Page 1

Matrix

TM

UPS

User’s Manual

208/240 Vac,

60 Hz version

NOTE: Printing this document may cause

printer overflow. If this occurs, try printing

small groups of pages.

American Power Conversion

American Power Conversion n 132 Fairgrounds Road

West Kingston, Rhode Island n 02892 n Phone (401) 789-5735

Part Number: 990-7007-B Revision: 3 Date: 12/21/94 Approved: DAA

Note: Specifications contained herein are subject to change without notice.

Copyright © 1994 American Power Conversion. All rights reserved.

Page 2

1. Introduction

2. Safety

3. Presentation

Isolation Unit (IU)

Electronics Unit (EU)

Battery Pack

4. Installation

Receiving Inspection, Protection Strategies,

Moving the UPS, Placement

Input Voltage Selection

Module Interconnections

Emergency Power Off (EPO) Interface

Start-up

Input Plug Incompatibility

5. Operation

Modes of operation

Display and controls operation

6. UPS Monitoring

Computer interface port

Table of Contents

7. Difficulty

Troubleshooting chart

Fault messages

Replacing the Electronics Unit

Replacing or adding Battery Packs

Obtaining service

8. Storing the UPS

9. Specifications

Recharge and Run Times

Page 3

1. Introduction

1.1 Overview

The UPS is a high-power enhanced line interactive uninterruptible power source designed to provide clean, reliable AC

power to computer, data handling, and telecommunications loads. Normally, the UPS operates "on-line" and provides

power to the load derived from the input utility source. When operating on-line, the UPS continuously regulates the load

voltage by compensating for voltage fluctuations occurring over a wide range on the utility. A multilevel transformer tap

changing circuit provides this regulation while attaining extremely high levels of on-line efficiency. In response to the

need to adjust the load voltage, the UPS temporarily operates the load from power derived from the battery while an

appropriate transformer tap change is made. In the event of unacceptable line conditions, transfer of load power from the

utility to the inverter occurs synchronously and is virtually seamless under all conditions. The voltage waveshape

delivered during "on-battery" operation is a low distortion sine wave. Resynchronization and retransfer of load power to

the utility is automatic upon recovery of the line voltage to within normal limits.

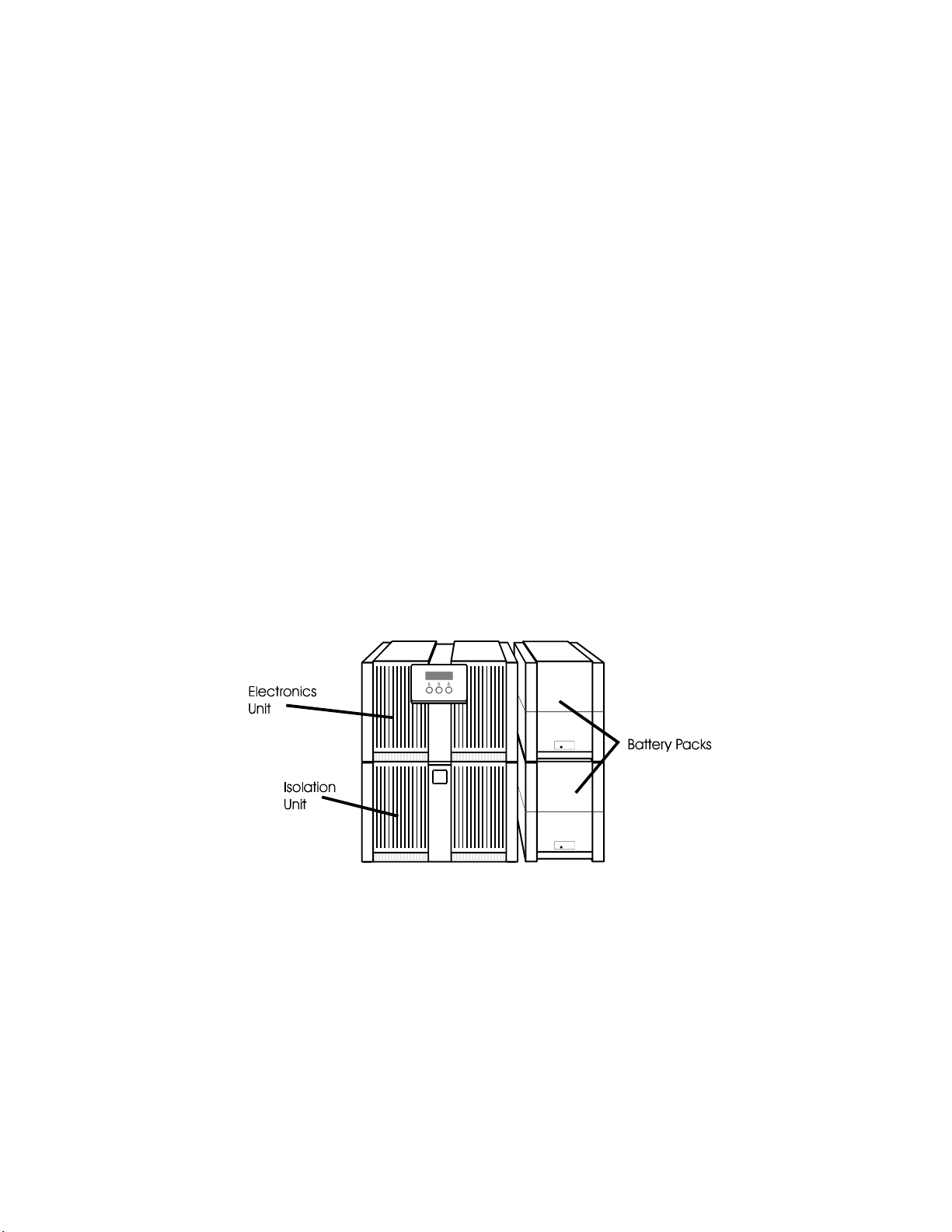

A complete UPS system consists of three module types. The UPS is comprised of an Electronics Unit

(EU), mounted atop an Isolation Unit (IU). Numerous Battery Packs can be purchased and plugged

together on-site to provide the desired run time. The EU is self-connecting to the IU when mounted and

is secured in place with the turn of an oversized hand screw. The EU contains the UPS’s microprocessor

controls, inverter, battery charger, transfer and tap changing circuits, remote interfaces, and the user

control and display panel. The IU contains the UPS’s isolation transformer, EMI/RFI filtering and surge

suppression circuits, bypass circuit, and the utility and load wiring interfaces. The Battery Packs are

"daisy chained" pack-to-pack, and to the EU, using a heavy duty cable and lockable connector system.

Intelligent communications between Battery Packs and the EU is provided via a flat cable terminated

with modular plugs. Each Battery Pack contains four high capacity batteries and microprocessor

controlled electronics for communications and for battery pack voltage and current monitoring.

1.2 Hot Swappable Modules

The Isolation Unit is capable of autonomous operation and allows service or upgrade of the Electronics Unit without

interruption of power to the load. In addition, a worn Battery Pack can be replaced, or new packs can be added, while

maintaining power to the load. In the event of EU failure, functions controlled by the EU are automatically bypassed and

the IU operates autonomously. For servicing, this bypass mode may be selected manually.

1.3 Emergency Power Off (EPO)

For applications where, for safety reasons, power to all room equipment may be cut off, the UPS provides a remote

Emergency Power Off interface.

Page 4

1.4 Display

Local UPS user interface is served by a display and control panel containing a back-lit 2x16 character display and three

pushbuttons. Using the pushbuttons, menus for the display of UPS status information, UPS control commands, UPS

setup, UPS tests, and UPS diagnostics are shown. Critical UPS functions can be password protected. A loud audible

alarm warns of operating modes that could result in the loss of power to the load without user intervention.

1.5 Remote Interfaces

The UPS provides a remote computer interface capable of full RS-232 communications. When combined with

PowerDoctor UPS monitoring software and a serially connected local DOS PC, all functions of the local display and

control panel are duplicated and power quality related events can be logged. PowerChute plus offers all the features of

PowerDoctor, plus the ability to control orderly and unattended network or multi-user computer system shutdown during

an extended power outage. Also available for the UPS is the SNMP (Simple Network Management Protocol) Adapter to

provide load type independent remote monitoring and management across Ethernet or Token Ring based LANs or

WANs capable of routing IP messages. Using any standard Network Management System (NMS) and the SNMP

Adapter, the UPS becomes manageable through a single familiar interface - from across your building to across the

world.

2. Safety

CAUTION !

n To reduce the risk of electric shock, disconnect the Uninterruptible Power Source from the mains before installing

computer interface signal cable (when used). Reconnect the power cord only after all signalling interconnections have

been made.

n Connect the Uninterruptible Power Source to a two-pole, three-wire grounding mains receptacle. The receptacle must

be connected to appropriate branch protection (fuse or circuit breaker). Connection to any other type of receptacle may

result in a shock hazard and may violate local electrical codes.

n This Uninterruptible Power Source has an internal energy source (the battery) that cannot be deenergized by the user. The output may be energized when the unit is not connected to a mains

supply.

n To properly de-energize the Uninterruptible Power Source in an emergency, move the rear panel I/O switch to the O

(off) position and disconnect the power cord from the mains.

n Avoid installing the Uninterruptible Power Source in locations where there is water or excessive humidity.

n Do not allow water or any foreign object to get inside the Uninterruptible Power Source. Do not put objects

containing liquid on or near the unit.

n To reduce the risk of overheating the Uninterruptible Power Source, avoid exposing the unit to the direct rays of the

sun. Avoid installing the unit near heat emitting appliances such as a room heater or stove.

