Page 1

Service Handbook

Residential FVIR

Gas Water Heaters

MODELS:

GCV, GCVH, GVR, GCVL, GVRL, GCVT - SERIES 300/301

XCV, XVR, XCVL, XGV, XVRL, XCVT - SERIES 300/301

LOW LEAD

CONTENT

THIS SERVICE HANDBOOK IS FOR USE BY QUALIFIED SERVICE PROFESSIONALS ONLY.

327726-001

May 2014

Page 2

TABLE OF CONTENTS

General Safety .................................................................................................................................................... 4

Completed Installation (typical) ......................................................................................................................... 6

System Basics ..................................................................................................................................................... 7

Honeywell® Gas Control Valve/Thermostat ............................................................................................................................ 7

Gas Pressures ............................................................................................................................................................ 7

BASICS

BASICS

Combustion Chamber with TCO Switch .................................................................................................................................. 8

Lighting the Pilot / Diagnostic Flash Codes ......................................................................................................... 9

Lighting the Pilot: ................................................................................................................................................................... 9

If the Status Light Does Not Blink: ........................................................................................................................................... 9

If the Pilot Does Not Light: ...................................................................................................................................................... 9

If the Pilot Lights but the Status Light Does Not Blink: ............................................................................................................ 9

Diagnostic Flash Codes .......................................................................................................................................................... 10

Temperature Settings ................................................................................................................................................ 7

0 Flashes (LED not lit) ............................................................................................................................................ 10

Status Light On (solid) ........................................................................................................................................... 10

1 Flash ..................................................................................................................... .............................................. 10

2 Flashes ................................................................................................................................................................ 10

4 Flashes ................................................................................................................................................................ 10

5 Flashes ................................................................................................................................................................ 10

7 Flashes ................................................................................................................................................................ 10

8 Flashes ................................................................................................................................................................ 10

System Checks .................................................................................................................................................. 11

Draft Test .............................................................................................................................................................................. 11

Connections Check ................................................................................................................................................................ 11

Gas Pressure Checks .............................................................................................................................................................. 11

Thermopile Check (Open Circuit) .......................................................................................................................................... 12

Thermopile Check (Closed Circuit) ........................................................................................................................................ 12

Common Issues ................................................................................................................................................ 13

No Hot Water ........................................................................................................................................................................ 13

Not Enough Hot Water .......................................................................................................................................................... 13

Lower Seasonal Water Temperatures ....................................................................................................... 13

Faulty Shower Control Valve/Faucet Valve ............................................................................................... 14

Thermostat Set Too Low ........................................................................................................................... 14

An Increase in Hot Water Usage ............................................................................................................... 14

Undersized Water Heater ......................................................................................................................... 14

Reversed Water Connections ................................................................................................................... 14

Leak in the Plumbing System ................................................................................................................. 14

Sediment Buildup in the Tank ................................................................................................................... 14

2 • Residential Standard Gas Water Heater Service Handbook

2 • Residential Standard Gas Water Heater Service Handbook

2 • Residential Standard Gas Water Heater Service Handbook

Page 3

Tank Leak ............................................................................................................................................................................... 15

Condensation .......................................................................................................................................................... 15

Leaking Plumbing Connections ............................................................................................................................... 15

Drips from the T&P Relief Valve Discharge Pipe ..................................................................................................... 15

Temperature Too High ........................................................................................................................................................... 16

Low Water Pressure .............................................................................................................................................................. 16

Water Odor ........................................................................................................................................................................... 16

Service Procedures ........................................................................................................................................... 17

Removing the Manifold/Burner Assembly ............................................................................................................................ 17

Removing the Burner from the Manifold/Burner Assembly ................................................................................................. 17

Replacing the Pilot/Thermopile Assembly ............................................................................................................................ 17

External Inspection and Cleaning of the Base-Ring Filter ..................................................................................................... 18

Cleaning the Combustion Chamber and Flame Arrestor....................................................................................................... 18

Replacing the Manifold/Burner Assembly ............................................................................................................................ 19

Testing the Igniter System ..................................................................................................................................................... 19

Removing and Replacing the Gas Control Valve/Thermostat ................................................................................................ 20

Removing the Gas Control Valve/Thermostat: ........................................................................................................ 20

Replacing the Gas Control Valve/Thermostat: ........................................................................................................ 20

Draining and Flushing ............................................................................................................................................................ 20

BASICS

BASICS

Supplements..................................................................................................................................................... 21

Evaluating Combustion and Ventilation Air Supply ............................................................................................................... 21

Attic Installations .................................................................................................................................................................. 23

Overview ................................................................................................................................................................. 23

Pilot Outage .................................................................................................................. .......................................... 23

Elevated Air Temperature: ........................................................................................................................ 24

Insufficient Makeup Air ............................................................................................................................ 24

Blocked Air Screen or Flame Arrestor ....................................................................................................... 24

Improper Venting of the Water Heater .................................................................................................... 24

Decompression ........................................................................................................................................ 25

Wind ........................................................................................................................................................ 25

Water Damage .................................................................................................................. ...................................... 25

Elevated Water Temperature .................................................................................................................................. 25

Field Installation of Draft Hoods ........................................................................................................................................... 26

Tools and Materials ................................................................................................................................................. 26

Types of Draft Hoods Covered in this Section ......................................................................................................... 26

Types of Vent Pipe Covered in this Section ............................................................................................................. 27

Installation Procedure ........................................................................................................ ..................................... 27

Coupling .................................................................................................................................................................. 27

Type B Draft Hood Connectors ................................................................................................................................ 28

Residential Standard Gas Water Heater Service Handbook • 3

Residential Standard Gas Water Heater Service Handbook • 3

Residential Standard Gas Water Heater Service Handbook • 3

Page 4

GENERAL SAFETY

Your safety and the safety of others is extremely important in the servicing of this water heater. Many safety-related messages and

instructions have been provided in this handbook and on your water heater to warn you and others of a potential hazard. Read

and obey all safety messages and instructions throughout this handbook as well as those found in the Installation Instructions/

Use & Care Guide.

It is very important that the meaning of each safety message is understood by you and others who service this water heater.

The information contained in this handbook is designed to answer commonly faced situations encountered in the operation of

the standard Residential Gas product line and is not meant to be all-inclusive. If you are experiencing a problem not covered in

BASICS

BASICS

this handbook, please contact the Technical Information Center listed on the back cover of this handbook for further assistance.

Additional information is also available on the web site listed on the back cover of this handbook.

This handbook is intended for use by licensed plumbing professionals and reference should be made to the Installation Instructions

and Use & Care Guide accompanying the product. This handbook contains supplemental information to the Installation Instructions

and Use & Care Guide.

When servicing residential water heaters, it is essential that you return the unit to a safe condition before you leave the site. All

original components must be re-installed and all safety measures must be implemented. In addition, the recommended water

temperature setting is 120° F.

IMPORTANT: It is recommended that on every service call, an inspection & cleaning of the base ring filter and flame arrestor be

performed. See page 18.

Tools Required (for servicing gas models):

• Phillips head screw driver

• 3/8, 7/16, & 3/4 inch open end wrenches

• 3/16 inch Allen wrench

• 1-1/16 inch – 6 point – socket – for anode removal

• Electrical multimeter (with alligator leads)

• Digital or analog manometer

• Gas pressure gauge

• Water pressure gauge

• Thermometer

• Hose – to drain tank

• Container – to measure gallons per minute flow

Digital Manometer

4 • Residential Standard Gas Water Heater Service Handbook

4 • Residential Standard Gas Water Heater Service Handbook

Page 5

Fire or Explosion Harzard

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell Natural or LP gas.

Do not expose water heater control to excessive gas

pressure.

Use only gas shown on rating plate.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

period of non-use.

BASICS

BASICS

Read instruction manual before

installing, using or servicing

water heater.

Fire or Explosion Harzard

Hydrogen gas can be produced in a hot water system after

a period of non-use (generally two or more weeks).

Hydrogen gas is extremely flammable and can ignite.

To return hot water system to service, open a hot water

faucet in kitchen for several minutes before using electrical

appliances.

Do not smoke or have open flame near faucet while it is open.

Leave hot water faucet open until the sound of escaping

air stops.

After extended period of non-use,

purge gases from hot water system.

Residential Standard Gas Water Heater Service Handbook • 5

Residential Standard Gas Water Heater Service Handbook • 5

Page 6

COMPLETED INSTALLATION ΈTYPICALΉ

Exhaust Vent to

Ouside of Building

Union

Gas Supply

BASICS

BASICS

See Labels and

Installation Instructions

and Use & Care Guide

for clearances.

