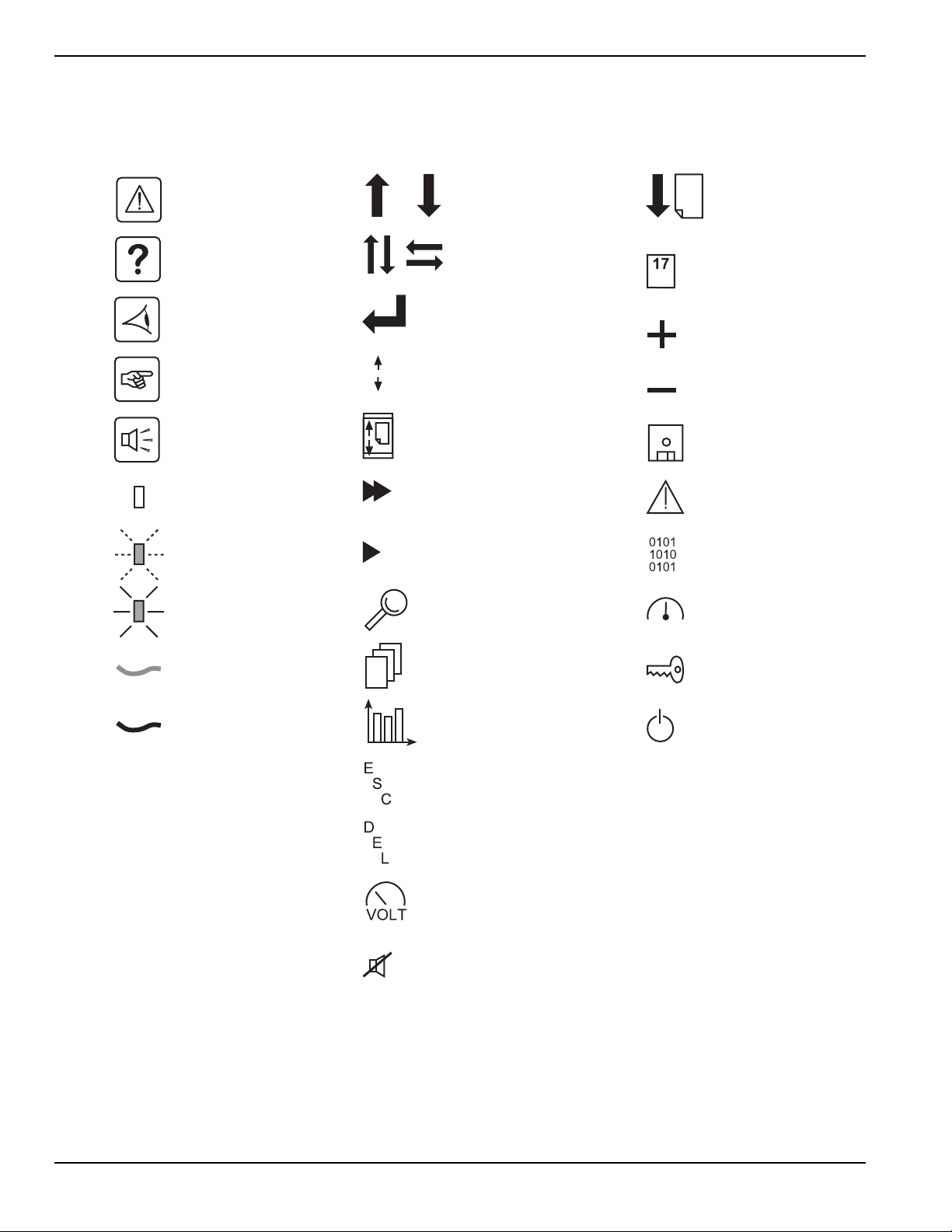

Symbol Usage

Document Icons Display Icons

Danger, these instructions

are imperative.

Information, advice, help

Visual indication

Action

Audio signal

LED OFF

LED flashing

LED ON

Vertical selection

Other selection

Enter / Confirm

Event scroll in log

Page scroll in log

Fast forward

Forward

Details

may

Move up or down one

page

Event selection in log

by date and time

Increase

Decrease

Save

Alarm

Status conditions

Settings

Ground cables

Other cables

Circular menu

Graphical display

Return to previous display

Delete

Access to measurements

Buzzer off

Maintenance

Control

Page 13

Installation and User Manual

Section Descriptions VII86-174010-00 B00

Section Descriptions

1 Introduction

Provides a general description of the MGE Galaxy 5000 system’s intended use, single line, major components, and

mechanical specifications.

2 Setup and Installation

Guides the user through performing connections required for initial installation. Included are the electrical specifications and connection details.

3 Operation

Provides startup, shutdown, and normal operation of the MGE Galaxy 5000 UPS. Describes the operation of the

mimic-panel LEDs.

4 Maintenance

Identifies alarm conditions, UPS isolation operation, and maintenance and safety information on servicing batteries

for the MGE Galaxy 5000.

A Glossary provides definitions of abbreviations and terms used in this manual.

Page 14

(This page left blank intentionally)

MGE Galaxy 5000

VIII 86-174010-00 B00

Page 15

Introduction

Thank you for selecting a Schneider Electric product to protect your electrical equipment. The MGE Galaxy 5000

range has been designed with the utmost care. We recommend that you take the time to read this manual to take

full advantage of the many features of your UPS. Schneider Electric pays great attention to the environmental

impact of its products. Measures that have made MGE Galaxy 5000 a reference in environmental protection include:

◗ the eco-design approach used in product development,

◗ production in an ISO 14001 certified factory,

◗ recycling of the MGE Galaxy 5000 at the end of its service life.

To discover the entire range of Schneider Electric products and the options available for the MGE Galaxy 5000

range, we invite you to visit our web site, www.mgeups.com, or contact your local Schneider Electric representative.

All products in the MGE Galaxy 5000 range are protected by patents. They implement original technology not

available to competitors of Schneider Electric.

To take into account evolving standards and technology, equipment may be modified without notice. Indications

concerning technical characteristics and dimensions are not binding unless confirmed by Schneider Electric.

This document may be copied only with the written consent of Schneider Electric. Authorized copies must be

marked "MGE Galaxy 5000 Installation and User Manual” no. 86-174010-00. We invite you to visit our web site,

www.mgeups.com, or contact your local Schneider Electric representative.

1.0 Scope

Provides a general description of the MGE Galaxy 5000 system’s intended use, single line major components, and

mechanical specifications.

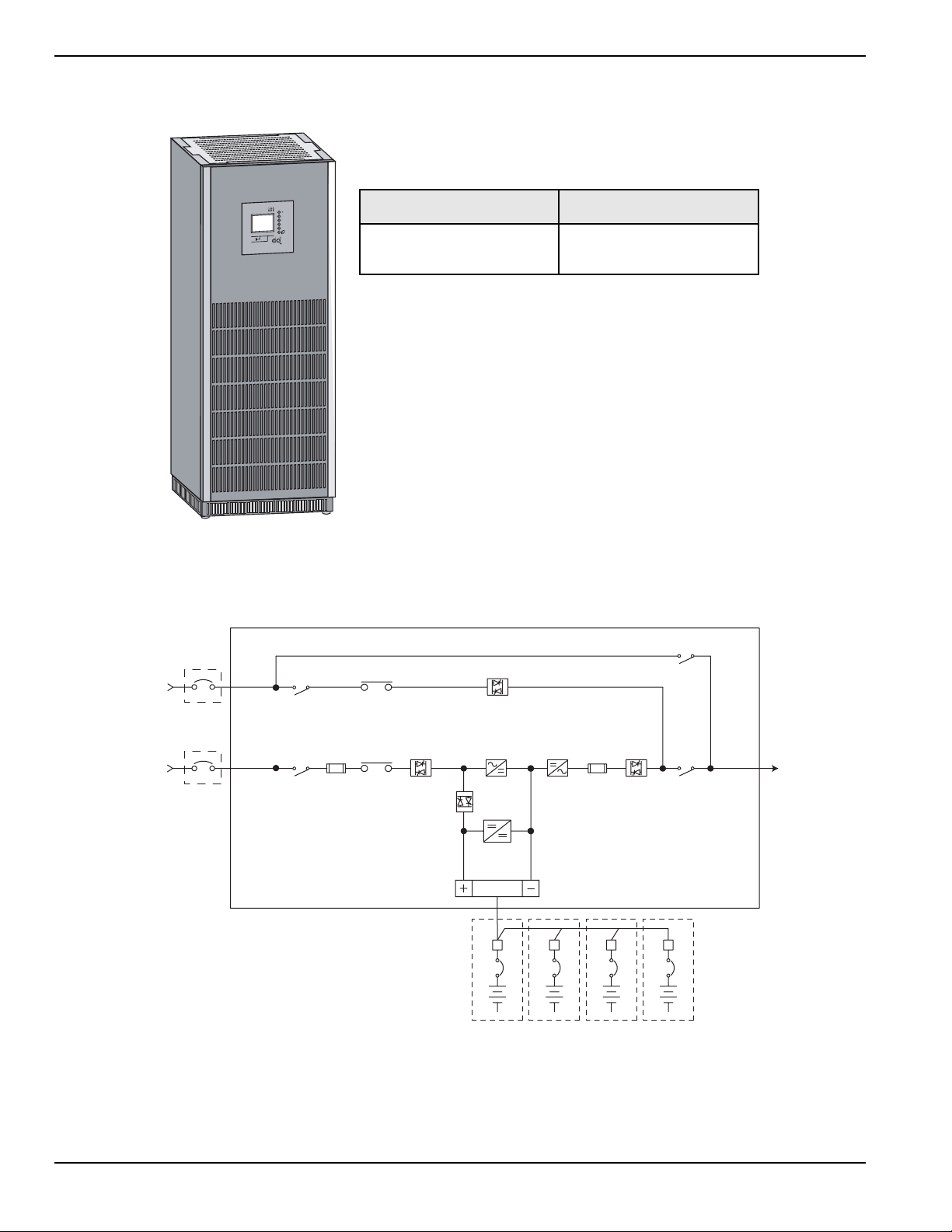

1.1 General Description

The MGE Galaxy 5000 is a three phase double conversion uninterruptible power supply (UPS), designed for