Page 5

3. Presentation

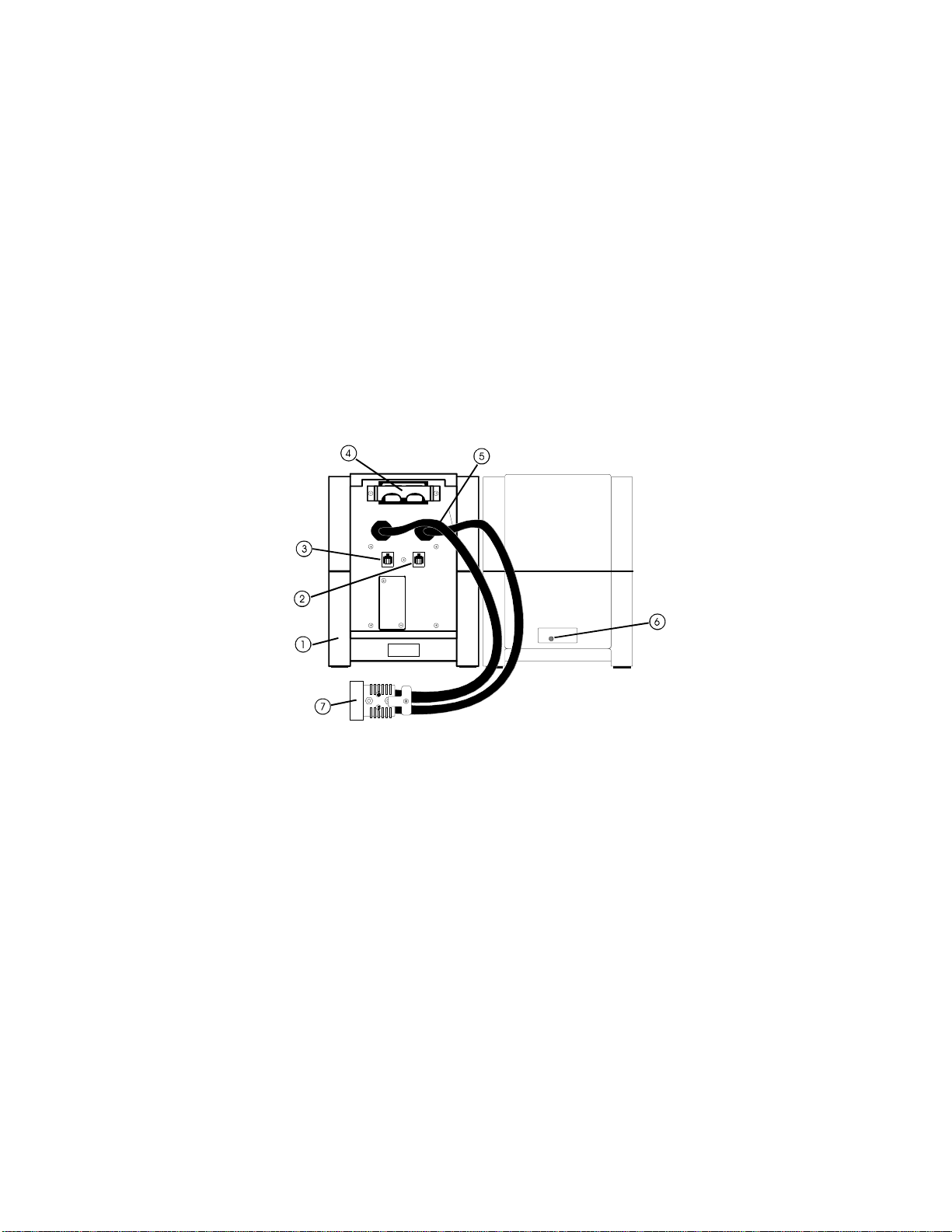

3.1 Isolation Unit (IU)

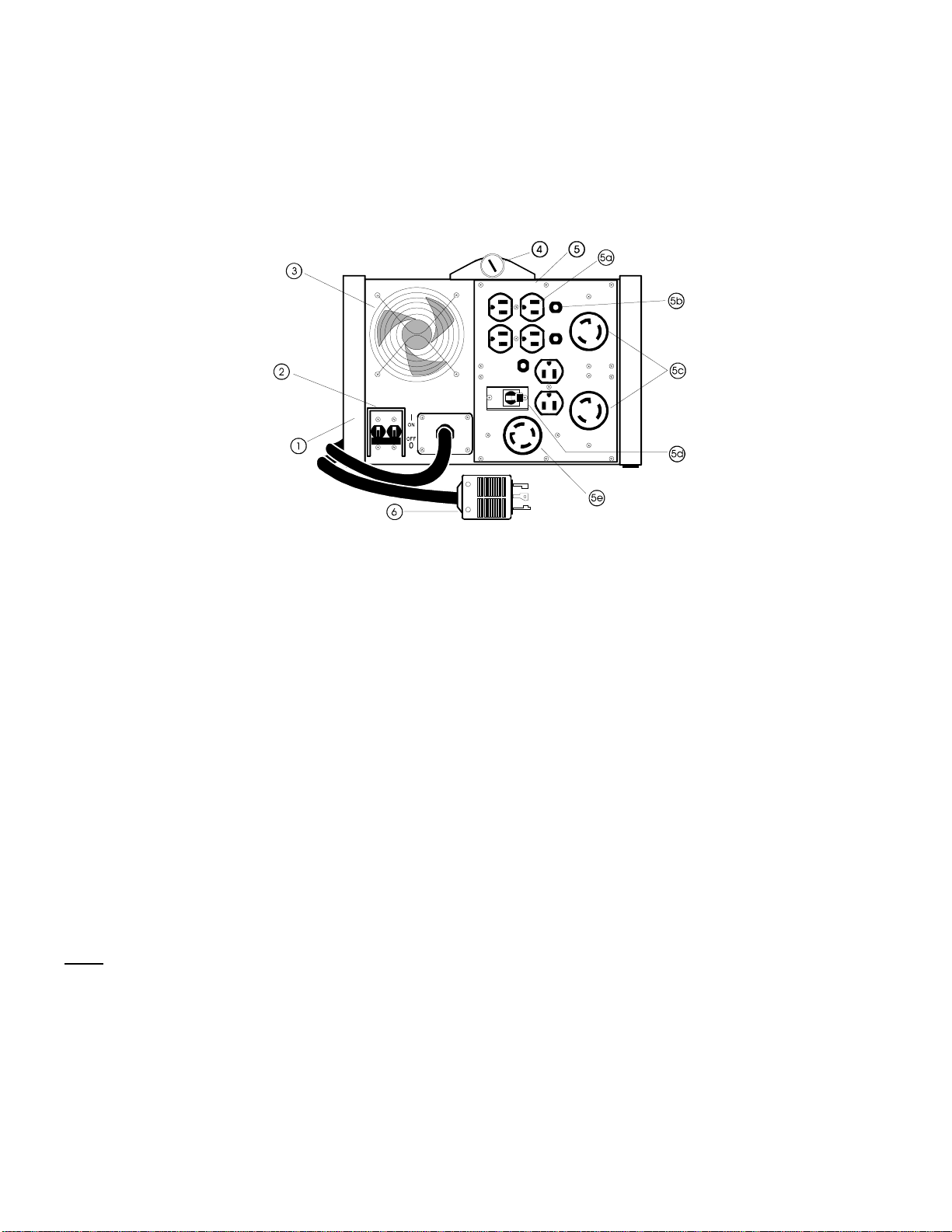

Rear View of Isolation Unit

1. Isolation Unit (IU)

The Isolation Unit contains the UPS’s isolation transformer, EMI/RFI and surge suppression, bypass circuits including

an auxiliary power supply, and utility and load wiring interfaces. The IU is capable of autonomous operation and allows

service of the Electronics Unit without interruption of power to the load.

2. Input circuit breaker (power ON / OFF)

The input circuit breaker controls power to the UPS. It protects the UPS and the service wiring from extreme overloads.

3. Cooling fan

The fan exhausts air from the IU and operates whenever the input circuit breaker is ON (I). If the fan fails, the UPS will

indicate an alarm condition. Under such conditions, the UPS will remain operating and is capable of delivering full

power to the load.

4. EU separating screw

The Electronics Unit separating screw is turned counter-clockwise to remove the EU for service. If this action is taken

while the UPS is on-line, the UPS will automatically transfer to bypass operation. See the Difficulty section of this

manual for the proper EU replacement procedure.

Note: The UPS’s display is blank when the EU separating screw is loosened. Control of the UPS is regained when the

screw is tightened and any control button is pressed.

5. Power distribution plate

The power distribution plate is removable for access to the input voltage selection taps. Optional Power Distribution

Unit (PDU) accessories are available from the factory with wiring devices other than those provided on the power

distribution plate. These PDU accessories are plugged into either a NEMA L6-30R receptacle 208 Vac output, or the

NEMA L14-30R receptacle 120/240 Vac output.

Page 6

5a. NEMA 5-15R receptacles

Six 15 Amp rated NEMA 5-15R outlets provide a nominal 120 Vac for multiple small loads.

5b. NEMA 5-15R receptacle circuit breaker

Each NEMA 5-15R duplex receptacle is protected by a circuit breaker. This protection is necessary because the UPS is

capable of delivering more than the receptacle’s maximum current rating. The 3000VA model UPS power distribution

plate’s upper two NEMA 5-15R duplex receptacles are protected by a 12 Amp circuit breaker. The lower NEMA 5-15R

duplex receptacle is protected by a 15 Amp circuit breaker. All NEMA 5-15R duplex receptacles on the 5000VA model

UPS are protected by a 15 Amp circuit breaker.

5c. NEMA L6-30R receptacles

Two 30 Amp rated NEMA L6-30R twist-lock outlets provide 208 Vac for large loads.

5d. NEMA L14-30R receptacle circuit breaker

The 3000VA model UPS power distribution plate’s NEMA L14-30R and NEMA 5-15R receptacles are protected by a

two pole, 25 A circuit breaker. The 5000VA model UPS power distribution plate’s NEMA L14-30R is protected by a

two pole, 30 A circuit breaker.

5e. NEMA L14-30R receptacle

The 30 Amp rated NEMA L14-30R receptacle provides a nominal 120/240 Vac output.

6. NEMA L6-30P input plug

The 30 Amp rated input plug has a twist-lock feature to prevent accidental disconnection.

Page 7

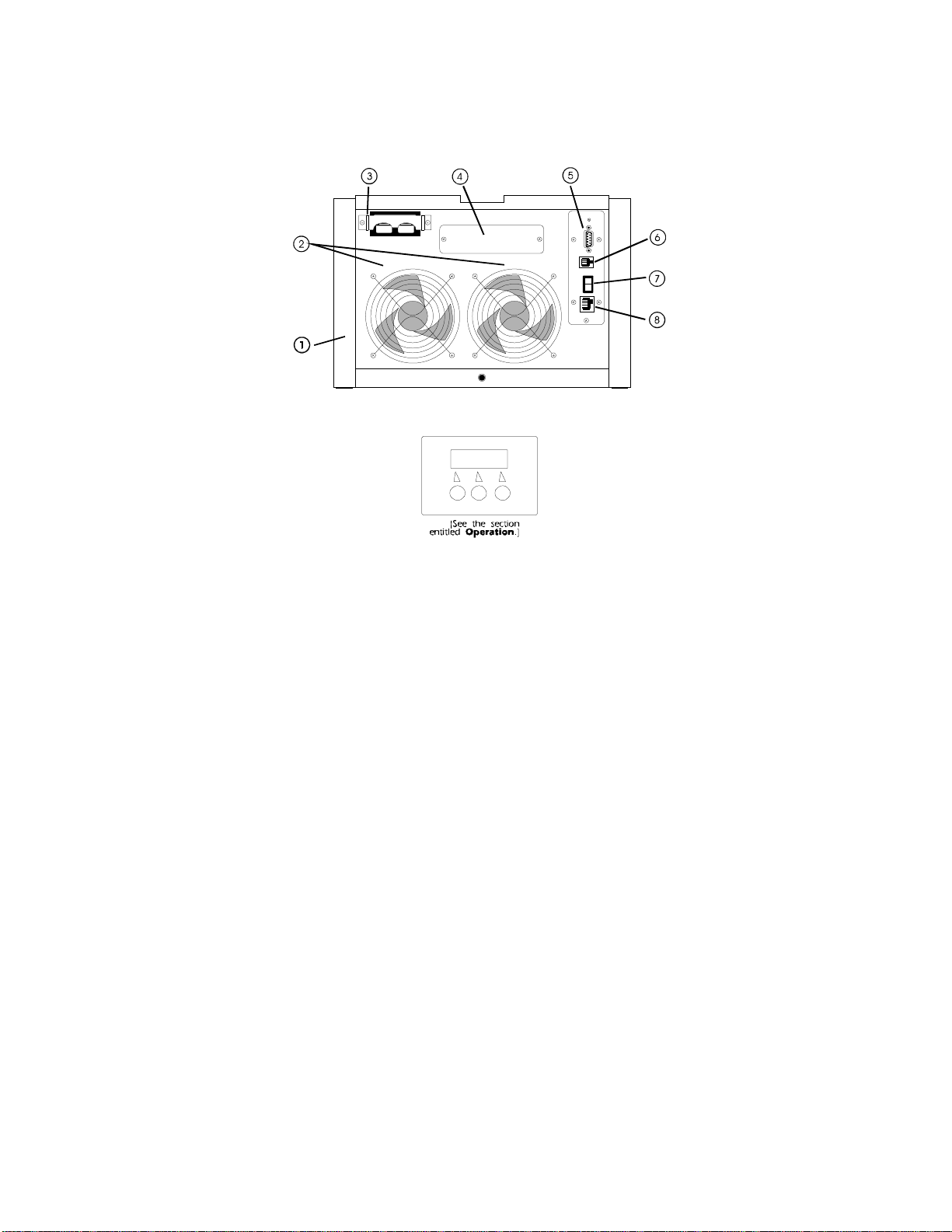

3.2 Electronics Unit (EU)

1. Electronics Unit (EU)

Rear View of the Electronics Unit

The Electronics Unit contains the UPS’s microprocessor controls, inverter, battery charger, transfer and tap changing

circuits, remote interfaces, and the user control and display console. The EU may be separated from the IU for service.

See the manual section entitled Difficulty for instructions on removal of the EU.

2. Cooling fans

The EU cooling fans operate at two speeds depending upon mode of operation. The fans turn faster when the UPS is

heavily loaded while operating on-battery. If either of the fans fail while operating on-line, the UPS will indicate an

alarm condition and transfer to bypass operation. It either of the fans fail while operating on-battery, the UPS will

immediately indicate an alarm condition. Initially, the UPS will continue to provide power to the load. However, when

heavily loaded the UPS will eventually shut down in order to prevent the EU from overheating.

3. Battery Pack coupler

Battery Packs are connected at this coupler. A coupler clamp is installed over the coupler opening as furnished from the

factory. See the manual section entitled Installation for instructions on how to lock mated couplers.

4. Accessory panel

The EU is furnished with an opening that accepts accessories that work with the UPS. Call your dealer or the factory for

information on available accessories.

5. Computer interface port

See UPS Monitoring section of this manual for information on this interface port. Connect only factory supplied or

authorized UPS monitoring cables to this port.

Page 8

6. Battery communications jack

The Battery Pack communications cable from the Battery Pack OUTPUT is connected at this jack.

7. Manual bypass switch

Pressing the manual bypass switch causes the UPS to transfer to the bypass mode of operation. While in this mode, the

load is supplied with power conditioned by the IU. However, the load will not be protected from utility voltage sags,

swells or blackouts. The EU is removed for service when the UPS is operating in bypass. See the Operation section of

this manual for more details on this mode of operation.

8. Emergency Power Off jack

For applications where, for safety reasons, power to all room equipment must be cut off, the UPS provides a remote

Emergency Power Off interface. A modular 6 position plug with offset latch fits this jack. See the Installation section

of this manual for instructions on how to connect to the jack.

3.3 Battery Pack

Rear View Front View

1. Battery Pack

The Battery Pack contains four series connected nominal 12 Vdc high-capacity sealed lead-acid batteries. Built-in ultralow power consumption battery pack voltage and current monitoring electronics report pack status to the UPS. To

conserve battery capacity, the internal electronics are shut down when the battery communications cable is not

connected to the UPS, or when the UPS is not running.

2. INPUT battery communications jack

This input accepts battery status signals from the OUTPUT of another Battery Pack in the system. No connection is

made to this jack in a single Battery Pack system.

3. OUTPUT battery communications jack

The Battery Pack sends status signals to the UPS or to the INPUT of another Battery Pack (in a multiple Battery Pack

system) from this jack.

Page 9

4. Battery Pack panel coupler

Additional Battery Packs are connected to this panel coupler. A coupler clamp is installed over the coupler opening as

furnished from the factory. See the Installation section of this manual for instructions on how to lock mated couplers.

5. Battery Pack cables

Each Battery Pack cable is made from "welding grade" wire to withstand abrasion or crimping in rough duty

applications.

6. Replace Battery indicator

The Replace Battery indicator is illuminated when the Battery Pack can no longer sustain a charge due to wear. See the

Difficulty section of this manual if the indicator is lit.

