Page 1

FOR INSTALLATION BY QUALIFIED SERVICE PERSONNEL ONLY

CONVERSION KIT INSTRUCTIONS

Models DRE & DVE 52, 80, & 120

Commercial Electric Water Heaters

Series 100

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY.

PL E ASE R EAD TH O ROU GHLY BEFO RE

ATTEMPTING ANY CONVERSION.

PRINTED 0210 196678-003

1

500 Tennessee Waltz Parkway

Ashland City, TN 37015

1-800-433-2545

www.hotwater.com

Page 2

FOREWORD

The purpose of this manual is to explain how to change the voltage and wattage of your commercial electric water heater

by changing the elements. This manual is not intended to explain the rebuilding of commercial electric water heaters

in the eld.

Addition of heating elements or subtraction of heating elements in the eld is not approved by Underwriters Laboratories,

Inc., and therefore, is not allowed and should not be attempted.

Please note the limitation that “both the heater required and the heater to be converted must be found on the same

page” (in this manual) must be followed. Before attempting any conversion read the detailed instructions contained on

pages 8, 9, 10 and 11.

SAFETY

Be sure to disconnect appliance from electrical supply before working on or near the electrical system of the heater.

Never touch electrical components with wet hands or when standing in water.

REQUIRED ABILITY

CONVERSION OF ANY WATER HEATER LISTED IN THIS MANUAL REQUIRES ABILITY EQUIVALENT

TO THAT OF A LICENSED ELECTRICAL TRADESMAN.

TABLE OF CONTENTS

Foreword ............................................................... 2

Conversion Materials ............................................. 2

Conversion Guidelines ....................................... 3

Conversion Instructions

Introduction .......................................................... 4

Heater Preparation .............................................. 4

Page

KW Conversion (Element Replacement) ............. 4

Voltage Conversion ............................................. 4-5

Phase Conversion ............................................... 5-6

Caution ................................................................ 6

Final Assembly .................................................... 6-7

Check List ............................................................ 7

Miscellaneous Information ................................... 7-8

CONVERSION MATERIALS

1. Screw Plug Element Remover: Part no. 9000429015 or 1-1/2” deep well socket and ratchet.

Page

2. Screwdrivers: Two required, one #2 phillips and one slotted screwdriver.

3. Conversion kit: Includes conversion instructions, replacement electrical elements, conversion kit label, and caution

label.

4. Thread sealer: When replacing screw-in type elements, be sure to use Dow Corning® silicone sealant (bathtub sealer)

on threads.

2

Page 3

CONVERSION GUIDELINES

Be sure to read and understand the conversion limitations and instructions prior to conversion.

1. No addition or substraction of heating elements are allowed in the conversion process;

2. Conversion kits are designed for specic voltage with Delta conguration, no other conguration or voltage is

allowed;

3. Refer to “Branch Circuit Section” in User’s Manual for electrical specications;

4. Check all water and electrical connections for tightness after conversion.

TO USE THE TABLE:

1. Find the element number of the heater that you wish to convert.

2. Find the total kilowattage under “Desired Input” column, then move across the Table on same line to voltage

desired. The kit number required for the conversion will be the one where the desired KW row intersects the voltage

column.

3. Order the appropriate kit number.

4. Follow the conversion instructions detailed on pages 9 through 13 to complete conversion.

5. Fill out the check list on Page 12 after completing the unit conversion.

CONVERSION KIT NUMBER TABLE

Desired Input Conversion Kit No. At Desired Voltage

Models Allowed

Total kW

For Conversion

6 2 9005587105 9005600105 9005615105 9005621105

9 3 9005588105 9005601105 9005616105** 9005622105

DVE/DRE

52, 80, 120

12 4 9005589105 9005602105 9005617105 9005623105

13.5 4.5 9005585105 9005597105 9005612105** 9005618105

15 5 9005586105 9005598105 9005613105** 9005619105

18 6 N/A 9005599105 9005614105 9005620105

18 3 9005592105 9005606105 9005627105** 9005632105

24 3 9005593105 9005607105 9005628105 9005633105

27 4.5 9005590105 9005603105 9005624105** 9005629105

30 5 9005591105 9005604105 9005625105** 9005630105

36 6 N/A 9005605105 9005626105 9005631105

36 4 9005596105 9005611105 9005637105 9005641105

40.5 4.5 9005594105 9005608105 9005634105** 9005638105

DVE 52, 80, 120

45 5 9005595105 9005609105 9005635105** 9005639105

54 6 N/A 9005610105 9005636105 9005640105

with

3 Elements

DVE/DRE

52, 80, 120

with

6 Elements

DRE 80, 120

with

9 Elements

Element kW

208V 240V 277V 480V

* No conversion kits available for 50 gallon capacity 9 element models equipped with surface-mounted thermostat.

** Indicates the conversion kit with Incoloy Elements.

3

Page 4

CONVERSION INSTRUCTIONS

REQUIRED ABILITY

CONVERSION OF ANY WATER HEATER LISTED IN THIS MANUAL REQUIRES ABILITY EQUIVALENT

TO THAT OF A LICENSED ELECTRICAL TRADESMAN

I. INTRODUCTION

Satisfying a customer order for a commercial electric heater from inventory may require modication to the KW input,

the voltage, or the phase. Conversions may involve revision to 1, 2, or all 3 of these electrical characteristics.

II. HEATER PREPARATION

The heater should be placed in a well lit area. Complete removal of the shipping crate is not required. The front of the

heater with the control box will be visible through the clear plastic. Cut a 3-sided ap into the plastic, cut should be on

top, bottom and right side approximately 4” from the wooden edge.

Release the two control panel screws on the water heater door.

To expose elements, remove the foam door inside the control panel.

Remove the T & P valve (separate package).

III. KW CONVERSION (ELEMENT REPLACEMENT)

A. Remove wires from one element at a time. It is not necessary to tag loose wires as the wiring schematic is

inside the control panel door.

B. Remove element from heater using part no. 9000429015 or 1-1/2” deep well socket and ratchet. Return the

elements to appropriate storage bin.

C. Open the appropriate conversion kit and remove the elements. Check each element to ensure correct voltage

and wattage.

D. Install the new element, starting it by hand. A new “O” ring gasket should be installed on each element. Element

threads should be lubricated with Dow Corning® silicon sealant (or equal). Screw element into tting until it

seats. Tighten 1/2 to 3/4 turn with wrench.

