Page 1

A.O. SMITH

SERVICE HANDBOOK

Residential Gas and Electric

Water Heaters

Prepared by the Technical Training

Department Asland City, Tennessee

The first portion of this Service Handbook addresses service issues

associated with Residential Gas Water Heaters that are atmospherically

vented and use a thermocouple as their electrical source.

The second portion of this Handbook addresses service issues of

Residential Electric Water Heaters having one or two heating elements

and common wiring configurations for these models.

Printed in USA 0402 Part No. TC-049-R2

$15.00

Page 2

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

TABLE OF CONTENTS

Page

Introduction

Terms......................................................... 1

Tools .......................................................... 2

Residential Gas Water Heaters

Guidelines.................................................. 3

Installation.................................................. 5

Operations and Servicing

Construction............................................... 6

Control ....................................................... 6

Burner ........................................................ 7

Normal Operations .................................... 7

Temperature .............................................. 8

Gas ............................................................ 8

Water Flow................................................. 9

Service..................................................... 10

Procedures and Conditions ..................... 11

Multiple Heater Piping ............................. 14

Exhaust Venting Notes ............................ 15

Residential Electric Water Heaters

Installation................................................ 16

Standard Illustrations............................... 17

Guidelines................................................ 18

Elements.................................................. 19

Thermostat............................................... 20

Page

Residential Electric continued

C-2 Circuit..........................................21

C-2 Sequence of Operation...............22

A-6 Circuit ..........................................23

A-6 Wiring Diagram ...........................24

A-7 .....................................................25

A-7 Wiring Diagram ...........................27

Certification and Approvals................29

Simultaneous Dual Elements ............30

C-2 Service ........................................31

C-2 Voltage Checks...........................32

C-2 Grounded Element Check ..........34

A-6 Service ........................................35

A-6 Element Test...............................35

A-6 Voltage Check.............................36

A-6 Grounded Element Test..............38

A-7 Service ........................................39

A-7 Element Test...............................40

A-7 Voltage Checks...........................41

A-7 Grounded Element Test..............44

Miscellaneous Information.................45

A.O. Smith Technical Bulletins 46

RESIDENTIAL GAS AND ELECTRIC HANDBOOK INTRODUCTION

This service handbook is designed to aid in servicing and troubleshooting A.O. Smith

Residential Gas and Electric water heaters in the field. No duplication or reproduction of this book

may be made without the express written authorization of the A.O. Smith Water Products

Company.

The following text and illustrations will provide you with a step-by-step procedure to verify

proper installation, operation, and troubleshooting procedures. Additional quick reference data is

included to assist you in servicing this product.

The information contained in this handbook is designed to answer commonly faced

situations encountered in the operation of the Residential Gas and Electric product line and is not

meant to be all-inclusive. If you are experiencing a problem not covered in this handbook, please

contact the A.O. Smith Technical Information Center at 1-800-527-1953 or your local A.O. Smith

Water Products Company representative for further assistance. Additional information is also

available on the web site www.hotwater.com

plumbing professionals and reference should be made to the instructional manual accompanying

the product. This handbook contains supplemental information to the Residential Gas and

Electric instructional manual.

. This handbook is intended for use by licensed

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

1

Page 3

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

Qualifications

Tools Required:

For servicing gas models:

•

Cross top screw driver

•

3/8, 7/16, ¾ inch open end wrenches

•

3/16 inch Allen wrench

•

11/16 inch – 6 point – socket – for anode removal

•

set of marked drill bits

•

electrical multimeter

•

gas pressure gauge or monometer

•

water pressure gauge

•

thermometer

•

tubing cutter if pilot tube is to be replaced

•

hose – to drain tank

•

container – to measure gallons per minute flow

For servicing electric models:

•

1 1/16 inch – 6 point – socket (for anode removal)

•

1 ½ inch deep socket – to remove an element

•

electrical multimeter

•

water pressure gauge

•

thermometer

•

hose – to drain tank

•

container – to measure gallons per minute flow

Rev 1 adds Technical Bulletins

Rev 2 corrects illustration errors

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

2

Page 4

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

GENERAL SECTION

SERVICE GUIDELINES

MISCELLANEOUS INFORMATION

Draw efficiency

temperature decreases 25 degrees F. A 40 gallon water heater will typically provide 70% (28

gallons) of this “usable” hot water. The burner or elements are allowed to operate during this test.

Incoming, cold water mixes the remaining stored water below this 25 degree limitation.

Energy Factor

water heater. The higher the energy factor, the more efficient the water heater will be.

Recovery rate

might be that a water heater has a recovery rate of 30 gallons of water per hour at 80 degree F.

(Fahrenheit) temperature rise.

Thermal efficiency

which enters the water. A percentage of the total BTU passes out through the vent piping.

is the quantity of hot water available to the consumer before the outlet water

is an indicator of the combined thermal efficiency and standby efficiency of a

is the amount of water that is heated to a set temperature, per hour. An example

is approximately the amount of generated BTU (British Thermal Units),

Temperature rise

the desired hot (outlet) setting. Typically this is assumed to be 40 degrees entering water, 120

degrees desired stored water or 80 degrees “temperature rise.”

Standby efficiency

water heat loss per hour is desired.

is the increase in the temperature from its coldest “inlet” water temperature to

– the water heater’s ability to contain heat in the tank. A minimum of tank

Water cannot

Water expands

Minerals and gases

(for all practical purposes) be compressed.

when it is heated.

will separate from water as temperature increases.

Formulas:

BTU (British Thermal Unit)

1 BTU = 252 cal = 0.252 kcal

1 cal = 4.187 Joules

BTU X 1.055 = Kilo Joules

BTU divided by 3,413 = Kilowatts

To convert

C.

One gallon

Pounds X .45359 = Kilogram

Gallons X 3.7854 = Liters

% of Hot

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

from Fahrenheit to Centigrade: (Degrees F – 32) times 5/9, or .556, equals degrees

of (120° F, 49°C) water weighs approximately 8.25 pounds.

= (Mixed Temp. – Cold) divided by (Hot Temp. – Cold)

is the heat required to raise 1 pound of water 1°F

3

Page 5

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

General Section – continued

% Thermal Efficiency

BTU Output

GPH

= (BTU/H Input X % Eff.) divided by (Temp. Rise X 8.25)

One cubic foot

One “therm”

One cubic foot

One gallon

= GPH X 8.25 X Temp. Rise X 1.0

of Natural Gas contains about 1000 BTU of heat.

is equal to 100,000 BTU

of Propane Gas contains about 2500 BTU of heat.

of Propane gas contains about 91,250 BTU of heat.

= (GPH X 8.25 X Temp. Rise X 1.0) divided by BTU/H Input

SERVICE HANDBOOK

One pound

of Propane gas contains about 21,600 BTU of heat.

One pound of gas pressure is equal to 27.7 inches water column pressure

Inches of Water Column X .036091 = PSI

Inches of Water Column X .073483 = Inches of Mercury (Hg.)

Centimeters = Inches X 2.54

MM (millimeters) =Inches X 25.4

Meters = Inches X .0254

Doubling the diameter of a pipe will increase its flow capacity (approximately) 5.3 times.

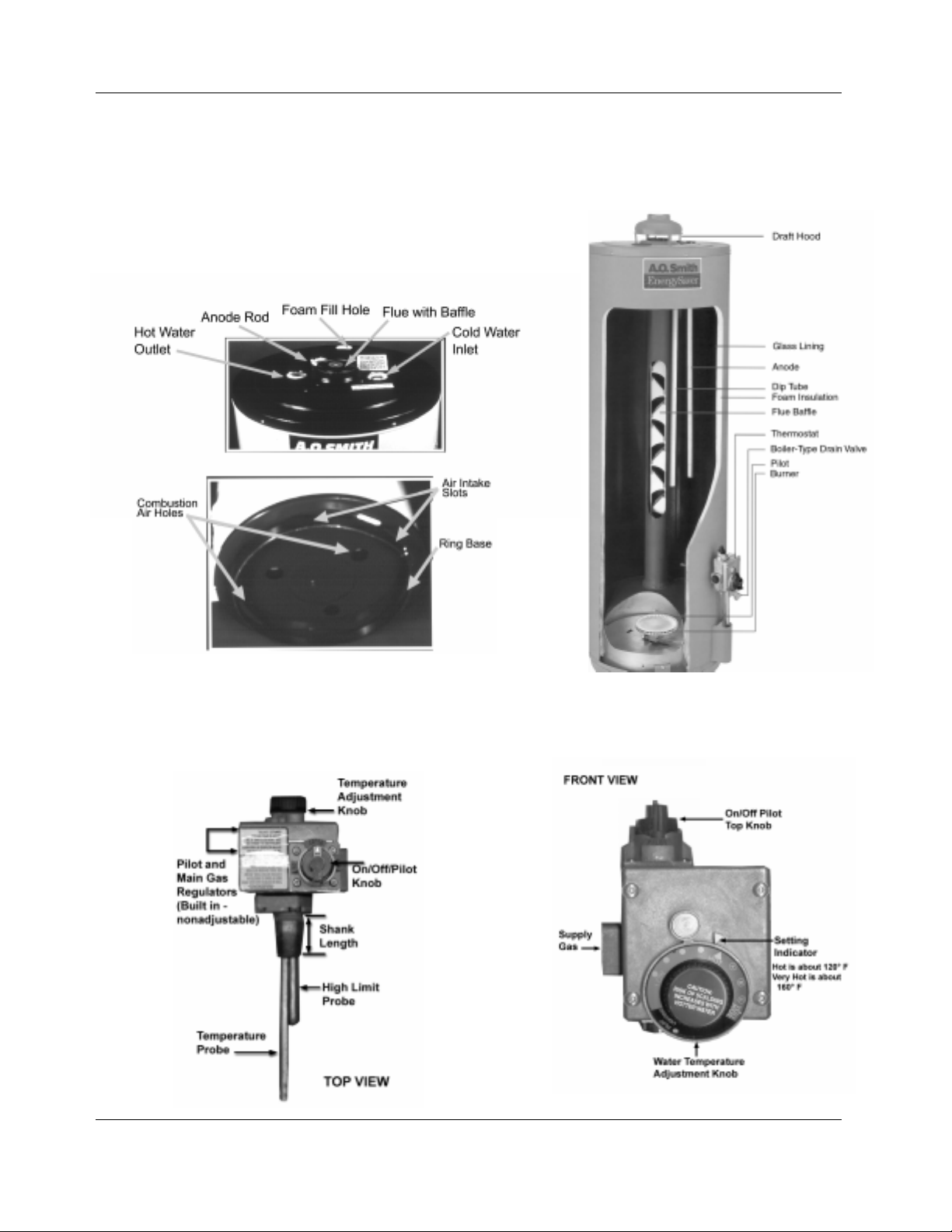

CONSTRUCTION:

Tank

is constructed of steel.

The inside of the tank is constructed of a

to metal contact and rusting of the tank.

An

anode rod

the top of the water heater. This metal rod offers secondary protection of the tank against

corrosion where the application of glass is not possible (threaded tank openings). These areas

will have small areas of water to metal contact.

All water heaters will contain at least

limit

(to prevent water temperatures approaching the “steam” level).

will be installed within the tank. The hex-head plug end of the anode is visible on

