Page 1

INSTALLATION - OPERATION - MAINTENANCE

Low Lead Content

C US

LISTED

Solar Water Heater

Instruction Manual

DIRECT SOLAR WATER HEATERS

FOR POTABLE WATER HEATING ONLY

ALL TECHNICAL AND WARRANTY QUESTIONS: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, PLEASE WRITE TO THE COMPANY LISTED ON THE RATING PLATE ON THE WATER HEATER.

PRINTED 1215 184441-005

KEEP THIS MANUAL IN THE POCKET ON HEATER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

1

1

Page 2

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use, and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to

warn you and others of a potential injury hazard. Read and obey all safety messages and instructions throughout this

manual. It is very important that the meaning of each safety message is understood by you and others who install, use,

or service this water heater.

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER

WARNING

CAUTION

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety

message, and how to avoid the risk of injury.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or injury.

CAUTION indicates a potentially hazardous situation

which, if not avoided, could result in minor or moderate

injury.

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, could result in property damage.

IMPORTANT DEFINITIONS

• QualiedInstaller:A qualied installer must have ability equivalent to a licensed tradesman in the elds of plumbing and electrical

installation of these appliances. This would include a thorough understanding of the requirements of the National Electrical Code and

applicable local electrical and plumbing codes (and tools necessary to conrm proper installation and operation of the water heater) as

they relate to the installation of electric water heaters. The qualied installer must have a thorough understanding of the water heater

Instruction Manual.

• Service Agency: A service agency also must have ability equivalent to a licensed tradesman in the elds of plumbing and electrical

installation of these appliances. This would include a thorough understanding of the requirements of the National Electrical Code and

applicable local electrical and plumbing codes (and tools necessary to conrm proper installation and operation of the water heater) as

they relate to the installation of electric water heaters. The service agency must have a thorough understanding of the water heater

Instruction Manual.

2

Page 3

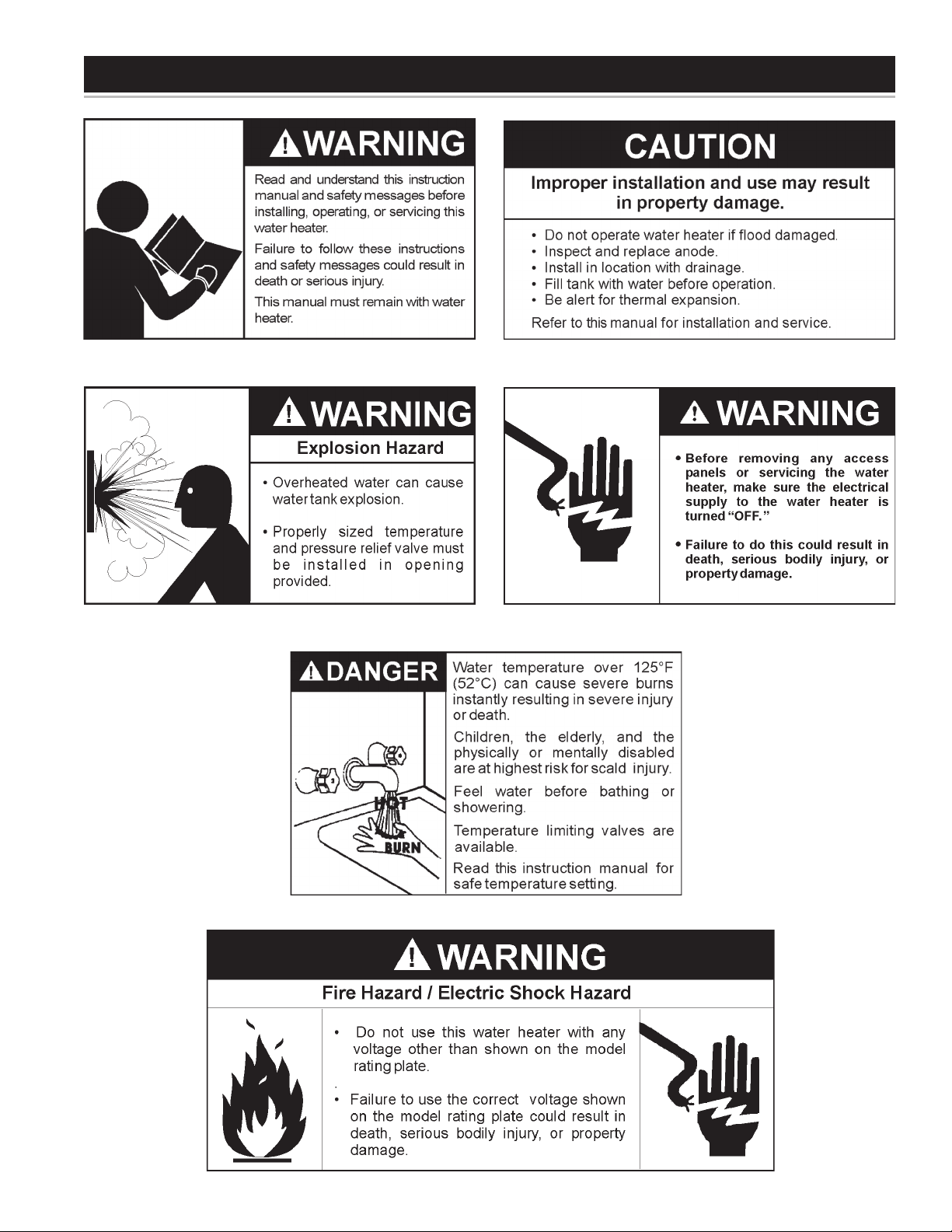

GENERAL SAFETY

3

3

Page 4

INTRODUCTION

Thank You for purchasing this solar water heater. Properly

installed and maintained, it should give you years of trouble

free service.

Abbreviations Found In This Instruction Manual:

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• AHRI - Air-Conditioning, Heating, and Refrigeration Institute

• NEC - National Electrical Code

• NFPA - National Fire Protection Association

• UL - Underwriters Laboratories Inc.

• CSA - Canadian Standards Association

PREPARING FOR THE INSTALLATION

1. Read the “General Safety” section of this manual rst and then

the entire manual carefully. If you don’t follow the safety rules,

the solar water heater will not operate properly. It could cause

DEATH, SERIOUS BODILY INJURY, AND/OR PROPERTY

DAMAGE.

This manual contains instructions for the installation,

operation, and maintenance of the electric water heater. It also

contains warnings throughout the manual that you must read

and understand. All warnings and all instructions are essential

to the proper operation of the water heater and your safety.

READ THE ENTIRE MANUAL BEFORE ATTEMPTING TO

INSTALL OR OPERATE THE SOLAR WATER HEATER.