E. Rewire the element as directed on wiring schematic, located inside control panel door. Screw terminals must be

snug, however, caution must be exercised. Overtightening may break the terminal block, requiring replacement

of the element.

F. Repeat steps A thru E for all other elements being replaced.

IV. VOLTAGE CONVERSION

A. Surface thermostat models merely require installation of the appropriate elements to accomplish a change in

voltage. See KW conversion step III.

B. Immersion thermostat models require installation of the appropriate elements AND may also require a

transformer tap change. Immersion thermostat models are equipped with a transformer having 5 connections:

common, 208, 240, 277 and 408 and 2 secondary connections. See the following diagrams.

Only one wire need be changed on the transformer to change voltage. Remove the wire from the terminal

marked 208, 240, 277 or 480 and attach it to the appropriate terminal marked 208, 240, 277 or 480.

C. Do not change the common connections or the secondary wire connections.

4

Page 5

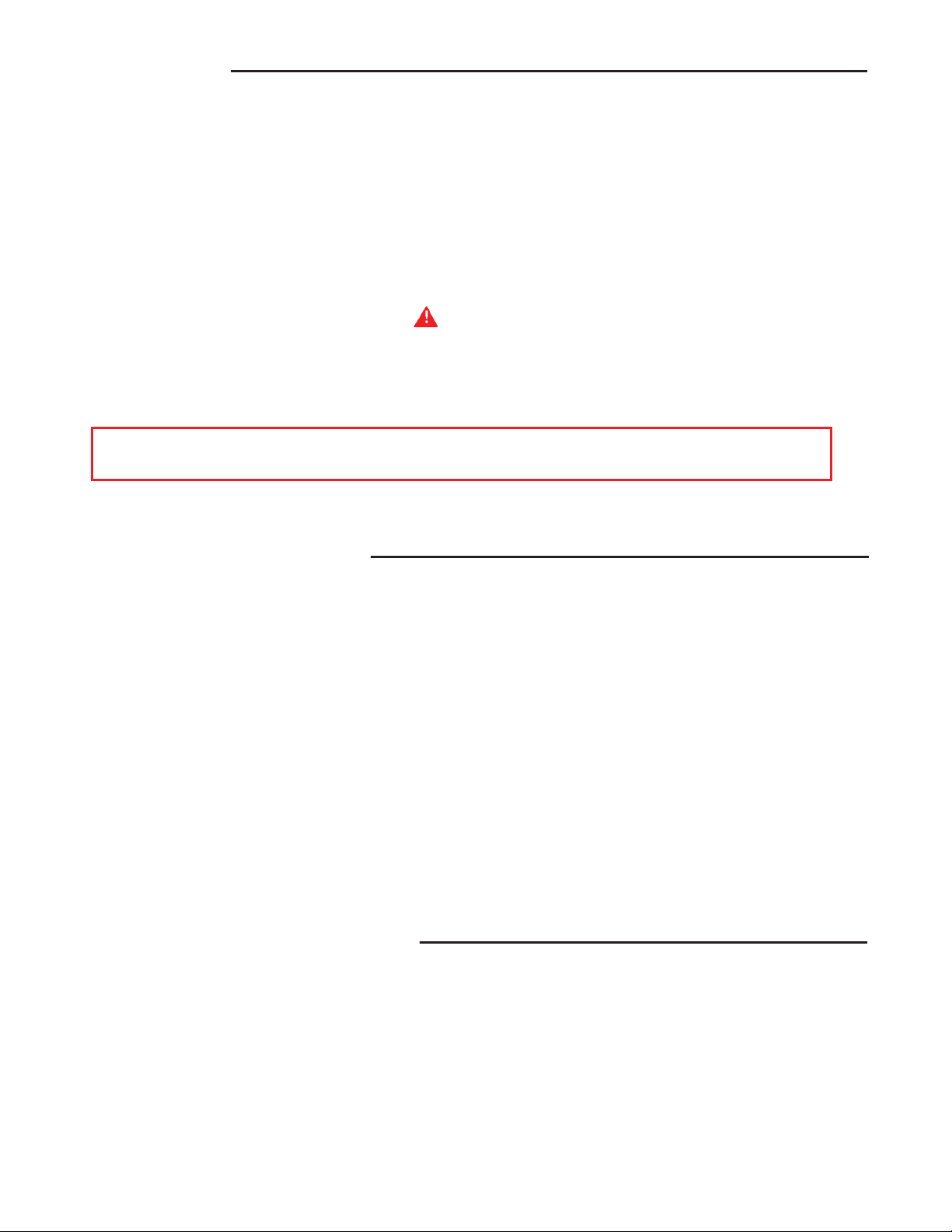

480

277

240

208

COM

IMMERSION THERMOSTAT MODEL TRANSFORMER

CONNECTION TABLES

Volts Line On Load on

208 Common & 208

240 Common & 240 Secondary

277 Common & 277 120V

480 Common & 480

V. PHASE CONVERSION

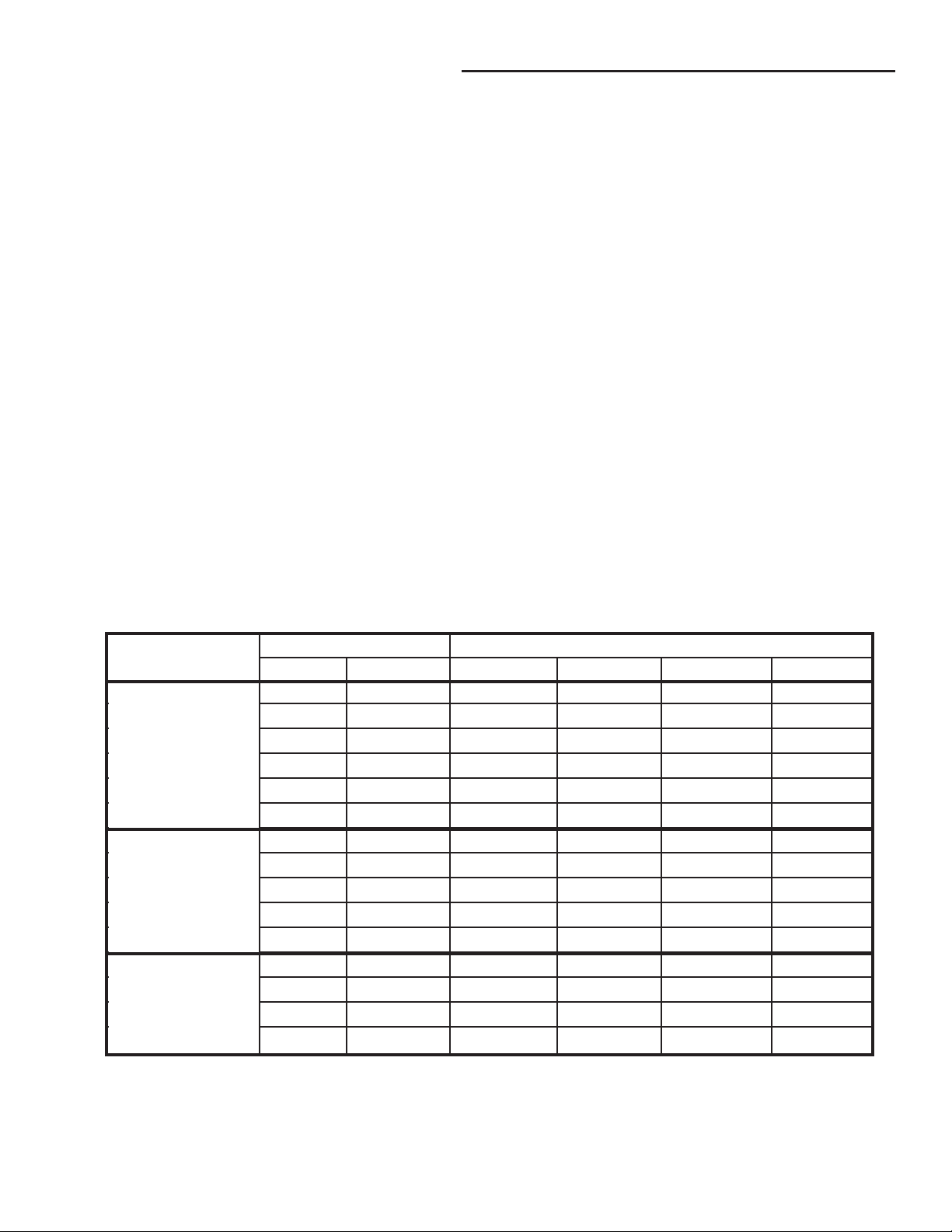

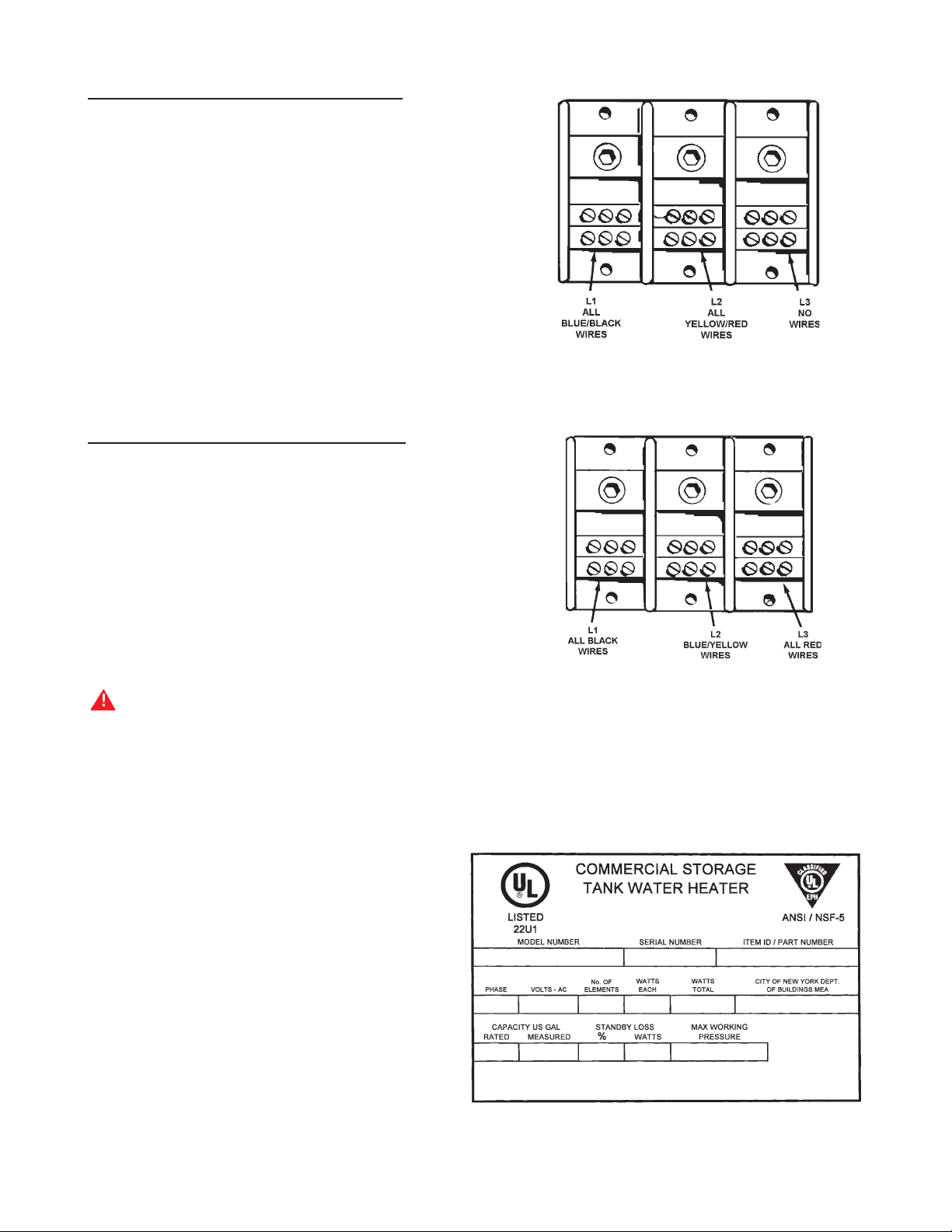

A. IMMERSION THERMOSTAT MODEL

THREE PHASE TO SINGLE PHASE

1. Disconnect blue wires and yellow wires from terminal L-3.

IMMERSION THERMOSTAT MODEL TRANSFORMER

IMMERSION THERMOSTAT MODEL

SINGLE PHASE TERMINAL BLOCK

2. Connect all blue wires to terminal L-1 (with black wires).

3. Connect all yellow wires to terminal L-2 (with red wires).

4. Incoming power will be connected to

terminals L-1 and L-2 at job site.