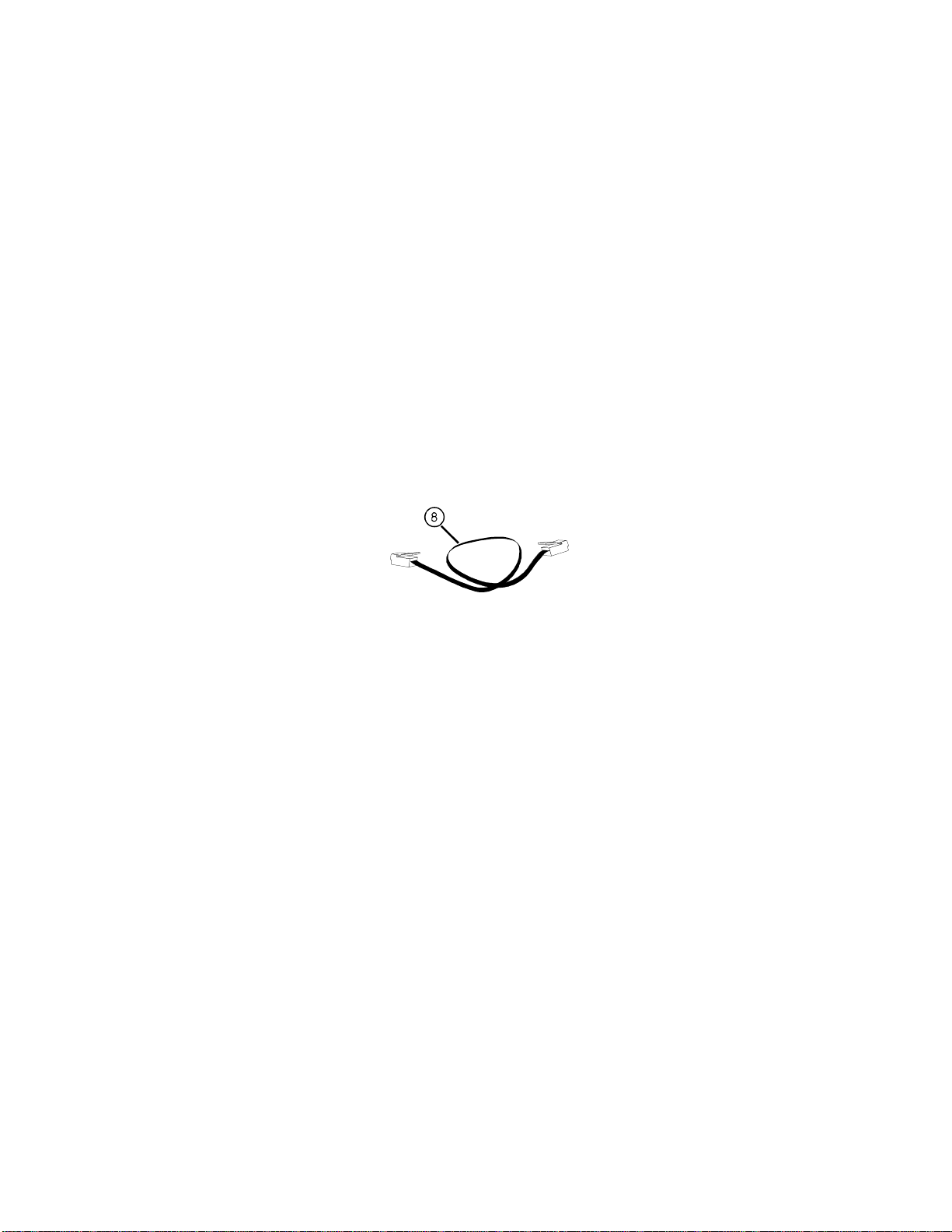

7. In-line Battery Pack coupler

The in-line Battery Pack coupler connects to the UPS or to a panel coupler on another Battery Pack.

8. Battery communications cable

Each Battery Pack is supplied with a battery communications cable.

4.0 Installation

4.1 Receiving Inspection

Once the UPS has been removed from its shipping container, it should be inspected for damage that may have occurred

while in transit. Immediately notify the carrier and place of purchase if any damage is found. The packing materials are

made from recyclable materials and should be saved for reuse or disposed of properly.

4.2 Protection Strategies

This UPS provides high performance power line protection to the loads. There are, however, other potential entry points

for damaging surges in information systems. These include serial ports (RS-232, RS-422, RS-485, etc.), parallel ports,

telephone lines, and network connections. These other entry points must be considered in developing a comprehensive

system protection strategy. Contact your dealer or call the number on the back cover of this manual for information on a

complete set of related products designed to accomplish total system protection.

Sensitive information systems can be further safeguarded by following these guidelines:

n Verify that all electrical outlets are properly grounded.

n Connect information systems to a different electrical service branch than heavy motor loads like air

conditioners, copiers, refrigerators, and heavy industrial machinery.

n Plug all power protection and information system equipment into the same branch where possible.

Page 10

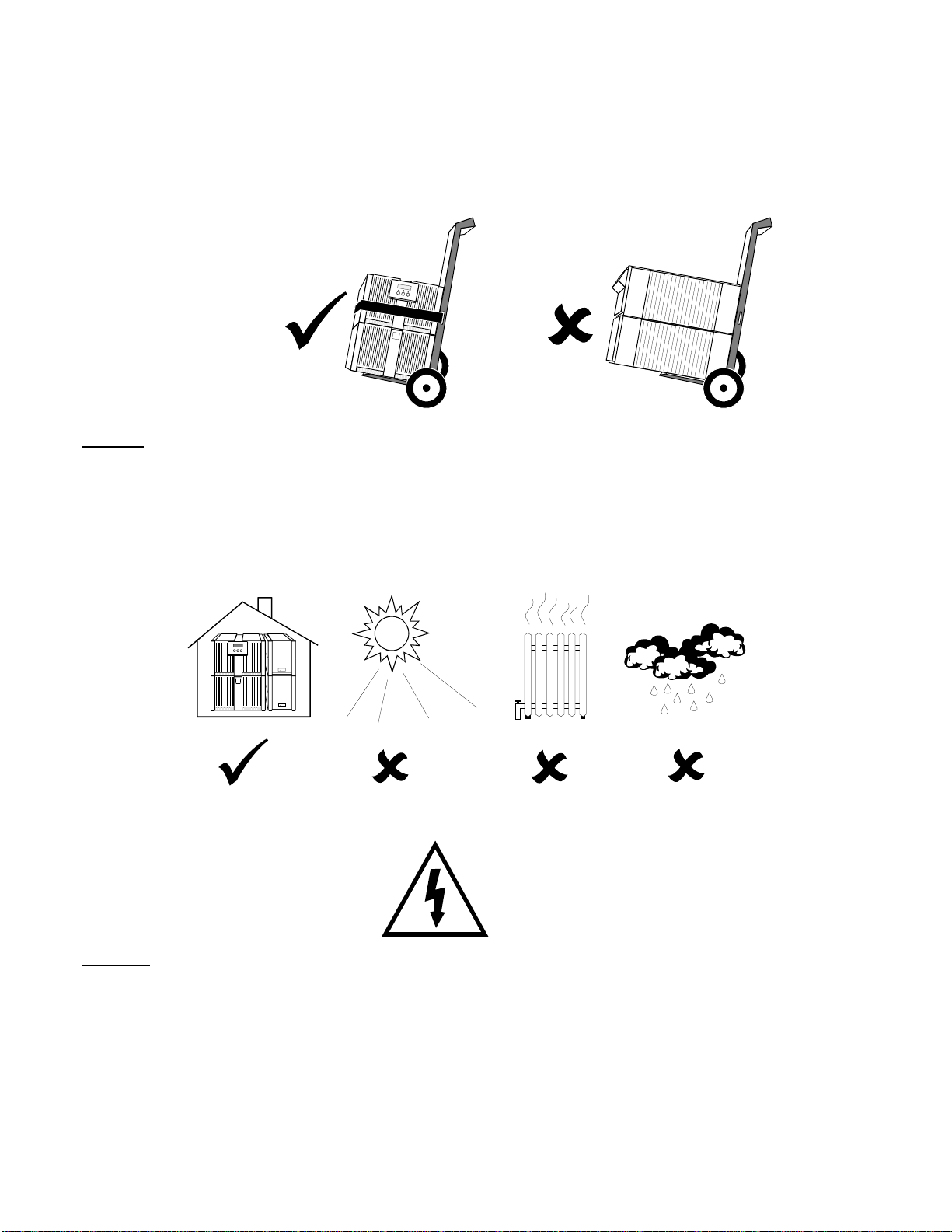

4.3 Moving the UPS

The UPS is heavy and should be moved to the operating site by hand truck. Two people are necessary to

load the UPS into position on the truck noseplate. Load the UPS onto the hand truck as shown below.

Use hand truck straps to stabilize the load while moving.

n Caution: Never attempt to lift the UPS by the Electronics Unit or by the EU separating screw!.

4.4 Placement

The UPS may be installed in any protected environment. The location should provide adequate air flow

around the unit, in an atmosphere free from excessive dust. Do not operate the UPS in an environment

where the ambient temperature or humidity is outside the limits given in the Specifications section of

this manual.

n Warning: Risk of electric shock exists inside the UPS. Input voltage tap selection and power distribution panel

replacement should be performed only by qualified service personnel.

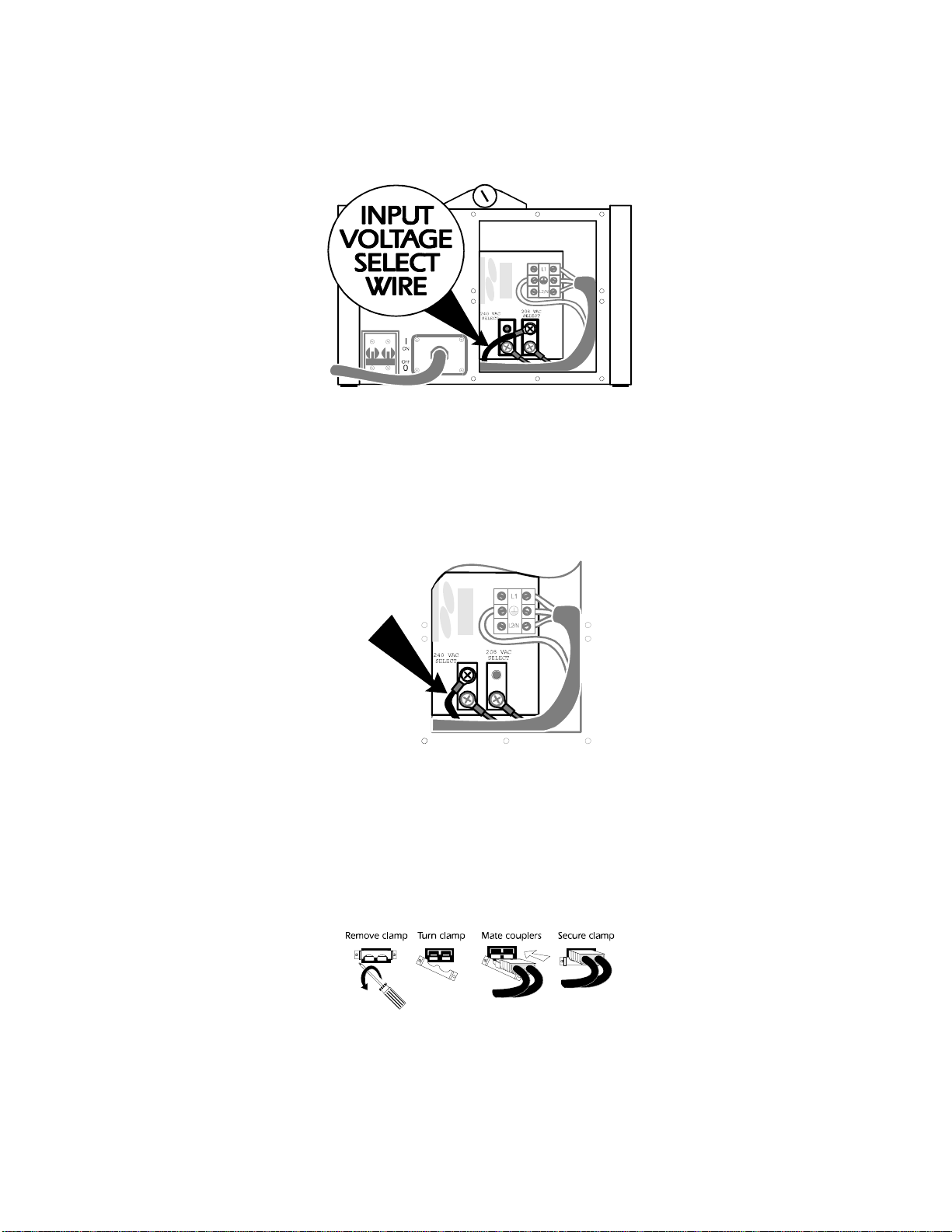

4.5 Input Voltage Selection

As furnished, the UPS is configured to operate from a single phase 208 Vac source. In applications where it is desired to

operate from a 240 Vac source, the UPS must be reconfigured. To reconfigure the UPS, follow the steps listed below.

4.5.1. Turn off (0) the UPS’s input circuit breaker and unplug the input cord.

Page 11

4.5.2. Using a medium size phillips screwdriver, remove all 10 screws that secure the power distribution

plate to the rear of the Isolation Unit. Move aside the power distribution plate. Take care not to strain

the wires connected to the devices on the plate.

208 Vac Input Configuration

4.5.3. Remove the phillips head 10-32 x 3/8" SEM screw holding the red Input Voltage Select Wire (see illustration) to

the tap bar marked "208 VAC SELECT."

4.5.4. Move the red Input Voltage Select Wire to the tap bar marked "240 VAC SELECT" and tighten the screw.

4.5.5. Check your work before reattaching the power distribution plate. Take care not to crimp or pinch

any of the wires connected to the devices on the power distribution plate.