flexibility to meet a wide range of application requirements. The MGE Galaxy 5000 offers many options to allow you

to customize a solution to meet your unique specifications. The options offered include, but are not limited to,

adjacent and remote battery cabinets, input and output isolation transformers, distribution options, parallel system

bypass cabinets, and a variety of communication cards.

1 — 186-174010-00 B00 Introduction

Page 16

MGE Galaxy 5000

1 — 2 86-174010-00 B00

Figure 1-1: MGE Galaxy 5000 UPS Cabinet.

Figure 1-2: Single Line Diagram

Introduction

UPS power rating (KVA) Dimensions (H x W x D)

40-130 75” x 28” x 33.4”

1900 x 712 x 850 mm

MGE GALAXY 5000 UPS SYSTEM WITH BATTERY SINGLE LINE DIAGRAM

Optional

Bypass

Input

480Y VAC

Main

Input

480 VAC

Bypass

Input

Main

Input

UPS

Q4S

Input

Fuses

KA2

KA1Q1

Input

Static

Switch

Battery

Static Switch

PFC

Boost

Rectifier

Battery

Charger

CB

Output

Static

Output

Fuses

Switch

Inverter

CB CB CB

Q3BP

Q5N

Output

To

Critical

Load

Page 17

Installation and User Manual

1 — 386-174010-00 B00

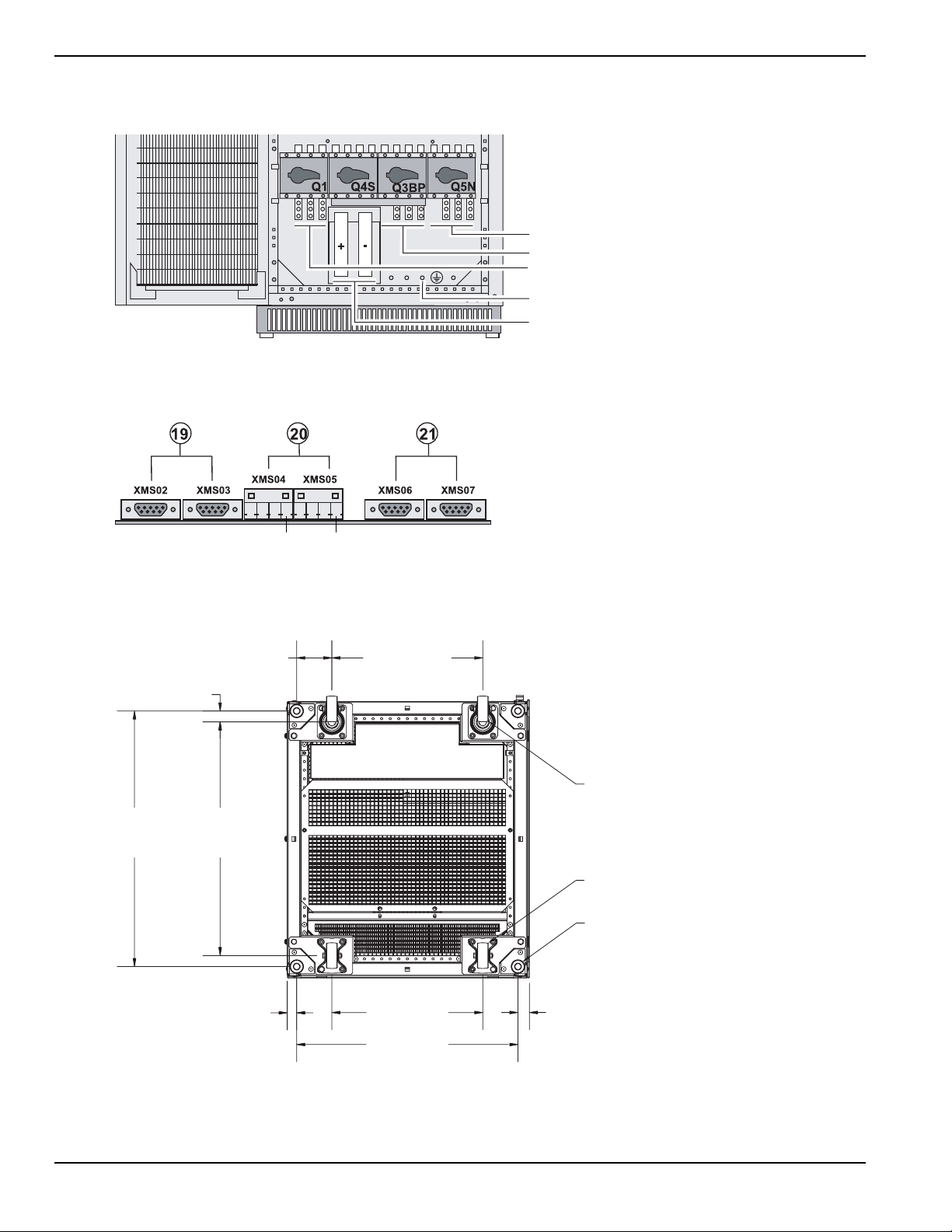

1.2 Inside the UPS Cabinet, Access to Connections

Figure 1-3: Inside MGE Galaxy 5000 UPS Cabinet

(

Introduction

(1) Connectors for auxiliary interconnections of

parallel UPS units (INTN PCA), optional

(2) User-machine interface display

(3) Slot for relay communications card

(4) Open slots for optional communication cards

(5) Open cabinet door

(6) Screw-type terminal block for connections of

contacts and coils for two external battery

circuit breakers XMB07, XMB08

(7) Screw-type terminal block for connection of

remote emergency power off (REPO) XMB06

(

8) Q1: input switch for normal AC input

(9) Q4S: input switch for bypass AC input

(10) Q3BP: bypass switch

(11) Q5N: UPS output switch

(12) Protection cover for power connections

(13) Screw-type terminal block for connection of

contacts for parallel circuit breakers TB6,

optional

Page 18

MGE Galaxy 5000

1 — 4 86-174010-00 B00

Figure 1-4: Power Connection Terminals

Figure 1-5: INTN PCA for Auxiliary Interconnections of Parallel UPSs

1.3 UPS Cabinet Bottom View Layout

Figure 1-6: MGE Galaxy 5000 Cabinet Bottom View Layout

Introduction

(14) Terminals for load output

(15) Terminals for bypass AC input

(16) Terminals for normal AC input

(17) Main grounding connector

(22) Connection of external battery

(+/- poles)

(19) DB9 connectors: exchange-current

information

(20) Screw connectors: position information

on Q5N, Q4S and Q3BP switches, from

the external bypass

(21) DB9 connectors: CAN communication

information between UPSs

PIN 1 PIN 1

4.04 (102.50)

1.26 (32.00)

29.33

(745.00)

26.81

(681.00)

1.08 (27.50) 1.32 (33.50)

17.32 (440.00)

swivel casters (2)

fixed casters (2)

levelers (4)

17.32 (440.00)

25.39 (645.00)