B. IMMERSION THERMOSTAT MODEL

SINGLE PHASE TO THREE PHASE

1. Disconnect blue wires from terminal L-1.

2. Disconnect yellow wires from terminal L-2.

3. Connect all blue wires and yellow wires to terminal L-3.

4. Incoming power will be connected to terminals

L-1, L-2 and L-3 at job site.

IMMERSION THERMOSTAT MODEL

THREE PHASE TERMINAL BLOCK

5

Page 6

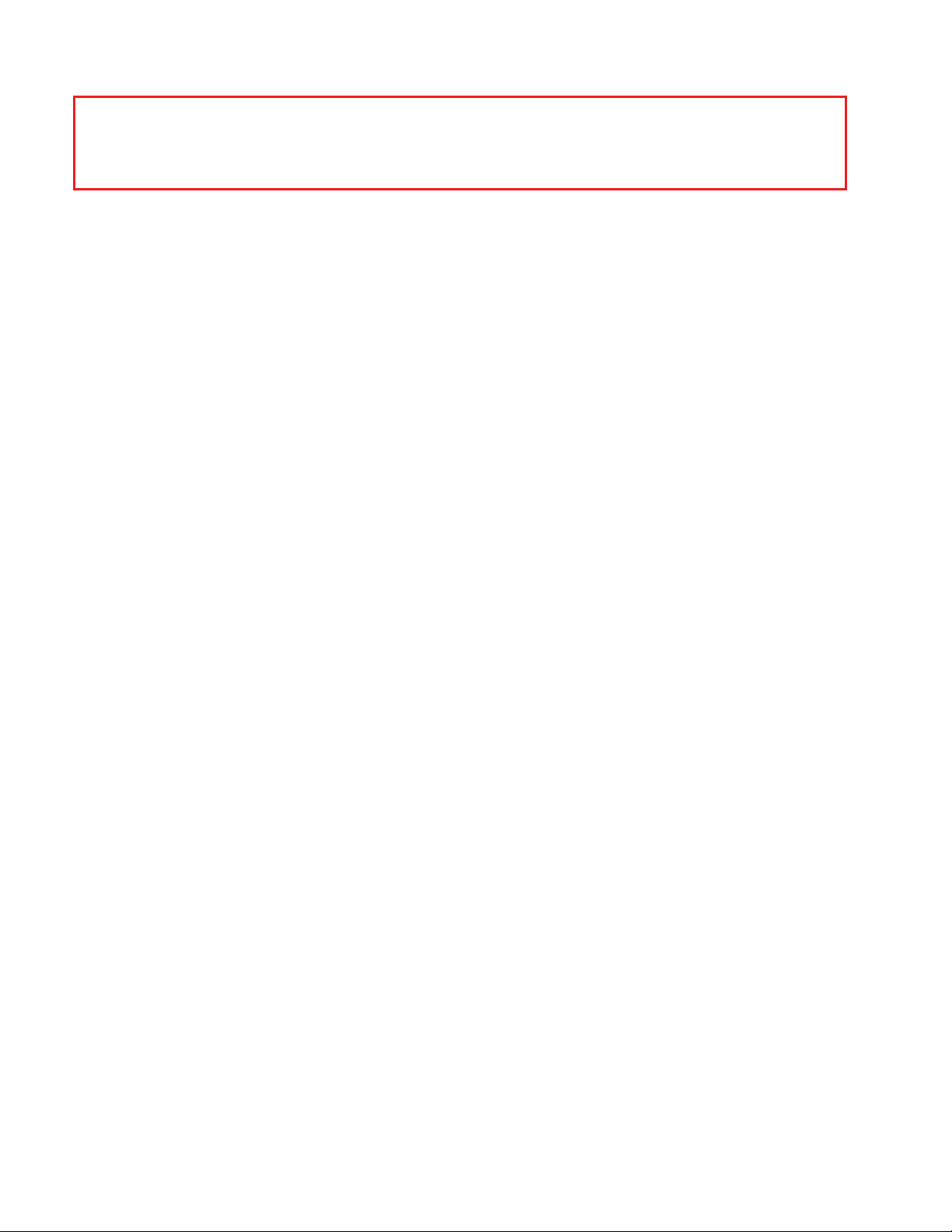

C. SURFACE THERMOSTAT MODEL

THREE PHASE TO SINGLE PHASE

1. Disconnect blue wires from terminal L-2.

2. Connect all blue wires to terminal L-1

(with black wires).

3. Disconnect all red wires from terminal L-3.

4. Connect all red wires to terminal L-2 (with yellow wires).

5. Incoming power will be connected to

terminals L-1 and L-2 at job site.

SURFACE THERMOSTAT MODEL

SINGLE PHASE TERMINAL BLOCK

D. SURFACE THERMOSTAT MODEL

SINGLE PHASE TO THREE PHASE

SURFACE THERMOSTAT MODEL

THREE PHASE TERMINAL BLOCK

1. Disconnect blue wires from terminal L-1

2. Disconnect red wires from terminal L-2.

3. Connect all blue wires to terminal L-2 (with yellow wires).

4. Connect red wires to terminal L-3.

5. Incoming power will be connected to

terminals L-1, L-2 and L-3 at job site.

VI. CAUTION

Recheck all terminals for tightness, proper wiring per schematic, and neatness of wiring, Heater should

be no less than factory constructed quality and appearance.

CHECK ALL WATER AND ELECTRICAL CONNECTIONS FOR TIGHTNESS

VII. FINAL ASSEMBLY

A. CONTROL PANEL

Replace foam door. Cover all elements

and thermostats as originally constructed.

Replace T & P valve package, close door,

relatch and tighten the two control panel screws.

B. RATING PLATE MODIFICATION

Following is a sample of the standard rating

plate supplied on the front of the control panel

door.

SAMPLE RATING PLATE

6

Page 7

The voltage, element KW, total KW data of the rating plate must be modied by covering them with the label provided in

the conversion kit. Be sure the new ratings on the label match the conversion you have just completed.

Peel off the back of the label and paste over the four lines as shown on the revised rating plate below.

SAMPLE RATING PLATE WITH CONVERSION LABEL

C. Peel off back of caution label and attach label to upper right hand corner of control panel door.

D. CRATE IDENTIFICATION

Using a black magic marker, cross out heater identication on crate as appropriate. In bold letters, write

new electrical specications in crate, matching those on the revised rating plate.

E. SHIPPING CRATE

Close and tape the plastic ap on front of crate.

CHECK LIST

All affected parts have been installed properly and have been checked for tightness.

