Page 1

Hunter Industrial

Pentium Processor™

Motherboard

Installation Guide

Page 2

Introduction

Contents

Introduction ...................................... V

Hunter Industrial - An Overview....................................... V I

Chapter 1 Pre-Configuration ............ 2

Handling Precautions ............................................................ 2

Static W arning ...................................................................... 2

Step 1 - Setting the Jumpers ............................ 4

Jumper Locations ................................................................. 5

Standard I/O Enable ............................................................. 6

Mouse IRQ Enable............................................................... 6

CMOS Reset ....................................................................... 6

I/O Port IRQ Selection ......................................................... 7

IDE Drives Selection ............................................................ 7

Clock Speed Selection ......................................................... 8

Display Selection .................................................................. 9

Cache Size ........................................................................... 9

Step 2 - DRAM, CPU and Cables Installation......10

Hunter Industrial Memory Configuration........................... 10

Installing Memory Modules ................................................. 10

CPU Installation ................................................................. 12

Installing Cables.................................................................. 14

Power and Control Panel Cables ........................................ 14

Installing Peripheral Cables ................................................. 17

Chapter 2 - W inBIOS Setup ............ 18

Starting WinBIOS Setup..................................................... 18

Using a Mouse with WinBIOS Setup .................................. 18

Using the Keyboard with WinBIOS Setup........................... 18

I

Page 3

Hunter Industrial - Installation Guide

W inBI OS Se tup Ma in Me nu ............................................... 19

Default Settings................................................................... 19

Section 1 - Setup............................................... 2 0

Standard Setup ................................................................ 20

Date/Time........................................................................... 20

Floppy Drive A, B .............................................................. 20

Pri Master/Pri Slave............................................................ 20

Sec Master/Sec Slave......................................................... 20

Configuring an MFM Drive ................................................. 20

User-Defined Drive ............................................................ 21

Configuring IDE Drives ....................................................... 21

Configuring a CD-ROM Drive ............................................ 22

Advanced Setup ............................................................... 22

Quick Boot ........................................................................ 22

BootUp Sequence .............................................................. 22

BootUp NumLock ............................................................. 22

Floppy Drive Swap ............................................................ 22

Floppy Drive Seek ............................................................. 23

Mouse Support .................................................................. 23

T ypematic Rate................................................................... 23

System Keyboard............................................................... 23

Primary Display .................................................................. 23

Password Check ................................................................ 23

OS/2 Compatible Mode ..................................................... 23

W ait For F1 if Error............................................................ 24

Press <F1> to continue....................................................... 24

Hit Del Message Display..................................................... 24

Hit <DEL> if you want to run Setup .................................... 24

Internal Cache .................................................................... 24

External Cache ................................................................... 24

System BIOS Shadow Cacheable....................................... 24

Chipset Setup................................................................... 25

Memory Hole ..................................................................... 25

DRAM Speed .................................................................... 25

IRQ12/M Mouse Function ................................................. 26

II

Page 4

Introduction

8-Bit I/O Recovery Time (SYSCLK).................................. 26

16-Bit I/O Recovery Time (SYSCLK)................................ 26

Power Management Setup............................................... 26

Power Management/APM .................................................. 26

Timeout (Minute) ................................................................ 26

Green PC Monitor Power State .......................................... 27

V ideo Power Down Mode.................................................. 27

Hard Disk Power Down Mode ........................................... 27

Hard Disk Timeout (Minute) ............................................... 27

Standby Timeout (Minute)................................................... 27

Suspend Timeout (Minute) .................................................. 28

Slow Clock Ratio ............................................................... 28

Display Activity .................................................................. 28

PCI/PnP Setup................................................................. 29

Plug and Play A ware OS .................................................... 29

PCI Burst Mode................................................................. 29

PCI Concurrency / PCI Latency Timer (in PCI Clocks)....... 29

PCI Streaming / PCI VGA Palette Snoop ........................... 30

PCI IDE Bus Master .......................................................... 30

Offboard PCI IDE Card ..................................................... 30

Offboard PCI IDE Primary IRQ ......................................... 30

Offboard PCI IDE Secondary IRQ..................................... 30

Reserved Memory Size....................................................... 31

Reserved Memory Address ................................................ 32

Peripheral Setup.............................................................. 32

Onboard FDC.................................................................... 32

Onboard Serial Port1 ......................................................... 32

Onboard Serial Port2 ......................................................... 32

On-board Parallel Port ....................................................... 32

Parallel Port Mode ............................................................. 33

Parallel Port DMA.............................................................. 33

Onboard PCI IDE .............................................................. 33

Section 2 - Utility .............................................. 3 4

Section 3 - Security .......................................... 3 4

Setting a Password ............................................................. 35

III

Page 5

Hunter Industrial - Installation Guide

Changing a Password ......................................................... 35

Anti-V irus........................................................................... 36

Section 4 Default .............................................. 37

Original .............................................................................. 37

Optimal .............................................................................. 37

Fail-Safe ............................................................................ 37

Chapter 3 - Upgrading..................... 38

Upgrading the System Memory ........................................... 38

Upgrading the Microprocessor............................................ 38

Upgrading the Cache Memory ............................................ 38

Appendix A - Tech. Specifications .. 40

Appendix B - Flash Bios.................. 58

Appendix C - Troubleshooting ........ 60

Appendix D - Glossary of Terms..... 62

IV

Page 6

Introduction

Introduction

Thank you for your purchase of the Hunter Industrial system board. The

Hunter Industrial system board design was based on the Intel Triton™

chipset providing the ideal platform for getting the most power of the Intel

Pentium™ processor. With proper installation and maintenance, your

Hunter Industrial will provide years of high performance and trouble free

operation.

This manual provides a detailed explanation into the installation and use of

the Hunter Industrial system board. This manual is written for the novice

PC user/installer. However, as with any major computer component

installation, previous experience is helpful and should you not have prior

experience, it would be prudent to have someone assist you in the

installation. This manual is broken down into 3 chapters and 4 appendix.

Chapter 1 - System Board Pre-Configuration

This chapter provides all the necessary information for installing

the Hunter Industrial. Topics discussed include: Installing the

CPU (if necessary), DRAM installation, jumper settings for CPU,

cache and standard I/O. Connecting all the cables from the system

board to the chassis and peripherals.

Chapter 2 - BIOS Configuration

This chapter discusses the final step in getting your system up and

running - running the BIOS SETUP program.

Chapter 3 - Upgrading

The Hunter Industrial provides a number of expansion options

including memory and cache. All aspects of the upgrade possibilities are covered.

Appendix A - Technical Specifications

A complete listing of all the major technical specifications of the

Hunter Industrial is provided.

Appendix B - Flash BIOS Programming

Provides all the information necessary to program your optional

AMIBIOS Flash BIOS.

V

Page 7

Hunter Industrial - Installation Guide

Appendix C - Troubleshooting

This Chapter lists the solutions for the most common questions

on the Hunter Industrial operation.

Appendix D - Glossary Of Terms

Static Electricity Warning!

The Hunter Industrial has been designed as rugged as possible but can still

be damaged if jarred sharply or struck. Handle the motherboard with care.

The Hunter Industrial also contains delicate electronic circuits that can be

damaged or weakened by static electricity. Before removing the Hunter

Industrial from its protective packaging, it is strongly recommended that

you use a grounding wrist strap. The grounding strap will safely discharged

any static electricity built up in your body and will avoid damaging the

motherboard. Do not walk across a carpet or linoleum floor with the bare

board in hand.

Hunter Industrial - An Overview

The Hunter Industrial represents the ultimate in system board technology.

No other system board available today provides such impressive list of

features:

CPU Support

Intel P54C Pentium™ Processor

AMD K5 Pentium™ Processor

CPU Clock Speeds

75, 90, 100, 120, 133, 150, 166 and 200MHz.

Supported Bus Clocks

50, 60 and 66 MHz.

VI

Page 8

Memory

32 or 36-bit JEDEC standard FPM or EDO SIMMS - 70ns minimum

access speed Memory capacity: 1 to 128MB.

High Speed DRAM Cache

256K of write-back direct-mapped asynchronous cache.

ROM BIOS

AMI© WinBIOS™ BIOS with optional FLASH ROM for easy

field upgrades.

On-Board I/O

• Up to 4 enhanced IDE drives: two PCI IDE controllers

• 2 Floppies up to 2.88 Mb

• Two high speed RS-232 serial ports 16Byte FIFO (16550)

• One Centronics™ compatible bidirectional parallel port

EPP/ECP mode compatible

• PS/2 mouse port

Introduction

Conventions Used in this Manual

When instructed to enter keyboard keystrokes, the text will be noted by:

Enter Keystroke

Information displayed on the screen other than figure is displayed as:

Enter Password

Information presented in a text box denotes special interest. There are two

types:

Important Information - such as static warnings, or

very important instructions

Notes - Such as a brief discussion of memory

types.

VII

Page 9

Chapter 1: Pre-Configuration

Chapter 1

This chapter provides all the necessary information for installing the Hunter

Industrial into a standard PC chassis. The topics discussed ar: installing

the CPU (if necessary), DRAM installation, jumper settings for CPU, cache

and standard I/O.

Pre-Configuration

Handling Precautions

The Hunter Industrial has been designed to be as rugged as possible but

it can be damaged if dropped, jarred sharply or struck. Damage may also

occur by using excessive force in performing certain installation procedures

such as forcing the system board into the chassis or placing too much

torque on a mounting screw.

Take special care when installing or removing the system memory SIMMs.

Never force a SIMM into a socket. Screwdrivers slipping off a screw and

scraping the board can break a trace or component leads, rendering the

board unusable. Always handle the Hunter Industrial with care.

Special Warranty Note:

Products returned for warranty repair will be inspected for damaged caused by improper installation and misuse as described in the previous section and the static warning below. Should the board

show signs of abuse, the warranty will become void

and the customer will be billed for all repairs and

shipping and handling costs.

Static Warning

The Hunter Industrial contains delicate electronic semiconductors that are

highly sensitive to static electricity. These components, if subjected to a

static electricity discharge, can be weakened thereby reducing the serviceable life of the system board. BEFORE THE BOARD IS REMOVED FROM

ITS PROTECTIVE ANTISTATIC PACKAGING TAKE PROPER PRECAUTIONS! Work on a conductive surface that is connected to ground.

Before touching any electronic device, ground yourself by touching an

unpainted metal object or, and highly recommended, use a grounding strap.