Page 19

Installation and User Manual

1 — 586-174010-00 B00

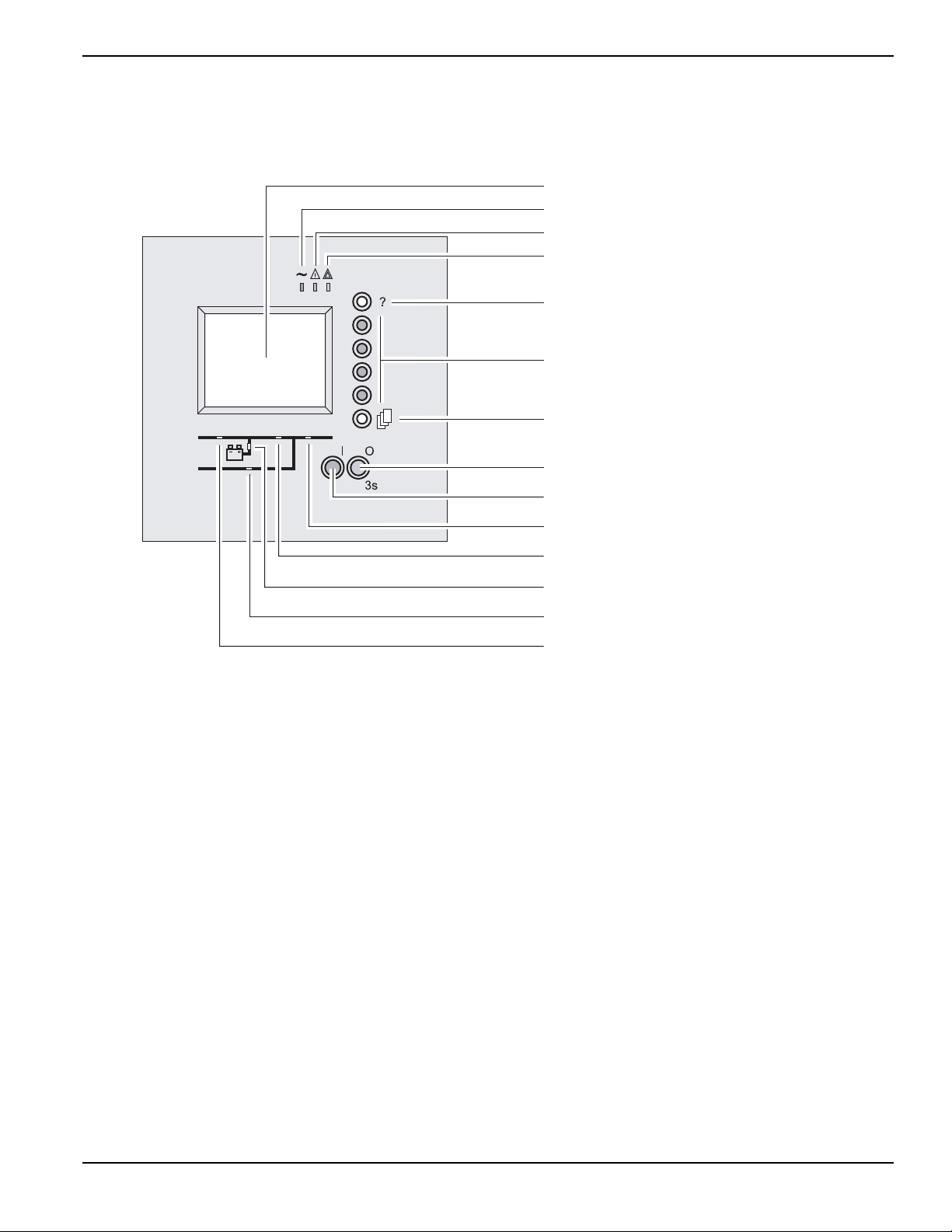

1.4 User-Machine Interface Display

Figure 1-7: User-Machine Interface Display

Introduction

(30) Graphical display

(31) Load protected LED

(32) Minor fault LED

(33) Major fault LED

(34) Help key

(35) Function keys

(36) Menu key

(38) OFF button

(37) ON button

(42) Load supplied LED

(40) UPS ON LED

(41) Operation on battery power LED

(43) Bypass in operation LED

(39) PFC ON LED

Page 20

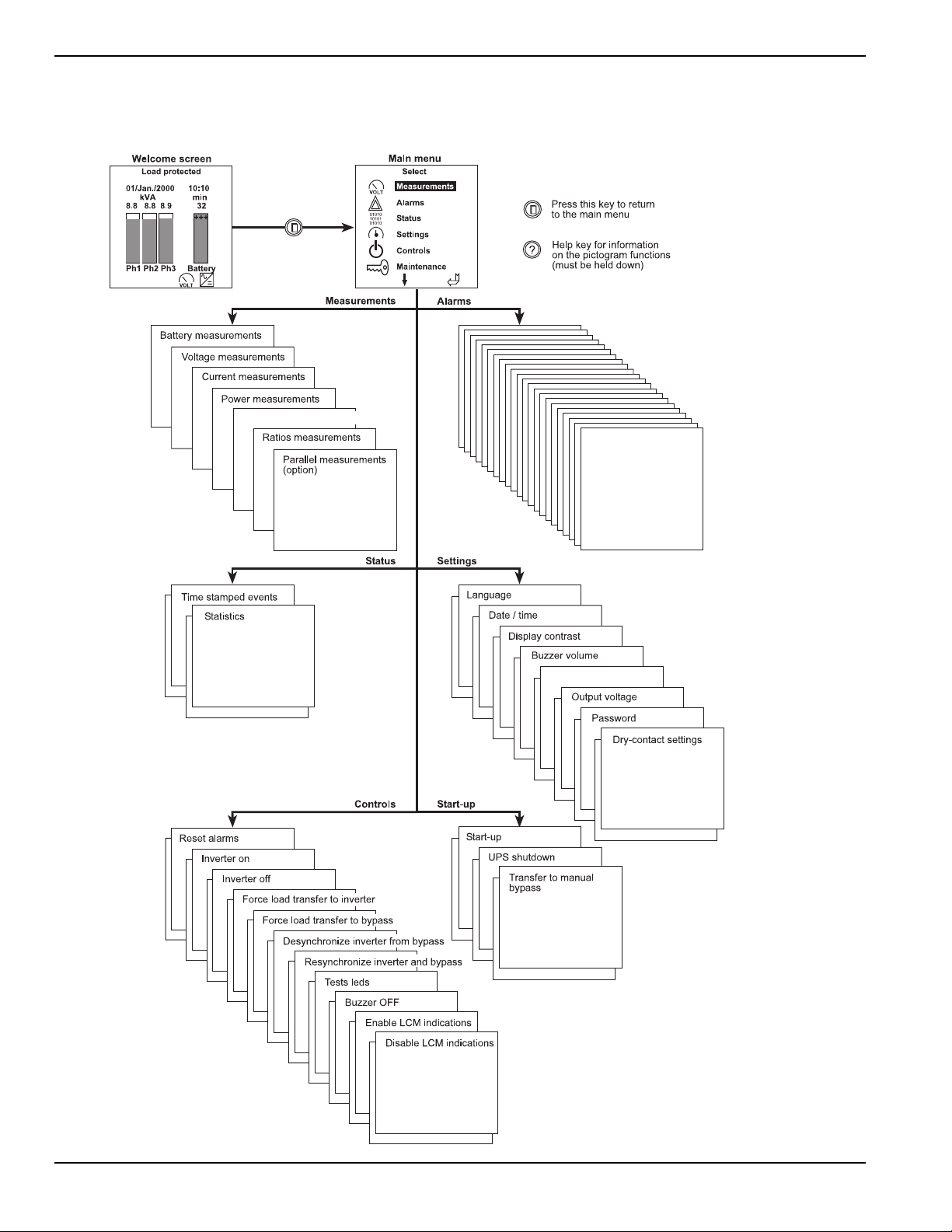

1.5 Display Screens

Figure 1-8: Display Screens

MGE Galaxy 5000

Introduction1 — 6 86-174010-00 B00

Frequency measurements

Personalization

Page 21

Installation and User Manual

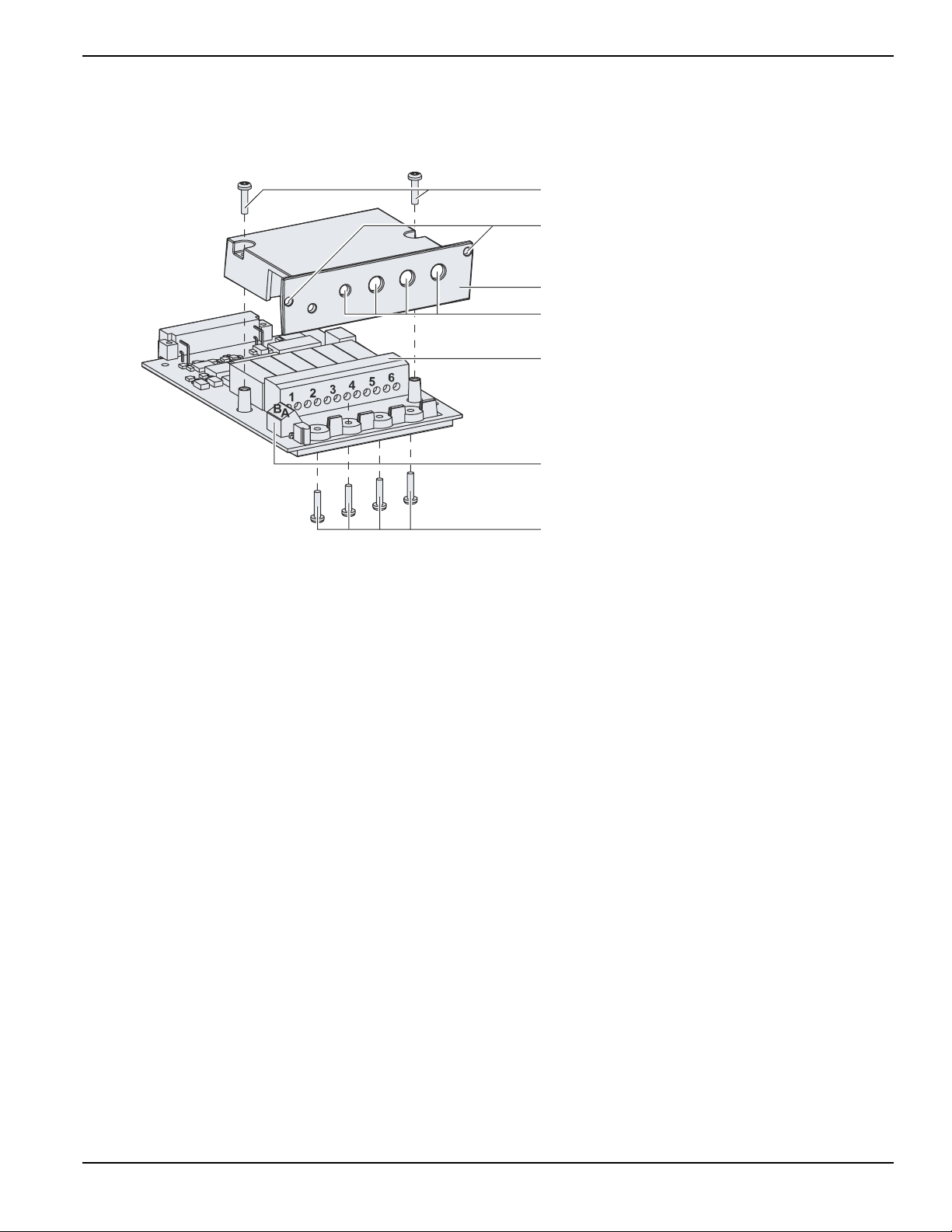

1.6 Relay Communication Card

Figure 1-9: Relay Communication Card

Introduction 1 — 786-174010-00 B00

(50) Card cover screws

(51) Card screw holes

(52) Card cover

(53) Cable entry holes

(54) Output terminal block

(55) Input terminal block

(56) Cable clamping screws

Page 22

(This page left blank intentionally)

MGE Galaxy 5000

Introduction1 — 8 86-174010-00 B00

Page 23

Setup and Installation

2.0 Scope

Guides the user through performing connections required for initial installation. Included are the electrical specifications and connection details.

2.1 Location

To ensure correct ventilation, leave nothing on top of the UPS.

Leave three feet of free space in front of the UPS for door opening.

The UPS cabinet rests on four levelers positioned in the four corners of the cabinet to spread the weight.

The UPS must be installed in a room with restricted access (qualified personnel only).

Figure 2-1: Installation of UPS

2 — 186-174010-00 B00 Setup and Installation

Page 24

2.1.1 Layout of Cabinets

Figure 2-2: Layout of Cabinets (typical)

2.2 Electrical Specifications

Table 2-1: Electrical Specifications for the MGE Galaxy 5000

Output Power Rating (0.9 PF) 40KVA 50KVA 60KVA 80KVA 100KVA 130KVA

UPS Voltage (input/output) 480/480 480/480 480/480 480/480 480/480 480/480

Input/Output Requirements & Frequency Three phase, Three wire + G, 60Hz

Input Phase Rotation A, B, C Clockwise

Input Power Factor > 0.98

Input Current/Input Current with Battery

Charging Current

48A/59A 59A/70A 71A/88A 94A/111A 117A/150A 151A/182A

Maximum Input Current with Charging Current

(at low line -10%)

57A 70A 85A 111A 148A 182A

Bypass/Output Current 48A 60A 72A 96A 120A 156A

Battery Voltage 356VDC End Voltage 432VDC Nominal 490VDC Max. Floating Voltage

Max. Battery Current at Battery Voltage

(432 VDC at 100% Load)

90A 113A 135A 180A 225A 293A

Max. Battery Current at End-Voltage

(356 VDC at 100% Load)

109A 137A 164A 219A 273A 355A

Battery Disconnect Circuit Breaker Rating 175A, 250A, 400A

Input, Bypass, Maintenance Bypass and

Output Switch Rating

125A 250A

Input and Output Fuse Rating 160A 315A

MGE Galaxy 5000

Setup and Installation2 — 2 86-174010-00 B00

TOP VIEW

DISTRIBUTION TRANSFORMER MBC

UPS BATTERY

Page 25

Installation and User Manual

CAUTION Only an authorized electrical professional should access electrical connections.

A severe shock hazard exists.

2.3 Connection of Power Cables in a Single UPS

Figure 2-3: Single UPS With Common Normal and Bypass AC Inputs

Figure 2-4: Single UPS With Separate Normal and Bypass AC Inputs

To access the connections, remove cover (see Section 1.3).

1 - The grounding conductors must be connected to the UPS

grounding-plate connections (17).

2 - Connect the three phases of the normal AC source to

connection (16).