2. The installation must conform with these instructions and the

local code authority having jurisdiction and the requirements of

the power company. In the absence of local code requirements

follow NFPA-70, the National Electrical Code (current

edition), which may be ordered from: National Fire Protection

Association, 1 Batterymarch Park, Quincy, MA 02269.

3. If after reading this manual you have any questions or do not

understand any portion of the instructions, call the local utility

or the manufacturer whose name appears on the rating plate.

4. Carefully plan your intended placement of the water

heater. INSTALLATION OR SERVICE OF THIS WATER

HEATER REQUIRES ABILITY EQUIVALENT TO

THAT OF A LICENSED TRADESMAN IN THE FIELD

INVOLVED. PLUMBING AND ELECTRICAL WORK

ARE REQUIRED.

Examine the location to ensure the water heater complies with

the “Facts to Consider About the Location” section in this manual.

5. For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during

an earthquake. See instructions for correct installation

procedures. Instructions may be obtained from California

Ofce of the State Architect, 400 P Street, Sacramento, CA

95814.

6. Massachusetts Code requires this water heater to be installed

in accordance with Massachusetts 248-CMR 2.00: State

Plumbing Code and 248-CMR 5.00.

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE............................2

GENERAL SAFETY..................................................................3

INTRODUCTION ...................................................................... 4

Preparing for the Installation...............................................4

TABLE OF CONTENTS ............................................................ 4

TYPICAL INSTALLATION ......................................................... 5

LOCATING THE NEW SOLAR WATER HEATER ....................6

Facts to Consider About the Installation .............................6

Insulation Blankets .............................................................6

INSTALLING THE NEW SOLAR WATER HEATER ............6-11

Local Codes........................................................................6

Temperature-Pressure Relief Valve .................................6-8

Closed System/Thermal Expansion ...................................8

Locating the Solar Water Heater ........................................8

Water Piping ..................................................................8-10

Filling the Solar Water Heater with Water .........................10

T&P Valve and Pipe Insulation (Selected Models) ........... 10

Wiring of Element ........................................................ 10-11

Thermostat ....................................................................... 11

Tank Sensor...................................................................... 11

OPERATION ........................................................................... 12

Temperature Regulation ................................................... 12

Temperature Settings .......................................................12

Temperature Adjustment...................................................12

FOR YOUR INFORMATION ...................................................13

Thermal Expansion...........................................................13

Strange Sounds ................................................................ 13

Water Odor .......................................................................13

“Air” in Hot Water Faucets ................................................13

High Temperature Shut Off System ..................................13

MAINTENANCE ................................................................14-15

Draining & Flushing .......................................................... 14

Element ............................................................................14

Heating Element Replacement ......................................... 14

Thermostat Removal / Replacement ................................ 14

Anode Rod Inspection ...................................................... 15

Temperature-Pressure Relief Valve Operation .................15

Water Heater Sounds .......................................................15

REPAIR PARTS ......................................................................16

Repair Parts Schedule......................................................16

4

Page 5

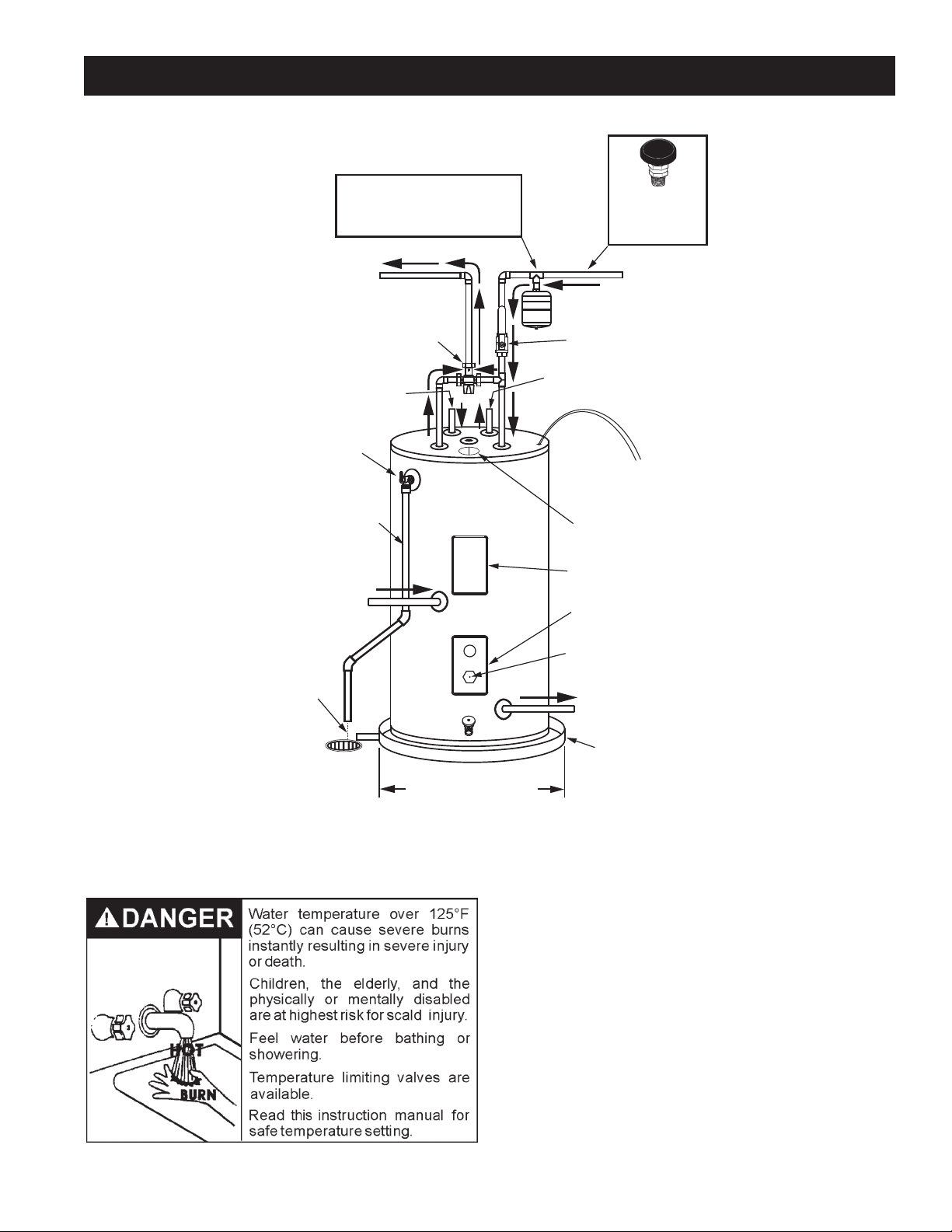

TYPICAL INSTALLATION

Check all connections for leaks. Consult the local utility company to examine installation for propriety and safety.

