Page 1

SERVICE MANUAL

E

N99111100

E

N

THESE DOCUMENTS ARE FOR REPAIR SERVICE INFORMATION ONLY. EVERY REASONABLE

EFFORT HAS BEEN MADE TO ENSURE THE ACCURACY OF THIS MANUAL; WE CANNOT

GUARANTEE THE ACCURACY OF THIS INFORMATION AFTER THE DATE OF PUBLICATION AND

DISCLAIMS RE LIABILITY FOR CHANGES, ERRORS OR OMISSIONS.

MANUFACTURE DATA: Jul-29-04

0

Page 2

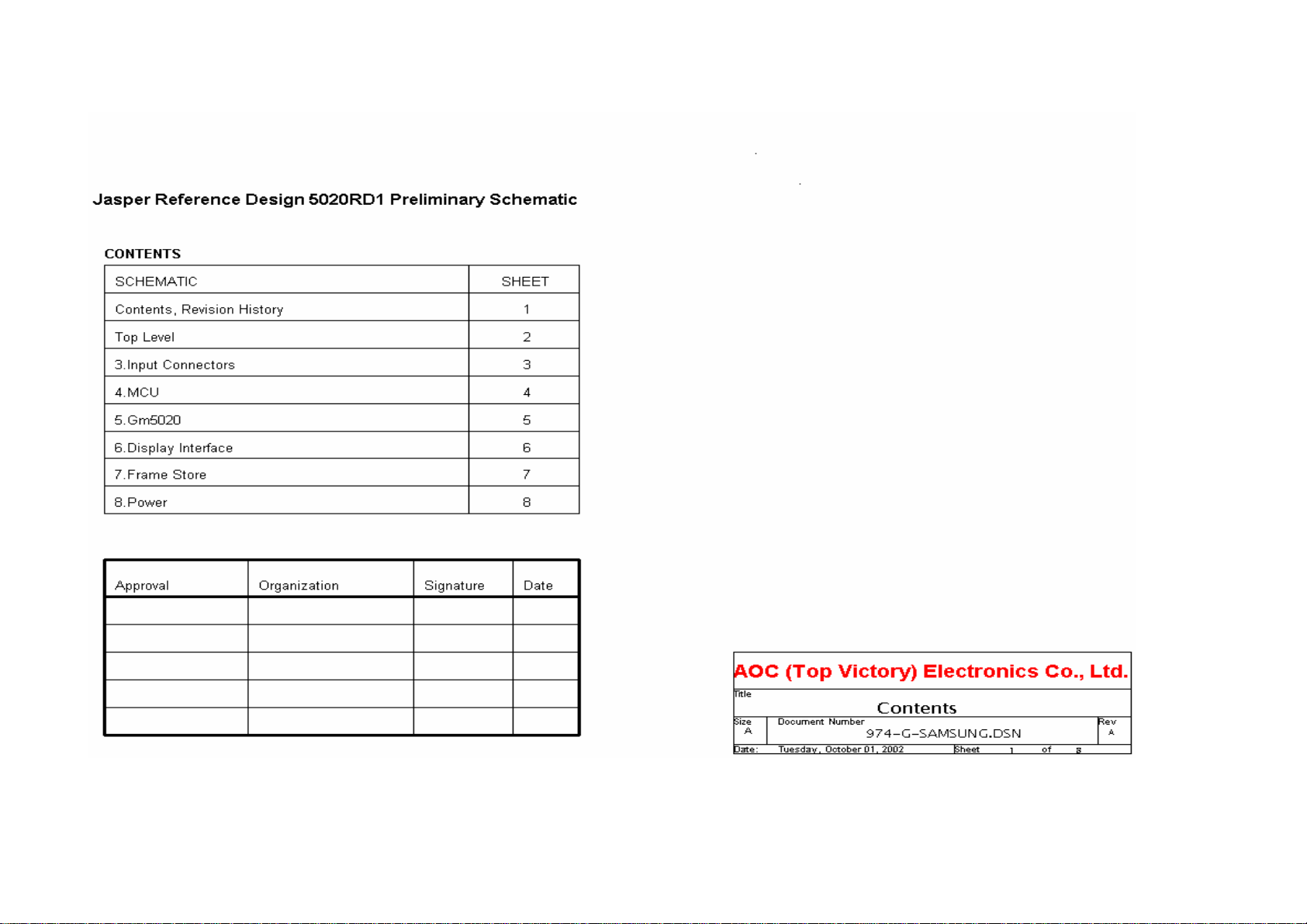

TABLE OF CONTENTS

1. SPECIFICATIONS FOR LCD MONITOR 3

1-1 GENERAL PECIFICATIONS 3

1-2 LCD MONITOR DESCRIPTION 4

1-3 PANEL SPECIFICATION (AU EN02)

