Page 1

23" LCD Color Monitor AOC i2430Ve

Service

Service

Service

Horizontal Frequency

30-83 kHz

TABLE OF CONTENTS

Description Page Description Page

Table of Contents…………………..…………………..…...1

Revision List.…...................................................……......2

Important Safety Notice.….….............................……......3

1.Monitor Specification..............................………............4

2.LCD Monitor Description……….…………………….......5

3.Operation Instruction.…………...................……...........6

3.1.General Instructions....................................…..........6

3.2.Control Buttons and Connections...............................6

3.3.OSD Setting…...........................................................8

4.Input/Output Specification...............……………….......20

4.1.Input Signal Connector...............………..................20

4.2.Preset Display Modes……..........................21

4.3.Panel Specification…………..……………………..22

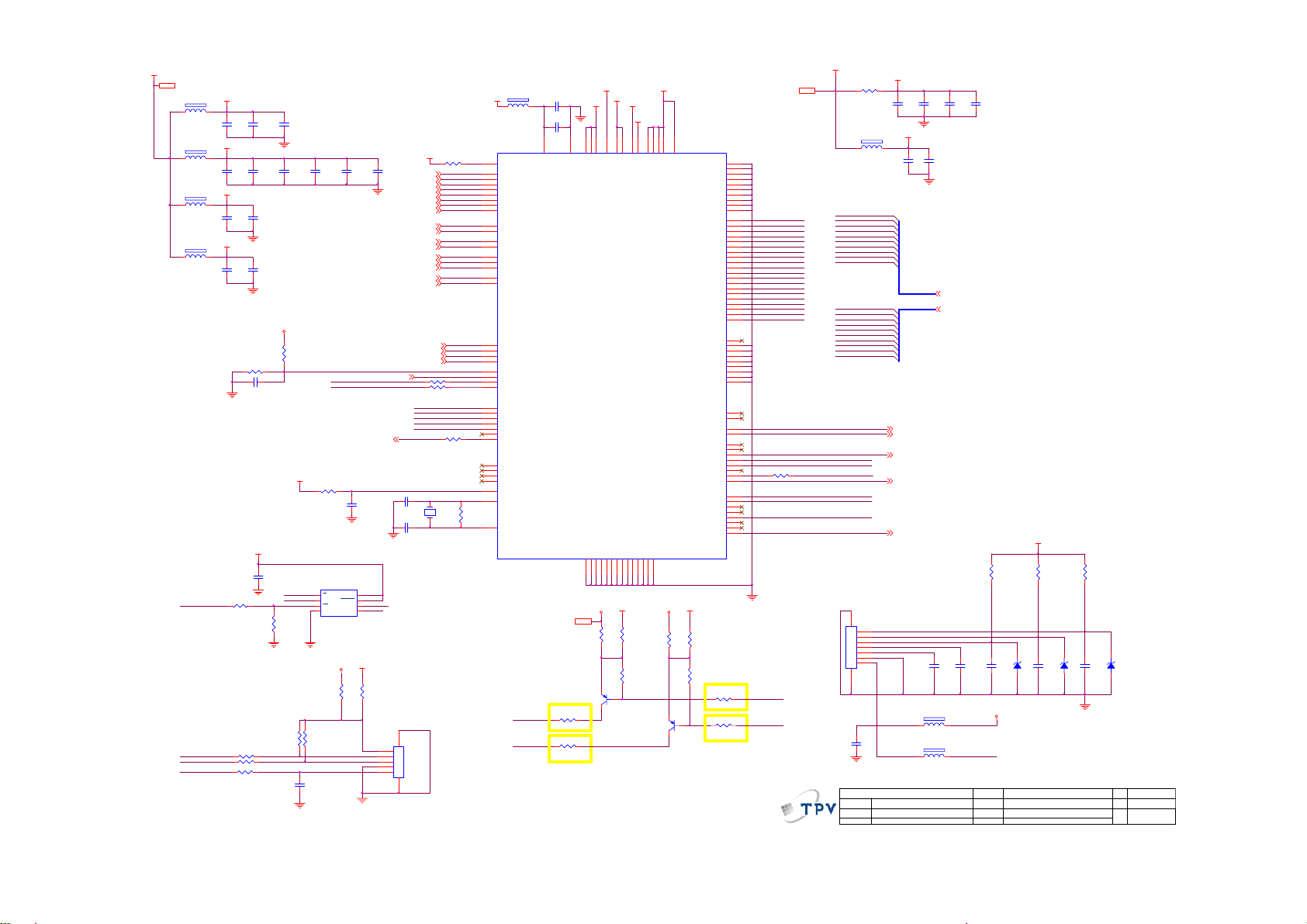

5.Block Diagram….........................................................24

5.1.Main Board…..….............................................24

5.2.Power Board…………..…………………………......25

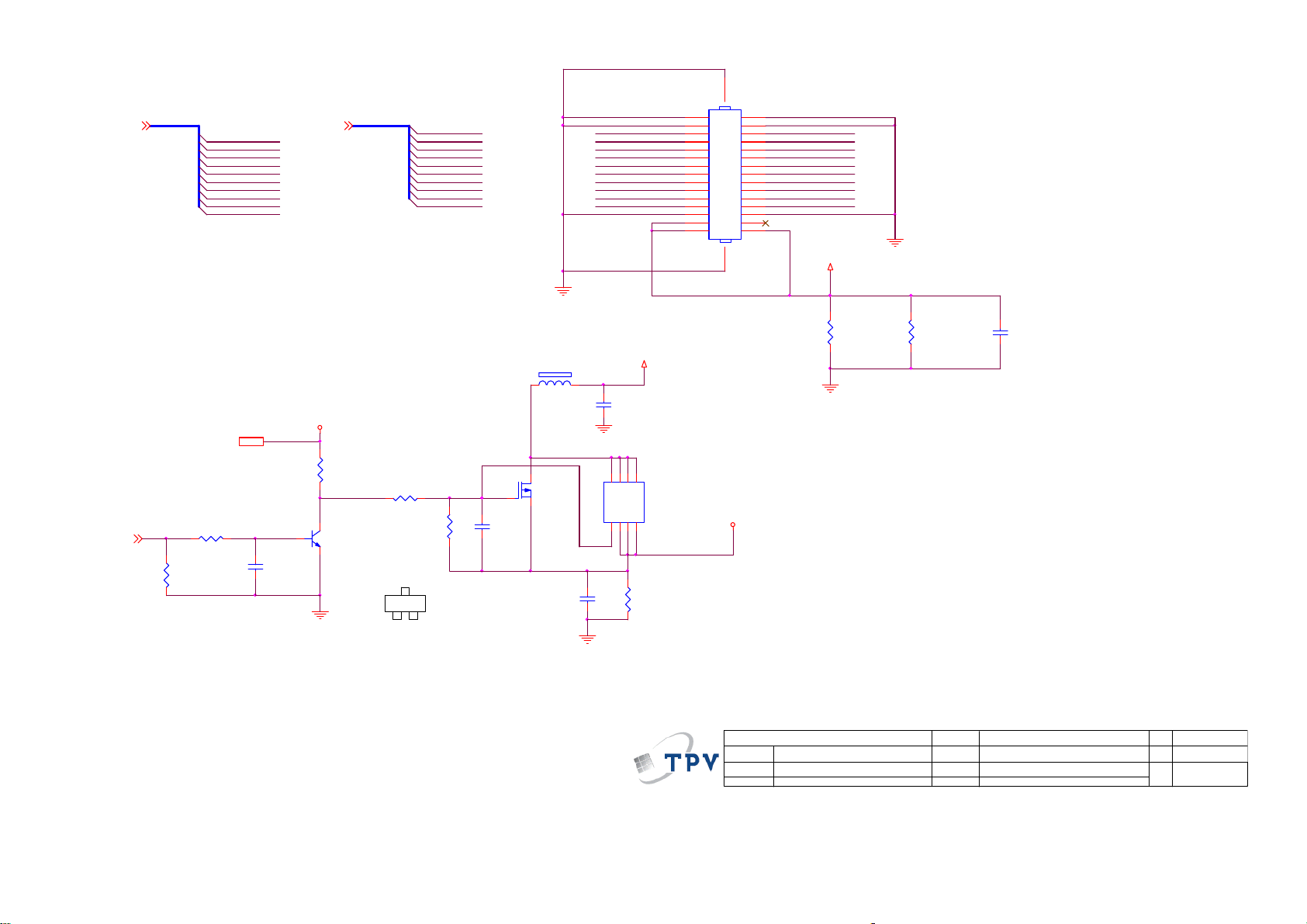

6.Schematic…………..….........................................26

6.1.Main Board..…….…...........................................26

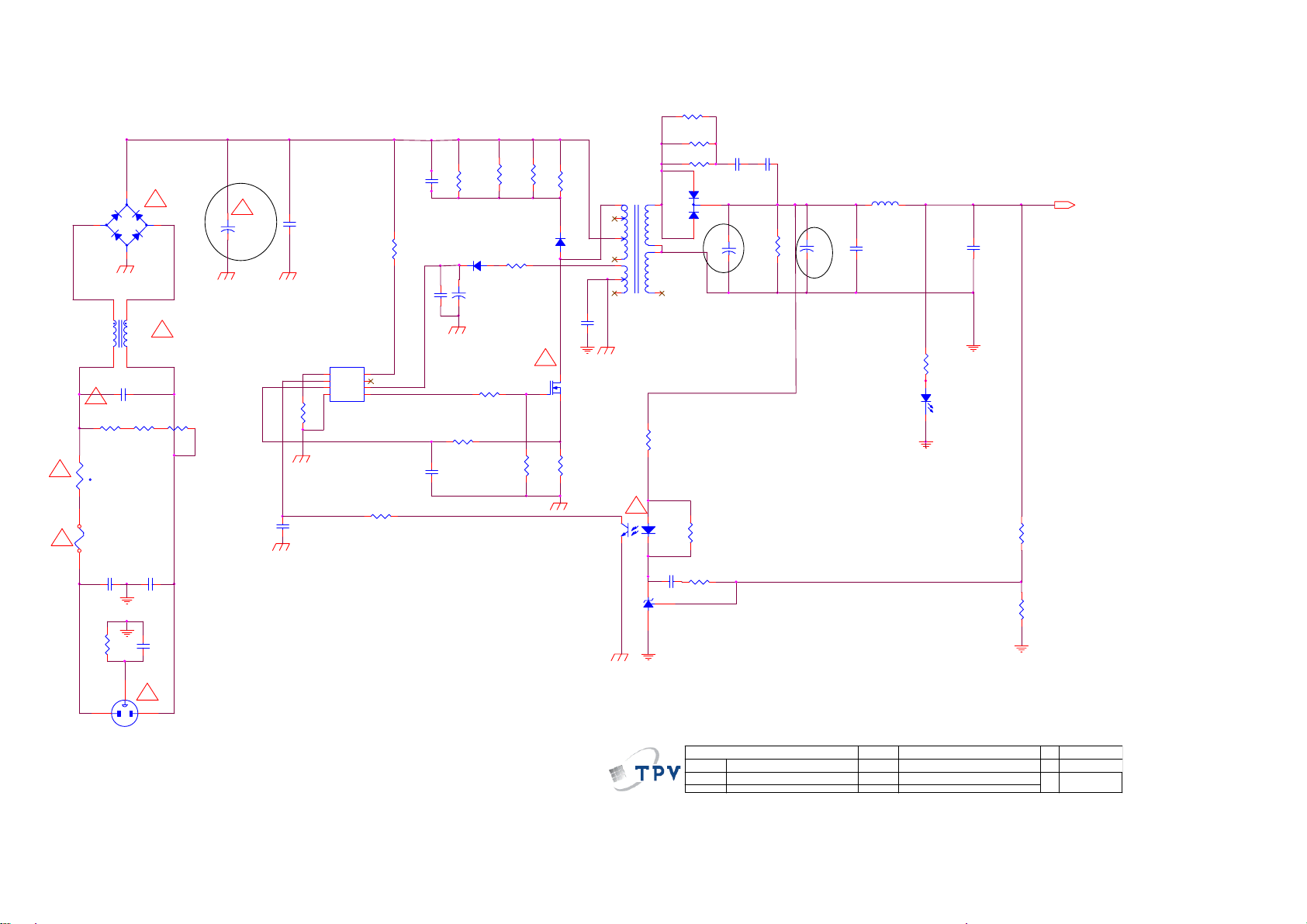

6.2.Power Board..……….........................................30

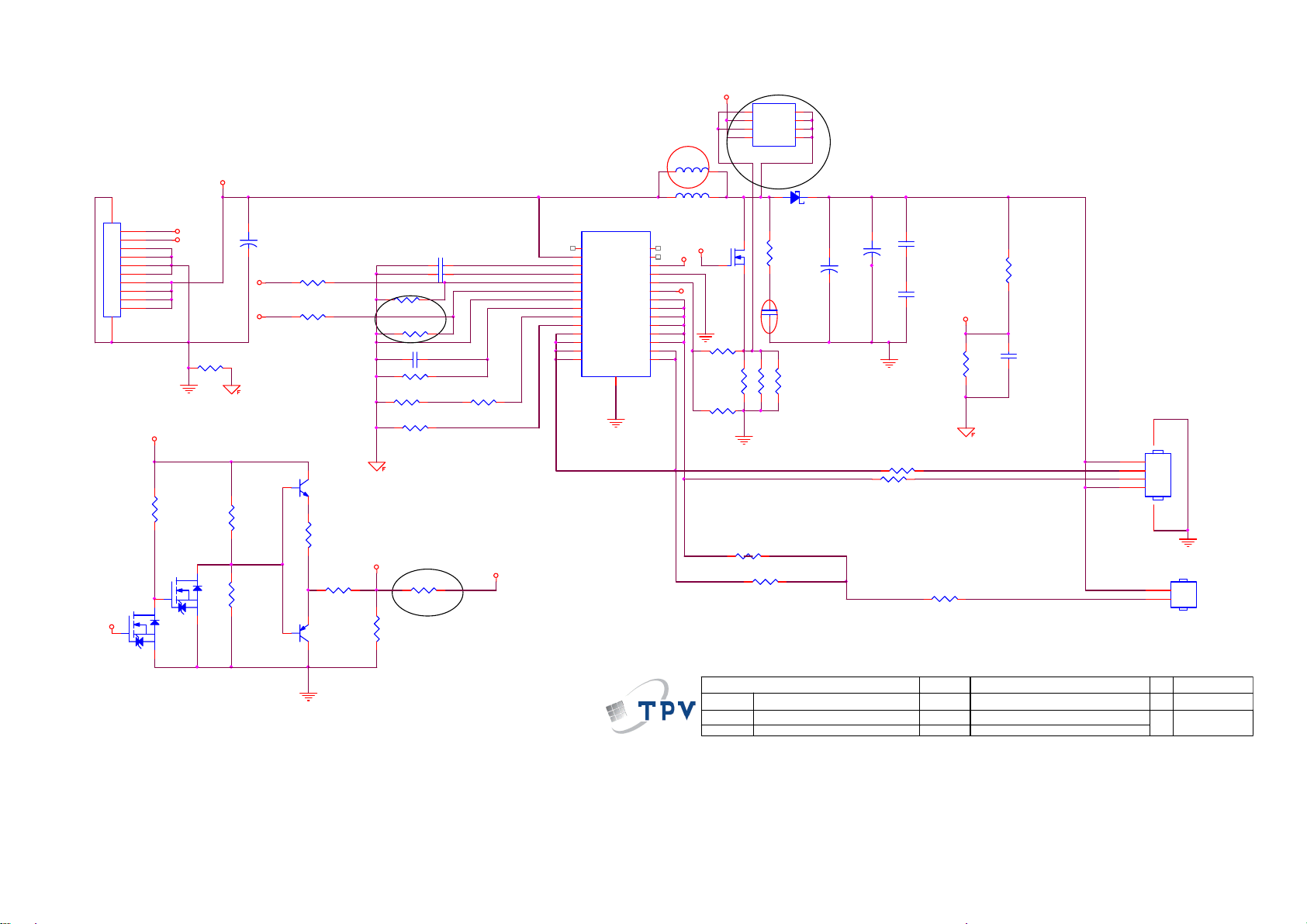

6.3.Key Board..……….........................................32

6.4.Light Sensor Board...............................................33

7.PCB Layout..………..............................................34

7.1.Main Board………..…........................................34

7.2.Power Board….…..............................................35

7.3.Key Board………..…..........................................37

7.4. Light Sensor Board.….........................................37

8.Maintainability………............................................38

8.1.Equipments and Tools Requirement…...............38

8.2.Trouble Shooting…..………...............................39

9.FOS Testing………..…………………………………43

10.Firmware and DDC Instruction……………….….47

11.White-Balance,Luminance Adjustment…............65

12. Mechanical Instructions………………….....….......67

13.Monitor Exploded View……................................72

14.BOM List…………..……………………….............73

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE

CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING

ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFOMER FOR THIS UNIT WHEN SERVICING

1

Page 2

Revision List

Revision Date Revision History Remark

TDAGNT2EWWA4HNE

A00 Jan.-12-2011 Initial release

TDAGNT2DWWA4HNE

TDAGNT2FWWA4HNE

2

Page 3

Important Safety Notice

Proper service and repair is important to the safe, reliable operation of all AOC Company Equipment. The service

procedures recommended by AOC and described in this service manual are effective methods of performing service

operations. Some of these service operations require the use of tools specially designed for the purpose. The

special tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to understand that these CAUTIONS and NOTICES ARE

NOT EXHAUSTIVE. AOC could not possibly know, evaluate and advise the service trade of all conceivable ways in

which service might be done or of the possible hazardous consequences of each way. Consequently, AOC has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not

recommended by AOC must first satisfy himself thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

Hereafter throughout this manual, AOC Company will be referred to as AOC.