glass lining

one thermostat

bonded to the steel. This prevents water

(to operate the heater) and

one high

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

4

Page 6

V

See Manual and

Labels For Installation

Clearances

Typical Model

and Rating

Plate Location

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

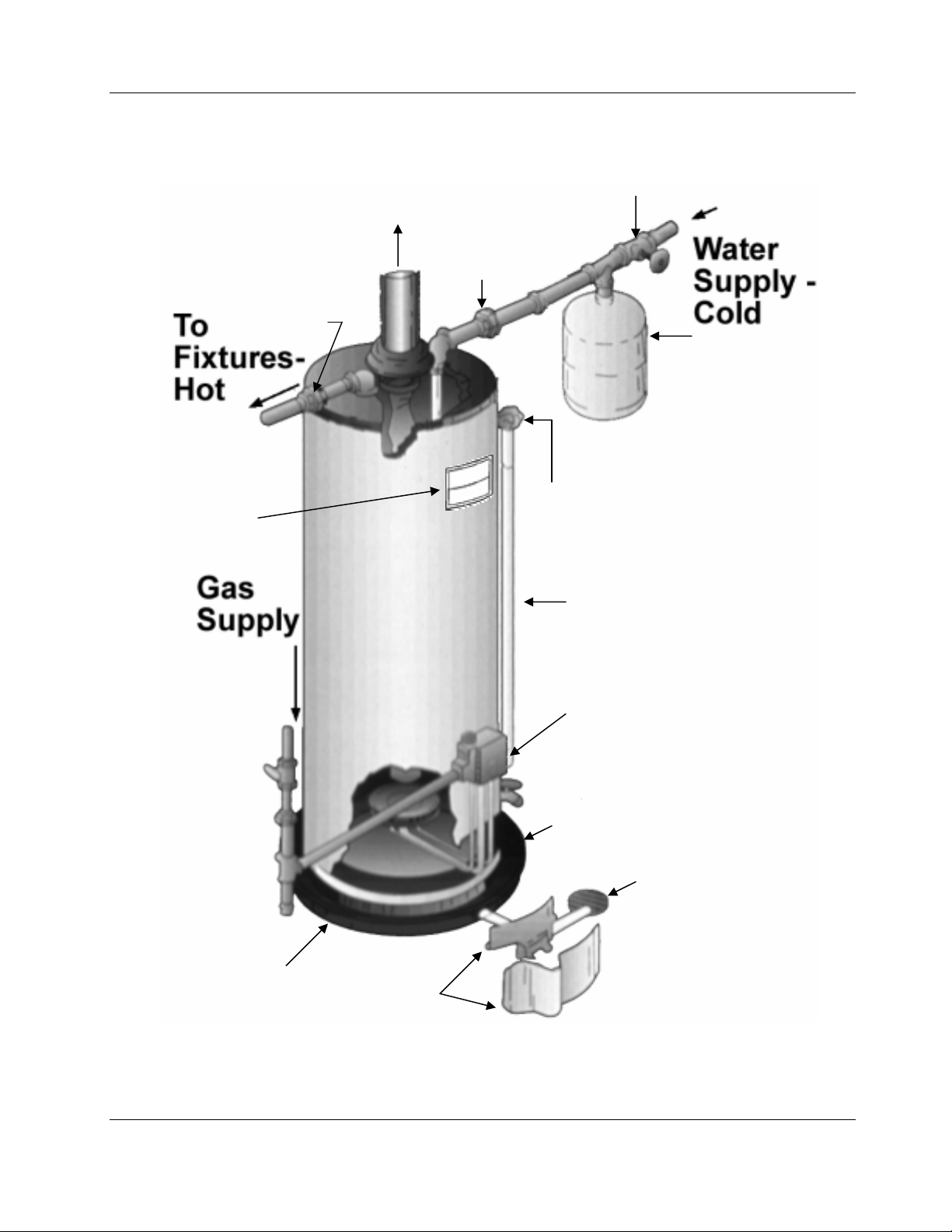

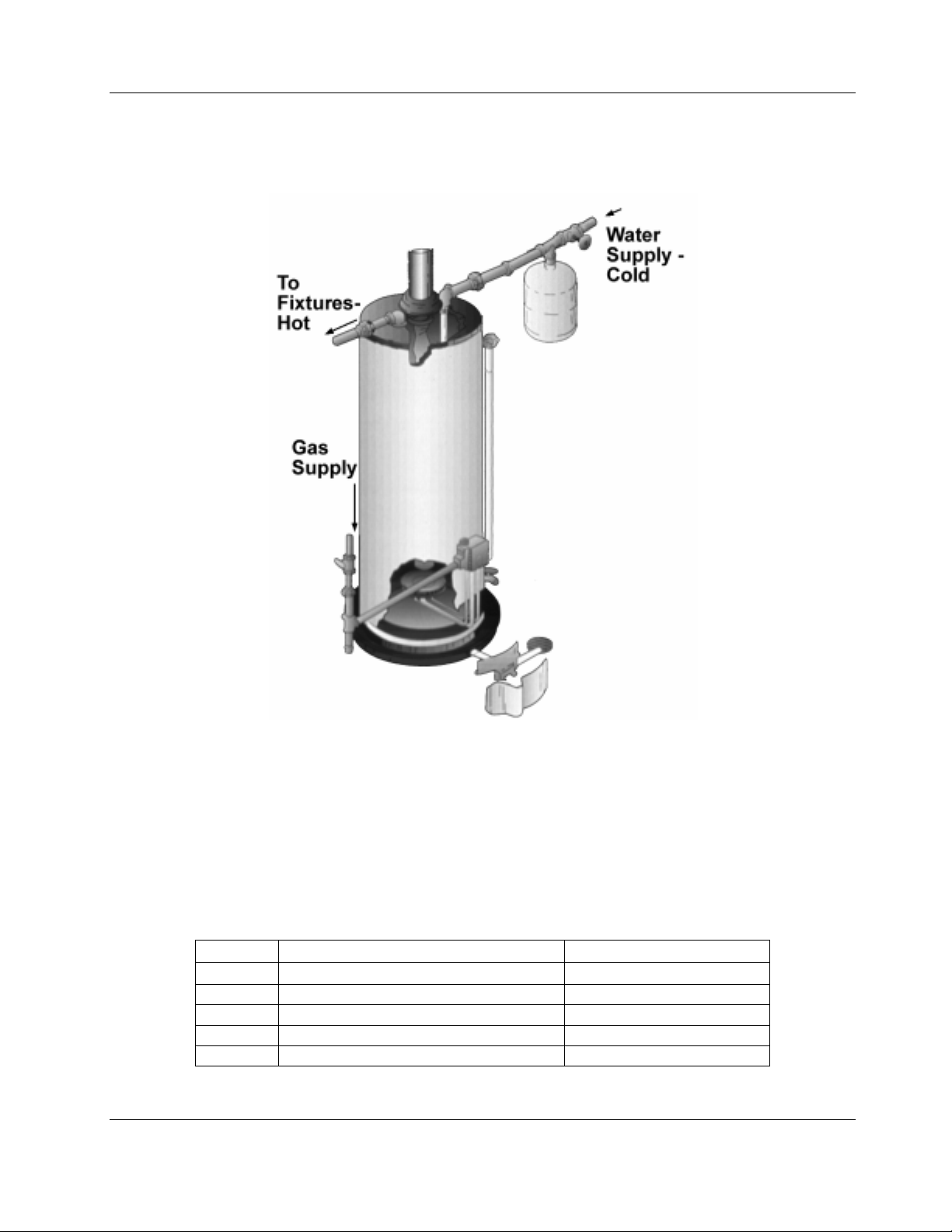

INSTALLATION OF RESIDENTIAL GAS WATER HEATER

Exhaust Vent to

Outside of Building

Union

Union

Water

Shut Off

alve

Expansion Tank

Pressurize to Equal

Supply Water

Pressure

Temperature And

Pressure Relief

Valve – Do Not

Reuse Old Valve.

Maximum Gas Supply

13.8” w.c. or ½ PSI

Minimum

4.5” w.c. –Natural Gas

11.0” w.c. Propane Gas

Air Is Drawn In For

Combustion. Keep

Area Clean And Free

From Flammables And

Flammable Vapors

Installation Must Follow Local Codes and Instruction Manual Guidelines

Temperature and

pressure relief valve

tube piped to within 6”

of drain.

Thermostat –

Recommending

setting of 125°F.

Safety Pan – Piped to

Drain

Drain

Inner and

Outer Doors –

Reinstall After

Lighting Pilot.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

5

Page 7

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

RESIDENTAL GAS WATER HEATER SERVICE

This portion of this manual applies to the Operations and Servicing of Residential Gas, Tank

Type, Water Heaters, which are vented atmospherically and use a thermocouple as their electrical

source.

Construction: See also “General” section of this

manual.

Contro

main gas regulator, pilot gas regulator, on-off-pilot knob, controls water temperature, has a

temperature adjustment knob, and a high water temperature limit safety.

l: There is one control on this style of water heater. The control has a

▲(delta)

Note: The word “Hot”

may or may not be

present on the control

knob

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

6

Page 8

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas – continued

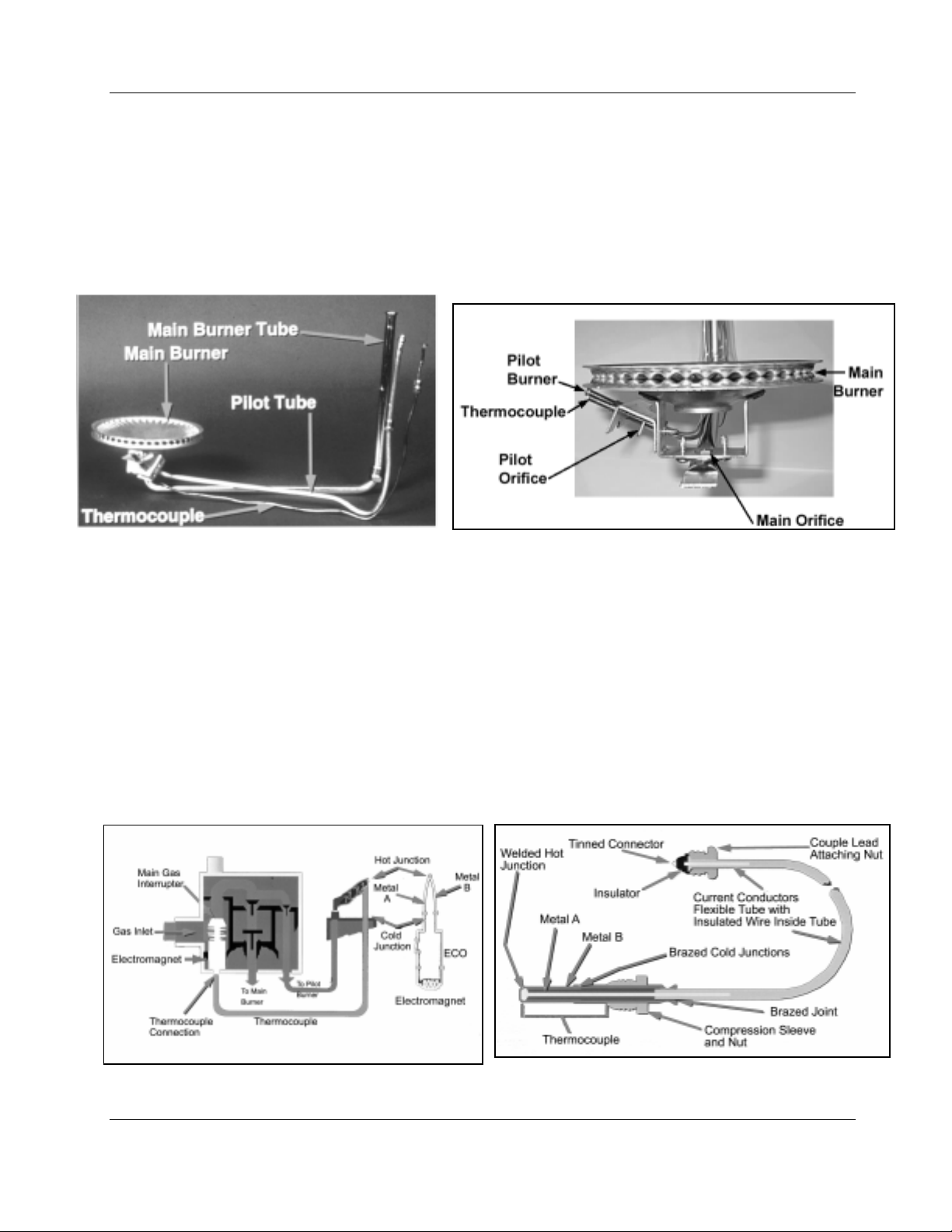

Burner:

supply tube, pilot burner, pilot burner orifice, pilot burner gas supply tube and thermocouple.

The pilot burner remains on once it is manually lit. When incoming cold water activates the

thermostat, gas flows to the main burner. The pilot flame ignites this gas. The main flame burns

until the tank reaches set temperature then the thermostat interrupts this main gas flow.

The burner assembly consists of the main burner, main burner orifice, main burner gas

SERVICE HANDBOOK

AFTER HAVING CONFIRMED THAT THE WATER HEATER HAS BEEN INSTALLED

PER THE INSTALLATION MANUAL INSTRUCTIONS:

Normal Operation

Electrical:

thermocouple gets hotter, it generates a small (cannot be detected without an electrical meter)

electrical current to the bottom of the control valve. This current powers the electromagnet and

holds open the safety valve as long as the pilot flame is heating the thermocouple. DANGER! If

the pilot is extinguished, it can take up to 180 seconds for the thermocouple to cool sufficiently to

close the safety valve.

The Pilot Flame heats the end of a thermocouple. As the

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

7

Page 9

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas – continued

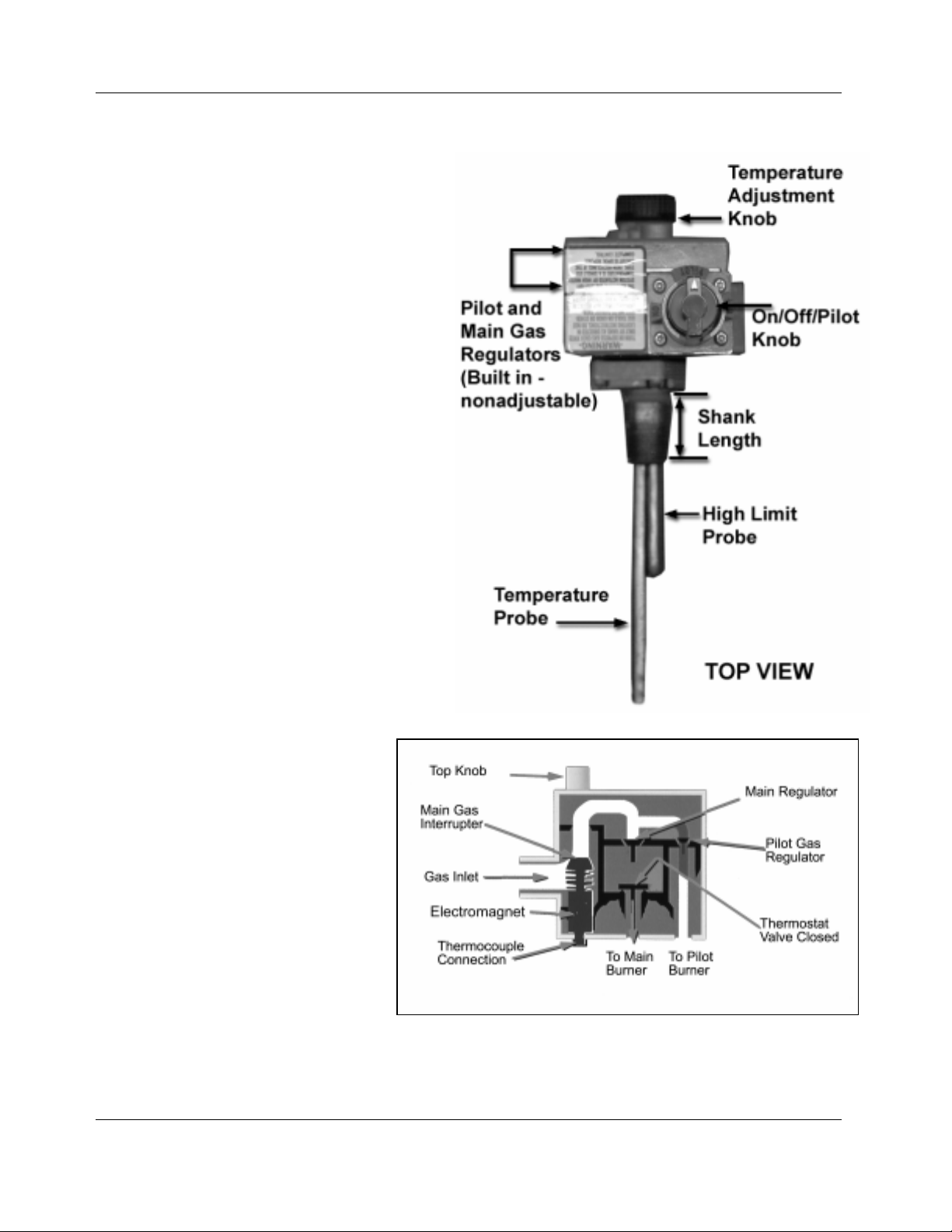

Temperature:

onto the back of the control are immersed

inside the tank water. One probe (the

shorter) acts as a temperature high limit. If

water gets excessively hot, a sensor within

the probe opens, interrupts the small

electrical current to the gas valve, and gas

flow through the control is interrupted. If this

safety sensor opens, the entire control must

be replaced.

The longer probe contains a metal rod that

expands and contracts as water temperature

around the probe cools and heats. As the

rod expands, it pushes against a lever

actuated gas valve. If the regulator is

pushed sufficiently, gas flow is interrupted to

the main burner. Adjusting the temperature

dial changes the distance the rod must

expand or contract to open or close the gas

valve.

Two metal probes mounted

SERVICE HANDBOOK

Gas:

When you prepare to light the pilot,

you are instructed to turn the top

knob to the pilot position and depress

the knob. When the knob is

depressed gas will flow to the pilot

burner only. You then have to

(manually) ignite this pilot gas. When

the pilot is lit, the flame must heat the

thermocouple until it generates

sufficient electricity to the gas valve

to allow you to release the knob while

gas continues to flow to the pilot.

When the top knob is turned to the

“ON” position, gas is also available to

the main burner if the thermostat calls

for heat.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

8

Page 10

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas - continued

Water Flow:

main forces cold water into the water heater. This pushes hot water out of the tank.