1

Page 10

Hunter Industrial - Installation Guide

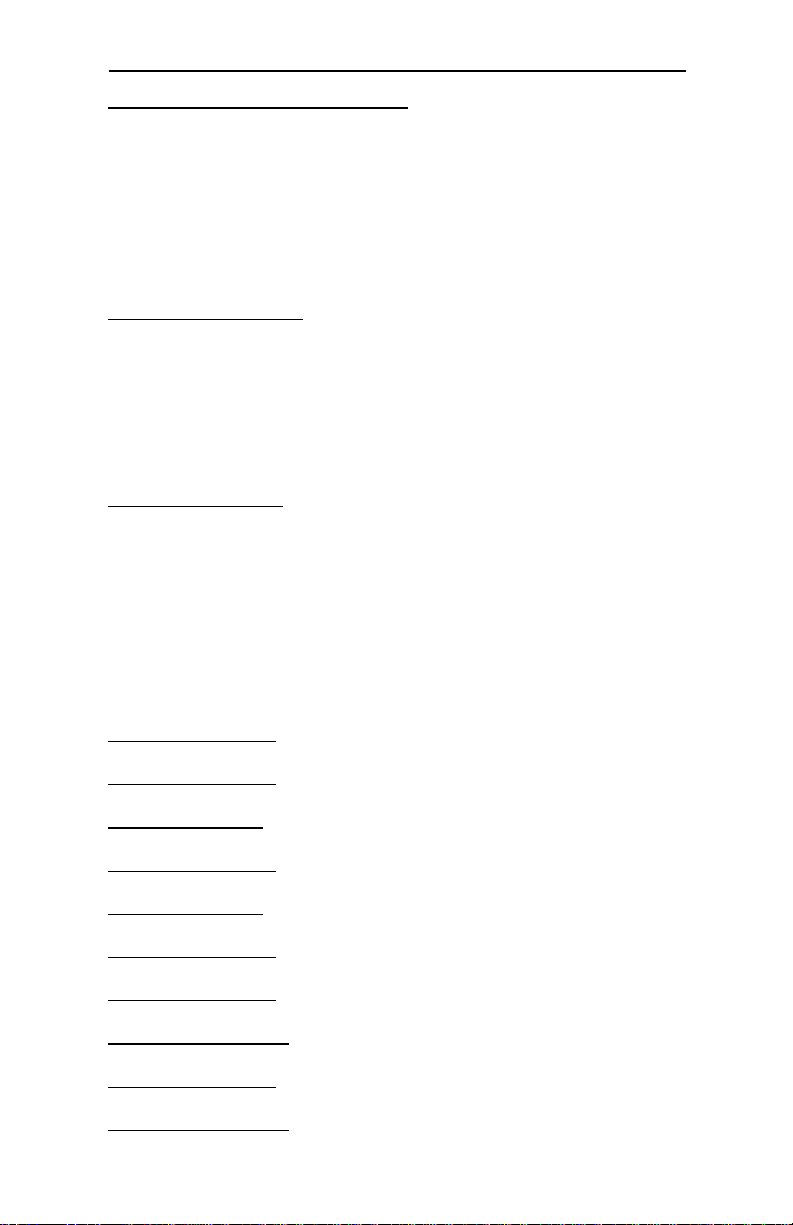

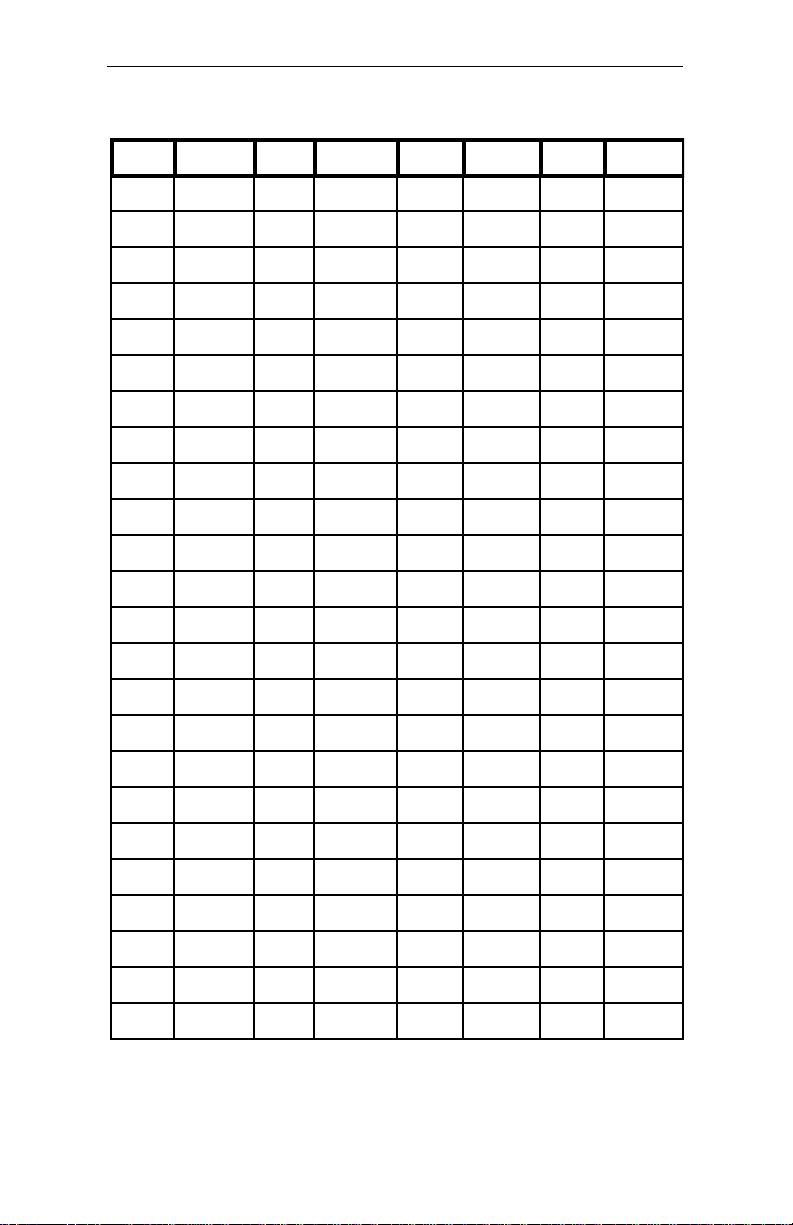

Figure 1-1 Hunter Industrial System Board

Step 1 - Setting the Jumpers

Serial Ports

IDE

Interface

ISA Slots

Intel

Triton

Chipset

PS/2

Keyboard

Power

Connector

Parallel

Port

Floppy

Controller

Memory

Modules

AMIBIOS

2

Microprocessor

External

Cache

Auxiliary

Keyboard

Page 11

Chapter 1: Pre-Configuration

Your Hunter Industrial is equipped with a large number of peripherals and

has the ability to run at a variety of speeds without the need to change any

crystals or oscillators. As such, there is a large number of configuration

jumpers on the board. Taken step by step, setting these jumpers is easy.

We suggest you review each section and follow the instructions.

Jumper Types

Jumpers are small copper pins attached to the system board. Covering two

pins with a shunt closes the connection between them. The Hunter

Industrial examines these jumpers to determine specific configuration

information. There are three different categories of jumpers on the Hunter

Industrial.

A. Two pin jumpers are used for binary selections such as enable,

disable. Instructions for this type of jumper are open, for no shunt

over the pins or closed, when the shunt covers the pins.

B . Three or four pin jumpers are used for multiple selection. Instruc-

tions for these jumpers will indicate which two pins to cover. For

example: for JPx 2-3 the shunt will be covering pins 2 and 3 leaving

pins 1 and 4 exposed.

C . Grouped Jumpers are used when a certain function has multiple

selections. There are two grouped jumpers on the board and

careful attention should be given when setting these jumpers.

Instructions for grouped jumpers are similar to those above Jumper Location and Pin Numbers.

3

Page 12

Hunter Industrial - Installation Guide

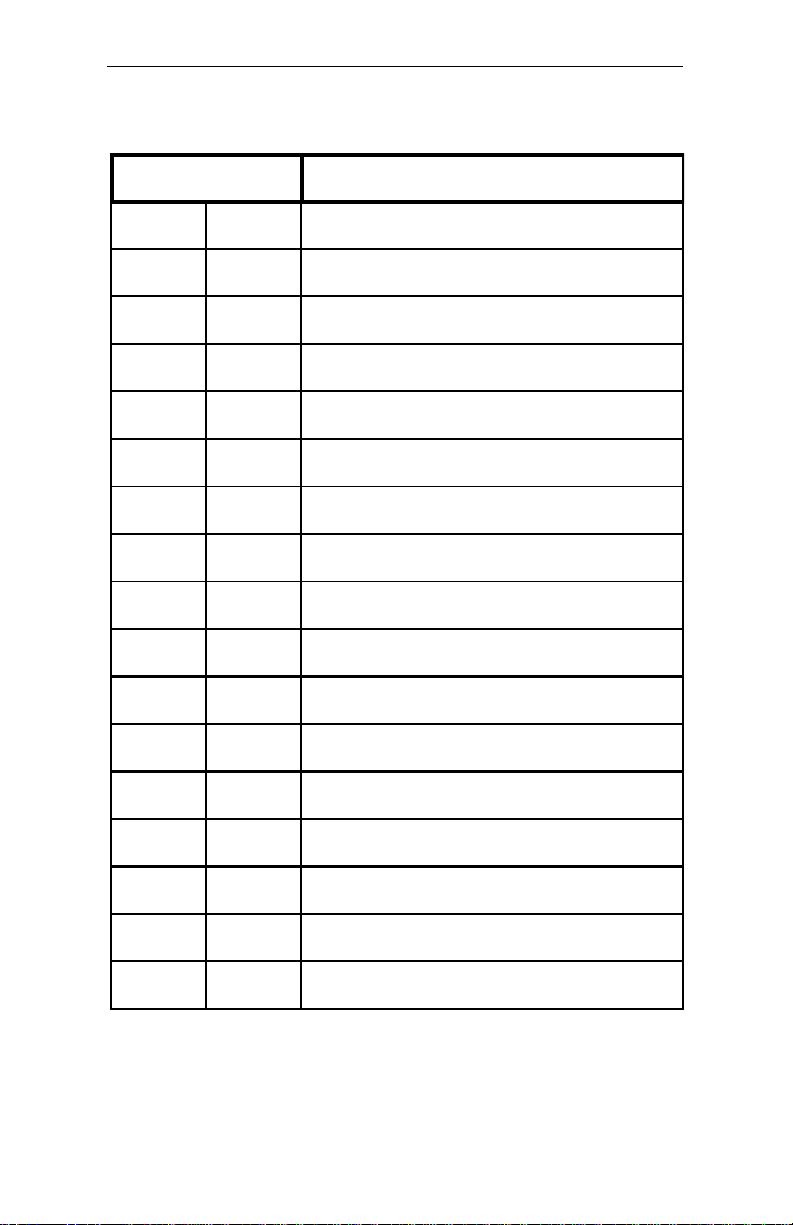

Jumper Locations

Use the diagram below and the tables on the following pages to locate and

set the on-board configuration jumpers.

JP18

JP21

JP22

JP13 JP17

JP19

JP20

JP7

JP9

JP16

JP14

JP10

4

JP28

JP2

JP26

Page 13

Chapter 1: Pre-Configuration

Standard I/O Enable

The Hunter Industrial standard I/O consists of the two serial ports, the

parallel port and floppy disk controller. Jumper JP17 is used to enable

or disable these ports.

Table 1-1 Standard I/O Enable

I/O Enable Disable

JP17 1-2* 2-3

Mouse IRQ Enable

The PS/2 type mouse port on your Hunter Industrial uses IRQ 12 as its

interrupt request line. To enable the interrupt (default) leave Jumper

JP10 on pins 2-3. To disable the interrupt and subsequently the mouse

controller, move the jumper to pins 1-2.

Table 1-2 Mouse IRQ Enable

IRQ12 Disable Enable

JP10 1-2 2-3*

CMOS Reset

This option is provided as a convenience for those who need to reset the

CMOS registers. It should always be set to “Normal” for standard

operation. If the CMOS needs to be reset turn off the system, move JP9

to 2-3, turn the system on, move JP9 back to 1-2 and reset the motherboard.

Table 1-3 CMOS Reset

RTC Normal Reset

JP9 1-2 2-3*

5

Page 14

Hunter Industrial - Installation Guide

I/O Port IRQ Selection

The parallel port and both serial ports must have their IRQs. Normally,

these settings can be left in their default settings and only when conflicts

arise should they be changed. Jumper JP20 is used to select the parallel

port IRQ. Jumper JP19 is used to select the first serial port's IRQ. Jumper

JP18 is used to select the second serial port's IRQ. Use Table 1-8 to select

the IRQs for these options.