WARNING

Use of substitute replacement parts, which do not have the same, specified safety characteristics may create shock,

fire, or other hazards.

Under no circumstances should the original design be modified or altered without written permission from AOC.

AOC assumes no liability, express or implied, arising out of any unauthorized modification of design.

Servicer assumes all liability.

FOR PRODUCTS CONTAINING LASER:

DANGER-Invisible laser radiation when open AVOID DIRECT EXPOSURE TO BEAM.

CAUTION-Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

CAUTION -The use of optical instruments with this product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR PART NUMBERS IN THE PARTS LIST SECTION OF

THIS SERVICE MANUAL.

Take care during handling the LCD module with backlight unit

-Must mount the module using mounting holes arranged in four corners.

-Do not press on the panel, edge of the frame strongly or electric shock as this will result in damage to the screen.

-Do not scratch or press on the panel with any sharp objects, such as pencil or pen as this may result in damage to

the panel.

-Protect the module from the ESD as it may damage the electronic circuit (C-MOS).

-Make certain that treatment person’s body is grounded through wristband.

-Do not leave the module in high temperature and in areas of high humidity for a long time.

-Avoid contact with water as it may a short circuit within the module.

-If the surface of panel becomes dirty, please wipe it off with a soft material. (Cleaning with a dirty or rough cloth may

damage the panel.)

3

Page 4

Monitor Specifications

4

Page 5

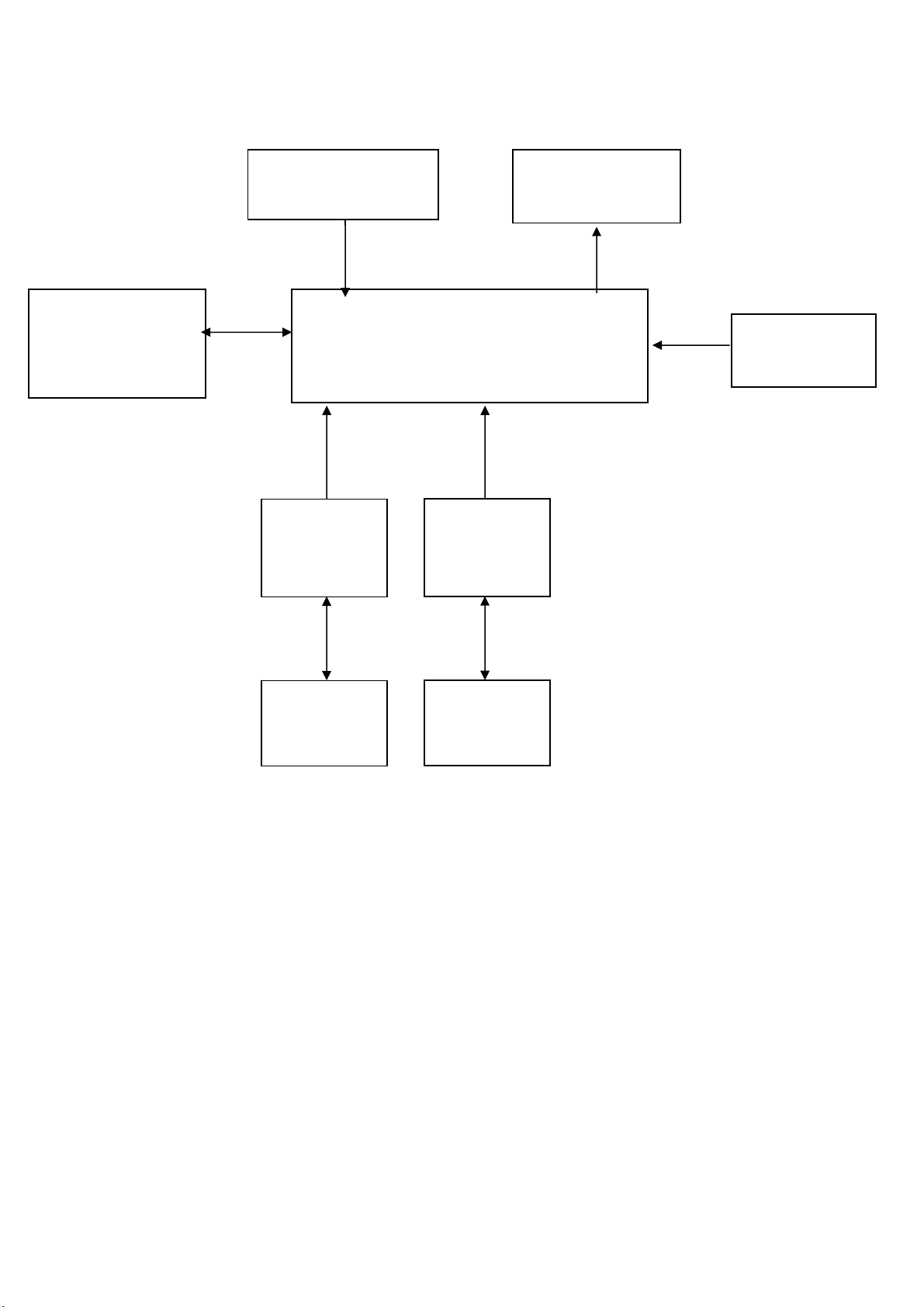

LCD Monitor Description

The LCD MONITOR will contain a main board, a power board, a key board which house the flat panel control logic,

brightness control logic and DDC.

The power board will provide AC to DC Inverter voltage to drive the backlight of panel and the main board chips

each voltage.

PWPC board

(Include: adapter, inverter)

AC-IN

100V-240V

Monitor Block Diagram

LED Drive.

Main Board

Key board

Flat Panel and

LED backlight

HOST Computer

RS232 Connector

For white balance

adjustment in factory

mode

Video signal DDC

5

Page 6

3. Operating Instructions

3.1 General Instructions

Press the power button to turn the monitor on or off. The other control knobs are located at front panel of the monitor

(See Figure ). By changing these settings, the picture can be adjusted to your personal preferences.

* The power cord should be connected.

* Press the power button to turn on the monitor. The power indicator will light up.

3.2 Control Buttons and Connections

4:3 or wide image ratio hot key: When there is no OSD, press> continuously to change 4:3 or wide image ratio. (If

the product screen size is 4:3 or input signal resolution is wide format, the hot key is disable to adjust)

e-Sensor hot key. When there is no OSD,Press < continuously to select the e - Sensor mode(e-Sensor mode hot

key may not be available in all mode ls). e-Sensor:The infrared sensor can detect if user is in front of monitor and

adjust monitor brightness automatically to save power. When it is on, we can select the detect range

[Near,Average,Far] by using hot-key.

Auto configure hot key When there is no OSD, press Auto/Source button continuously about 2 second to do auto

configure (Only for the

Source hot key When the OSD is closed, press Source butt on will be Source hot key function. Press Source button

continuously to select the input source showed in the message bar , press Menu/Enter button to change to the

source selected.

6

Page 7

1.Power

2.Analog (DB-15 VGA cable)

3.Power

To protect equipment, always turn off the PC and LCD monitor before connecting.

1. Connect the power cable to the AC port on the back of the monitor.

2. Connect one end of the 15-pin D-Sub cable to the back of the monitor and connect the other end to the computer's D-Sub

port.

3. (Optional – Requires a video card with DVI port) - Connect one end of the DVI cable to the back of the monitor and connect

the other end to the computer‟s DVI port.

4. Connect the audio cable to audio in port on the back of the monitor.

5. Turn on your monitor and computer.

If your monitor displays an image, installation is complete. If it does not display an image, please refer

Troubleshooting

.

7

Page 8

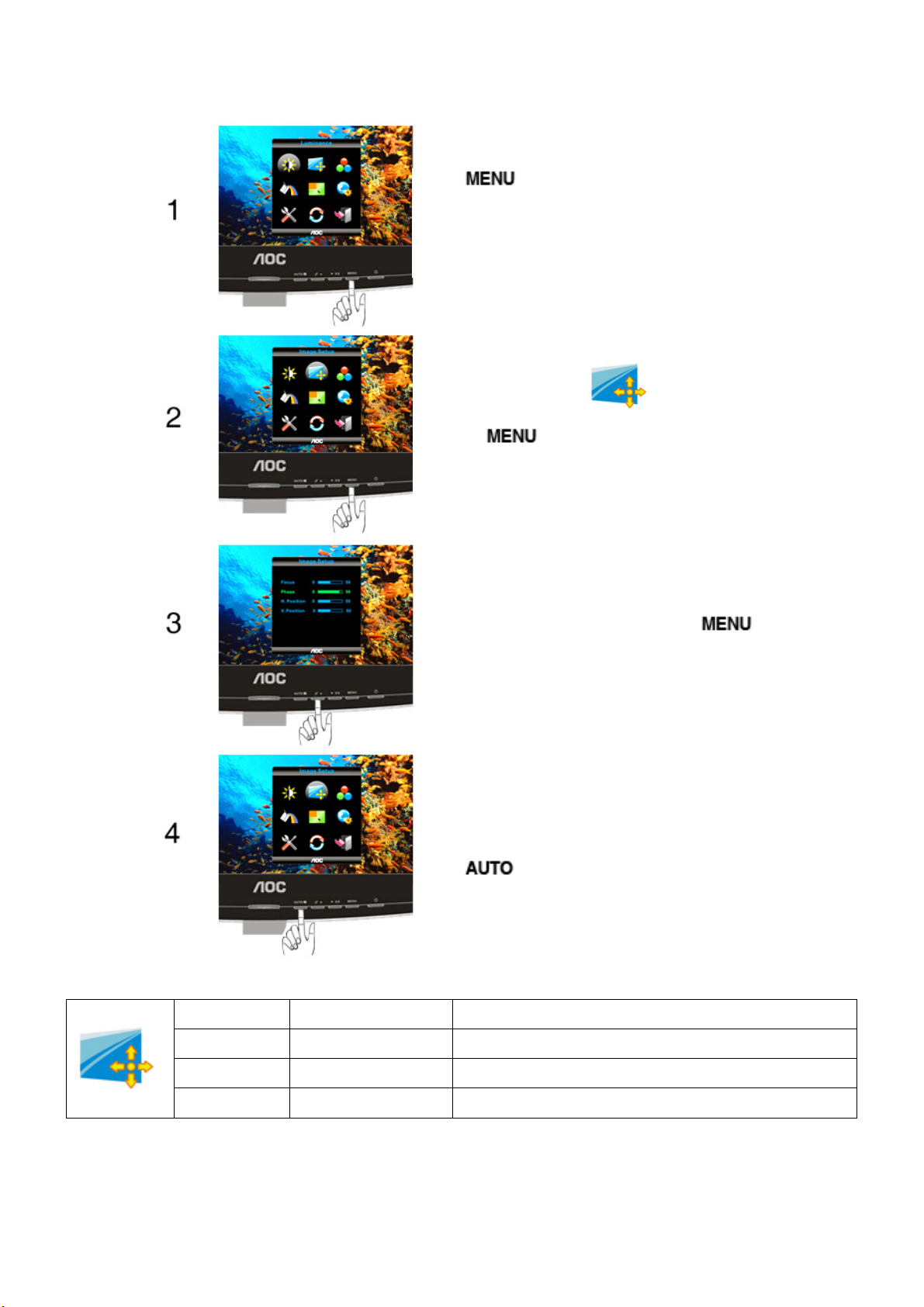

3.3 OSD Setting

1) Press the MENU-button to activate the OSD window.

2) Press ◄ or ► to navigate through the functions. Once the desired function is highlighted, press the

MENU-button to activate sub-menu . Once the desired function is highlighted, press MENU-button to activate it.

3) Press ◄ or ► to change the settings of the selected function. Press ◄ or ► to select another function in

sub-menu . Press AUTO to exit . If you want to adjust any other function, repeat steps 2-3.

4) OSD Lock Function: To lock the OSD, press and hold the MENU button while the monitor is off and then press

power button to turn the monitor on. To un-lock the OSD - press and hold the MENU button while the monitor is off

and then press power button to turn the monitor on.

5)e-Sensor hot key: When there is no OSD,Press ◄ continuously to select the e-Sensor mode(e-Sensor mode hot

key may not be available in all models).

Notes:

1) If the product has only one signal input, the item of "Input Select" is disable to adjust.

2) If the product screen size is 4:3 or input signal resolution is wide format, the item of "Image Ratio" is disable to

adjust.

3) One of DCR, Color Boost, and Picture Boost functions is active, the other two function is turned off accordingly.

8

Page 9

Luminance

Press (Menu) to display menu.

Press Menu to display MENU

Press ◄ or ► to select (Luminance), and

press

Press ◄ or ►to select submenu, press to

enter, and press ◄ or ► to adjust.

Press to exit.

to enter.

9

Page 10

Brightness 0-100 Backlight Adjustment

Contrast 0-100 Contrast from Digital-register.

Standard

Eco mode

Text

Internet

Game

Movie

Sports

Gamma1 Adjust to Gamma1

Gamma

Gamma2 Adjust to Gamma 2

Gamma3 Adjust to Gamma 3

DCR On/OFF

Standard Mode

Text Mode

Internet Mode

Game Mode

Movie Mode

Sports Mode

Enable dynamic contrast ratio

10

Page 11

Image Setup

Press (Menu) to display menu.

Press ◄ or ► to select (Image Setup),

and press

Press ◄ or ► to select submenu, press to

enter, and press ◄ or ► to adjust.

Press to exit.

to enter.

Clock 0-100 Adjust picture Clock to reduce Vertical-Line noise.

Phase 0-100 Adjust Picture Phase to reduce Horizontal-Line noise

H.Position 0-100 Adjust the horizontal position of the picture.

V.Position 0-100 Adjust the vertical position of the picture.

11

Page 12

Color Temperature

Press (Menu) to display menu.

Press ◄ or ► to select (Color

Temperature), and press

Press ◄ or ► to select submenu, press to

enter, and press ◄ or ► to adjust.

Press to exit.

to enter.

Warm

Normal

Cool

sRGB

User

6500K

7300K

9300K

Red Red Gain from Digital-register

Green Green Gain Digital-register.

Blue Blue Gain from Digital-register

Recall Warm Color Temperature from EEPROM.

Recall Normal Color Temperature from EEPROM.

Recall Cool Color Temperature from EEPROM.

Recall SRGB Color Temperature from EEPROM.

12

Page 13

Color Boost

Press (Menu) to display menu.

Press ◄ or ► to select (Color Boost),

and press

Press ◄ or ► to select submenu, press to

enter, and press ◄ or ► to adjust.

to enter.

Press to exit.

Full Enhance on or off Disable or Enable Full Enhance Mode

Nature Skin on or off Disable or Enable Nature Skin Mode

Green Field on or off Disable or Enable Green Field Mode

Sky-blue on or off Disable or Enable Sky-blue Mode

AutoDetect on or off Disable or Enable AutoDetect Mode

Demo on or off Disable or Enable Demo

13

Page 14

Picture Boost

Press (Menu) to display MENU.

Press ◄ or ► to select

press

Press ◄ or ► to select Bright Frame. Select “on” to

activate Picture Boost.

Press ◄ or ► to select submenu, press to

enter, and press ◄ or ► to adjust.

to enter.

(Picture Boost); and

Press to exit.

Frame Size 14-100 Adjust Frame Size

Brightness 0-100 Adjust Frame Brightness

Contrast 0-100 Adjust Frame Contrast

H. position 0-100 Adjust Frame horizontal Position

V.position 0-100 Adjust Frame vertical Position

Bright Frame on or off Disable or Enable Bright Frame

14

Page 15

OSD Setup

Press (Menu) to display menu.

Press ◄ or ► to select (OSD Setup),

and press

Press ◄ or ► to select submenu, press to

enter, and press ◄ or ► to adjust.

Press to exit.

to enter.

OSD Setup

H.Position 0-100 Adjust the horizontal position of OSD

V.Position 0-100 Adjust the vertical position of OSD

Timeout 5-120 Adjust the OSD Timeout

Transparence 0-100 Adjust the transparence of OSD

Language

Select the OSD language

15

Page 16

Extra

Press (Menu) to display menu.

Press ◄ or ► to select (OSD Setup),

and press

Press ◄ or ► to select submenu, press

to enter, and press ◄ or ► to adjust.

to enter.

Press to exit.

16

Page 17

Auto

Input Select

Auto Config yes or no Auto adjust the picture to default

Image Ratio wide or 4:3 Select wide or 4:3 format for display

DDC-CI yes or no Turn ON/OFF DDC-CI Support

Off Timer 0~24hours

Analog

Digital

Select to Auto Detect input signal

Select Analog Sigal Source as Input

Select Digital Sigal Source as Input

Select timing to turn off the monitor.

Information

Show the information of the main image and

sub-image source

17

Page 18

Reset

Press (Menu) to display menu.

Press ◄ or ► to select (Reset), and

press

Press◄ or ► to select YES or NO.

Press to exit.

to enter.

Reset yes or no Reset the menu to default

18

Page 19

Exit

Press (Menu) to display menu.

Press ◄ or ► to select (Exit); and press

to enter.

