A.O. Smith Gold DRE Technical Documents

Commercial Electric Water Heaters

®

GOLD SERIES COMMERCIAL ELECTRIC WATER HEATERS

Designed for use as a recovery heater having its own storage tank. Note: Not recommended

for sanitizing water applications.

FEATURES

Meets the standby loss requirements of the U. S. Department of Energy and current edition

of AHRAE/IESNA 90.1.

GOLD ELEMENTS - DRE models ship with the Goldenrod 24K gold plated elements (see

element availability chart on back). Patented Goldenrod elements provide long life and superior

scaling resistance. Low watt density means lower surface temperature to minimize scale buildup

and more surface to heat water. Goldenrod elements carry a one-year warranty against failure

due to lime scale build-up.

GLASSLINED TANK - Three sizes: 50, 80 and 119 gallon capacity. Tank interior is coated

with glass specially developed by A. O. Smith for water heater use. Tanks rated at 150 psi

(1034 kPa) working pressure (ASME 150 psi). Foam insulation reduces costly heat loss.

MODELS

DRE-52, 80, 120

FUSING - Protects all elements, thermostats, and internal wiring circuits against excess current

fl ow. Meets National Electrical Code requirements that non-ASME tanks must have internal

fusing when current draw exceeds 48 amps. Available as an option on Canadian built heaters.

STANDARD VOLTAGES - 208, 240 and 480V single-phase and three-phase delta. Convertible

from three-phase to single-phase (in fi eld) and vice versa. 277V single-phase also available.

TERMINAL BLOCK - Factory installed. Just bring the service to the heater and connect to block.

CONTROLS - One temperature control (adjustable through a range of 120° to 180°F) and

manual reset high temperature cut-off per element. Thermostat step control may be achieved

by varying settings on individual temperature controls. Located behind hinged control

compartment door for quick, easy access.

OTHER STANDARD FEATURES -

£

Surface mounted thermostats

anode rods for maximum corrosion protection £ Cabinet has bonderized undercoat with baked

enamel fi nish £ Bottom inlet and top outlet openings £ Brass drain valve £ CSA Certified

and ASME rated T&P relief valve £ Single panel control box. £ THREE YEAR LIMITED TANK

WARRANTY - For complete warranty information, consult written warranty.

OPTIONS -

£

UL and cUL listed conversion kits to adjust voltage and kW requirements in the fi eld before

and after installation £ ASME 150 psi tank construction £ International voltages - 220, 380,

400, 415, 575, and 600 volts, three phase available with Y connected elements £ MANIFOLD

KITS - for multiple tank installations. Two heaters -part # 9003429205, three heaters- part #

9003430205 and four heaters- part # 9003431205

£

Simplifi ed circuitry, color coded for ease of service £ Two

ANSI /NSF-5

Revised October 2012

Low Lead Content

Page 1 of 2

AOSCE15300

®

Commercial Electric Water Heaters

RECOVERY RATE IN GALLONS PER HOUR AT TEMPERATURE RISE OF

Standard

kW Input

6 20,478 82

9 30,717 123

12 40,956 164

13.5 46,075 184

15 51,195 205

18 61,434 246

24 81,912 328

27 92,151 369

30 102,390 410

36 122,868 492

40.5 138,226 554

45 153,585 615

54 184,302 738

Figured at 1 kW (3413 BTU) = 4.1 Gallons at 100°F temperature rise.