Table 1-4 I/O Port IRQ Selection

Port Jumper 1-2 2-3 Open

Parallel Port JP20 IRQ 7* IRQ 5 Disable

First Serial

Port

Second Serial

Port

JP19 IRQ 4* IRQ 5 Disable

JP18 IRQ 3* IRQ 9 Disable

IDE Drives Selection

The Hunter Industrial supports up to 4 IDE drives:

2 IDE drives on the primary PCI IDE controller

2 IDE drives on the secondary PCI IDE controller

The IDE interfaces can be configured in the BIOS.

6

Page 15

Chapter 1: Pre-Configuration

Clock Speed Selection

The jumpers JP2, JP7 and JP 26 allow you to choose the appropriate CPU

speed, without changing crystals and oscillators.

Table 1-5 Clock Frequency

Clock Frequency JP7

50MHz 1-2

60MHz 3-4

66MHz 5-6*

Table 1-6 Clock Speed Selection

50 MHz 60MHz 66Mhz JP2 JP26

75 90 100 1-2 1-2 1.5x

100 120 133 2-3 1-2 2.0x

150 180 200 1-2 2-3 3.0x

N/A 150 166 2-3 2-3 2.5x

Table 1-7 DMA Configuration for ECP Parallel Port

Port Jumper 1-2* 3-4 5-6 7-8

JP21 Disabled DMA 3 DMA 5 DMA 6

ECP

DMA

JP22 Disabled DMA 3 DMA 5 DMA 6

Always move Both jumpers (JP21 and JP22) together.

Multiplier

7

Page 16

Hunter Industrial - Installation Guide

Display Selection

Select the type of display trough JP14, 1-2 for color and 2-3 for

monochrome.

Table 1-8 Display Selection

Display 1-2 2-3

JP14 Mono Color*

Cache Size

The jumper JP28 allows you to choose the cache size desired.

Table 1-9 Cache Size Selection

Cache Size 256K 512K

JP28 1-2* 2-3

Flash BIOS

The jumper JP13 allows you to choose the Flash BIOS setup.

Table 1-10 Flash BIOS Selection

Flash BIOS Intel 5V Flash

JP13 1-2* 2-3

8

Page 17

Chapter 1: Pre-Configuration

Step 2 - DRAM, CPU and Cables

Installation

Depending upon how your Hunter Industrial is configured you may need

to install the following:

• DRAM (SIMMs)

• CPU

Hunter Triton Configuration

The Hunter Industrial uses standard or EDO 70ns access speed

or faster SIMMs. It is very important that the quality of the

SIMMs is good. Undesirable operation of the system may result

if poor quality SIMMs are used. Always purchase your memory

from a reliable source.

The Hunter Industrial uses standard 32 or 36-Bit

SIMMs. They are slight larger than other 9-Bit

SIMMs that are also commonly used on systems

boards. They are configured into four, 8-Bit (or 1

Byte) sections. Thus, a total of 32 Bits ( no parity)

or 36 Bits (with parity) are stored. This is often

confusing because these SIMMs are commonly

referred to as 256K by 32 or 36 or 1MB by 32 or 36.

To determine the actual capacity of the SIMM,

simply multiply the 256K, 512K or 1MB by 4. Thus

the actual SIMMS capacity is 1MB, 2MB and 4MB

respectively.

Installing Memory Modules

The Hunter Industrial has 4 memory module sockets. The order in wich

they should be populated is from the inside of the board outward. Note that

each socket is labeled: SM1, SM2, SM3, SM4. Refer to figure 1.3.

At least TWO memory modules MUST be installed

at a time.

9

Page 18

Hunter Industrial - Installation Guide

When inserting the memory modules, note the notch on the edge of each

module. This notch is designed to permit insertion in only one way. This

notch must be pointed towards the keyboard connector.

Start with the innermost socket (SM1). Gently place the module into the

desired socket at a 30-45° angle. Then gently rotate or rock the module

into an upright position. Never force a memory module into its

socket. Rather, double check the notch and gently rock it into place.

When the module has been properly installed, the metal latches on either

side of the memory module will “click” into place. (See figure 1-2).

Repeat the mentioned steps until all memory modules are installed. No

jumpers are involved in DRAM configuration.

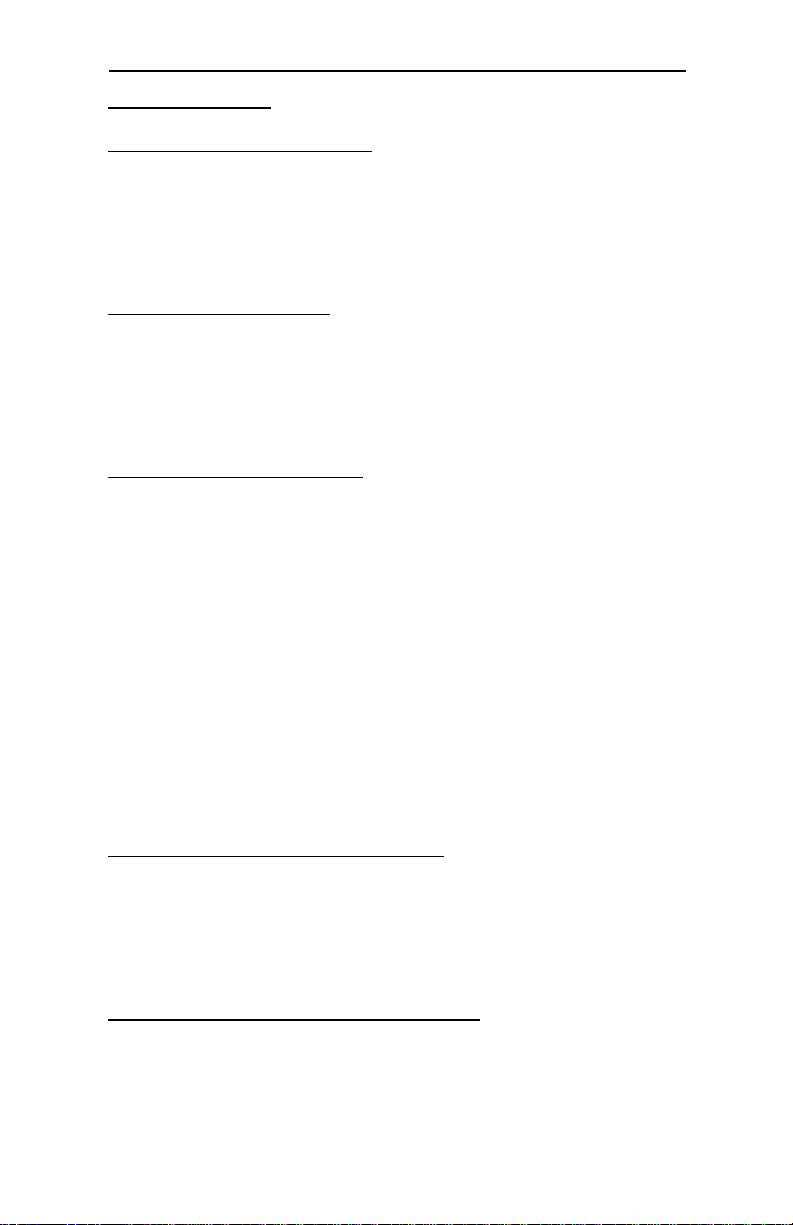

Figure 1-2 SIMM Insertion

10

Gently place the SIMM into the desired socket

at 30°- 45° angle.

Then gently rotate or rock the SIMM into an

upright position. Never force a SIMM into

its socket.

Double check the notch and gently rock it into

place if properly installed the SIMM will "click".

Page 19

Chapter 1: Pre-Configuration

Figure 1-3 Memory Modules Socket Locations

SM1

SM2

SM3

SM4

Bank 0

Bank 1

CPU Installation

The Hunter Industrial currently supports the following CPUs:

• Intel P54C Pentium 75, 90, 100, 120, 150, 166 and 200MHz.

• AMD K5 75, 90, 100 and 133MHz.

1. Improper installation of the CPU may cause

permanent damage to both the system board and

the CPU. -- Void of warranty

2. Always handle the CPU by the edges, never

touch the pins.

3. Always use a heatsink and CPU fan.

11

Page 20

Hunter Industrial - Installation Guide

Using Figure 1-4, locate the diagonal notch on the CPU chip. This notch

represents pin one. The Pentium processor also has small dot as well

indicating pin 1. DO NOT USE THE CHIP LOGO OR LETTERING

TO LOCATE PIN ONE.

Locate the CPU socket on your Hunter Industrial system board. Pin 1 on

the socket is located in the lower left hand corner of the socket.

Figure 1-4 CPU Alignment

To install the Pentium processor lift the lever of the ZIF socket and gently

insert the CPU. Make sure the CPU is inserted all the way. Lower the

lever. See figure 1-5.

Figure 1-5 CPU Socket alignment

Pin # 1 Lever

12

Page 21

Chapter 1: Pre-Configuration

This completes the installation of the CPU. Now is a good time to double

check both the CPU and SIMM installation to make sure that these devices

have been properly installed.

Installing Cables

Power and Control Panel Cables

Figure 1-6 Power and Control Panel Cables

Orange - Power good

Red +5V

P8

P9

Yellow +12V

Blue -12V

Ground

Ground

Ground

Ground

White -5V

Red +5V

Red +5V

Red +5V

Connect the power supply cables to the system board. There is no formal

convention for color coding the wires on power supplies except for ground

wires which are black. Use figure above to determine the proper cable

locations.

Next install the control panel cables for each of the control panel headers.

These headers are located along the bottom of the board. Again, there is

no standard convention for color coding these cables. However, the

connectors for “Key lock/Power LED” and “Speaker” are keyed. While

the actual connector on the cable harness may not be keyed, there will

probably be a wire missing.

13

Page 22

Hunter Industrial - Installation Guide

Figure 1-7 On-Board Connectors Location

J10 - Serial 2

IDE 2

PCI IDE 2

IDE1

PCI IDE 1

J11 - Serial 1

J5 - PS/2 Mouse

J6

Keyboard

P1

Power AT

J9

Floppy

J16

Speaker

J18

Power LED/

Kbd lock

J17

IDE LED

J15

Reset

J13

IR (optional)