1-3-1 PANEL FEATURE

1-3-2 DISPLAY CHARACTERISTICS

1-3-3 OPTICAL CHARACTERISTICS

1-3-4 PARAMETER GUIDE LINE FOR CCFL INVERTER

1-4 FACTORY PRESET TIMING LIST

1-5 INTERFACE CONNECTOR

2. PRECAUTION AND NOTICES 9

2-1 ASSEMBLY PRECAUTION 9

2-2 OPERATIONG PRECAUTION 9

2-3 STORAGE PRECAUTION 9

2-4 HIGH VOLTAGE WARNING 9

3. OPERATING INSTRUCTIONS 10

4. ADJUSTMENT 12

4-1 ADJUSTMENT CONDITIONS AND PRECAUTIONS 12

4-2 ADJUSTMENTS METHOD. & DESCRIPTION

4-2-1 WHITE BALANCE, LUMINANCE ADJUSTMENT

4-2-2 OSD ADJUSTMENT

5. BLOCK DIAGRAM 15

5-1 SPECIAL FUNCTION WITH PRESS KEY 15

5-2 CIRCUIT FUNCTION DESCRIPTION 15

5-2-1 MAIN BOARD

5-2-2 INVERTER/POWER BOARD

5-3 SOFTWARE FLOW CHART

6. MAINTAINABILITY

6-1 EQUITMENT AND TOOLS REQUIRED

6-2 TROUBLE SHOOTING

6-2-1 INTERFACE-BOARD TROUBLE-SHOOTING CHART

6-2-2 INVERTER –MODULE TROUBLE SHOOTING CHART 23

6-2-3 KEYBOARD-MODULE TUOUBLE SHOOTING CHART 25

7. MECHANICAL OF CABINET FRONT DIS-ASSEMBLY 27

8. POWER SYSTEM AND CONSUMPTION CURRENT 28

9. SCHEMATICS 29

9-1 MAINBOARD SCHEMATIC DIAGRAM 29

9-2 Adapter Board SCHEMATICS 37

9-3 Inverter Board SCHEMATICS 38

10. PCB LAYOUT 39

11. EDID CONTENT 40

12.BOM LIST 41

PAGE

5

5

5

6

6

7

8

12

12

13

15

16

16

18

18

18

18

1

Page 3

1. SPECIFICATIONS FOR LCD MONITOR

1-1 GENARAL SPECIFICATION

1. LCD-Panel:

Active display area 19 inch diagonal

Pixel pitch 0.294 mm x 0.294 mm

Pixel format 1280 x 1024 RGB vertical stripe arrangement

2. Display Color:

8-bit, 16.7 million colors

3. External Controls:

Auto Config/Exit, Brightness (up key), contrast (down key), Menu/Enter, Power

indicator, Power button

4. Input Video Signal:

Analog-signal 0.7Vpp

Video signal termination impedance 75 OHM

Digital-input TMDS

5. Scanning Frequencies:

Horizontal: 30 KHz - 92 KHz

Vertical: 55 Hz – 85 Hz

Pixel clock: 158 MHz

6. Factory Preset Timing: 26

Input signal tolerance: H tolerance ± 1 KHz, V tolerance ±3lines from center

frequency

7. Input Power Source:

Switching Mode Power Supply

AC 100 – 240 V, 50/60 Hz Universal Type

8. Operating Temperature: 0°C - 40°C Ambient

Non-operating Temperature: -20°C - 60°C

9. Humidity:

Operating: 15% to 90% RH

Non Operating: 15% to 90%RH

10. Weight: 5.9 kg for monitor only, 8,7kg with packing.

11. External Connection: 15Pin D-type Connector &24 pin DVI-D, AC power-

Cord

12. View Angle: Min.70 H and V

13. Outside dimension: Width x Height x Thickness = 432x 440 x 198 mm

14. Plug and Play: VESA DDC1/DDC2B

15. Power saving: Compatible VESA DPMS

16. Audio performance (optional): Each speaker shall accept up to 3.0 watt of audio

power without damage or exceeding the frequency response and total harmonic

distortion specification and audio amplifier shall provide two channels of audio up to

2.0 watts per channel from 100Hz to 20kHz.