Exit Exit the main OSD

LED Indicator

Status LED Color

Full Power Mode Blue

Active-off Mode Orange

19

Page 20

4. Input/Output Specification

4.1 Input Signal Connector

Analog connectors

Pin Number 15-Pin Side of the Signal Cable

1 Video-Red

2 Video-Green

3 Video-Blue

4 N.C.

5 Detect Cable

6 GND-R

7 GND-G

8 GND-B

9 +5V

10 Ground

11 N.C.

12 DDC-Serial data

13 H-sync

14 V-sync

15 DDC-Serial clock

DVI connectors

Pin No. Signal Name Pin No. Signal Name Pin No. Signal Name

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 02 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4 Shield 11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

4 TMDS Data 4- 12 TMDS Data 3- 20 TMDS Data 55 TMDS Data 4+ 13 TMDS Data 3+ 21 TMDS Data 5+

6 DDC Clock 14 +5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground(for+5V) 23 TMDS Clock +

8 N.C. 16 Hot Plug Detect 24 TMDS Clock -

20

Page 21

4.2 Preset Display Modes

21

Page 22

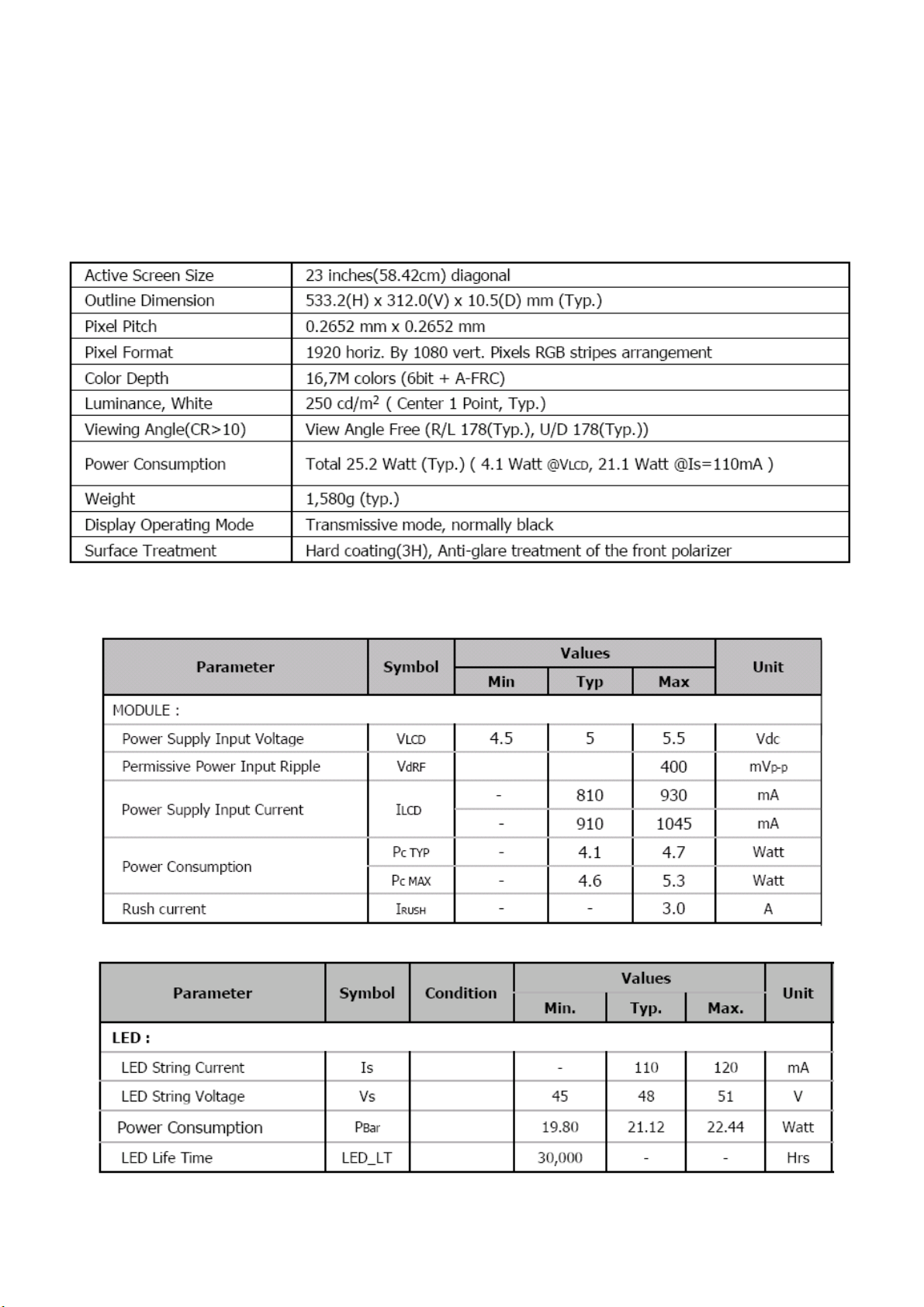

4.3 Panel Specification

4.3.1 General Features

LM230WF3 is a Color Active Matrix Liquid Crystal Display with a Light Emitting Diode ( White LED) backlight

The matrix employs a-Si Thin Film Transistor as the active element. It is a transmissive type display operating in the

normally black mode. It has a 23 inch diagonally measured active display area with FHD resolution (1080 vertical by

1920 horizontal pixel array) Each pixel is divided into Red, Green and Blue sub-pixels or dots which are arranged in

vertical stripes. Gray scale or the brightness of the sub-pixel color is determined with a 8-bit gray scale signal for each

dot, thus, presenting a palette of more than 16,7M colors with A-FRC (Advanced Frame Rate Control).

4.3.2 General Specifications

4.3.3 Electrical Characteristics

LED Bar Electrical Characteristics

(Ta= 25± 2℃, VLCD =5.0V, VLCD=5.0V, Fv=60Hz,)

4.3.4Optical Characteristics

22

Page 23

(Ta=25 °C, VLCD=5V, fV=60Hz Dclk=144MHz, IBL=110mA)

23

Page 24

5. Block Diagram

5.1 Main Board

FLASH MEMORY

Pm25LD020C-SCE

(U402)

Crystal 12MHZ

(X401)

D-Sub

Scalar NT68668AUFG

(Include :MCU,ADC,OSD etc)

H sync

V sync

RGB

(U401)

DVI

LCD Interface

(CN301)

Key Control

Interface

(CN401)

DVI

Input

signal

Connector

(CN101)

DDC1_SCL

DDC1_SDA

EEPROM

M24C02

(U101)

Connector

(CN102)

DDC2_SCL

DDC2_SDA

EEPROM

M24C02

(U102)

24

Page 25

(

5.2 Power Board

AC input

EMI filter

Bridge

Rectifier

and Filter

Transformer

(T901)

Rectifier

diodes

Start Resistor

(R904)

PWM Control

LD7750GS

IC901)

Power Switch

(Q901)

Photo coupler

(IC903)

14.5V

L801

D801

MOSFET

(Q806)

OFF

DIM

PWM Control

MP3389EF

(U801)

14.5V

5V

Feedback

Circuit

Regulator

(IC904)

LED

(CN803)

25

Page 26

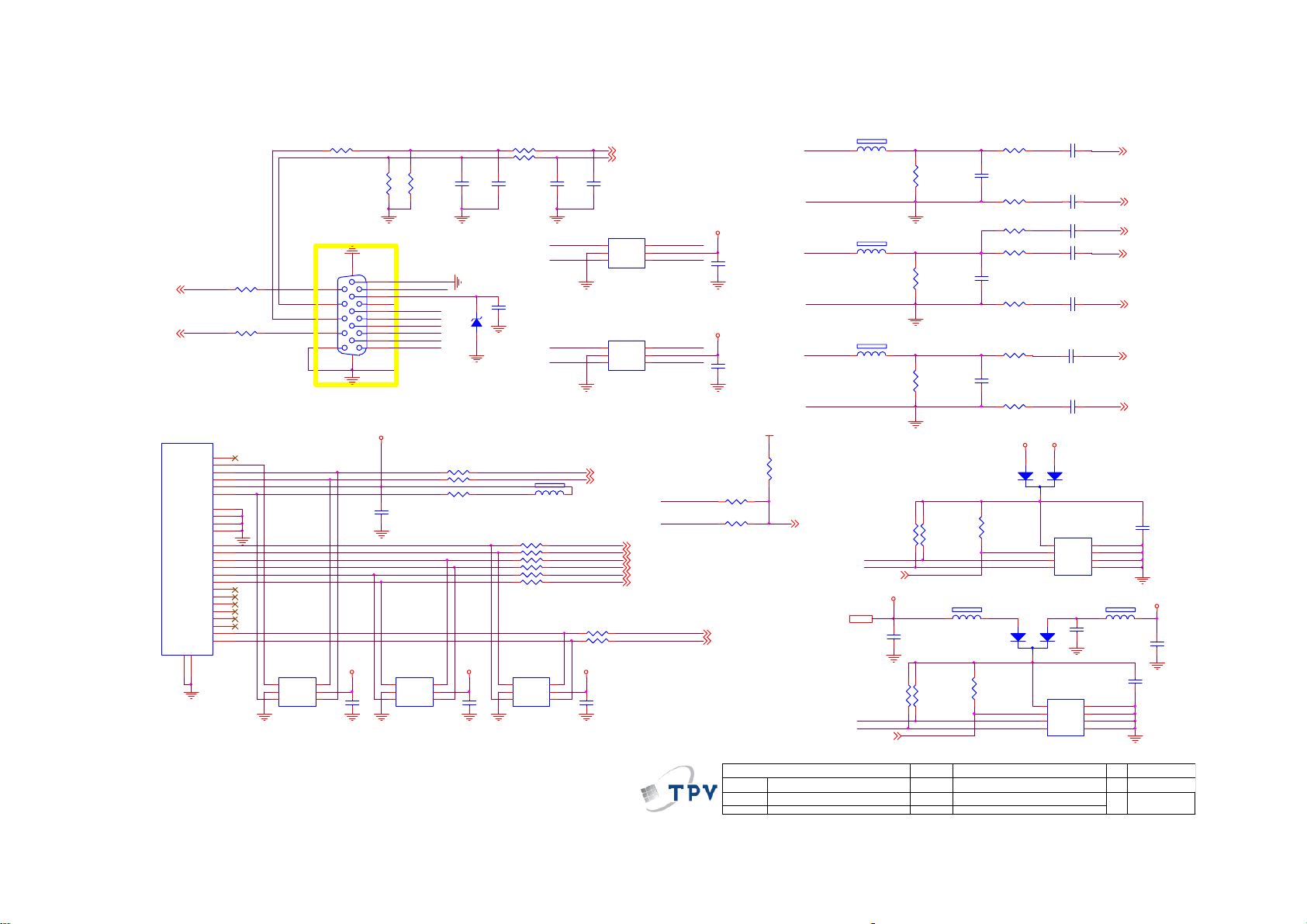

6. Schematic

6.1 Main Board

715G4002M01000004S

R101

DDC1_SCL5

DDC1_SDA5

DDC 1_SCL

DDC 1_SDA

CN102

JACK

VSYN C

SYNC GND

DDC SCL

DDC SDA

HPD

1/3shield

2/4shield

0/5shield

clk shield

DAT0+

DAT0-

DAT1+

DAT1-

DAT2+

DAT2-

DAT3+

DAT3-

DAT4+

DAT4-

DAT5+

DAT5-

GND26GND

25

+5V

clk+

clk-

100OHM1/16W

R113

100OHM1/16W

8

DET_DVI

15

6

7

14

DVI_HPD

16

11

3

19

22

18

17

10

9

2

1

13

12

5

4

21

20

23

24

U107

AOZ8105CI

1

I/O1

2

GND

I/O23I/O3

H_Sync

R102 0R05 1/ 10W

V_Sync

CN101

D-SUB 15P

DSUB_SCL

DSUB_SDA

2010/1/13

modify type

6

I/O4

5

VDD

4

R103 10 0OHM1/16W

R104 10 0OHM1/16W

C103

R106

2.2K 1/16W

15

14

13

12

11

17 16

C121

100N 16V

10

5

9

4

8

3

7

2

6

1

DVI_5V

DET_VGA

C112

100N 16V

U105

AOZ8105CI

1

I/O1

2

GND

I/O23I/O3

R107

2.2K 1/16W

VGA_BVGA_B+

VGA_GVGA_G+

VGA_RVGA_R+

I/O4

VDD

6

5

4

ZD101

RLZ5.6B

R118 100 OHM1/16W

R119 100 OHM1/16W

R120 10K+-5%1/16W

ESD_VCC 1ESD_VCC 1

22P 50V

DSUB_5V

C122

100N 16V

C104

22P 50V

C124

100N 16V

FB106 300 OHM

R126 10OHM1/16W

R127 10OHM1/16W

R128 10OHM1/16W

R129 10OHM1/16W

R130 10OHM1/16W

R131 10OHM1/16W

U106

AOZ8105CI

1

I/O1

2

GND

I/O23I/O3

C127

NC/22P 50V

DSUB_SCL

DSUB_SDA

VGA_G+

VGA_R+ VGA_B+

DDC2_SCL

DDC2_SDA

6

I/O4

5

VDD

4

DSUB_H 5

DSUB_V 5

C128

NC/22P 50V

U104

AOZ8105CI

1

I/O1

I/O4

2

GND

VDD

I/O23I/O3

U103

AOZ8105CI

1

I/O1

I/O4

2

GND

VDD

I/O23I/O3

DDC 2_SCL 5

DDC 2_SDA 5

RX0P

RX0P 5

RX0N

RX0N 5

RX1P

RX1P 5

RX1N

RX1N 5

RX2P

RX2P 5

RX2N

RX2N 5

R132 10OHM1/16W

R134 10OHM1/16W

ESD_VCC 1

C120

100N 16V

6

5

4

6

5

4

H_Sync

V_Sy nc

DET_VGA

DET_VGA

DET_DVI

RXCP

RXCN

ESD_VCC

ESD_VCC

100K 1/16W

220K 1/16W 5%

RXCP 5

RXCN 5

C125

100N 16V

C126

100N 16V

R135

R139

VCC3. 3

VGA_B+

VGA_B-

VGA_G+

VGA_G-

VGA_R+

VGA_R-

R133

390K +/ -5% 1/16W

DET_CABLE 5

CMVCC13,4,5

FB102

1 2

0R05 1/10W

11/30/2009

FB103

1 2

0R05 1/10W

11/30/2009

FB101

1 2

0R05 1/10W

11/30/2009

4.7K 1/16W

DDC1_SCL

DDC1_SDA

DDC_WP5

CMVCC1

R137

4.7K 1/16 W

DDC2_SCL

DDC2_SDA

DDC_WP5

R124

C118

1N 50V

ESD_VCC 1

R108

75OHM 1/16W

R112

75OHM 1/16W

R116

75OHM 1/16W

ESD_VCC

R125

4.7K 1/16 W

FB104

300 OHM

R138

4.7K 1/16W

R105

10OHM1/16W

C105

5PF 50V

R109

47 OHM 1/16W

470 OHM 1/16W

R111

10OHM1/16W

C109

5PF 50V

R114

47 OHM 1/16W

R115

10OHM1/16W

C113

5PF 50V

R117

47 OHM 1/16W

D101

BAV70

R123

22K 1/16W

D102

BAV70

R136

22K 1/16W

R110

CMVCC1

2

2

DSUB_5V

1

3

U101

8

VCC

7

WP

6

SCL

5

CAT24C02WI -GT3

1

3

U102

8

VCC

7

WP

6

SCL

5

CAT24C02WI -GT3

C111

47nF 16V

VSS4SDA

A0

A1

A2

VSS4SDA

C102

47nF 16V

C106

47nF 16V

C107

1N 50V

C108

47nF 16V

C110

47nF 16V

C114

47nF 16V

A0

A1

A2

C115

100N 16V

220N16V

1

2

3

220N16V

1

2

3

300 OHM

C117

DSUB_B+ 5

DSUB_B- 5

DSUB_SOG 5

DSUB_G+ 5

DSUB_G- 5

DSUB_R+ 5

DSUB_R- 5

C116

FB105

DVI_5V

C119

1N 50V

T P V ( Top Victory Electr onics C o . , Ltd. )

Date

G4002-M0D-000-0040-100416

2.0.I NPUT

絬 隔 瓜 絪 腹

Key Component

OEM MO DEL

TPV MODEL

PCB NAME

Sheet

AOC e2040VA

e2040VA

26Tuesday , April 27, 2010

of

Size

Rev

称爹

B

C

<

称爹

>

26

Page 27

CN301

32

PA[0..9]5 PB[0.. 9]5

PA[0.. 9]

PA0 LVA3P

PA1 LVA3M

PA2 LVACKP

PA3 LVACKM

PA4 LVA2P

PA5 LVA2M

PA6 LVA1P

PA7 LVA1M

PA8 LVA0P

PA9 LVA0M

PB[0.. 9]