3 - Connect the three phases of the bypass AC source to

connection (15).

4 - Connect the three phases supplying the load to connection

(14).

5 - Connect external battery (+/-) to connection (22).

6 - Tie the cables down to the frame.

7 - Put the cover back in place.

To access the connections, remove cover (see Section 1.3).

1 - The grounding conductors must be connected to the UPS

grounding-plate connections (17).

2 - Connect the three phases of the normal AC source to

connection (15).

3 - Connect the three phases supplying the load to connection

(14).

4 - Connect external battery (+/-) to connection (22).

5 - Tie the cables down to the frame.

6 - Put the cover back in place.

Setup and Installation 2 — 386-174010-00 B00

14.56”

22

22

14.56”

Page 26

2.4 Redundant Parallel Configuration (Maximum Two UPS Units for Pn)

These configurations do not have an external System Bypass Cabinet (SBC).

Figure 2-5: Parallel UPS With Common Normal and Bypass AC Inputs

Figure 2-6: Parallel UPS With Separate Normal and Bypass AC Inputs

CAUTION If the two UPSs are placed side by side, connect as indicated above. In the other

configurations, always make sure that the cables between the UPSs and bypass

AC source have the same cross-section and the same length. The same is true

for the cables between the UPSs and the load.

To access the connections, remove cover

(see Section 1.3).

1 - The grounding conductors must be

connected to the grounding-plate of each

UPS (17).

2 - Connect the three phases of the normal

AC source to connection (16) in each UPS.

3 - Connect the three phases of the bypass AC

source to connection (15) in each UPS unit.

4 - Connect the three phases of the supplied

loads to connection (14) in UPS1.

5 - Connect (14) in UPS2 to (14) in UPS1

using the three load conductors.

6 - Connect the external battery (+/-) to

connections (22) in UPS1 and UPS2.

7 - Tie the cables down to the cabinet frames.

8 - Put the covers back in place.

To access the connections, remove cover

(see Section 1.3).

1 - The grounding conductors must be

connected to the grounding-plate of each

UPS (17).

2 - Connect the three phases of the bypass

AC source to connection (15) in each UPS.

3 - Connect the three phases of the supplied

loads to connection (14) in UPS1.

4 - Connect (14) in UPS2 to (14) in UPS1

using the three load conductors.

5 - Connect the external battery (+/-) to

connections (22) in UPS1 and UPS2.

6 - Tie the cables down to the cabinet frames.

7 - Put the covers back in place.

MGE Galaxy 5000

Setup and Installation2 — 4 86-174010-00 B00

UPS 1

14.56” 14.56”

22 22

To loadTo loadTo Load

UPS 2

Ground

To Normal / Bypass

AC Source

UPS 1

14.56”

22

To Loa d

To Normal

AC Source

UPS 2

22

14.56”

Ground

To Byp a s s

AC Source

Page 27

Installation and User Manual

2.5 Auxiliary Interconnections Between UPSs in Parallel Configurations

Figure 2-7: Redundant Parallel Configuration (Maximum Two UPS)

Exchange-current interconnections (19):

Link connectors XMS02 and XMS03 on the

two UPS units.

CAN // interconnections (21):

Fit a blue plug on connector XMS06 on

UPS1. Link connector XMS07 on UPS1 to

connector XMS06 on UPS2. Fit a red plug

on connector XMS07 on UPS2.

Note: The supplied cables (33 ft) limit the

distance between the two UPS units to

approximately 20 ft.

Setup and Installation 2 — 586-174010-00 B00

19 19 19 19

UPS 1

PCA INTN

21 21 21 21

Blue

plug

UPS 2

Red plug

PCA INTN

Page 28

Figure 2-8: Parallel Configuration for Increased Capacity (Four UPSs)

These configurations have an external System Bypass Cabinet (SBC).