When a hot water faucet is opened, water pressure from the well tank or street

SERVICE HANDBOOK

Operation:

heater relies on the expansion and contraction of a metal rod, when the thermostat dial is set at

an indicated setting (“▲” is recommended as a starting setting. This is approximately 120

degrees F.) the heater may shut off at 110 to 130° F. The heater will consistently shut off at this

same temperature. For this same reason, water temperature may drop 15 - 25° F, around the

temperature probe, before the main burner is activated. Keep in mind that hot water in the upper

part of the tank will probably be very near the “shut off” temperature of the control while incoming

cold water drops the water temperature around the thermostat probe. Also, short repeating

heating cycles caused by small hot water uses can cause temperatures at the point of use to

exceed the thermostat setting by up to 30° F.

A residential water heater is not a precise operating appliance. Because the water

Setting Approximate Temperature (°F) Time To Cause Injury

Hot (▲)

A 130° ± 10° 30 Seconds

B 140° ± 10° 5 Seconds

C 150° ± 10° 1.5 Seconds

Very Hot 160° ± 10° Under 1 Second

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

120° ± 10° 5 Minutes

9

Page 11

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas - continued

SERVICE HANDBOOK

Service:

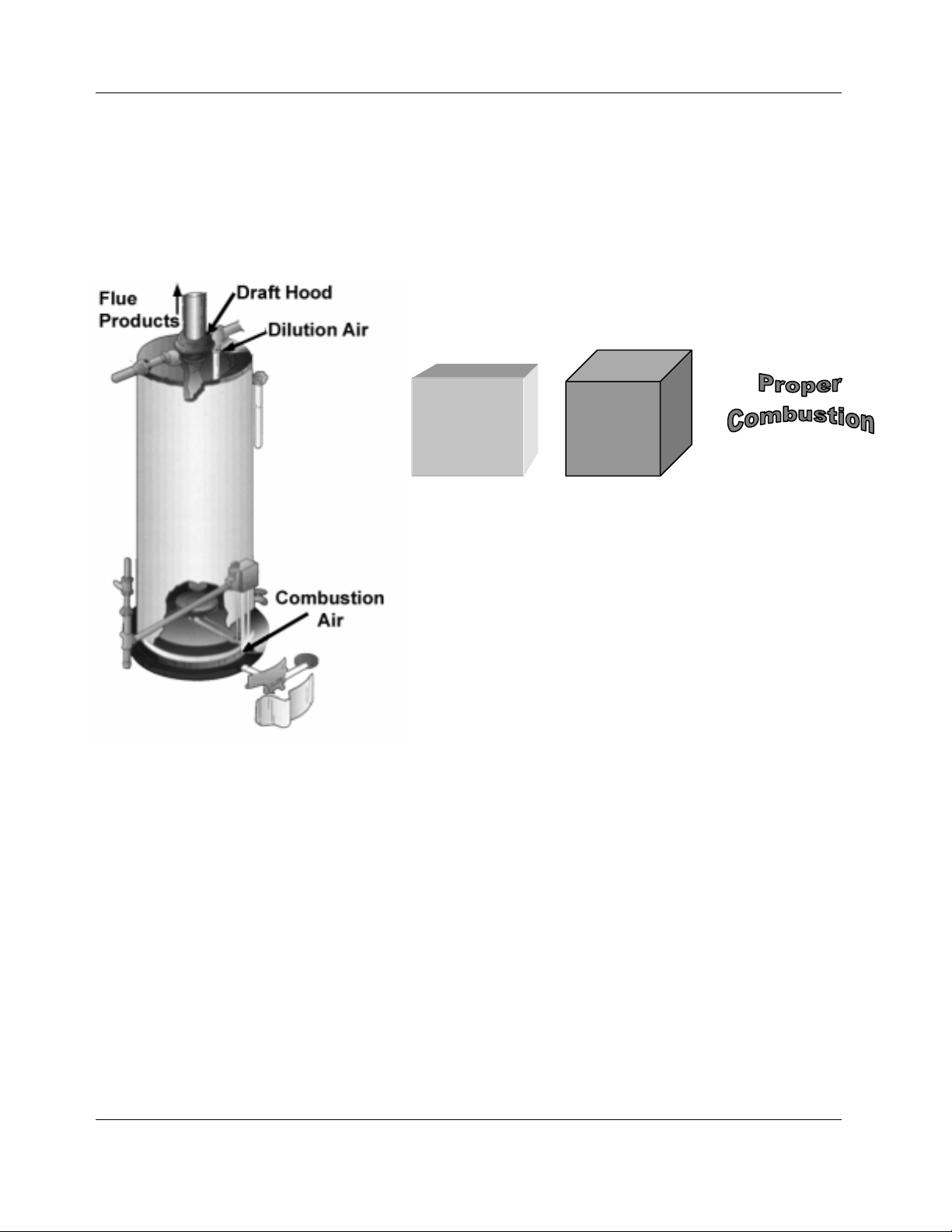

Air:

A gas burning appliance requires the oxygen contained in 12.5 cubic feet of air (at sea level)

for every 1000 BTU of heat that is generated. If your water heater has a BTU per hour input of

40,000 BTU then a minimum of 500 (40 times 12.5) cubic feet of clean air must be available. This

oxygen will mix with the gas for a clean, blue flame in the burner chamber and provide dilution air

for flue products.

(Enters

Here)

(Enters Here)

Do not forget that your gas (or oil) furnace and gas clothes dryer also require a like amount of air.

When calculating air supply provisions, also consider the presence of whole house exhaust fans

or other exhaust fans competing for the same air supply.

Air must be allowed to enter the heater chamber from the base of the heater and also enter the

flue vent from below the draft hood. Do not block these areas with insulation blankets or

obstructions lying around the base of the heater.

Lack of Oxygen:

dilution, the result will be:

• Pilot outage

• Yellow burner flame

• Sooting water heater

• Possible carbon monoxide

• Smell of burnt gas in the room

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

If a sufficient supply of oxygen (air) is not available for combustion and

1,000

BTU

Fuel

10

+=

12.5

Cubic

Feet of

Air

Page 12

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas – continued

The instruction manual gives guidelines under “Air Requirements” and “Unconfined “ or “Confined

Space” sections. If you want to test for a lack of air:

1. Turn on every appliance and fan that exhausts air from the utility room and/or house.

Make sure all windows and doors are closed, as well as chimney dampers.

2. Open a hot water faucet so that the main burner will ignite

3. Remove the outer door of the water heater – not the inner door

4. Monitor the flame characteristics for several minutes

If the flame begins to “yellow” open a door or window, to the outdoors, to see if additional air

corrects this back to blue. If it does, the room needs more air supply. Perform draft test at draft

hood of water heater with match or smoke source to verify.

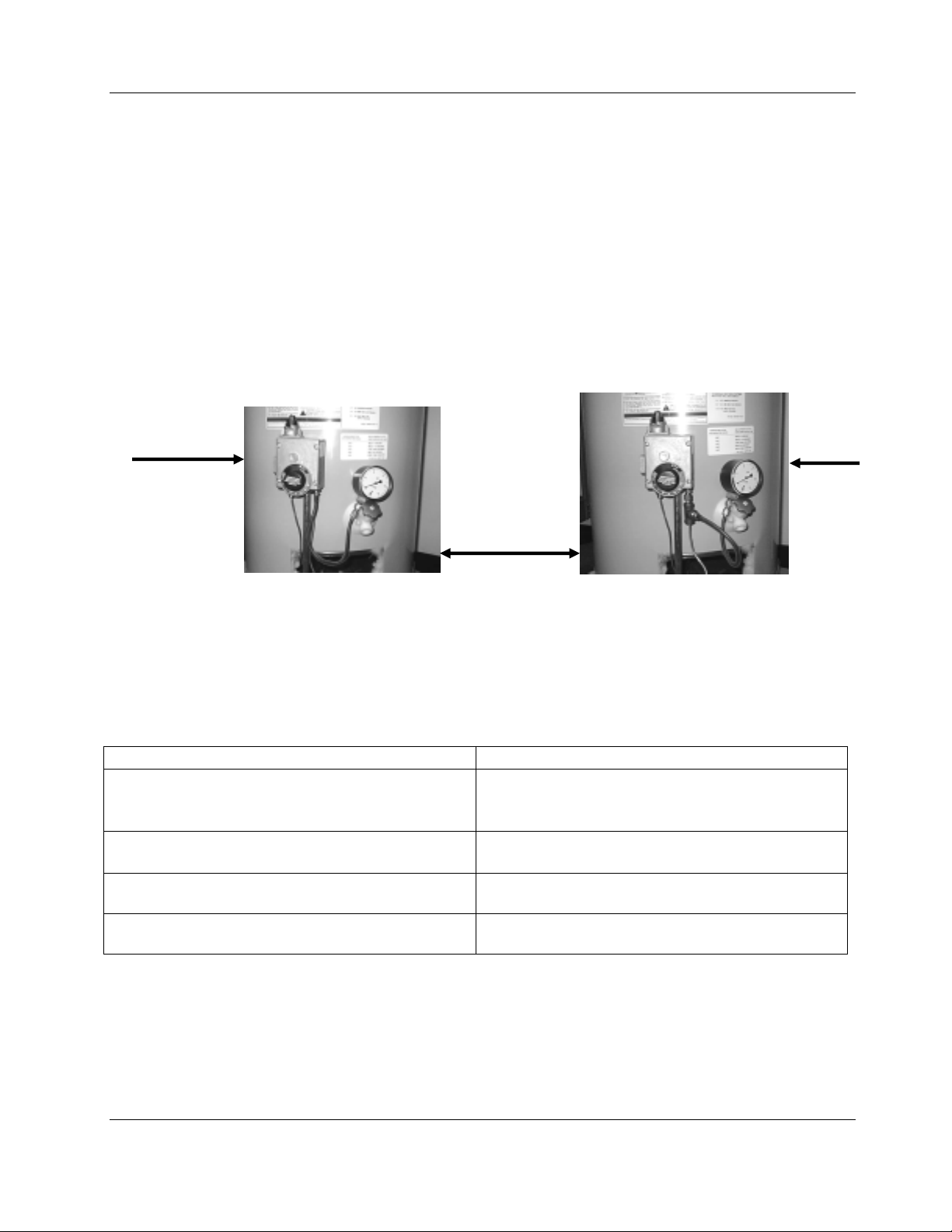

Manifold

Gas Pressure

Test

Gas pressure checks are done with flowing gas.

Supply gas pressure

possible.

Pilot gas pressure

checks are taken ahead of the gas control and as close to the heater as

checks are taken by using fitting adapters to tap into the pilot gas tubing.

Manifold (main burner) gas pressure

of the control valve.

Desired gas pressures will be noted on the gas valve label.

SERVICE HANDBOOK

Testing with

Gas

Pressure

Gauge

is measured using the Allen wrench tap on the bottom

Pilot Gas

Pressure

Test

If … … then

supply gas pressure is under desired pressure

setting

supply gas pressure is over desired pressure

pilot gas pressure is more than +/- .3 inch

W.C. from desired

manifold gas pressure is more than +/- .3 inch

W.C. from desired

Additional considerations when pilot or main burner flames are too large or too small:

• Incorrect orifice

• Dirt in orifice or gas supply tubing

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

• increase supply gas pressure regulator

setting and,

• increase supply gas piping size.

• add gas pressure regulator.

• reduce setting on existing regulator.

replace the control valve.

replace the control valve.

11

Page 13

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas - continued

SERVICE HANDBOOK

Sooting causes

:

If … … then

the burner is clean but the chamber and/or flue

are sooted

the main burner, chamber and flue are sooted check the following:

check for lack of supply air.

•

incorrect orifice

•

excessive gas pressure

•

loose main burner

•

cross threaded orifice

•

gas control valve gas seepage

•

loose gas connection in burner assembly.

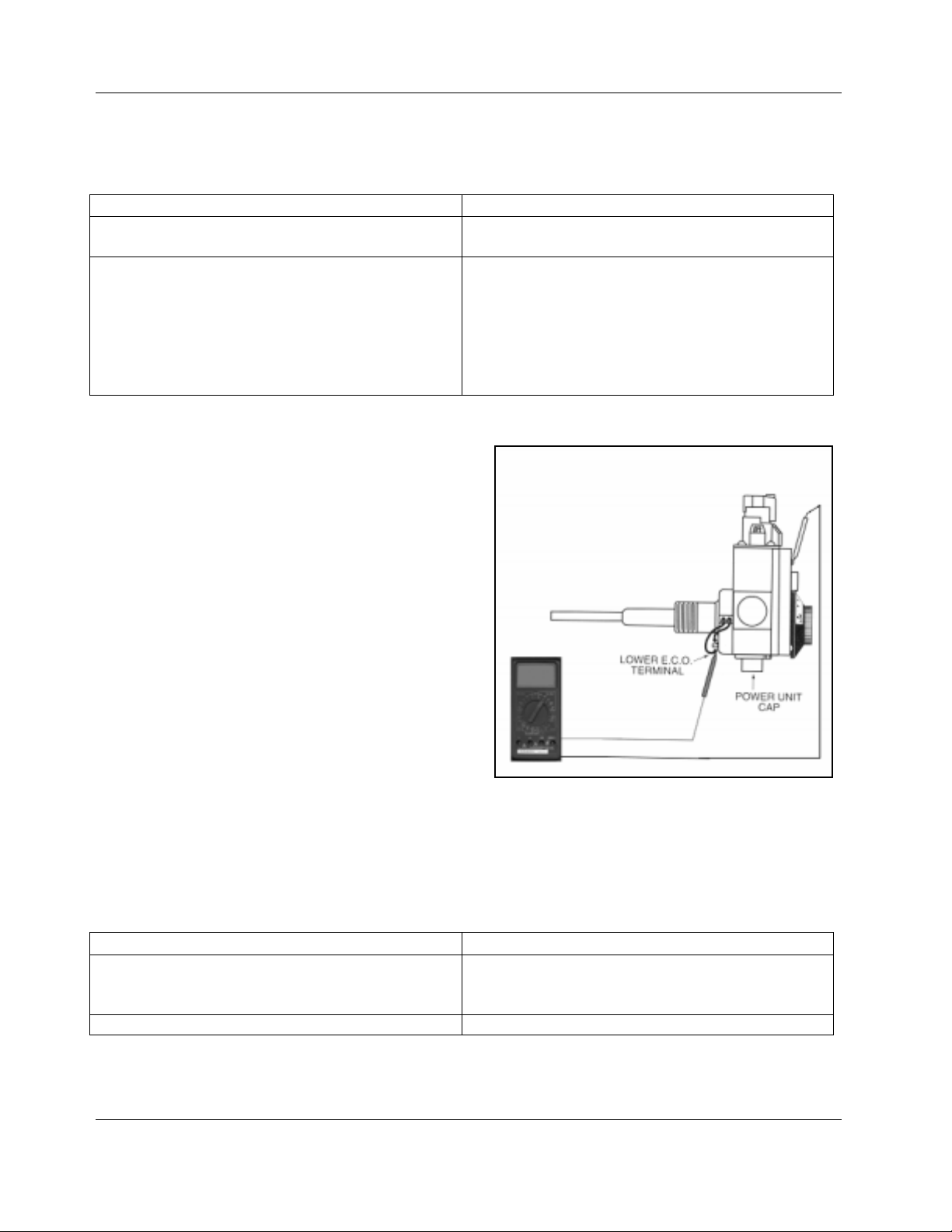

Electrical Testing

This type of water heater has its own electrical

generating system.