29

LVB3PPB0

LVB3MPB1

LVBCKPPB2

LVBCKMPB3

LVB2PPB4

LVB2MPB5

LVB1PPB6

LVB1MPB7

LVB0PPB8

LVB0MPB9

LVB2M RXO2LVBCKM RXOC-

LVACKM RXEC-

27

RXO0-LVB0M

25

RXO1-LVB1M

23

21

19

RXO3-LVB3M

17

RXE0-LVA 0M

15

RXE1-LVA 1M

13

RXE2-LVA 2M

11

9

RXE3-LVA 3M

7

5

3

1

CONN

30

28

RXO0+ LVB0P

26

RXO1+ LVB1P

24

RXO2+ LVB2P

22

RXOC+ LVBCKP

20

RXO3+ LVB3P

18

RXE0+ LVA0P

16

RXE1+ LVA1P

14

RXE2+ LVA2P

12

RXEC+ LVACKP

10

RXE3+ LVA3P

8

6

4

2

31

PANEL_VC C

R301

220 OHM 1/4W

C305

1UF16V

PANEL_VC C

C302

22UF 16V

5

4

U301

D8D7D6D

NC/ AO4411

S1S2S3G

R308

NC/ 10K1/16W

CMVCC1

FB301

1 2

120 OHM

CMVCC1

CMVCC12,4,5

R305

10K+-5%1/16W

PPWR_ON#5

R304

22K 1/16W

R303

4.7K 1/16W

C304

100N 16V

Q302

LMBT3904LT1G

11/30/2009

R306

100K 1/16W

3

1

G

Q301

AO3401A

C303

R307

NC

220N16V

D

2

S

R302

220 OHM 1/4W

C301

100N 16V

AO3401L

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

G4002-M0D-000-0040-100416

3.0.OU TPU T

Date

OEM MO DE L

TPV MODEL

PCB NAME

Sheet

AOC e2040VA

e2040VA

36Tuesday , April 27, 2010

of

Size

Rev

称爹

B

C

<

称爹

>

27

Page 28

CN702

1112

1

2

3

4

5

6

7

8

9

10

CONN

BKLT-EN

C702

100N 16V

BKLT-VBRI

BKLT-VBRI

BKLT-EN

CMVCC1

R702

10K+-5%1/16W

Q701

LMBT3904LT1G

+12V

R704 22K 1/16W

CMVCC1

R705

10K+-5%1/16W

VCC3.3

R703

10K+-5%1/16W

R706

100OHM1/16W

R707

0R05 1/10W

R708

NC/0 R05 1/10W 5%

on_BACKLIGHT 5

CMVCC1

adj_BACKLIGHT 5

CMVCC1

12

12

VCC3.3

12

12

D708

D707

SR34

SR34

D703

SR34

D704

SR34

C706

100N 16V

G1117-33T43UF

C708

100N 16V

SOT 223

U704

VI3VO

1

SOT 252

U703

NC/AZ1117D-1. 8-E1

3

1

SOT 252

U702

3

SOT 223

U701

VI3VO

1

GND

OUT2IN

GND

ADJ(GND)1VOUT(TAB)2VIN

Both 223 and 252

foot-print

2

GND

2

Both 223 and 252

foot-print

C705

100N 16V

VCC3.3

Dropout voltage must

< 0.8V @ 600mA

C707

C709

22UF 16V

100N 16V

Dropout voltage must

< 0.8V @ 400mA

VCC1.8

C704

22UF 16V

C715

1N 50V

2010/1/13

Add C721

R712

100K 1/16W

C712

100nF 25V

C721

10uF 25V

+12V

+

C718

180uF 16V

C720

100N 16V

+12V 6

Place a large Pad

with TOP

C719

100nF 25V

R727

300K

2010/1/13

180k => 300k

FB702

1 2

BEAD

2010/1/13

SMD => Dip

R711

33K 1/16W 5%

C713

100N 16V

2010/1/25

Add FB703

FB703

0R05 1/10W

9

Thermal Pad

8

SW

BST

7

VIN

6

COMP

FREQ

5

U705 MP1584EN

3

2

1

Pad 璶 TOP and Button常璶Τ

1

2

EN

3

FB4GND

D701

SR34

1 2

JACK

CN701

C722

150pF 50V

R726

100K 1/16W

C710

1N 50V

L701 22uH

C711

NC/1N 50V

2010/1/13

1000p => NC

Pad 璶 TOP and Button

R713

6.8K +-1% 1/16W

R714

1.3K 1%

Add C714

reduce

noise

常璶Τ

C714

1N 50V

C723

+

10uF 25V

C716

470uF 10V

2010/1/25

Add C723

C716

ぃ 繦獽 ノ

DC-DC pulse

noise

CMVCC1

CMVCC1 2,3,5

C717

ZD702

NC/RLZ 6.2B

1 2

,

G4002-M0D-000-0040-100416

4.0.POWER

11/30/2009

100N 16V

穦

Τ

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

Date

OEM MOD EL

TPV MOD EL

PCB NAME

Sheet

AOC e2040VA

e2040VA

46Tuesday, April 27, 2010

of

C

Size

C

Rev

<

称爹

>

称爹

28

Page 29

VCC3.3

VCC3.3 2,4

FB404

300OHM

FB405

300OHM

FB406

NC/300OHM

FB407

300OHM

WP

PS_O/P

PS_EN

PS_DISTANCE

4.7UF 10V

4.7UF 10V

4.7UF 10V

4.7UF 10V

C413

C0805

C416

C0805

C421

C0805

C423

C0805

AVCC

DVDD

ADC_VAA33

ADC_BIAS

6

C414

1UF16V

2

C417

100N 16V

28

C422

100N 16V

17

C424

1UF16V

R416

220K 1/16W 5%

C425 100N 16V

DVDD

C429

220N16V

R401 100OHM1/16W

12/3/2009

10K1/16W

R419 100OHM1/16W

R420 100OHM1/16W

R422 4.7K 1/16W

15

C415

1UF16V

C418

100N 16V

CMVCC1

R415

100K 1/16W

SPI_CE

SPI_SO

R402

10K+-5%1/16W

R417

5V_DET

DVDD

10K+-5%1/16W

0R05 OHM

C408

1UF16V

5351

C419

100N 16V

R403

1

S

2

DO

3

W

Vss4DIO

A25L020AO-F

R427

R418

10K+-5%1/16W

U402

CMVCC1

90

HOLD

KEY1

KEY2

Vcc

C437

100N 16V

8

7

6

C

5

VCC3.3

116

DET_CABLE2

DDC_WP2

C427

100N 16V

SPI_CK

SPI_SI

R428

NC/0R05 1/ 16W

CN402

CONN

C438

100N 16V

C426 47pF 50V

C428 47pF 50V

1

2

3

4

5

DSUB_H2

DSUB_V2

DSUB_B+2

DSUB_B-2

DSUB_SOG2

DSUB_G+2

DSUB_G-2

DSUB_R+2

DSUB_R-2

DDC2_SDA2

DDC2_SCL2

DDC1_SDA2

DDC1_SCL2

DDC_WP

67

R414

AVCC

470R 1/16W 1%

RX2P2

RX2N2

RX1P2

RX1N2

RX0P2

RX0N2

RXCP2

RXCN2

DET_CABLE

R436 1K 1/16W

R437 1K 1/16W

11/30/2009

SPI_CE

SPI_SO

SPI_SI

SPI_CK

WP

R435

100OHM1/16W

X401

14.31818MHZ/32PF

1 2

RX2+

RX2RX1+

RX1RX0+

RX0RXC+

RXC-

AHS0

AVS0

B0+

B0-

SOG_DET

G0+

G0-

R0+

R0-

DDCSDA2

DDCSCL2

DDCSDA1

DDCSCL1

R434

1M 1/16W

125

126

104

105

106

107

108

127

128

VCC3.3

16

4

5

7

8

10

11

13

14

41

42

19

20

21

22

23

24

25

34

35

46

47

30

33

48

29

49

50

31

32

1

FB403

300OHM

U401

REXT

RX2+

RX2RX1+

RX1RX0+

RX0RXC+

RXC-

HSYNCI1

VSYNCI1

BIN1+

BIN1-

SOG1I

GIN1+

GIN1-

RIN1+

RIN1-

PB7/DDC_SDA1*

PB6/DDC_SC L1*

PB5/DDC_SDA0*

PB4/DDC_SC L0*

PB3/ADC3/INTE1

PB2/ADC2/INTE0

PB1/ADC1

PB0/ADC0

SPI_CE

SPI_SO

SPI_SI

SPI_CLK

PD4

PD5

PD6

P35

P34

P31/TXD

P30/RXD

RSTB

OSCI

OSCO

NT68668AFG/C

LED_G

LED_R

100N 16V

45

PLL_DVDD

2010/1/25

C406

4.7UF 10V

C0805

C407

43

PLL_GND

CMVCC12,3,4

0R05 OHM

LMBT3906LT1G

R404

220 OHM 1/10W

R405

330OHM 1/10W

2010/1/25

LED

獹

ADC_VAA

52

115

CVDD

GND

3

44

R406

Q401

AVCC

26

119

CVDD

CVDD_ZP

DGND

DGND/CGND

GND

64

78

109

23

ADC_VAA18

NC

DGND/CGND

101

ADC_BIASCVDD

6

15

AVCC

AVCC

AGND

PGND

9

12

18

VCC3.3CMVCC1

R407

NC/0R05 1/ 16W

R410

4.7K 1/16W

1

ADC_VAA33

28

51

17

DVDD

ADC_BIAS

ADC_VAA33

AGND

ADC_GNDA

NC

NC

NC

27

63

89

112NC111

0R05 OHM

LMBT3906LT1G

DVDD

90

116

53

2

NC

DVDD

DVDD

DVDD_ZP

R408

23

Q402

1

VCC3.3CMVCC1

R409

NC/0R05 1/ 16W

R411

4.7K 1/16W

TCLK1M

TCLK1P

TCLK2M

TCLK2P

INT_VSO

INT_HSO

PWMA*

PWMB*

PC4/PW M1

PC3/PW M0

PA7/PWM9*

PA6/PWM8*

PA5/PWM7*

PA4/PWM6*

PA3/PWM5

PA1/PWM3

PA2/PWM4

PA0/PWM2

10K+-5%1/16W

10K+-5%1/16W

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

T0M

T0P

T1M

T1P

T2M

T2P

T3M

T3P

T4M

T4P

T5M

T5P

T6M

T6P

T7M

T7P

VCKI

V7

V6

V5

V4

V3

V2

V1

V0

PC7

PC6

PC5

PC2

PC1*

PC0*

R412

R413

2010/1/25

LED

100

99

98

97

96

95

94

93

92

91

88

87

86

85

84

83

82

81

80

79

77

76

75

74

73

72

71

70

69

68

62

61

60

59

58

57

56

55

54

113

114

117

118

103

102

124

123

122

110

121

120

40

39

38

37

36

67

66

65

2010/1/25

獹

PA9

PA8

PA7

PA6

PA5

PA4

PA3

PA2

PA1

PA0

R426 1K 1/16W

LED_GRN/BLUE

LED_ORANGE

VCC1.84

PB9

PB8

PB7

PB6

PB5

PB4

PB3

PB2

PB1

PB0

11/30/2009

VCC1.8

LED_GRN/BLUE

LED_ORANGE

C436

NC/100N 16V

adj_BACKLIGHT

Volume

on_BACKLIGHT

POWER_KEY#

AUDIO_MUTE

PS_O/P

PS_EN

PS_DISTANCE

Panel_ON

Key Component

CVDD

FB401

0R05OHM1/8W

C439

4.7UF 10V

C0805

FB402

300OHM

C404

4.7UF 10V

C0805

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PA8

PA9

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PB8

PB9

CN401

89

1

2

3

4

5

6

7

CONN

T P V ( Top Victory Electronics Co . , Ltd. )

G4002-M0D-000-0040-100416

絬 隔 瓜 絪 腹

5.0.SCALER

Date

ADC_VAA

26

PA[0..9]

PB[0..9]

adj_BACKLIGHT 4

Volume 6

on_BACKLIGHT 4

AUDIO _MUTE 6

PPWR_ON # 3

KEY1

KEY2

POWER_KEY #

LED_G

LED_R

C431

1 2

1 2

11552

C401

100N 16V

C405

100N 16V

100N 16V

FB408

NC/120 OHM

FB409

NC/120 OHM

PA[0.. 9] 3

PB[0.. 9] 3

C402

100N 16V

119

C403

100N 16V

VCC3.3

C432

100N 16V

R431

LED_R

OEM MOD EL

TPV MODEL

PCB NAME

R432

3.9K1/16W

3.9K1/16W

ZD401

C433

CMVCC1

Sheet

C434

100N 16V

100N 16V

NC/RLZ5.6B

AOC e2040VA

e2040VA C

of

56Tuesday, April 27, 2010

R433

ZD402

3.9K1/16W

ZD403

C435

100N 16V

NC/RLZ5.6B

NC/RLZ5.6B

C

Size

Rev

称爹

>

<

称爹

29

Page 30

6.2 Power Board

Adapter 715G 901 2 4A

更改料件

1

!

12

!

!

+

3

-

GBU408

4

1

4

L901

30mH

2

3

C903 0. 47UF275V

!

R901

R902

680K 1/4W +- 5%

680K 1/4W +- 5%

NR901

NTCR

t

F901

FUSE

0.001uF

0.001uF

C901

C902

水波纹干扰对策

BD901

2

!

R903

680K 1/4W +- 5%

!

+

C904

100uF 450V

10nF

C911

0.01uF

C925

1

2

3

C908

100K 1/8W

IC901

CT

COMP

CS

GND4OUT

LD7750GS

R904

47KOHM +-5% 1/4W

8

HV

7

NC

6

VCC

5

R920

10R 1/4W

C926

2200PF2KV

C912

330pF

C922

0.1uF

430K 1/4W

R922

R914

430K 1/4W

1N4007

D902

C906

+

47uF/50V

R908

47 OHM 1/4W + -5%

220R 1/8W 5%

R909

R910

10K OHM 1/4W + -5%

R906

430K 1/4W

R907

2R2 1/4W 5%

430K 1/4W

R967

!

SMK0965F

D901

1N4007

C909

3300pF 250V

Q901

R911

0.62OHM2W

IC903

PC123X2YFZ OF

1

2

3

4

5

6

7

43

T901

!

51 OHM +-5% 1/4W

51 OHM +-5% 1/4W

51 OHM +-5% 1/4W

8

9

10

11

R918

510 OHM +-1% 1/4W

12

C915

0.022uF/ 50V

IC904

R923

R913

R912

D904

3

V30100C-E3/ 4W

2

1

C919

680UF 25V

R968

2.2KOHM 1/10W

R917

4.7KOHM +-5% 1/4W

C914

2N2 500V

R924

+

(NC)10K 1/ 8W 5%

更改料件

C916

2N2 500V

+

C921

680UF 25V

C918

NC

L902

1.1uH

R986

20K +-5% 1/8W

LED2

LED

C920

4.7uF/ 25V

R919

9.76K1/4 W

R916

2K49 1/8W 1%

+12V

R921

1 MOHM +-5% 1/4W

3

CN901

SOCKET

C923

1U 25V

!

12

T P V ( Top Victory Electronics Co . , Ltd. )

G901-1-15-X-3-100201

絬 隔 瓜 絪 腹

Key Component

02.ADAPTER

Date

OEM MO DEL

TPV MODEL

PCB NAME

Sheet

HP X20/X22/X23LED

ADPCA1248HA1

715G901-1-15

22Wednesday , June 30, 2010

of

Size

Rev

称爹

A3

1.0

<

称爹

>

30

Page 31

Converter 715G4119P01002004C

+14.5 V

ON/OF F

DIM

R818

0R05 1/4W

Q804

NC/ RK7002FD5T116

+

C809

100UF 50V

ON/OF F

DIM

R825

NC

R823

NC

CONN

CN801

1112

1

2

3

4

5

6

7

8

9

10

+14.5V

R824

NC

DR

Q805

NC/ RK7002FD5T116

R806

1K 1/10W

R808

1K 1/10W

Q802

NC/ MMBT3904

R817

NC

R821

NC

Q803

NC/ MMBT3906

C801 0.47uF 50V

C802 68NF 50V

R807 100K 1/10W

R810 100K 1/10W

C808

R803

R804

100K 1/10W

R826

3.3R 1/8W 5%

NC

R802 200K 1/10W 5%

30K 1/10W 1%

R822

10K 1/10W

R819

30K 1/10W 1%

DRGATE

U801

1

NC

2

VIN

3

VCC

4

COMP

5

EN

6

DBRT

7

GND

8

OSC

9

ISET

10

BOSC

11

LED12

12

LED11

13

LED10

LED914LED8

MP3389EF

VFAULT

PGND

ISENSE

E-Pad

29

GATE

OVP

LED1

LED2

LED3

LED4

LED5

LED6

LED7

NC

L802NC/ 22uH

22uH

28

27

DR

26

25

24

23

22

21

20

19

18

17

16

15

L801

GATE

OVP

GATE

1

2

3

4

Q801

NC/AOD4126

R815

1R 1/8W 5%

R812

NC

R811

R829

0R05OHM1/8W

R830

Q806

S1

D1

G1

D1

S2

D2

G2

D2

APM8005KCTRG

D801

1 2

SK310B

R801

10 OHM 1% 1/4W

C805

220P 100V

R813

R814

NC

0.3 OHM

0.3 OHM

0R05OHM1/8W

8

7

6

5

C810

+

4.7UF 100V

C810

NC

+

R827

C803

47N 50V

C804

47N 50V

1 OHM +-5% 1/8W

R828

1 OHM +-5% 1/8W

R831

OVP

R809

7.5K + -1% 1/10W

1 OHM +-5% 1/8W

R805

300K +- 5% 1/8W

C806

100pF 50V

CN802

56

1

2

3

4

CONN

CN803

1

2

CONN

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

G4119-P2A-000-0040-2-100826

01.CON VERTER

Date

OEM MO DE L

TPV MODEL

PCB NAME

Sheet

e940swa

LNPCA9401AH D1

715G4119-P2A-000-004C

12

of

Size

Rev

称爹

31

Custom

B

OD M MOD EL

Page 32

6.3 Key Board

715G4014K01000004C

CN001

LBADC 1

1

LBADC 2

2

DC_POWERON

3

LED_1#

4

LED_2#

5

6

CONN

C001

0.1uF 50V

1

3

LED001

LED

2

R001 2KOHM 1% 1/10W

R002 0 R01 1/ 10W

C002

0.1uF 50V

R003 2KOHM 1% 1/10W

R004 1K 1/10W

SGND

LBADC2

LBADC1

(AUTO) (DOWN-)

LED

CONNECTOR

OK

AUTO

DOWN

MENU

(2.0K)

(0)

(2K)

(1K)

(UP+)

1.118V

0V

1.118V

0.673V

(MENU) (Power)