MGE Galaxy 5000

Setup and Installation2 — 6 86-174010-00 B00

PCA INTN

UPS 1

Blue

plug

20

SBC

20

UPS 1

TB2

UPS 3

Red

plug

21 21 21 21

Blue

plug

910

78

UPS 4

19 19 19 19

PCA INTN

UPS 2

20

20

UPS 2

Interconnections with the external system

bypass cabinet (20):

◗ Interconnect terminals 7, 8, 9, and 10 on the

auxiliary terminal block TB2 in the system

bypass cabinet to UPS terminal blocks

XMS04/XMS05 pins 1, 2, 3, and 4 respectively.

◗ Create a loop connection between the cabinet

and the UPSs as shown in Figure 2-8.

Details of terminal block connections.

4321

no

m

mo

C

TB2

SBC

7

7

8

8

9

9

10

10

XMS04 /

XMS05

1

1

2

2

3

3

4

4

Note: The interconnection cables for the

SBC are not supplied

Exchange-current interconnections (19):

Use the XMS02 and XMS03 connectors to

create a loop between the UPSs (all the XMS02

and XMS03 connectors must be used).

CAN // interconnections (21):

Daisy-chain the UPSs using the XMS06

and XMS07 connectors. Fit a blue plug on the

first UPS unit and a red plug on the last UPS

(all the XMS06 and XMS07 connectors must

be used).

UPS 4

Red plug

UPS 3

To ensure sufficient isolation of

exchange-current, CAN and external

bypass cabinet cables, they must be run

separately from the power cables.

Note: The supplied cables are 33 ft long.

Page 29

Installation and User Manual

Fitting the Protection Cover for the Auxiliary Interconnection Cables

The protection cover supplied with the parallel connected UPS units protects the user against direct contact with

voltages other than SELVs and ensures the auxiliary interconnection cables are maintained in position.

Figure 2-9: Fitting the Protection Cover for the Auxiliary Interconnection Cables

Note: Tie down the cables as indicated in the diagram in Section 2.9.

2.6 Connection of General Shutdown or Remote Emergency Power Off (REPO) Terminal Block

Figure 2-10: Connection of General Shutdown or Remote Emergency Power OFF (REPO) Terminal Block

CAUTION Pressing the general shutdown button causes UPS shutdown and opening of the

battery circuit breaker (with opening of the bypass static switch depending on

personalization settings). The Remote Emergency Power Off (REPO) notion is

applicable to installations where pressing the button also causes the upstream

Normal AC source and bypass AC source circuit-breakers to open. In parallel

configurations, there must be a single general shutdown button with a separate

contact for each UPS unit.

1 - Remove the wire jumper from terminal block (7).

2 - Connect the general shutdown NC contact to terminals 1 and 2 (SELV).

3 - Tie the cable down as illustrated in Section 2.9.

Setup and Installation 2 — 786-174010-00 B00

XMB08 XMB07 XMB06

Page 30

2.7 Adding Communication Cards

Figure 2-11: Adding Communication Cards

MGE Galaxy 5000

Setup and Installation2 — 8 86-174010-00 B00

Page 31

Installation and User Manual

2.8 Connection of the Relay Communications Card

CAUTION Isolate and lock-out all power sources for this card before making connections.

Never connect SELV (safety extra low voltage) and non-SELV circuits to the

different outputs of the same card.

1 - Remove the cover (52) secured by the screws (50).

2 - Run the communications cables through the cable entry holes (53).

3 - Connect the conductors to the input (55) and output (54) terminal blocks.

4 - Put the cover back in place and secure it with the screws (50).

5 - Tighten the screws (56) to lock the cables.

6 - Indicate the locations of the power sources on the labels.

7 - Insert the card in its slot.

8 - Secure the card with two screws (51).

Figure 2-12: Connection of Relay Communication Card

Setup and Installation 2 — 986-174010-00 B00

Page 32

2.8.1 Characteristics of the Contacts on the Relay Communications Card

Figure 2-13: Characteristics of the Contacts on the Relay Communications Card

Communications Card Connection Example

If a SELV (safety extra low voltage) source is used, it must always be possible to isolate the communications card from

the upstream source to ensure the safety of personnel working on the installation.

MGE Galaxy 5000

Setup and Installation2 — 10 86-174010-00 B00

Low battery warning

Load on battery power

Load on automatic bypass

Load on UPS

Characteristics of the output contacts:

Permissible voltage: 250V AC, 30V DC.

Permissible current: 2 A.

Cable: 4 x 0.93 mm2, Ø 6.6 ± 0.3 mm.

Characteristics of the input contacts:

Switched voltage: 5 V DC

Consumption: 10 mA.

Cable: 4 x 0.34 mm2, Ø 5 ± 0.5 mm.

Battery fault

UPS OFF

General alarm

UPS ON

AC

communication

card

Disconnecting device that can be locked

Page 33

Installation and User Manual

2.9 Routing the Control/Communications Cables

Single UPS

Figure 2-14: Routing the Control/Communications Cables for Single UPS

CAUTION To ensure sufficient isolation of control and communication cables, they must

be run separately from the power cables. Reinforce the insulation of these control

and communication cables if any risk of contact with the power cables exists.

Cable description Insulation level Location on illustration

Relay communication card SELV 3

Optional communication card SELV or LV 4

External battery circuit-breaker cables SELV 6

General-shutdown cable SELV 7

Setup and Installation 2 — 1186-174010-00 B00

Separate the control and communication

cables from the power cables.

Run the cables together in front of the

protection panels and tie them to the

panels as indicated.

Free slots for optional communication

cards. See installation drawing for proper

card placement.

Slot for relay communications card

Tie

General-shutdown cable (not supplied)

and external battery circuit breaker cable

must be tied down separately.

Ties

Page 34

Parallel UPS

Figure 2-15: Routing the Control/Communications Cables for Parallel UPS

CAUTION To ensure sufficient isolation of exchange-current, CAN and external bypass

cabinet cables, they must be run separately from the power cables. Reinforce

the insulation of these control and communication cables if any risk of contact

with the power cables exists.

Cable description Insulation level Location on illustration

External bypass cabinet cable ELV 1

CAN cables SELV 1

Exchange-current cables SELV 1

Relay communication card SELV 3

Optional communication card SELV or LV 4

External battery circuit-breaker cables SELV 6

General-shutdown cable SELV 7

MGE Galaxy 5000

Setup and Installation2 — 12 86-174010-00 B00

Separate the control and communication

cables from the power cables.

Run the cables together in front of the

protection panels and tie them to the

panels as indicated.

Parallel-connection cables for connection

to the SBC (not supplied). The CAN and

current exchange cables are supplied.

Free slots for optional communication

cards. See installation drawing for proper

card placement.

Slot for relay communications card

Ties

General-shutdown cable (not supplied)

and external battery circuit breaker cable

must be tied down separately.

Ties

Page 35

Operation 3 — 186-174010-00 B00

Operation

CAUTION All operations concerning system start-up and compliance with standards and

regulations, including those related to the battery cabinet, must be carried out

by trained and certified personnel before using the UPS.

3.0 Scope

Provides startup, shutdown, and normal operation of the MGE Galaxy 5000 UPS. Describes the operation of the

mimic-panel LEDs.

3.1 Shutting Down a Single UPS

The UPS remains energized unless it is shut down.

Figure 3-1: Shutting Down a Single UPS

1 - Press a button to exit sleep mode.

2 - Press the OFF button (38) for 3 seconds.

The load is no longer protected by the UPS. It is

supplied via the bypass.

3 - Set the battery circuit breaker of the auxiliary cabinets

to OFF.

4 - Set the input switch Q1 (8) to OFF.

The charger no longer operates to keep the batteries

fully charged.

5 - Open the upstream circuit breakers of the Normal AC

source and Bypass AC source to completely power off

the UPS.

Page 36

3.2 Restarting a Single UPS

Check that switches Q4S (9) and Q5N (11) are closed. If this is the case, continue with this procedure, otherwise

refer to Section 4.4.1 "Return to the Normal Operation, Single UPS".

Figure 3-2: Restarting a Single UPS

3.3 Shutting Down a Parallel Configuration

Figure 3-3: Shutting Down a Parallel Configuration

1 - Press a button on each unit to exit sleep mode.

2 - Press the OFF button (38) on each unit for 3 seconds.

The load is no longer protected by the UPSs. It is

supplied via the bypass.

3 - Set the battery circuit breakers of the auxillary cabinets

to the OFF position.

4 - Set the input switch Q1 (8) in each UPS to the OFF

position.

The charger no longer operates to keep the batteries

fully charged.

5 - Open the upstream circuit breakers of Normal AC source

and Bypass AC source to completely power off the

installation.

1 - Set the Normal AC source input switch Q1 (8) to the

ON position.

2 - Wait until the end of the start sequence.

3 - Set the battery circuit breaker of the auxiliary cabinets

to the ON position.

The UPS starts automatically.

LED (31) is ON.

The load is protected by the UPS.

If LED (31) remains OFF, press the ON button (37) (the UPS

is in manual start mode) and confirm if necessary by

pressing the function key (35) marked .