Union

To Fixtures - Hot

Tempered Water

Untempered

Hot Water

To Fixtures

Cold

Water

Inlet

Water

Water

Shut-Off

Valve

Temperature-Pressure Relief Valve

with discharge piped to an

adequate drain. Do not cap or plug.

Supply- Cold*

*Massachusett: Install

a vacuum relief in cold

water line per section

19 MGL 142.

Expansion Tank

Pressurized to Equal

Supply Water Pressure*

(Relieve water pressure

on the expansion tank

before adjusting air

pressure.)

Hot

Water

Outlet

Mixing Valve

(Set to 120°F)

Follow the Mixing

Valve Manufacturer’s

Instructions

Union

Sediment Trap

3” Minimum.

Base Ring Filter:

Air is drawn in for combustion. Keep area clean

and free from flammables and flammable vapors.

Manual Gas

Shut-off Valve

Gas Control Valve/Thermostat

Recommended setting of 120°F.

Do not cap or plug.

6” Maximum Air Gap

NOTE: Local codes

may vary.

Drain

Metal Drain Pan piped to an adequate drain.

NOTE: Drain pan diameter must be at least

2 inches wider than the diameter of the

water heater.

The water heater must be installed according to all local and state codes or in the absence of local

and state codes, the “National Fuel Gas Code” ANSI Z223.1(NFPA 54)- current edition.

* NOTE: If on a well system, the expansion tank should be set to the maximum pressure of the pump tank.

Figure 1.

6 • Residential Standard Gas Water Heater Service Handbook

6 • Residential Standard Gas Water Heater Service Handbook

Page 7

SYSTEM BASICS

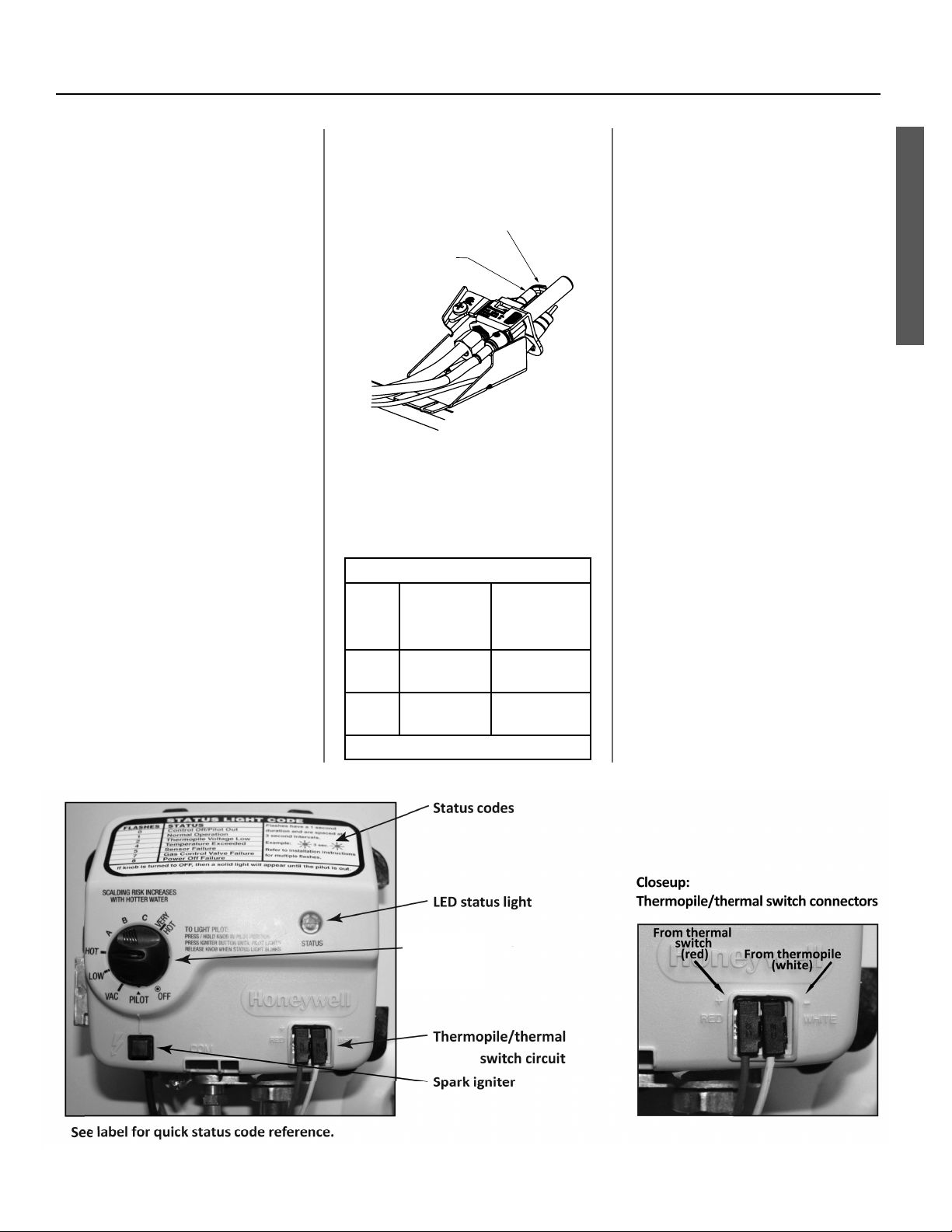

Honeywell® Gas Control

Valve/Thermostat

Water heaters covered by this handbook

are equipped with Honeywell gas

control valve/thermostats.

• The Honeywell valve uses a

thermopile instead of a thermocouple

as did previous designs.

• Heat on the thermopile generates

750 to 900 millivolts (open circuit).

• When heated by the pilot and

connected to the Honeywell control,

the thermopile generates at least

350 millivolts (closed circuit). This

voltage opens the power head

in the control, allowing gas to

flow. It also powers the onboard

diagnostics (status light). See

Figure 2.

• The Honeywell valve uses a standard

push-button piezo igniter. See “Spark

Igniter” in Figure 2B.

• Status codes are printed on the face

of the control for easy reference

(Figure 2B.)

• The LED status light shows the

current status of the control as well

as possible error codes for easy

diagnosis. For more information on

error codes, see “Lighting the Pilot /

Diagnostic Flash Codes” on page 9.

WŝůŽƚŇĂŵĞŚĞĂƚƐƚŚĞƌŵŽƉŝůĞ

ĞŶĂďůŝŶŐŐĂƐĐŽŶƚƌŽůǀĂůǀĞ

ƚŚĞƌŵŽƐƚĂƚŽƉĞƌĂƟŽŶ

Pilot

Thermopile

Figure 2.

Gas Pressures

Ensure that the following pressures are

observed and maintained:

Table 1. GAS PRESSURES

GAS MAXIMUM

SUPPLY

PRESSURE

NAT 14 InWC 5.0 InWC

LP 14 InWC 10.0 InWC

Min. Supply Pressure: See Rating Plate.

MANIFOLD

GAS

PRESSURE

(± 0.4 InWC)

(± 0.5 InWC)

The gas control valve\thermostat also

includes a temperature limiting ECO

(Energy Cut Off) system. This system

will shut off the water heater if the

water temperature becomes excessive.

Should the water temperature get

too high, the main burner and pilot

will shut off automatically. Once the

pilot is relit, the status light will flash

a code (4 flashes), indicating an overtemperature condition. See “Lighting

the Pilot / Diagnostic Flash Codes” on

page 9 for more information.

NOTE: Honeywell is a registered trademark

of Honeywell International, Inc.