INSTALL THERMAL EXPANSION

TANK IF WATER HEATER IS

INSTALLED IN A CLOSED

TEMPERED

WATER

OUTLET

FROM

COLLECTOR

(SOLAR LOOP)

TEMPERATURE

PRESSURE

RELIEF VALVE

DISCHARGE PIPE

(DO NOT PLUG)

FROM

COLLECTOR

(SOLAR LOOP)

(ALTERNATE)

WATER SYSTEM

MIXING

VALV E

VACUUM RELIEF

VALV E

INSTALL PER

LOCAL CODES

COLD

WATER

INLET

WATER INLET

SHUTOFF

VALV E

TO PUMP

(SOLAR LOOP)

SENSOR

WIRES

ELECTRICAL

JUNCTION BOX

HEATING ELEMENT

ACCESS COVER

TANK SENSOR STUD

ACCESS COVER

6” AIR GAP

TO SUITABLE

DRAIN

DRAIN

VALV E

AT LEAST 2” GREATER

THAN THE DIAMETER

OF THE WATER HEATER.

Figure 1.

Water (Potable) Heating: All models are considered suitable

for water (potable) heating only.

TANK SENSOR STUD

TO PUMP

(SOLAR LOOP)

(ALTERNATE)

SUITABLE DRAIN PAN

HOTTER WATER CAN SCALD:

Water heaters are intended to produce hot water. Water heated to a

temperature which will satisfy space heating, clothes washing, dish

washing, and other sanitizing needs can scald and permanently injure

you upon contact. Some people are more likely to be permanently

injured by hot water than others. These include the elderly, children,

the inrm, or physically/mentally disabled. If anyone using hot water

in your home ts into one of these groups or if there is a local code

or state law requiring a certain temperature water at the hot water

tap, then you must take special precautions. In addition to using

the lowest possible temperature setting that satises your hot water

needs, a means such as a mixing valve should be used at the hot

water taps used by these people or at the water heater. Mixing valves

are available from your local plumbing contractor. Consult a Qualied

Installer or Service Agency. Follow mixing valve manufacturer’s

instructions for installation of the valves. Before changing the factory

setting on the thermostat, read the “Temperature Regulation” section

in this manual.

5

5

Page 6

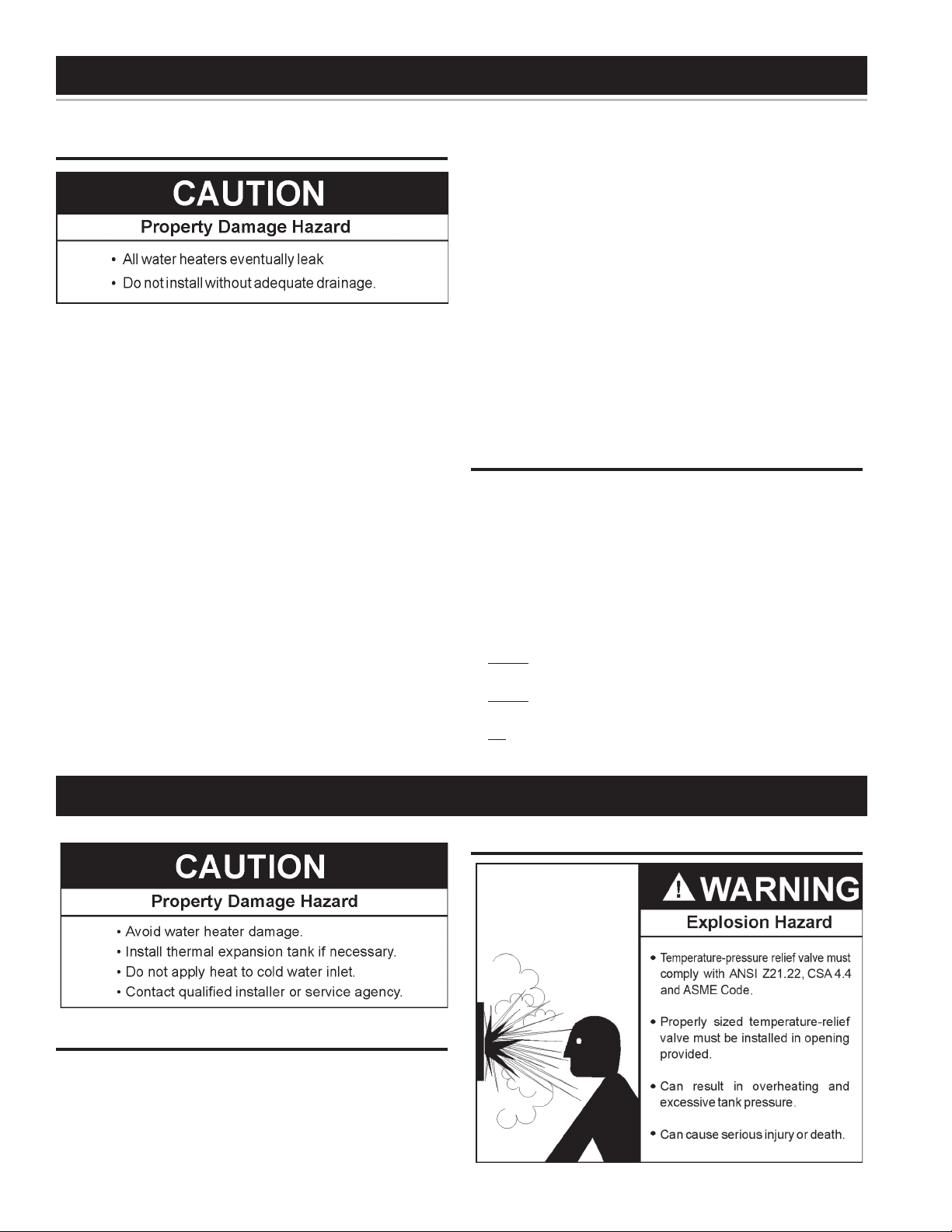

LOCATING THE NEW SOLAR WATER HEATER

FACTS TO CONSIDER ABOUT THE LOCATION

Carefully choose an indoor location for the new solar water

heater, because the placement is a very important consideration

for the safety of the occupants in the building and for the most

economical use of the water heater.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must

be observed:

1. Select a location indoors as close as practical or centralized

to the water piping system as possible. The solar water

heater should be located in an area not subject to freezing

temperatures.

2. Selected location must provide adequate clearances (4”/101.6

mm) for servicing parts such as the thermostats, drain valve, and

relief valve. Adequate clearance for servicing this water heater

should be considered before installation, such as changing the

anodes, etc.

3. The solar water heater should be located so it is not subject to

physical damage by moving vehicles or area ooding.

Installation of the solar water heater must be accomplished in

such a manner that if the tank or any connections should leak,

the ow will not cause damage to the structure. For this reason,

it is not advisable to install the solar water heater in an attic or

upper oor. When such locations cannot be avoided, a suitable

metal drain pan should be installed under the solar water heater.