240 Vac Input Configuration

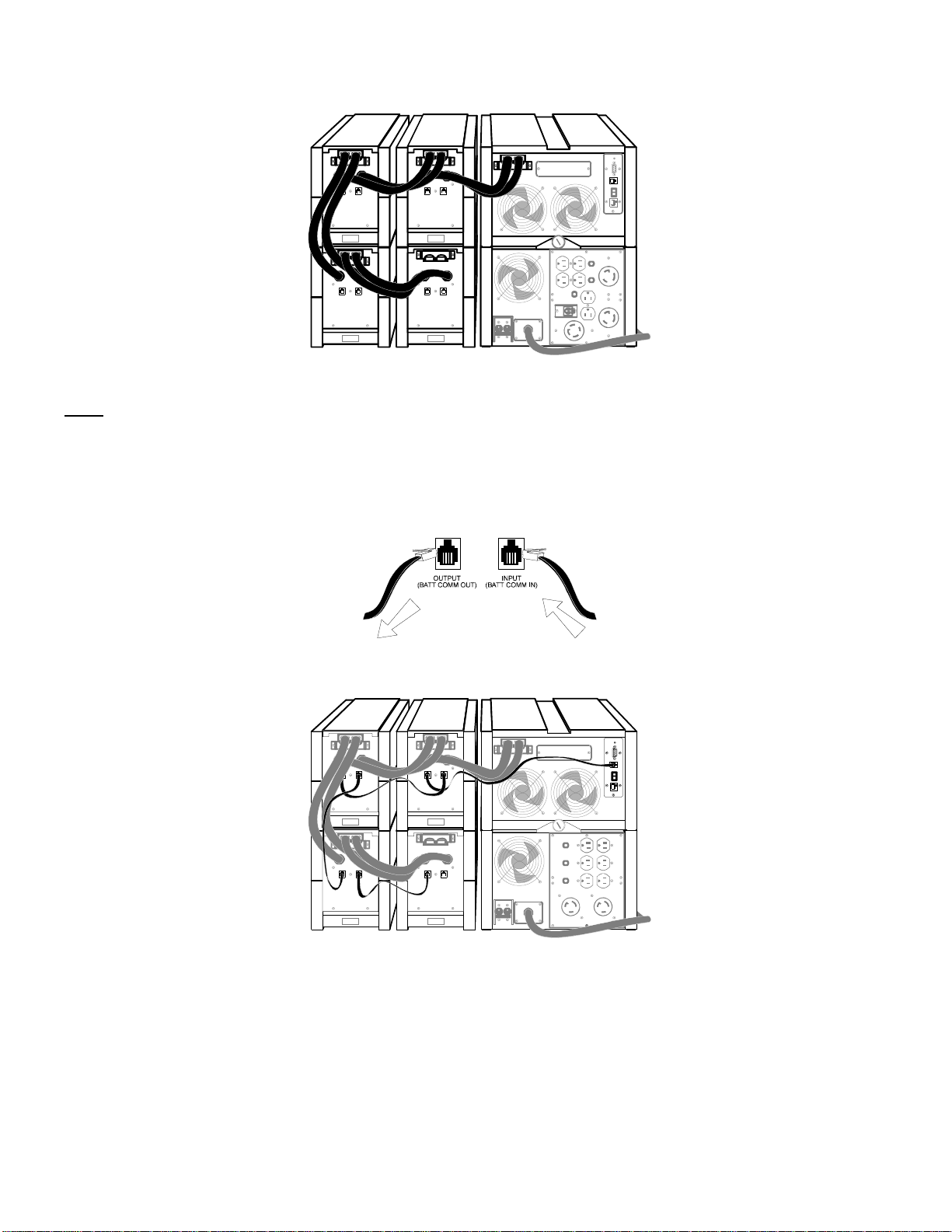

4.6 Module Interconnections

Follow the instructions listed below to install and lock the battery couplers.

4.6.1. Using a phillips screwdriver, remove the battery coupler clamps from the Electronics Unit and from all but one

Battery Pack.

4.6.2. Turn the battery coupler clamp and refasten loosely at one side.

4.6.3. Mate the battery couplers in the fashion shown below. The Battery Packs are electrically connected in parallel.

4.6.4. Fasten remaining side of battery coupler clamp to lock couplers in place.

Page 12

Typical installation showing mated battery couplers

Note: To reduce the risk of toppling, do not stack equipment more than 2 units high.

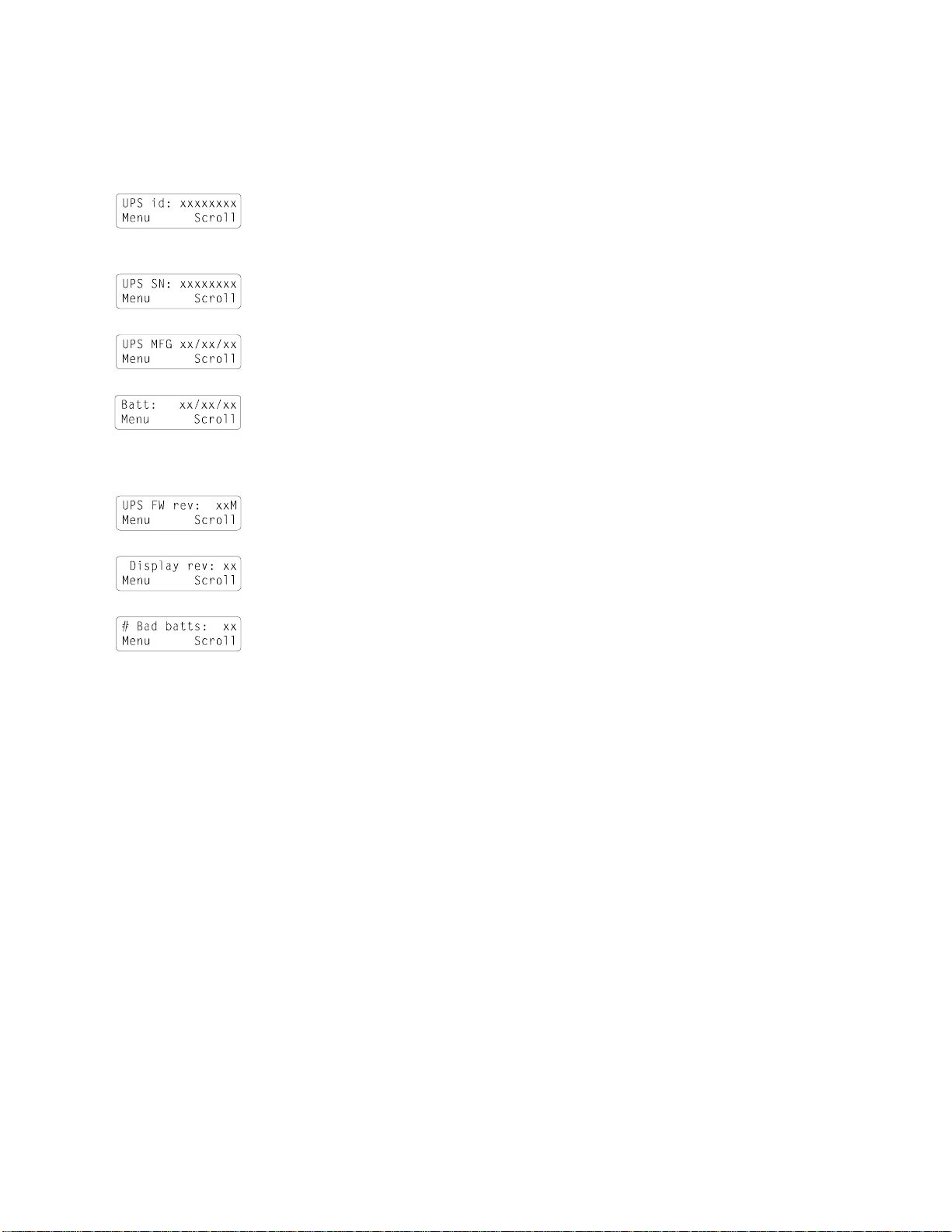

Follow the instructions listed below to install the battery communications cables.

4.6.5. Mate the battery cable plugs in the fashion illustrated below.

4.6.6. Each cable must connect between a Battery Pack OUTPUT and either the UPS’s BATT COMM

input, or another Battery Pack INPUT.

TO: UPS BAtt COM, or From: Battery Pack OUTPUT

TO: Battery Pack INPUT (multiple Battery Pack systems)

Typical installation showing mated battery communications cables

Page 13

4.7 Emergency Power Off (EPO) Interface

The UPS may be switched off by a remotely operated Emergency Power Off control. Such a configuration is common in

computer rooms and laboratories where, for safety reasons, power to the loads must be disconnected. The EPO interface

is a 6 position modular jack with an offset latch. Connection to a remotely located EPO switch may be accomplished as

shown below.

Caution: The EPO interface is a Safety Extra Low Voltage (SELV) circuit and may be connected only to other SELV

circuits.

Caution: The EPO interface is designed to monitor circuits that have no determined voltage potential.

Such closure circuits may be provided by a switch or relay properly isolated from the utility.

Connection of the EPO interface to any circuit other than a closure type circuit may cause damage to

the Electronics Unit.

Page 14

4.8 Start-Up

To start the UPS, follow the instructions listed below.

4.8.1 If a UPS monitoring signal cable is to

be installed, connect it to the Electronic

Unit’s Computer Interface Port. For more

details on the computer interface port, see

the manual section entitled UPS

Monitoring.

4.8.2 Plug the UPS’s input plug into a twist-

lock L6-30R two-pole, three wire

grounding outlet.

Note: See section 4.9 if the UPS’s plug is

not compatible with the available wall

outlet.

4.8.3 Plug all loads to be protected into the

UPS. Do not exceed the UPS’s maximum

capacity as listed in the Specifications

section of this manual. The total load

capacity is continuously monitored by the

UPS and is displayed once the UPS is

switched on.

4.8.4 Power the UPS by switching On the

input circuit breaker.

Note: The UPS may make a "bump" noise

when first switched on. This is normal. The

UPS will not make this sound again.

Note: If the input circuit breaker is rapidly

switched On - Off - On, the UPS may be

caused to operate in the bypass mode.

Follow the display prompts to return to

normal on-line operation.

4.8.6 The UPS should display its status as

"On-Line." When first turned on, the UPS

may adjust the on-line output voltage. Soft

"clicking" sounds may be heard when this

is accomplished. This is normal.

Note: See the Difficulty section of this

manual if the UPS displays a fault

message.

4.8.7 Switch on the protected loads and

check the UPS’s display. Total load

capacity is displayed as a percent of the

UPS’s full rated capacity. It should read

below 100%. If above 100%, the UPS

Page 15

will indicate an overload.

4.8.8

4.9 Input Plug Incompatibility

The UPS is furnished with a twist-lock L6-30P input plug rated to 250V/30A. If it is found that this plug is not

compatible with the available wall outlet, the outlet receptacle should be changed. In some cases, new service wiring

must be installed.

4.9.1 If the service wiring has been installed correctly using one of the receptacle types listed below, a

qualified electrician may be called to replace the receptacle with an L6-30R. In these installations, new

service wiring will not be required. The receptacle type is normally embossed on the receptacle face

(the suffix "R" may not be present).

l L6-20R (only the 3000VA model UPS can be used with this service)

l 6-20R (only the 3000VA model UPS can be used with this service)

l 6-30R

l 6-50R

l 7-30R

l 7-50R

l L14-30R

l L15-30R

l L21-30R

4.9.2 If the service wiring has been installed correctly using one of the receptacle types listed below, a qualified

electrician must be called to install new service wiring for the UPS. In general, these receptacle types are used at

installations where only 120V service is available or where no service ground exists. The receptacle type is normally

embossed on the receptacle face (the suffix "R" may not be present).

l L5-15R

l 5-15R

l L5-20R

l 5-20R

l L5-30R

l 5-30R

l 5-50R

l L18-30

5.0 Operation

5.1 Modes of Operation

When switched on, the UPS will operate in any of five modes of operation depending upon the condition of

the UPS, the UPS’s batteries, the UPS’s loads, and the input utility voltage. These five modes are sleep,

standby, on-line, on-battery, and bypass.

Page 16

5.1.1 Sleep Mode

While in the sleep mode of operation, the UPS’s display is inactive and no voltage is present at the output. The

UPS enters the sleep mode following a 5 minute interval when no commands are given while in the standby

mode (see following section). Following a 5 minute interval, the UPS will enter the sleep mode from the onbattery mode when shut down due to battery capacity exhaustion or overload. This is done to conserve battery

capacity. To "awaken" the UPS to make it receptive to commands, any one of the front panel pushbuttons may

be pressed.

Some versions of PowerChute plus allow the user to put the UPS to sleep and awaken it after a user set interval.

5.1.2 Standby mode

While in the standby mode of operation, the UPS’s display and control interface is active, but no voltage is

present at the output. The UPS enters the standby mode of operation when first "awakened" from the sleep

mode. The UPS is awakened when any one of the three front panel pushbuttons is pressed.

5.1.3 On-line mode

Once commanded to power the loads, the UPS is normally in the on-line mode of operation. While in this

mode, the UPS delivers power to the loads derived from the utility and maintains proper battery charge. In

this mode, the UPS regulates the output voltage to within a narrow band and serves to isolate the load from

surges and electrical noise brought by the service wiring. A multilevel transformer tap changing circuit

provides this regulation and isolation while maintaining extremely high efficiency. In response to the need

to adjust the load voltage, the UPS temporarily operates the load from power derived from the battery while

an appropriate transformer tap change is made. Remote on-battery signalling is disabled when this action is

accomplished.