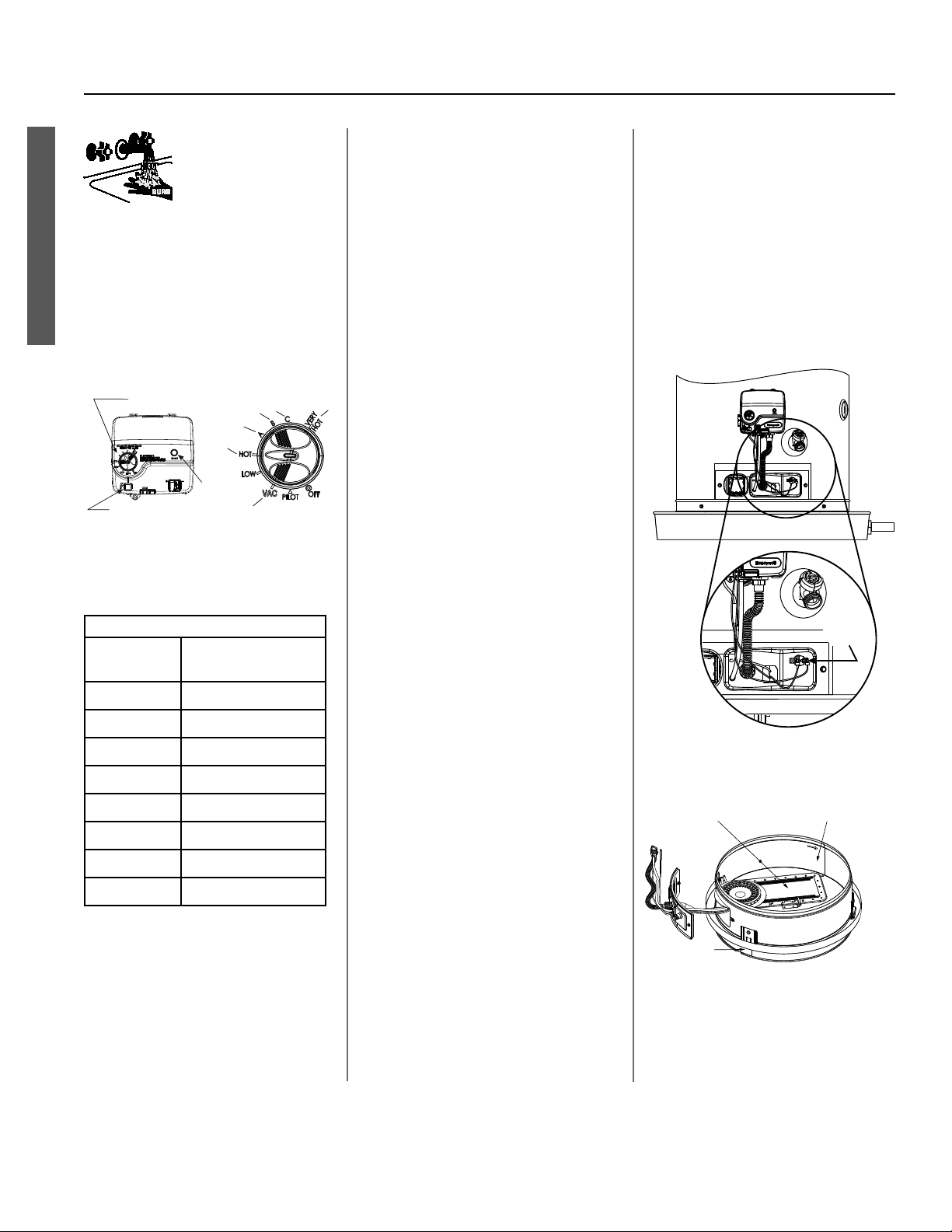

Temperature Seƫ ngs

The water temperature setting can be

adjusted from 55°F to 155°F. Simply

turn the gas control/temperature Knob

to the desired setting/temperature.

See Figure 3.

NOTE: The temperatures indicated are

approximates. The actual temperature

of the heated water may vary.

BASICS

Figure 2B

Temperature Control Knob

Temperature control ranges:

ͻϱϱΣ&ͲϭϱϱΣ&ǁŝƚŚsƐĞƫŶŐ

ͻϵϭΣ&ͲϭϱϱΣ&ǁŝƚŚŽƵƚsƐĞƫŶŐ

* Some models do not

ŝŶĐůƵĚĞĂs;ǀĂĐĂƟŽŶͿƐĞƫŶŐ

Residential Standard Gas Water Heater Service Handbook • 7

*

Page 8

Scalding Risk

A water heater

can make water

hot enough to

cause severe burns

instantly, resulting in severe injury or

death. Higher temperatures increase

BASICS

the risk of scalding, but even at 120°F,

hot water can scald. See Table 2.

Thermostatic mixing valves at each

point of use reduce the risk of scalding.

HONEYWELL® GAS CONTROL VALVE/THERMOSTAT

GAS CONTROL/TEMPERATURE KNOB

VAC

IGNITER

TEMPERATURES SHOWN ARE APPROXIMATES AND MAY VARY.

SOME MODELS ARE CERTIFIED FOR 180°F. SEE RATING PLATE.

Figure 3.

Table 2.

Water

Temperature

120°F (49°C) More than 5 minutes

125°F (52°C) 1½ to 2 minutes

130°F (54°C) About 30 seconds

135°F (57°C) About 10 seconds

140°F (60°C) Less than 5 seconds

145°F (63°C) Less than 3 seconds

150°F (66°C) About 1½ seconds

155°F (68°C) About 1 second

IMPORTANT: Water temperature

in the tank can be higher than the

thermostat setting. Some of the

reasons are:

• Incoming water temperature is

higher than the set point (e.g.,

solar-heated water).

§140°F

§130°F

120°F

MARK

STATUS

LIGHT

§55°F

Time to Produce

a Serious Burn

§150°F

§155°F

• The water heater and/or pipes

are located in an area with high

ambient temperatures (e.g., an

attic). See also “Attic Installations”

on page 23.

• Certain usage patterns, such as

short hot water draws or no hot

water use for long periods of

time, can cause the tank water

temperature to rise higher than the

thermostat setting. Modern water

heaters are very well insulated

and retain heat so efficiently that,

under certain circumstances,

the tank water temperature can

increase over time, particularly

when hot water is not being used.

This “heating” effect can be caused

by the pilot flame itself.

CombusƟ on Chamber

with TCO Switch

Combustion air is drawn through the

base-ring filter and flame arrestor and

into the combustion chamber. (See

Figure 5.) Sufficient combustion air is

critical to the operation of the water

heater.

IMPORTANT: The flame arrestor

and filter should be inspected and

cleaned during each service call. See

page 18 for instructions.

Also, each water heater covered by

this handbook is equipped with a

resettable TCO switch (thermal switch),

designed to shut off the gas supply in

the event that the water heater has

been exposed to high combustion

chamber temperatures caused by one

of the following events:

• Flammable vapors (e.g., spilled

gasoline)

• Poor combustion caused by a

blocked vent

• Insufficient combustion air.

A resettable thermal switch is

illustra

ted in Figure 4. Its reset button

is located in the center of the switch,

directly between the terminals.

IMPORTANT: If the thermal switch has

been tripped, determine the cause

and correct it before returning the

water heater to service. Ensure that

there are no flammable vapors

present. However, a tripped thermal

switch is most likely caused by poor

combustion (e.g., blocked vent or dirty

filter/arrestor).

THERMAL SWITCH (TCO) LOCATION

THERMAL

SWITCH

(TCO)

Figure 4.

FLAME ARRESTOR

BASE-RING

FILTER

COMBUSTION CHAMBER

Figure 5.

8 • Residential Standard Gas Water Heater Service Handbook

Page 9

LIGHTING THE PILOT / DIAGNOSTIC FLASH CODES

LighƟ ng the Pilot:

1. Read and follow the lighting

instructions on the water heater’s

label.

2. Turn the control knob to “Pilot.”

Press the knob in fully and hold it in.

(The knob will travel in about 1/4inch if it is set to Pilot correctly.)

3. While holding the control knob in,

click the igniter button continuously

for up to 90 seconds or until the

Status Light begins to blink.

If the status light does not begin

to blink after 90 seconds, STOP.

Release the control knob. Wait

10 minutes before attempting to

relight the Pilot. Repeat these steps

2-3 times, if necessary.

The circuitry in this gas valve

requires that you wait 10 minutes

between lighting attempts.

If the Status Light blinks, release

the gas control/temperature knob

and turn it to the desired setting.

(“Hot” is approximately 120°F).

'ĂƐŽŶƚƌŽůdĞŵƉĞƌĂƚƵƌĞ<ŶŽď

/ŐŶŝƚĞƌƵƩŽŶ

Figure 6.

If the Status Light Does

Not Blink:

1. Wait 10 minutes before another

lighting attempt.

2. If the status light did not blink, repeat

the lighting procedure by following

the lighting instructions on the water

heater’s label. Remove the outer

door. The control knob must be set

to Pilot and held in continuously

while clicking the igniter button

(about once per second for up to

90 seconds). To observe the Pilot,

remove the outer door and look

through the view port (sight glass).

See Figure 7.

3. Continue clicking the Igniter button

(for up to 90 seconds) until pilot

lights.

4. Once the pilot is lit, continue to hold

the control knob in until the Status

Light begins to blink.

5. Release control Knob and set Knob to

desired temperature setting. (“Hot”

is approximately 120°F.)