SW004

SW

UP

SW003

SW

AUTO

SGND

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

Date

SW005

SW

DOWN

TBD

2.0. key

MENU

SW002

SW

POWER

OEM MO DEL

TPV MO DE L

PCB NA ME

Sheet

SW001

SW

N/A

e2040V D

TBD

of

22Thursday , Nov ember 05, 2009

Size

Rev

称爹

B

称爹

>

<

32

Page 33

6.4 Light Sensor Board

715G3995T01000004C

10K 1/16W 5%

C019

100uF 16V

C013

100N 16V

ZD014

1 2

NC/UDZSNP5.6B

R019

1K 1/16W 5%

VCC

R022

+

VCC

R017

NC

12

LED011

LED

R018

33 OHM 1/8W

Q012

SST2222A

VCC

MX_OU TPUT

VCC

Q013

SST2222A

R023

33 OHM 1/8W

C018

100N 16V

1

VDD

2

GP5/T1CKI/P1A*/OSC1/CLKIN

3

GP4/AN3/C IN1-/T1G/P1B*/OSC 2/CLKOU T

4

GP3/T1G*/MCLR/VPP

1K 1/16W 5%

R026

NC

R014

U011

GP2/AN2/T0CKI/INT/COUT/CCP1/P1A

PIC12F 615-I/SN

VCC

C012

100N 16V

84

5

+

7

U012B

LM358DR

VCC

R024

10K 1/16W 5%

GP0/ AN0/CIN+/P1B/ICSPDAT

GP1/AN1/C IN0-/VREF/ ICSPCLK

-

R016

100K1/16W

6

23

VSS

NC/ 100R 1/16W 5%

100K 1/16W 5%

VCC_IN

R020

1K 1/16W 5%

1

Q011

MMBT2907AK

C016

100N 16V

8

7

6

5

4K7 1/16W 5%

C011

1uF 16V

R012

R015

IR_RX

R013

1

C020

100N 16V

R021

1K 1/16W 5%

VCC

100R 1/16W 5%

R025

VCC

84

+

-

VCC_ IN

C015

100N 16V

3

2

U012A

LM358DR

SEN_ON

C017

100N 16V

IR_TX

R011

NC/ 100R 1/16W 5%

ZD013NC/UDZSNP5.6B

1 2

1 2

VCC_I N

SEN_ON

MX_OU TPU T

IR_TX

IR_RX

SEN_ON

MX_OU TPU T

IR_TX

ZD011NC/UDZSNP5.6B

ZD012NC/UDZSNP5.6B

1 2

1

2

3

4

5

CN011

CONN

U013

3

VCC

2

GND

1

VOUT

KSM-603TM2M

IR_TX

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

Date

G3995-T01-000-0040-100415

PIC12F 615-I/SN

33

OEM MODEL

TPV MO DE L

PCB NAME

Sheet

40TH

40TH A

Power Sensor

of

22Friday , April 16, 2010

Size

Rev

称爹

A

称爹

>

<

Page 34

7. PCB Layout

7.1 Main Board

715G4002M01000004S

34

Page 35

7.2 Power Board

Adapter 715G 901 2 4A

35

Page 36

Converter 715G4119P01002004C

36

Page 37

7.3 Key Board

715G3371 2

7.4 Light Sensor Board

715G3995T01000004C

37

Page 38

8. Maintainability

8.1 Equipments and Tools Requirement

1. Voltmeter.

2. Oscilloscope.

3. Pattern Generator.

4. DDC Tool with an IBM Compatible Computer.

5. Alignment Tool.

6. LCD Color Analyzer.

7. Service Manual.

8. User Manual.

38

Page 39

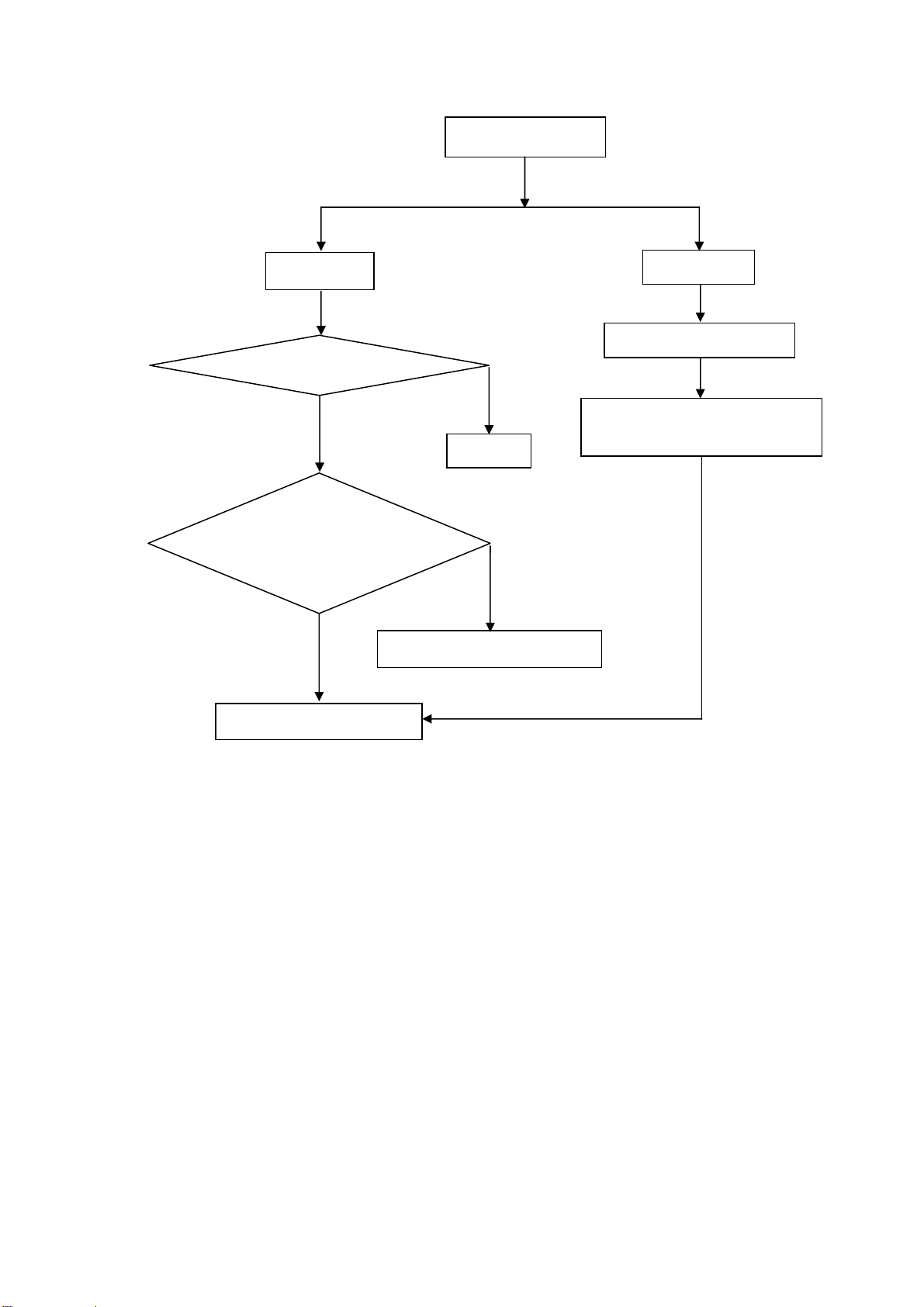

8.2 Trouble Shooting

1.No Power

No power

Check power cable is

tightened?

OK

Check Power “On/Off”

is “On”?

OK

Check the LED

indicate is OK?

OK

NG

Re-plug the power cable

NG

Turn on the Power “On/Off” switch

NG

Check the AC power

Replace the converter board

NG

Replace main board and check connections

NG

Replace key board and check connections

39

Page 40

2. No Video (Power LED Blue)

No Video (Power LED Blue)

Press the power

button is OK?

OK

Replace the converter

board

NG

Replace the main

board and connection

NG

Replace the main board

OK

The end

OK

The end

NG

Check the LVDS/FFC

cable or panel

NG

Replace the key board

OK

Replace the LVDS/FFC

cable or panel

40

Page 41

3. DIM

DIM (image overlap, focus or flicker)

Reset in factory mode

NG

Set to the optimal

frequency, select the

recommended frequency

NG

Readjust the phase and pixel

clock in the user mode

NG

Pull out signal cable and

check “Self Test Feature

Check” is ok?

NG

Replace the main board

NG

Replace the panel

OK

OK

The end

OK

The end

OK

The end

OK

Check the signal cable

and the PC

NG

OK

The end

41

Page 42

4. Color is not optimal

Replace the signal cable

Replace the main board

Miss color

NG

Pull out the signal cable

and check the screen

color display is normal?

NG

Replace the signal cable or PC

Color is not optimal

OK

The end

OK

Color shift

Reset the factory mode

NG

In the user mode, set the” color

settings” until customer satisfy

NG

42

Page 43

9. FOS Testing

9.1 Brightness Measurement

Max. Brightness>250 cd/㎡(typ).

Test conditions:

- Center of display

- Video input (RGB) = 0,700V for Analog Input

- Brightness control is set to max

- Contrast control is set to max.

Min. brightness measurement:

< 45% of Max luminance (max luminance = max contrast + max brightness)

Test conditions: - Center of display

- Video input (RGB) = 0.700V for Analog Input

- Brightness control is set to min.

- Contrast control is set to min.

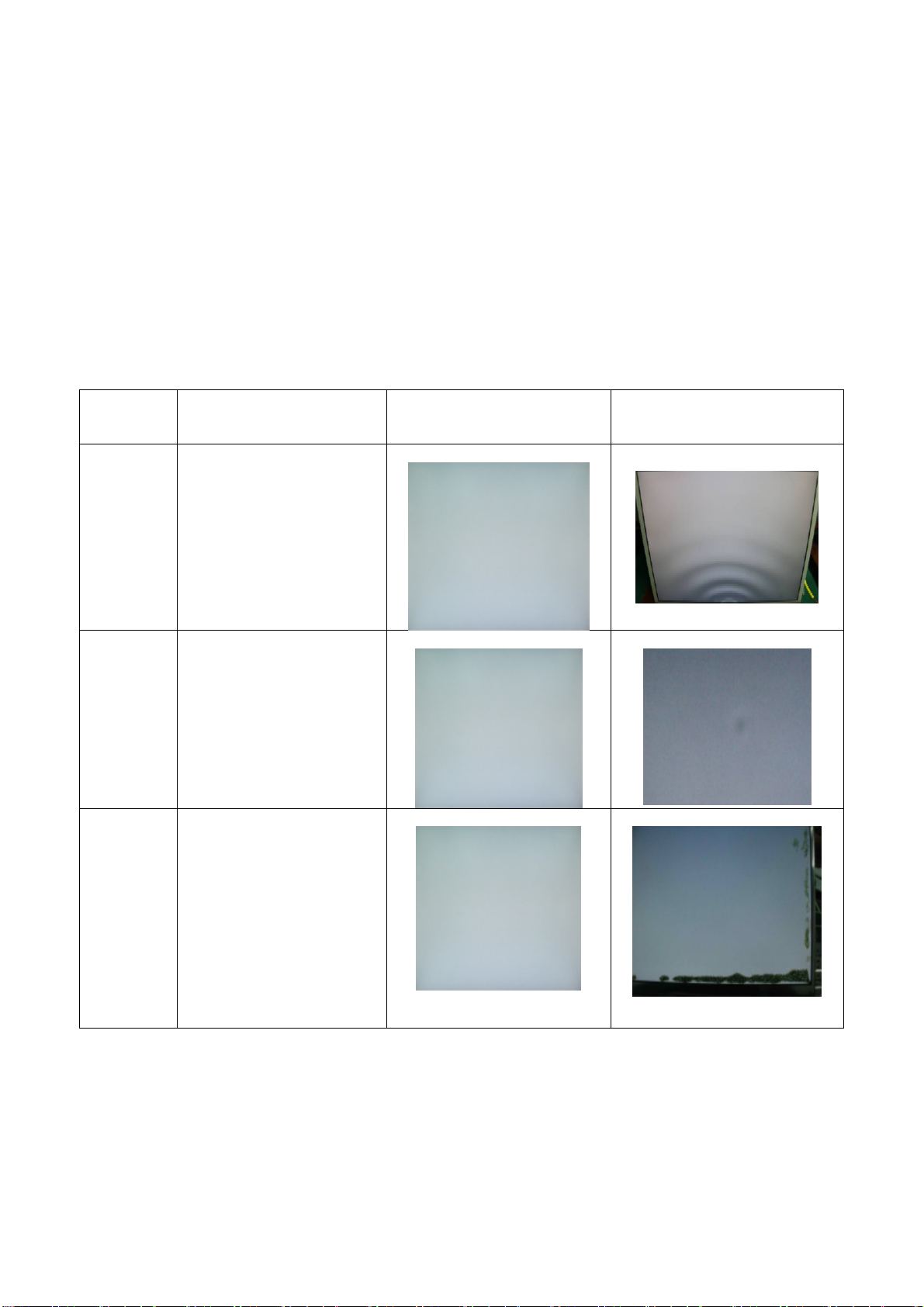

9.2 Patterns Testing

Condition

Item

(Resolution, Commended

test paten)

Normal picture Abnormal Picture

Waterwave

noise

Mura

LCD

bubble

1.1920x1080 (60 Hz)

2. White pattern

1. 1920x1080 (60 Hz)

2. Black pattern or White

pattern.

1. 1920x1080 (60 Hz)

2. Black pattern or White

pattern

43

Page 44

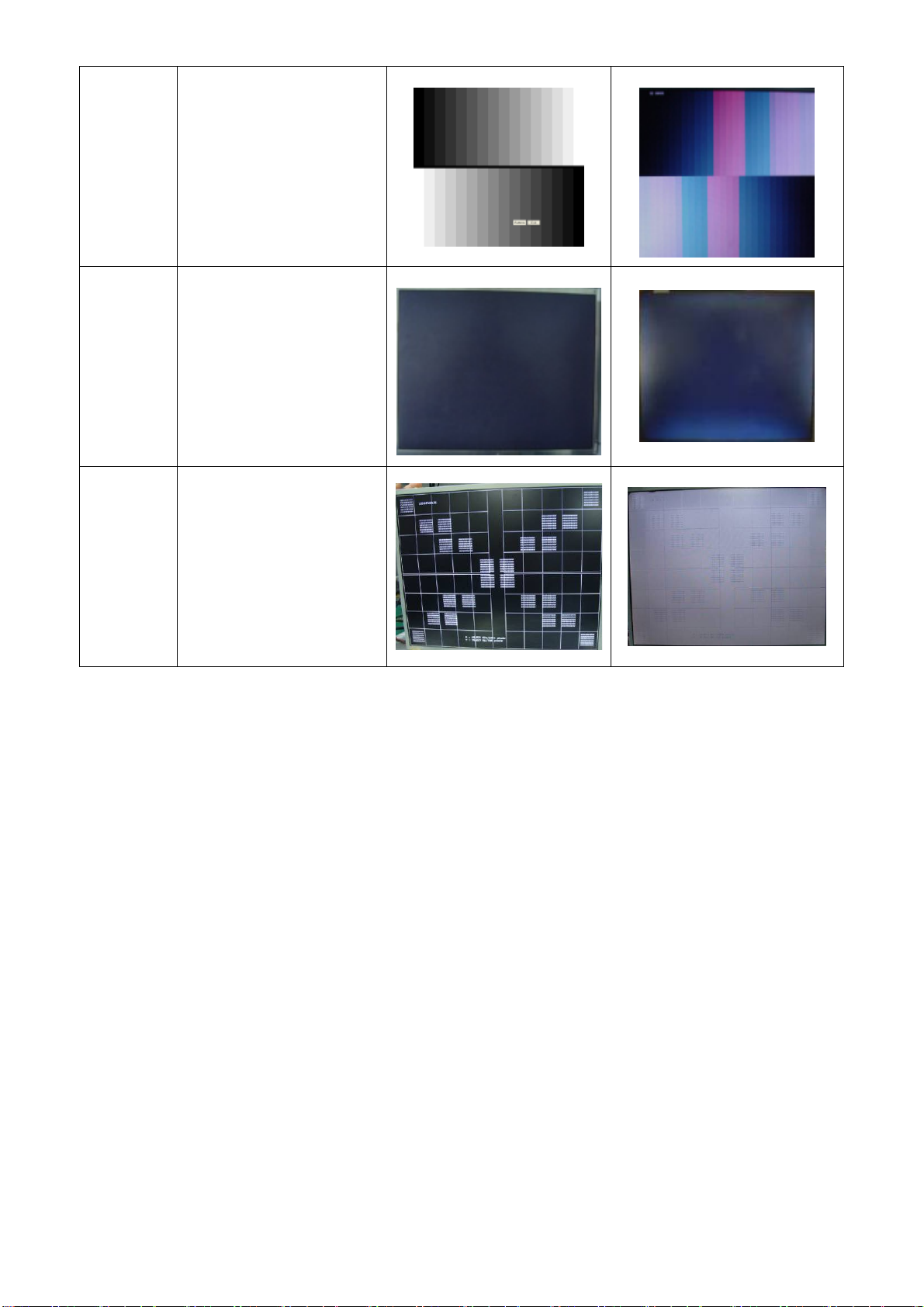

Cross line

Half line

1. 1920x1080 (60 Hz)

2. Black pattern

1. 1920x1080 (60 Hz)

2. Black pattern or White

pattern

H-Line

V-Line

1. 1920x1080 (60 Hz)

2. Black pattern, Red

pattern, Green pattern or

Blue pattern.

1. 1920x1080 (60 Hz)

2. Black pattern or White

pattern

H-Strip

1 1920x1080 (60 Hz)

2. Black pattern, Gray scale

pattern, Red pattern, Green

pattern or blue pattern .