All affected wires have been checked for tightness.

New elements have been wired per wiring diagram label on the unit.

New elements have been tightened properly.

New elements have been leak checked.

New rating plate overlay has been installed properly over the existing rating plate.

VIII. MISCELLANEOUS INFORMATION.

A. NON STANDARD CONSTRUCTION

At 480 and 240 volts, 18KW is normally supplied using three 6,000 watt elements. They can however, be

constructed using six 3,000 watt elements.

At 480 volts and 240 volts, 36KW is normally supplied using six 6,000 watt elements. It can however, be supplied

using nine 4,000 watt elements.

7

Page 8

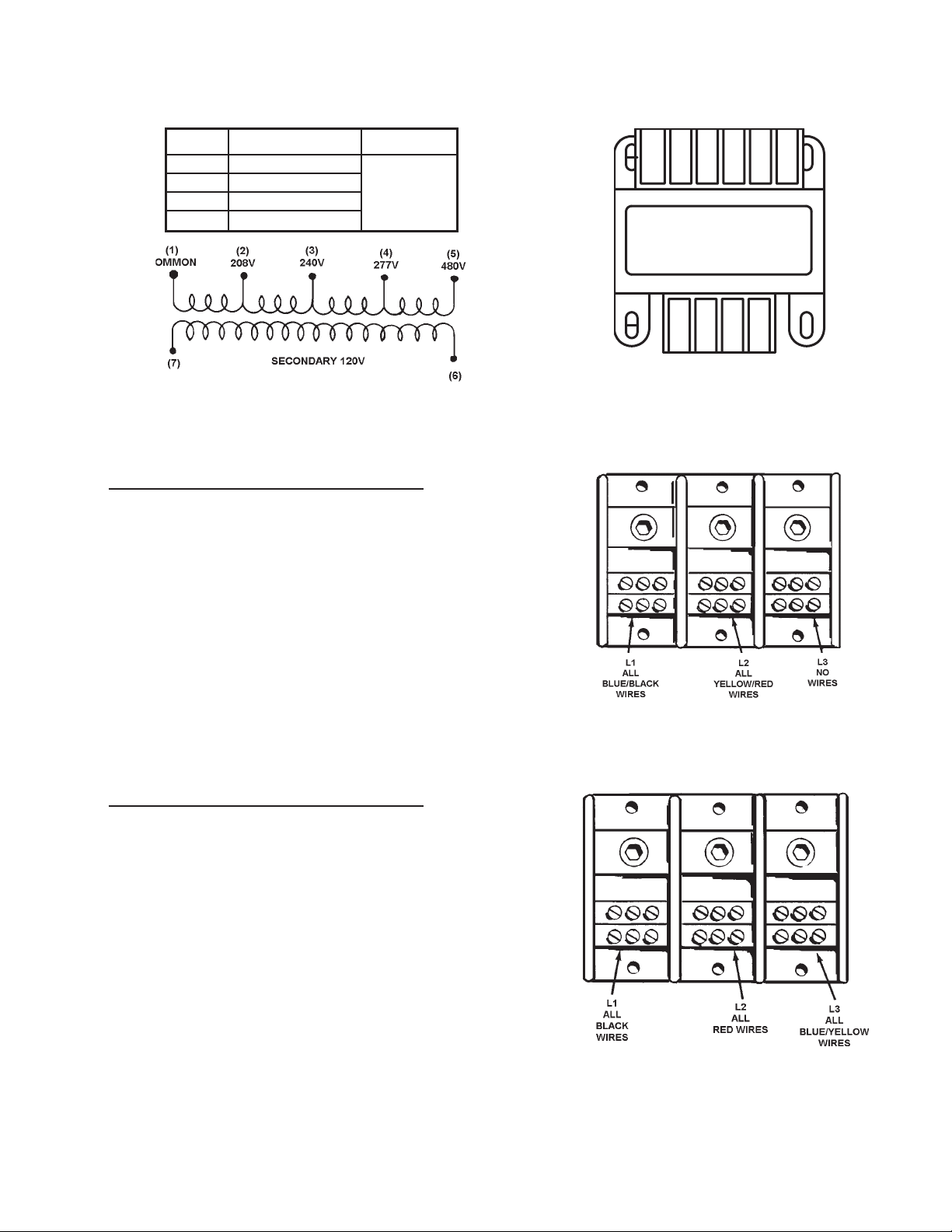

B. ELEMENT SIZE VERIFICATION

All elements are marked with both wattage and voltage. Verication can be made by measuring the ohms

resistance across the terminals of the elements. Element must be disconnected from the circuit. The following

table gives resistance in ohms for all elements used in commercial electric water heaters.

OHMS RESISTANCE TABLE

VOLTAGE

WATTAGE 208 240 480

2000 21.63 28.80 115.20

3000 14.42 19.20 76.80

4000 10.82 14.40 57.60

4500 9.61 12.80 51.20

5000 8.65 11.52 46.08

6000 7.21 9.60 38.40

Element ohms resistance should be within ±5% of the above values.

Examples: Elements with an ohm resistance of 14 ohms indicates that it is either a 3,000 watt/208 volt element

and/or a 4,000 watt/240 volt element (dual rated type).

FULL LOAD CURRENT IN AMPERES

Number KW Single (1) phase Three (3) Phase

KW of Each

Input Elements Elements 208V 240V 480V 208V 240V 480V

6 2.0 28.8 25.0 12.5 16.7 14.4 7.2

9 3.0 43.3 37.5 18.8 25.0 21.7 10.8

12 4.0 57.7 50.0 25.0 33.3 28.9 14.4

13.5 4.5 64.9 56.3 28.1 37.5 32.5 16.2

15 5.0 72.1 62.5 31.3 41.6 36.1 18..0

18 6.0 - - - - 75.0 37.5 - - - - 43.3 21.7

3

18 3.0 86.5 - - - - - - - - 50.0 - - - - - - - 24 4.0 115.4 100.0 50.0 66.6 57.7 18.9

27 4.5 129.8 112.5 56.3 74.9 65.0 32.5

30 5.0 144.2 125.0 62.5 83.3 72.2 36.1

36 6.0 - - - - 150.0 75.0 - - - - 86.6 43.3

36 4.0 173.1 - - - - - - - - 99.9 - - - - - - - -

40.5 4.5 194.7 168.8 84.4 112.4 97.4 48.7

45 5.0 216.3 187.5 93.8 124.9 108.3 54.1

54 6.0 - - - - 225.0 112.5 - - - - 129.9 65.0

NEVER OPERATE THE HEATER WITHOUT FILLING WITH WATER PER THE FILLING INSTRUCTIONS. FAILURE

TO DO SO WILL DAMAGE INTERNAL PARTS.