6. Replace the outer door.

If the Pilot Does Not

Light:

1. Wait 10 minutes before another

lighting attempt. If the pilot does not

light, the Igniter may not be sparking

or the unit may not be getting gas (or

for a new installation, there may still

be air in the gas line). Each time you

click the igniter button, you should

be able to see the spark by looking

through the view port. See Figure 7.

(You may have to darken the room

lights to see the spark.) You do not

have to push the Control Knob in

to check the Igniter button. Simply

look through the sight glass while

clicking the Igniter button and look

for a spark. If you can’t see a spark

when the Igniter button is clicked,

check the wiring connections from

the Igniter button and make sure

that they are tight.

2. If you see the igniter spark, try

relighting the pilot by following the

instructions on the water heater’s

label. Ensure that the gas supply is

turned on. There may be air in the

gas line, and several lighting attempts

may be needed to completely fill the

line with gas and successfully light

the pilot.

'^KEdZK>V>sd,ZDK^TAT

'^KEdZK>

dDWZdhZ<EK

W/K/'E/dZhddKE

V/tWKZd

KhdZKKZ

EKd^,KtE

VAC

Figure 7.

d,ZDKW/>

t/ZKEEd/KE^

THERMAL

SWITCH

ΈdKΉ

If the Pilot Lights but the

Status Light Does Not

Blink:

1. If the pilot lights, continue to hold the

control knob in until the status light

blinks. If the pilot is lit and remains

lit for 90 seconds and the Status Light

still does not blink, the thermopile

connections may be loose, the

thermal switch may need to be reset,

or the thermopile may be defective.

2. Remove the outer door.

3. Press the reset button on the thermal

switch (TCO switch). See Figure 7.

4. If the switch clicks, it may have

tripped. Do not light the pilot if

flammable vapors are present.

Check flame arrestor for signs

of discoloration (which could be

caused by flammable vapors). If the

flame arrestor is discolored, do not

attempt to relight the Pilot. Have the

water heater inspected by a qualified

service technician.

5. Check the wiring connections

from the thermopile and thermal

switch (TCO) to the gas control

valve/thermostat. Ensure that

all wiring connections are tight.

See Figure 7.

6. Replace the outer door.

PILOT/FLASH CODES

Residential Standard Gas Water Heater Service Handbook • 9

Page 10

7. Wait 10 minutes and try to light the

Pilot according to the instructions

on the water heater’s label.

8. While clicking the igniter button

continuously, the control knob must

be set to Pilot and held in until the

Status Light blinks. Once the status

light blinks, release the control knob

and set the knob to the desired

temperature setting. (“Hot” is

approximately 120°F.)

DiagnosƟ c Flash Codes

NOTE: In each case, the flash code will

occur, followed by a 3 second pause,

and then will repeat.

PILOT/FLASH CODES

0 Flashes (LED not lit)

Indication/Condition:

Control Off/Pilot Out.

Check/Repair:

1. Follow the lighting instructions on the

front of the water heater and attempt

to relight the pilot. Confirm that

the pilot is lit by looking through the

viewport (Figure 16, p. 17).

2. If pilot will light but does not

hold, check for a tripped thermal

switch. (Measure continuity by

placing a meter lead on each of

the two terminals. Continuity

means that it was not tripped.) If

thermal switch is tripped, check for

flammable vapors in the area and

ensure that the unit has adequate

combustion air and proper draft

before relighting. (You can reset

the thermal switch by pressing the

reset button in its center.) Also,

ensure that the filter and flame

arrestor are clean (p. 18).

3. If the pilot will light and does hold,

record any status codes and follow

the procedures relating to that code.

4. If pilot will not light at all, verify the

piezo igniter is producing a spark

and the unit is getting the correct

supply gas pressure. See “Testing

the Igniter System” (p. 19);

“Gas Pressure Checks” (p. 11).

Also, check the thermopile wiring

connections (Figure 16, p. 17).

Status Light On (solid)

Indication/Condition:

Pilot light was recently extinguished

and the thermopile is cooling down.

Check/Repair:

1. Turn the gas control valve/

thermostat knob to OFF.

2. Wait 10 minutes for the thermopile

to cool, then attempt to relight

the pilot by following the lighting

instructions on the water heater’s

label. NOTE: This gas control valve/

thermostat has built-in circuitry

that requires waiting 10 minutes

between lighting attempts.

Until the Thermopile reaches its

normal operating temperature,

the status light will not blink, even

if the pilot is lit. It may take up to

90 seconds of continuous pilot

operation before the thermopile

reaches normal operating

temperature and the Status Light

starts to blink.

1 Flash

Indication/Condition:

Normal Operation (bright/dim

heartbeat)

Check/Repair: No corrective action

necessary.

2 Flashes

Indication/Condition:

Thermopile voltage low.

Check/Repair:

1. Check all wiring connections for loose

or damaged wires. Correct if needed.

2. Check the millivolt output on the

thermopile. If output is less than 350

millivolts DC, replace the thermopile.

See also “Condensation” on page 15.

4 Flashes

Indication/Condition:

Temperature exceeded (ECO activated).

Check/Repair:

1. Turn gas control valve/thermostat

knob to OFF.

2. Turn the main gas supply OFF.

3. Replace the gas control valve/

thermostat.

5 Flashes

Indication/Condition: Sensor failure.

Check/Repair:

1. Turn gas control valve/thermostat

knob to OFF.

2. Turn the main gas supply OFF.

3. Replace the gas control valve/

thermostat.

7 Flashes

Indication/Condition:

Internal control failure.

Check/Repair:

1. Turn gas control valve/thermostat

knob to OFF.

2. Turn the main gas supply OFF.

3. Replace the gas control valve/

thermostat.

8 Flashes

Indication/Condition: Power off failure.

Check/Repair:

1. If the pilot flame is present when

the control knob is set to the OFF

position, replace the gas control

valve/thermostat.

2. If the pilot flame is not present when

the control knob is set to the OFF

position, wait 10 minutes for the

thermopile to cool, then relight the

unit. If this condition returns, replace

the gas control valve/thermostat.

10 • Residential Standard Gas Water Heater Service Handbook

Page 11

SYSTEM CHECKS

Explosion Risk

WARNING! Before performing any

test, check the area around the water

heater for any source of a flammable

vapor (i.e gasoline, paint thinners,

etc.). If any sources are found, do not

proceed until they are removed.

DraŌ Test

WARNING! Burn Hazard. Do not

touch the vent. Doing so can cause

burns.

After successfully lighting the water

heater, allow the main burner to

operate for five minutes. Close all

windows and doors and turn on all

gas appliances and air-moving devices

(range hoods, bathroom exhaust fans,

ceiling fans, etc.) in the home. Also,

close any fi replace dampers.

After five minutes, pass a newly

exƟ nguished match about one inch (1”)

from the draŌ hood’s relief opening.

Smoke from the match should be steadily

drawn into the opening, indicaƟ ng proper

draŌ and a funcƟ oning vent system.

DRAFT HOOD

RELIEF

MATCH

OPENING

ConnecƟ ons Check

Some issues can be caused by faulty

connections. Refer to the following list

of connections when troubleshooting

the system:

• Igniter wire (Figure 9). See also

“Testing the Igniter System” on

page 19.

• Thermopile/thermal switch wires

at the gas control valve/thermostat

(Figure 9).

• Wire connections at the thermal

switch (TCO). A disconnected

thermal switch wire can cause the

pilot to become inoperable. See

Figure 4, page 8.

See also “Diagnostic Flash Codes” on

page 10.

From Thermopile (White)

From Thermal Switch (Red)

• Supply gas pressure checks are

measured before the gas control

valve/thermostat and as close

to the water heater as possible.

NOTE: The dynamic gas pressure

(burner on) should be measured

with all appliances operating that

use the common gas supply.

• Manifold (main burner) gas

pressure is measured at the

pressure tap on the bottom of

the gas control valve/thermostat.

See Figure 9 and Figure 11. Use a

3/16” Allen wrench to remove the

pressure tap plug, then attach the

gas gauge.

NOTE: Gas outlet pressures will be listed

on the gas control valve/thermostat’s

pressure label. See Figure 10. Also,

gas supply pressure requirements are

shown on the water heater labeling.

GAS PRESSURE LABEL (OUTLET PRESSURE)

GAS

PRESSURE

GAUGE

VAC

MANIFOLD GAS PRESSURE TEST

CONNECTED AT

PRESSURE TAP

Figure 10.

SYSTEM CHECKS

Figure 8.