44

Page 45

V-St rip

1. 1920x1080 (60 Hz)

2. Black pattern, Gray scale

pattern, Red pattern, Green

pattern or blue pattern .

Abnormal

display

Gray defect

1. 1920x1080 (60 Hz)

2. Gray scale pattern

1. 1920x1080 (60 Hz)

2. Gray scale pattern

Video noise

Color tint

1. 1920x1080 (60 Hz)

2. Gray scale pattern

1. 1920x1080 (60 Hz)

2. Gray scale pattern

45

Page 46

Gray scale

failure

Light

leakage

Fuzzy

video

1. 1920x1080 (60 Hz)

2. Gray scale pattern

1. 1920x1080 (60 Hz)

2. Black pattern or White

pattern

1. 1920x1080 (60 Hz)

2. Pane picture

46

Page 47

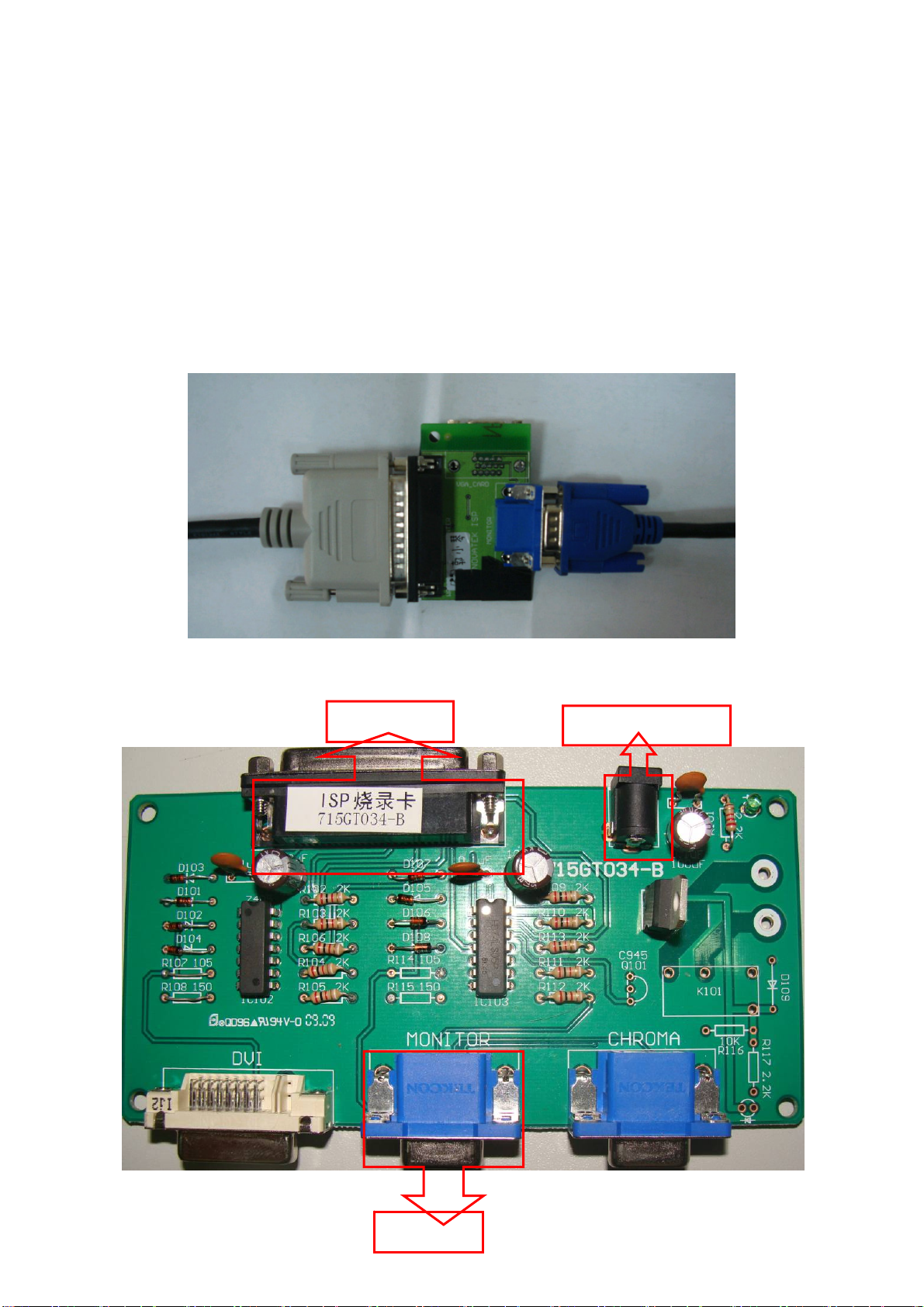

10.Firmware and DDC Instruction

10.1Firmware Instruction(TSUM IC ISP for exemple NT68676)

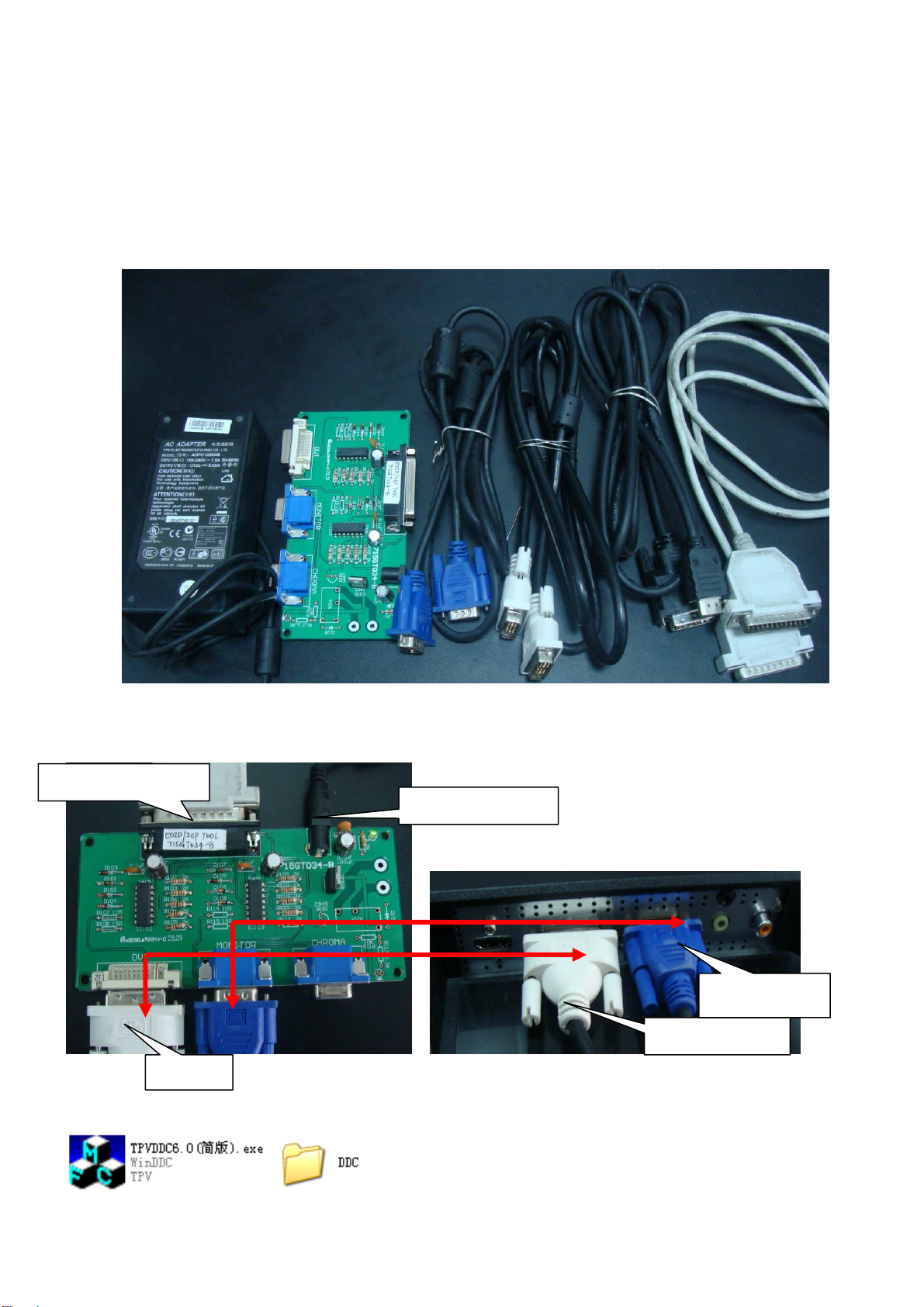

Step 1:OPERATION CONDITIONS:

1) An i486 (or above) personal computer or compatible.

2) Microsoft operation system Windows 95/98/2000/XP.

3) ISPTool programs programs.

4) Printer cable and VGA cable.

5) ISP board (PN: 715GT034-B,715GT048-1 or715GT035-A).

6) ISP Firmware/Software

Step 2:Connection:

1) LPT cable connect PC and ISP board ;

2) VGA cable connect monitor and ISP board ;

3) Reference picture as below

NO1. TPV Part No. : 715GT048-1 or 715GT035-A(715GT048-1 or 715GT035-A)

NO2. TPV Part No : 715GT034-B(NEW LCD EDID TOOL :715GT034-B)

To PC LPT Port

Connect 12V power

To Monitor

47

Page 48

ISP TOOL front side ISP TOOL reverse side

Step 3: Programming:

1. Double-click the icon

2. Install tool programme

2.1 decompress

PS:NT68168F Scale IC must use V4.566 version.

2.2 Double-click

to install Port95nt print driver,

.

3. ISP Tool

3.1. Choose ”writer” as follow picture.

48

Page 49

3.2.Double-click icon

4.Click TOOL “Option”, ”FE2P Mode Enable” TOOL show“√”

and run it:

49

Page 50

5.Click tool “Option” choose” Setup ISP tool” and then choose LPT Port,the next ,choose NVT Type (default),click

“Auto Detect”to choose the appropriate speed。Click”Confirm change”。

6.Click“Load File” to use the proper software:

50

Page 51

Click“Auto”

AUTO

Click “Send MX2026 CMD”

Click“AUTO”,when appear “pass” as follow picture that burning is successful:

51

Page 52

Note: After installation, you must restart the PC to take the setup to effect.

Step4:Check whether the FW version is correct, then do “Auto Color” and “Reset”.

a. For VGA, if can’t use the recommended optimal resolution; for DVI, if no video with PC source, while picture is

normal with chroma source, it’s the reason for “DDC Loss”, so pls do DDC programming.

b. When the monitor connects the DVD or other play devices with DVI->HDMI cable, and play the HD video with

copyright, while the low-resolution, snowflake point or no video with normal audio; But picture is normal with PC

source, pls programming the “HDCP code” or replace the new main board. (Pls refer to the “HDCP code”

programming as below)

Step5:HDCP Write SOP

I. Prepare condition:

1. Prepare one PC and the system is WIN98/NT/2000/XP, make sure the PC have Print Port.

2. Install Port95nt Software, the way of the install Port95 (LPT PORT drive):

a. selects the software of Port95nt.exe, and run it,

b. After install ok, restart the PC.

3. Connect the cable and Jig:

a. Use the Print cable to connect the PC and HDCP card.

b. Connect the VGA cable with the ISP record card, the picture of Print cable, VGA cable and ISP card as below:

Connect to PC LPT

Connect to Monitor

ISP Tool TPV P/N: 715GT034-B

Connect to Signal Source

(e.g.: Chroma/PC etc)

DC 12V

52

Page 53

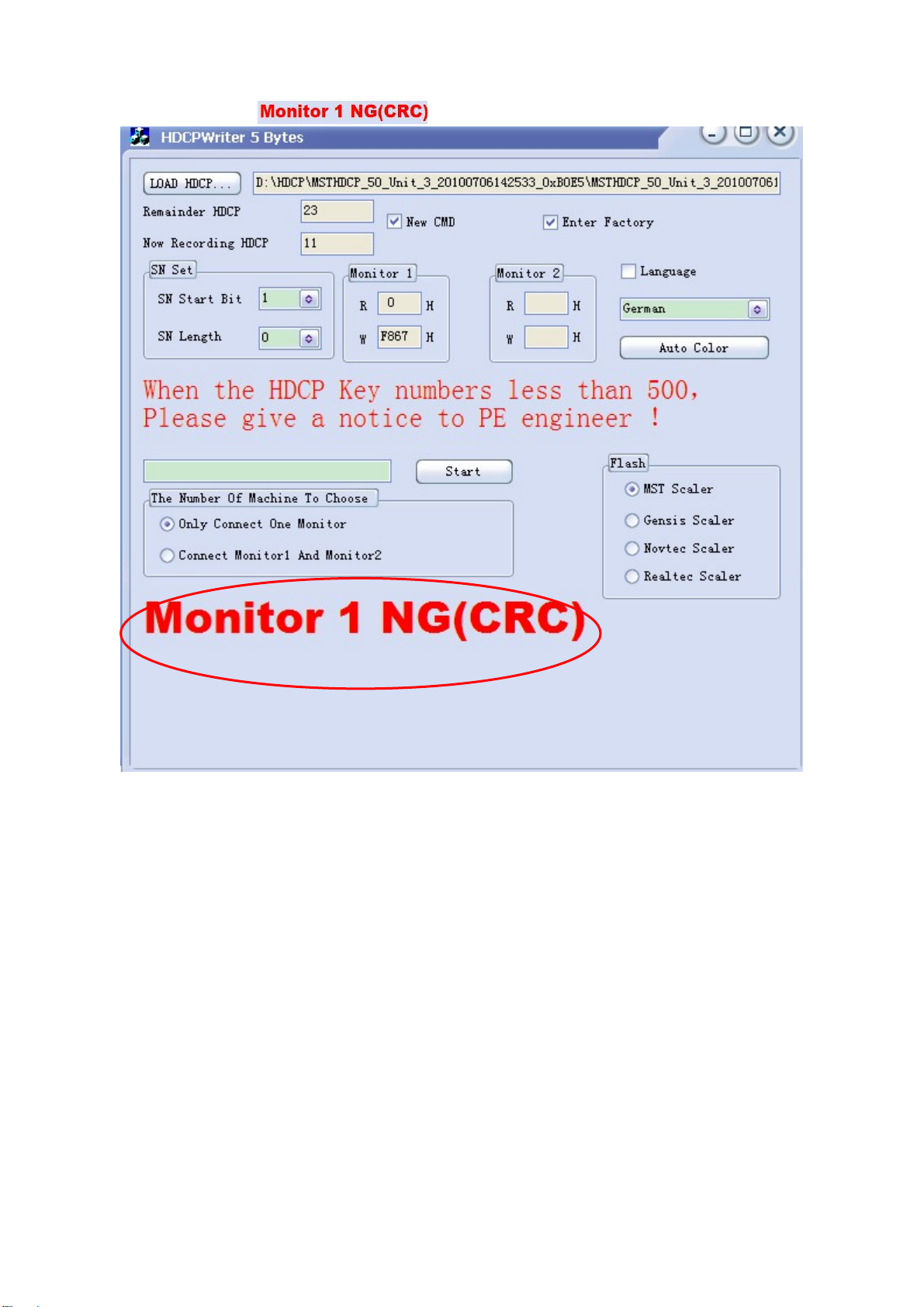

II. HDCP Write Step:

Step1. Double click “HDCP20091026.exe”

Step2. Click “Load HDCP…”. choose the corresponding “*.BIN” by scaler IC (MST Scaler) ,then click “Open” as

below.

53

Page 54

Step3. Pls choose the item remarked in red (i.e.: New CMD/Only Connect One Monitor/MST Scaler), then click

“Start” to write HDCP, when display “Monitor 1 PASS” means Write OK.

54

Page 55

III. Check HDCP.

USE “Blu-Ray Disc” DVD to check whether the monitor with DVI connector displays normally.

If error message appeared “

” as below:

1. Check whether the HDCP writer is correct.

2. Check whether the tool is correct or not, and check the connection between PC, Monitor and tool. In addition,

check whether the tool’s power supply is available.

3. If still no work, pls modify the “config.ini” as below, and then try again.

Modify Step: Right click “config.ini”-> Open with “Notepad”->”OK”-> Modify the HDCP value (350->500,

150->300, 500->700)->Save.

PS: You can also open “config.ini” directly if you have opened it through “Open with ‘Notepad’ ” before.