If LED (31) still remains OFF and either of LEDs (32) or (33)

is ON, a fault has occurred (see Section 4.1).

MGE Galaxy 5000

Operation3 — 2 86-174010-00 B00

35

Page 37

Installation and User Manual

3.4 Restarting a Parallel Configuration

Check that switches Q4S (9) and Q5N (11) are closed. If this is the case, continue with this procedure, otherwise

refer to Section 4.4.2 or Section 4.4.3 "Return to the Normal Operation, Parallel UPS".

Figure 3-4: Restarting a Parallel Configuration

1 - Check that the output switch CB2 in the external

system bypass cabinet is closed.

2 - Check that the bypass switch CB1 in the external

system bypass cabinet is open.

Then carry out steps 3 to 5 below on each of the UPSs.

3 - Set the Normal AC source input switch Q1 (8) to the

ON position.

4 - Wait until the end of the start sequence.

5 - Set the battery circuit breaker of the auxiliary cabinets

to the ON position.

The UPSs start automatically. On each unit, LEDs (32)

and (33) go OFF and LED (31) goes ON.

The load is protected by the UPSs.

If LED (31) remains OFF, press the ON button (37) on

each UPS (the UPS is in manual start mode) and confirm

if necessary by pressing the function key (35) marked .

If LED (31) still remains OFF and either of LEDs (32) or

(33) is ON, a fault has occurred (see Section 4.1).

Operation 3 — 386-174010-00 B00

Page 38

3.5 Operation of Mimic-Panel LEDs

The MGE Galaxy 5000 system is simple to operate and yet provides a wealth of continuous monitoring and

diagnostic features to ensure proper operation. Operators gain access to information in the MGE Galaxy 5000

system through the display and its integrated LED mimic panel.

Figure 3-5: Operation of Mimic-Panel LEDs

Single UPS Start Sequence on Normal AC Input

Single UPS Start Sequence on Bypass AC Input

Steps Action LED (39) LED (40) LED (41) LED (42) LED (43)

1 Q4S open Off Off Off Off Off

2 Close Q4S Off Off red Off green

3 Close Q5N Off Off red green green

4 Open Q3BP Off Off red green green

5 Close Q1 green Off red green green

6 Close Battery CB green Off Off green green

7 Press ON button (37) green green Off green Off

Steps Action LED (39) LED (40) LED (41) LED (42) LED (43)

1 Q1 open Off Off Off Off Off

2 Close Q1 green Off red Off red

3 Close Battery CB green Off Off Off red

4 Close Q4S green Off Off Off green

5 Close Q5N green Off Off green green

6 Open Q3BP green Off Off green green

7 Press ON button (37) green green Off green Off

MGE Galaxy 5000

Operation3 — 4 86-174010-00 B00

37

Page 39

Installation and User Manual

3.6 Operating Modes

Normal (Double Conversion) Mode

This is the standard operating mode, set by default in the factory. Two possible cases:

Figure 3-6: Normal (Double Conversion) Operating Mode

3.7 Load on Battery Power

The load continues to be protected by the UPS when the normal AC source is not available. Power is supplied by

the battery.

Figure 3-7: Load on Battery Power

Transfer to Battery Power

End of Battery Power

LED (33) is ON.

The buzzer sounds intermittently.

The load is transferred on the bypass AC input if it is

present.

LED (32) is ON.

The buzzer sounds intermittently.

The load is supplied by the battery.

The display indicates any anomalies related to the AC source or the UPS as well as remedial action

if applicable.

Press the function key (35) indicated by the display to turn the buzzer OFF.

1 - Normal AC source available:

LED (31) is ON.

The load is protected by the UPS.

2 - Normal AC source not available:

LED (32) is ON.

The buzzer sounds intermittently.

LED (41) on the mimic-panel is green.

The load is supplied by the UPS from battery power.

Operation 3 — 586-174010-00 B00

Page 40

3.8 UPS Personalization

Access to the Personalization Functions

CAUTION Personalization must be carried out with switches Q1 (8) and Q5N (11) open (OFF)

and switch Q4S (9) closed (ON).

Figure 3-8: UPS Personalization

Personalization Settings

Operating Mode

Frequency

Automatic Bypass

Transfer to bypass AC source Enabled

Disabled – disabled when

limiting

Transfer to bypass with bypass AC source out of

tolerances

Enabled Disabled

UPS output frequency 60 Hz 60Hz

Tolerance for bypass AC source 8 % 0.5 - 1 - 2 - 4 %

Synchronization speed with bypass AC source 2 Hz / s 1 Hz / s

Function Factory setting Options

UPS operating mode NORMAL

UPS automatic start Disabled Enabled

Authorized number of starts 4 1 to 255

Delay before reset of number of executed

automatic starts

4 seconds 1 to 60 seconds

MGE Galaxy 5000

Operation3 — 6 86-174010-00 B00

1 - Press the menu key (36).

2 - Select "Settings", then "Personalization" using the

function keys (35) or .

3 - Confirm by pressing the function key (35) .

4 - Enter the password by successively selecting each icon

using the corresponding function key.

5 - Confirm by pressing the function key (35) .

6 - To save the personalization settings, confirm by

pressing the function key (35) .

The password

To change the password, see the Settings menu.

is factory set.

Page 41

Installation and User Manual

Battery

3.9 Display Messages List

Low battery warning threshold if battery monitor

inactive

40% remaining backup time

20 - 60 - 80 % remaining

backup time

Low battery warning threshold if battery monitor

active

4 minutes of battery backup

time

1 to X minutes of battery

backup time

Interval between two battery tests 30 days 1 to 180 days

Operation 3 — 786-174010-00 B00

Fault of downgraded mode

Internal CAN communication fault

External CAN communication fault

CAN communication relay fault

UPSs not connected by CAN cable

Resynchronizing

CAN communication resynchronization fault

Loss of communication with UPS 1

Loss of communication with UPS 2

Loss of communication with UPS 3

Loss of communication with UPS 4

Loss of communication with UPS X

Fault, filtering of customer communication

Customer communication disabled

Generic fault on equipment

Emergency Power Off (EPO)

UPS personalization fault

Personalization does not match UPS

Transfer to bypass disabled

Major Fault on subassembly

Charger fault

Bypass static switch fault

PFC fault

Inverter fault

Power supply board fuse blown

Fan fault

TVSS fault

Internal and external switches

Q3BP switch closed

Q5N switch open

Q4S switch open

External Q3BP switch closed (MBC or SBC CB1)

External Q5N switch open (MBC or SBC CB2)

External Q4S switch open (MBC CB3)

Abnormal bypass operation

Abnormal external bypass operation

Fault or state of installation

Installation overload

Non-redundant installation

Inverter starting

Not enough inverters for load connection

Not enough bypass static switches

Inverter ready for load connection

Fault or state on Normal AC

Q1 switch open

Normal AC source downgraded

Normal AC input phase rotation fault

Normal AC fuse blown

Normal AC source static switch failure

Normal AC source outside tolerances

Normal AC backfeed (KA1) is open

Normal AC backfeed (KA1) fault

Fault or state on Bypass AC or Bypass Static Switch

Bypass source present

Bypass static switch overload

AC Bypass static switch thermal overload

Bypass input phase rotation fault

Bypass source outside tolerances

Bypass AC backfeed (KA2) is open

Bypass AC backfeed (KA2) fault

Fault or state for PFC

PFC overload

PFC thermal overload

Starting

Fault or state standard charger

Low battery warning

Low battery shutdown

Battery circuit breaker open (QF1) (Battery Cabinet #1 or #3)

Battery circuit breaker 2 open (QF2) (Battery Cabinet #2 or #4)

End of theoretical battery service life

Battery temperature fault

Battery deep discharge

Battery room temperature fault

Battery test result not OK

Battery test in progress

Charger shutdown by PFC overload

Fault or state inverter

Inverter current limiting

Inverter overload

Inverter thermal overload

Inverter fuse blown

Inverter and bypass desynchronized

Fault or state load

Abnormal presence of output voltage

Load short circuit

Fault or state external synchronization

External sync frequency outside tolerances

UPS on external synchronization

Page 42

3.10 Operation of the Relay Communication Card (Dry Contacts)

All systems are equipped with this remote transmissions card (also known as SECI).

A complete specification exists for the card used in MGE Galaxy 5000.

This card is used for the transmission of information between the system and the environment.

Two inputs and six outputs are available for the user (see the table below for the default programming).

3.10.1 Standard Mode

It is compatible with all MGE systems that are I

2

C compatible.

All the SA1 microswitches must be set to OFF (if two SECI cards are installed in the unit, the second card must

be identified differently. On the second card, microswitch 1 on SA1 must be set to ON).

In this mode, the relays switch when the UPS changes status. The information listed below is transmitted if the

parameters were enabled in UPS Tuner.

The indications 1.X become 2.X for a second identical card in the UPS.

Contacts are of the NO (normally open) type.

(1) The general alarm can be tested by opening the battery circuit breaker.