The UPS’s display indicates the percent of rated load applied at the output when operating on-line.

5.1.4 On-battery mode

When in the on-battery mode of operation, the UPS provides power to the load derived by the UPS’s inverter from the

Battery Packs. The voltage waveshape delivered during on-battery operation is a low distortion sine wave. While onbattery, the UPS regulates the output voltage and frequency to within a narrow band. The UPS operates in the on-battery

mode during the user defeatable start-up or scheduled battery tests. The UPS operates on-battery when the line voltage

or frequency has fallen outside the limits given in the Specifications section of this manual or has become extremely

distorted by, for example, noisy adjacent service branch loads or an overburdened fuel generator source.

Operation on-battery is limited in duration and is dependent upon available battery capacity and load. Local users are

alerted to this mode of operation by visual and audible indicators. When on-battery, the UPS displays available run time

and emits a sequence of four "beeps" every 30 seconds. During an extended utility failure, the battery capacity will

eventually become too low to support the load and the UPS will shut down. The UPS will alert the user to a low battery

condition 2, 5, 7, or 10 minutes prior to shut down, depending upon the user setting. The UPS will emit a "beep" once

every second to warn local users of the low battery condition. The UPS alerts remote users to on-battery operation and

low battery conditions via serial communications or simple signalling from the computer interface port.

Page 17

5.1.5 Bypass mode

When in the bypass mode of operation, the load is supplied power conditioned by the Isolation Unit. However, the load

will not be protected from utility voltage sags, swells or blackouts. The UPS will automatically transfer to bypass

operation when a failure occurs within the Electronics Unit. Detected EU failures include blocked fan, battery charger

fault, overtemperature and welded main relay; see section 7.2 for a complete list of fault messages. The UPS will also

automatically transfer to bypass if the EU separating screw is loosened (as if the EU were to be pulled off the IU). A

manual bypass switch located on the EU is used when maintenance of the EU is required. In all cases, the UPS must be

returned to on-line operation manually.

Local users are alerted to this mode of operation by visual and audible indicators. When in bypass, the UPS displays the

reason for bypass (fan failure, EU switch actuated, etc.) and "beeps". The UPS alerts remote users to the bypass

conditions via serial communications from the computer interface port.

5.1.6 Transfer between modes of operation

Transfer of load power to and from all modes of operation occurs synchronously with the utility voltage phase. See the

Specifications section of this manual for transfer time ratings.

5.2 Display and Controls Operation

The UPS is equipped with a 2x16 character back lit liquid crystal display (LCD) and three button keypad user interface.

The display is structured with five main menu screens and a default screen. Each main menu screen allows access to

several sub-menu screens. Using the pushbuttons, the user can scroll through the menus and access information or

control choices for UPS operation, status, diagnostics, set-up, and tests. The main menu and sub-menu selections are

described in the following sections.

5.2.1 Default screens

5.2.2 Main menu screens

The UPS’s mode of operation is displayed by the default screen. Important fault messages

are also communicated by the default screen. The UPS will show the default screen and

the main menu screens when the Menu key is successively pressed. The UPS will

automatically show the default screen after there has been no keypad activity in the

previous 3 minutes or whenever warranted by a change in mode of operation or failure.

Examples of the most common default screens are shown at the left.

The UPS will show the main menu screens when any default screen key is pressed or

when the Menu key is successively pressed. The five main menu screens are show in

order at the left.

The main menu screens allow access to screens that display operational choices or

show information on UPS status, diagnostics, set-up and tests. Access to the

sub-menu screens is gained by pressing the Scroll key. To return to the main

menu, press the Menu key.

Page 18

5.2.3 UPS Control menu

The UPS Control menu allows the user to access sub-menus that show UPS switch on/off and bypass in/out operation

choices. To avoid accidentally powering or unpowering the load when a UPS on/off control choice is mistakenly

entered, the UPS will ask the user to confirm the choice.

5.2.4 UPS Status menu

The UPS Status menu allows the user to access sub-menus that show UPS, Battery Pack, utility, and load parameter

values. These parameters are described below.

This screen shows the true rms input line voltage. The accuracy of this measurement

±5% of the full scale value of 285 Vac.

is

This screen shows the UPS’s true rms line-line output voltage.

The accuracy of this measurement is

This screen shows the applied load as a percentage of the UPS’s full rated capacity.

The accuracy of this measurement is

This screen shows the estimated run time available in minutes. The indication is

based on available battery capacity and the applied load. The UPS keeps track

of changing battery performance and adjusts the available run time indicated for

weak batteries nearing the end of their service life.

±5% of the full scale value of 285 Vac.

±4% of the full scale value of 105%.

This screen shows the internal temperature of the Electronics Unit in degrees

Centigrade. The indicated temperature rises when the UPS is operating on-battery

and when the ambient temperature rises.

This screen shows the available battery capacity as a percent of the fully charged condition.

This screen shows the frequency to which the UPS’s output is synchronized.

The accuracy of this measurement is

This screen shows the number of Battery Packs connected in the system.

This screen shows the number of XR Battery Packs connected in the system.

This screen shows the number of bad or worn battery Packs connected in

the system. To identify the bad Battery Packs, locate the packs having an

illuminated Replace Battery indicator.

±1% of the full scale value of 63 Hz.

Page 19

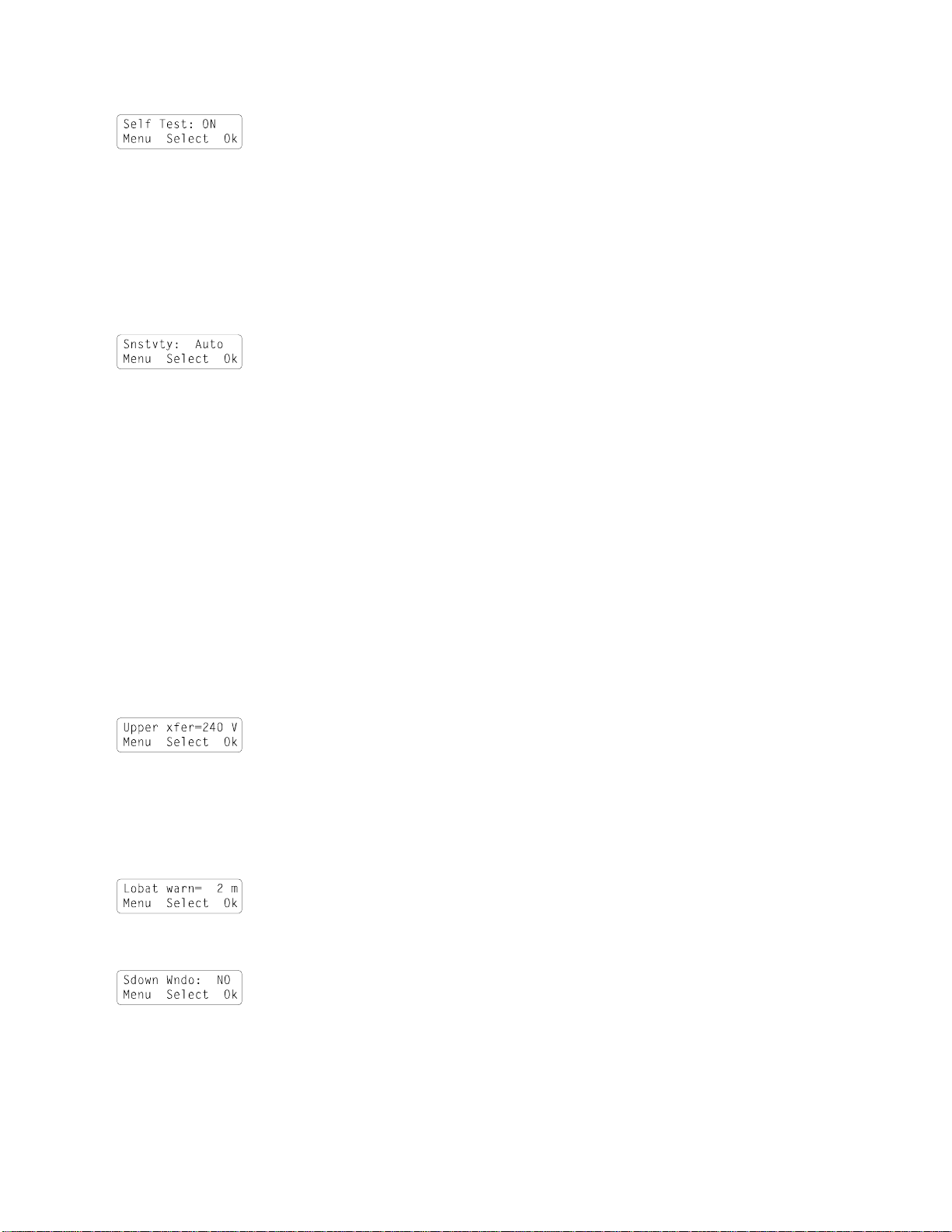

5.2.5 UPS Diagnostics menu

The UPS Diagnostic menu allows the user to access information that may be useful when troubleshooting the UPS.

This screen shows the UPS’s identity name. The name set by the factory can

be changed to an 8 character alphanumeric name using optional UPS

monitoring application software.

This screen shows the UPS’s serial number set by the factory.

This screen shows the UPS’s date of manufacture set by the factory.

This screen shows the date of the last Battery Pack replacement. It is set to the

date of manufacture by the factory. The date set by the factory can be updated

when new Battery Packs are installed using optional UPS monitoring

application software.

This screen shows the firmware instruction set revision for the Electronic

Unit’s UPS control microprocessor.

This screen shows the firmware instruction set revision for the

Electronic Unit’s display microprocessor.

This screen shows the number of bad or worn Battery Packs connected

in the system. To identify the bad Battery Packs, locate the packs having

an illuminated Replace Battery indicator.

Page 20

This screen shows the number of Battery Packs reporting that their voltage level

has reached the proper "float" voltage.

This screen shows the UPS’s battery voltage. The accuracy of this measurement

is ±5% of the full scale value of 68 Vdc.

This screen shows the cause of the latest transfer to on-battery operation.

This information is updated each time the UPS is caused to transfer to on-battery

operation.

l If the UPS has transferred to on-battery operation due to a utility voltage

notch or spike, the display will report the transfer cause as a notch/spike.

l If the UPS has transferred to on-battery operation due to an unacceptable

rate of change in the output voltage, the display will report the transfer cause as dV/dt.

l If the UPS has transferred to on-battery operation to maintain proper output voltage

regulation in response to high or low utility voltage, the display will report the

transfer cause as Hi Line V or Lo Line V.

l If the UPS has transferred to on-battery operation to conduct battery tests,

the display will report the transfer cause as Self test.

This screen shows the rms current drawn by the UPS's load in Amps. The accuracy

of this measurement is ±5% of the full scale value of 35 Amps.

This screen shows the Volt-Amps drawn by the UPS's load as a percent of

full rated capacity. The accuracy of this measurement is ±5% of the full

scale value of 105%.

Page 21

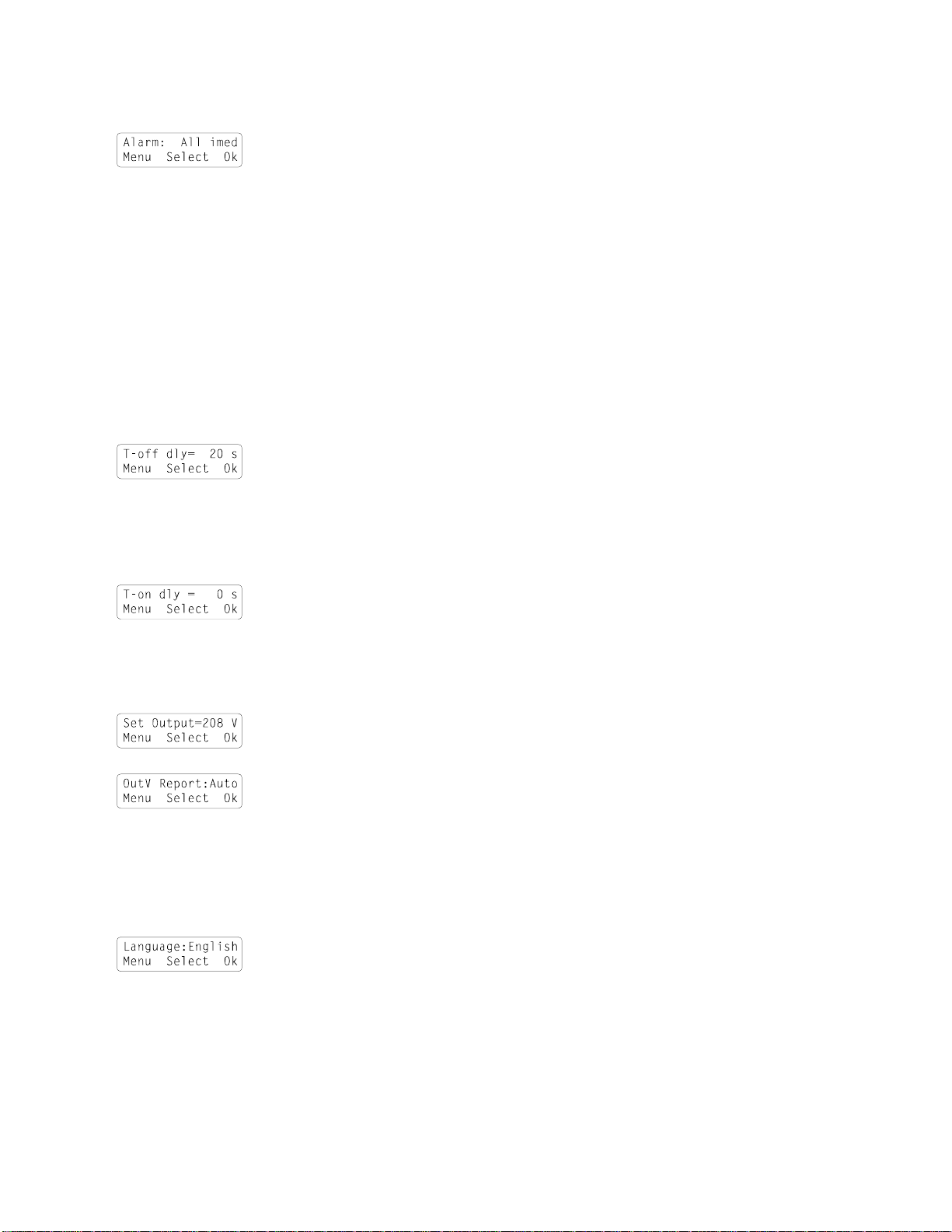

5.2.6 UPS Setup

The UPS Setup menu allows the user access to sub-menus that show special UPS function choices. Function choices are

selected with the Select key. Other sub-menus and function choice confirmation can be accessed by pressing the Ok key.