55

Page 56

56

Page 57

350 ->500

150 ->300

500 ->700

57

Page 58

10.2 DDC Instruction

Tool list:

1. DDC board:715GT034-B

2. Software (WA.DAT&WD.DAT&*. CONFIG.INI)

3. LPT driver software

4. LPT cable, D-SUB CABLE ,DVI CABLE and DVI to HDMI CABLE

5. 12V( Adapter)

6. TPVDDCHDMI and TPVDDC6.0

7. PC

Tool picture

For VGA&DVI BURNING: DDC Board as the follow picture:

TO PC LPT

DC 12V power

DVI

Install software:

Note:Burning softsare and EDID data must be put in the same folder as follow picture:

VGA

LCD DVI port

58

Page 59

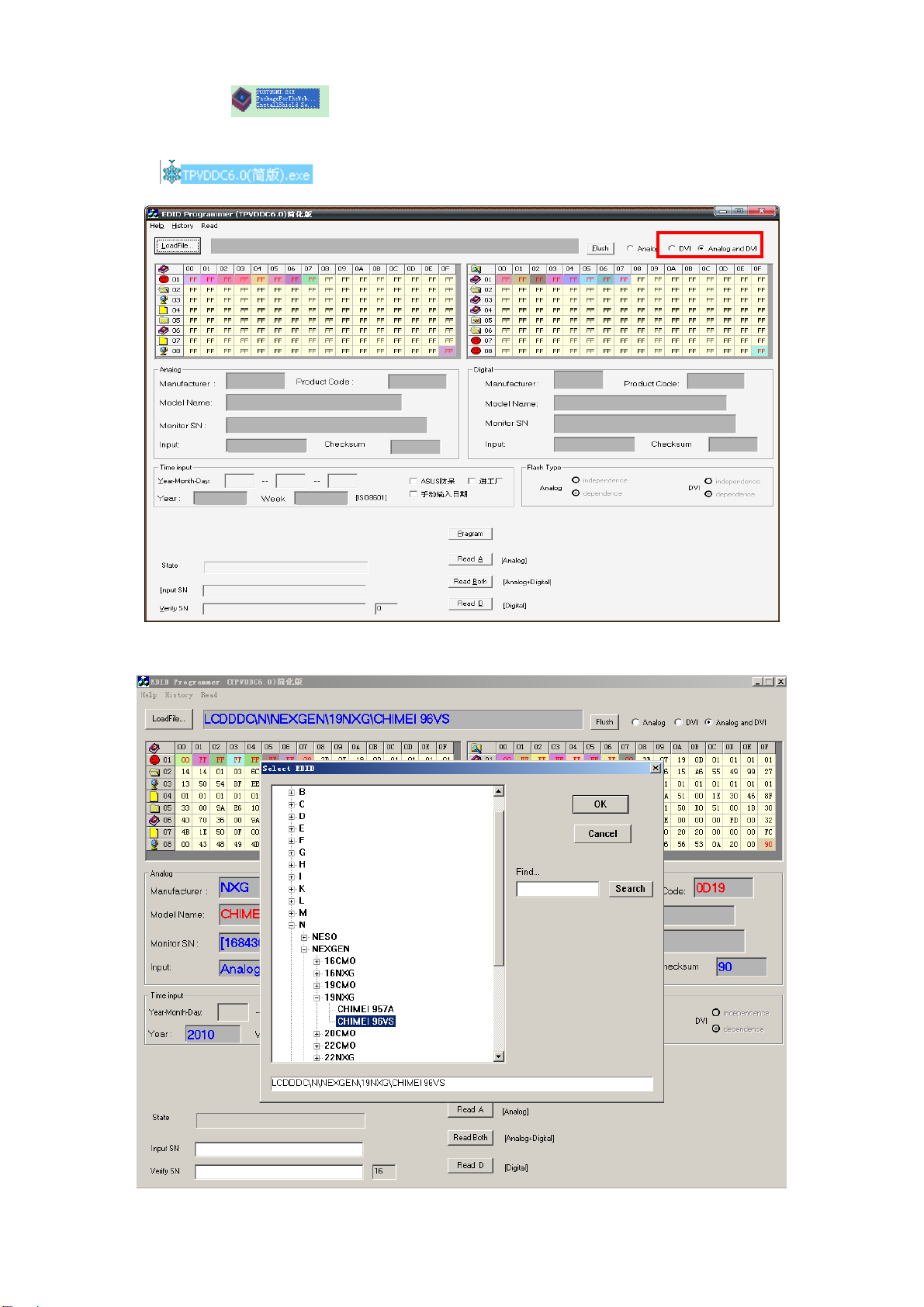

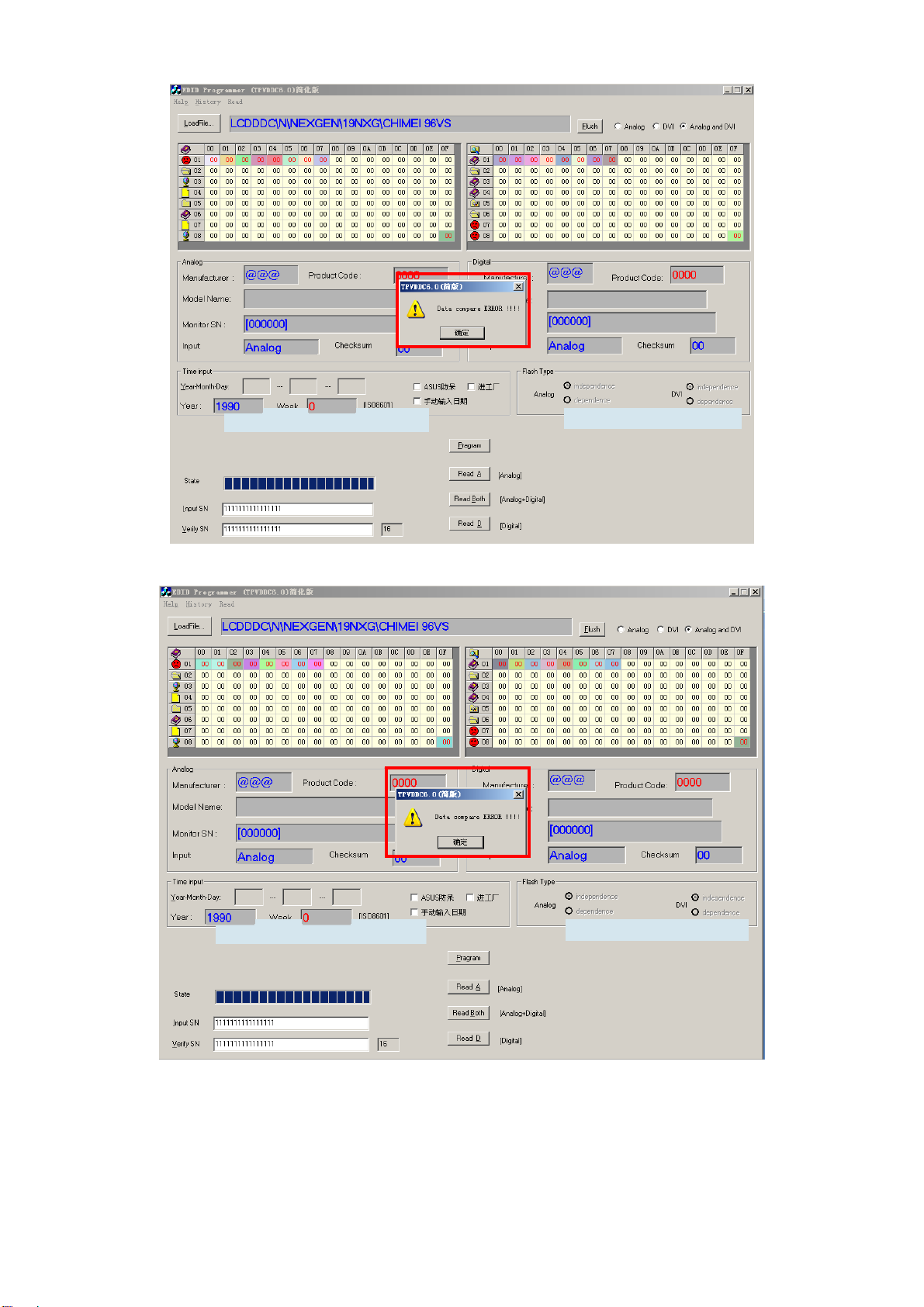

VGA&DVI Burning:

1.Double-click the icon “ ” to install Port95nt print driver, and then restart the computer.

Double-click

, select “Analog and DVI” show as follow picture

2. Click “Load file” and select as follow picture.then click “LCDDDC”

EX: DDCModelName:CHIMEI96VS

59

Page 60

3. Click “ok” show as follow picture.

4.Input same SN twice and date. Click “Pragram” to burn. When appear “pass” as follow picture that burning is

successful.

60

Page 61

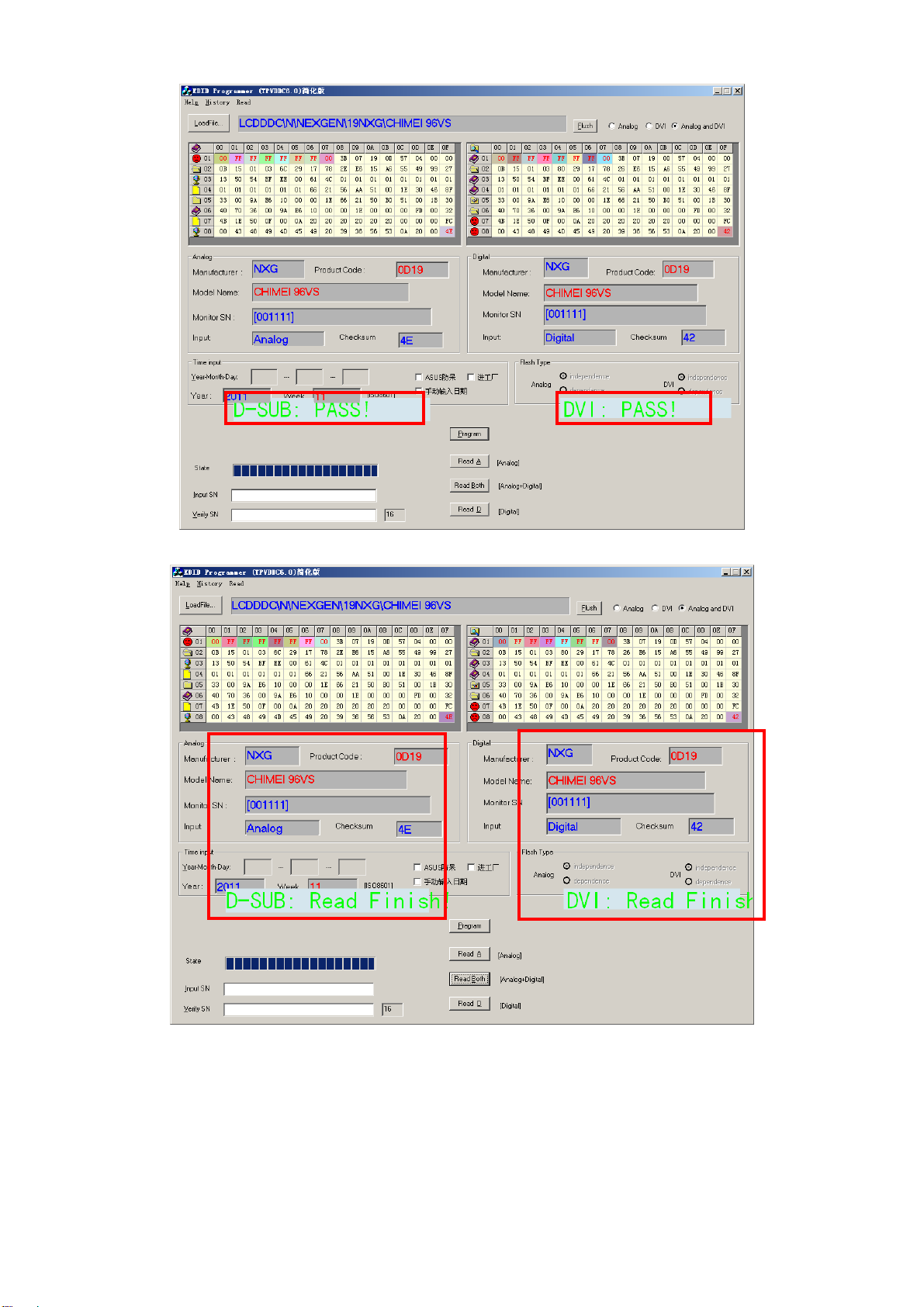

5. Click “program”,

Note:1. Appear fault as follow , please input SN twice and burning again.

61

Page 62

Note:2. When appear “pass” as follow picture that burning is successful.

Note3:Click “Read both” show as follow picuture..If read SN and model name are same as before inputing as before

that burning is successful.

62

Page 63

Note4:Appear fault as follow, please check the connection of LPT cable , Tool adapter cable and LCD power.

Note5:Appear fault as follow,please check the connection of VGA and the connection of DVI

63

Page 64

Note6:

If the burn software is unsuccessfulll, appear fault:

1. For VGA,the resolution will be not the best achieve.

2. For DVI,No picture,no sound.

If program failed, in VGA mode, you can’t use the optimal resolution.

When Read is OK, program is NG, pls do take following action:

1. For VGA,cut off the 9th pin (connect the monitor).

2. For DVI, cut off the 14th pin (the shortest pin, power supply).

3. Connect the EEPROM WP pin to ground.

64

Page 65

11. White- Balance, Luminance Adjustment

Approximately 30 minutes should be allowed for warm up before proceeding white balance adjustment.

How to setting MEM channel you can reference to chroma 7120 user guide or simple use “SC” key and

“NEXT” Key to modify xyY value and use “ID” key to modify the TEXT description Following is the procedure to do

white-balance adjust .

1. Setting the color temp.

A. 6500K color

Warm color temp. parameter is x=313±30, y=329±30, Y>150cd/ m

B. 7300K color

Normal color temp. parameter is x=302±30 ,y=318±30, Y>150cd/ m

C. 9300K color

Cool color temp. parameter is x=283±30, y=297±30, Y>150cd/ m

D. sRGB color:

sRGB color temp. parameter is x=313±30, y=329±30, Y>150cd/ m

2

(typ)

2

2

(typ)

2

(typ)

(typ)

2. Enter into the factory mode:

Press the MENU button, pull out the power cord, then plug the power cord. Then the factory OSD will be at the

left top of the panel.

3. Bias adjustment:

Set the Contrast

to 50; Adjust the Brightness to 90.

4. Gain adjustment:

A. Adjust Warm (6500K) color-temperature

1. Switch the chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 3 (with up or down arrow on chroma 7120)

2

3. The LCD-indicator on chroma 7120 will show x=313±30, y=329±30, Y>150cd/ m

4. Adjust the RED on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN on factory window until chroma 7120 indicator reachedthe value G=100

6. Adjust the BLUE on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item4, 5, 6) until chroma 7120 RGB value meet the tolerance =100±2

(typ)

B. Adjust Normal (7300K) color-temperature

1. Switch the chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 4(with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x=302±30, y=318±30, Y>150cd/ m2(typ)

4. Adjust the RED on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN on factory window until chroma 7120 indicator reachedthe value G=100

6. Adjust the BLUE on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4, 5, 6) until chroma 7120 RGB value meet the tolerance =100±2

65

Page 66

C. Adjust Cool (9300K) color-temperature

1. Switch the Chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM. Channel to Channel 9 (with up or down arrow on chroma 7120)

2

3. The LCD-indicator on chroma 7120 will show x=283±30, y=297±30, Y>150cd/ m

4. Adjust the RED on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN on factory window until chroma 7120 indicator reached the value G=100

6. Adjust the BLUE on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4, 5, 6) until chroma 7120 RGB value meet the tolerance =100±2

D. Adjust sRGB color-temperature

1. Switch the chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 10 (with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x=313±30, y=329±30, Y>150cd/ m

4. Adjust the RED on factory window until chroma 7120 indicator reached the value R=100

(typ)

2

(typ)

5. Adjust the GREEN on factory window until chroma 7120 indicator reachedthe value G=100

6. Adjust the BLUE on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4, 5, 6) until chroma 7120 RGB value meet the tolerance =100±2

E. Turn the Power-button off to quit from factory mode.

66

Page 67

12. Mechanical Instructions

1. Put monitor on the EPE cushion

2. Put monitor front side upwards and top side face to yourself.

67

Page 68

3.Open the top side of front bezel with fingers.

4. Open whole front bezel with a special disassembly tool.

68

Page 69

5.Put panel side downwards and take off back cover

6.Remove lamp cable\ aluminum foil\KEPC\ e-SENSOR BOARD\ hexagonal screws.

69

Page 70

7.Turn over main frame and remove screws

70

Page 71

8.Judge the failure position ,disassemble CNPC or CBPC or e-SENSOR BOARD or KEPC and repair

71

Page 72

13.Monitor Exploded View

72

Page 73

14. BOM List

Note: The parts information listed below are for reference only, and are subject to change without notice. Please go

to http://cs.tpv.com.cn/hello1.asp for the latest information.