17. USB hub (optional): 1 up-stream and 4 down-streams

2

Page 4

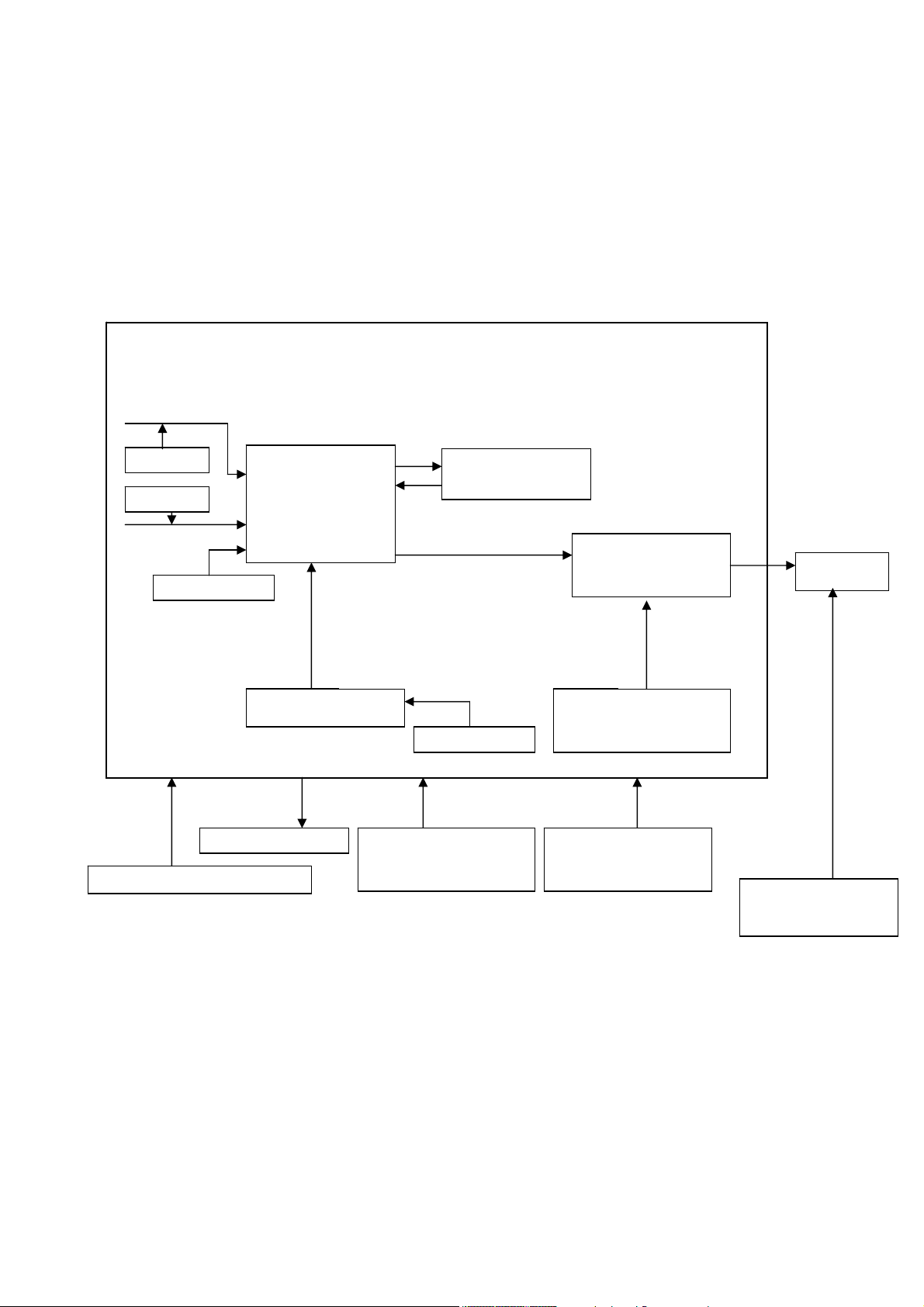

1-2 LCD MONITOR DESCRIPTION

p

Osc

The LCD monitor contains main-board, Inverter module, keyboard, audio module,

USB-hub module and External Adapter.

The main-board controls all logic signals such as panel control logic, backlight

control logic, …etc.

The Inverter module will drive the backlight of panel.

The Adapter supplies power to the LCD monitor.

Analog RGB

DDC-chip

-

DVI input

DC 12V 5Amp

illator 24

-

Gm5020 (U600)

MCU (U502)

Main-board Block diagram

Frame store

Data Digital RGB

Panel Control Signal:

Phs, Pvs, PclkA/B,

Pdis

e

Communication signal:

Hclk, Hfs, Hdata0

Crystal 24 MHz

Audio module

(optional)

LVDS chip

PANEL

Panel Power 5V

Panel-Power Control

(U203)

USB hub module

(optional)

INVERTER

module

3

Page 5

1-3 PANEL SPECIFICATION (AU EN02)

1-3-1 Panel Feature

- 19 inch Color TFT-LCD

- ALL input signals are 2 Channel LVDS interface compatible

- Supported the SXGA(H1280Pixel × V1024Lines) resolution

- By applying 16.7M colors (RGB 8 bit data)