Drain pans are available from your local plumbing contractor.

Such a drain pan must have a minimum length and width of at

least 2 inches (51 mm) greater that the water heater dimensions

and must be piped to an adequate drain.

Water heater life depends upon water quality, water pressure and the

environment in which the water heater is installed. Water heaters are

sometimes installed in locations where leakage may result in property

damage, even with the use of a drain pan piped to a drain. However,

unanticipated damage can be reduced or prevented by a leak detector

or water shut-off device used in conjunction with a piped drain pan.

These devices are available from some plumbing supply wholesalers

and retailers, and detect and react to leakage in various ways:

• Sensors mounted in the drain pan that trigger an alarm or turn off

the incoming water to the water heater when leakage is detected.

• Sensors mounted in the drain pan that turn off the water supply to

the entire home when water is detected in the drain pan.

• Water supply shut-off devices that activate based on the

water pressure differential between the cold water and hot

water pipes connected to the water heater.

INSULATION BLANKETS

Insulation blankets are available to the general public for external

use on electric water heaters but are not necessary with this

product. The purpose of an insulation blanket is to reduce the

standby heat loss encountered with storage tank heaters. Your

water heater meets or exceeds the National Appliance Energy

Conservation Act standards with respect to insulation and standby

loss requirements, making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions below. Failure to follow these

instructions can result in re, serious personal injury, or death.

• Do not cover the temperature and pressure relief (T & P) valve

with an insulation blanket.

• Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

• Do obtain new warning and instruction labels for placement on

the blanket directly over the existing labels.

INSTALLING THE NEW SOLAR WATER HEATER

LOCAL CODES

The installation of solar water heater must be in accordance with

these instructions and all applicable local codes and electric utility

requirements. In the absence of local codes, install in accordance

with the current edition of the National Electrical Code (NFPA-70).

TEMPERATURE-PRESSURE RELIEF VALVE

6

Page 7

This heater is provided with a properly certied combination

temperature - pressure relief valve by the manufacturer.

The valve is certied by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed equipment

of materials as meeting the requirements for Relief Valves for Hot

Water Supply Systems, ANSI Z21.22 • CSA 4.4, and the code

requirements of ASME.

7If replaced, the valve must meet the requirements of local codes,

but not less than a combination temperature and pressure relief

valve certied as indicated in the above paragraph.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostatic working pressure of

the water heater (150 psi = 1,034.21 kPa) and a discharge

capacity not less than the water heater input rate as shown

on the model rating plate (Electric heaters - watts x 3.412

equal BTU/hr rate).

For safe operation of the water heater, the relief valve must

not be removed from its designated opening nor plugged.

The temperature-pressure relief valve must be installed directly

into the tting of the water heater designed for the relief valve.

Position the valve downward and provide tubing so that any

discharge will exit only within 6 inches (152.4 mm) above an

adequate drain, or external to the building or structure. Be

certain that no contact is made with any live electrical part. The

discharge opening must not be blocked or reduced in size under

any circumstances. Excessive length, over 30 feet (9.14 m), or

use of more than four elbows can cause restriction and reduce

the discharge capacity of the valve.

No valve or other obstruction is to be placed between the relief

valve and the tank. Do not connect tubing directly to discharge

drain unless a 6 inch air gap is provided. The relief valve must

be allowed to discharge water in sufcient quantities, should

circumstances demand, to prevent bodily injury, hazard to life,

or property damage. If the discharge pipe is not connected

to a drain or other suitable means, the water ow may cause

property damage.

• Must not be capped, blocked, plugged or contain any valve

between the relief valve and the end of the discharge line.

• Must terminate a maximum of six inches above a oor drain

or external to the building. In cold climates, it is recommended

that the discharge line be terminated at an adequate drain

inside the building.

• Must be capable of withstanding 250°F (121°C) without

distortion.

• Must be installed to allow complete drainage of both the valve

and discharge line.

WATER INLET

SHUTOFF

VALV E

TEMPERATURE

PRESSURE

RELIEF VALV E

The Temperature & Pressure Relief Valve:

• Must not be in contact with any electrical part.

• Must be connected to an adequate discharge line.

• Must be rated higher than the working pressure shown on the

rating plate of the water heater

The Discharge Pipe:

• Must not be smaller than the pipe size of the relief valve or

have any reducing coupling installed in the discharge line.

6” AIR GAP

TO SUITABLE

7

7

DISCHARGE PIPE

(DO NOT PLUG)

DRAIN

DRAIN

VALV E

Figure 2.

Page 8

Figure 3.

WARNING: The temperature-pressure relief valve should be

manually opened once a year. Caution should be taken to ensure that

(1) no one is in front of or around the outlet of the temperaturepressure relief valve discharge line, and (2) the water manually

discharged will not cause any bodily injury or property damage

because the water may be extremely hot.

If after manually operating the valve, it fails to completely reset and

continues to release water, immediately close the cold water inlet

to the water heater, follow the draining instructions, and replace

the temperature-pressure relief valve with a new one.

WARNING: If the temperature-pressure relief valve on the water

heater weeps this may be due to thermal expansion. The water

supply serving this solar water heater may have a check valve

installed. Contact the water supplier or local plumbing contractor

on how to control this situation. Do not plug the temperaturepressure relief valve.

CLOSED SYSTEM/THERMAL EXPANSION

sized expansion tank in a closed system will void the warranty

on the water heater in the event of tank failure. It is important

to follow the thermal expansion tank manufacturers’ installation

instructions and to adjust the expansion tank pressure to match

the water supply pressure. Contact a plumbing service agency

or your retail supplier regarding the installation of a thermal

expansion tank.

LOCATING THE SOLAR WATER HEATER

If you have a choice of where to install the solar water heater,

these ideas may help you decide.

1. Put the solar water heater indoors as close as possible to where

you use the most hot water. This water heater is not

intended for outdoor installation.

2. It is handy to have a oor drain, tub or sink nearby. That will

make it easy to drain water from the water heater. It is also a

good place to end the drain line of the temperature-pressure

relief (T & P) valve.

3. The solar water heater or the pipes and the connections may,

in time, leak. Put the water heater in a place where a water

leak will not damage anything.

4. You must not put the water heater in an area where it might

freeze. You must turn off the electricity to the water heater

before you drain it, to protect the heating elements.

5. Make sure that you are able to reach the drain valve and all

access panels when the water heater is in place. This will make

it easy to service the water heater.

6. The water heater must be level before you begin the piping.

Most public water systems in North America are required to

prevent water owing from points of use (residences, businesses,

etc.) back into the supply system in order to maintain water quality.