3.10.2 Programmable Mode

This operating mode is specific to the MGE Galaxy 5000. The description in this document concerns only the MGE

Galaxy 5000.

Microswitch 3 on SA1 must be set to ON (if two SECI cards are installed in the unit, the second card must be

identified differently. On the second card, microswitch 1 on SA1 must be set to ON).

In this mode, it is possible to assign predefined operating status conditions (see the complete list) to the various

SECI output relays and predefined UPS commands to the SELV inputs.

Assignments are made using the MGE Galaxy 5000 user-machine interface.

Outputs Factory configuration Other possible signals for each contact

1.1 General alarm - Overload

- PFC fault

- Inverter fault

- Charger fault

- Automatic-bypass fault

- Bypass AC source out of tolerances

- Battery-temperature fault

- Ventilation fault

- Emergency power OFF activated

- Battery circuit breaker(s) open

- Phase inversion on normal or bypass AC input

- Fuses blown

- Transfer to AC bypass disabled

- Operation in ECO mode

- Load on maintenance bypass

1.2 Battery fault

1.3 Load on UPS

1.4 Load on automatic bypass

1.5 Load on battery power

1.6 Low battery warning

Inputs Factory configuration Other possible signals for each contact

1 A UPS ON - Temperature fault in room

- Transfer to bypass AC input disabled

- Transfer to bypass AC input disabled if it is out of tolerances

- UPS not synchronized with the bypass AC input

1.B UPS OFF

MGE Galaxy 5000

Operation3 — 8 86-174010-00 B00

Page 43

Installation and User Manual

3.10.3 List of Operating Status Conditions That May be Assigned to an SECI Output

Operating status

conditions

Description

GENERAL ALARM PFC fault OR

Inverter fault OR

Bypass static switch fault OR

Charger fault OR

Thermal overload on AC bypass OR

Normal AC input fuse blown OR

ALIN board input fuse blown OR

Q3BP and Q5N are closed simultaneously OR

External Q3BP and external Q5N are closed simultaneously OR

EPO activated OR

Battery backup time ended, shift to wait mode OR

Battery temperature fault > 45°C , charger shutdown OR

Battery deep discharge OR

Charger shutdown due to battery room temperature outside tolerances OR

Abnormal presence of voltage on the output before closing the bypass static

switch. (frequency converter) OR

UPS in downgraded mode OR

External CAN communication fault OR

Internal CAN communication fault (GDEN, MIZNUS and CHAN) OR

CAN cable physically cut OR

CAN communication relay fault OR

UPS personalization fault.

BATTERY FAULT The battery will soon reach the end of its theoretical service life OR

Battery must be checked (following a faulty battery test)

LOAD ON UPS Inverter connected to the load and operating on normal AC input.

Battery operations due to a BPI or battery test are signalled as operation on the

normal AC input.

LOAD ON AUTOMATIC

BYPASS

The static switch on the AC bypass is closed.

LOAD ON BATTERY

POWER

Inverter connected to the load and operating on battery power.

Battery operations due to a battery test are not signalled.

LOW BATTERY WARNING Battery has reached the low-battery warning level (voltage or time). The two

thresholds may be user set.

OVERLOAD One of the unit modules (rectifier, inverter or AC bypass) is overloaded (thermal or

instantaneous).

Operation 3 — 986-174010-00 B00

Page 44

PFC FAULT Neutral leg fault OR

Neutral leg IGBT temperature outside tolerances OR

Voltage difference between 2 DC half-buses outside tolerances OR

Top DC half-bus voltage outside tolerances OR

Bottom DC half-bus voltage outside tolerances

PFC fault OR

DC-bus voltage at end of CSR1 walk-in is lower than a threshold OR

DC-bus voltage at end of DC walk-in is lower than a threshold OR

DC-bus voltage is higher than the high threshold OR

DC-bus voltage is lower than the minimum threshold

Mean DC-bus voltage is higher than the maximum setpoint OR

Mean DC-bus voltage is lower than the minimum setpoint OR

DC-bus voltage is higher than the fast hardware threshold OR

Temperature of the static switch on the AC normal outside tolerances OR

Temperature of the battery static switch outside tolerances OR

Rectifier is current limiting OR

Rectifier thermal overload OR

PFC IGBT base-plate temperature outside tolerances OR

IGBT inductor temperature outside tolerances.

INVERTER FAULT Inverter short-circuit detected OR

Inverter current limiting OR

Inverter static switch failure OR

Temperature fault on inverter static switch OR

Inverter base-plate temperature outside tolerances OR

Inverter thermal overload OR

Inverter phase-1 fuse has blown OR

Inverter phase-2 fuse has blown OR

Inverter phase-3 fuse has blown OR

Inverter phase-1 voltage amplitude outside tolerances OR

Inverter phase-2 voltage amplitude outside tolerances OR

Inverter phase-3 voltage amplitude outside tolerances OR

Instantaneous inverter voltage outside tolerances OR

Inverter relay for parallel connection is faulty.

CHARGER FAULT Fault of non-isolated supply on charger board OR

Fault of isolated supply on charger board OR

Opening fault on battery circuit breaker no. 1 OR

Opening fault on battery circuit breaker no. 2 OR

Charger IGBT temperature outside tolerances OR

Difference in charge-current measurements between safety and measurement

systems OR

Charge current on measurement system close to zero OR

Charge current on safety system close to zero OR

Charge current is higher than safety level OR

Difference in voltage measurements between safety and measurement systems

OR

Voltage on measurement system close to zero OR

Voltage on safety system close to zero OR

Battery voltage higher than safety level OR

Charger fuse blown.

AUTOMATIC-BYPASS

FAULT

Supply fault for the static switch on the AC bypass OR

Fault on static switch on AC bypass OR

Temperature of the static switch on the AC bypass outside tolerances.

BYPASS AC SOURCE OUT

OF TOLERANCE

Bypass AC source outside of tolerances (voltage and/or frequency).

MGE Galaxy 5000

Operation3 — 10 86-174010-00 B00

Page 45

Installation and User Manual

Galaxy 5000 can be equipped with up to two SECI cards maximum. In this case, the second card must be identified

differently. On the second card, microswitch 1 on SA1 must be set to ON.

BATTERY TEMPERATURE FAULT Battery ambient temperature outside tolerances.

VENTILATION FAULT Excessive temperature on one or more inductors OR

Inverter or AC bypass static switch fan fault.

EMERGENCY POWER OFF

ACTIVATED

EPO set on control-monitoring board OR

EPO set on charger board.

BATTERY CIRCUIT BREAKER(S)

OPEN

One or two Battery circuit breaker is open.

PHASE ROTATION FAULT Phase inversion on normal AC input OR

Phase inversion on AC bypass.

FUSES BLOWN Fuse blown at normal AC input OR

Charger fuse has blown OR

Power supply board fuse has blown OR

Inverter phase-1 fuse has blown OR

Inverter phase-2 fuse has blown OR

Inverter phase-3 fuse has blown.

TRANSFER TO BYPASS DISABLED Transfer to AC bypass disabled (control and monitoring board checks

for disabling by the personalization and/or an SECI input).

ECO MODE ACTIVATED The unit is operating in ECO mode. It is configured for ECO mode and

the static switch on the AC bypass is closed.

MAINTENANCE POSITION Switch Q5N is open.

CHECK THE UPS A Life Cycle Monitoring alarm has been activated:

◗ End of warranty.

◗ End of AC capacitor service life

◗ End of DC capacitor service life

◗ End of fan service lives.

◗ End of power supply board service life.

◗ End of battery service life.

Operation 3 — 1186-174010-00 B00

Page 46

(This page left blank intentionally)

MGE Galaxy 5000

3 — 12 86-174010-00 B00

Page 47

4 — 186-174010-00 B00 Maintenance

Maintenance

4.0 Scope

Identifies alarm conditions, UPS isolation operation, and maintenance and safety information on servicing batteries

for the MGE Galaxy 5000.

4.1 Identification of Alarms

Alarm conditions are identified by LEDs (31), (32), (33) and the buzzer.

Table 4-1: Identification of Alarms

Detailed information on all alarms is supplied on the display.

1 - On the screen, select the alarm for which information is required.

2 - Hold down the corresponding function key to display the possible causes of the fault and the required action.

4.2 Life Cycle Monitoring (LCM)

Figure 4-1: Life Cycle Monitoring (LCM)

◗ The "Life Cycle Monitoring" (LCM) function provides UPS

maintenance advice to guarantee installation availability for the

user.

◗ The display gives 3 messages enabling the following to be

identified:

- The end of the contractual legal warranty: "End of warranty

check recommended".

- Regular maintenance requirements and the end of service life for

consumable components: "Technical check recommended".

- The end of the battery service life: "Battery check required".

In addition to these messages, the minor fault LED (32) lights up

and the buzzer sounds.

These messages can be deleted by pressing the function key (35).

This also causes LED (32), to go out, the buzzer to stop and the

removal of the "Global Alarm" remote signaling.

To completely disable LCM indications, use the display to enter the

password required to disable the function.