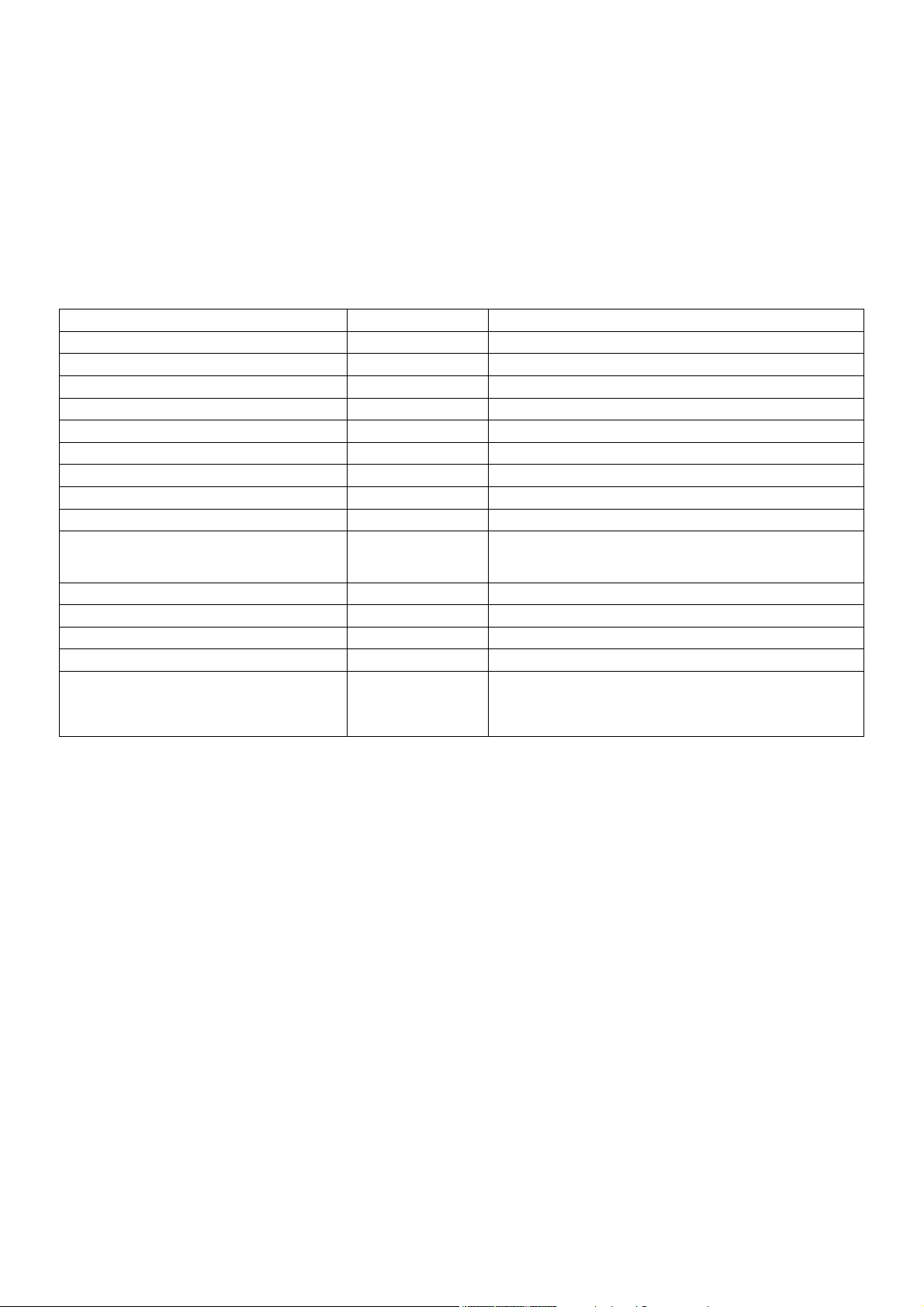

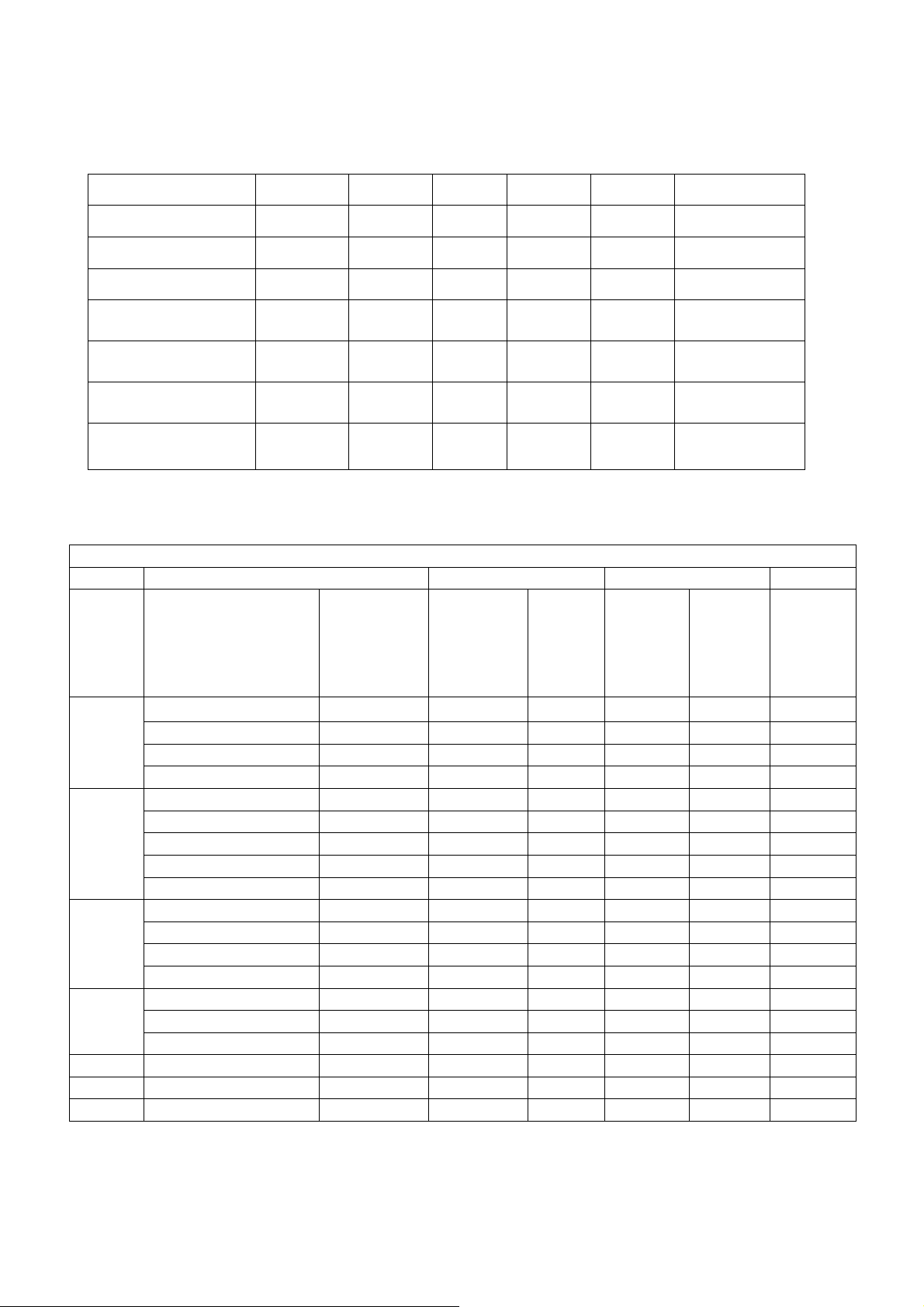

1-3-2 Display Characteristics

ITEM UNIT SPECIFICATIONS

Screen Diagonal [mm] 480(19”)