To accomplish this, back ow preventers such as check valves,

are installed in the water line going to each point of use. Typically

the back ow preventer will be installed at the water meter or

inside a building where the supply line enters the building. This

device allows water to ow into the residence but does not allow

it to ow back into the water supply. This creates what is known

as a “Closed System”. As water is heated by the water heater,

the water in the system attempts to expand, but has nowhere to

go resulting in an increase in pressure. This increase in pressure

in the system may cause the temperature-pressure relief valve to

open to relieve the pressure. Water will drip from the temperature

and pressure relief valve. Premature tank failure will result if this

condition is not corrected. To prevent this condition, a properlysized thermal expansion tank should be installed in the cold

water supply to the water heater. Failure to install a properly

WATER HEATERS EVENTUALLY LEAK. The installation of the

water heater must be accomplished in such a manner that if the

tank or any connections should leak, the ow of water will not

cause damage to the area adjoining the water heater or to lower

oors of the structure. When such locations can’t be avoided, a

suitable drain pan should be installed under the water heater. Such

a pan should be no greater than 1-1/2 (45mm) inches deep, have

a minimum length and width of at least two inches (51mm) greater

than the water heater dimensions and must be piped to an

adequate drain.

WATER PIPING

8

Page 9

HOTTER WATER CAN SCALD:

Water heaters are intended to produce hot water. Water heated to

a temperature which will satisfy space heating, clothes washing,

dish washing, cleaning and other sanitizing needs can scald and

permanently injure you upon contact. Some people are more likely to

be permanently injured by hot water than others. These include the

elderly, children, the inrm, or physically/mentally disabled. If anyone

using hot water in your home ts into one of these groups or if there is

a local code or state law requiring a certain temperature water at the

hot water tap, then you must take special precautions. In addition to

using the lowest possible temperature setting that satises your hot

water needs, a means such as a mixing valve should be used at the

hot water taps used by these people or at the water heater. Valves

for reducing point of use temperature by mixing cold and hot water

are also available.

Consult a Qualified Installer or Service Agency. Follow

manufacturer’s instructions for installation of the valves.

Before changing the factory setting on the thermostat, read the

“Temperature Regulation” section in this manual.

This water heater shall not be connected to any heating systems

or component(s) used with a non-potable water heating appliance.

Use properly sized water heaters for spa or hot tub use.

Toxic chemicals, such as those used for boiler treatment shall not

be introduced into this system.

As water is heated, it expands (thermal expansion). In a closed

system, the volume of water will grow. As the volume of water

grows, there will be a corresponding increase in water pressure

due to thermal expansion. Thermal expansion can cause premature

tank failure (leakage). This type of failure is not covered under the

limited warranty. Thermal expansion can also cause intermittent

temperature-pressure relief valve operation: water discharged from

the valve due to excessive pressure build up. The temperaturepressure relief valve is not intended for the constant relief of thermal

expansion. This condition is not covered under the limited warranty

WARNING: Toxic chemicals such as used for treatment of boilers

or non-potable water heating appliances shall never be introduced

into a potable water space heating system.

Figure 4.

The solar water heater will work better if you keep the hot water

runs short. You will also get hot water faster and with less heat loss.

The illustration shows the correct valves and ttings that you

will need to install the solar water heater. Threaded (3/4”) water

connections are supplied through the tank top.

Figure 5.

A properly-sized thermal expansion tank should be installed on all

closed systems to control the harmful effects of thermal expansion.

Thermal expansion tanks are available through a local plumbing

contractor. Contact the local plumbing inspector, water supplier

and/or service agency for assistance in controlling these situations.

This water heater is design certied to be used with a potable

water system. When connecting water piping with solder joints

use only lead free solder.

WARNING: This solar water heater shall not be connected to any

heating systems or component(s) previously used with a nonpotable water heating appliance.

If this solar water heater is also used for space heating applications,

all piping and components connected to the solar water heater

shall be suitable for use with potable water.

This water heater has been design certied as a solar water heater

complying with Standards for Safety - UL 174/CAN/CSA C-22.2.

The particular application of this water heater described (above

paragraph) may be subject to review and approval by local code

ofcials.

1. Purchase the ttings that you need to connect the pipes.

Remember that you have to connect both the hot and cold

water pipes.

2. Apply a light covering of pipe joint compound to each outside

thread before making connection.

3. Connect the cold water supply pipe to the cold water inlet of

your solar water heater as follows:

a. Look at the top cover of the solar water heater. The hot

and cold connections are marked there.

b. A non-metallic dip tube is supplied to carry cold water from

the tank top to the bottom. Be sure that it is in the cold water

inlet.

c. If using copper tubing, solder tubing to an adapter

BEFORE you attach the adapter to the cold water inlet.

DO NOT solder the cold water supply pipe directly to

the cold water inlet connection. It might harm the dip tube.

d.

The cold water supply line must have a shut-off valve and union

4. Use a union to connect the hot water supply pipe to the solar

9

9

.

Page 10

water heater’s hot water outlet.

CAUTION: Operating an empty or partially lled solar water heater

will result in damage to the tank.

If a solar water heater is installed in a closed water system; such as

one having a back ow preventer, check valve or water meter with

check valve in the cold water supply line, means shall be provided

to control thermal expansion. Contact the water supplier or local

plumbing contractor on how to control this situation.

INSTALLATION IN RESIDENTIAL GARAGES: The solar water

heater must be located and/or protected so it is not subject to

physical damage by a moving vehicle.

FILLING THE SOLAR WATER HEATER WITH WATER

5. Never alter or modify the certied construction of the water

heater system or its components, or bypass any safety

features. Doing so voids all warranties.

T&P VALVE and PIPE INSULATION (Selected Models)

TEMPERED

WATER

OUTLET

FROM

COLLECTOR

(SOLAR LOOP)

FROM

COLLECTOR

(SOLAR LOOP)

(ALTERNATE)

DRAIN

VALV E

WATER INLET

SHUTOFF

VALV E

TO PUMP

(SOLAR LOOP)

TO PUMP

(SOLAR LOOP)

(ALTERNATE)

COLD

WATER

INLET

Remove insulation for T&P Valve and pipe connections from

carton.

Fit pipe insulation over the incoming cold water line and the hot

water line. Make sure that the insulation is against the top cover of

the heater.

Fit T&P Valve insulation over valve. Make sure that the insulation

does not interfere with the lever or outlet of the T&P valve.

Secure all insulation using tape.

Figure 6.

Before lling the solar water heater with water, the pump station

storage tank loop must be connected to the water heater.

The solar water heater is equipped with top and side pump station

water loop connections. Cap or plug the connections that are not

used in your application.

1. Close the solar water heater drain valve. The drain valve is on

the lower front of the solar water heater.

2. Open the cold water supply to the solar water heater. NOTE:

THIS VALVE MUST BE LEFT OPEN WHEN THE SOLAR

WATER HEATER IS IN USE.