The sub-menus and function choices are described below. All sub-menu screens are shown with the factory set function

choice.

Note: Function choice values are subject to change - when necessary, the meaning of new values will be explained in

errata sheets.

Page 22

This screen shows selected UPS self test function choice. The self test determines

the readiness of the UPS to supply power to the load in the event of utility failure.

The benefit of this test is that the user is warned of conditions that could otherwise

cause unexpectedly short run times.

l ON - UPS conducts self test immediately upon start-up.

l OFF - Self test function is disabled.

l 7 day - The UPS conducts the self test automatically upon start-up and once every

7 days thereafter.

l 14 day - The UPS conducts the self test automatically upon start-up and once

every 14 days thereafter.

This screen shows the selected utility failure sensitivity function choice. The

UPS can be set to automatically adapt to utility service conditions where

extreme voltage distortion is present or where severe rapid voltage excursions

occur. Such conditions are typically created by inexpensive fuel generators

or by unusually long branch circuits burdened by heavy cyclic loads.

Nearby arc welding or heavy industry equipment can also affect the quality of service.

l AUTO - UPS automatically adapts to utility service quality. This adaptive

mode is selected to reduce frequent transfers to on-battery operation which

could unnecessarily exercise the battery, shortening its life. Normally, the

UPS provides load voltage regulation within a narrow band. In response to

rapid and frequent utility voltage fluctuations, the UPS relaxes the load

voltage regulation. This relaxed regulation band remains within the bounds

recommended by telecommunications and computer manufacturers.

See the Specifications section of the manual for the regulation ratings.

l High - UPS remains sensitive to aberrant line voltages. Load voltage

regulation stays within the narrow band.

l Low or Medium - UPS is insensitive to aberrant line voltages. The load

voltage regulation is relaxed to a widened band.

The voltage at which the UPS will transfer to on-battery operation is

adjustable for service conditions where extremely high utility voltages

persist and it is known that the loads can withstand the elevated voltage.

l When configured for operation from a 208V service, the transfer voltage

choices are 240V, 244V, 248V, and 252V.

l When configured for operation from a 240V service, the transfer voltage

choices are 276V, 264V, 253V, and 282V.

The minimum interval between activation of the UPS’s audible, visual and

signalled low battery alarm warnings and shut down of the UPS due to

battery capacity exhaustion is user settable.

l The function choices are 2, 5, 7, and 10 minutes.

The UPS may be set to shut down before usable battery capacity is

spent. This conserves battery capacity in the event of successive outages.

l The function choices for the amount of on-battery run time to be

conserved are NO (none) and 2, 5, and 8 minutes.

Page 23

For applications where the UPS is used as a remote power source or where

the UPS frequently transfers to on-battery operation due to poor service

quality, the function of the audible alarm may be altered so that it will

not become an annoyance.

l All imed - A sequence of four beeps is sounded immediately upon transfer

to on-battery operation. The UPS sounds the beep sequence every 30 seconds

while operating on-battery. When low battery conditions are reached, the alarm

changes to a beep once every second.

l 30s delay - The on-battery audible alarm is disabled for the first 30 seconds

of on-battery operation.

l Low Batt - The audible alarm is disabled during on-battery operation until

low battery conditions are reached.

l Disable - The audible alarm is disabled during on-battery operation and

low battery conditions.

Many computer networks that issue UPS shutdown commands are unable to

do so as the last part of a shutdown routine. For these applications, the UPS

provides a settable delay interval before shut down to allow the network to

finish its shutdown routine.

l Shut down delay function choices are 20, 180, 300, and 600 seconds.

A delay interval before energizing the output following return of normal

utility voltage, or following a scheduled shut down, may be set by the user.

This delay is useful in applications that require staggered power up of

equipment connected at various sources.

l Load power delay function choices are 0, 60, 180, and 300 seconds.

This function has no meaning for the 208/240 Vac, 60 Hz version UPS. The

display will always respond 208 V.

The UPS can be set to report the output voltage from either the nominal 208V

or 240V output. This can be accomplished regardless of whether the input is

configured for operation from 208V or 240V service. When an optional power

distribution plate or Power Distribution Unit (PDU) is installed, the UPS should

be set to report the correct output voltage. When the Auto function is chosen, the

reported nominal output voltage is scaled according to the input tap selected

(see section 4.5).

The UPS can be set do display all menu choices in either English, French,

German, or Spanish.

Page 24

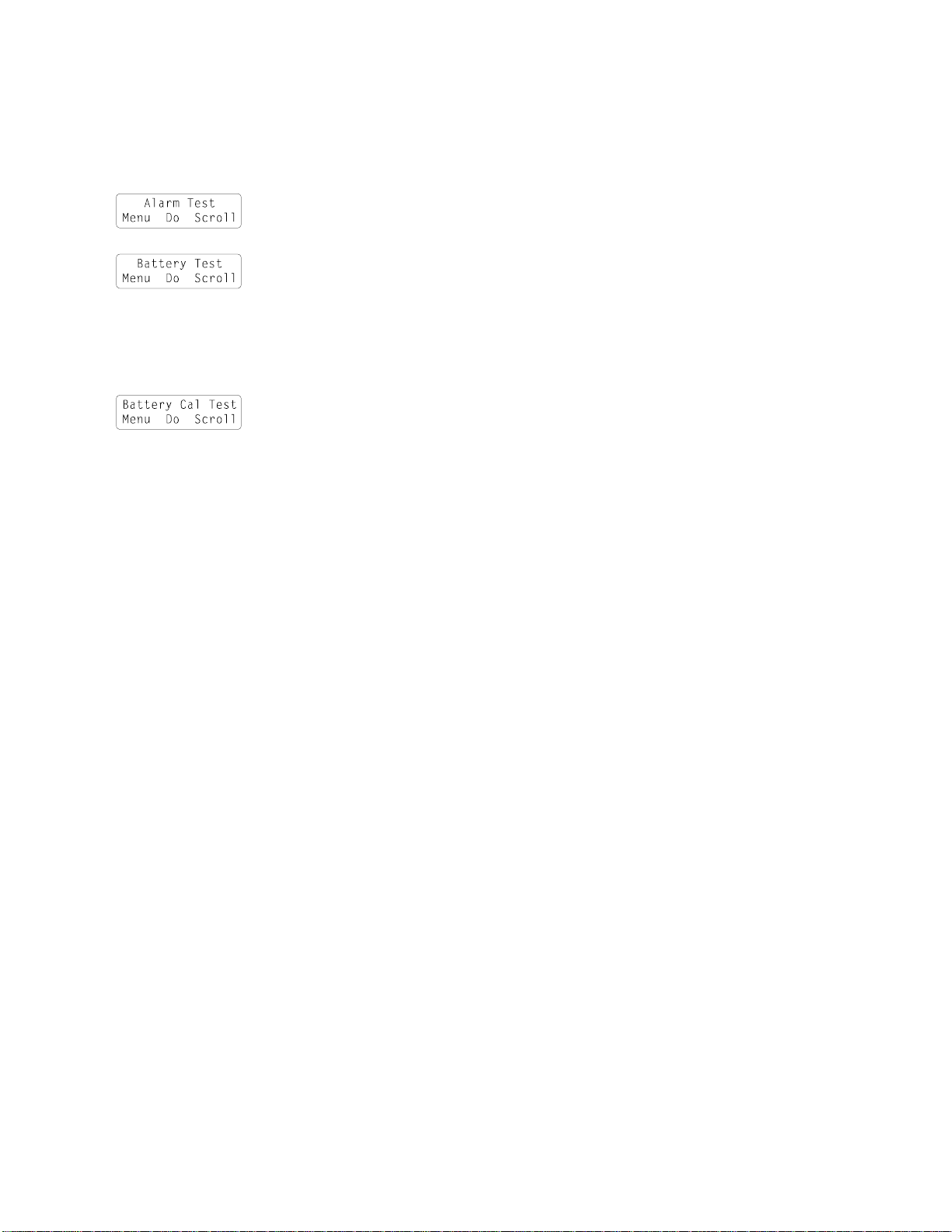

5.2.7 UPS Tests

The UPS Tests menu allows the user to access sub-menus that show operation confirmation functions.

This screen shows the audible alarm test sub-menu. When the Do key is

pressed, the UPS will briefly sound the audible alarm.

This screen shows the battery test sub-menu. When the Do key is pressed,

the UPS will perform a self test to determine the readiness of the UPS and

the batteries to operate the load while on-battery. When conducting this test,

the UPS operates on-battery. The UPS does not signal the on-battery condition

at the computer interface port during this test. The display will report PASS

or FAIL at the end of the test.

This screen shows the battery run time calibration test sub-menu.

To calibrate the UPS’s run time display following installation, press

the Do key. If the calibration test is not conducted, the UPS provides

only a rough estimate of run time until actual battery statistics can be

acquired during an extended utility failure.

When the Do key is pressed, the UPS will perform the test only if battery

capacity is at 100%. The test is completed and the UPS returns to normal

on-line operation when the batteries are discharged to approximately

25% of their full capacity. The calibration test can be aborted at any

time during the test.

5.2.8 Password protection

All functions accessed by the UPS Control, UPS Setup and UPS Tests menus may be password protected to prevent

operation of the unit in a fashion not intended by the UPS manager. The password settings are accessed by optional UPS

monitoring application software.

Page 25

6.0 UPS Monitoring

6.1 Overview

A UPS system alone provides excellent protection from brief power problems. However, during an extended power

outage an unattended computer system will eventually shut down due to battery capacity exhaustion. To prevent data

corruption when the UPS shuts down, the computer must be informed by the UPS of impending shut down and take

appropriate file-saving measures. This important function is called UPS monitoring. The UPS’s computer interface port

is the means by which your UPS communicates with a computer system.

Some computer operating systems have built-in UPS monitoring. These systems require various hardware interfaces.

Interface kits for all operating systems that support UPS monitoring are available from your dealer. In addition, your

dealer also offers PowerChute software which enhances such built-in UPS monitoring. Versions of PowerChute are

available which add the UPS monitoring function to the many operating systems which do not inherently provide UPS

monitoring.

6.2 Interface Kits

A series of interface kits is available for operating systems that provide UPS monitoring. Each interface kit includes the

special interface cable required to convert status signals from the UPS into signals which individual operating systems

recognize. Each kit includes all necessary installation instructions. Systems for which interface kits are offered include

Novell, LAN Manager, LANtastic, Banyan VINES and IBM AS/400.

6.3 PowerChute Software

PowerChute software provides complete data protection for most operating systems. This software is a background

process that monitors the UPS through a RS-232 serial port on the host. PowerChute offers user notification of

impending shutdown, power event logging, auto-restart upon power return and UPS battery conservation features. For

selected operating systems, PowerChute offers sophisticated power diagnostic and network power management features.

These include interactive battery testing; scheduled server shutdowns, reboots and battery testing; detailed power quality

logging and a remote, real time, graphical power status display showing UPS loading and battery conditions.

PowerChute is available for many platforms including Novell, OS/2, AppleShare, XENIX, most UNIX-based operating

systems, and DEC VAX/VMS.

Caution: Use only factory supplied or authorized UPS monitoring cables!

Page 26

6.4 Computer Interface Port

The computer interface port is diagrammed below for your reference. Those with technical abilities wishing to use this

port in a special application should be aware of the following limitations and capabilities of the interface.

n Outputs at pins 3, 5 and 6 are actually open collector outputs which must be pulled up to a common

referenced supply no greater than +40 Vdc. The transistors are capable of a maximum non-inductive

load of 25 mAdc. Use only Pin 4 as the common.

n The output at Pin 2 will generate a LO to HI RS-232 level upon transfer of the output load to power

derived from the UPS’s battery. The pin is normally at a LO RS-232 level.

n The UPS will shut down when a HI RS-232 level, sustained for 4.5 s, is applied to Pin 1. The UPS

responds to this signal, following a delay, only during utility failures (load is operating from the

UPS’s internal power source).

n An unregulated +24 Vdc appears at Pin 8 of the interface port whenever the UPS is powered. The

supply is limited to 40 mAdc maximum.

Page 27

7.0 Difficulty

CAUTION !

n This Uninterruptible Power Source contains potentially hazardous voltages. Do not attempt to disassemble the unit.

