Page 1

Commercial Gas

Circulating Water Heater

BURKAY

®

ENERGY SAVING COPPER HEAT EXCHANGER

FEATURES

ALL NON-FERROUS WATERWAYS

■ Rustproof because water comes in contact with nothing but copper, brass or bronze

■ Copper transfers heat eight times faster than ferrous metals yet offer remarkable

structural strength without excessive weight

■ Free from the effects of thermal shock

EFFICIENT COPPER COIL COMBUSTION CHAMBER

■ Continuous coils of tightly wound copper tubing form a unique combustion chamber

■ Water circulating thru the coils, around the flame, captures radiant heat which may

otherwise be lost

HIGH EFFICIENCY STAINLESS STEEL BURNER

■ Developed especially for A. O. Smith water heaters using the very latest burner

principles

FORCED WATER CIRCULATION IMPROVES SYSTEM EFFICIENCY

■ Water moving at 2 to 4 feet per second helps to prevent lime buildup and also scrubs

extra heat from the copper coil combustion chamber

AUTOMATIC SAFETY CONTROLS AND ELECTRONIC IGNITION

■ Proven pilot ignition system provides flame failure response in less than one (1) second

■ Redundant high limit controls and gas valves assure safe shutoff in the event of

overheating or flame failure

■ Requires 120V 60Hz, maximum inlet gas pressure of 14” WC and activation of heater by

external temperature control

THERMAL BALANCER (HW-200M, HW-225M)

■ Patented thermal balancer functions as a pump shutoff delay switch

■ It allows the pump and heater to activate simultaneously but delays pump shut off for

120 ± 30 seconds after heater shuts down

■ This allows the high temperature water to clear the heater thus utilizing all heat that

had been generated plus educing the scale forming tendencies of motionless hot water

(Not to be used on booster recovery systems

PRESSURE RELIEF VALVE

■ 125 psi

MAIN BURNER REGULATION

■ Factory adjusted for gas required

JACKET

■ Prefinished with a bonderized coating followed by a baked on enamel finish.

CERTIFICATION

■ All models are design-certified by CSA International, according to ANSI Z21.10.3 - CSA

4.9 standards governing Circulating Water Heaters

■ Models are ASME certified and are design-certified by NSF International to NSF

Sanitation 5

■ Models meet the thermal efficiency and standby loss requirements of the U.S.

Department of Energy and current edition of ASHRAE/IESNA 90.1.

WORKING PRESSURE

■ 160 psi

LIMITED WARRANTY OUTLINE

■ If the coil, heat exchanger or burner should fail within 5 years, under the terms of

the warranty, then A. O. Smith will furnish a replacement part; installation, labor

handling and local delivery are extra. THIS OUTLINE IS NOT A WARRANTY. For complete

information, consult the written warranty or A. O. Smith.