When two dissimilar metals are joined together

and this joint is heated, a small, electrical current

will be produced. A thermocouple uses this

science.

TO GROUND

Thermocouple output test

Procedures/Conditions:

Meter set for DC millivolt testing

Test from lower ECO (emergency cut off or energy cut off) solder joint to ground.

Note: If pilot will not stay lit, manually hold the top knob down in the pilot position. This allows

gas to flow to the pilot. Light the pilot and continue to hold this knob down while conducting the

test.

If … … then

reading test of at least 13 MV is not present

reading test of at least 13 MV is present continue to next test.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

•

check that flame contacts end of

thermocouple

•

replace thermocouple.

12

Page 14

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas - continued

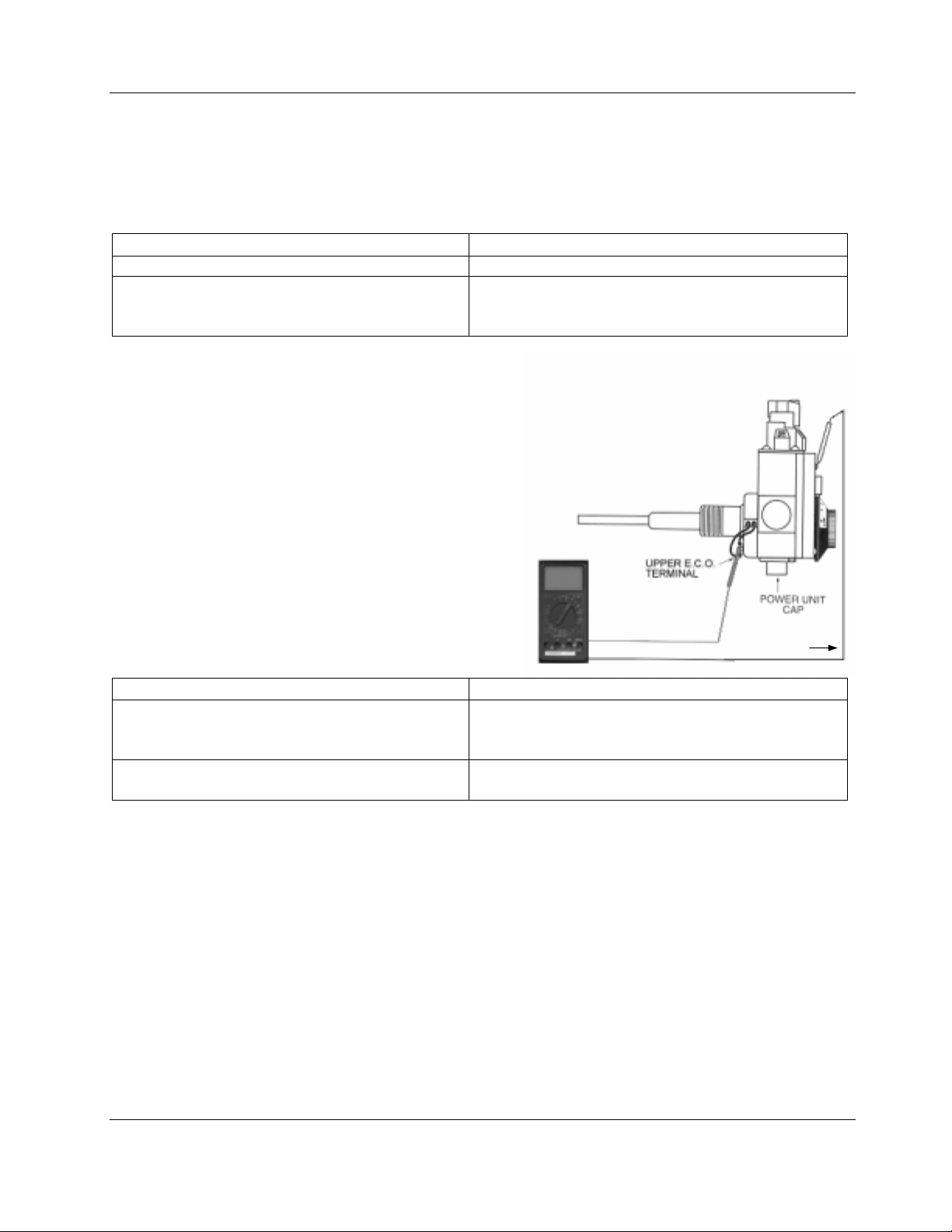

Electrical Testing– continued

Millivolt dropout test

Procedure:

Move meter probe to upper ECO solder joint and ground

through copper magnet winding and ECO (Emergency Cut Off)

SERVICE HANDBOOK

If … … then

reading of at least 10 MV is not present replace the control valve.

reading of more than 10 MV is present but,

gas to the pilot shuts off each time knob is

released

Safety drop out test

– the safety gas shutoff

should interrupt gas through

the valve when MV current

drops to 1-3 MV.

replace the control valve.

Procedures:

Meter still connected to upper ECO solder joint and

ground.

Turn Top Knob to “off” position

Millivolt output will decrease as thermocouple cools

TO GROUND

If… … then

internal safety does not activate between 1

and 3 MV (you will hear a “click” inside the

valve)

*internal safety does activate between 1 and

3 MV

*Note: A “click” sound should be heard from the valve as the main gas interrupter snaps up to the

“closed” position.

replace the control valve.

valve is within tolerance and will interrupt gas

flow if pilot looses heat or ECO opens.

Condensation

Flue gas products contain moisture. If these flue gas products are cooled to their “dew point”,

they become visible moisture – condensation.

Flue gas may become cooled by:

• Cold supply air temperatures

• Cool surfaces – generally, if tank water temperatures drop below 110°F, the flue pipe surface

and/or bottom tank head will be cool enough to cause condensation.

• Increased combustion efficiency – higher thermal efficiency means that an increased amount

of heat is transferring from the flue gas into the water. If you transfer (approximately) 87.5%,

or more, the moisture in the flue gas will condense.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

13

Page 15

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas – continued

SERVICE HANDBOOK

Condensation is a mild acid – it will corrode steel

Condensation

• water dripping is heard (only) while the main burner is on,

• there is “water” around the heater just after the heater has been operating,

• there are small, black or red granules on the main burner or top of the heater or

• corroded jacket or vent piping is noted.

is usually noted when:

If … … then

any of the above conditions exist

•

raise the supply air temperature or

•

increase stored water temperature or

•

increase the size of the tank

You would not wish to lower combustion

efficiency – this would waste gas. Use

materials (stainless steel, PVC etc.) that

will not be affected by the condensation

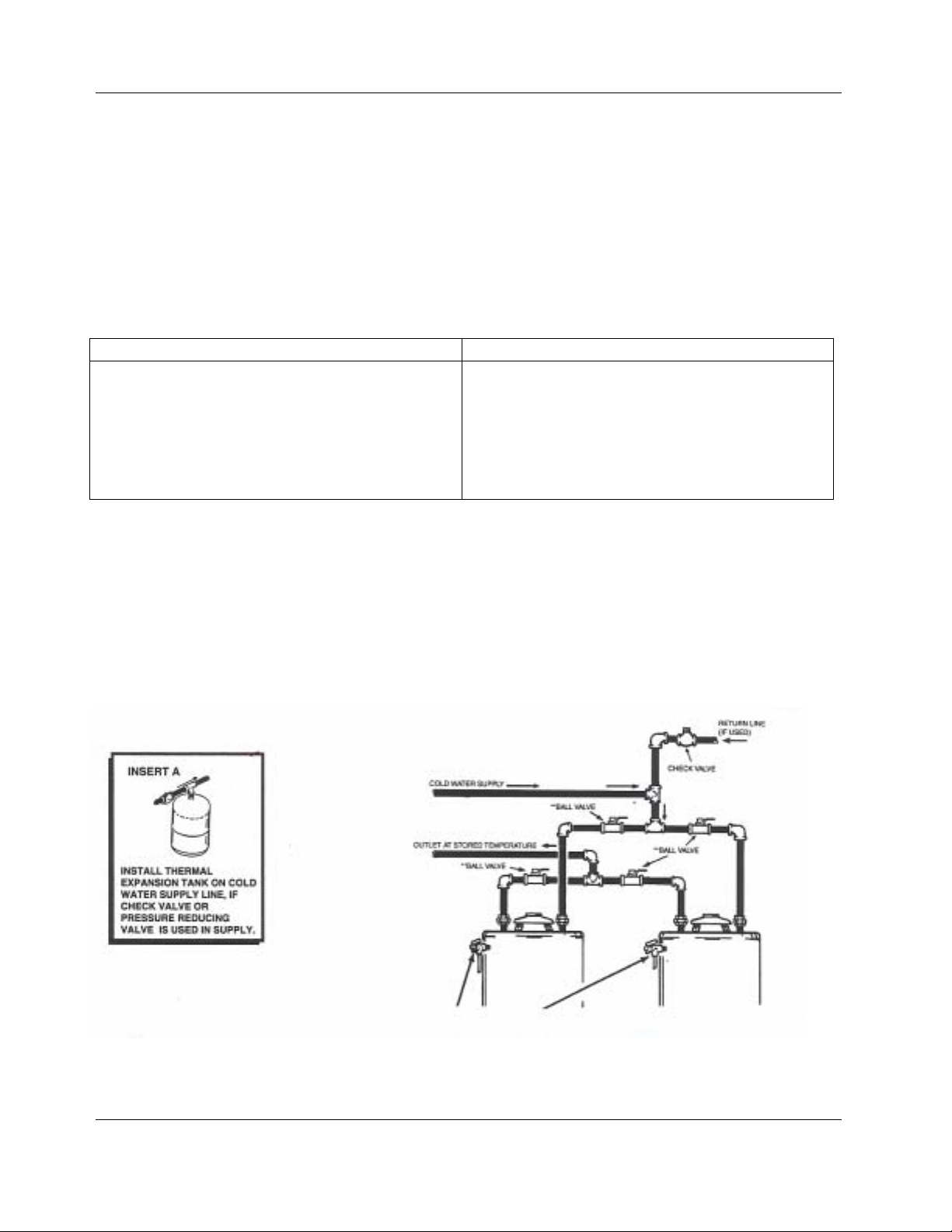

Suggested Multiple Heater Water Piping Required For

Proper Operation of Top Connect Models

Installed in accordance with local codes.

TEMPERATURE/PRESSURE RELIEF VALVES

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

14

Page 16

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Gas – continued

SERVICE HANDBOOK

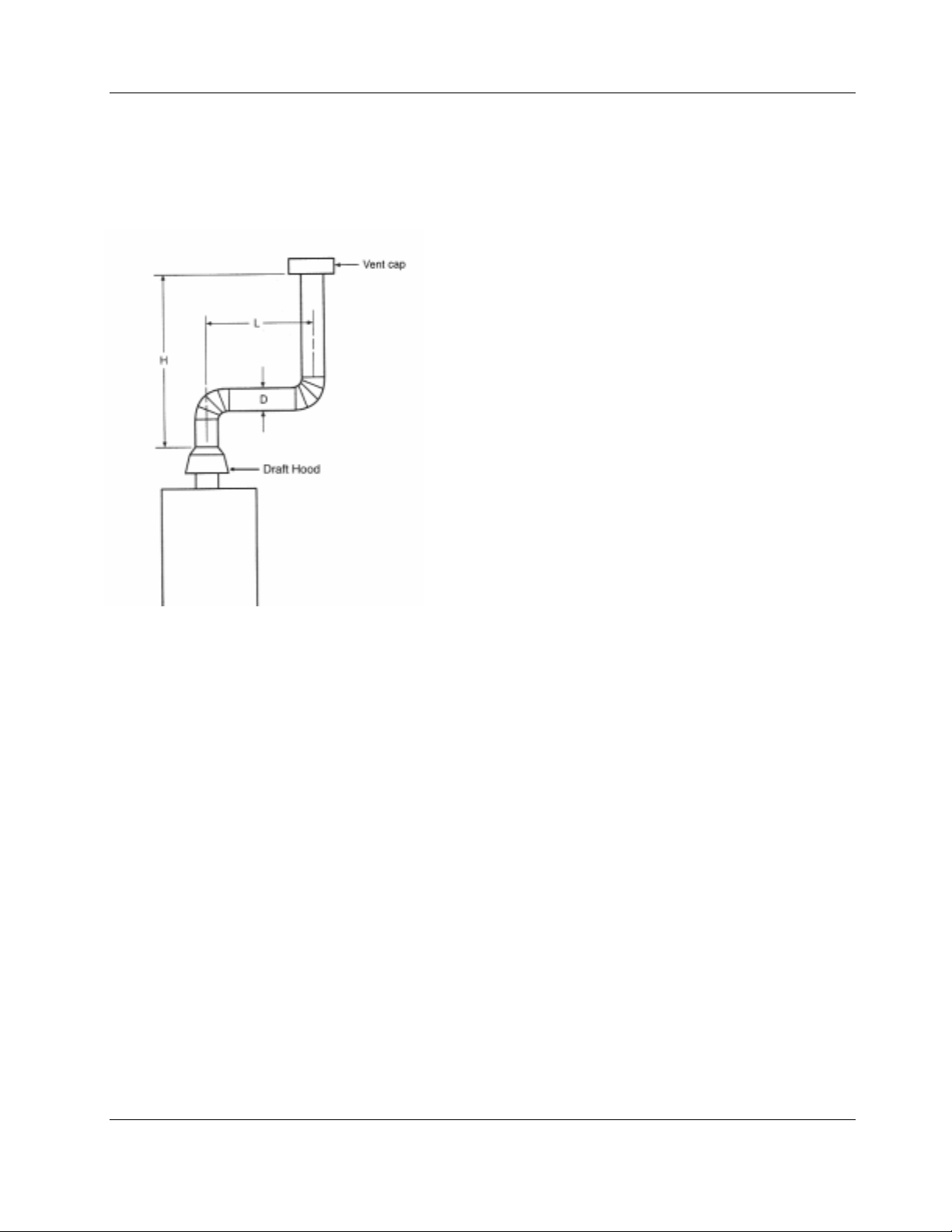

Exhaust Venting Notes

Follow current National Fuel Gas Code requirements for proper installation.

“D” – Typically, same or larger diameter as Draft Hood

outlet

“L” – Horizontal piping slopes upward ¼” per foot from

heater to chimney or vertical vent

Length of horizontal not more than 75% of “H”

“H” – Not less than 5 feet

Maximize vertical distance to first elbow

See the “Technical Bulletins Section “ of this manual for explanations of:

Water Hammer

Mineral Buildup

Aluminum Hydroxide

Condensation

Discolored Water

Smelly Water

Chlorination Process

Lack of hot water

Thermal Expansion

Temperature and Pressure Relief Valve Operation

Parts Replacement

in the products. To order the current, correct replacement part for your model gas water heater,

you must know the model number and (complete) serial number of your water heater. This

information will be located on a black and white label, on the front of your water heater – this label

will also display a star within a circle (the A.G.A. symbol). A sample might be:

Model “PGCG-50 – 242” “Ser No. MB99-(numbers) – 242”.