The unit contains no user serviceable parts. Repairs are performed only by factory trained service personnel.

n This Uninterruptible Power Source uses batteries. The batteries will eventually become too weak to provide rated

autonomous operation. To obtain battery replacement or repair service, please call the Customer Service telephone

number written on the cover of this manual for information on the Service Center nearest you.

n The batteries used by this Uninterruptible Power Source are recyclable. Proper disposal of the batteries is

required. The batteries contain lead and pose a hazard to the environment and human health if not disposed of

properly. Please refer to local codes for proper disposal requirements or return the unit to a factory authorized

Service Center for battery replacement or disposal.

n Battery replacement should be performed or supervised by personnel familiar with the danger of batteries and the

required precautions. Keep unauthorized personnel away from batteries. When replacing batteries, use the same number

and type of sealed lead acid batteries as were originally contained in your UPS.

n CAUTION - Do not dispose of battery or batteries in a fire. The batteries may explode.

n CAUTION - Do not open or mutilate the battery or batteries. They contain an electrolyte which is toxic and harmful

to the skin and eyes.

n CAUTION - A battery can present a risk of electrical shock and high short circuit current. When replacing batteries,

wrist watches and jewelry such as rings should be removed. Use tools with insulated handles.

Page 28

7.1 Troubleshooting Chart

Problem Possible Cause Action to Take

The UPS’s input circuit breaker is tripped

(1/2 of handle is down).

UPS will not turn on.

UPS operates on-battery even

though normal utility voltage is

thought to exist.

UPS beeps occasionally. This is normal. None. The UPS is protecting the loads.

UPS does not provide expected

back up time.

UPS display shows "No Battery

Communication".

EU separating screw is loose.

Circuit closure present at the Emergency

Power Off interface.

Very high line voltage.

Highly distorted line voltage.

The UPS’s batteries are discharged from

recent utility outage.

The UPS’s batteries are weak due to age

or wear.

One or more battery pack cables is not

properly connected.

Reduce the load on the UPS by unplugging

equipment and reset the circuit breaker.

Tighten the EU separating screw (do not

overtighten).

Check the EPO connections. See section

4.7.

Test the line voltage with the UPS voltage

meter (see section 5.2.4). If necessary,

adjust the UPS upper transfer voltage (see

section 5.2.5).

Inexpensive fuel powered generators can

cause distorted line voltages. Desensitize

the UPS to the distortion (see section

5.2.5).

None. The UPS’s batteries require

recharging after extended or successive

outages.

The batteries wear faster when put into

service often and when operated at

elevated temperatures.

Check connections to and from each

battery pack and the EU. See section 4.6.

UPS display shows "In Bypass

Mode Press Any Key".

UPS display shows "UPS in

BYPASS chk rear switch"

Output voltage reading incorrectg

after installation of a new power

distribution plate.

Output voltage outside rated

regulation band.

The UPS does not power the load

immediately following the return of

normal utility voltage.

Battery pack coupler not properly mated

with the EU coupler.

Input circuit breaker cycled on-off-on too

quickly.

The manual bypass switch at the rear of

the EU is in the bypass position.

Output voltage reporting incorrectly set.

Upper transfer voltage set higher than the

factory setting.

The UPS has relaxed load voltage

regulation to compensate for distorted or

fluctuating utility voltage.

The turn on delay set to a non-zero value.

Check battery pack connections. See

section 4.5.

Follow display prompts to return to normal

on-lone operation.

Chage the switch setting to resume normal

on-line operation.

Change the output voltage reporting setup.

See section 5.2.6.

If necessary, change the upper transfer

voltage setting. See section 5.2.5.

Set the UPS’s utility failure sensitivity to

"High" to maintain narrow band

regulation. See section 5.2.5.

Set the turn on delay to the desired value.

See section 5.2.6.

Page 29

7.2 Fault Messages

The UPS will display one of the below illustrated screens when a fault internal to the UPS has been detected. See

section 7.5 which covers obtaining service.

7.2.1 Replace Electronics Unit (EU)

A DC imbalance fault results in bypass operation - load power is lost during a utility failure.

Overheating within the EU results in bypass operation - load power is lost during a

utility failure.

Failure of either EU fan while operating on-battery may cause overheating within

the EU. Overheating while on-battery will result in the loss of load power.

Failure of either fan while operating on-line will result in bypass

operation - load power may be lost during a utility failure.

A battery charger fault results in bypass operation - load power is lost during a

utility failure.

A main relay fault results in loss of load power. Remove the EU to resume

load power in the bypass mode - load power is lost during a utility failure.

7.2.2 UPS requires service

The UPS may remain operating when this IU fan fault message is encountered.

Schedule UPS service when convenient.

Do not attempt manual bypass operation when this fault message is

encountered as load power will be lost. Schedule UPS service when convenient.

If the input voltage tap configuration has been changed, a qualified technician

should reinspect the connections - see section 4.5. An output voltage select

fault results in bypass operation - load power is lost during a utility failure.

A bypass relay fault will result in permanent bypass operation - load power

will be lost during a utility failure.

Page 30

7.2.3 Battery status

The UPS’s battery status displays alert you to problems with the batteries connected to the UPS

This screen indicates that there may be problems with the connections

between Battery Packs or between the UPS and the Battery Packs.

This screen indicates that the UPS’s batteries are too low to support

the load connected to the UPS. The UPS cannot restart until the batteries

have recharged.

This screen indicates that one or more battery packs connected to the UPS

need to be replaced. Check the Replace Battery indicators on the front of

the Battery Packs to see which ones need to be replaced.

This screen indicates that the UPS cannot establish communications

with any Battery Packs. Verify that the battery communications cables

are secure.

This screen indicates that the UPS detected a change in the number of

Battery Packs connected to the UPS. Check that the number of battery

packs connected to the UPS matches the number shown on the display.

If the numbers do not match, check the battery communications cable

connections.

Press a key to clear the message.

This screen indicates that the battery is low and requires recharging after an

extended mains failure (on-battery). The load has been shut off.

Page 31

7.3 Replacing the Electronics Unit

The UPS allows replacement of a failed Electronics Unit without interruption of power to the load.

The Isolation Unit is capable of autonomous operation and provides power to the load isolated from

EMI/RFI noise and surges.

To replace a failed EU, follow the procedures listed below.

7.3.1 Put the UPS into the bypass mode of operation by actuating the manual bypass switch at the rear of the EU.

Note: Transfers to bypass mode using the manual bypass switch occur within 10 mS typically. The transfer back

from the bypass mode occurs in 0 mS.

7.3.2 Using a coin or large flat blade screwdriver, unscrew the EU separating screw and pull back.

7.3.3 Using a Phillips screwdriver, loosen the Battery Pack coupler lock at the rear of the EU and disconnect the pack

coupler. Disconnect the Battery Pack communications cable from the jack at the rear of the EU.

7.3.4 If necessary, disconnect cables connected at the computer interface port and the Emergency Power Off interface.

7.3.5 Grasp the EU at the slots shown in the illustration and pull straight up and away from the IU.

7.3.6 Follow the above procedures in reverse to install the replacement EU. Once the replacement EU is installed, press

any key to regain control of the UPS.

Page 32

7.4 Replacing or Adding Battery Packs

The Electronics Unit will display this message when any one of the connected Battery Packs requ

Battery Packs that can no longer sustain a charge are identified by an illuminated Replace Battery

Always check the number of Battery Packs reported by the UPS (UPS Status menu) after a

If this fault message is encountered, check the communications cables to, and from each B

You can expect to receive 3 to 6 years of service life from the Battery Packs when installed in a cool, dry location. The

Battery Pack's life is shortened when operated in an environment where the ambient temperature is normally above 30°C

(86°F).

Battery Packs can be added or replaced at any time, regardless of mode of operation. See the procedures listed below to

replace a worn Battery Pack.

Caution: If the first Battery Pack in the string (connected directly the Electronics Unit) is replaced, the UPS will not be

able to support the load in the event of a utility failure during the time that the battery string is uncoupled from the EU.

Always place the UPS in bypass when this Battery Pack is replaced.

7.4.1 Disconnect both INPUT and OUTPUT battery communications cables connected at the worn Battery Pack.

7.4.2 Remove the clamps securing the in-line coupler and panel coupler (if necessary) at the worn Battery Pack.

7.4.3 Unmate the couplers at the worn Battery Pack and return it to the factory for recycling.

7.4.4 If necessary, remove the panel coupler clamp. Set the new Battery Pack in place.

7.4.5 Mate the in-line and panel couplers on the new Battery Pack.

7.4.6 Secure the couplers with the coupler clamps.

7.4.7 Plug-in the battery communications cables at the new Battery Pack. See the illustration in section 4.9.6.

Note:

Battery Packs.

Note:

section 4.9.6.

Page 33

7.5 Obtaining Service

The troubleshooting chart in section 7.1 covers most of the difficulties that a user may encounter under conditions other

than a failure of the UPS itself. For problems not covered in the chart, or when the UPS’s display shows Call for service,

the procedures outlined below should be followed.

If your UPS should require service:

n See the troubleshooting chart and eliminate the obvious. A tripped UPS circuit breaker is the most

common problem encountered and is user resettable once excessive loads are unplugged from the UPS.

n If the circuit breaker is OK, note your UPS model, serial number and date of purchase. Contact the

Customer Service Department at the phone number given on the cover of this booklet.

n Be prepared to provide a description of the problem. A technician will help you solve the problem over the phone if

possible, or will give you a Return Material Authorization Number (RMA#).

n If the UPS is within the warranty period, repairs will be performed free of charge. If it is not within the warranty

period, there will be a charge for repair.

n Pack the UPS in its original packaging. If you no longer have the original shipping materials, ask the technician

about obtaining a new set. It is very important that you pack the UPS properly to avoid damage in transit. Never use

styrofoam beads for packaging a Battery Pack or Electronics Unit because they will settle through beads and become

damaged. Damages sustained in transit are not covered under warranty. Enclose a letter in the package with your name,

RMA#, address, copy of sales receipt, description of trouble, phone number and check (if necessary).

n Mark your RMA# on the outside of the package. The factory cannot accept any package without this marking.

n Return your UPS via insured, prepaid carrier to the address on the rear of this booklet.

Page 34

8.0 Storing the UPS

8.1 Storage Conditions

The UPS should be covered and stored in a cool dry location. The UPS should be stored with the Battery Packs in a

fully charged state. That is, the reported battery capacity should be at 100% before the UPS is switched off for storage.

Disconnect the Battery Packs from the UPS and from each other (where applicable). Store the Battery Packs in an

upright position.

8.2 Extended Storage

To achieve expected run time following extended storage, the UPS should be allowed to refresh the Battery Packs every

6 months in environments where the ambient temperature is -15°C to +30°C (5°F to 86°F). For extended storage in

environments where the ambient temperature is +30°C to +45°C (86°F to 113°F), the UPS should be allowed to refresh

the Battery Packs every 3 months.

9.0 Specifications

Note: Where specification ratings differ, values for the UPS configured for 240 Vac operation are given in brackets [ ].

9.1 Input

Nominal input voltage: single phase 208 Vac [240 Vac].

Nominal input frequency: 60 Hz.

On-line efficiency @ full load: > 92%, > 93% with fully charged batteries for the 3000VA and

5000VA models, respectively.

Input circuit breaker: 20 Amp, 30 Amp; for the 3000VA and 5000VA models, respectively.

Input connector: NEMA L6-30P (250V/30A).

9.2 Transfer Characteristics

Frequency limits for on-line operation: 60 Hz, ±5%.

Input voltage limits for on-line operation: -25% to +15% of the nominal input voltage.

Transfer to/from on-battery: 0 ms typical with computer loads, 1.5 ms maximum. Transfer occurs

synchronous with the utility voltage phase.

Transfer to/from bypass: Transfers to and from bypass occur synchronously with the utility voltage

phase. Transfers both to and from bypass mode occur in 0 mS typically.

9.3 Output Characteristics

Maximum load: 3000 VA or 2250 W @ 0.75 power factor; 4700 VA or 3750 W @ 0.8 power factor

[5000 VA, 3750 W @ 0.75 power factor] for the 3000VA and 5000VA models, respectively.

Nominal output voltages: 208 Vac / 120 Vac [240 Vac / 120 Vac].

On-line voltage regulation: ±5%. When "Auto" or "Low" utility failure sensitivity is selected by the

user, the output voltage regulation may become relaxed to +5%, -12%.

On-line frequency regulation: 60 Hz, ±5% (synchronized to the utility).

On-battery output voltage regulation: ±5%.

On-battery output frequency regulation: 60 Hz, ±0.1 Hz unless synchronized to utility frequency

during utility brownout.

On-battery output voltage total harmonic distortion: < 5%.

Page 35

Protection: overcurrent and short circuit protected, latching shutdown upon overload.

Output connections: (6) NEMA 5-15R receptacles, (1) NEMA L14-30R receptacle, and (2) NEMA

L6-30R receptacles.

9.4 Noise and Surge Isolation

Isolation: galvanic isolation, output neutral bonded to ground.

Normal mode EMI/RFI noise attenuation: 40 to 60 dB over 100 kHz to 30 MHz range.

Common mode EMI/RFI noise attenuation: 40 to 60 dB over 100 kHz to 30 MHz range.

Normal mode let-through: < 1% of applied ANSI C62.41 Category A or B ±6 kV test.

Common mode let-through: < 2% of applied ANSI C62.41 Category A or B ±6 kV test.

9.5 Battery Pack

Battery type: spill proof, maintenance free sealed lead-acid.

Nominal battery pack voltage: 48 Vdc.