Active Area [mm] 376.32(H) x 301.056(V)

Pixel Pitch 1280(x3) x 1024

Pixel Arrangement [mm] 0.294(per one triad) x 0.294

Display Mode R.G.B Vertical Stripe

White Luminance (Center) [cd/m²] 250 cd/m²@7mA (Typ)

Contrast Ratio 600:1(Typ)

Optical Response Time [msec] 25(Typ)

Nominal input Voltage VDD [Volt] +5.0V

Power consumption

(VDD line + CCFL line)

[Watt]

28W (Typ.) (w/o Inverter, All white pattern)

Weight [Grams] 2700(Typ)

Physical Size [mm] 404.2(W) x330 (H) x20 (D)(Typ)

Electrical Interface Even/Odd R/G/B data, 3 sync signal Clock

Support Color 16.7M colors (RGB 8-bit data)

Temperature Range

Operating

Storage (Shopping)

[℃]

[℃]

0 to +50

-20 to +60

4

Page 6

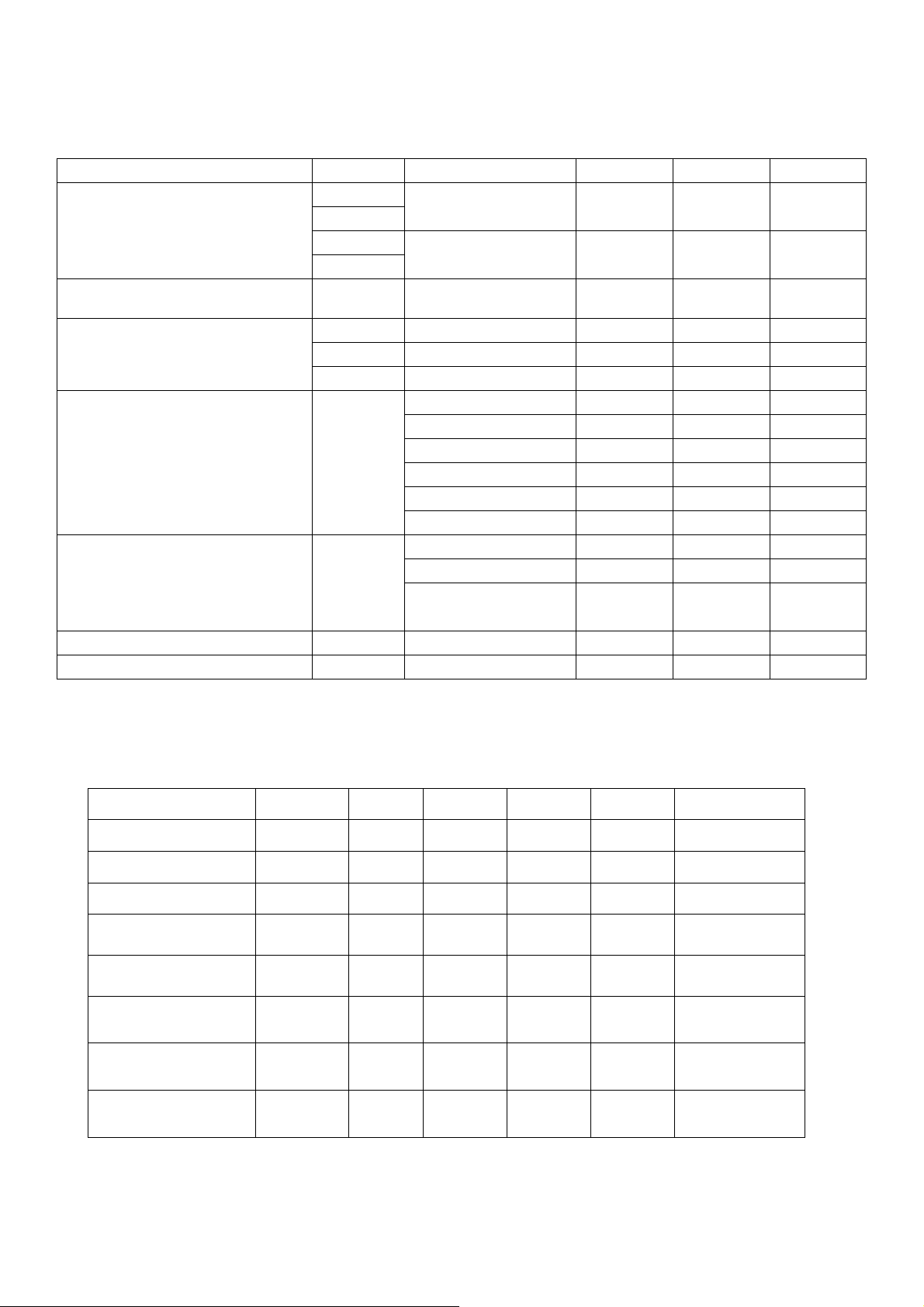

1-3-3 Optical Characteristics

The optical characteristics are measured under stable conditions at 25℃ (Room

Temperature):

ITEM UNIT CONDITIONS MIN TYP. MAX.