– The parts on these models change often due to improvements/changes

To order parts, contact your local A.O. Smith Contractor or Distributor, phone AOS

parts at 800-433-2545 or contact A. O. Smith on Web site “www.hotwater.com”

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

15

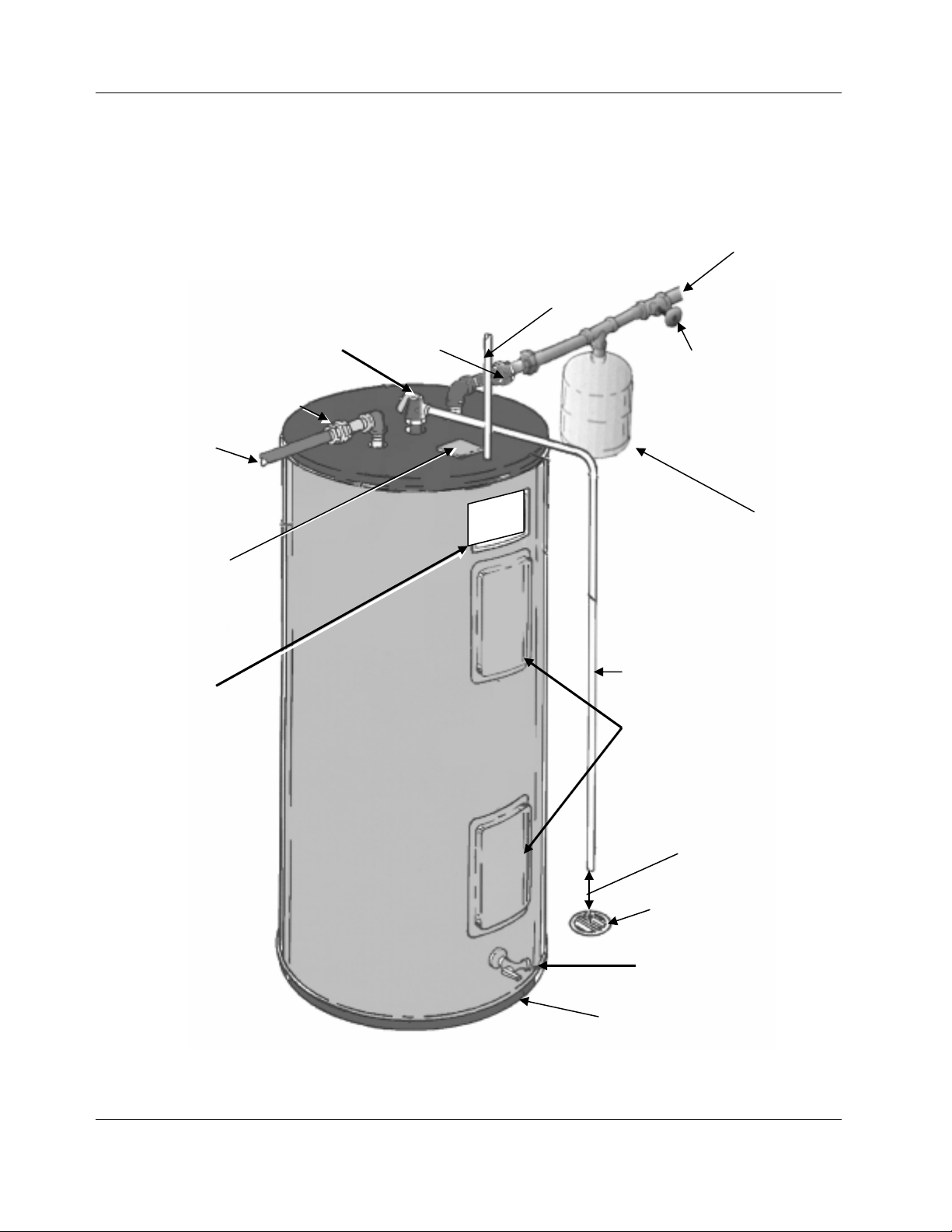

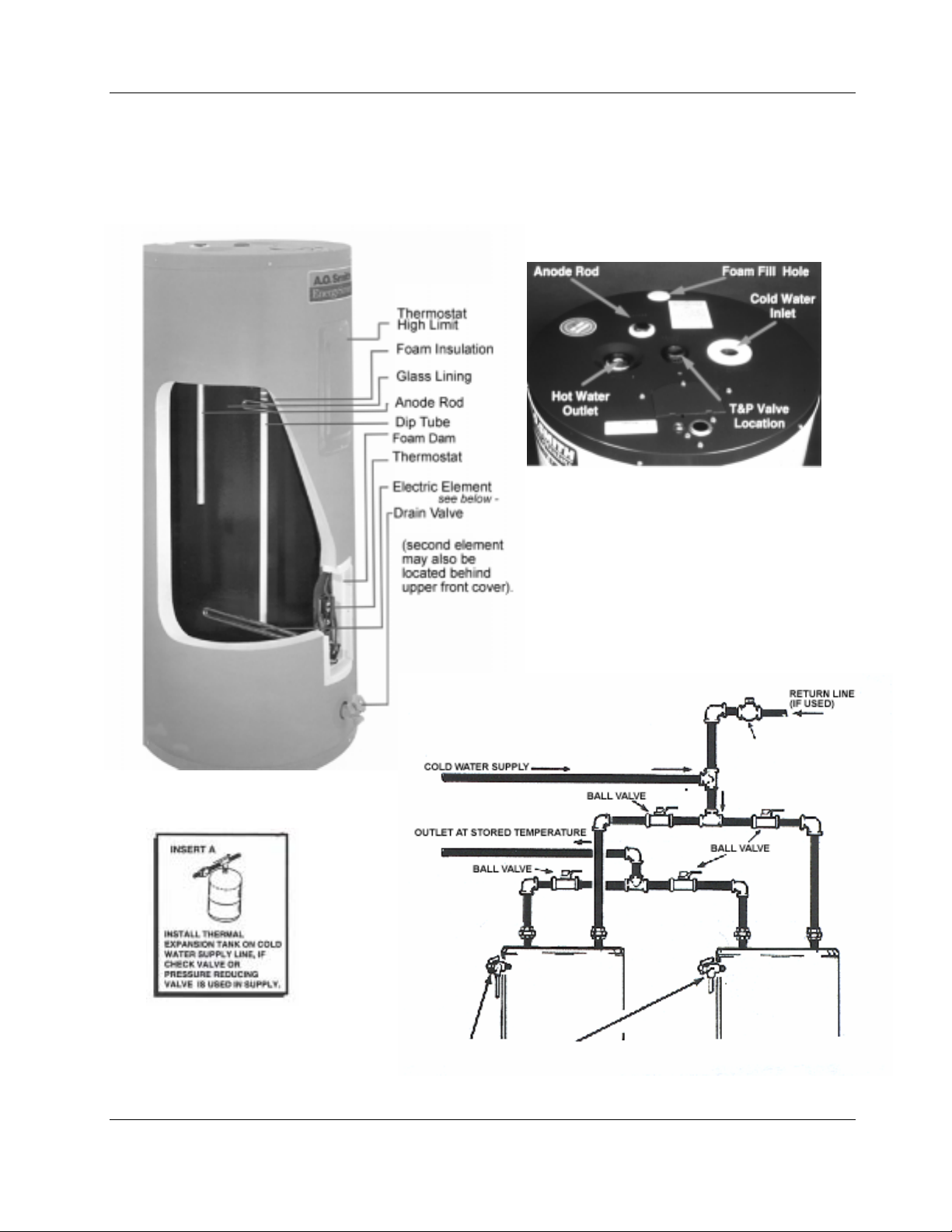

Page 17

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

STANDARD RESIDENTIAL ELECTRIC WATER HEATERS

SOME MODELS MAY HAVE SIDE OR REAR CONNECTIONS

TEMPERATURE AND

PRESSURE RELIEF VALVE

OPENING MAY BE ON SIDE

OR TOP OF HEATER. DO

NOT REUSE OLD VALVE

SERVICE HANDBOOK

INSTALLATION

TO †FUSED

ELECTRICAL

SUPPLY

(BREAKER BOX)

UNION

COLD WATER

INLET LINE

SHUTOFF

VALVE

HOT WATER

TO FIXTURES

ELECTRICAL

JUNCTION BOX

ADJACENT

CONDUIT

ENTRANCE

RATING PLATE

WITH MODEL

AND SERIAL

NUMBER

UNION

†FUSE SHOULD BE RATED

AT AMPERAGE INDICATED

ON RATING PLATE TIMES

125%

INSTALL THERMAL

EXPANSION TANK AFTER

SHUT OFF VALVE. PREPRESSURIZED TO EQUAL

SUPPLY WATER

PRESSURE

DRAIN LINE

ACCESS PANELS – WATER

TEMPERATURE ADJUSTMENT

IS BEHIND THESE PANELS.

RECOMMENDED SETTING IS

°

6” AIR GAP

SEE MANUAL

AND LABELS

FOR

INSTALLATION

CLEARANCES

INSTALL DRAIN PAN TO PREVENT

INSTALLATION MUST FOLLOW LOCAL CODES AND INSTRUCTION MANUAL GUIDELINES.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

16

FLOOR

DRAIN VALVE

Page 18

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

STANDARD RESIDENTIAL ELECTRIC WATER HEATERS

This portion of this manual applies to the Operation and Servicing of Residential Electric,

Tank Type, Water Heaters. The illustrations are for two element models but the

information also applies to single element models.

Multiple Heater Water Piping

Required for Proper Operation

of Top Connect Models

TEMPERATURE/PRESSURE RELIEF VALVES

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

17

Page 19

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

STANDARD RESIDENTIAL ELECTRIC WATER HEATER SERVICE GUIDELINES

Construction

See “General Section” for features common to both gas and electric models.

Miscellaneous:

Amperage (Amps) (1 phase) = Watts divided by Volts

Amperage (3 phase) = (Watts X .577) divided by Volts

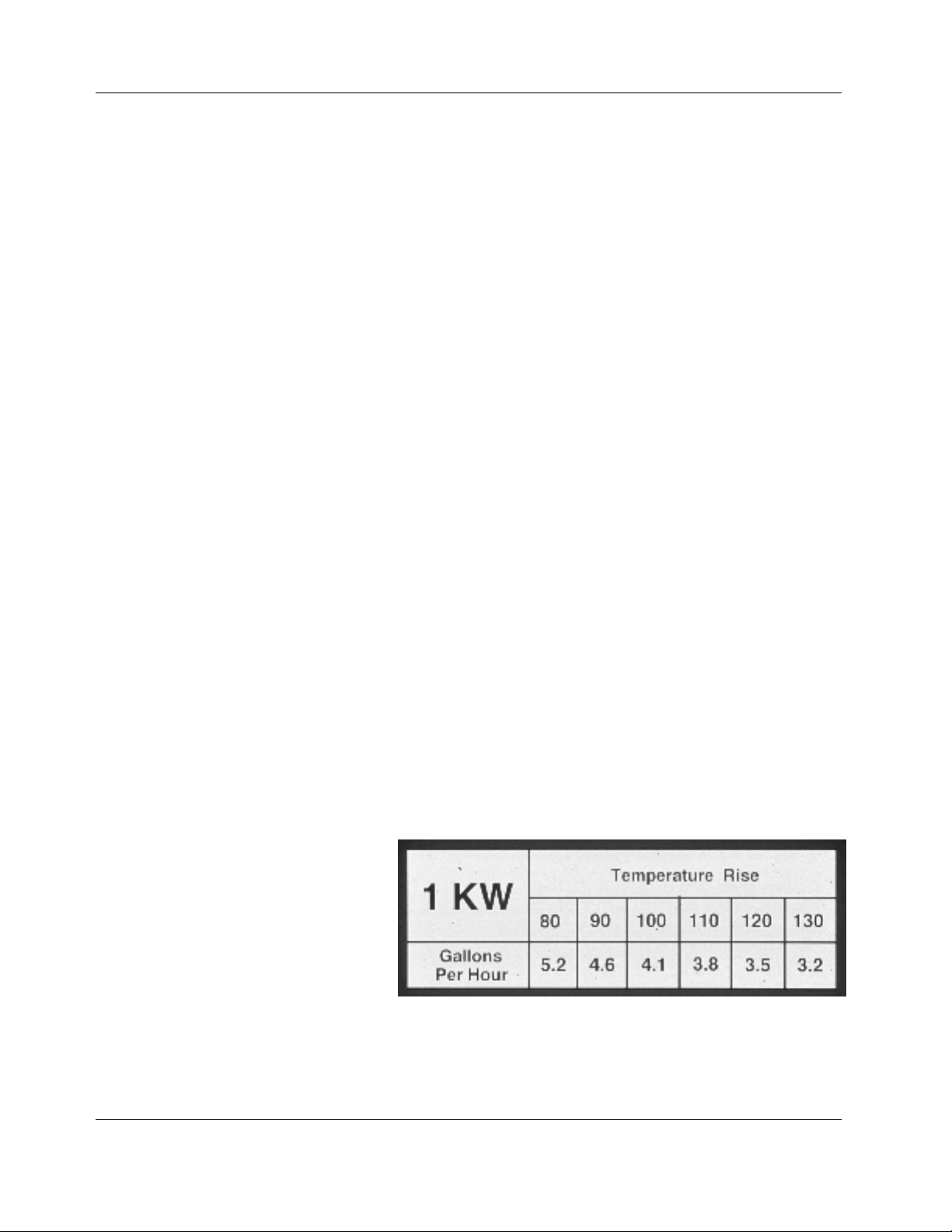

KW Required = (GPH X 8.25 X Temp. Rise X 1.0) divided by (3413)

Ohms = Volts divided by Amperes

One kilowatt is equal to 1000 watts

One kilowatt is equal to 3,413 BTU

Recovery Rate = (KW X 3413) divided by (Temp. Rise X 8.25)

Rise (F°) = (KW X 3413) divided by (GPH X 8.25)

Supply electrical fusing or breakers should be sized at least 125% of expected heater

amperage.

Water weighs 8.25 pounds per gallon at 120°F (49°C).

% of Hot water = (Mixed temp. – Cold) divided by (Hot temp. – Cold)

Heating element(s)

This style water heater will have

one or two electric, heating

elements immersed in the tank.

One element will always be

located low in the tank; a second

element is commonly located

down about 1/3 of the tank height from the top of the tank. These elements will seldom

be wired to operate at the same time. (If they operate at the same time, amperage draw

doubles, wire gauge size increases, fuse size increases and little is gained in heat

recovery.)

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

18

Page 20

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

(

(

)

(

Residential Electric – continued

Since the element (s) are - very nearly - totally immersed in the tank, thermal efficiency is

assumed to be 100%. – all of the Btu (Watts) generated, enter the water.