3. Fill the solar water heater until a constant ow of water runs out

an opened hot water faucet. This will let out air in the solar

water heater and the piping. Close the faucet and solar loop

air vent after all air has been purged and the water comes out

with constant ow. You must not turn the electricity on until

the solar water heater is full of water. IF ANY AIR IS LEFT

IN THE TOP OF THE SOLAR WATER HEATER OR IN THE

PUMP STATION STORAGE TANK LOOP THE HEATING

ELEMENT WILL BURN OUT IMMEDIATELY.

4. Check all the new water piping for leaks. Fix as needed.

Figure 7.

WIRING OF ELEMENT

Never use water heater unless it is completely full of water. To

prevent damage to the tank and heating element, the tank must

be lled with water. Water must ow from the hot water faucet

before turning on power.

You must provide all wiring of the proper size outside of the

water heater. You must obey local codes and electric company

requirements when you install this wiring.

If you are not familiar with electric codes and practices, or if you

10

Page 11

have any doubt, even the slightest doubt, in your ability to connect

the wiring to this water heater, obtain the service of a competent

electrician. Contact a local electrical contractor and/or the local

electric utility.

WATER HEATERS EQUIPPED FOR ONE VOLTAGE ONLY: This

water heater is equipped for one type voltage only. Check the

rating plate near the bottom access panel for the correct voltage.

DO NOT use this water heater with any voltage other than the

one shown on the model rating plate. Failure to use the correct

voltage can cause problems which can result in DEATH, SERIOUS

BODILY INJURY, OR PROPERTY DAMAGE. If you have any

questions or doubts consult your electric company.

If wiring from your fuse box or circuit breaker box was aluminum

for your old water heater, replace it with copper wire. If you wish

to reuse the existing aluminum wire, have the connection at the

water heater made by a competent electrician. Contact a local

electrical contractor and/or the local electric utility.

1. Provide a way to easily shut off the electric power when working

on the water heater. This could be with a circuit breaker or

fuse block in the entrance box or a separate disconnect switch.

2. Install and connect a circuit directly from the main fuse or circuit

breaker box. This circuit must be the right size and have its

own fuse or circuit breaker.

3. If metal conduit is used for the grounding conductor:

A. The grounding electrode conductor shall be of copper,

aluminum, or copperclad aluminum. The material shall be of

one continuous length without a splice or joint.

B. Rigid metal conduit, intermediate metal conduit, or electrical,

metallic tubing may be used for the grounding means if conduit

or tubing is terminated in ttings approved for grounding.

C. Flexible metal conduit or exible metallic tubing shall

be permitted for grounding if all the following conditions

are met:

• The length in any ground return path does not exceed 6 feet

(1.8 m).

• The circuit conductors contained therein are protected by

overcurrent devices rated at 20 amperes or less.

• The conduit or tubing is terminated in ttings approved

for grounding.

• For complete grounding details and all allowable

exceptions, refer to the current edition of the Nation

Electrical Code NFPA 70.

4. A standard 1/2” (1.27 cm) conduit opening has been made in

the water heater junction box for the conduit connections.

5. Use wire nuts and connect the power supply wiring to the wires

inside the water heater’s junction box.

6. The water heater must be electrically “grounded” by the installer.

A green ground screw has been provided on the water heater’s

junction box. Connect ground wire to this location.

7. Replace the wiring junction cover using the screw provided.

Figure 8.

CAUTION: If wiring from the fuse box or circuit breaker box was

aluminum for the old tank, replace it with copper wire. If you wish

to reuse the existing aluminum wire, have the connection at the

solar water heater made by a competent electrician. Contact your

local utility to arrange for a professional electrician.

BLACK

RED

F

C)(49

F

(60 C)

F

C)(66

BLACK

RED

ELEMENT

Figure 9.

THERMOSTAT

Each thermostat is factory preset at 120°F (49°C) to reduce the

risk of scald injury. This setting has proven by experience to be

most satisfactory from the standpoint of operational costs and

household needs.

Solar water heaters installed in Florida require the thermostat(s)

to be set at 125°F (52°C). If you wish to adjust the settings, see

the “Temperature Adjustment” section of this installation manual.

TANK SENSOR

The surface mount tank sensor should be attached to the sensor

stud behind the lower door by placing the hole in the sensor over

the stud provided and securing in place with a nut. The end of the

tank sensor shall be connected to the red wires in the opening with

wire nuts (with no regard for polarity). The other ends of the red

temperature sensor extension extend from the top of the tank and

shall be connected to the controller in the tank sensor position.

11

11

Page 12

THERMOSTAT

HIGH LIMIT

OPERATION

TEMPERATURE REGULATION

HOTTER WATER CAN SCALD: Solar water heaters are intended

to produce hot water. Water heated to a temperature which will

satisfy clothes washing, dish washing, and other sanitizing needs

can cause scalds resulting in serious personal injury and/or death.

Some people are more likely to be permanently injured by hot water

than others. These include the elderly, children, the inrmed, or

physically handicapped. If anyone using hot water in your home

ts into one of these groups or if there is a local code or state

law requiring a certain temperature water at the hot water tap,

then you must take special precautions. In addition to using the

lowest possible temperature setting that satises your hot water

needs, some type of tempering device, such as a mixing valve

should be used at the hot water taps used by these people or at

the solar water heater. Mixing valves are available at plumbing

supply or hardware stores. Follow manufacturers instructions for

installation of the valves. Before changing the factory setting of

the thermostat, read the Temperature Adjustment section.

KEEPING THE THERMOSTAT SETTING AT 120°F (49°C) WILL

REDUCE THE RISK OF SCALDS. Never allow small children to

use a hot water tap, or to draw their own bath water. Never leave

a child or handicapped person unattended in a bathtub or shower.

TEMPERATURE SETTINGS

NOTE: Residential solar water heaters will not supply sanitizing

hot water for dishwashers.

The thermostat is factory set at its lowest position which

approximates 120°F (49°C) (Hot) and is adjustable if a different

water temperature is desired. Read all warnings in this manual

and on the solar water heater before proceeding.

CONTROL

RESET

BUTTON

ADJUSTABLE

WITH

HIGH LIMIT

Water

Temperature

°F(°C)

110 (43)

116 (47)

116 (47)

122 (50)

131 (55)

140 (60)

149 (65)

154 (68)

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong, 9/15/1978)

Time for 1st Degree

Burn

(Less Severe Burns)

(normal shower temp.)

(pain threshold)

35 minutes

1 minute

5 seconds

2 seconds

1 second

Instantaneous

Time for Perma-

nent Burns 2nd &

3rd Degree (Most

Severe Burns)

45 minutes

5 minutes

25 seconds

5 seconds

2 seconds

1 seconds

Figure 10.