Viewing Angle

Contrast ratio Normal Direction 400 600

Response Time (Note 1)

Color Coordinates (CIE) White

White Luminance at CCFL

7.0mA

(central point)

[degree]

[degree]

[degree]

[degree]

[m sec] Raising Time – 15 25

[m sec] Falling Time – 10 15

[m sec] Raising +Falling – 25 40

[cd/㎡]

Horizontal (Right)

CR=10(Left)

Vertical (Up)

CR=10(Down)

Red x 0.604 0.634 0.664

Red y 0.324 0.354 0.384

Green x 0.278 0.308 0.338

Green y 0.576 0.606 0.636

Blue x 0.108 0.138 0.168

Blue y 0.057 0.087 0.117

White x 0.28 0.31 0.34

White y 0.3 0.33 0.36

200 250 –

75

75

85

85

85

85

–

–

–

–

Luminance Uniformity (Note 2) [%] 75 80 –

Crosstalk (in 75Hz)(Note 3) [%] 1.5

1-3-4 Parameter guide line for CCFL Inverter

INVERTER MAX BRINGTHNESS (Vadj: 3.0v), LOAD=100KΩX4(ROOM

TEMPERATURE 25℃ ±4℃)

ITEM SYMBOL MIN. TYP. MAX. UNIT REMARK

Input voltage Vin 10.8 12 13.2 V

Input current Iin --- 1950 2200 mA FOR 4 LOAD

Output Current Iout 6.0 7.0 8.0 mA FOR 1 LOAD

Frequency

H.V open Vopen 1550 1700 1850 Vrms NO LOAD

H.V Load Vload 620 670 720 Vrms RL=100KΩ

Start voltage Vst

F 45.0 50.0 55.0 KHZ

1870 1970 2070 Vrms RL=CCFL

FOR 1 LOAD

Protect delay time PDT

1 1.5 3 Sec

5

Page 7

INVERTER MIN BRINGTHNESS (Vadj:0.0v), LOAD=100KΩX4(ROOM

TEMPERATURE 25℃ ±4℃)

ITEM SYMBOL MIN. TYP. MAX. UNIT REMARK

input voltage Vin 10.8 12 13.2 V

input current Iin 470 520 mA FOR 4 LOAD

Output Current Iout 2.5 3.0 3.5 mA FOR 1 LOAD

Frequency

F 45.0 50.0 55.0 KHZ

FOR 1 LOAD

H.V open Vopen 1550 1700 1850 Vrms NO LOAD

Start voltage Vst

1650 1970 2050 Vrms RL=CCFL

H.V Load Vload 270 320 370 Vrms RL=100KΩ

1-4 FACTORY PRESET TIMING LIST

VESA MODES

Horizontal Vertical

Nominal

Frequenc

Mode Resolution Total

y

+/-

0.5kHz

640x480@60Hz 800 x 525 31.469 N/P 59.940 N/P 25.175

VGA

640x480@72Hz 832 x 520 37.861 N/P 72.809 N/P 31.500

640x480@75Hz 840 x 500 37.500 N/P 75.00 N/P 31.500

640x480@85Hz 832 x 509 43.269 N/P 85.008 N/P 36.000

800x600@56Hz 1024 x 625 35.156 N/P 56.250 N/P 36.000

800x600@60Hz 1056 x 628 37.879 N/P 60.317 N/P 40.000

SVGA

800x600@72Hz 1040 x 666 48.077 N/P 72.188 N/P 50.000

800x600@75Hz 1056x 625 46.875 N/P 75.000 N/P 49.500

800x600@85Hz 1048x631 53.674 N/P 85.061 N/P 56.250

1024x768@60Hz 1344x806 48.363 N/P 60.004 N/P 65.000

XGA

1024x768@70Hz 1328x806 56.476 N/P 70.069 N/P 75.000

1024x768@75Hz 1312x800 60.023 N/P 75.029 N/P 78.750

1024x768@85Hz 1376x808 68.677 N/P 84.997 N/P 94.500

1280x1024@60Hz 1688x1066 63.981 N/P 60.020 N/P 108.000

SXGA

1280x1024@75Hz 1688x1066 79.976 N/P 75.025 N/P 135.000

1280x1024@85Hz 1728x1072 91.146 N/P 85.024 N/P 157.500

1152x 864@75Hz 1600x900 67.500 N/P 75.000 N/P 108.000

1280x960@60Hz 1800x1000 60.000 N/P 60.000 N/P 108.000

1280x960@85Hz 1728x1011 85.938 N/P 85.002 N/P 148.500

Notice: For digital input, the resolution 1280x1024@ 85hz, 1280x960@ 85Hz are not

supported.

Sync

Polarit

y

Nomina

l

Freq.

+/- 1 Hz

Sync

Polarity

Nominal

Pixel

Clock

(MHz)