SERVICE HANDBOOK

B.

A.

C.

•

Watt Density

= the density of the wattage output of the element compared to the surface

area of the element (i.e. “High Watt Density Element” will have the most wattage per square

inch of element surface. If the above elements generated 4,500 w. each, “B” might be

considered a “high” watt density element, “A” a medium and “C” a low.)

• Voltage Notes:

120 volt AC circuit

240 volt AC circuit

Hot)

L1 L2

L2L1

Hot

Hot)

L1 to Ground = 120 Volts

L2 to Ground = 0 Volts

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

19

L1 or L2 to Ground = 120 Volts

L1 L2 = 240 Volts

Page 21

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

SERVICE HANDBOOK

Surface Mounted Thermostat (s) and High Limit (s)

The thermostats and high limits are held against the side of the tank. As the tank surface heats or

cools, a metal disc inside of the control expands or contracts to open or close electrical contacts

in the controls.

They will satisfy within 10°F of setting. The tank surface has to cool 8 - 15°F to reactivate these

controls.

Newer

Model Circuit Older Models

2

59T-Style 4100

2

59T-Style 4000

A-6, A-7 X A-6 Upper Tank 110-170

A-6, A-7,

Models

X X Lower Tank 110-170

1

Location

C-2

3

89T33

3

89T13

2

59T-Style 4000

2

AW-Style 7135

A-6 X Upper Tank 90-150

C-2, A-7 X Lower Tank 90-150

A-6 X Lower Tank 90-150

A-7 X X Upper Tank 110-170

4

66T-Style 4400

A-6, A-7,

X X Lower Tank 190°

C-2

3

89T

A-6, A-7,

X 170°

C-2

1

”

Older” = series 916 or older.

“Newer” = series 917 or more current – (Began approximately January, 1996)

2

Older 59T controls had a maximum setting of 170°F. Replacement 59T controls will stop at

150°F.

3

89T controls are combination High Limit/Thermostat, one piece controls.

4

66T limits may be mounted onto 59T thermostats.

Temperature

Range °F

66T4400

59T4100

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

Thermostat

20

Combination High Limit &

Thermostat

89T 33

Page 22

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

After having confirmed that the water heater

has been installed per the installation

manual instructions:

C-2 Circuit

• Single element

• Single thermostat

• Single High Limit

SERVICE HANDBOOK

C-2 Circuit

Prior to 1996

Power Enters High

Limit 1 and 3

Through High Limit

1, 2 and 3, 4

Through High Limit (2) Jumper

to Thermostat (1) Terminal

And High Limit (4) to Element

Thermostat 1, 2 is Closed

Element is “On”

Tank Water is Heated

Thermostat 1, 2 Opens

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

21

Page 23

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

g

3

Residential Electric – continued

Normal Sequence of Operation

SERVICE HANDBOOK

C-2 Circuit – Standard on most single element

water heaters.

• Single Element

• Single Thermostat

• Single High Limit

Operation from a cold tank of water.

C -

2 CIRCUIT

Post 1995

Power Enters

Hi

h Limit – L1 and L

Through High Limit

L1 to T2 and L3 to L4

Thermostat

WIRING DIAGRAM

Note: If used on a normally two element heater,

controls will be located behind the upper service

cover and the element behind the lower service

cover.

T2 Contacts

Open

T2 Contacts Closed

Power To Element

Element Heats Water

Thermostat Satisfies

T2 Contacts Open

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

22

Page 24

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

, 1,

Residential Electric – continued

SERVICE HANDBOOK

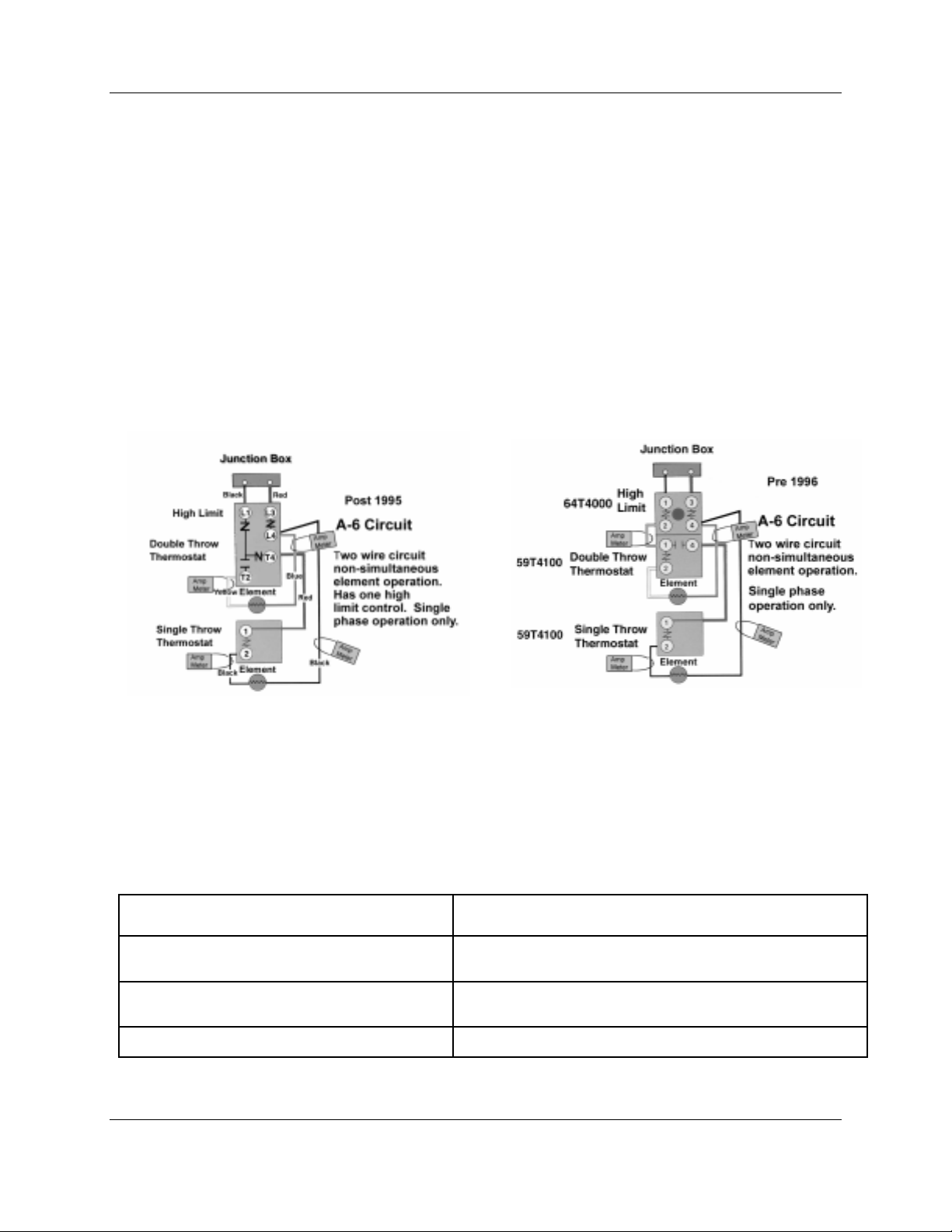

A-6 Circuit

• 2 Elements

• 2 Thermostats

• 1 High Limit

Operation: From cold tank of water

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

Power Enters High-Limit

1, 4 Contacts Open

Power Interrupted to

Upper Element

Upper Thermostat, 1,

2 Open

A-

Through High Limit

Upper Thermostat

1, 2 Contacts Closed

Power to Upper Element

Element Heats Water

Upper Thermostat Satisfied

Switch Power to Lower

Thermostat – Upper

Thermostat

Lower Thermostat

Contacts Open

6 CIRCUIT

4 Closed

23

Lower Thermostat

Contacts Closed

Power to Lower

Element

Element Heats

Water

Lower

Thermostat

Satisfied

Lower 1, 2 open

Power Interrupted

to Lower Element

Page 25

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

SERVICE HANDBOOK

WIRING DIAGRAM

A-6 Circuit

• 2 Elements

• 2 Thermostats

• 1 High Limit

A-6 Circuit

element water heaters non-simultaneous/interlocked operation

- Standard on dual

Operation: From cold tank of water

A-6 Circuit - Post 1995

Power Enters High-Limit

Through High Limit

Upper Thermostat

L1/T4 Contacts Open

L1/T2 Contacts Closed

Power to Upper /Element

Element Heats Water

Upper Thermostat Satisfied

.

Lower Thermostat

Contacts Closed

Power to Lower Element

Element Heats Water

Lower Thermostat

Satisfied

Power Interrupted to

Power Interrupted to Upper Element

Open

L

1/T2

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

Switch Power to Lower Thermostat

Closed

L

1/T4

Lower Thermostat Contacts Open

24

Lower Element

Lower 1, 2

Open

Page 26

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

SERVICE HANDBOOK

A-7 Circuit

• 2 Elements

• 2 Thermostats

• 2 High Limits

• 4 wire

*Some electrical utilities give discounts if electricity is used during “Off Peak” times of the day. This circuit

allows use of an “Off Peak” meter, which interrupts power to the lower element during the time of day when

electricity is more expensive. This customer relies on additional hot water storage to meet their needs while

this element is off.

Prior to 1996

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

25

Page 27

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

Cold tank of water

• Single Electrical Service

• Single Phase

SERVICE HANDBOOK

A-7 Circuit

Prior to 1996

Fused Disconnect

Power Enters

Terminal 1 Of Upper

High Limit And Terminal

3 Of Upper Thermostat

Upper High Limit 1, 2 Is Closed

Upper Thermostat 3, 4 Is Open

Upper Thermostat 1, 2 Is Closed

No Power

To Lower

High Limit

Term 1

Upper Element Is On

Top 1/3 Of Tank Is Heated

Upper Thermostat 1, 2 Opens,

3, 4 Closes

Power From Upper Thermostat 1

To Lower High Limit 1.

Lower High Limit

1, 2 Is Closed

Terminal 3 Of Upper

High Limit And Term 3

Of Lower High Limit

Upper High Limit 3, 4

Is Closed

Lower High Limit 3, 4

Is Closed

Lower Thermostat 1, 2 Is Closed

Lower Element Heats Bottom 2/3 Of Tank

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

26

Page 28

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

SERVICE HANDBOOK

A-7 Circuit

• 2 Elements

• 2 Thermostats

• 2 High Limits

• 4 Wire

WIRING DIAGRAM

A-7 – Post 1995

Four wire circuit for non-simultaneous element operation.

This circuit permits off-peak meter usage and connection to 3 phase supply circuit.

*Interrupts power to lower element

during “peak” charges time of day.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

27

Page 29

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

Cold tank of water

• Single Electrical Service

• Single Phase

SERVICE HANDBOOK

A-7 Circuit

Post 1995

Fused Disconnect

No Power

to Lower

High Limit

Terminal 1

Power to Upper High Limit 1,

and Upper Thermostat 3

Upper High Limit 1, 2 is Closed.

Upper Thermostat 3, 4 is Open

Upper Thermostat 1, 2 is Closed

Upper Element is On

Top 1/3 of Tank is Heated

Upper Thermostat 1, 2 Opens

Upper Thermostat 3, 4 Closes

Power Flows Between

Upper Thermostat 4 and

Lower High Limit L1

Power to Upper High Limit 3

and Lower High Limit L3

Upper High Limit 3, 4 is Closed

Lower High Limit L3, L4 is Closed

Lower High Limit L1 and

Lower Thermostat T2 is Closed

Lower Element Heats Bottom 2/3 of Tank

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

28

Page 30

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

Residential Electric – continued

CERTIFICATION AND APPROVALS

UL – UL-174 applies to Residential Electric Water Heaters

The following paragraph describes the relationship between ASHRAE, NAECA and the

Department of Energy’s ENERGY FACTOR as it relates to the residential electric product lime.

All of the A.O. Smith residential electric water heaters meet this code.

The American Society of Heating, Refrigeration and Air Conditioning Engineer (ASHRAE)

guidelines follow the National Appliance Energy Conservationist Act (NAECA). NAECA follows

the Department of Energy (DOE) test procedures of the 1990 code of federal regulation, title 10,

part 430 (64) which establishes minimum Energy Factors (EF) for water heaters of 12 kilowatts

or less and a storage capacity of at least 20, but not more than 120 gallons.

Formula -The minimum EF allowed = .93 - .00132 x V (volume of storage)

Example (EES-52; 50 gal. x .00132 = .066 Then .93 - .066 = .854 minimum allowable energy

factor).

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

29

Page 31

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

(

)

Residential Electric – continued

SERVICE HANDBOOK

Three Phase – Unbalanced Circuit

Upper/Lower

3000/3000 25.0/14.4 21.7/12.5 10.8/6.3

4000/4000 33.3/19.2 28.9/16.7 14.4/8.3

4500/4500 37.5/21.6 32.5/18.8 16.2/9.4

5000/5000 N/A 36.1/20.8 18.0/10.4

6000/6000 N/A N/A 21.7/12.5

Note: Residential heaters may or may not offer the ability to wire elements for simultaneous

operation. If they are wired for non-simultaneous operation, amperage will be as if wired single

phase.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

3 Supply Wires

6 Element Wires

See A-7 Circuit

3 Supply Wires

4 Element Wires

SIMULTANEOUS DUAL ELEMENTS

(both elements ‘on’ when entire tank is cold)