6

9

CAUTION

8

Page 9

NOTES

9

Page 10

500 Tennessee Waltz Parkway

Ashland City, TN 37015

1-800-433-2545

www.hotwater.com

Page 11

INSTALLATION PAR DES SPÉCIALISTES QUALIFIÉS UNIQUEMENT

INSTRUCTIONS TROUSSE DE CONVERSION

Modèles DRE et DVE 52, 80 et 120

Chauffe-eau électriques commerciaux

Série 100

ATTENTION

LE TEXTE EN ROUGE OU ENCADR É DE

ROUGE VISE À ASSURER LA SÉCURITÉ

DES UTILISATEURS. IL FAUT DONC LE LIRE

ATTENTIVEMENT AVANT DE CONVERTIR LE

CHAUFFE-EAU.

IMPRIMÉ 0210 196678-003

11

500 Tennessee Waltz Parkway

Ashland City, TN 37015, États-Unis

1 800 433-2545

www.hotwater.com

Page 12

AVANT-PROPOS

Le présent manuel vise à expliquer comment modier la puissance nominale des chauffe-eau électriques commerciaux

décrits ou leur circuit pour qu’ils fonctionnent à une autre tension d’alimentation. Son objectif n’est pas d’expliquer

comment reconstruire un chauffe-eau électrique commercial sur place.

L’ajout et la soustraction d’éléments chauffants sur place ne sont pas des pratiques approuvées par Underwriters

Laboratories, Inc. Par conséquent, elles sont interdites et ne doivent même pas être entreprises.

Il convient de noter et de respecter la limitation suivante : le chauffe-eau après conversion et le chauffe-eau avant

conversion doivent être ceux visés par le présent manuel. Avant de convertir un appareil, lire les instructions détaillées

(pages 8-11).

SÉCURITÉ

S’assurer de couper l’alimentation électrique du chauffe-eau avant de commencer des travaux sur son système électrique

ou à proximité de celui-ci. Ne jamais toucher des composantes électriques lorsqu’on a les mains mouillées ou les pieds

dans l’eau.

COMPÉTENCES REQUISES

LA CONVERSION DES CHAUFFE-EAU DÉCRITS DANS LE PRÉSENT MANUEL EXIGE DES

COMPÉTENCES ÉQUIVALENTES À CELLES D’UN ÉLECTRICIEN QUALIFIÉ.

TABLE DES MATIÈRES

Avant-propos ......................................................... 2

Matériaux requis .................................................... 2

Guide de conversion ........................................... 3

Instructions de conversion

Introduction .......................................................... 4

Préparation .......................................................... 4

Page

Page

Conversion de puissance

(remplacement des éléments) ........................... 4

Conversion de tension ......................................... 4-5

Conversion de phase........................................... 5-6

Attention............................................................... 6

Assemblage nal ................................................. 6-7

Liste de vérication .............................................. 7

Renseignements supplémentaires ...................... 7-8

MATÉRIAUX REQUIS

1. Douille pour retirer les éléments : no de pièce 9000429015 ou clé à douille munie d’une douille profonde de 1 ½ po.

2. Deux tournevis : un à tête en étoile no 2 et un à tête plate.

3. Trousse de conversion : manuel d’instructions, pièces de remplacement électriques, étiquette de conversion et

étiquette de mise en garde.

4. Scellant pour letage : pour les éléments chauffants vissés, il faut appliquer du scellant à la silicone de marque

Dow Corning® (scellant pour baignoires) sur les lets.

12

Page 13

GUIDE DE CONVERSION

Avant de convertir un chauffe-eau, il faut lire et comprendre les instructions et les restrictions qui s’appliquent.

1. Il est interdit d’augmenter ou de réduire le nombre d’éléments chauffants;

2. Chaque trousse de conversion est conçue pour une tension d’utilisation en particulier et un circuit en conguration

Delta;

3. Pour connaître les caractéristiques du circuit, voir la section « Circuit de dérivation » du manuel d’instructions du

chauffe-eau;

4. Une fois la conversion terminée, il faut s’assurer que la tuyauterie d’eau ne présente aucune fuite et que les

connexions électriques sont serrées.

UTILISATION DU TABLEAU :

1. Dans la première colonne, trouver le nombre d’éléments que comporte le chauffe-eau.

2. Dans la colonne « Puissance voulue », trouver la puissance totale du chauffe-eau après sa conversion, puis trouver

la tension d’utilisation. Le numéro de pièce de la trousse de conversion est à l’intersection de la ligne « Puissance

voulue » et de la colonne « Tension d’utilisation ».

3. Commander la trousse appropriée.

4. Suivre les instructions de conversion détaillées (pages 9-13).

5. La conversion terminée, remplir la liste de vérication (page 12).

NUMÉRO DE PIÈCE DE LA TROUSSE DE CONVERSION

Modèles pouvant

être convertis

DVE/DRE 52,

80 et 120

avec

3 éléments

DVE/DRE 52,

80 et 120

avec

6 éléments

DVE 52 et

DVE/DRE 80 et 120

avec

9 éléments

Puissance voulue Tension d’utilisation

kW (tot.) kW (élément) 208 V 240 V 277 V 480 V

6 2 9005587105 9005600105

9 3

12 4

13,5

15 5

18 6 s.o. 9005599105 9005614105

18 3

24 3

27 4,5

30 5

36 6 s.o. 9005605105 9005626105

36 4

40,5

45 5

54 6 s.o. 9005610105 9005636105

4,5

4,5

9005588105

9005589105

9005585105

9005586105

9005592105

9005593105

9005590105

9005591105

9005596105

9005594105

9005595105

9005615105

9005601105 9005616105**

9005602105

9005597105 9005612105**

9005598105 9005613105**

9005606105

9005607105

9005603105

9005604105

9005611105 9005637105

9005608105

9005609105

9005617105

9005627105**

9005628105 9005633105

9005624105**

9005625105**

9005634105**

9005635105**

9005621105

9005622105

9005623105

9005618105

9005619105

9005620105

9005632105

9005629105

9005630105

9005631105

9005641105

9005638105

9005639105

9005640105

* Il n’y a pas de trousse de conversion pour un chauffe-eau de 50 gallons avec 9 éléments et un thermostat monté en surface.