6

Page 8

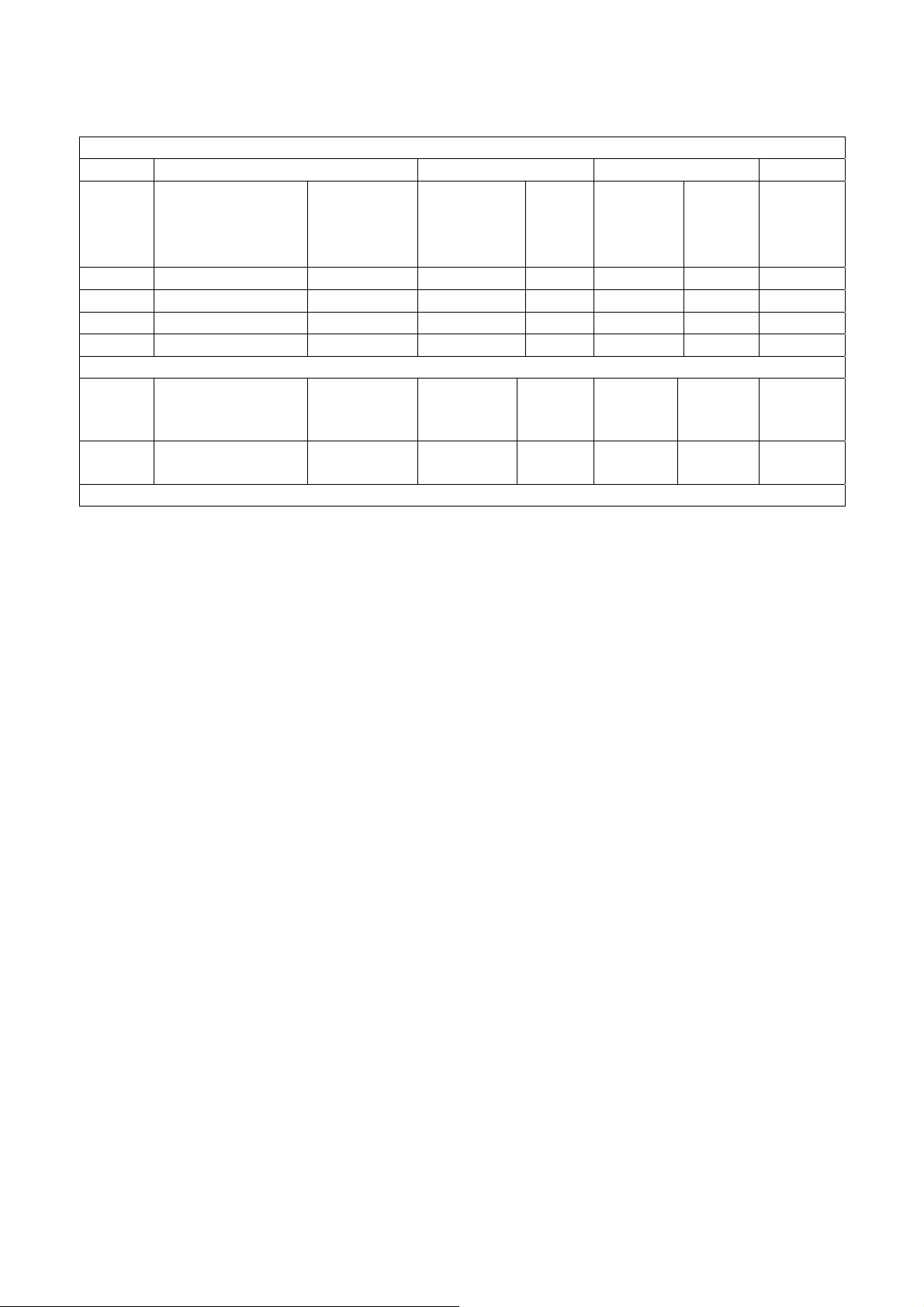

IBM MODES

Horizontal Vertical

Nominal

Pixel

Clock

(MHz)

Mode Resolution Total

Nominal

Frequency

+/- 0.5kHz

Sync

Polari

ty

Nominal

Freq.

+/- 1 Hz

Sync

Polarit

y

DOS 720x400@70Hz 900 x 449 31.469 N 70.087 P 28.322

720x400@85Hz 936 x 446 37.927 N 85.039 P 35.550

DOS 640x400@70Hz 800 x 449 31.469 N 70.087 P 25.175

DOS 640x350@70Hz 800 x 449 31.469 P 70.087 N 25.175

MAC MODES

VGA

640x480@67Hz 864x525 35.000 N/P 66.667 N/P 30.240

SVGA

832x624@75Hz 1152x667 49.725 N/P 74.551 N/P 57.283

All modes will automatically optimize the screen size with “ AUTO-config “ function, except

3 dos- modes: 640x480@60hz, 720 x 400@70hz, 640x350@70hz.

1-5 INTERFACE CONNECTION

(A) AC-Power Cable

(B) Video Signal Connectors and Cable

(C) DVI-D and DVI cable

(D) Audio cable (optional)

(E) USB cable (optional)

(F) External Adapter

7

Page 9

2. PRECAUTIONS AND NOTICES

2-1 ASSEMBLY PRECAUTION

(1) Please do not press or scratch LCD panel surface with anything hard. And do not

soil LCD panel surface by touching with bare hands (Polarizer film, surface of

LCD panel is easy to be flawed)

In the LCD panel, the gap between two glass plates is kept perfectly even to

maintain display characteristic and reliability. If this panel is subject to hard

pressing, the following occurs:

(a) Uniform color

(b) Orientation of liquid crystal becomes disorder

(2) Please wipe out LCD panel surface with absorbent cotton or soft cloth in case of

it being soiled.

(3) Please wipe out drops of adhesive like saliva and water in LCD panel surface

immediately.

They might damage to cause panel surface variation and color change.

(4) Do not apply any strong mechanical shock to the LCD panel.

2-2 OPERATING PRECAUTIONS

(1) Please be sure to unplug the power cord before remove the back-cover. (Be sure

the power is turn-off)

(2) Please consider that LCD backlight takes longer time to become stable of

radiation characteristic in low temperature than in room temperature.

(3) Please pay attention not to displaying the same pattern for very long-time. For

image might stick on LCD.

2-3 STORAGE PRECAUTIONS

(1) When you store LCD for a long time, it is recommended to keep the temperature

between 5℃-40℃ without the exposure of sunlight and to keep the humidity less

than 85% RH.