HW-120M,

HW-160M,

HW-200M AND

HW-225M

A. O. Smith Corporation • 500 Tennessee Waltz Parkway • Ashland City, TN 37015 • 800-527-1953 Toll-free USA

www.hotwater.com

Revised September 2014

AOSDG25500

Page 1 of 2

Page 2

Commercial Gas

Circulating Water Heater

BURKAY

®

ENERGY SAVING COPPER HEAT EXCHANGER

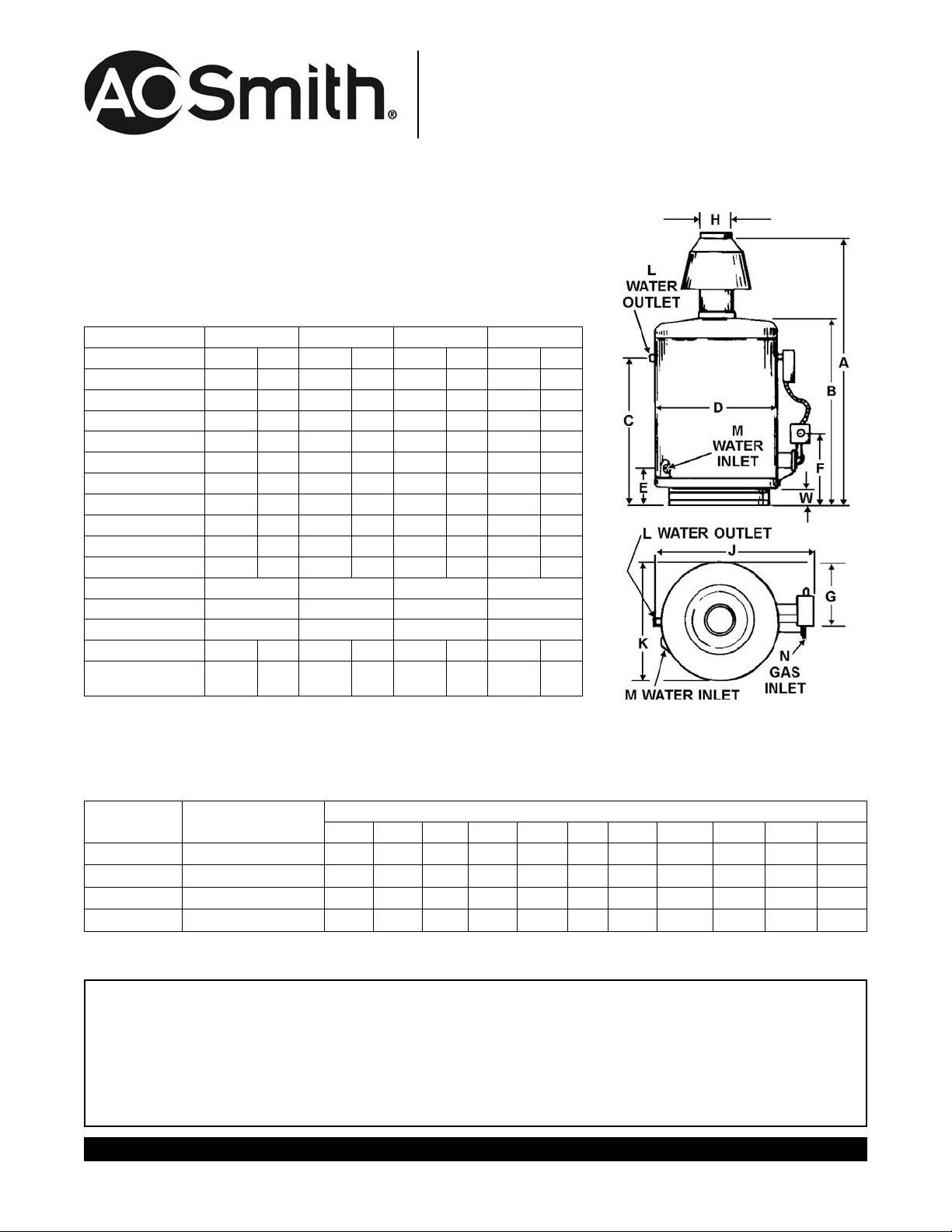

DIMENSIONS AND CAPACITY DATA

ROUGH-IN DIMENSIONS

MODELS HWH-120 HWH-160 HWH-200 HWH-225

DIMENSIONS

A

B

C

D

E

F

G

H

J

K

L

M

N

W

Approx. Shipping

Weight

Inches mm Inches mm Inches mm Inches mm

49 3/8 1254 50 1/8 1273 53 1/4 1353 60 1524

30 3/8 772 30 3/8 772 33 1/8 841 33 1/8 841

23 5/8 600 23 5/8 600 27 1/8 689 27 1/8 689

20 3/4 527 20 3/4 527 20 3/4 527 20 3/4 527

5 1/2 140 5 1/2 140 5 1/2 140 5 1/2 140

10 254 10 254 10 254 10 254

11 13/16 300 11 13/16 300 11 13/16 300 11 13/16 300

6 152 7 178 7 178 7 178

26 11/16 678 26 11/16 678 26 11/16 678 26 11/16 678

20 3/4 527 20 3/4 527 20 3/4 527 20 3/4 527

1 1/4 NPT 1 1/4 NPT 1 1/4 NPT 1 1/4 NPT

1 NPT 1 NPT 1 NPT 1 NPT

1/2 NPT 1/2 NPT 1/2 NPT 1/2 NPT

1 3/4 44 1 3/4 44 1 3/4 44 1 3/4 44

120 lbs. 54 Kg. 155 lbs. 70 Kg. 165 Lbs. 75 Kg. 175 lbs. 79 Kg.

HEATER PERFORMANCE DATA

NOTE: To compensate for the effects of high altitude areas above 2,000 feet, input rating and therefore recovery ratings should be reduced approximately

4% for each 1,000 feet above sea level.

MODEL

HW-120M 120,000 300 240 200 171 150 133 120 109 100 92 86

HW-160M 160,000 385 308 257 220 193 171 154 140 128 118 110

HW-200M 199,000 487 389 324 278 243 216 195 177 162 150 139

HW-225M 225,000 Nat. Gas Only 543 434 362 310 271 241 217 197 181 167 155

Recovery rating of models shown in chart above are obtained by actual efficiency test data, by a recognized Certification Agency

INPUT RATING BTU/HR.

NAT. & PROPANE GAS

40 50 60 70 80 90 100 110 120 130 140

Suggested Specification

Water Water Heater(s) shall be Model No. as manufactured by A. O. Smith, or an approved equal. Heater(s) shall be gas-fired, as certified by CSA International,

NSF capable of supplying GPH at 100°F temperature rise when equipped to burn gas, and bear the ASME code symbol. Heater(s) shall be reverse flow type

having all non-ferrous waterways, and employing a copper finned heat exchanger and a tightly wound copper coil combustion chamber. Water heater(s) shall be

equipped with an electric gas valve of the step-opening type, a 195° auto-reset fixed high limit control which will break the electric circuit on temperature rise,

intermittent electronic ignition with one (1) second shutdown in the event of pilot flame failure, a gas pressure regulator properly set for the gas to be supplied,

stainless steel main burners, and a coil limit switch for shutoff in event of excessive water temperature, thermal balancer (Models HW-200M and HW-225M), and

a certified draft diverter. Certified for combustible flooring. Outer jacket shall be of baked enamel finish. Fully illustrated instruction manual to be included. Coil,

heat exchanger and burner shall have a 5 year limited warranty as outlined in the written warranty.

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

A. O. Smith Corporation • 500 Tennessee Waltz Parkway • Ashland City, TN 37015 • 800-527-1953 Toll-free USA

www.hotwater.com

TEMPERATURE RISE - DEGREES F - GALLONS PER HOUR

Revised September 2014

Page 2 of 2

AOSDG25500

Loading...

Loading...