** Trousse de conversion avec éléments en alliage Incoloy.

13

Page 14

INSTRUCTIONS DE CONVERSION

COMPÉTENCES REQUISES

LA CONVERSION DES CHAUFFE-EAU DÉCRITS DANS LE PRÉSENT MANUEL EXIGE

DES COMPÉTENCES ÉQUIVALENTES À CELLES D’UN ÉLECTRICIEN QUALIFIÉ

I. INTRODUCTION

Pour satisfaire un client qui commande un chauffe-eau commercial standard, il faut possiblement convertir sa puissance

nominale ou la tension ou la phase à laquelle il est utilisé. Une, deux ou trois de ces caractéristiques électriques peuvent

être modiées.

II. PRÉPARATION

La conversion du chauffe-eau doit être effectuée dans un endroit bien éclairé. Il est inutile de retirer l’appareil de son

emballage. La face avant du chauffe-eau et la boîte de commande sont visibles à travers le lm en plastique. Couper

celui-ci à 4 po (10 cm) du cadre en bois, sur trois côtés (haut, côté droit et bas) pour former un rabat.

Enlever les deux vis du panneau de commande situé sur la porte avant.

Pour exposer les éléments, retirer la mousse isolante à l’intérieur du panneau de commande.

Retirer l’emballage contenant la soupape de décharge à sécurité thermique.

III. CONVERSION DE PUISSANCE (REMPLACEMENT DES ÉLÉMENTS)

A. Débrancher les ls d’un premier élément. Comme le schéma de câblage gure sur la face intérieure de la porte

du panneau de commande, il est inutile de les étiqueter.

B. Retirer l’élément avec la pièce no 9000429015 ou une clé à douille munie d’une douille profonde de 1 ½ po.

Placer les éléments enlevés dans le compartiment de stockage approprié.

C. Retirer les éléments de la trousse appropriée et s’assurer que la puissance et la tension de chacun correspondent

aux caractéristiques voulues.

D. Placer le nouvel élément dans son logement. Prendre soin d’installer un nouveau joint d’étanchéité. Lubrier le

letage de l’élément avec du scellant à la silicone de marque Dow Corning® ou son équivalent. Visser l’élément à

la main jusqu’à ce qu’il soit bien en place. Serrer ensuite d’un demi-tour ou de trois quarts de tour avec la clé.

E. Rebrancher l’élément tel qu’indiqué sur le schéma de câblage. Les bornes à vis doivent être bien serrées, mais

sans excès. Sinon, la plaquette de bornes risque de se briser, ce qui obligerait à remplacer l’élément.

F. Répéter les étapes A à E pour chaque élément.

IV. CONVERSION DE TENSION

A. Pour qu’un chauffe-eau muni d’un thermostat monté en surface puisse être utilisé à une autre tension

d’alimentation, il suft de changer les éléments, tel qu’indiqué à la section III, « Conversion de puissance ».

B. La conversion des modèles munis d’un thermostat immergé exige le changement des éléments ET possiblement

la modication des connexions au niveau du transformateur. Le transformateur des modèles concernés ont

cinq bornes, soit une commune, 208 V, 240 V, 277 V et 408 V, ainsi que deux bornes secondaires. Voir les

diagrammes de la page suivante.

Pour changer la tension à laquelle le chauffe-eau peut être utilisé, seule la connexion d’un l doit être changée.

Il suft de débrancher le l à la borne 208, 240, 277 ou 480 et de le rebrancher à la borne appropriée.

C. Ne pas changer les connexions à la borne commune et aux bornes secondaires.

14

Page 15

480

277

240

208

COM

Volts Connexions Tension

208 Commune et 208

240 Commune et 240

277 Commune et 277

480 Commune et 480

CONNEXIONS DU TRANSFORMATEUR

MODÈLES À THERMOSTAT IMMERGÉ

TRANSFORMATEUR DES MODÈLES À

THERMOSTAT IMMERGÉ

Circuit

secondaire

120 V

V. CONVERSION DE PHASE

A. MODÈLES À THERMOSTAT IMMERGÉ

CONVERSION DE TROIS PHASES À UNE PHASE

1. Débrancher les ls bleus et les ls jaunes de la borne L3.

2. Brancher les ls bleus à la borne L1 (avec les ls noirs).

3. Brancher les ls jaunes à la borne L2 (avec les ls rouges).

4. L’alimentation électrique se fait aux bornes L1 et L2;

la connexion est effectuée sur place.

B. MODÈLES À THERMOSTAT IMMERGÉ

CONVERSION D’UNE PHASE À TROIS PHASES

1. Débrancher les ls bleus de la borne L1.

2. Débrancher les ls jaunes de la borne L2.

MODÈLES À THERMOSTAT IMMERGÉ

BLOC DE CONNEXION

ALIMENTATION MONOPHASÉE

MODÈLES À THERMOSTAT IMMERGÉ

BLOC DE CONNEXION

ALIMENTATION TRIPHASÉE

3. Brancher les ls bleus et les ls jaunes à la borne L3.

4. L’alimentation électrique se fait aux bornes L1, L2 et L3;

la connexion est effectuée sur place.

15

Page 16

C. MODÈLES À THERMOSTAT MONTÉ EN SURFACE ALIMENTATION TRIPHASÉE À MONOPHASÉE

1. Débrancher les ls bleus de la borne L2.

2. Brancher les ls bleus à la borne L1 (avec les ls noirs).

3. Débrancher les ls rouges de la borne L3.

4. Brancher les ls rouges à la borne L2 (avec les ls jaunes).

5. L’alimentation électrique se fait aux bornes L1 et L2;

la connexion est effectuée sur place.

D. MODÈLES À THERMOSTAT MONTÉ EN SURFACE -

ALIMENTATION MONOPHASÉE À TRIPHASÉE

1. Débrancher les ls bleus de la borne L1.

BLOC DE CONNEXION DES MODÈLES

THERMOSTAT MONTÉ EN SURFACE

ALIMENTATION MONOPHASÉE

BLOC DE CONNEXION DES MODÈLES

À THERMOSTAT MONTÉ EN SURFACE

ALIMENTATION TRIPHASÉE

2. Débrancher les ls rouges de la borne L2.

3. Brancher les ls bleus à la borne L2 (avec les ls jaunes).

4. Brancher les ls rouges à la borne L3.

5. L’alimentation électrique se fait aux bornes L1, L2 et L3;

la connexion est effectuée sur place.