If the main burner has been operaƟ ng

for fi ve minutes, but the match smoke

driŌ s around or is blown away from

the opening, turn the gas control knob

OFF. Do not operate the water heater

until proper adjustments or repairs are

made to the vent pipe system and/or air

supply (p. 21). Always check the filter

and flame arrestor first and clean them,

if necessary (p. 18).

Igniter Wire

Manifold Flex Tube Nut:

ͻWƌŽƉĂŶĞ>ĞŌͲŚĂŶĚƚŚƌĞĂĚƐ

ͻEĂƚƵƌĂůZŝŐŚƚͲŚĂŶĚƚŚƌĞĂĚƐ

Manifold

Pressure Tap

(1/8” NPT-RH)

Figure 9.

Gas Pressure Checks

Gas pressure checks are made with

flowing gas. Use a gas pressure gauge

capable of reading pressure in inches

of water column.

Residential Standard Gas Water Heater Service Handbook • 11

CONNECTED AT PRESSURE TAP

Figure 11.

Page 12

Table 3.

Gas Pressures

IF . . .

...the supply gas

pressure is lower

than required...

. . . THEN

• increase the

supply gas

pressure regulator

setting

and/or

• increase supply

gas piping size.

2. Insert multimeter leads into the

connectors. The multimeter must

be set to read millivolts DC (on a

scale that can read 750 millivolts).

Reference Figure 12.

Thermopile Check

(Closed Circuit)

Follow the lighting instructions to light

the pilot. Once the pilot is lit, you can

check the output of the thermopile

with one of the following tests. A

reading above 350 mV DC indicates

that the thermopile is working

properly.

INSERT MULTIMETER LEADS INTO

THERMOPILE PLUGS AT CONTROL.

PILOT MUST BE LIT.

SYSTEM CHECKS

...the supply

gas pressure

is higher than

required...

...the manifold

gas pressure

is not within

+/- 10% of the

value shown

on the gas

pressure label...

NOTE: The gas

pressure label

lists the gas

valve outlet

pressure. This

is the same as

the manifold

pressure. See

Figure 10.

• add a gas pressure

regulator.

• reduce the setting

on the existing

regulator.

• ensure that there

is adequate supply

gas pressure

• ensure that the

main burner

orifice is the

correct size for

the model being

tested.

• if the above

tests have been

performed and

the results were

correct, replace

the gas control

valve (p. 20).

Thermopile Check

(Open Circuit)

The following test will check the DC

voltage generated by the thermopile

when the pilot light is lit.

1. Remove the connectors from the

gas control valve/thermostat (red

and white wires). Use needle-nose

pliers.

USE A MULTIMETER TO CHECK THE OUTPUT OF

THE THERMOPILE (MEASURED IN MILLIVOLTS).

SHOWN ABOVE - MULTIMETER PROBES ARE

INSERTED INTO THE THERMOPILE PLUGS. THESE

PLUGS WERE REMOVED FROM THE RECEPTACLE AT

THE BOTTOM, RIGHT-HAND CORNER OF THE GAS

CONTROL VALVE/ THERMOSTAT.

Figure 12.

3. Follow the lighting instructions to

light the pilot. Once the pilot is lit,

continue to hold the gas control

knob in until this test is complete.

You may need assistance from

another person to do this. The

voltage reading should rise

gradually as the thermopile heats

up. After a few minutes, you should

have a reading of at least 350 mV

DC. A reading above 350 mV DC

indicates that the thermopile is

working properly.

4. When you are finished, plug the

connectors back into the gas

control valve/thermostat. If the

connectors are separate (not a

double connector), ensure that the

red wire connector is to the left and

the white wire connector is to the

right. See Figure 2B, page 7. If

the status light does not blink once

every three seconds, replace the

gas control valve/thermostat.

MULTIMETER SET TO READ mV.

MINIMUM ACCEPTABLE

MEASUREMENT: 350 mV DC.

Figure 13.

INSERT ONE MULTIMETER LEAD INTO

THE NEGATIVE PLUG ON THE CONTROL

(WHITE WIRE).

TOUCH THE OTHER LEAD TO A

TERMINAL ON THE THERMAL

SWITCH (TCO).

MULTIMETER SET TO READ mV.

PILOT MUST BE LIT.

MINIMUM ACCEPTABLE

MEASUREMENT: 350 mV DC.

Figure 14.

12 • Residential Standard Gas Water Service Handbook

Page 13

COMMON ISSUES

Fire and Explosion Hazard

WARNING! Do not

attempt to light the water

heater if flammable vapors or liquids

are present. Do not store or use

gasoline or other flammable vapors

and liquids in the vicinity of this or any

other gas appliance. Storage of or use

of gasoline or other flammable vapors

or liquids in the vicinity of this or any

other appliance can result in serious

injury or death.

No Hot Water

If water is not being heated, check the

following:

1. Look at the gas control valve/

thermostat. Is it flashing? If so,

solutions for restoring hot water are

listed below. See also “Diagnostic

Flash Codes” on page 10.

1 Flash

Normal Operation

(This code may occur after you

relight the pilot.)

Once the water heater has

completed a heating cycle, it should

provide an adequate amount of

hot water. If it does not, see “Not

Enough Hot Water.” If the pilot

lights for a while, then goes out, see

“0 Flashes (LED not lit)” on page 10.

2 Flashes

Thermopile voltage is low

Possible causes/solutions:

• Thermopile is getting weak.

• Check wiring and connections.

• If necessary, replace the

thermopile. See “Replacing

the Pilot/Thermopile

Assembly” on page 17.

4, 5, or 7 Flashes

If you observe one of these

flash codes, refer to “Diagnostic

Flash Codes” on page 10.

8 Flashes

Power Off Failure

Often, this error can be cleared

by turning the pilot off, letting

it cool down for ten minutes,

then relighting it according to

the lighting instructions. See

“8 Flashes” on page 10.

2. If the status light is not lit, see

“0 Flashes (LED not lit),” page 10.

That section will help you investigate

causes related to the thermal switch

(TCO), spark ignition, gas pressures,

and thermopile connections.

NOTE: The pilot must be lit for

the status light (LED) to flash.

Heat from the pilot causes the

thermopile to generate voltage.

Without this voltage, the gas control

valve/thermostat cannot operate.

Remember: it may take up to 90

seconds to heat the thermopile

enough to power the status light.

3. If you completed step 2 and

the pilot will not light, check for

air in the gas line. (This is fairly

common with recent work/new

installations.) If there is air in

the gas line, bleed the line as

necessary. Make sure to hold the

gas control knob in fully and hold it

in. In most cases, energy efficient

pilot orifices are so small that it

may be difficult to clear the air by

holding the knob in.

When you are finished, try to light

the pilot. (Follow the lighting

instructions on the water heater.)

Remember to hold the control

knob in for at least 90 seconds so

the pilot can heat up.

Did the pilot light? If it did, check

the following:

A. If the pilot did not light, replace

the pilot. (The entire pilot/

thermopile assembly must be

replaced). The most likely cause

is contamination in the pilot

tube.

A. If the pilot is lit and the status

light is flashing, refer to

“Diagnostic Flash Codes” on

page 10.

B. If the pilot is lit, but the status

light did not start flashing, check

the thermopile (p. 12). If its

output is 350 mV or less, it must

be replaced. If its output is

greater than 350 mV, replace the

gas control valve/thermostat.

Not Enough Hot Water

Check the following if the water is not

hot enough or if the hot water runs out

too quickly:

Possible causes

• Lower seasonal water temperatures

• Faulty shower control or faucet

valve

• Thermostat is set too low

• Increased hot water usage

• Water heater is too small to meet

demand

• Reversed plumbing connections

• Plumbing system leak

• Sediment buildup in the tank

Verify the water temperature at

the temperature/pressure relief

valve. Check the mixing valve/

shower control settings. Also

check for leaks, heavy usage, and

extremely cold incoming water.

In all cases, clean the filter and

flame arrestor (p. 18), then

conduct a draft test (p. 11).

A description of each cause and its

solution(s) is listed below.

Lower Seasonal Water Temperatures

In some areas, water coming into the

tank is much colder during winter

COMMON ISSUES

Residential Standard Gas Water Heater Service Handbook • 13

Page 14

and early spring months. Even when

the water heater is working properly,

it may take longer to fully heat the

water. As a result, hot water may not

be available as quickly as it is during

warmer months.

Faulty Shower Control Valve/Faucet

Valve

Check the hot water at all faucets in

the home. Some may have built-in

thermostat or pressure-balance mixing

valves that may need adjustment or

replacement. If you get hot water from

some outlets but not others, adjust/

replace each fixture as necessary.