J12

Parallel

J7

Aux.Keyboard

J19

CPU Fan +12V

14

Page 23

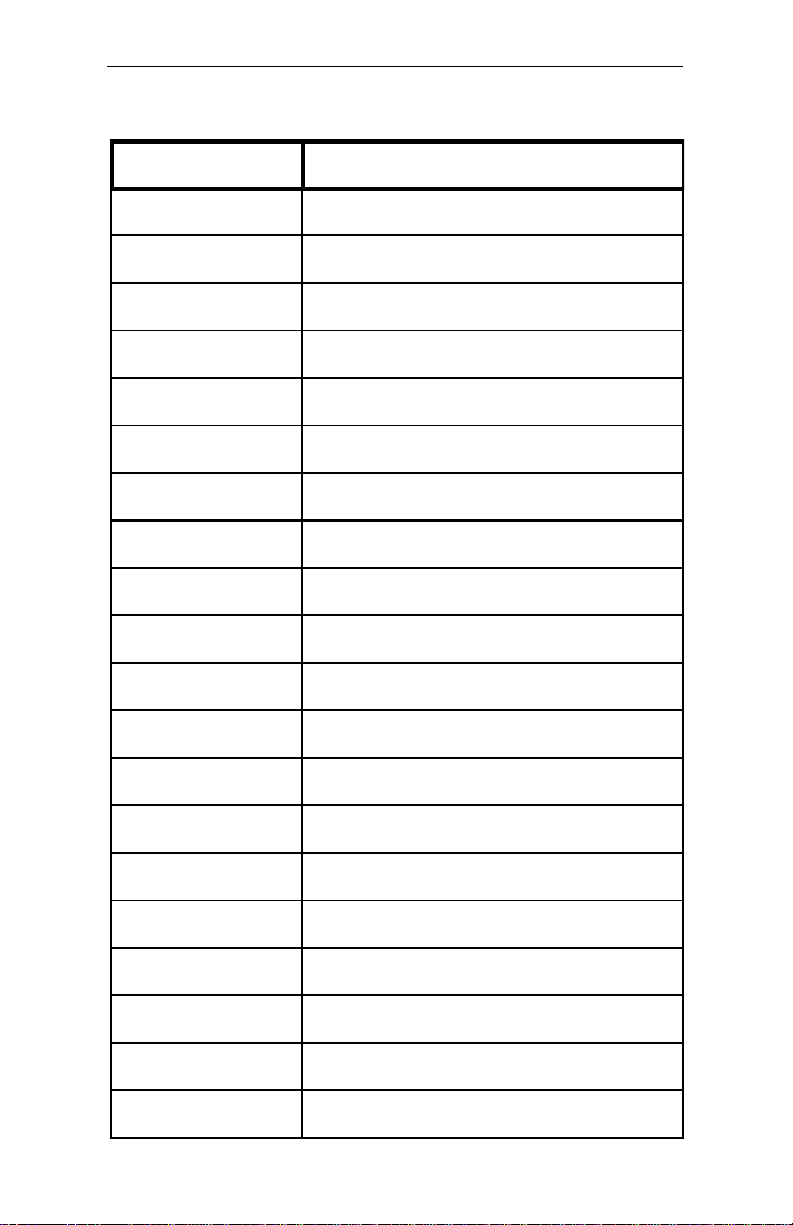

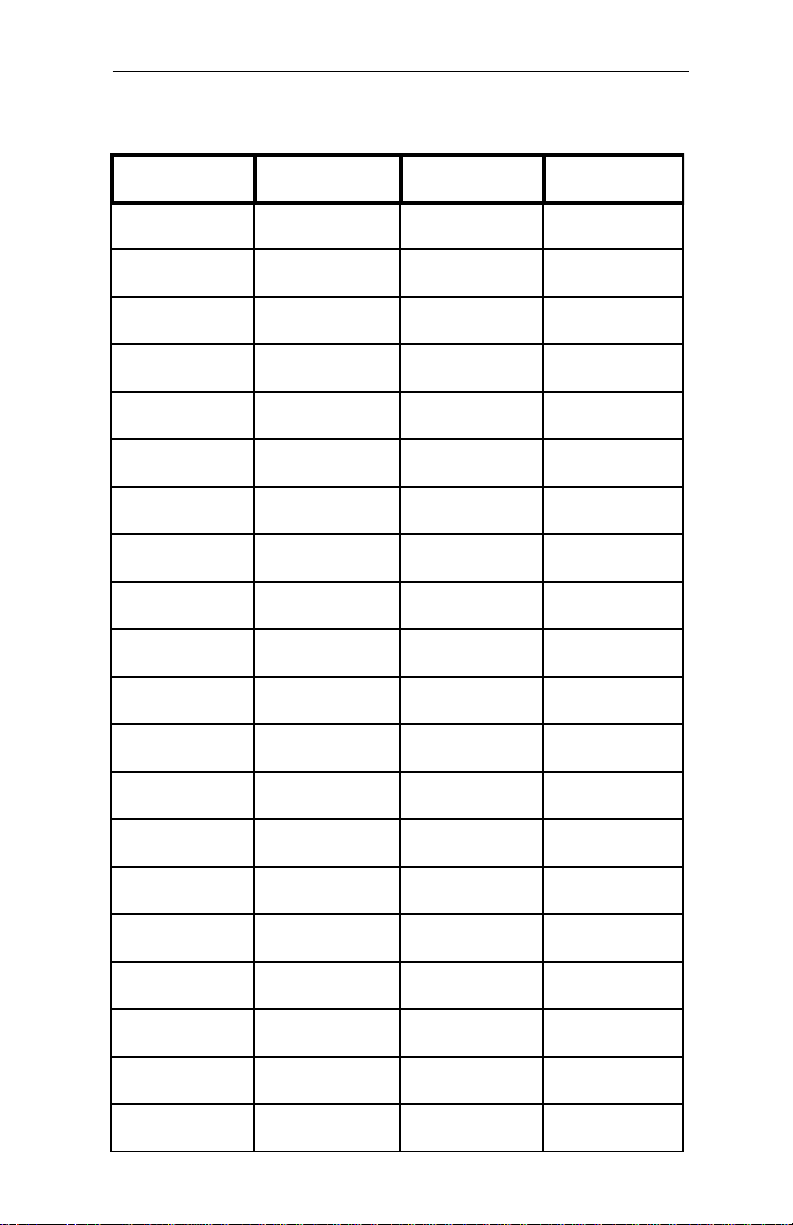

Table 1-11 Control Panel Connectors

Connector Description

J5 PS/2 mouse

J6 Keyboard

J7 Aux. Keyboard

J9 Floppy

J10 Serial 2

J11 Serial 1

J12 Parallel

J13 Infra Red Interface

J15 Reset

Chapter 1: Pre-Configuration

J16

J17 IDE LED 1-positive/2-signal

J18

J19 CPU Fan 1&3-GND/2-12V

P1 AT Power

IDE 1 PCI IDE

IDE 2 PCI IDE

1-SPK/2-key/3-GND/4-VCC

Speaker

1-LED/2-key/3-GND/

4&5-keylock

15

Page 24

Hunter Industrial - Installation Guide

Installing Peripheral Cables

Begin with the top of the Hunter Industrial system working left to right.

Refer Figure 1-1 for the locations of each of the peripheral connectors.

Now it is a good time to install the internal peripherals such as floppy and

hard disk drives. Do not connect the power cable to these peripherals as it

is easier to attach the bulky ribbon cables before the smaller power

connectors. If you are installing more than one IDE drive double check your

master/slave jumpers on the drives. Review the information supplied with

your drive for more information on this subject.

Connect the floppy cable (not included) to the system board. Then connect

remaining ends of the ribbon cable to the appropriate peripherals.

Finally, connect the IDE cable (not included) to the system. Then connect

remaining ends of the ribbon cable to the appropriate peripherals. This

concludes the hardware installation of your Hunter Industrial system.

Now it is a good time to re-check all of the cable connections to make

sure they are correct. It is also a good idea to label each of the external

peripheral connectors - COM1, COM2, Mouse and Parallel.

16

Page 25

User's Notes:

Chapter 1: Pre-Configuration

17

Page 26

Hunter Industrial - Installation Guide

Chapter 2

WinBIOS Setup

Your Hunter Industrial features an AMI BIOS with available a new type of

system BIOS Setup utility. WinBIOS Setup has a graphical user interface

that permits mouse access, and is so compact that it can reside on the

same ROM as the system BIOS. The system configuration parameters are

set via WinBIOS Setup. Since WinBIOS Setup resides in the ROM BIOS,

it is available each time the computer is turned on.

Starting WinBIOS Setup

As POST executes, the following appears:

Hit <DEL> if you want to run SETUP

Using a Mouse with WinBIOS Setup

WinBIOS Setup has a built-in mouse driver and can be accessed

by either a serial or PS/2-type mouse.

Using the Keyboard with WinBIOS Setup

18

WinBIOS Setup has a built-in keyboard driver that uses simple

keystroke combinations:

Keystroke Function

<Tab> Move to the next window or field.

, , , Move to the next field to the right, left, above, or

below.

<Enter> Select in the current field.

+ Increments a value.

- Decrements a value.

<Esc> Closes the current operation and return to previous

level.

<PgUp> Returns to the previous page.

<PgDn> Advances to the next page.

<Home> Returns to the beginning of the text.

<End> Advances to the end of the text.

<Alt> <H> Access a help window.

<Alt> <Spacebar> Exit WINBIOS Setup.

Alphabetic keys A to Z are used in the Virtual Keyboard, and are not

case-sensitive.

Numeric keys 0 to 9 are used in the Virtual Keyboard and Numeric

Keypad.

Page 27

WinBIOS Setup Main Menu

The WinBIOS Setup main menu is organized into four windows.

Each window corresponds to a section in this chapter.

Each section contains several icons. Clicking on each icon

activates a specific function. The WinBIOS Setup icons and

functions are described in this chapter. Some options may not be

available in your BIOS. The sections are:

Setup: Described in Section 1. This section has five

icons that permit you to set system configura-

tions: standard setup, advanced setup, chipset

setup, power management setup and periph

eral setup.

Utilities: Described in Section 2. This section has two

icons that perform system functions.

Security: Described in Section 3. This section has three

icons that control WinBIOS security features.

Default: Described in Section 4. This section has

three icons that permit you to select a group of

settings for all WinBIOS Setup options.

Chapter 2: Bios Configuration

Default Settings

Original: Returns settings to previous settings.

Optimal: These settings provide the best performance

Fail-Safe: These settings are more likely to configure a

characteristics.

workable computer when something is wrong.

If you cannot boot the computer successfully,

select the Fail-Safe WinBIOS Setup options

and try to diagnose the problem after the com-

puter boots. These settings do not provide

optimal performance.

19

Page 28

Hunter Industrial - Installation Guide

Section 1Setup

WINBIOS Setup can have up to six separate screens. Different types of

system configuration parameters are set on each screen.

Standard Setup

Standard Setup options are displayed by choosing the Standard

icon from the WINBIOS Setup menu. All Standard Setup options

are described below.

Date/Time

Select the Date/Time option to change the date or time. The current

date and time are displayed. Enter new values through the displayed window.

Floppy Drive A, B

Choose the Floppy Drive A or B icon to specify the floppy drive

type. The settings are 360 KB 5¼”, 1.2 MB 5¼”, 720 KB 3½”,

1.44 MB 3½”, or 2.88 MB 3½”.

Pri Master Pri Slave

Sec Master Sec Slave

Choose these icons to configure the hard disk drive named in the

option. When you click on an icon, the following parameters are

listed: Type, LBA/Large Mode, Block Mode, 32Bit Mode, and PIO

Mode. All parameters relate to IDE drives except Type.

Configuring an MFM Drive

If configuring an old MFM hard disk drive, you must know the

drive parameters (number of heads, number of cylinders, number

of sectors, the starting write precompensation cylinder, and drive

capacity). Choose Type and choose the appropriate hard disk

drive type (1 - 46). If the drive parameters of your MFM drive do

not match any drive type listed, select User in the Type field and

enter the drive parameters on the screen that appears.

20

Page 29

User-Defined Drive

If you are configuring a SCSI drive or an MFM, RLL, ARLL, or ESDI

drive with drive parameters that do not match drive types 1-46, you

can select the User in the Type field. You must then enter the drive

parameters on the screen that appears. The drive

parameters include:

Cylinder (number of cylinders),

Hd (number of heads),

WP (starting write precompensation cylinder),

Sec (number of sectors),

Size (drive capacity).

Configuring IDE Drives

If the hard disk drive to be configured is an IDE drive, select the

appropriate drive icon (Pri Master, Pri Slave, Sec Master, or Sec

Slave). Select the IDE Detect icon to automatically detect all drive

parameters.

The BIOS automatically detects the IDE drive parameters (including ATAPI CD-ROM drives) and displays them. Click on the OK

button to accept these parameters Or you can set the parameters

manually if you are absolutely certain that you know the correct

IDE drive parameters.