Typical battery life: 3 to 6 years (depends upon number of discharge cycles and normal ambient

temperature).

Recharge time: see table in section 9.9.

Maximum number of Battery Packs: limited only by desired recharge time.

9.6 Environment

Operating temperature: 0°C to 40°C (32°F to 104°F).

Storage temperature: -15°C to 45°C (5°F to 113°F).

Operating and storage relative humidity: 0 to 95%, non-condensing.

Operating elevation: 0 to 3,000 m (10,000 ft).

Storage elevation: 0 to 15,000 m (50,000 ft).

Electromagnetic immunity: IEC 801-2, 801-3, 801-4, 801-5; severity level III or IV.

Audible noise: < 55 dBA at 1 m (3 ft).

9.7 Physical

UPS dimensions (EU and IU mated): 17.8" H x 13.8" W x 17.8" D (45.2 x 35.1 x 45.2 cm).

Battery pack dimensions: 9.1" H x 6.9" W x 17.8" D (23.1 x 17.5 x 45.2 cm).

UPS weight (EU and IU mated): 145 lb (65.8 kg), 176 lb (79.8 kg) for the 3000VA and 5000VA

models, respectively.

Electronics Unit (EU) weight: 40 lb (18.1 kg), 45 lb (20.4 kg) for the 3000VA and 5000VA models,

respectively. Add 8 lbs (3.6 kg) for shipping independent of IU.

Battery pack weight: 64 lbs (29.0 kg). Add 5 lbs (2.3 kg) for shipping independent of UPS.

Total shipping weight - 3000VA model: 244 lb (110.7 kg). Includes weight of packaging, mated EU

and IU, and one (1) Battery Pack.

Total shipping weight - 5000VA model: 344 lb (156.0 kg). Includes weight of packaging, mated EU

and IU, and two (2) Battery Packs.

Color: beige.

9.8 Approvals

Safety approvals: UL per 1778, CSA per C22.2.

EMC verification: FCC, CDC Class A verified.

Page 36

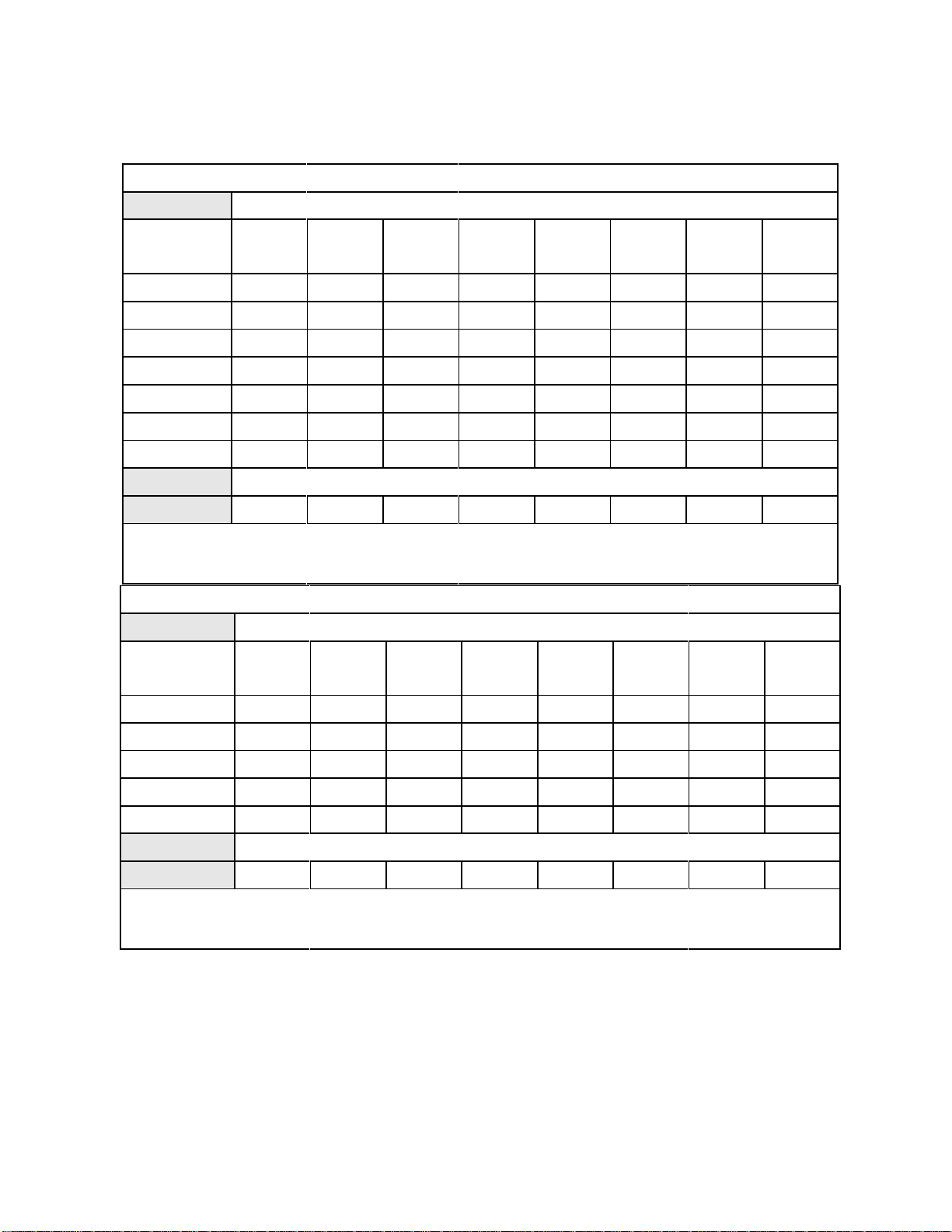

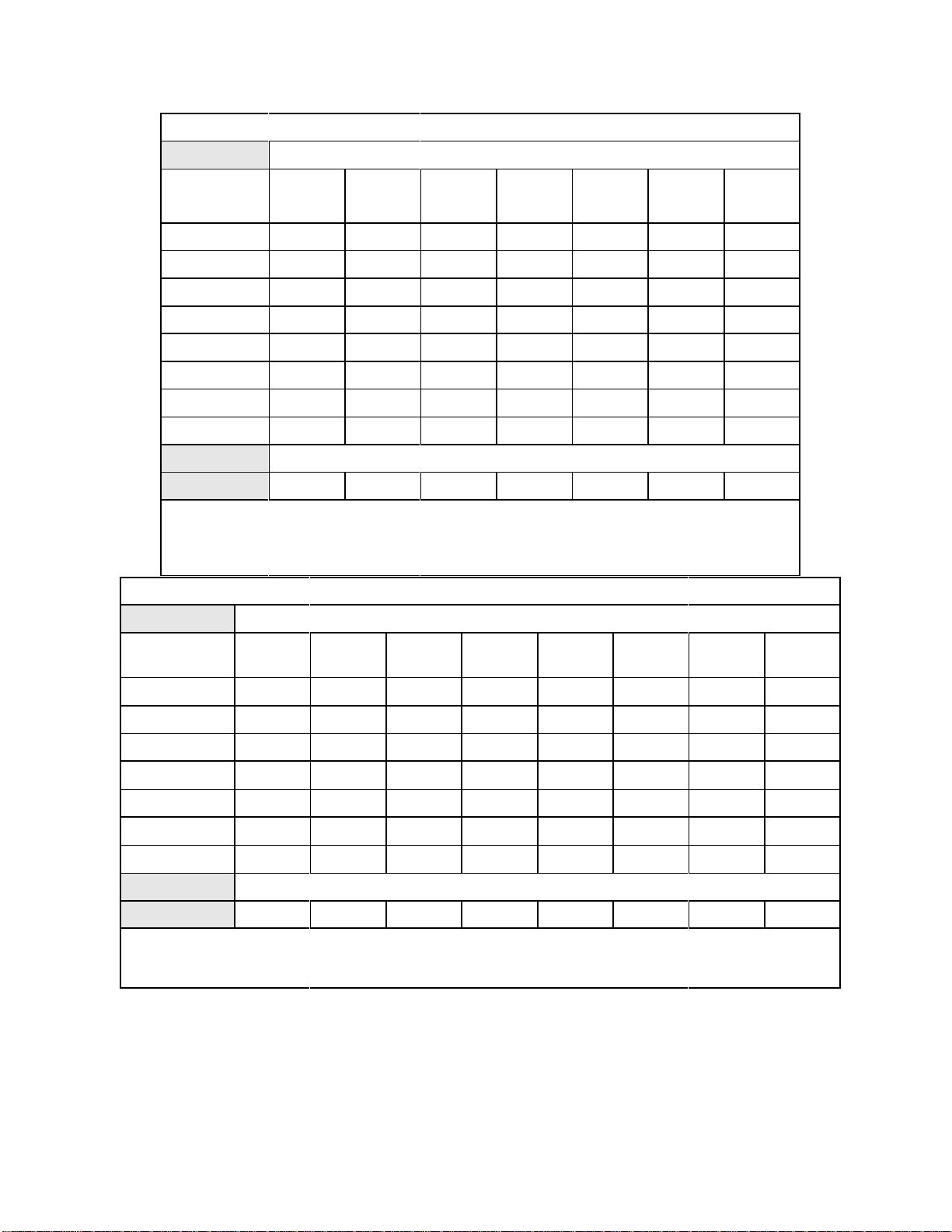

9.9 Typical On-Battery Run Times

Typical On-Battery Run Time Versus Load, 3000 VA Matrix-UPS with SmartCells, in Hours

Number of SmartCells

Computer Load

(VA)

250 3.07 7.20 11.56 15.93 20.29 24.65 29.02 33.38

500 1.46 3.52 5.80 8.24 10.69 13.13 15.57 18.01

1000 0.57 1.46 2.46 3.52 4.58 5.80 7.02 8.24

1500 0.33 0.83 1.46 2.11 2.81 3.52 4.23 4.99

2000 0.22 0.57 0.99 1.46 1.93 2.46 2.99 3.52

2500 0.17 0.46 0.78 1.18 1.59 1.99 2.45 2.90

3000 0.13 0.36 0.62 0.92 1.25 1.59 1.92 2.30

Calculations based on loads with a .75 power factor. Lower power factor loads will yield higher run times.

Run times are typical at 25° C (77° F).

Recharge times to 90% of rated capacity after discharge into 50% of rated load.

Typical On-Battery Run Time Versus Load, 3000 VA Matrix-UPS with SmartCell XR Battery Packs, in Hours

Computer Load

(VA)

1 2 3 4 5 6 7 8

Recharge Time, in Hours

1.2 2.8 2.7 3.8 4.9 6 7 8.1

Number of SmartCell XR Battery Packs

1 2 3 4 5 6 7 8

1000 3 6.75 10.75 14.75 18.75 22.75 26.75 30.75

1500 1.8 4.3 6.9 9.5 12.1 14.7 17.3 19.9

2000 1.2 3 5 7 9 11 13 15

2500 0.9 2.4 4 5.6 7.2 8.8 10.4 12

3000 0.75 1.8 3.25 4.7 6.15 7.6 9.05 10.5

Recharge Time, in Hours

3.8 8.1 12.5 16.9 21.3 25.7 30.1 34.5

Calculations based on loads with a .75 power factor. Lower power factor loads will yield higher run times.

Run times are typical at 25° C (77° F).

Recharge times to 90% of rated capacity after discharge into 50% of rated load.

Page 37

Typical On-Battery Run Time Versus Load, 5000 VA Matrix-UPS with SmartCells, in Hours

Number of SmartCells

Computer Load

(VA)

500 3.07 5.02 7.20 9.38 11.56 13.75 15.93

1000 1.46 2.46 3.52 4.58 5.80 7.02 8.24

1500 0.83 1.46 2.11 2.81 3.52 4.23 4.99

2000 0.57 0.99 1.46 1.93 2.46 2.99 3.52

2500 0.46 0.78 1.18 1.59 1.99 2.45 2.90

3000 0.36 0.62 0.92 1.25 1.59 1.92 2.30

4000 0.24 0.42 0.62 0.83 1.08 1.33 1.59

5000 0.17 0.31 0.46 0.62 0.78 0.98 1.18

The case of one SmartCell does not apply to 5000 VA Matrix-UPS.

Calculations based on loads with a .75 power factor. Lower power factor loads will yield higher run times.

Run times are typical at 25° C (77° F).

Recharge times to 90% of rated capacity after discharge into 50% of rated load.

2 3 4 5 6 7 8

Recharge Time, in Hours

2.8 2.7 3.8 4.9 6 7 8.1

Typical On-Battery Run Time Versus Load, 5000 VA Matrix-UPS with SmartCell XR Battery Packs, in Hours

Number of SmartCell XR Battery Packs

Computer Load

(VA)

1 2 3 4 5 6 7 8

1000 3 6.75 10.75 14.75 18.75 22.75 26.75 30.75

1500 1.8 4.3 6.9 9.5 12.1 14.7 17.3 19.9

2000 1.2 3 5 7 9 11 13 15

2500 0.9 2.4 4 5.6 7.2 8.8 10.4 12

3000 0.75 1.8 3.25 4.7 6.15 7.6 9.05 10.5

4000 0.53 1.25 2.25 3.25 4.25 5.25 6.25 7.25

5000 0.37 0.9 1.6 2.4 3.2 4 4.8 5.6

Recharge Time, in Hours

3.8 8.1 12.5 16.9 21.3 25.7 30.1 34.5

Calculations based on loads with a .75 power factor. Lower power factor loads will yield higher run times.

Run times are typical at 25° C (77° F).

Recharge times to 90% of rated capacity after discharge into 50% of rated load.

Loading...

Loading...