Element

Wattage

Full Load Current in Amperes

Connected to Three Phase Power

(Terminal L2/ Terminals L1 & L3

208V 240V 480V

30

Page 32

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

SERVICE HANDBOOK

SERVICE

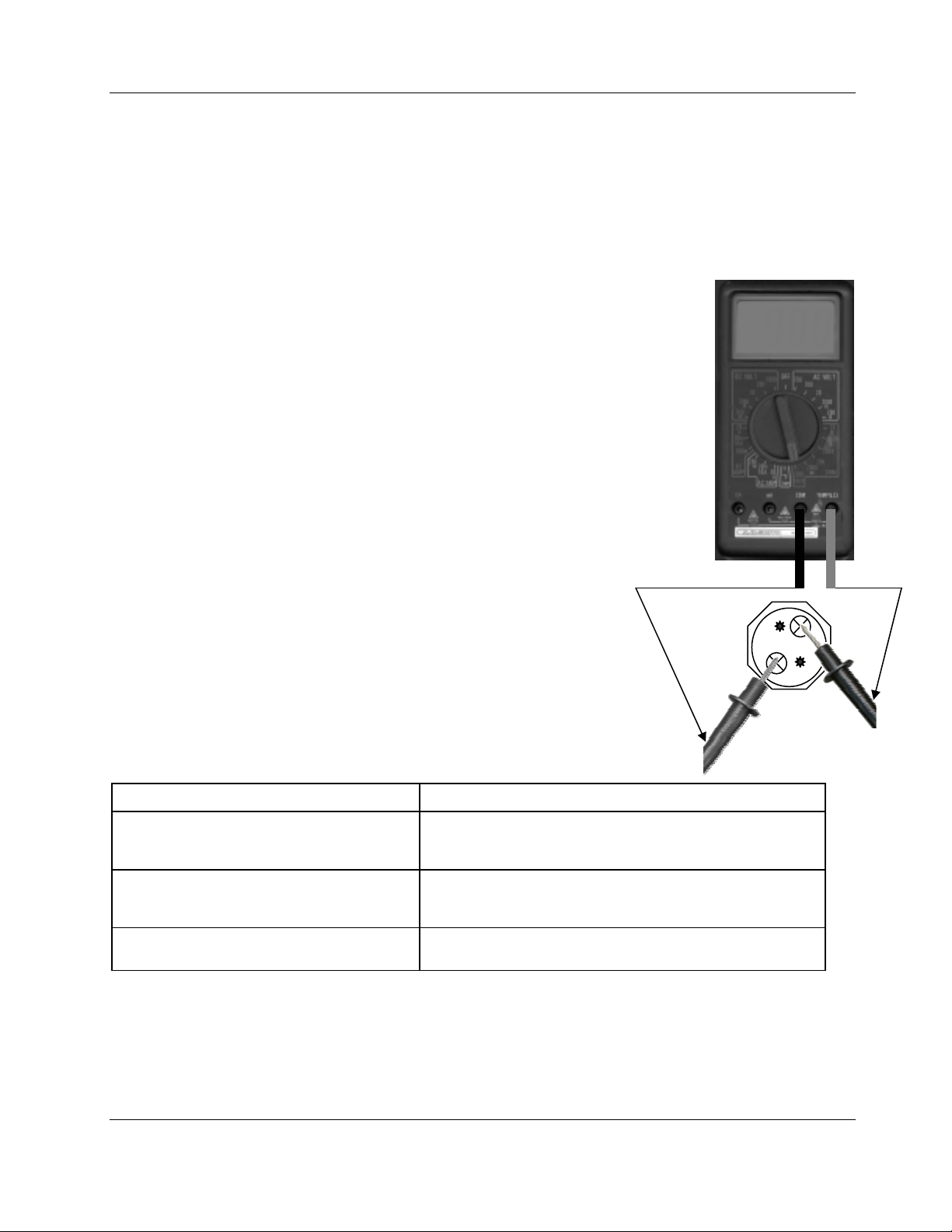

Testing C-2 type – single element, single controls type circuit

Element Test

OHMS Resistance Check**

Test Conditions:

This test uses the multimeter's battery as the electrical supply.

Procedures:

Power to the water heater is "OFF".

Multimeter set to OHMS scale testing.

Black lead "Common" port.

Red lead in "Ω" or " OHMS" port.

Dial indicator set to scale above expected indication.

Note: Volts divided by amps = OHMS

Disconnect wires from the element terminals.

Test probe on each terminal of an element

See OHMS Resistance Table – Page 45

Element

If … … then

proper resistance (+7.5%) is present continue testing.

meter reads "0"

meter reads "1" or off scale replace element.

** The above test can also be conducted with the element removed from the tank.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

• check OHM scale setting.

• replace element

31

Page 33

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

C-2 – service continued

SERVICE HANDBOOK

Complaint: No Hot Water

Conditions:

Tank water cold

Power on

Procedure:

Multimeter set for

AC voltage check

Voltage Checks

Test voltage between 1 and 3 or L1 and L3 of high limit.

If … … then

rated voltage is not present

rated voltage is present continue to next step.

•

check circuit breaker (fused disconnect)

•

check wire connections in heater junction

box

•

check position of heater ON/OFF switch-if

applicable.

Test voltage between 2 and 4 or L1 and L4 of high limit

If …

rated voltage is not present

… then

•

•

press high limit reset button

replace high limit (after conducting

thermostat check)

rated voltage is present continue to next step.

Test voltage between 4 and 2 or T2 and L4

If …

rated voltage is not present

rated voltage is present continue to next step.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

… then

•

check jumper between high limit 2 and

thermostat 1or

•

on T2, L4 test-replace control.

32

Page 34

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

C-2 service “No Hot Water” – continued

SERVICE HANDBOOK

Test between the two element terminals

If …

rated voltage is not present check wiring from control.

rated voltage is present

… then

•

•

repeat Ohms resistance test of element

check for water leaks in piping or fixtures.

Complaint: Water Too Hot

Conditions:

Tank water above thermostat setting +10°F

Power on

Voltage Check

Test between 4 and 2 or L4 and T2

If …

rated voltage is present replace thermostat control.

lower than rated voltage is present test for grounded element.

no voltage is present test complete.

… then

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

33

Page 35

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

C-2 – service “Water Too Hot” – continued

SERVICE HANDBOOK

Grounded Element Check – Amperage Method

Grounded Element Test – using “clamp type” Amperage Meter. Many multimeters

could be used to conduct this test but be certain that possible amperage will not exceed

the multimeter’s limit.

Complaint:

becomes

the heater.

A grounded element is suspected whenever the water temperature

excessively hot

and/or the end user

must push the high limit reset

to reactivate

Amperage measures the flow of current through a wire.

Watts divided by volts = Amps

Conditions:

Power on

Thermostat is satisfied

59T4000

89T13

Test around red wire then black wire to element.

If …

amperage is noted (indicating flowing power) replace the element.

amperage is not noted the element is not grounded.

… then

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

34

Page 36

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

SERVICE HANDBOOK

A-6 Circuit Servicing

Testing A-6 - two element, two thermostat, one high limit, two wire circuit type water

heaters.

Wired non-simultaneously – When the upper element satisfies, power switches to the

lower thermostat and element.

Element Test

OHMS Resistance Check**

Test Conditions:

This test uses the multimeter's battery as the electrical

supply.

Power to the water heater is "OFF".

Multimeter set to OHMS scale testing.

Black lead "Common" port.

Red lead in "Ω" or " OHMS" port.

Dial indicator set to scale above expected indication.

Note: Volts divided by amps = OHMS

Disconnect wires from the element terminals.

Test probe on each terminal of an element

See OHMS Resistance Table – Page 45

Element

If … … then

proper resistance (+7.5%) is

continue testing.

present

meter reads "0"

• check OHM scale setting.

• replace element.

meter reads "1" or off scale

replace element.

** The above test can also be conducted with the element removed from the tank.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

35

Page 37

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

A-6 service – continued

SERVICE HANDBOOK

Testing with the Multimeter

Probes installed to test for "voltage - (black test lead is “common".)

Dial set to AC - Voltage scale - set dial to highest voltage scale or scale above the

expected voltage. Do not set the meter to a scale below the voltage expected.

Complaint: No hot water

Test Conditions:

Tank is full of cold water.

Power is "on" to the heater

Voltage Check

Test between 1 and 3 or L1 and L3

If … … then

correct supply voltage is present continue.

correct supply voltage is NOT present

• check disconnect breaker.

• check wiring to the heater.

Test between 2 and 4 or L1 and L4

If … … then

correct supply voltage is present continue

correct supply voltage is NOT present,

still no power replace High Limit (High Limit/Thermostat on

push Manual Reset - if power is now supplied,

conduct thermostat and element checks.

89T)

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

36

Page 38

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

A-6 service Voltage Check “No Hot Water” – continued

SERVICE HANDBOOK

Test between Thermostat 2 and High Limit 4 or T2 and L4

If … … then

supply voltage is present: continue.

supply voltage is not present

•

check jumper between high limit 2 and

thermostat 1.

•

replace thermostat – (tank must be 15°F

cooler than setting to activate thermostat.

Complaint: Lack of Hot Water

Conditions:

Upper thermostat satisfied

Lower portion of tank still calling for heat

Test between high limit 4 and thermostat 4 and L4 and T4

If … … then

correct supply voltage is present continue.

correct supply voltage is not present

•

check that tank water temp has satisfied

the upper thermostat.

•

replace the upper thermostat.

Test between high limit 4 and lower thermostat 1 or L4 and 1

If … … then

correct supply voltage is present continue.

correct supply voltage is not present check wiring connections.

Test between high limit 4 and lower thermostat 2 or L4 and 2

If … … then

correct supply voltage is present continue.

correct supply voltage is not present replace lower thermostat.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

37

Page 39

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

A-6 service – continued

Grounded Element Test

Meter.

limits of the multimeter will not be exceeded.

Many multimeters could be used to conduct this test but be certain that the amperage

SERVICE HANDBOOK

–

Amperage Method - using “clamp type” Amperage

Complaint:

becomes

reactivate the heater.

Amperage

Watts

A grounded element is suspected whenever the water temperature

excessively hot

measures the flow of current through a wire.

divided by volts = Amps

and/or the end user

must push the high limit reset

to

Test Conditions

Wires on the water heater are all connected to their proper terminals.

Power to the heater is "on".

Both thermostats are satisfied.

Clamp the jaws of the Amp Meter around each wire connected to the elements –

one wire at a time.

If …

meter reads the proper amperage (+5, 10%)

meter reads approximately ½ of the

proper amperage

meter reads NO amperage thermostat and element are not grounded.

… then

the thermostat is calling for heat.

replace the element.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

38

Page 40

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

SERVICE HANDBOOK

Testing The A-7 Wiring Circuit

A-7 Circuit:

Two elements

Two thermostats

Two high limits

Four wires

Non-simultaneous operation or simultaneous

Prior To 1996 Post 1995

Supply wiring may be a: (See Pages 25 and 27)

1. three wire, 3 phase circuit:

2. two wire, single phase circuit or

3. connection to an off peak meter or time clock.

This third, wiring system interrupts power to the lower thermostat during the designated

time period but does not interrupt power to the upper thermostat.

If the consumer uses enough of the stored hot water to drop tank temperature at the top

of the tank to call for upper element activation, then the upper element will reheat the

upper third of the tank

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

39

Page 41

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

A-7 Service – continued

SERVICE HANDBOOK

Element Test

OHMS Resistance Check**

Test Conditions:

Element(s) not heating or water becoming excessively hot.

This test uses the multimeter's battery as the electrical

supply.

Procedure:

Power to the water heater is "OFF".

Multimeter set to OHMS scale testing.

Black lead "Common" port.

Red lead in "Ω" or " OHMS" port.

Dial indicator set to scale above expected indication.

Note: Volts divided by amps = OHMS

Element

Disconnect wires from the element terminals.

See OHMS Resistance Table – Page 45

Test probe on each terminal of an element

If … … then

proper resistance (+7.5%) is present continue testing.

meter reads “0”

•

check OHM scale setting

•

replace element.

meter reads “1” or off scale replace element.

** The above test can also be conducted with the element removed from the tank.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

40

Page 42

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

A-7 Voltage Check

SERVICE HANDBOOK

Voltage Checks

These tests are conducted on the heater, below the junction box.

Complaint: No Hot Water

Test Conditions:

Tank is full of cold water (or at least 15°F below the upper thermostat setting).

Power on

Upper thermostat calling for heat

Multimeter set to the proper AC voltage scale

Test between upper high limit terminals 1 and 3

If … … then

the proper voltage is not present

(disconnect)

the proper voltage is present check wiring in heater junction box

check power from the breaker (fused

disconnect).

continue to next step.

Test between upper high limit terminals 2 and 4

If … … then

the proper voltage is not present push the reset button – if this establishes

proper voltage, conduct thermostat and

element checks before changing the high

limit.

pushing the reset does not restore voltage replace the high limit.

the proper voltage is present continue to the next step.

Test between upper high limit 4 and upper thermostat 2

If … … then

the proper voltage is not present high limit

and upper thermostats 2

the proper voltage is present

•

check the jumper between upper

thermostat 1 and high limit 2.

•

replace the upper thermostat

•

conduct upper element checks.

•

top 1/3 of tank should be hot.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

41

Page 43

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

A-7 Voltage Check - continued

SERVICE HANDBOOK

Complaint: Lack of Hot Water

Test Conditions:

Upper thermostat satisfied

Test between upper high limit 4 and upper thermostat 4

If … … then

proper voltage is not present replace upper thermostat.

proper voltage is present continue to next step.

Test between lower high limit terminal 1 and 3 or L1 and L3

If … … then

proper voltage is not present

proper voltage is present continue to next step.

•

check wiring to upper thermostat and

heater junction box.

•

check that off peak meter is not

“Open”.

Test between lower high limit 2 and 4 or L1 and L4

If … … then

proper voltage is not present push lower high limit reset.

pushing reset restored voltage

pushing reset did not restore voltage replace lower high limit

proper voltage is present continue to next step

•

conduct lower thermostat check

•

conduct lower element checks

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

42

Page 44

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

A-7 service – Voltage Checks “Lack of Hot Water” – continued

SERVICE HANDBOOK

Test Condition

Lower tank water is at least 15°F below lower thermostat setting

Test between lower high limit 4 and lower thermostat 2 or lower high limit L4 and

lower thermostat T2

If … … then

proper voltage is not present:

proper voltage is present: continue to next step.

•

check jumper between lower high limit

2 and lower thermostat 1.

•

replace lower thermostat.

Test between the terminals of the lower element

If … … then

proper voltage is not present: check wire connections to lower controls.

proper voltage is present: conduct grounded element checks.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

43

Page 45

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

Residential Electric – continued

A-7 – continued

SERVICE HANDBOOK

Grounded Element Test – Amperage Method – Using “clamp type” Amperage

Meter. Many multimeters could be used to conduct this test but be certain that the

thermostat is satisfied or the amperage limits of the multimeter may be exceeded.

Complaint: A grounded element is suspected whenever the water temperature

becomes excessively hot and/or the end user must push the high limit reset to

reactivate the heater.

Amperage measures the flow of current through a wire.

Watts divided by volts = Amps

Conditions

Power on

Thermostats are satisfied

Clamp the jaws of the Amp Meter around each wire connected to an element –

one wire at a time.

If … … then

meter reads the proper amperage

(+5, -10%)

meter reads approximately ½ of the

proper amperage

meter reads NO amperage thermostat and element are not grounded

the thermostat is calling for heat

replace the element

Note: Amperage will only be indicated while electricity flows through a wire.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

44

Page 46

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

Miscellaneous Residential Electric Water Heater Service Items:

• Watts divided by Volts = Amps

Supply wire gauge and fuse (breaker) protection must be at least 125% of the expected

Amperage draw of the water heater.

• Volts times Amps = Watts

Replace elements with elements rated at the same wattage and voltage indicated on the

heater model and rating plate. Installing an element with a higher voltage rating or wattage

output may create a safety hazard by overloading the heater wiring or supply wiring or

fusing. Installing an element with a lower wattage or voltage rating will reduce performance.

• Normally, a residential electric water heater with two elements will have only one element

operate at a time. If the upper element or thermostat fails, the customer will be out of hot

water. If the lower element or thermostat fails, the customer should still have 1/3 of the

tank with hot water.

• With two element heaters, the lower element and thermostat will cycle more frequently

than the upper element and thermostat. For this reason, the lower element will normally

accumulate lime faster and fail more often than the upper element. Lower thermostats will

fail more often than upper thermostats.

• Replacement elements:

Replace elements with an element having the most surface area (low watt density)

available for your water heater. By spreading the heat of the element over a greater area,

lime (calcium) buildup rate should be reduced.