Chapter 2: Bios Configuration

• Click on LBA/Large Mode and choose On to enable support

for IDE drives with capacities greater than 528 MB.

• Click on Block Mode and choose On to support IDE drives

that use Block Mode.

• Click on 32Bit Mode and click on On to support IDE drives

that permit 32-bit accesses.

• Click on PIO Mode to select the IDE Programmed I/O mode.

PIO programming also works with ATAPI CD-ROM drives.

The settings are Auto, 0, 1, 2, 3, 4, or 5. Click on Auto to allow

the BIOS to automatically find the PIO mode that the IDE drive

being configured uses. If you select 0-5 you must make

absolutely certain that you are selecting the PIO mode

supported by the IDE drive being configured.

21

Page 30

Hunter Industrial - Installation Guide

Configuring a CD-ROM Drive

Select the appropriate drive icon (Pri Master, Pri Slave, Sec Master,

or Sec Slave). Choose the Type parameter and select CDROM. You

can boot the computer from a CD-ROM drive. You can also choose

Auto and let the BIOS automatically set the correct drive parameters.

Advanced Setup

Advanced Setup options are displayed by choosing the Advanced icon from the WINBIOS Setup main menu. All Advanced

Setup options are described in this section.

Quick Boot

Set this option to Enabled to instruct the BIOS to boot quickly

when the computer is powered on. This option replaces the old

Above 1 MB Memory Test Advanced Setup option. The settings

are: enabled and disabled.

The Optimal and Fail-Safe default settings are Enabled.

BootUp Sequence

This option sets the sequence of boot drives (floppy drive A:, hard

disk drive C:, or a CD-ROM drive) that the BIOS attempts to boot

from after AMIBIOS POST completes. The settings are

C:,A:,CDROM, CDROM,A:,C:, or A:,C:, CDROM.

The default settings are C:,A:,CDROM.

BootUp NumLock

Set this option to Off to turn the Num Lock key off when the

computer is booted so you can use the arrow keys on both the

numeric keypad and the keyboard. The settings are On or Off. The

default settings are On.

Floppy Drive Swap

Set this option to Enabled to permit drives A: and B: to be

swapped. The settings are Enabled or Disabled. The default

settings are Disabled.

22

Page 31

Floppy Drive Seek

Set this option to Enabled to specify that floppy drive A: will

perform a Seek operation at system boot. The settings are Dis-

abled or Enabled. The optimal and fail-safe default settings are

Disabled.

Mouse Support

When this option is set to Enabled, the BIOS supports a PS/2-type

mouse. The settings are Enabled or Disabled. The default settings are Enabled.

Typematic Rate

This option specifies the speed at which a keyboard keystroke is

repeated. The settings are Fast or Slow. The Optimal and Fail-Safe

default settings are Fast.

System Keyboard

This option specifies that a keyboard is attached to the computer.

The settings are Present or Absent. The Optimal and Fail-Safe

default settings are Present.

Chapter 2: Bios Configuration

Primary Display

This option specifies the type of display monitor and adapter in

the computer. The settings are Mono, CGA40, CGA80, EGA/VGA,

or Absent. The Optimal and Fail-Safe default settings are EGA/

VGA.

Password Check

This option enables password checking every time the computer

is powered on or every time WINBIOS Setup is executed. If Always

is chosen, a user password prompt appears every time the computer is turned on. If Setup is chosen, the password prompt

appears if WINBIOS is executed.

The Optimal and Power-On defaults are Setup.

OS/2 Compatible Mode

Set this o ption to Enabled to permit the BIOS to run with IBM OS/

2. The settings are Enabled or Disabled. The default settings are

Disabled.

23

Page 32

Hunter Industrial - Installation Guide

Wait For F1 if Error

The BIOS POST error messages are followed by:

Press <F1> to continue

If this option is set to Disabled, the BIOS does not wait for you

to press the <F1> key after an error message. The settings are

Disabled or Enabled. The Optimal and Fail-Safe default settings

are Enabled.

Hit Del Message Display

Set this option to Disabled to prevent the message

Hit <DEL> if you want to run Setup

from appearing on the first BIOS screen when the computer boots.

The settings are Disabled or Enabled. The Optimal and Fail-Safe

default settings are Enabled.

Internal Cache

This option specifies the caching algorithm used for L1 internal

cache memory. The settings are: Disabled or Write Back (default).

External Cache

This option specifies the caching algorithm used for L2 secondary

(external) cache memory. The settings are:Disabled or Enabled

(default).

System BIOS Shadow Cacheable

When this option is set to Enabled, the contents of the F0000h

system memory segment can be read from or written to L2

secondary cache memory. The contents of the F0000h memory

segment are always copied from the BIOS ROM to system RAM

for faster execution. The settings are Enabled or Disabled. The

Optimal default setting is Enabled. The Fail-Safe default is Dis-

abled.

24

Page 33

C000,16K Shadow

C400,16K Shadow

C800,16K Shadow

CC00,16K Shadow

D000,16K Shadow

D400,16K Shadow

D800,16K Shadow

C000,16K Shadow

These options control the location of the contents of the 16KB of

ROM beginning at the specified memory location. If no adaptor

ROM is using the named ROM area, this area is made available to

the local bus. The settings are: Enabled, Disabled and Cached.

In the BIOS for the Intel Triton chipset, the E000h page is used as

ROM during POST, but shadowing is disabled and the ROM CS#

signal is disabled to make the E000h page available on the local

bus.

Chapter 2: Bios Configuration

Chipset Setup

Memory Hole

Use this option to specify an area in memory that cannot be

addressed on the ISA bus. The settings are Disabled, 512-640K

or 15-16MB. The default setting is Disabled.

DRAM Speed

Specify the RAS access speed of the SIMMs installed in the

motherboard as system memory. The settings are 60ns or 70 ns.

The default is 70ns.

25

Page 34

Hunter Industrial - Installation Guide

IRQ12/M Mouse Function

Set this option to Enabled to specify that IRQ12 will be used for

the mouse. The settings are Disabled or Enabled. The Optimal and

Fail-Safe default settings are Enabled.

8-Bit I/O Recovery Time (SYSCLK)

This option specifies the length of the delay (in SYSCLKs)

inserted between consecutive 8-bit I/O operations. The settings

are 1, 2, 3, 4, 5, 6, 7, or 8. The Optimal and Fail-Safe default settings

are 1.

16-Bit I/O Recovery Time (SYSCLK)

This option specifies the length of the delay (in SYSCLKs)

inserted between consecutive 16-bit I/O operations. The settings

are 1, 2, 3, 4, 5, 6, 7, or 8. The Optimal and Fail-Safe default settings

are 1.

Power Management Setup

Power Management Setup options are displayed by choosing the

Power Mgmt icon from the WINBIOS Setup main menu. All Power

Management Setup options are described in this section.

Power Management/APM

Set this option to Enabled to enable the power management and

APM (Advanced Power Management) features. The BIOS uses

the RTC Alarm function to wake the computer at a pre-specified

time. The settings are Enabled or Disabled or Instant On. The

default settings are Disabled.

Inst-On Timeout (Minute)

This option allow the stand by feature. Set the time from Disabled

up to 15 minutes. The default setting is Disabled.

26

Page 35

Chapter 2: Bios Configuration

Green PC Monitor Power State

This option specifies the power management state that the

Green PC-compliant video monitor enters after the specified

period of display inactivity has expired. The settings are Off,

Standby, or Suspend. The default setting is Standby.

Video Power Down Mode

This option specifies the power management state that the video

subsystem enters after the specified period of display inactivity

has expired. The settings are Disabled, Standby, or Suspend.

The default settings are Disabled.

Hard Disk Power Down Mode

This option specifies the power management state that the hard

disk drive enters after the specified period of display inactivity

has expired. The settings are Disabled, Standby, or Suspend.

The default settings are Disabled.

Hard Disk Timeout (Minute)

This option specifies the length of a period of hard disk inactivity. When this period expires, the hard disk drive enters the

power-conserving mode specified in the Hard Disk Power

Down Mode option described on the previous page. The settings are Disabled, 1 Min (minutes), and all one minute intervals

up to and including 15 Min. The default settings are Disabled.

Standby Timeout (Minute)

This option specifies the length of the period of system inactivity when the computer is in Full-On mode before the computer

is placed in Standby mode. In Standby mode, some power use is

curtailed. The settings are Disabled, 1 Min, 2 Min, and all one

minute intervals up to and including 15 Min. The default settings

are Disabled.

27

Page 36

Hunter Industrial - Installation Guide

Suspend Timeout (Minute)

This option specifies the length of the period of system inactivity

when the computer is already in Standby mode before the computer is placed in Suspend mode. In Suspend mode, nearly all

power use is curtailed. The settings are Disabled, 1 Min, 2 Min,

and all one minute intervals up to and including 15 Min. The default

settings are Disabled.

Slow Clock Ratio

This option specifies the speed at which the system clock runs in

power saving modes. The settings are expressed as a ratio

between the normal clock speed and the power down clock speed.

The settings are 1:1, 1:2 (half as fast as normal), 1:4 , 1:8, 1:16,

1:32, 1:64, or 1:128. The default setting is 1:8.

Display Activity

This option specifies if the BIOS is to monitor activity on the

display monitor for power conservation purposes. When this

options set to Monitor and there is no display activity for the

length of time specifed in the value in the Full-On to Standby

Timeout (Min) option, the computer enters a power saving state.

The settings are Monitor or Ignore. The default settings are

Ignore.

IRQ 3 - Monitor

IRQ 4 - Monitor

IRQ 5 - Ignore

IRQ 7 - Monitor

IRQ 9 - Ignore

IRQ 10 - Ignore

IRQ 11 - Ignore

IRQ 12 - Monitor

IRQ 13 - Ignore

IRQ 14 - Monitor

28

Page 37

IRQ 15 - Monitor

These options enable event monitoring. When the computer is in

a power saving mode, activity on the named interrupt request line

is monitored by the BIOS. When any activity occurs, the computer

enters Full On mode.

Each of these options can be set to Monitor or Ignore. The default

setting for all options are as above indicated.

PCI/PnP Setup

PCI/PnP Setup options are displayed by choosing the PCI/PnP

Setup icon from the WINBIOS Setup main menu. All PCI/PnP

Setup options are described in this section

Plug and Play Aware OS

Set this option to Yes if the operating system installed in the

computer is Plug and Play-aware. The BIOS only detects and

enables PnP ISA adapter cards that are required for system boot.

The Windows 95 operating system detects and enables all other

PnP-aware adapter cards. Windows 95 is PnP-aware. Set this

option to No if the operating system (such as DOS, OS/2, Windows 3.x) does not use PnP. You must set this option correctly or

PnP-aware adapter cards installed in your computer will not be

configured properly. The settings are No or Yes. The Optimal and

Fail-Safe default settings are No.

Chapter 2: Bios Configuration

PCI Burst Mode

Set this option to Enabled to enable PCI burst mode. The settings

are Disabled or Enabled. The Optimal default setting is Enabled.

The Fail-Safe default setting is Disabled.

PCI Concurrency

PCI Latency Timer (in PCI Clocks)

This option sets latency of all PCI devices on the PCI bus. The

settings are in units equal to PCI clocks. The settings are 32, 64,

96, 128, 160, 192, 224, or 248. The Optimal and Fail-Safe default

settings are 64.

29

Page 38

Hunter Industrial - Installation Guide

PCI Streaming

PCI VGA Palette Snoop

This option must be set to Enabled if any ISA adapter card

installed in the computer requires VGA palette snooping. The

settings are Disabled or Enabled. The Optimal and Fail-Safe

default settings are Disabled.