TEMPERATURE ADJUSTMENT

To adjust the temperature setting:

1. Turn off the heater electrical supply. Do not attempt to adjust

thermostat with power on.

2. Remove the thermostat access panel(s) and fold up insulation

to expose the thermostats. Do not remove the plastic personnel

protectors covering the thermostats.

3. Using a at tip screwdriver, rotate the adjustment knob to the

desired temperature setting.

4. Replace the insulation and access panels and turn on heater

electrical supply.

A non-adjustable high temperature limit control operates before

steam temperatures are reached. The high limit is in the same

area as the upper thermostat and must be reset manually when it

operates. BECAUSE THE HIGH LIMIT OPERATES ONLY WHEN

ABNORMALLY HIGH WATER TEMPERATURES ARE PRESENT,

IT IS IMPORTANT THAT A QUALIFIED SERVICE AGENT BE

CONTACTED TO DETERMINE THE REASON FOR OPERATION

BEFORE RESETTING.

12

Page 13

FOR YOUR INFORMATION

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed

system, the volume of water will grow. As the volume of water

grows, there will be a corresponding increase in water pressure

due to thermal expansion. Thermal expansion can cause premature

tank failure (leakage). This type of failure is not covered under the

limited warranty. Thermal expansion can also cause intermittent

temperature-pressure relief valve operation: water discharged from

the valve due to excessive pressure build up. The temperaturepressure relief valve is not intended for the constant relief of thermal

expansion. This condition is not covered under the limited warranty

A properly-sized thermal expansion tank should be installed on all

closed systems to control the harmful effects of thermal expansion.

Thermal expansion tanks are available through a local plumbing

contractor. Contact the local plumbing inspector, water supplier

and/or service agency for assistance in controlling these situations.

STRANGE SOUNDS

Possible noises due to expansion and contraction of some metal

parts during periods of heat-up and cool-down do not necessarily

represent harmful or dangerous conditions.

WATER ODOR

In each water heater there is installed at least one anode rod (see

parts sections) for corrosion protection of the tank. Certain water

conditions will cause a reaction between this rod and the water.

The most common complaint associated with the anode rod is one

of a “rotten egg smell” in the hot water. This odor is derived from

hydrogen sulde gas dissolved in the water. The smell is the result

of four factors which must all be present for the odor to develop:

“AIR” IN HOT WATER FAUCETS

HYDROGEN GAS: Hydrogen gas can be produced in a hot

water system that has not been used for a long period of time

(generally two weeks or more). Hydrogen gas is extremely

ammable and explosive. To prevent the possibility of injury

under these conditions, we recommend the hot water faucet,

located farthest away, be opened for several minutes before any

electrical appliances which are connected to the hot water system

are used (such as a dishwasher or washing machine). If hydrogen

gas is present, there will probably be an unusual sound similar to

air escaping through the pipe as the hot water faucet is opened.

There must be no smoking or open ame near the faucet at the

time it is open.

HIGH WATER TEMPERATURE SHUT OFF SYSTEM

A non-adjustable high temperature limit control operates

before steam temperatures are reached. The high limit is

in the same area as the upper thermostat and must be

reset manually when it operates. BECAUSE THE HIGH LIMIT

OPERATES ONLY WHEN ABNORMALLY HIGH WATER

TEMPERATURES ARE PRESENT, IT IS IMPORTANT THAT A

QUALIFIED SERVICE AGENT BE CONTACTED TO DETERMINE

THE REASON FOR OPERATION BEFORE RESETTING.

A. A concentration of sulfate in the supply water.

B. Little or no dissolved oxygen in the water.

C. A sulfate reducing bacteria which has accumulated within the

water heater (this harmless bacteria is nontoxic to humans).

D. An excess of active hydrogen in the tank. This is caused by

the corrosion protective action of the anode.

Smelly water may be eliminated or reduced in some water heater

models by replacing the anode(s) with one of less active material,

and then chlorinating the water heater tank and all hot water lines.

Contact the local water heater supplier or service agency for

further information concerning an Anode Replacement Kit and this

chlorination treatment. If the smelly water persists after the anode

replacement and chlorination treatment, we can only suggest that

chlorination or aeration of the water supply be considered to eliminate

the water problem.

Do not remove the anode leaving the tank unprotected. By

doing so, all warranty on the water heater tank is voided.

• Turn off the heater electrical supply. Do not attempt to reset

thermostat with power on.

• Remove the screw securing the outer door and remove door.

• Fold up the insulation to expose the reset button.

• Reset the high limit by pushing in the red button marked

“RESET”.

13

13

Page 14

MAINTENANCE

DRAINING & FLUSHING

and wattage rating by matching it to the rating plate on the water

heater. Position the new gasket(s) on the element and insert

it into the water heater tank (Figure 12). Tighten the element

by turning it clockwise until secure.

7. Close the drain valve. Open the nearest hot water faucet and

allow the tank to ll completely with water. To purge the lines

of any excess air and sediment, keep the hot water faucet

The water heater should be drained if being shut down during

freezing temperatures. It is recommended that the tank be drained,

and ushed every 6 months to remove sediment which may buildup

during operation. To drain the tank perform the following steps:

1. Disconnect the electrical power to the water heater.

2. Open a hot water faucet until water is no longer hot.

3. Close the cold water inlet valve and open a hot water faucet.

4. Connect a hose to the drain valve and terminate it to an

adequate drain.

5. Open the water heater drain valve and the nearest hot water

faucet. Allow all the water to drain from the tank. Flush the tank

with water as needed to remove sediment.

6. Close the drain valve and completely rell the water heater tank.

7. Reconnect electrical power to the water heater. If the water

heater is going to be shut down for an extended period, the

drain valve should be left open.

open for 3 minutes after a constant ow of water is obtained.

8. Check for leaks around the element(s).

9. Reconnect the electrical wires to the element and securely

tighten the screws. Replace the plastic thermostat cover

making sure the attachment points are engaged on the

thermostat.

10. Replace the access cover(s).

11. Make certain the tank is lled with water. Applying electric

current to heater elements not submerged in water will destroy

them.

12. Reconnect electrical power to the water heater.

THERMOSTAT REMOVAL / REPLACEMENT

Figure 12

SCREW-IN

ELEMENT

SPUD

GASKET

ELEMENT

In some water areas, scale or mineral deposits will build up on

heating elements. This build up will cause a rumbling noise.

Follow the element replacement directions to remove the elements

from the tank. Soaking in vinegar and scraping will remove the

mineral deposit. Be careful not to bend the element.

HEATING ELEMENT REPLACEMENT

Replacement heating elements must be of the same style and

voltage/wattage rating as the ones presently in the water heater.

This information can be found on the ange or terminal block of

the element or on the water heater data plate.