NOTE: A mixing valve issue is not a

water heater defect and is not covered

by the water heater warranty.

Thermostat Set Too Low

Scalding Risk

A water heater can

make water hot

enough to cause

severe burns instantly, resulting

in severe injury or death. Higher

temperatures increase the risk of

scalding, but even at 120°F, hot water

can scald. See Table 2 on page 8

before proceeding. Thermostatic

mixing valves at each point of

COMMON ISSUES

use reduce the risk of scalding.

If you’ve checked all of the faucets

and shower controls and the water

temperature is still too cool, the water

heater’s thermostat may be set too

low. See “Temperature Settings” on

page 7 for instructions on how

to adjust the thermostat. If there

still isn’t enough hot water, set the

thermostat to a higher setting and

install a thermostatic mixing valve at

each point of use.

An Increase in Hot Water Usage

If hot water is running out during

holidays, weekends, or family

gatherings, the demand for hot

water may be exceeding the water

heater’s capacity. Hot water usage

can be reduced by washing clothes in

cold water, installing flow restrictors

on shower heads, and taking other

conservation steps.

Undersized Water Heater

If water is frequently too cool, the

water heater may be too small. If

the water heater is old, the best

solution may be to replace it with a

larger model. If the water heater is

in good condition, you may set the

thermostat to a temperature above

120°F and install thermostatic mixing

valves at each point of use. Set each

thermostatic mixing valve’s delivery

temperature to 120°F to reduce the

risk of scalding. (See “Temperature

Settings” on page 7.)

This method can increase the effective

size of the water heater by about 30%.

Reversed Water Connec ons

If the hot and cold water connections

are reversed, it may appear as if the

water heater isn’t producing much

hot water. This problem is usually

identified at the time of installation.

Confirm that the home’s hot water

pipe is connected to the water heater’s

hot water outlet, not the cold water

inlet. If the connections are reversed,

switch them to the correct position.

NOTE: The water heater’s hot water

outlet will be marked with an “H” or

“HOT,” or will be color coded red.

Leak in the Plumbing System

A leak in the home’s plumbing system

can overload the water heater’s ability

to heat water. In that case, the water

heater can be working, but there will

be little or no hot water. Check the

plumbing system for leaks and repair

as necessary.

Sediment Buildup in the Tank

If the water heater is several years old

and/or is installed in an area known for

hard water, there may be a buildup of

sediment at the bottom of the tank.

Sediment buildup may reduce the

efficiency of the water heater and may

reduce the amount of available hot

water.

Drain and flush the tank (page 20).

You may also treat the tank with a

lime/scale removal solution that is

approved for potable water heaters.

14 • Residential Standard Gas Water Service Handbook

Page 15

Tank Leak

CondensaƟ on

If you see small puddles of water in

the drain pan or hear sizzling sounds

as water drips on the burner, the

water heater may be producing

condensation. Condensation may drip

onto the burner or other hot surfaces

to produce a sizzling sound. On some

models, this may actually cause the

pilot to go out.

Condensation usually occurs when the

water heater tank is full of cold water.

Condensation will most likely occur:

• During holidays, weekends, or

family gatherings when there is an

increase in your home’s hot water

usage.

• During the winter and early spring

months when incoming water

temperatures are at their lowest.

• If the water heater is a new

installation.

• If a large amount of hot water is

used in a short period of time.

• If the water heater is too small for

the home’s hot water demands.

In most cases, condensation

should disappear once the water

heater reaches normal operating

temperature, or when the home’s hot

water demands return to normal.

If the water heater is too small for the

home’s typical hot water demands,

the water heater may produce

condensation regularly. In that case, a

larger water heater is recommended.

NOTE: Condensation may cause a “2

Flashes” error code, indicating low

thermopile voltage. This condition

may clear up as the tank begins to

warm. See “2 Flashes” on page 10

Leaking Plumbing ConnecƟ ons

If there’s water on the floor around

the bottom of the water heater, check

the plumbing connections on top of

the tank. Use a dry paper towel to

wipe around the hot and cold pipe

connections on top of the water

heater. If the paper towel is wet after

wiping a connection, repair the leak(s).

Drips from the T&P Relief Valve

Discharge Pipe

A small amount of water dripping from

the temperature and pressure (T&P)

relief valve usually means the home’s

water pressure is too high or you

need a properly sized and pressurized

thermal expansion tank. A large

amount of hot water coming from the

T&P discharge pipe may be due to the

tank overheating.

WARNING! Do not cap or plug the

T&P relief valve or discharge pipe,

and do not operate the water heater

without a functioning T&P relief Valve.

This could cause an explosion.

Refer to Figure 1 on page 6 while

reviewing this section.

• Water pressure too high. High water

pressure can cause the T&P relief

valve to drip. Install a pressure

reducing valve (PRV) on the main

cold water supply line. Adjust the

PRV to between 50 and 60 psi.

• Thermal Expansion Tank. Install

a Thermal Expansion Tank. If a

Thermal Expansion Tank is already

installed and the T&P Relief Valve

discharge pipe drips, the Thermal

Expansion Tank may be pressurized

to the wrong pressure or the internal

bladder may be defective. Refer to

the instructions that came with the

Thermal Expansion Tank for more

information.

• Debris. In rare cases, debris can

stick inside the T&P relief valve

preventing the valve from seating

fully. In that case, the T&P relief

valve discharge pipe will drip. You

may be able to clear debris from

the T&P Relief Valve by manually

operating the valve, allowing small

quantities of water to flush out the

debris. See the label on the T&P

relief valve for instructions.

If the water pressure is between 50

and 60 psi, a thermal expansion tank is

installed and properly pressurized, and

the valve has been cleared of any debris,

and it still drips, the valve may be broken.

Install a new T&P relief valve.

COMMON ISSUES

Residential Standard Gas Water Heater Service Handbook • 15

Page 16

Temperature Too High

Scalding Risk

A water heater can

make water hot

enough to cause

severe burns instantly, resulting

in severe injury or death. Higher

temperatures increase the risk of

scalding, but even at 120°F, hot water

can scald. See Table 2 on page 8

before proceeding. Thermostatic

mixing valves at each point of

use reduce the risk of scalding.

If the water temperature is too hot:

• Install or adjust the thermostatic

mixing valves for each point-of-use

(see manufacturer’s instructions), or

• Adjust the temperature setting on

the water heater. See “Temperature

Settings” on page 7.

Low Water Pressure

Check both the cold and hot water at a

sink to determine if the lower pressure

is only on the hot water side. If the low

pressure is on the hot water side only,

the primary causes of this are:

• Melted heat traps or dip tube.

Soldering copper pipes while they are

connected to the water heater can

melt the heat traps inside the hot and

cold water connections or the dip tube

(cold water side). Melted heat traps or

a melted dip tube can restrict the flow

of hot water. If that’s the case, replace

the heat traps or dip tube.

• Partially closed supply valve. Open

the water heater’s supply valve fully.

Water Odor

Harmless bacteria normally present

in tap water can multiply in water

heaters and give off a “rotten egg”

smell. Although eliminating the

bacteria that causes “smelly water”

with a Chlorination system is the only

sure treatment, in some cases, the

standard anode rod that came with the

water heater can be replaced with a

special zinc anode rod which may help

reduce or eliminate the odor. Contact

Technical Assistance for availability.

NOTE: To protect the tank, an anode rod

must be installed in the water heater at

all times or the warranty is void.

In cases where the “rotten egg” smell

is pronounced, you can raise the tank

temperature to 140°F in order to

reduce bacteria growth in the tank.

WARNING! Higher temperatures

increase the risk of scalding. If

you set the temperature setting

higher than 120°F, thermostatic

mixing valves at each point-of-use

are particularly important. See

“Temperature Settings” on page 7.

COMMON ISSUES

16 • Residential Standard Gas Water Service Handbook

Page 17

SERVICE PROCEDURES

Removing the Manifold/

Burner Assembly

1. Turn the gas control/temperature

knob to the “OFF” position (Figure

6 on page 9).

2. Before performing any

maintenance, it is important to

turn off the gas supply to the water

heater at the manual gas shutoff valve (Figure 1, p. 6). This

valve is typically located beside the

water heater. Note the position of

the shut-off valve in the open/on

position, then proceed to turn it

off.

3. With the unit shut-off, allow

sufficient time for the water heater

to cool before performing any

maintenance.

'^KEdZK>

dDWZdhZ<EK

VAC

IGNITER

hddKE

IGNITER

>

WIRE

IGNITER

WIRE

W/>Kd

TUBE

Figure 15.