PCI IDE Bus Master

Set this option to Enabled to specify that the IDE controller on the

PCI local bus has bus mastering capability. The settings are

Disabled or Enabled. The Optimal and Fail-Safe default settings

are Disabled.

Offboard PCI IDE Card

This option specifies if an offboard PCI IDE controller adapter card

is used in the computer. You must also specify the PCI expansion

slot on the motherboard where the offboard PCI IDE controller

card is installed. If an offboard PCI IDE controller is used, the

onboard IDE controller on the motherboard is automatically

disabled. The settings are Erase, Auto, Slot1, Slot2, Slot3, or

Slot4.

If Auto is selected, AMIBIOS automatically determines the correct

setting for this option. The Optimal and Fail-Safe default settings

are Auto.

In the AMIBIOS for the Intel Triton chipset, this option forces IRQ

14 and 15 to a PCI slot on the PCI local bus. This is necessary to

support non-compliant PCI IDE adapter cards.

Offboard PCI IDE Primary IRQ

This option specifies the PCI interrupt used by the primary IDE

channel on the offboard PCI IDE controller. The settings are

Disabled, INTA, INTB, INTC, INTD, or Hardwired. The Optimal

and Fail-Safe default settings are Disabled.

Offboard PCI IDE Secondary IRQ

This option specifies the PCI interrupt used by the secondary IDE

channel on the offboard PCI IDE controller. The settings are

Disabled, INTA, INTB, INTC, INTD or Hardwired. The Optimal

and Fail-Safe default settings are Disabled.

30

Page 39

IRQ3

IRQ4

IRQ5

IRQ7

IRQ9

IRQ10

IRQ11

IRQ12

IRQ14

IRQ15

Chapter 2: Bios Configuration

These options specify the bus that the named interrupt request

lines (IRQs) are used on. These options allow you to specify IRQs

for use by legacy ISA adapter cards.

These options determine if the BIOS should remove an IRQ from

the pool of available IRQs passed to BIOS configurable devices.

The available IRQ pool is determined by reading the ESCD

NVRAM (Flash BIOS ROM only). If more IRQs must be removed

from the pool, the end user can use these PCI/PnP Setup options

to remove the IRQ by assigning the option to the ISA/EISA setting.

Onboard I/O is configurable by AMIBIOS. The IRQs used by

onboard I/O are configured as PCI/PnP.

The settings are PCI/PnP or ISA/EISA. The Optimal and Fail-Safe

default settings are ISA/EISA and IRQ14 and IRQ 15 PCI/PnP.

Reserved Memory Size

This option specifies the size of the memory area reserved for

legacy ISA adapter cards.

The settings are Disabled, 16K, 32K, or 64K. The Optimal and

Fail-Safe default settings are Disabled.

31

Page 40

Hunter Industrial - Installation Guide

Reserved Memory Address

This option specifies the beginning address (in hex) of the

reserved memory area. The specified ROM memory area is reserved for use by legacy ISA adapter cards.

The settings are C0000, C4000, C8000, CC000, D0000, D4000,

D8000, or DC000. The Optimal and Fail-Safe default settings are

C0000.

Peripheral Setup

Peripheral Setup options are displayed by choosing the Peripheral

Setup icon from the WINBIOS Setup main menu. All Peripheral

Setup options are described in this section.

Onboard FDC

This option enables the floppy drive controller on the motherboard.

The settings are Enabled, Disabled or Auto. The Optimal default

setting is Auto. The Fail-Safe default setting is Auto.

Onboard Serial Port1

This option enables serial port 1 on the motherboard and specifies

the base I/O port address for serial port 1.

The settings are Auto, 3F8h, 2F8, 3E8, 2E8 or Disabled. The

Optimal and Fail-Safe default settings are Auto.

Onboard Serial Port2

This option enables serial port 2 on the motherboard and specifies

the base I/O port address for serial port 2.

The settings are Auto, 3F8h, 2F8, 3E8, 2E8 or Disabled. The

Optimal and Fail-Safe default settings are Auto.

On-board Parallel Port

This option enables the parallel port on the motherboard and

specifies the parallel port base I/O port address. The settings are

Auto, 378h, 278h, 3BC, or Disabled. The Optimal and Fail-Safe

default setting are Auto.

32

Page 41

Parallel Port Mode

This option specifies the parallel port mode. ECP and EPP are both

bi-directional data transfer schemes that adhere to the IEEE P1284

specifications. The settings are: Normal, Bi-Directional, EPP,

ECP.

Parallel Port DMA

This option is only available if the setting for the Parallel Port

Mode option is ECP.

The settings are Disabled, DMA CH (channel) 0, DMA CH 1, or

DMA CH 3. The default setting is Disabled.

Refer to Hardware Jumper settings on Chapter

one for JP 21 and JP22 when setting for these

options.

Chapter 2: Bios Configuration

Onboard PCI IDE

This option specifies the onboard IDE controller channels that will

be used. The settings are Primary, Secondary, Both, or Disabled.

The Optimal and Fail-Safe default settings are Primary.

33

Page 42

Hunter Industrial - Installation Guide

Section 2Utility

The following icons appear in this section:

Detect IDE and

Language

Detect IDE

This option allows the detection of an IDE hard drive automatically.

Language

English support only.

Section 3Security

AMIBIOS Password Support

Three icons appear in this part of the WINBIOS Setup screen:

Supervisor,

User,

Anti-Virus.

Two Levels of Passwords

Both the Supervisor and the User icons configure password

support. If you use both, the Supervisor password must be set

first. The system can be configured so that all users must enter a

password every time the system boots or when WINBIOS Setup

is executed, using either or both the Supervisor password or User

password.

34

Page 43

Chapter 2: Bios Configuration

If You Do Not Want to Use a Password

Just press <Enter> when the password prompt appears.

Setting a Password

The password check option is enabled in Advanced Setup by

choosing either Always (the password prompt appears every time

the system is powered on) or Setup (the password prompt appears

only when WINBIOS is run). The password is stored in CMOS

RAM. The following screen appears when you select the password icon from the WINBIOS Setup main menu.

You can enter a password by:

Typing the password on the keyboard or

Selecting each letter via the mouse.

When you select Supervisor or User, the BIOS prompts for a

password. You must set the Supervisor password before you can

set the User password. Enter a 1 – 6 character password. The

password does not appear on the screen when typed. Make sure

you write it down. If you forget it, you must drain CMOS RAM and

reconfigure the system.

Changing a Password

Select the appropriate password icon (Supervisor or User) from

the Security section of the WINBIOS Setup main menu. Enter the

password and press <Enter>. The screen does not display the

characters entered. After the new password is entered, retype the

new password as prompted and press <Enter>.

If the password confirmation is incorrect, an error message appears. If the new password is entered without error, press <Esc>

to return to the WINBIOS Main Menu. The password is stored in

CMOS RAM after WINBIOS completes. The next time the system

boots, you are prompted for the password if the password

function is present and is enabled.

35

Page 44

Hunter Industrial - Installation Guide

Remember the Password

Keep a record of the new password when the password is

changed. If you forget the password, you need to reset the CMOS

memory (refer to JP 9 on jumper settings - chapter 1)

Anti-Virus

When this icon is selected from the Security section of the

WINBIOS Setup main menu, the BIOS issues a warning when any

program (or virus) issues a Disk Format command or attempts to

write to the boot sector of the hard disk drive. The settings are

Enabled or Disabled. If enabled, the following appears when a

write is attempted to the boot sector. You may have to type N

several times to prevent the boot sector write.

Boot Sector Write!!!

Possible VIRUS: Continue (Y/N)? _

The following appears after any attempt to format any cylinder,

head, or sector of any hard disk drive via the BIOS INT 13 Hard Disk

Drive Service:

36

Format!!!

Possible VIRUS: Continue (Y/N)? _

Page 45

Section 4 Default

The icons in this section permit you to select a group of settings

for all WINBIOS Setup options. Not only can you use these icons

to quickly set system configuration parameters, you can choose

a group of settings that have a better chance of working when the

system is having configuration-related problems.

Original

Choose the Original icon to return to the system configuration

values present in WINBIOS Setup when you first began this

WINBIOS Setup session.

Optimal

You can load the optimal default settings for the WINBIOS by

selecting the Optimal icon. The Optimal default settings are bestcase values that should optimize system performance. If CMOS

RAM is corrupted, the Optimal settings are loaded automatically.

Chapter 2: Bios Configuration

Fail-Safe

You can load the Fail-Safe WINBIOS Setup option settings by

selecting the Fail-Safe icon from the Default section of the

WINBIOS Setup main menu.

The Fail-Safe settings provide far from optimal system performance, but are the most stable settings. Use this option as a

diagnostic aid if the system is behaving erratically.

37

Page 46

Hunter Industrial - Installation Guide

Chapter 3: Upgrading

Upgrading the System Memory

The Hunter Industrial allows an upgrade of the system memory up to

128MB, using SIMMs memory modules. Please refer to chapter one for

proper memory installation.

Upgrading the Microprocessor

The Hunter Industrial currently supports the following CPUs:

-Intel P54C Pentium 75, 90, 100, 120, 150, 166 and 200MHz.

-AMD K5 Pentium Processor 75, 90, 100 and 133MHz

To upgrade the Microprocessor, please refer to Chapter 1 for proper

installation and jumper settings.

38

Page 47

User's Notes:

Chapter 3: Upgrading

39

Page 48

Hunter Industrial - Installation Guide

Appendix A

Chip Sets

Core Logic

Intel Triton 430FX Chip-Set

Peripheral I/O

Chips & Technologies 735A or

Standard microsystems FDC37C665

Micro Processor Support

-Intel 3.3V Pentium processors 75, 90, 100, 120, 133, 150, 166,

and 200MHz

-AMD K5 Pentium processors 75, 90, 100, 120, 133, 166MHz

System Memory

Technical

Specifications

Memory Capacity

1 to 128MB of FPM or EDO DRAM memory.

Memory Type

Four sockets for JEDEC compatible (72 pin) 32 bit SIMMs, 70ns

access speed or faster. All memory configurations is automatic

through BIOS.

Supports FPM and EDO memories.

36 bit SIMMS can be used, but parity is not supported

Cache Memory

Cache on board with 256K asynchronous cache SRAMS.

40

Page 49

Appendix A: Technical Specifications

Bios

System BIOS

AMI WinBIOS with standard CMOS Setup, Peripheral Setup,

Power Management, Automatic Hard Disk Detection and Advanced Chip-set Setup.

Flash BIOS

Optional feature for System BIOS. Flash programming done

through BIOS

Embedded Interfaces

IDE

Two PCI EIDE controllers. Supports up to 4 devices

Floppy

Up to two floppy disk drives. Sizes supported are: 5.25" 360K and

1.2MB; 3.5" 720K, 1.44MB and 2.88MB. Floppy Tape and CD ROM

compatible. 34 pin header on-board.

Serial Ports

Two high speed 16550 compatible UARTS.

BIOS configurable as COM1 - 4.

Parallel Port

One Centronics compatible, bi-directional (PS/2 compatible).

Microsoft/HP EPC/EPP high speed.

Mouse Port

One PS/2 compatible mouse controller with 6 pin mini-din connector cable.

Expansion Slots

Seven 16 bit ISA slots.

41

Page 50

Hunter Industrial - Installation Guide

Miscellaneous

CMOS/Battery

RTC with lithium battery. No external battery is required.

Control Panel Connections

Reset, Keylock, Speaker, CPU fan (12V). LEDs for power and IDE.

CPU Socket

Standard ZIF (Zero Insertion Force), socket 7.