LED (31) LED (32) LED (33) Buzzer Significance

– – Intermittent Normal AC source not available

– – Intermittent

UPS shut down following end of

battery power

– – Intermittent

UPS shut down on fault requiring

servicing by after-sales support

Page 48

4.3 UPS Isolation

4.3.1 UPS Isolation Single UPS

To isolate the UPS from the electrical power source and supply the load directly by the normal or bypass AC source,

follow the instructions below.

Figure 4-2: UPS Isolation

ATTENTION Power is present on the power connection terminals.

1 - Press a button to exit sleep mode.

2 - Shut down the UPS by pressing the OFF button (38) for

3 seconds.

The load is no longer protected by the UPS.

3 - Set bypass switch Q3BP (10) to ON.

4 - Set output switch Q5N (11) to OFF.

5 - Set the battery circuit breaker of the auxiliary cabinets

to OFF.

6 - Set the input switch Q1 (8) to OFF.

7 - Set the switch Q4S (9) to OFF.

8 - Wait until the display and LEDs go off.

The load is no longer protected by the UPS, but

continues to be supplied with AC power.

UPS maintenance or servicing can now be carried out.

MGE Galaxy 5000

Maintenance4 — 2 86-174010-00 B00

Page 49

Installation and User Manual

4.3.2 UPS Isolation Parallel UPS Without External Bypass Cabinet

Shutdown and isolation of the first UPS:

Figure 4-3: Parallel UPS Configuration Without External Bypass Cabinet

ATTENTION Power is present on the power connection terminals.

Shutdown and isolation of the second UPS:

1 - Press a button to exit sleep mode.

2 - Shut down the UPS by pressing the OFF button (38) for 3 seconds.

3 - Set bypass switch Q3BP (10) to ON.

4 - Set output switch Q5N (11) to OFF.

5 - Set the battery circuit breaker of the auxiliary cabinets to OFF.

6 - Set the input switch Q1 (8) to OFF.

7 - Set the switch Q4S (9) to OFF.

8 - Wait until the display and LEDs go off.

The load is no longer protected by the UPS, but continues to be supplied with AC power.

UPS maintenance or servicing can now be carried out.

ATTENTION Power is present on the power connection terminals.

1 - Check that the two UPSs are operating.

2 - Press a button to exit sleep mode.

3 - Shut down the UPS by pressing the OFF button (38) for

3 seconds.

4 - Set output switch Q5N (11) to OFF.

5 - Set the battery circuit breakers of the auxiliary cabinets

to OFF.

6 - Set the input switch Q1 (8) to OFF.

7 - Set the switch Q4S (9) to OFF.

8 - Wait until the display and LEDs go off.

The load is still protected by the other UPS.

Maintenance or servicing can now be carried out on the

UPS that has been shut down.

Maintenance 4 — 386-174010-00 B00

Page 50

4.3.3 UPS Isolation Parallel UPS With External Bypass Cabinet

Shutdown and isolation of one UPS:

Figure 4-4: Parallel UPS Configuration With External Bypass Cabinet

Shutdown and isolation of all the UPSs:

Figure 4-5: Shutdown and Isolation of all the UPSs

1 - On each UPS, press a button to exit sleep mode.

2 - Shutdown each UPS by pressing their OFF buttons (38)

for 3 seconds.

3 - Depress the “transfer initiate” switch on the SBC. Unlock

“KS” and remove key “A”.

4 - Insert key “A” into CB1. Unlock and close CB1.

5 - Open CB2 and lock open, and remove key “B”.

6 - Insert key “B” into key interlock “KS” and turn to lock.

7 - Open output isolation CB11-16, as applicable, and open all

Q5N (11) switches of each UPS.

8 - Open battery CB of each UPS.

9 - Open Q1 (8) and Q4S (9) switches of each UPS.

10 - Turn off all inputs to the UPSs.

11 - Wait until the control electronics of all UPS units have

fully shutdown.

The load is no longer protected by the UPSs, but

continues to be supplied with AC power.

UPS maintenance or servicing can now be carried out.

1 - First check that the total capacity of the remaining UPSs

is sufficient to supply the connected load.

2 - Press a button to exit sleep mode.

3 - Shut down the UPS by pressing the OFF button (38) for

3 seconds.

4 - Set output switch Q5N (11) to OFF.

5 - Set the battery circuit breaker of the auxiliary cabinets

to OFF.

6 - Set the input switch Q1 (8) to OFF.

7 - Set the switch Q4S (9) to OFF.

8 - Wait until the display and LEDs go off.

MGE Galaxy 5000

Maintenance4 — 4 86-174010-00 B00

CB11

CB12

CB13

CB14

CB15

CB16

KS

KB

KA

CB2

CB1

Page 51

Installation and User Manual

Maintenance 4 — 586-174010-00 B00

4.4 Return to the Normal Operation

4.4.1 Return to Normal Single UPS

Figure 4-6: Return to the Normal Operation for Single UPS

1 - Check that bypass switch Q3BP (10) is ON and that all other

switches are OFF.

2 - Set switch Q4S (9) to ON.

3 - Set output switch Q5N (11) to ON.

4 - Wait until the display goes on and check that there are no

faults on the static switch on the bypass line.

5 - Set bypass switch Q3BP (10) to OFF.

6 - Set the input switch Q1 (8) to ON.

7 - Set the battery circuit breaker of auxiliary cabinets to ON.

The UPS starts automatically.

LED (31) is ON.

If LED (31) remains OFF, press the ON button (37) (the UPS is

in manual start mode) and confirm if necessary by pressing the

function key (35) marked .

If LED (31) still remains OFF and either of LEDs (32) or (33) is

ON, a fault has occurred (see Section 4.1).

Page 52

MGE Galaxy 5000

Maintenance4 — 6 86-174010-00 B00

4.4.2 Return to Normal Parallel UPS Without External Bypass Cabinet

Restart the UPS unit for which switch Q3BP (10) is ON and the other switches are OFF.

CAUTION It is imperative to restart this UPS. Otherwise, load power is lost if the other UPS

is shut down.

Figure 4-7: Parallel UPS Configuration Without External Bypass Cabinet

1 - Set the input switch Q4S (9) to ON.

2 - Set output switch Q5N (11) to ON.

3 - Check that the UPS is listed by the display, then confirm by

pressing the function keys (35).

4 - Set bypass switch Q3BP (10) to OFF.

5 - Set the input switch Q1 (8) to ON.

6 - Set the battery circuit breaker of the auxiliary cabinets to ON.

The UPS starts automatically. LED (31) is ON.

The load is protected by the UPS.

If LED (31) remains OFF, press the ON button (37) on each UPS

(the UPS is in manual start mode) and confirm, if necessary, by

pressing the function key (35) marked .

If LED (31) still remains OFF and either of LEDs (32) or (33) is

ON, a fault has occurred (See Section 4.1).

Page 53

Installation and User Manual

Maintenance 4 — 786-174010-00 B00

Restart the UPS for which all switches are set to OFF.

1 - Set the input switch Q4S (9) to ON.

2 - Set output switch Q5N (11) to ON.

3 - Check that all the UPS units present in the installation are

included in the list on the display and confirm by pressing

the function buttons (35).

4 - Set the input switch Q1 (8) to ON.

5 - Set the battery circuit breaker of the auxiliary cabinets to

ON.

The UPS restarts and LED (31) is ON.

If LED (31) remains OFF, press the ON button (37) on each

UPS (the UPS is in manual start mode) and confirm,

if necessary, by pressing the function key (35) marked .

If LED (31) still remains OFF and either of LEDs (32) or (33) is

ON, a fault has occurred (see Section 4.1).

Page 54

4.4.3 Return to Normal Parallel UPS With External Bypass Cabinet

Figure 4-8: Parallel UPS Configuration With External Bypass Cabinet

1 - Check that all switches on the UPSs are set to OFF.

2 - Apply bypass and input power to UPSs.

3 - Set switch Q4S (9) on each UPS to ON.

4 - Set output switch Q5N (11) on each UPS and CB11-CB16,

as applicable, to ON.

5 - Check that all the UPSs present in the installation are

included in the list on the display and confirm by pressing

the function button (35) on each UPS.

6 - Set CB2 in the external system bypass cabinet to ON.

7 - Set CB1 in the external system bypass cabinet to OFF.

8 - Set the input switch Q1 (8) on each UPS unit to ON.

9 - Set the battery circuit breakers of the auxiliary cabinets to ON.

The UPS units start automatically. LED (31) is ON.

The load is protected by the UPS.

If LED (31) remains OFF, press the ON button (37) on each UPS

unit (the UPS is in manual start mode) and confirm, if

necessary, by pressing the function key (35) marked .

If LED (31) still remains OFF and either of LEDs (32) or (33) is

ON, a fault has occurred (see Section 4.1).

MGE Galaxy 5000

Maintenance4 — 8 86-174010-00 B00

Page 55

Installation and User Manual

4.5 Servicing Batteries

IMPORTANT SAFETY INSTRUCTIONS FOR SERVICING BATTERIES