4. Remove the outer door.

5. Disconnect the following from the

gas control valve/thermostat: pilot

tube (7/16” wrench), igniter wire

(from the igniter lead wire), and

manifold tube (3/4” wrench). See

Figure 15.

6. Disconnect the white and red

wires from the gas control valve/

thermostat (Figure 15). Use

needle nose pliers to grip the

connector(s). IMPORTANT: Grip

the connector carefully to prevent

damage. Do not grip or pull the

wires themselves.

7. Grasp the manifold tube and push

down slightly to free the manifold

tube and pilot tube.

WHITE

WIRE

ΈZ/',d

^/Ή

RED WIRE

Έ>&d^/Ή

DE/&K>dh

8. Remove the screws (1/4” nut

driver) securing the manifold/

burner assembly to the combustion

chamber. (Figure 16.)

9. Carefully remove the manifold/

burner assembly from the

combustion chamber. BE SURE NOT

TO DAMAGE ANY INTERNAL PARTS.

'^KEdZK>V>sd,ZDK^TAT

'^KEdZK>

dDWZdhZ<EK

W/K/'E/dZhddKE

V/tWKZd

KhdZKKZ

EKd^,KtE

DE/&K>^Zt^ΈϮΉ

VAC

d,ZDKW/>

t/ZKEEd/KE^

THERMAL

SWITCH

ΈdKΉ

Figure 16.

Removing the Burner

from the Manifold/

Burner Assembly

Natural Gas (Low Nox) & L.P. Gas

Burner

1. Take off the burner by removing the

two (2) screws located underneath

the burner (Figure 17.).

2. Check the burner to see if it is dirty

or clogged. The burner may be

cleaned with soap and hot water.

IMPORTANT: DO NOT remove the

orifice.

BURNER SCOOP

(SOME MODELS)

SCREWS (2)

PILOT ASSEMBLY

(BOTTOM VIEW)

MANIFOLD

TUBE

BURNER

(BOTTOM VIEW)

Figure 17.

Replacing the Pilot/

Thermopile Assembly

A. Removing the Old Pilot/

Thermopile Assembly from

the Manifold Assembly

1. Remove the manifold door

assembly as described in

“Removing the Manifold/Burner

Assembly” section.

2. Remove the burner to access

the pilot/thermopile assembly.

Remove and keep the screws

securing the burner to the manifold

(Figure 17.) IMPORTANT: DO NOT

remove the orifice.

3. Remove the screw securing the

pilot/thermopile assembly to the

pilot bracket and keep for reuse

later (Figure 18.)

4. Lift the retainer clip straight up

from the back of the manifold

component block (using a flatblade screwdriver), then remove

the manifold component block

from the manifold door. See Figure

18. IMPORTANT: Be careful not

to bend or alter the position of

the pilot tube. It will be used as a

bending template for the new pilot

assembly. Note the placement/

order of the wires in the manifold

component block.

5. Lift the pilot/thermopile assembly

(including the igniter wire) from

the manifold assembly.

PILOT / THERMOPILE

ASSEMBLY SCREW

BURNER AND OTHER

FITTINGS NOT SHOW

FOR CLARITY.

RED WIRES TO

d,ZD>^t/d,ΈϮΉ

IGNITER

WIRE

MANIFOLD

COMPONENT

BLOCK

CONNECTORS

RETAINER

CLIP

PILOT TUBE

MANIFOLD DOOR

Figure 18.

SERVICE PROCEDURES

Residential Standard Gas Water Heater Service Handbook • 17

Page 18

B. Installing the New Pilot/

Thermopile Assembly

1. Read this step carefully before

proceeding. Using the old pilot/

pilot tube assembly as a guide,

bend the new pilot tube to match

the old one. Make only the bends

closest to the pilot before going to

the next step.

2. Route the new pilot tube and

wires through the opening in the

manifold door. See Figure 18 on

page 17.

PILOT/THERMOPILE ASSEMBLY

IGNITER

CONNECTOR

PILOT

PILOT/THERMOPILE

KEEdKZΈ^Ή

ΈKEEdd

GAS CONTROL VALVE/

d,ZDK^ddΉ

ASSEMBLY

FOR CLARITY, PILOT

TUBE NOT SHOWN .

Figure 19.

ORIFICE

ΈKDWKEEd^Ή

THERMOPILE

THESE TWO PARTS MAY BE

PILOT

PILOT BRACKET

EXPLODED VIEW OF PILOT/THERMOPILE ASSEMBLY.

FOR INFORMATIONAL PURPOSES ONLY. THE PILOT/THERMOPILE

ASSEMBLY SHOULD BE INSTALLED/SERVICED AS A SINGLE UNIT.

DO NOT DISASSEMBLE.

COMBINED ON SOME MODELS.

PILOT ASSEMBLY FOR CAST

BURNER NOT SHOWN.

Figure 20.

SERVICE PROCEDURES

3. Using the pilot screw removed

earlier, attach the new pilot/

thermopile assembly. Reattach

the burner to the manifold using

the screws removed earlier. NOTE:

If your burner includes a burner

scoop, make sure that it is oriented

to the pilot side of the manifold

tube. See Figure 17 on page 17.

THERMOPILE

THERMAL

SWITCH

CONNECTORS

ΈZt/Z^Ή

PILOT TUBE

4. Reinstall the manifold component

block in the manifold door. Ensure

that the pilot tube and wires are

positioned as shown in Figure 21.

5. Carefully bend the new pilot tube

to match the bend of the manifold

tube. NOTE: When bending, DO

NOT crimp or crease the pilot tube.

6. Before you proceed to the next

step, install the new brass ferrule

nut in the gas control valve/

thermostat’s pilot tube opening,

HAND TIGHT ONLY.

7. Install the manifold/burner

assembly.

ZΈнΉd,ZD>^t/d,t/Z

CONNECTS TO THE GAS CONTROL

VALVE\THERMOSTAT.

t,/dΈͳΉd,ZDKW/>

WIRE CONNECTS TO THE GAS

CONTROL VALVE\

THERMOSTAT.

RED THERMAL SWITCH WIRE

MANIFOLD

KDWKEEd

BLOCK

/'E/dZt/ZW^^^

THROUGH CENTER OF

DE/&K>KDWKEEd

>K<Έ^D>>^d,K>Ή

W/>KddhW^^^d,ZKh',KddKD,K>

K&DE/&K>KDWKEEd>K<Έ>Z'^d,K>Ή

CONNECTIONS AT

MANIFOLD DOOR

d,ZDKW/>t/Z^W^^

d,ZKh',dKW,K>K&

DE/&K>KDWKEEd

BLOCK

Figure 21.

External InspecƟ on and

Cleaning of the BaseRing Filter

1. At least annually, check the basering filter for any dust or debris that

may have accumulated on the filter

screen. See Figure 22. NOTE: If the

water heater is located in an area

that is subjected to lint and dirt,

it may be necessary to check the

base-ring filter more frequently.

2. Follow the Lighting Instructions to

turn off the water heater and allow

it to cool for 10 minutes before

attempting to clean the base-ring

filter.

3. Use a vacuum cleaner with a hose

attachment to remove any dust or

debris that may have accumulated

on the filter. NOTE: If you are

unable to inspect or clean the basering filter, follow the “Cleaning the

Combustion Chamber and Flame

Arrestor” instructions.

4. After the base-ring filter has

been cleaned, follow the Lighting

Instructions to return the water

heater to service.

COMBUSTION CHAMBER

DOOR GASKET

BASE-RING

FILTER

FLAME ARRESTOR

Figure 22.

Cleaning the

CombusƟ on Chamber

and Flame Arrestor

1. Follow procedure outlined in

“Removing the Manifold/Burner

Assembly.”

2. Use a vacuum cleaner/shop vac

to remove all loose debris in

the combustion chamber. See

Figure 22. Use compressed air to

clear any dust or debris that may

have accumulated in the flamearrestor. (To clean the flame

arrestor, you may use a soft plastic

brush under water heater. Vacuum

lint from brush. Repeat until brush

is clean.)

18 • Residential Standard Gas Water Heater Service Handbook

Page 19

3. Reassemble following the

procedure under “Replacing the

Manifold/Burner Assembly.”

Replacing the Manifold/

Burner Assembly

Explosion Risk

WARNING!

• Tighten both manifold door screws

securely.

• Remove any fiberglass between

gasket and combustion chamber.

• Replace viewport if glass is missing

or damaged.

• Replace manifold component block

if it is missing or has been removed.