VI. ATTENTION

Les bornes doivent être bien serrées, les connexions doivent être conformes aux schémas et le travail doit

être fait de sorte que le chauffe-eau converti respecte les exigences de qualité du travail en usine.

S’ASSURER QUE LA TUYAUTERIE D’EAU NE PRÉSENTE AUCUNE FUITE ET

QUE LES CONNEXIONS ÉLECTRIQUES SONT SERRÉES

VII. ASSEMBLAGE FINAL

A. PANNEAU DE COMMANDE

Replacer la mousse isolante an de recouvrir les

éléments et les thermostats comme ils l’étaient à

l’origine. Replacer l’emballage contenant la soupape

de décharge à sécurité thermique, refermer la porte

et replacer les deux vis du panneau de commande.

B. MODIFICATION DE LA PLAQUE SIGNALÉTIQUE

La plaque signalétique qui est xée sur la porte du

panneau de commande est reproduite ci-contre.

EXEMPLE DE PLAQUE SIGNALÉTIQUE

16

Page 17

L’étiquette fournie dans la trousse de conversion indique la tension d’utilisation, la puissance des éléments et la puissance

totale du chauffe-eau converti. Elle doit être collée sur la plaque signalétique d’origine. Il convient de s’assurer que les

caractéristiques gurant sur l’étiquette correspondent à la conversion effectuée.

Retirer le papier au verso de l’étiquette et la coller de façon à recouvrir les quatre lignes pertinentes de la plaque

signalétique d’origine, tel qu’indiqué ci-dessous.

PLAQUE SIGNALÉTIQUE TYPE AVEC ÉTIQUETTE DE CONVERSION

C. Retirer le papier au verso de l’étiquette de mise en garde et la coller dans le coin supérieur droit de la porte

du panneau de commande.

D. INDICATION SUR L’EMBALLAGE

Sur l’étiquette d’emballage, rayer au stylo feutre noir les caractéristiques qui ne s’appliquent plus. En majuscules,

écrire les nouvelles caractéristiques du chauffe-eau, telles qu’elle gurent sur la plaque signalétique révisée.

E. EMBALLAGE

Refermer le rabat du lm en plastique et le coller avec du ruban adhésif.

LISTE DE VÉRIFICATION

Chaque pièce touchée par la conversion est installée correctement et son serrage a fait l’objet d’une vérication.

Le serrage de chaque l touché par la conversion a fait l’objet d’une vérication.

Le câblage des nouveaux éléments respecte le schéma xé sur l’appareil.

Les nouveaux éléments sont serrés adéquatement.

L’étanchéité des nouveaux éléments a fait l’objet d’une vérication.

L’étiquette sur laquelle gurent les nouvelles caractéristiques a été posée sur la plaque.

VIII. RENSEIGNEMENTS SUPPLÉMENTAIRES

A. CONSTRUCTION NON STANDARD

Un chauffe-eau de 18 kW fonctionnant à une tension de 480 ou de 240 V est habituellement muni de 3 éléments

de 6 000 Watts. À l’occasion, il peut cependant être muni de 6 éléments de 3 000 Watts.

Un chauffe-eau de 36 kW fonctionnant à une tension de 480 ou de 240 V est habituellement muni de 6 éléments

de 6 000 Watts. À l’occasion, il peut cependant être muni de 9 éléments de 4 000 Watts.

17

Page 18

B. VÉRIFICATION DES CARACTÉRISTIQUES DES ÉLÉMENTS

La puissance et la tension d’utilisation sont indiquées sur chaque élément. Ces caractéristiques peuvent être conrmées

par une simple mesure de la résistance électrique aux bornes de l’élément. Pour faire la mesure, il faut débrancher

l’élément. Le tableau ci-dessous permet de déterminer la puissance et la tension de tout élément de chauffe-eau

commercial à partir de la résistance mesurée.

RÉSISTANCE ÉLECTRIQUE (Ω)

TENSION (V)

PUISSANCE (W) 208 240 480

2 000 21,63 28,80 115,20

3 000 14,42 19,20 76,80

4 000 10,82 14,40 57,60

4 500 9,61 12,80 51,20

5 000 8,65 11,52 46,08

6 000 7,21 9,60 38,40

La résistance mesurée devrait se situer à ±5 % des valeurs du tableau.

Exemple : Si la résistance mesurée est de 14 Ω, l’élément est soit un élément de 3 000 W fonctionnant à 208 V, soit

un élément de 4 000 W fonctionnant à 240 V (doubles valeurs nominales).

COURANT DE CHARGE TOTALE EN AMPÈRES

Alimentation monophasée Alimentation triphasée

Puissance Nombre Puissance

en kW d’éléments par élément 208 V 240 V 480 V 208 V 240 V 480 V

6 2,0 28,8 25,0 12,5 16,7 14,4 7,2

9 3,0 43,3 37,5 18,8 25,0 21,7 10,8

12 4,0 57,7 50,0 25,0 33,3 28,9 14,4

13,5 4,5 64,9 56,3 28,1 37,5 32,5 16,2

15 5,0 72,1 62,5 31,3 41,6 36,1 18,0

18 6,0 - - - - 75,0 37,5 - - - - 43,3 21,7

3

18 3,0 86,5 - - - - - - - - 50,0 - - - - - - - 24 4,0 115,4 100,0 50,0 66,6 57,7 18,9

27 4,5 129,8 112,5 56,3 74,9 65,0 32,5

30 5,0 144,2 125,0 62,5 83,3 72,2 36,1

36 6,0 - - - - 150,0 75,0 - - - - 86,6 43,3

36 4,0 173,1 - - - - - - - - 99,9 - - - - - - - 40,5 4,5 194,7 168,8 84,4 112,4 97,4 48,7

45 5,0 216,3 187,5 93,8 124,9 108,3 54,1

54 6,0 - - - - 225,0 112,5 - - - - 129,9 65,0

NE JAMAIS FAIRE FONCTIONNER LE CHAUFFE-EAU AVANT DE L’AVOIR REMPLI D’EAU CONFORMÉMENT

AUX INSTRUCTIONS DE REMPLISSAGE. LE NON-RESPECT DE CETTE EXIGENCE EMDOMMAGERA LES

COMPOSANTES INTERNES.

6

9

ATTENTION

18

Page 19

NOTES

19

Page 20

500 Tennessee Waltz Parkway

Ashland City, TN 37015, États-Unis

1 800 433-2545

www.hotwater.com

Loading...

Loading...