Elements constructed of Incoloy are much more durable than elements made of copper

with zinc coating.

• Many electric utilities offer discounts if you do not use electricity during certain times of the

day. Contact them – by purchasing a larger storage water heater, with special wiring (see

A-7 wiring circuit) for time clocks or “off peak meters”, you may save on monthly operating

costs.

Element with Links

Resistance of Element in Ohms (± 7.5%)

Rated Wattage Rated

Voltage

120 23.2 18.6 13.9 11.1 9.28 6.96 5.57

208 72.1 57.7 43.3 34.6 28.8 21.6 17.3

240 92.8 74.3 55.7 44.6 37.1 27.8 22.3

277 128 102 76.7 61.4 51.2 38.4 30.7

Voltage

120 4.64

208 14.4 12.4 10.8 9.61 8.65 7.85* 7.2

240 18.6 15.9 13.9 12.4 11.1 10.1* 9.28

277 25.6 21.9 19.2 17.1 15.3 14.0 12.8

480 76.8 65.7 57.5 51.1 45.7 41.8 38.4

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

600 750 1000 1250 1500 2000 2500

Rated Wattage Rated

3000 3500 4000 4500 5000 5500 6000

45

Page 47

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

A.O. SMITH TECHNICAL BULLETINS

The following are bulletins designed to help service the standard, residential gas and

electric model water heaters. These bulletins and more are available on the A. O. Smith

website www.hotwater.com.

This information is intended to supplement service and maintenance information found

in the heater installation and operation manual.

“Why water heaters leak” information .............................................. 47-48

Index of Technical Bulletins:

Water Hammer.................................................................................. 49

Mineral Buildup ................................................................................. 50

Aluminum Hydroxide ......................................................................... 51

Discolored Water............................................................................... 52

Smelly Water..................................................................................... 53

Chlorination Procedure...................................................................... 54

Not Enough Hot Water - Gas ............................................................ 55

Not Enough Hot Water – Electric ...................................................... 56

Thermal Expansion ...........................................................................57

Leaking Temperature and Pressure Relief Valve.............................. 59

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

46

Page 48

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

WHY WATER HEATER TANKS LEAK

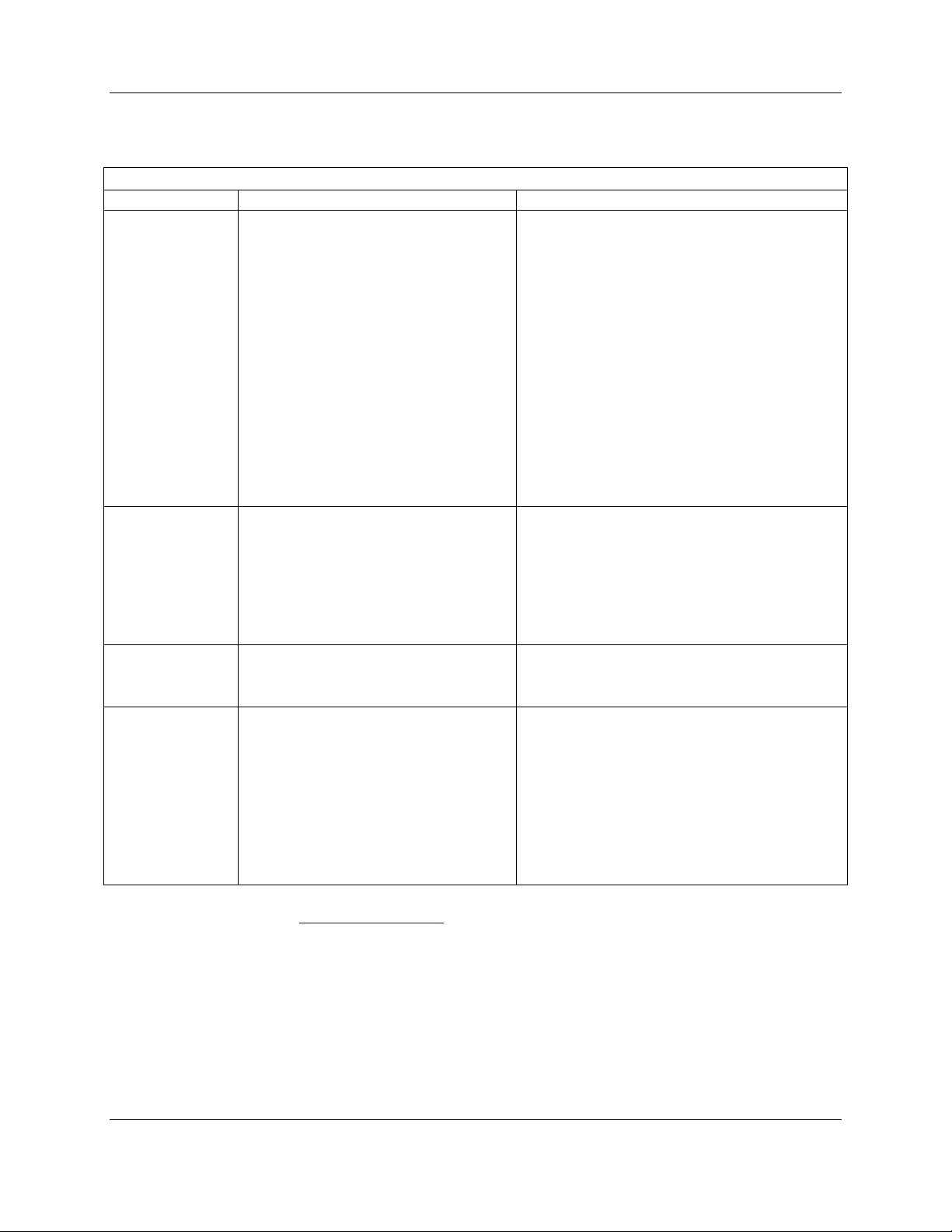

WHAT WHY PREVENTION

Water

Pressure

Water expands when it is heated

(Thermal Expansion). Water

cannot be compressed.

Excessive Pressure in the tank

causes failure of joints, welds or

gaskets.

Condensation

(Gas Water

Heaters)

Products of combustion contain

moisture. As the combustion

products cool the moisture

becomes liquid – carbonic acid.

The acid attacks the metal.

Higher efficiency water heaters

have cooler gases.

Recommended water storage

temperatures create cooler

surfaces.

Contaminated

Air

Bleaches, floor waxes,

detergents, salt and many other

household products contain

chemicals which, when drawn into

contact with a flame (a gas water

heater uses 12 cubic feet of air for

each 1000 BTU of heat

generated). When these

chemical vapors or dusts come

into contact with a flame or

electrical contact, various acids

form. These acids attack the

metal.

Soft Water Soft water minimizes mineral

buildup within the tank. Minimal

minerals maintain the water

heater at high efficiency but may

also expose interior surfaces to

corrosion. Mineral buildup in

some heaters prevents them

leaking while greatly reducing

efficiency.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

A Temperature and Pressure Relief

Valve limits pressure to a

maximum.

Adding a Thermal Expansion Tank

limits pressure to near supply water

pressure.

Install a water heater with capacity

to minimize significant stored water

temperature drop during usage.

Store water at a higher temperature

– install a mixing valve to reduce

danger of scalding.

Supply the heater with clean air.

“Direct Vent” water heaters use air

from outside of the building for

combustion.

A metal “Anode” rod within the tank

helps to prevent internal corrosion.

Maintain the self sacrificing “anode”

rod by inspecting the rod annually

and replacing when large “gouges”

appear in its surface.

47

Page 49

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

WHY WATER HEATER TANKS LEAK - Continued

WATER CONDITIONS

WHAT WHY PREVENTION

“Hard” Water

(Gas Water

Heaters)

“Hard” water contains minerals.

As water is heated the minerals

separate from the water and

attach to hot surfaces within the

tank. In gas water heaters, these

minerals “insulate” the heat

transfer surfaces conducting heat

from the burner through to the

water. These surfaces become

hotter than if they were clean.

Hotter surfaces mean more

expansion and contraction of the

metal as the burner cycles on and

off. The metal or weld joints

crack.

“Hard” Water

(Electric Water

Heaters)

See above explanation.

Lime (calcium) forms on the

electric elements.

Elements become excessively hot

and may split.

Split elements often leak to the

outside of the heater.

Water

Temperature

Water stored at 160°F (72 °C)

may be twice as corrosive as

water stored at 140°F (60°C)

Usage Each time the burner or elements

cycle on and off, a small amount

of metal expansion and

contraction take place. As

bending a piece of wire back and

forth will break the wire, this

expansion and contraction will

eventually crack tank joints or

welds.

For more detailed explanation on this information as well as additional service information, see

the A.O. Smith Web site www.hotwater.com

under “Technical Information”.

0801

form TC-063

“Flush” the sand from the tank every 6

months.

Delime the tank interior yearly.

Install a water softener in hard water

areas. These should be adjusted

according to manufacturer’s

recommendations, typically for 5 grains

hardness.

Inspect and clean elements as

necessary.

Add a water softener.

Install elements resistant to failure due to

Lime (mineral) build up.

Begin with a water heater setting of

120°F (49°C) and increase only as

necessary.

Purchasing a proper sized tank will

minimize burner or element operation

when only small quantities of hot water

are used.

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

48

Page 50

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

TECHNICAL BULLETIN

BULLETIN 11

WATER HAMMER

GENERAL

EFFECTS

THE FIX

NOTES

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

Water hammer is the destructive forces, pounding noises and vibration in a piping

system when water flowing through a pipeline is stopped abruptly. When water

hammer occurs, a high intensity pressure wave travels back through the piping

system until it reaches a point of some relief. The shock wave will then surge back

and forth between the point of relief and the point of stoppage until the destructive

energy is dissipated in the piping system. The violent action accounts for “banging”,

“thumping”, and/or intense vibration in the pipe line. Although noise is generally

associated with the occurrence of water hammer, it can occur without audible sound

or noise. Quick closure always causes some degree of shock with or without noise.

The common cause of water hammer is single lever faucets (sinks/lavatories) or

automatic solenoid valves (dishwashers, washing machines, etc.). The speed of the

valve closure time is directly related to the intensity of the surge pressure.

The damage from water hammer can manifest itself in a number of ways. The most

common are:

Expanded Tank Shell - This can be demonstrated by measuring the circumference at

•

various locations along the shell. Pressures in excess of the maximum design working

pressure can cause permanent deformation of the shell

Collapsed Flue Tube - This will choke off the ability to vent the products of combustion

•

causing the flame and/or combustion to spill out from the combustion chamber. Often

this will occur where thinning of the flue tube walls has occurred due to contamination

of the combustion air or because of excessive condensation

Inverted or Deformed Tank Heads - Often this accompanies collapsed flues, but one

•

or both heads can be deformed.

The only effective means of control is to install water hammer arrestors. These

devices have diaphragms, which separate an air chamber from the water in the piping

system. As the shock wave reaches this device, the air chamber absorbs the shock.

Arrestors should be located as close as possible to the source of the shock wave.

Since water hammer exposes the equipment to pressures in excess of its design

limits, failures caused by water hammer are not eligible for warranty consideration.

49

.

.

Page 51

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

TECHNICAL BULLETIN

BULLETIN 13

MINERAL BUILD-UP

SYMPTOMS

• Rumbling

CAUSE

THE FIX

NOTES

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

With the advent of high input and larger storage tanks in both commercial and

residential heaters, deliming has become a necessity of modern maintenance.

Lime (CaCO

Lime is present in every water system to some degree across the entire

United States. Since lime is inversely soluble [the more you heat, the more

lime comes out], higher usage, excessive hardness, and increased heating

surface can lead to a high incidence of “limed-up” heaters.

Symptoms often include a popping of water trapped under lime deposits or

the sizzling of water trapped next to elements, boiling it to steam.

Treatment of a “ limed-up“ heater is relatively simple. Since CaCO

the easiest way to dissolve it so it can be flushed from the heater is with an

acid. The most commonly used is phosphoric acid at a food-grade level.

Two common treatments marketed by A.O. Smith are Mag-Erad and Un-

Lime. Any well-stocked plumbing supply house should have a deliming

solution available.

The directions on the product should be followed explicitly.

For additional information and instructions in deliming water heaters and

boilers, please refer to the following pamphlets available from A.O. Smith:

• Why? When & How: To Remove Water Scale from Tank Type Water

• The Mag-Erad

• Up-N-Down

• All About Deliming Coil Type Water Heaters

), is the most notable factor when discussing water hardness.

3

Heaters

• Crackling

Method of Cleaning Gas Fired Water Heaters

Transfer Kit

50

• Popping

is a base,

3

Page 52

RESIDENTIAL GAS AND ELECTRIC WATER HEATER

SERVICE HANDBOOK

TECHNICAL BULLETIN

BULLETIN 14

ALUMINUM HYDROXIDE

SYMPTOMS

CAUSE

THE FIX

NOTE

A.O. Smith Water Products Company Training Department

©2002 Ashland City, Tennessee

“Crackling”, “gurgling”, or “popping” noises from new water heaters (installed less than

six months).

In a few isolated parts of the United States where the water supply has a relatively high pH (8+),

water conditions will react with the aluminum anode to form excessive amounts of aluminum

hydroxide on the anode and in the bottom of the tank. Aluminum hydroxide looks like “jelly

beads” or a green, blue or gray gel like substance in the heater drain or at faucet aerators

.

This procedure should only be performed by someone with abilities equal to a licensed

tradesman. Aluminum hydroxide can be removed by using one of the methods outlined.

If tank is new with no lime build-up to any degree:

1 Turn off the heater.

2 Remove the anode.

3 Flush the tank thoroughly with water.

4 Replace the aluminum anode (identifiable by smooth surface on plug) with magnesium

anode (identifiable by weld bead on plug).

If the tank is new with lime build-up to any degree:

1 Turn off the heater.

2 Drain the heater.

3 Remove the anode.

4 Add UN-LIME to the tank.

5

6 Shut off the water heater.

7 Allow the heated UN-LIME to stand for up to 12 minutes.

8 Drain and flush the tank. Caution: UN-LIME will still be hot.

9 Replace the original aluminum anode with a magnesium anode.

10 Fill the system with water.

11 On electric models, return the wiring to its original configuration.

12 Turn heater fuel “ON”.

Since aluminum hydroxide is a product of a chemical reaction dependent on the water condition,

any treatment is not considered warranty related.

20-40 gallon models (use 3 gallons of UN-LIME)

41-65 gallon models (use 5 gallons of UN-LIME)

66-100 gallon models (use 7 gallons of UN-LIME)

(On electric models, be certain the lower element is immersed in solution.)

Heat the UN-LIME to a temperature between 140°F to 160°F.

•

GAS - Heat for 7 to 10 minutes.

ELECTRIC - Power off and remove the yellow wire from terminal 2 on the upper thermostat.

•

Move the red wire from terminal 4 of the upper thermostat to terminal 2 of the upper

thermostat. This allows operation of the lower element only. Restore power to the heater.

Be certain that only the lower element is operating. Heat for 7 to 10 minutes.