• Replace door gasket if it is

damaged.

• Failure to follow these instructions

can result in death, explosion, or

fire.

1. Check the door gasket for damage

or imbedded debris prior to

installation. See Figure 22.

2. Inspect the viewport for

damage and replace as required

(Figure 16, page 17).

3. Insert the new manifold/

burner assembly into the burner

compartment, making sure that

the tab of the manifold tube

engages the slot of the bracket

inside the combustion chamber.

See Figure 23.

CLOSE-UP INSIDE VIEW OF

THE COMBUSTION CHAMBER.

SLOT

TIP

MANIFOLD TUBE

Figure 23.

BRACKET

4. Inspect the door gasket and make

sure there is no fiberglass insulation

between the gasket and the

combustion chamber. (Figure 22.)

5. Tighten the two screws that secure

the manifold/burner assembly to

the combustion chamber. (Use a

1/4” nut driver.) There should be no

space between the gasket part of

the manifold door and combustion

chamber

IMPORTANT: Do not operate the

water heater if the door gasket

does not create a seal between the

manifold door and the combustion

chamber.

6. Reconnect the manifold tube (3/4”

wrench) and pilot tube (7/16” wrench)

to the gas control valve/thermostat.

See Figure 15 on page 17. Do not

cross-thread or apply any thread

sealant to the fittings.

IMPORTANT: If you were supplied

with a new ferrule nut in a parts kit,

follow these steps to connect the

pilot tube:

A.) Install the ferrule nut into the gas

valve at the pilot tube location,

hand tight only.

B.) Insert the pilot tube into the

ferrule nut until the tube

bottoms out, then tighten the

nut with a 7/16” wrench until

the crimp connection seals to

the pilot tube.

C.) Continue to tighten until the nut

is tight in the gas valve.

7. Connect the white and red wires to

the gas control valve/thermostat

as shown in Figure 15, page 17.

Also, ensure that the red thermal

switch wires are connected to the

thermal switch (TCO switch) on the

manifold door. See Figure 21 on

page 18.

8. Reconnect the igniter wire. (Figure

15, page 17).

9. Turn on the gas supply to the water

heater at the manual gas shut-off

valve. (Figure 1, page 6).

10. Follow the lighting instructions

on the front of the water heater.

With the main burner lit, check

for leaks at the manifold and

pilot connections by brushing on

an approved noncorrosive leak

detection solution. If such a solution

is not available, use a mixture of

hand dish washing soap and water

(one part soap to 15 parts water)

or childrens’ soap bubble solution.

Bubbles forming indicate a leak.

Correct any leak found.

11. Verify proper operation, then

replace the outer door.

TesƟ ng the Igniter

System

The piezoelectric igniter system consists

of an igniter button, an electrode, and

wire. The pilot is ignited by an electric

spark generated when the igniter

button is pressed. See Figure 24.

THERMOPILE

PILOT

PILOT/

THERMOPILE

VAC

ELECTRODE

WIRE TO ELECTRODE

IGNITER BUTTON

Figure 24.

To test the igniter system, follow these

steps:

1. Turn off the gas to the water heater

at the manual gas shut-off valve.

(See Figure 1, page 6.)

2. Watch the electrode tip while

activating the igniter. (If the room

is dim enough, try looking through

the view port [Figure 16].)

A. A visible spark should jump from

the electrode. To avoid shock, do

not touch the burner or any metal

BRACKET

SERVICE PROCEDURES

Residential Standard Gas Water Heater Service Handbook • 19

Page 20

part on the pilot or pilot assembly.

If no spark is visible, check the

wire connections and make sure

that the electrode is not broken.

See also “Connections Check” (p.

11).

B. Replace the igniter if defective

(i.e., gas control valve/

thermostat and/or pilot/

thermopile assembly). Dirt and

rust on the pilot or electrode tip

can prevent the igniter spark.

Wipe clean with a damp cloth

and dry completely. Rust can

be removed from the electrode

tip and metal surfaces by lightly

sanding with an emery cloth or

fine grit sandpaper.

Removing and Replacing

the Gas Control Valve/

Thermostat

IMPORTANT: This water heater has a

resettable thermal switch installed. Do

not attempt to disable or modify this

feature in any way. Use only factory

authorized replacement parts.

Removing the Gas Control

Valve/Thermostat:

1. Turn the gas control/temperature

knob to the “OFF” position.

(Figure 6, page 9.)

2. Turn off the gas at the manual shutoff valve on the gas supply pipe.

(Figure 1, page 6.)

3. Drain the water heater. Refer to

the “Draining and Flushing” section

SERVICE PROCEDURES

and follow the procedure.

4. Disconnect the igniter wire from

the igniter lead wire. Use needle

nose pliers to disconnect the

red (+) and white (-) thermopile

wires. Disconnect the pilot tube

(7/16” wrench) and manifold

tube (3/4” wrench) at the gas

control valve/thermostat. See

Figure 15 on page 17.

5. Disconnect the ground joint

union in the gas piping. See

Figure 1, page 6. Disconnect

the remaining pipe from the gas

control valve/thermostat.

6. To remove the gas control valve/

thermostat, thread a 4” section of

gas pipe into the inlet and use it to

turn the gas control valve/thermostat

(counterclockwise.) Do not use a

pipe wrench or equivalent to grip

body. Damage may result, causing

leaks. Do not insert any sharp objects

into the inlet or outlet connections.

Damage to the gas control valve/

thermostat may result.

Replacing the Gas Control Valve/

Thermostat:

To replace the gas control valve/

thermostat, reassemble in reverse

order. When replacing the gas control

valve/thermostat, thread a 4” section

of gas pipe into the inlet and use it to

turn the gas control valve/thermostat

(clockwise). DO NOT OVER TIGHTEN;

damage may result.

• Be sure to use approved Teflon®

tape or pipe joint compound on the

gas piping connections and fitting

on the back of the gas control valve

that screws into the tank.

• Be sure to remove the pilot ferrule

nut from the new gas control valve/

thermostat.

• Turn the main gas supply on and

check the gas supply connections

for leaks. Correct any leak found.

Next, light the pilot and main

burner, then check the manifold

tube and pilot tube connections

for leaks. Correct any leak found.

Use an approved noncorrosive

leak detection solution. If such

a solution is not available, use

a mixture of hand dish washing

soap and water (one part soap to

15 parts water) or childrens’ soap

bubble solution. Bubbles forming

indicate a leak.

• Be sure tank is completely filled

with water before lighting and

activating the water heater. Follow

the “Lighting Instructions” on the

front of the water heater.

TEFLON® is a registered trademark of

E.I. Du Pont De Nemours and Company

Draining and Flushing

WARNING! Hot Water Discharge

Hazard:

• Keep clear of temperature/

pressure relief valve discharge.

• Temperature limiting valves are

available.

• Read instruction manual for

information on a safe temperature

setting.

It is recommended that the tank be

drained and flushed every 6 months

to remove sediment which may build

up during operation. The water heater

should be drained if being shut down

during freezing temperatures. To drain

the tank, perform the following steps:

1. Turn off the gas to the water heater

at the manual gas shut-off valve.

2. Open a nearby hot water faucet

until the water is no longer hot.

3. Close the cold water inlet valve.

4. Connect a hose to the drain valve

and terminate it to an adequate

drain or external to the building.

5. Open the water heater drain valve

and allow all of the water to drain

from the tank. Flush the tank with

water as needed to remove sediment.

6. Close the drain valve, refill the tank,

and restart the water heater as

directed in the lighting instructions.

(The lighting instructions are

posted on the front of the water

heater.) Ensure that the water

heater is full of water before you

light the pilot.

If the water heater is going to be

shut down for an extended period,

the drain valve should be left

open. IMPORTANT: Condensation

may occur when refilling the tank and

should not be confused with a tank

leak.

20 • Residential Standard Gas Water Heater Service Handbook

Page 21

SUPPLEMENTS

EVALUATING

COMBUSTION AND

VENTILATION AIR

SUPPLY

WARNING! Gas water heaters

require an adequate source of clean air

for combustion and ventilation.

Without sufficient air, a water heater

will have frequent pilot outages and

may emit excessive and abnormal

amounts of carbon monoxide.

Before beginning:

Calculate total BTU/HR rating of all

appliances

To calculate the combusƟ on air and

venƟ laƟ on required, add up the total

BTU/HR raƟ ngs of all gas burning

appliances (e.g., water heaters, furnaces,

clothes dryers) in the same area.

A water heater’s BTU/HR rating is on its

data plate, located next to the gas control