Form Factor

Baby AT Size - 8.6" x 13"

PCB Construction

Four Layer, dry film mask.

Manufacturing Process

Automated surface mount.

Reliability

MTBF: Higher than 48.000 hours

Environmental Operating Non-Operating

Temperature 0 to +55 -40 to +65 C

Humidity

Shock 2.5G @ 10ms 10G 10ms

Vibration 0.25 @ 5-100Hz 5G @ 5-100Hz

5 to 95% @ 40 C

non-condensing

5 to 95% @ 40 C

non-condensing

42

Page 51

Appendix A: Technical Specifications

Table A-1 Standard PC-AT I/O Map

Address (HEX) Device

000-01F DMA Controller

020-03F Interrupt Controller 1

040-05F Timer

070-07F

080-09F DMA Page Registers

0A0-0BF Interrupt Controller 2

0C0-0DF DMA Controller 2

0F8-0FF Math co-processor

1F0-1FF Hard Disk Controller

200-207 Game I/O

278-27F Prototype Card

2F8-2FF Serial Port 2

300-31F Parallel Printer Port

380-38F SDLC Bisynchronous 2

3B0-3AF Bisynchronous 1

3B0-3BF Monochrome Display/Printer

Real Time Clock (non-maskable interrupt)

3C0-3CF (Reserved)

3D0-3DF Color Graphics Display Adapter

3F0-3F7 Floppy Disk

3F8-3FF Serial Port COM1

43

Page 52

Hunter Industrial - Installation Guide

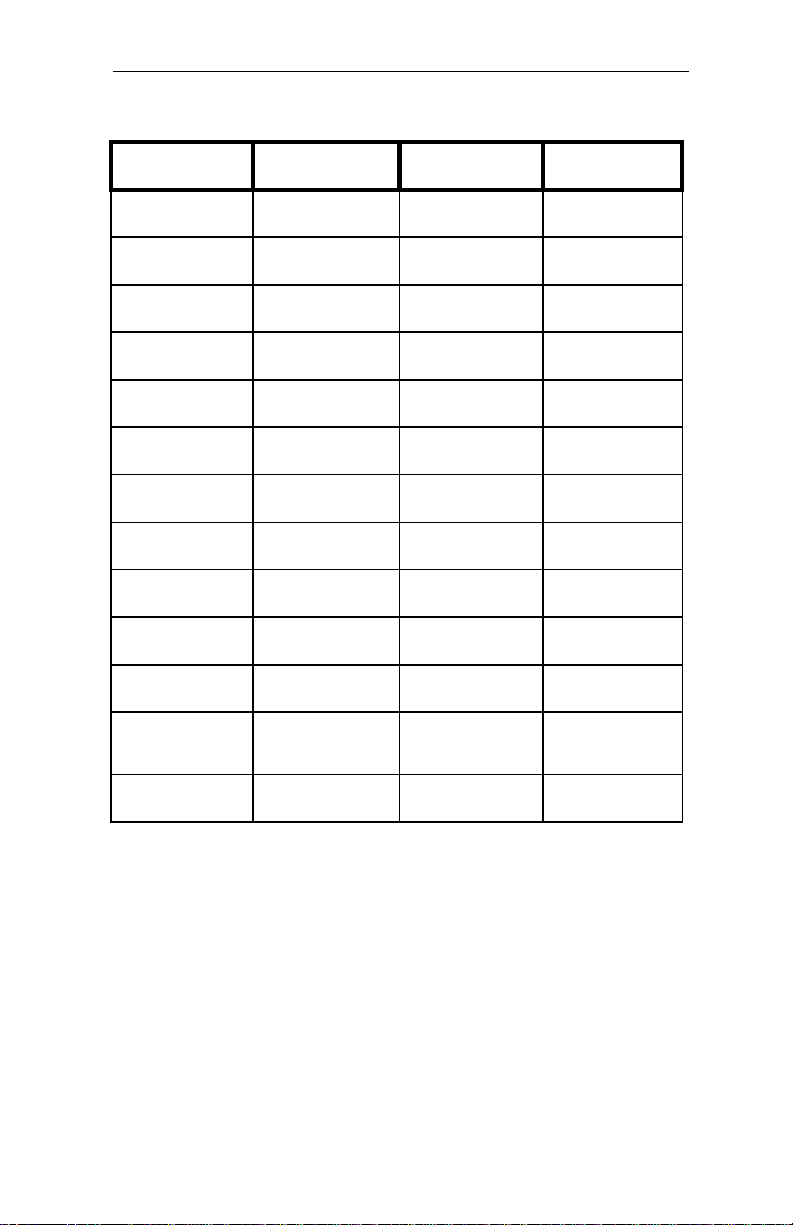

Table A-2 DMA Page Register and I/O address

Channel Function

Page Register I/O Hex Address

Channel 0 87

Channel 1 83

Channel 2 81

Channel 3 82

Controller 2: 16-bit (at Only - ports 0C0-0DF)

Channel 5 8B

Channel 6 89

Channel 7 8A

Refresh (AT) 8F

Table A-3 DMA Assignments

Channel Function

0 Reserved

1 SDLC

2 Floppy Disk

3 Spare

4 Cascade for CTRL

5 Spare (Reserved)

6 Spare (Reserved)

7 Spare (Reserved)

44

Page 53

Appendix A: Technical Specifications

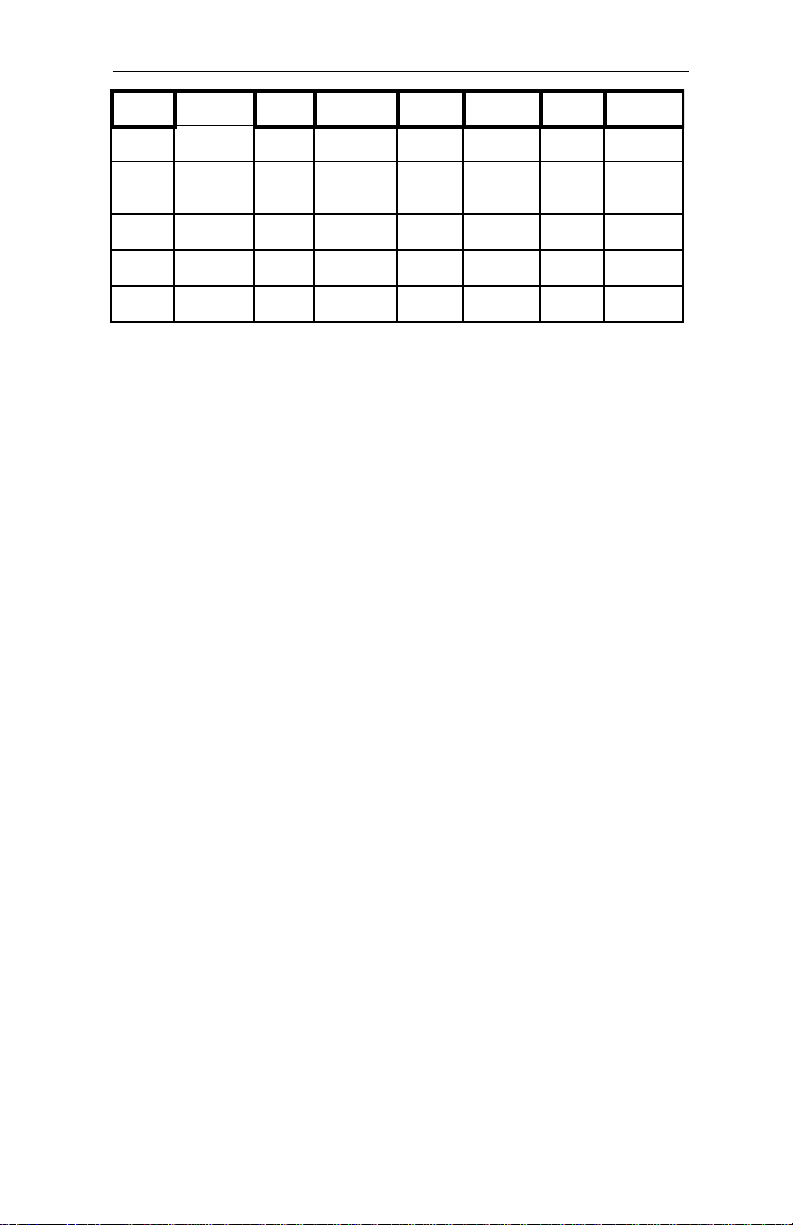

Table A-4 DMA Controller Register

DMA # Description

1 2

0 0C0 CH0 base and current address

1 0C2 CH0 base and current word count

2 0C4 CH0 base and current address

3 0C6 CH0 base and current word count

4 0C8 CH0 base and current address

5 0CA CH0 base and current word count

6 0CC CH0 base and current address

7 0CE CH0 base and current word count

8 0D0

9 0D2 Write request register

00A 0D4 Write single mask request register bit

00B 0D6 Write mode register

00C 0D8 Clear byte pointer Flip/Flop

00D 0DA

00E 0DC Clear mask register

00F 0DE Write all mask register bits

Read status register/write command register

Read temporary register / Write master clear

45

Page 54

Hunter Industrial - Installation Guide

Table A-5 Interrupts

Channel Name Function

NMI NMI Parity

0 IRQ0 System Timer Output 0*

1 KYBIRQ Keyboard Output Buffer Full

2 IRQ2 CTRL2 Interrupt (IRQ8-IRQ15)

3 IRQ3 Serial Port 2 (COM2)

4 IRQ4 Serial Port 1 (COM1)

5 IRQ5 Parallel Port 2

6 IRQ6 Floppy Disk Controller

7 IRQ7 Parallel Port 1

8 RTCIRQ Real Time Clock

9 IRQ9

10 IRQ10

11 IRQ11

Available

Available

Available

12 IRQ12 PS/2 Mouse

13 IRQ13 Math Coprocessor

14 IRQ14 Primary IDE

15 IRQ15

Secondary IDE

46

Page 55

Appendix A: Technical Specifications

Connectors Pin Outs

Table A-6 Serial Connectors

Pin# Name

1 -DCD

2 -DSR

3 RXD

4 -RTS

5 TXD

6 -CTS

7 -DTR

8 -RI

9 GND

10 N/C

47

Page 56

Hunter Industrial - Installation Guide

Table A-7 Floppy Disk Drive Connector

Pin# Name

2 RMP/LC

4 N/C

6 IDO

8 -INDEX

10 -MTRO

12 -DRV1

14 -DRVO

16 -MTR1

18 DIR

48

20 -STEP

22 -WDATA

24 -WGATE

26 -TRK0

28 -WPRT

29 ID0

30 -RDATA

32 HDSEL

33 ID1

34 DSKCHG

* GND

Page 57

Appendix A: Technical Specifications

Table A-8 Parallel DB25 Connector

Pin# Name

1 -STROBE

2 +DATA BIT 0

3 +DATA BIT 1

4 +DATA BIT 2

5 +DATA BIT 3

6 +DATA BIT 4

7 +DATA BIT 5

8 +DATA BIT 6

9 +DATA BIT 7

10 ACK1

11 BUSY

12 PAPER EMPTY

13 SLCT

14 AUTOFEED

15 ERROR

16 INIT

17 SLCT IN

18-25 GND

49

Page 58

Hunter Industrial - Installation Guide

Table A-9 IDE Connector

Pin# Name Pin# Name

1 -RST 21 N/C

2 GND 22 GND

3 D7 2 IOW

4 D8 3 GND

5 D6 24 IOR

6 D9 25 GND

7 D5 26 N/C

8 D10 27 BALE

9 D4 28 N/C

50

10 D11 29 GND

11 D3 30 IRQ14

12 D12 31 IO16

13 D2 32 SAI

14 D13 34 N/C

15 D1 35 SA0

16 D14 36 SA2

17 D0 37 CS0

18 D15 38 CS1

19 GNC 39 HDIND

20 N/C 40 N/C

Page 59

Appendix A: Technical Specifications

Table A-10 PS/2 Mouse Connector

Pin# Name

1 DATA

2 N/C

3 GND

4 +5V

5 CLOCK

6 N/C

Table A-11 Serial Port Cable Wire List

Pin# Signal Pin# 9 Pin

1 -DCD 8 1

2 -DSR 6 6

3 RXD 3 2

4 -RTS 4 7

5 TXD 2 3

6 -CTS 5 8

7 -DTR 20 4

8 -RI 22 9

9 GND 7 5

10 N/C N/C N/C

51

Page 60

Hunter Industrial - Installation Guide

Table A-12 Parallel Port Connector

Pin# Name Pin# Name

1 -STROBE 2 AUTOFEED

3 +DATA BIT 0 4 ERROR

5 +DATA BIT 1 6 INIT

7 +DATA BIT 2 8 SLCT IN

9 +DATA BIT 3 10 GND

11 +DATA BIT 4 12 GND

13 +DATA BIT 5 14 GND

15 +DATA BIT 6 16 GND

17 +DATA BIT 7 18 GND

52

19 ACK 20 GND

21 BUSY 22 GND

23

25 SLCT 26 N/C

PAPER

EMPTY

24 GND

Page 61

Appendix A: Technical Specifications

Table A-13 PCI Connector Pin Assignments

Pin# Assign. Pin# Assign.