1. Disconnect the electrical power to the water heater.

2. Drain water heater as directed in “Draining and Flushing” section.

3. Remove the access cover(s). Fold up the insulation from the

heater element(s). Remove the plastic thermostat cover from

the thermostat(s) making sure to disengage the attachment

point from the thermostat.

4. Disconnect the electrical wires from the heating element(s)

by loosening the screws (Figure 11). Remove the screw-in

element(s) by turning the element(s) counterclockwise with

a 1-1/2 inch socket wrench. Remove the existing gasket(s).

WIRES

ELEMENT

1. Turn “OFF” the electric power supply to the water heater.

2. Remove the outer door. Remove or fold up the insulation pad.

3. Models with Upper or Lower Thermostat with High Limit:

Lift out the tab as shown below to unclip the terminal cover

from the thermostat. The terminal cover can now be removed

from the thermostat.

SCREWS

Figure 11

5. Clean the area where the gasket(s) ts to the tank. If you

are replacing the bottom element, remove the accumulated

sediment on the bottom of the tank.

6. Make sure the replacement element(s) has the correct voltage

Figure 13

4. Disconnect wires from thermostat and slide out of the bracket.

5. Remove the thermostat from behind the thermostat bracket.

6. Place the new lower thermostat in the bracket making sure it

ts rmly against the tank.

14

Page 15

7. Attach the wires to the new thermostat.

NOTE: Some of the terminals may require straight-in wiring

through an eye-opening. If wires are now looped, recut and

strip wire 3/8” (9.525 mm) to a straight length and insert.

8. Put plastic terminal cover back in place.

9. Replace the insulation to cover the thermostat.

10. Replace outer door then turn the electric power on.

ANODE ROD INSPECTION

TEMPERATURE-PRESSURE RELIEF VALVE OPERATION

Each water heater contains at least one anode rod, which will

slowly deplete (due to electrolysis) prolonging the life of the water

heater by protecting the glass-lined tank from corrosion. Adverse

water quality, hotter water temperatures, high hot water usage,

and water softening methods can increase the rate of anode rod

depletion. Once the anode rod is depleted, the tank will start to

corrode, eventually developing a leak.

Certain water conditions will cause a reaction between the anode

rod and the water. The most common complaint associated with the

anode rod is a “rotten egg smell” produced from the presence of

hydrogen sulde gas dissolved in the water. IMPORTANT: Do not

remove this rod permanently as it will void any warranties. A special

anode rod may be available if water odor or discoloration occurs.

NOTE: This rod may reduce but not eliminate water odor problems.

The water supply system may require special ltration equipment

from a water conditioning company to successfully eliminate all

water odor problems.

Articially softened water is exceedingly corrosive because the

process substitutes sodium ions for magnesium and calcium ions.

The use of a water softener may decrease the life of the water

heater tank.

The anode rod should be removed from the water heater tank

every 3 years for inspection. NOTE: articially softened water

requires the anode rod to be inspected annually.

The following are typical (but not all) signs of a depleted anode rod:

• The majority of the rods diameter is less than 3/8” (9.5mm).

• Signicant sections of the support wire (approx. 1/3 or more

of the anode rod’s length) are visible.

If the anode rod show signs of either or both it should be replaced.

NOTE: Whether re-installing or replacing the anode rod, check for

any leaks and immediately correct if found.

In replacing the anode:

1. Turn off power to the water heater.

2. Shut off the water supply and open a

EXPOSED

SUPPORT

WIRE

nearby hot water faucet to depressurize

the water tank.

3. Drain approximately 5 gallons (19 L)

of water from tank. (Refer to “Draining

and Flushing” for proper procedures).

Close drain valve.

PITTED

ANODE

ROD

4. Remove old anode rod.

5. Use Teflon® tape or approved pipe

sealant on threads and install new

anode rod.

6. Turn on water supply and open a

nearby hot water faucet to purge air

from water system. Check for any

leaks and immediately correct any

if found.

7. Restart the water heater as directed

EXPOSED

SUPPORT

WIRE

Figure 14.

The temperature-pressure relief valve must be manually operated

at least once a year.

When checking the temperature-pressure relief valve operation,

make sure that (1) no one is in front of or around the outlet of the

temperature-pressure relief valve discharge line, and (2) that the

water discharge will not cause any property damage, as the water

may be extremely hot, see Figure 16.

If after manually operating the valve, it fails to completely reset and

continues to release water, immediately close the cold water inlet

to the water heater, follow the draining instructions, and replace

the temperature-pressure relief valve with a new one.

If the temperature-pressure relief valve on the water heater weeps

or discharges periodically, this may be due to thermal expansion.

You may have a check valve installed in the water line or a water

meter with a check valve. Consult your local water supplier or

service agency for further information. Do not plug or remove the

temperature-pressure relief valve.

WATER HEATER SOUNDS

1. The solar water heater is equipped with an immersion

heating element for fastest recovery. If the solar water

heater occasionally makes noises this is not a defect or a

safety hazard.

2. Lime or scale has accumulated on the heating element

causing a hissing sound. Element scale removal can be

accomplished by using vinegar or by scraping.

15

15

in this manual. See the Repair Parts Illustration for anode

rod location.

Figure 15.

Figure 16.

Page 16

REPAIR PARTS

REPAIR PARTS SCHEDULE

ORDERING REPAIR PARTS

The following parts may be ordered through the store you purchased the solar water heater from, or direct from the factory listed on

the model & rating plate located on the lower front of the solar water heater. Selling prices will be furnished on request or parts will

be shipped at prevailing prices and you will be billed accordingly. When ordering repair parts always give the following information:

(1) Part description, (2) Model serial number, (3) Element wattage, (4) Voltage, (5) Part number.

ITEM PART DESCRIPTION

1 Primary Anode 9003892005

2 Anode Outlet 9006827005

3 Primary Dip Tube 9002549005

4 Element w/Gasket 9003950115

5 Thermostat Bracket 9003898215

6 Thermostat w/High Limit 9007623015

7 Terminal Cover 9003914015

Access Panel

8

9 Sensor Mounting Plug 9007309005

10 Solar Loop Dip Tube (From Collector) 9006789005

11 Solar Loop Dip Tube w/Nipple (To Pump) 9006790005

12 Plastisert Nipple 9003976015

13 T&P Valve 9000728015

14 Drain Valve 9003906015

SERVICE

PART #

9003900005

RATING PLATE

A rating plate identifying the solar water heater will be found above the drain valve. When referring to the solar water heater, always

have the information listed on the rating plate readily available.

Fill in that information here:

MODEL NO. _______________________________________

SERIAL NO. _______________________________________

INSTALLATION DATE: _______________________________

16

Page 17

NOTES

17

17

Page 18

NOTES

18

Page 19

NOTES

19

19

Page 20

20

Loading...

Loading...