TDAGNT2EWWA4HNE

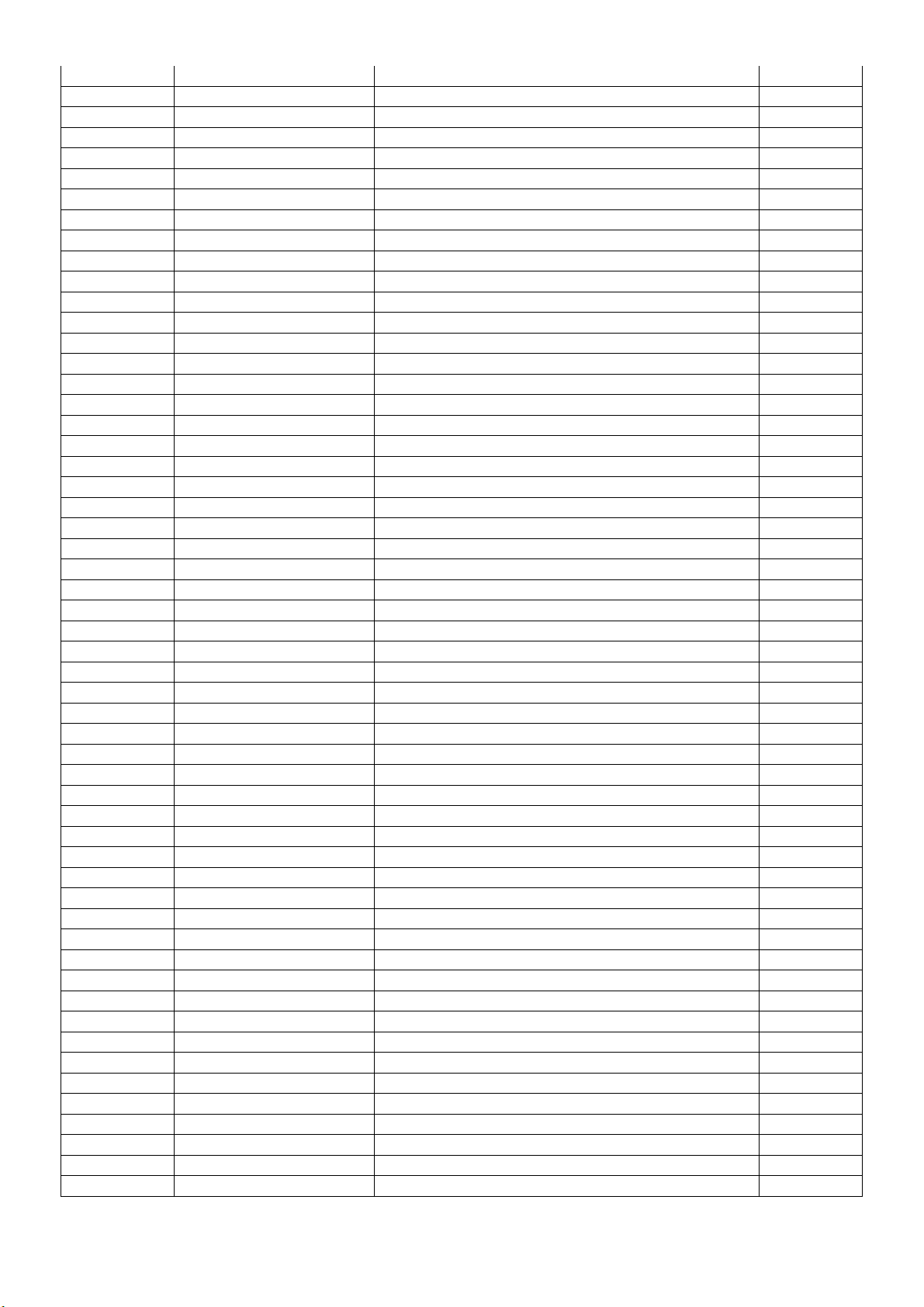

Location Part No. Description Remark

040G 581 26704 SHIPPING LABEL

040G 58162435A P/N LABEL FOR MANUAL PE BAG

052G 1150 C INSULATING TAPE

052G 1186 SMALL TAPE

052G 1211 B Conductive Tape 85mm *40mm *0.09mm

052G 2191 A PAPER TAPE

HDCP-L 070GHDCP500HDC NO-SUGGEST HDCP CODE

E09504 095G176J 6E03 FFC CABLE 6P 308 1.0

E09501 095G8018 3DE36 HARNESS 30P-30P 330MM 2nd source

E09501 095G8018 3TE36 HARNESS 30P-30P 330MM

E09503 095G8022 5DE01 HARNESS 5P(A1253)-5P(A1253) 260MM 2nd source

E09503 095G8022 5TE01 HARNESS 5P(A1253)-5P(A1253) 260MM

E09502 095G8022 7TE01 HARNESS 7P(1253)-6P(1253) 130

E09502 095G8022 7WE01 HARNESS 7P-6P 130MM 2nd source

E09505 095G802210TE01 HARNESS 10P(A1253)-10P(A1253) 90

E09505 095G802210WE01 HARNESS 10P(A1253)-10P(A1253) 90MM 2nd source

0D1G1030 8120 screw

705GHA34030 2440 BASE ASS'Y

705GHA34059 i2340v REAR COVER_STAND ASS'Y

E750 750GBG230F3B13N000 PANEL LM230WF3-SLB1 GZ LGD

A34G2365DAVA1M0130 BEZEL FOR i2340

H01G6009 1 Screw

H15G0035501101 MAIN FRAME FOR i2340

H33G0022 1 1L LENS_AOC_L201WA-2040LED

H33G0023AED 1B KEY PAD_AOC_L201WA-2040LED

H40G 58361512A esensor LABEL

H40G 58361513A win7 EPEAT EPA LABEL

H40G 58461523A I2340Ve POP LABEL

H41G780961522A e2040v QSG

H44GD009101 PULP

H44GD009201 PULP

H44GD009615 1A I2340Ve CARTON

H45G 77 6 PE PACKING

H45G 87 1 20 EPE COVER

H45G 87 1810H A EPE COVER FOR BASE

H52G6025 16 58 mylar

H70G201061546A I2340Ve CD MANUAL

Q45G 76 28 H A PE BAG FOR MANUAL

Q50G 4 10 TIE (Y1900221)

Q52G 1185 99 big carton tape for aoc

Q52G6019 14 TAPE

E09504 S95G176T6E03 FFC CABLE 6PIN P1.0MM 308MM 2nd source

705GHA34030 2440 BASE ASS'Y

0Q1G 130 8120 SCREW 42A9930011

A34G1867DAV 1M0130 BASE FOR 2440

H15G0042101 BASE BRACKET

705GHA34059 i2340v REAR COVER_STAND ASS'Y

0M1G1740 10120 SCREW 42A9940008

0Q1G 140 8120 SCREW T4X8

73

Page 74

A34G1865DBA 1B0100 STAND

A34G1866DBA 1B0100 STAND

A34G2366DAV 1M0100 REAR COVER FOR i2340

A37G0164012

HINGE_ASS¡¯Y

756GHACB A1073 MAIN BOARD-CBPC9NRA1H5

SMTCA-U402 100GANGD000W11 MCU ASS'Y-056G2233 11

808GI2340VETPE I2340VE Chinese Taipei ASS'Y

E08903 089G1745CAA 9 DVI CABLE 1500 2nd source

E08903 089G1745GAA 9 DVI CABLE 2nd source

E08903 089G1745HAA 9 DVI CABLE 1.5M

E08901 089G420A15N IS AC POWER CORD 1500MM TAIWAN

H26G 800504 2B barcode

H40G 24N61538A I2340VE TW ID LABEL

H40G 58261572A AOC TW WARRANTY LABEL

H40G 58461536A I2340VE TW CARTON LABEL

H41G780961540A TW WARRANTY BOOKLIST

CBPC9NRA1H5 MAIN BOARD

040G 45762412B CBPC LABEL

C718 067G204V181 3K CS CAP 180uF 16V 8*8 mm

C716 067G204V471 2K CS CAP 470uF 10V 8*8 mm

FB702 071G 5526A H CORE 6.0X3.5X3.5 127 25% 3.5X6.0

CN701 088G 304 11 C DC POWER JACK 3P 2.5mm

CN101 088G 35315FVCL D-SUB CONN 15P V/T 10.5mm WITH SCREW

CN102 088G 35424F VC DVI CONN 24P V/T WITH SCREW

X401 093G 2251B J CRYSTAL 12MHZ NXS12.000AC30F-KAB10

Q55G 23524 WELDING FLUX WITHOUT PB

Q55G 100625 TIN STICK_LOW ARGENTUM

CN402 033G8032 5F HR CONNECTOR

CN401 033G8032 7F HR CONNECTOR

CN702 033G803210F HR CONNECTOR 10P 1.25

U401 056G 562328 IC Scaler NT68668AUFG QFP-128

U704 056G 563113 IC G1117-18T63Uf 1A/1.8V SOT-223

U705 056G 563215 IC DC/DC MP1584EN SOIC8E

U702 056G 563512 IC G1117-33T43UF 1A/3.3V TO-252

U103 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U104 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U105 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U106 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U107 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U102 056G1133 34 M24C02-WMN6TP

U101 056G1133 34 M24C02-WMN6TP

U402 056G2233 11 IC Pm25LD020C-SCE SIOC-8(150mil) 2M

Q401 057G 417517 Tra LMBT3906LT1G -200mA/-40V SOT-23 LRC

Q402 057G 417517 Tra LMBT3906LT1G -200mA/-40V SOT-23 LRC

Q302 057G 417518 TRA LMBT3904LT1G 200mA/40V SOT-23 LRC

Q701 057G 417518 TRA LMBT3904LT1G 200mA/40V SOT-23 LRC

Q301 057G 763940 MOSFET AO3401A SOT-23

R406 061G0402000 JY NO-SUGGEST RST CHIPR MAX 0R05 OHM 1/16W

R408 061G0402000 JY NO-SUGGEST RST CHIPR MAX 0R05 OHM 1/16W

R427 061G0402000 JY NO-SUGGEST RST CHIPR MAX 0R05 OHM 1/16W

R115 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R111 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R105 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R134 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R132 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

74

Page 75

R131 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R130 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R129 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R128 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R127 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R126 061G0402100 JY NO-SUGGEST RST CHIPR 10 OHM +-5% 1/16W Y

R706 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R435 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R420 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R419 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R401 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R119 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R118 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R113 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R104 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R103 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R101 061G0402101 JY NO-SUGGEST RST CHIPR 100 OHM +-5% 1/16W

R437 061G0402102 JY NO-SUGGEST RST CHIPR 1KOHM +-5% 1/16W YA

R436 061G0402102 JY NO-SUGGEST RST CHIPR 1KOHM +-5% 1/16W YA

R426 061G0402102 JY NO-SUGGEST RST CHIPR 1KOHM +-5% 1/16W YA

R413 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R412 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R705 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R703 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R702 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R418 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R417 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R403 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R402 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R305 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R120 061G0402103 JY NO-SUGGEST RST CHIPR 10KOHM +-5% 1/16W Y

R726 061G0402104 JY RST CHIPR 100KOHM +-5% 1/16W YAGEO

R712 061G0402104 JY RST CHIPR 100KOHM +-5% 1/16W YAGEO

R415 061G0402104 JY RST CHIPR 100KOHM +-5% 1/16W YAGEO

R306 061G0402104 JY RST CHIPR 100KOHM +-5% 1/16W YAGEO

R135 061G0402104 JY RST CHIPR 100KOHM +-5% 1/16W YAGEO

R434 061G0402105 JY RST CHIPR 1000KOHM 1/16W YAGEO

R714 061G04021301FY RST CHIPR 1K3 +-1% 1/16W YAGEO

R106 061G0402222 JY RST CHIPR 2.2KOHM +-5% 1/16W YAGEO

R107 061G0402222 JY RST CHIPR 2.2KOHM +-5% 1/16W YAGEO

R704 061G0402223 JY RST CHIPR 22KOHM +-5% 1/16W YAGEO

R304 061G0402223 JY RST CHIPR 22KOHM +-5% 1/16W YAGEO

R136 061G0402223 JY RST CHIPR 22KOHM +-5% 1/16W YAGEO

R123 061G0402223 JY RST CHIPR 22KOHM +-5% 1/16W YAGEO

R139 061G0402224 JY RST CHIPR 220KOHM +-5% 1/16W YAGEO

R416 061G0402224 JY RST CHIPR 220KOHM +-5% 1/16W YAGEO

R727 061G0402304 JF RST 0402 300K 5% 1/16W FENGHUA

R711 061G0402333 JY RST CHIPR 33KOHM £«-5£¥ 1/16W YAGEO

R433 061G04023901FY RST CHIP 3.9KOHM 1% YAGEO

R432 061G04023901FY RST CHIP 3.9KOHM 1% YAGEO

R431 061G04023901FY RST CHIP 3.9KOHM 1% YAGEO

R133 061G0402394 JY RST CHIP R 390K +/-5% 1/16W YAGEO

R109 061G0402470 JY NO-SUGGEST RST CHIPR 47 OHM 5% 1/16W YAG

R114 061G0402470 JY NO-SUGGEST RST CHIPR 47 OHM 5% 1/16W YAG

R117 061G0402470 JY NO-SUGGEST RST CHIPR 47 OHM 5% 1/16W YAG

75

Page 76

R414 061G04024700FY RST CHIP 470R 1/16W 1%

R110 061G0402471 JY RST CHIPR 470OHM +-5% 1/16W YAGEO

R422 061G0402472 JY RST CHIPR 4.7KOHM +-5% 1/16W YAGEO

R411 061G0402472 JY RST CHIPR 4.7KOHM +-5% 1/16W YAGEO

R410 061G0402472 JY RST CHIPR 4.7KOHM +-5% 1/16W YAGEO

R303 061G0402472 JY RST CHIPR 4.7KOHM +-5% 1/16W YAGEO

R138 061G0402472 JY RST CHIPR 4.7KOHM +-5% 1/16W YAGEO

R137 061G0402472 JY RST CHIPR 4.7KOHM +-5% 1/16W YAGEO

R125 061G0402472 JY RST CHIPR 4.7KOHM +-5% 1/16W YAGEO

R124 061G0402472 JY RST CHIPR 4.7KOHM +-5% 1/16W YAGEO

R713 061G04026801FY RST CHIP 6K8 1/16W 1%

R108 061G0402750 JY NO-SUGGEST RST CHIPR 75OHM +-5% 1/16W YA

R112 061G0402750 JY NO-SUGGEST RST CHIPR 75OHM +-5% 1/16W YA

R116 061G0402750 JY NO-SUGGEST RST CHIPR 75OHM +-5% 1/16W YA

R707 061G0603000 JF RST CHIPR MAX 0R05 1/10W FENGHUA

R102 061G0603000 JF RST CHIPR MAX 0R05 1/10W FENGHUA

FB703 061G0603000 JF RST CHIPR MAX 0R05 1/10W FENGHUA

FB103 061G0603000 JF RST CHIPR MAX 0R05 1/10W FENGHUA

FB102 061G0603000 JF RST CHIPR MAX 0R05 1/10W FENGHUA

FB101 061G0603000 JF RST CHIPR MAX 0R05 1/10W FENGHUA

R404 061G0603221 JF ST CHIPR 220 OHM +-5% 1/10W FENGHUA

R405 061G0603331 JF RST CHIPR 330OHM +-5% 0603

FB401 061G0805000 JF RST CHIPR 0 OHM +-5% 1/8W FENGHUA

R302 061G1206221 JF RST CHIPR 220 OHM +-5% 1/4W FENGHUA

R301 061G1206221 JF RST CHIPR 220 OHM +-5% 1/4W FENGHUA

C107 065G040210232K A CAP 0402 1NF K 50V X7R

C118 065G040210232K A CAP 0402 1NF K 50V X7R

C119 065G040210232K A CAP 0402 1NF K 50V X7R

C714 065G040210232K A CAP 0402 1NF K 50V X7R

C422 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C425 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C427 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C431 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C432 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C433 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C434 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C435 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C437 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C438 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C702 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C705 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C706 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C708 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C709 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C713 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C717 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C720 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C112 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C115 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C120 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C121 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C122 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C124 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C125 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C126 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

76

Page 77

C301 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C419 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C418 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C417 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C407 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C405 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C403 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C402 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C401 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C304 065G040210412K Y CAP CHIP 0402 100N 16V X7R +/-10%

C712 065G040210427Z T NO-SUGGEST 0402 0.1UF 25V Y5V

C719 065G040210427Z T NO-SUGGEST 0402 0.1UF 25V Y5V

C722 065G040215131J Y CHIP 150pF 50V NPO YAGEO

C103 065G040222031J A CAP 0402 22PF J 50V NPO

C104 065G040222031J A CAP 0402 22PF J 50V NPO

C429 065G040222417Z A NO-SUGGEST CAP CHIP 0402 220nF Z 16V Y5V

C303 065G040222417Z A NO-SUGGEST CAP CHIP 0402 220nF Z 16V Y5V

C117 065G040222417Z A NO-SUGGEST CAP CHIP 0402 220nF Z 16V Y5V

C116 065G040222417Z A NO-SUGGEST CAP CHIP 0402 220nF Z 16V Y5V

C428 065G040227031J A CAP 0402 27PF 50V NPO

C426 065G040227031J A CAP 0402 27PF 50V NPO

C114 065G040247312K A 8.31HIP 0402 47nF K 16V X7R

C111 065G040247312K A 8.31HIP 0402 47nF K 16V X7R

C110 065G040247312K A 8.31HIP 0402 47nF K 16V X7R

C108 065G040247312K A 8.31HIP 0402 47nF K 16V X7R

C106 065G040247312K A 8.31HIP 0402 47nF K 16V X7R

C102 065G040247312K A 8.31HIP 0402 47nF K 16V X7R

C105 065G040250931J A CAP 0402 5PF J 50 NPO

C109 065G040250931J A CAP 0402 5PF J 50 NPO

C113 065G040250931J A CAP 0402 5PF J 50 NPO

C715 065G060310232K F CAP CHIP 0603 1NF K 50V X7R

C710 065G060310232K F CAP CHIP 0603 1NF K 50V X7R

C305 065G060310512K A CAP 0603 1UF 10% 16V X7R

C408 065G060310512K A CAP 0603 1UF 10% 16V X7R

C414 065G060310512K A CAP 0603 1UF 10% 16V X7R

C415 065G060310512K A CAP 0603 1UF 10% 16V X7R

C424 065G060310512K A CAP 0603 1UF 10% 16V X7R

C439 065G0805475A2K Y CAP CHIP 0805 4.7UF K 10V X7R

C423 065G0805475A2K Y CAP CHIP 0805 4.7UF K 10V X7R

C421 065G0805475A2K Y CAP CHIP 0805 4.7UF K 10V X7R

C416 065G0805475A2K Y CAP CHIP 0805 4.7UF K 10V X7R

C413 065G0805475A2K Y CAP CHIP 0805 4.7UF K 10V X7R

C406 065G0805475A2K Y CAP CHIP 0805 4.7UF K 10V X7R

C404 065G0805475A2K Y CAP CHIP 0805 4.7UF K 10V X7R

C721 065G120610625K Y CAP CHIP 1206 10uF K 25V X5R

C723 065G120610625K Y CAP CHIP 1206 10uF K 25V X5R

C302 065G120622617Z Y NO-SUGGEST CHIP 1206 22UF Z 16V Y5V