A01 TRST# A32 AD16

A02 +12V A33 --A03 TMS A34 FRAME#

A04 TDI A35 GND

A05 +5V A36 TRDY#

A05 INTA# A37 GND

A06 INTC# A38 STOP#

A07 +5V A39

A08 CLKC A40 SDONE

A09 +5V A41 SB0#

A10 CLCKD A42 GND B11 GNT3# B42 SERR#

A11 GND A43 PAR B12 GND B43 ---A12 GND A44 AD15 B13 GND B44 C/BE1#

A13 GNT1# A45 ---- B14 CLKA B45 AD14

A14 RST# A46 AD13 B15 GND B46 GND

A15 +5V (I/O) A47 AD11 B16 CLKB B47 AD12

Pin# Assign Pin# Assign.

B01 -12V B32 ad17

B02 TCK B33 C/BE2#

B03 GND B34 GND

B04 TDO B35 IRDY#

B05 +5V B36 ---B06 +5V B37 DEVSEL

B07 INTB# B38 GND

---- B08 INTD# B39 LOCK#

B09 REQ3# B40 PERR#

B10 REQ1#1 B41 ----

A16 GNT0# A48 GND B17 GND B48 AD10

A17 GND A49 AD09 B18 REQ0# B49 GND

A18 REQ2# A50 KEY B19 +5V(I/O) B50 KEY

A19 AD30 A51 KEY B20 AD31 B51 KEY

A20 ---- A52 C/BE0# B21 AD29 B52 AD08

A21 AD28 A53 ---- B22 GND B53 AD07

A22 AD26 A54 AD06 B23 AD27 B54 ---A23 GND A55 AD04 B24 AD25 B55 AD05

53

Page 62

Hunter Industrial - Installation Guide

Pin# Assign. Pin# Assign. Pin# Assign Pin# Assign.

A26

----

A58 AD00 B27 AD23 B58 AD01

A27 AD22 A59 +5V (I/O) B28 GND B59

A29 AD20 A60 REQ64# B29 AD21 B60 ACK64#

A30 GND A61 +5V B30 AD19 B61 +5V

A31 AD18 A62 +5V B31

----

B62 +5V

+5V

(I/O)

54

Page 63

Appendix A: Technical Specifications

Table A-14 ISA Connector Pin Assignments

Pin# Assign. Pin#

IOCHCH

A01

B01

A02 SD7 B02

A03 SD6 B03

A04 SD5 B04

A05 SD4 B05

A05 SD3 B06

A06 SD2 B07

A07 SD1 B08

A08 SD0 B09

A09 IOCHR B10

A10 AEN B11

A11 SA19 B12

A12 SA18 B13

A13 SA17 B14

A14 SA16 B15

A15

SA15

B16

Assign.

GND

RESETD

+5V

IRQ9

+5V

DRQ2

-12V

ENDXFR

+12V

GND

SMEMW#

SMERW#

IOW#

IOR#

DACK3#

DRQ3

Pin# Assign Pin# Assign.

C01 SBHE# d01 EMCS1

C02 LA23 D02 IOCS16

C03 LA22 D03 IRQ10

C04 LA21 D04 IRQ11

C05 LA20 D05 IRQ12

C06 LA19 D06

IRQ15

C07 LA18 D07 IRQ14

C08 LA17 D08 DACK0

C09 MEMR D09 DRQ0

MEMW#

C10

D10 DACK5

C11 SD8 D11 DRQ5

C12 SD9 D12 DACK6

C13 SD10 D13 DRQ6

C14 SD11 D14 DACK7

C15 SD12 D15 DRQ7

C16 SD13 D16 +5V

A16 SA14 B17

A17 SA13 B18

A18 SA12 B19

A19 SA11 B20

A20 SA10 B21

A21 SA9 B22

A22 SA8 B23

A23 SA7 B24

DACK1#

DRQ1

REFRES

SYSCLK

IRQ7

IRQ6

IRQ5

IRQ4

C17 SD14 D17 MASTE

C18 SD15 D18 GND

55

Page 64

Hunter Industrial - Installation Guide

Pin# Assign. Pin#

A24 SA6 B25

A25 SA5 B26

A26 SA4 B27

A27 SA3 B28

A29 SA2 B29

A30 SA1 B30

A31 SA0 B31

Assign.

DACK2#

TC

BALE

+5V

OSC

GND

Pin# Assign Pin# Assign.

56

Page 65

User's Notes:

Appendix A: Technical Specifications

57

Page 66

Hunter Industrial - Installation Guide

Appendix B Flash BIOS

programming

If your board has the optional FLASH BIOS installed, you will be able to

update your BIOS without having to replace the EPROM. The WinBios will

read the new BIOS file from a floppy disk, replace the old BIOS and reboot

your computer.

When updating your BIOS, make sure you have a disk with the correct BIOS

file (it’s size should be 128K).

Rename the file to “AMIBOOT.ROM”. Turn your computer off. Insert the

disk in Drive A:, turn the computer on while pressing <CTRL><HOME>.

Your computer will show no screen, but will beep to indicate what is being

done.

If the programming is successful, you should hear the 4 beeps and your

computer will reboot with the new BIOS.

Please never turn the power off while reprogramming a FLASH BIOS. Refer

to the table on the next page for beep errors.

58

Page 67

Table B-1 Flash Bios Beep Erros

Beeps Description

1 Insert diskette in floppy A:

Appendix B: Flash BIOS

2

3 Base memory error

4 Flash program successfull

5 Floppy read error

6 Keyboard controller BAT command failed

7 No FLASH EPROM detected

8 Floppy controller failure

9 Boot Block BIOS checksum error

10 Flash erase error

The AMI BOOT.ROM file was not found

in the root directory of floppy drive A

11 Flash program error

12 AMIBOOT.ROM file size error

59

Page 68

Hunter Industrial - Installation Guide

Appendix C Troubleshooting

Power-On Self Test

The BIOS featured in the Hunter Industrial provides all IBM

standard Power-On Self Test (POST) routines as well as enhanced

BIOS POST routines. The BIOS POST supports CPU internal

diagnostics. The BIOS POST checkpoint codes are accessible via

the manufacturing Test Port (I/O port 80h).

Post Phases:

Every time the system is powered on. The BIOS executes two

types of POST routines:

System Test and Initialization (test and initialize BIOS for

normal operations).

System Configuration Verification (compare defined configuration with hardware actually installed).

BIOS Error Reporting:

If the error occurs before the display device is initialized a series

of beeps sound. Beep codes indicate that a fatal error has occurred.

The BIOS beep codes are described on the next page.

If the error occurs after the display device is initialized the error

message is displayed. A prompt to press <F1> can also appear

power is on.

Fatal errors, which halt the boot process, are communicated

through a series of audible beeps.

60

Page 69

Appendix C: Troubleshooting

Table C-1 Beep Errors

Beeps Error Message Description

1 Refresh Failure

2 Parity Error

3

4 Timer Not Operational

5 Processor Error The CPU generated an error

6

7

8

9 ROM Checksum Error

Base 64 KB Memory

failure

8042 - Gate A20

failure

Processor Exception

Interrupt Error

Display Memory

Read/Write Error

The memory refresh circuitry is

faulty

Parity error in the base memory

(the first 64 KB block) of memory

Memory failure in the first 64 KB

A memory failure in the first 64

KB of memory, or timer 1 is not

functioning

Cannot switch to protect mode

The CPU on the CPU card

generated an exception interrupt

The system video adapter is

either missing or its memory is

faulty. This is not a fatal error.

The ROM checksum value does

not match the value encloded in

AMIBIOS

10

11

CMOS Shutdown

Register Read/Write

Error

Cache Memory Bad -Do not Enable Cache

The shutdown register for CMOS

RAM has failed

The cache memory test failed.

Cache memory is disabled. Do

not press <ctrl><alt><shift><+>

to enable cache memory

61

Page 70

Hunter Industrial - Installation Guide

Appendix D Glossary of Terms

Bidirectional Parallel Port:

An eight-bit port that can be used for an input as well as an output

device.

BIOS (Basic Input/Output Systems):

The on-board firmware which communicates with the display,

keyboard, printers and other peripheral devices.

Bus:

One or more electrical conductors that transmit power or binary

data to the various sections of a computer.

CMOS (Complementary Metal Oxide Semiconductor):

A technique of fabricating transistors which uses very low power.

CMOS RAM:

Random Access Memory made from CMOS transistors.

DMA (Direct Memory Access Channel):

A channel for transferring data from host main memory to and from

peripheraIs without direct involvement of the CPU resources.

DRAM (Dynamic Random Access Memory):

The main memory in your computer. It needs to be refreshed by

a memory or it will lose its information.

EPROM (Erasable Programmable Read Only Memory)

A programmable device which stores information regardless of

power. The information can be erased and new information

written.

62

Page 71

Appendix D: Glossary of Terms

Floating Point Unit (FPU):

A device which can perform calculations on numbers in floating point

format as opposed to simple integers.

IDE (Integrated Drive Electronics):

A standard of signalling and communicating with a device.

Interleave

Multiple banks of memory that overlap to reduce the access time

and eliminate wait states.

Interrupt:

Temporarily halting the operation of a digital computer to respond

to service an external event.

Interval Timer:

A device that can generate a pulse at a defined interval for

background tasks.

IRQ (Interrupt Request):

A signal channel used to trigger the CPU to temporarily change

tasks

.

Kilobyte (KB):

1024 bytes

ns (nano seconds):

1x10-9 seconds. (There are one billion nanoseconds in one second)

Page Mode:

The ability to read a whole line (page) of memory to reduce access

time

Parity:

A way to detect corrupted data in DRAM.

63

Page 72

Hunter Industrial - Installation Guide

Parallel Port:

An eight-bit port usually used for connecting a printer.

PCI (Peripheral Component Interconnect):

Local bus for PCs provide a high-speed data path between the CPU

and peripherals (video, disk, network, etc.). The PCI bus coexists

in the PC with the ISA or EISA bus. ISA and EISA boards still plug

into an ISA or EISA slot, while high- speed. PCI controllers plug