BTU/

Hour

3O°F

40°F

5O°F

60°F

70°F

8O°F

9O°F

100°F

110°F

120°F

17°C

22°C

28°C

33°C

39°C

45°C

50°C

56°C

62

310

2334916641155351333111627103

4659234974279622335319946174411553714034127311162810726100

123

620

46598372823107026661233

138

523

154

582

184

698

246

930

276

1047

307

1163

369

1396

418

1570

461

1745

554

2094

1117

1256

1398

1675

111

4199234979299

123

465

148

558

197

744

221

938

246

930

295

332

369

443

698

775

930

1241

1396

1551

1861

2094

2326

2791

102

3888833277291

123

105

465

399

164

140

620

532

185

158

609

509

205

176

775

665

246

211

930

798

277

237

1047

897

307

263

1163

997

359

316

1396

1196

55

2074918645169411553814335133

69

62

262

2335520950190461744316140150

68

2586123356211511944714944166

92

82

349

3107427967254622335721553199

123

109

465

4149837290338823107628670266

138

123

523

465

154

137

582

517

184

164

698

620

208

185

785

698

230

205

872

755

277

246

1047

930

61°C

25 9322852178197218

111

101

410

391923408532279299

123

112

465

423

148

134

556

508

166

151

628

634

184

168

698

634

221

201

837

761

130°F

67°C

72°C

102

3889535888332

123

113

465

429

138

128

582

537

154

142

582

537

185

170

696

644

140°F

78°C

66

105

399

119

498

132

498

158

598

142

153

158.1

Element

Wattage

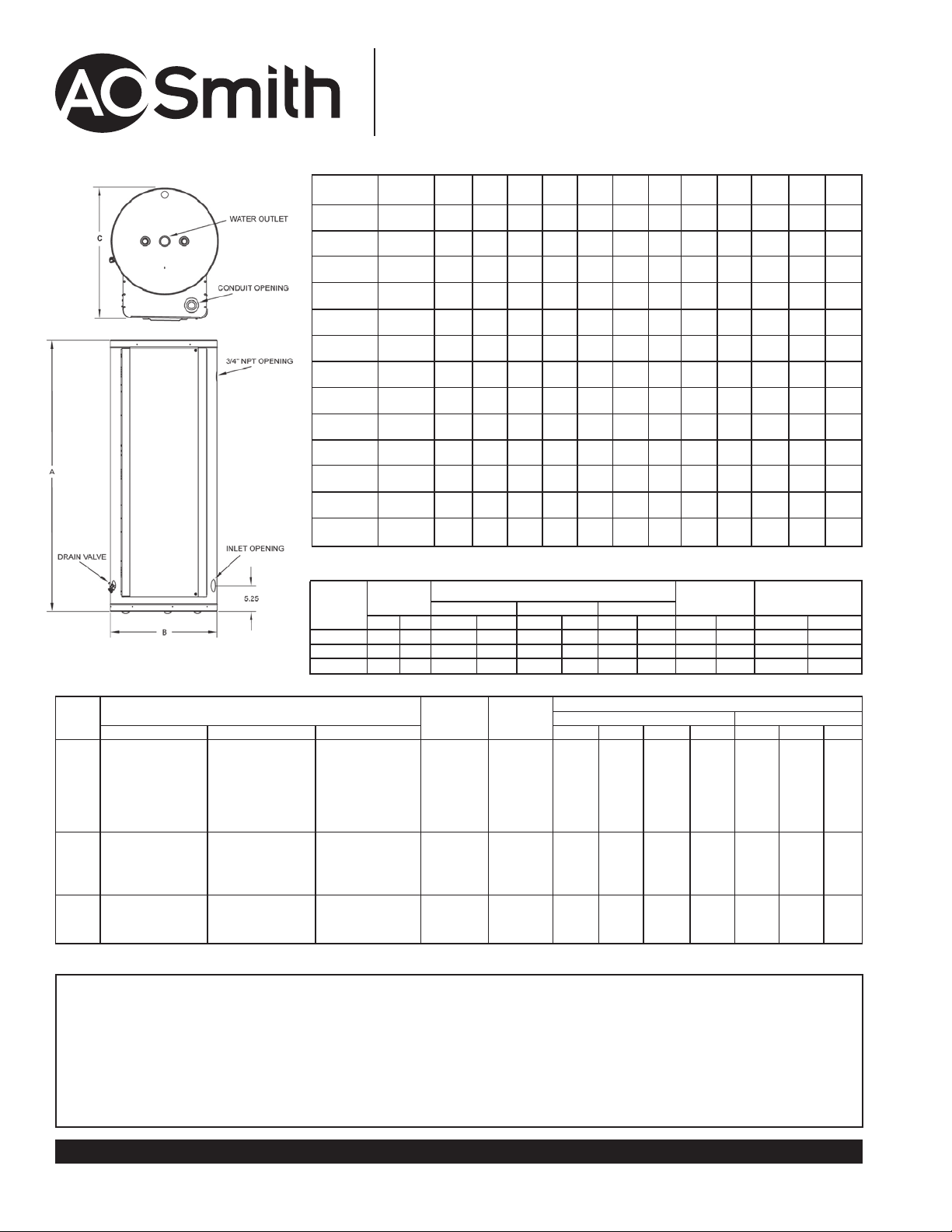

Dimensions

21 3/4

55.2

25 1/2

64.8

29 1/2

75.0

Inlet/

Outlet (NPT)

27

68.6

78.7

88.9

1 1/4

1 1/4

1 1/4

31

35

Full Load Current In Amperes

Single Phase Three Phase

Approx. Ship.

Wt. (Lbs.)

3.2 265 120

3.2 280 127

3.2 390 177

99.9 86.6 43.3

Model

Number

DRE-52

DRE-80

DRE-120

kW

Input

6 DRE-52-6 DRE-80-6 DRE-120-6 3 2,000 28.8 25.0 21.7 12.5 16.7 14.4 7.2

9 DRE-52-9 DRE-80-9 DRE-120-9 3 3,000 43.3 37.5 **32.5 18.8 25.0 21.7 10.8

12 DRE-52-12 DRE-80-12 DRE-120-12 3 4,000 57.7 50.0 43.3 25.0 33.3 28.9 14.4

13.5 DRE-52-13.5 DRE-80-13.5 DRE-120-13.5 3 4,500 64.9 56.3 **48.7 28.1 37.5 32.5 16.2

15 DRE-52-15 DRE-80-15 DRE-120-15 3 5,000 72.1 62.5 **54.2 31.3 41.6 36.1 18.0

18 DRE-52-18 DRE-80-18 DRE-120-18 3* 6,000 86.5 75.0 65.0 37.5 50.0 43.3 21.7

24 DRE-52-24

27 DRE-52-27 DRE-80-27 DRE-120-27 6 4,500 129.8 112.5 **97.5 56.3 74.9 65.0 32.5

30 DRE-52-30 DRE-80-30 DRE-120-30 6 5,000 144.2 125.0 **108.3 62.5 83.3 72.2 36.1

36 DRE-52-36 DRE-80-36 DRE-120-36 6 6,000 173.1 150.0 130.0 75.0

40.5 N/A DRE-80-40.5 DRE-120-40.5 9 4,500 194.7 168.8 **146.2 84.4 112.4 97.4 48.7

45 N/A DRE-80-45 DRE-120-45 9 5,000 216.3 187.5 **162.5 93.8 124.9 108.3 54.1

54 N/A DRE-80-54 DRE-120-54 9 6,000 N/A 225.0 194.9 112.5 149.9 129.9 65.0

*208 volt models may contain three (3) additional elements. ** Elements available in incoloy only.

Model Numbers

Tank Capacity in Gallons

DRE-80-24 DRE-120-24 6 4,000 115.4 100.0 86.6 50.0 66.6 57.7 28.9

Tank

Capacity

gal.

litre

50 189

80 300

119 450

ABC

in. cm in. cm in. cm in. cm Ib kg

55 3/4

60 1/4

62 1/4

Number

Of

Elements

SUGGESTED SPECIFICATION

The heater(s) shall be Gold Series Commercial Electric Model Number ______________ as manufactured by A. O. Smith. Heater(s) shall be rated at ____________

kW,_______volts, ____________ phase, 60 cycle AC, and listed by Underwriters’ Laboratories and approved to the NSF Standard 5 by UL. Tank(s) shall be ________

gallon capacity. Tanks shall be 50, 80 and 119 gallon capacity and shall have 150 psi working pressure and be equipped with extruded high density anode. All internal

surfaces of the heater(s) exposed to water shall be glasslined with an alkaline borosilicate composition that has been fused-t o-steel by firing at a temperature range

of 1400°F to 1600°F. Electric heating elements shall be low watt density Goldenrod 1” screw-in type. Each element shall be controlled by an

individually mounted thermostat and high temperature cut-off switch. All internal circuits shall be fused. The outer jacket shall be of baked enamel finish

and shall be provided with full size control compartment for performance of service and maintenance through hinged front panel and shall enclose the tank

with foam insulation. Electrical junction box with heavy duty terminal block shall be provided. The drain valve shall be located in the front for ease of

servicing. Heater tank shall have a three year limited warranty as outlined in the written warranty. Manufacturer shall supply ASME rated temperature and

pressure relief valve. Fully illustrated instruction manual to be included. Meets standby loss requirements of the U. S. Department of Energy and current edition of ASHRAE/IENSA 90.1..

V084V042V802V084V772V042V8029110805

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith Corporation reserves the right to make prod uct changes or improvements without prior notice.

Revised October 2012

www.hotwater.com

AOSCE15300

Page 2 of 2

Loading...

Loading...