(2) Please do not leave the LCD in the environment of high humidity and high

temperature such as 60℃ 90%RH.

(3) Please do not leave the LCD in the environment of low temperature; below -15℃.

2-4 HIGH VOLTAGE WARNING

The high voltage is only generated by INVERTER module; carelessly contacting the

transformer on this module can cause a serious shock. (The lamp voltage after

stable around 600V, with lamp current around 6.5mA, and the lamp starting voltage

was around 1650V, at Ta=25℃)

8

Page 10

3. OPERATING INSTRUCTIONS

This procedure gives you instructions for installing and using the LCD monitor

display.

1. Position the display on the desired operation and plug–in the power cord into

External Adapter AC outlet. Three-wire power cord must be shielded and is

provided as a safety precaution as it connects the chassis and cabinet to the

electrical conduct ground. If the AC outlet in your location does not have

provisions for the grounded type plug, the installer should attach the proper

adapter to ensure a safe ground potential.

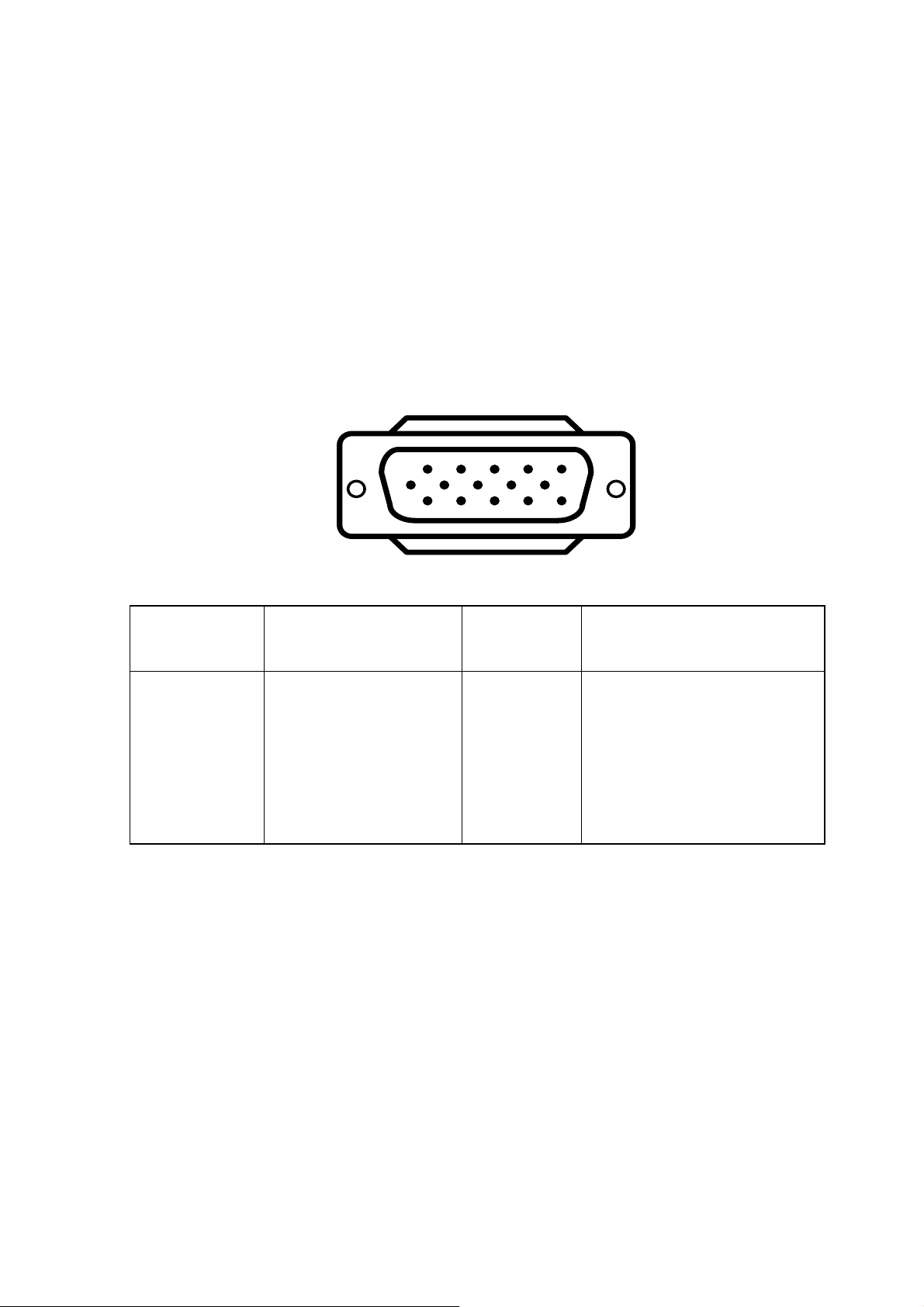

2. Connect the 15-pin color display shielded signal cable to your signal system

device and lock both screws on the connector to ensure firm grounding. The

connector information is as follow:

15 - Pin Color Display Signal Cable

PIN NO.

DESCRIPTION

1. RED 9. 5V power from VGA-card

2. GREEN 10. Detect Cable

3. BLUE 11. SYNC. GND

4. GND 12. DDC-Serial Data

5. GND 13. HORIZ. SYNC

6. GND-R 14. VERT. SYNC

7. GND-G 15. DDC Serial Data

8. GND-B

1

6

11 15

PIN NO.

5

10

DESCRIPTION

9

Page 11

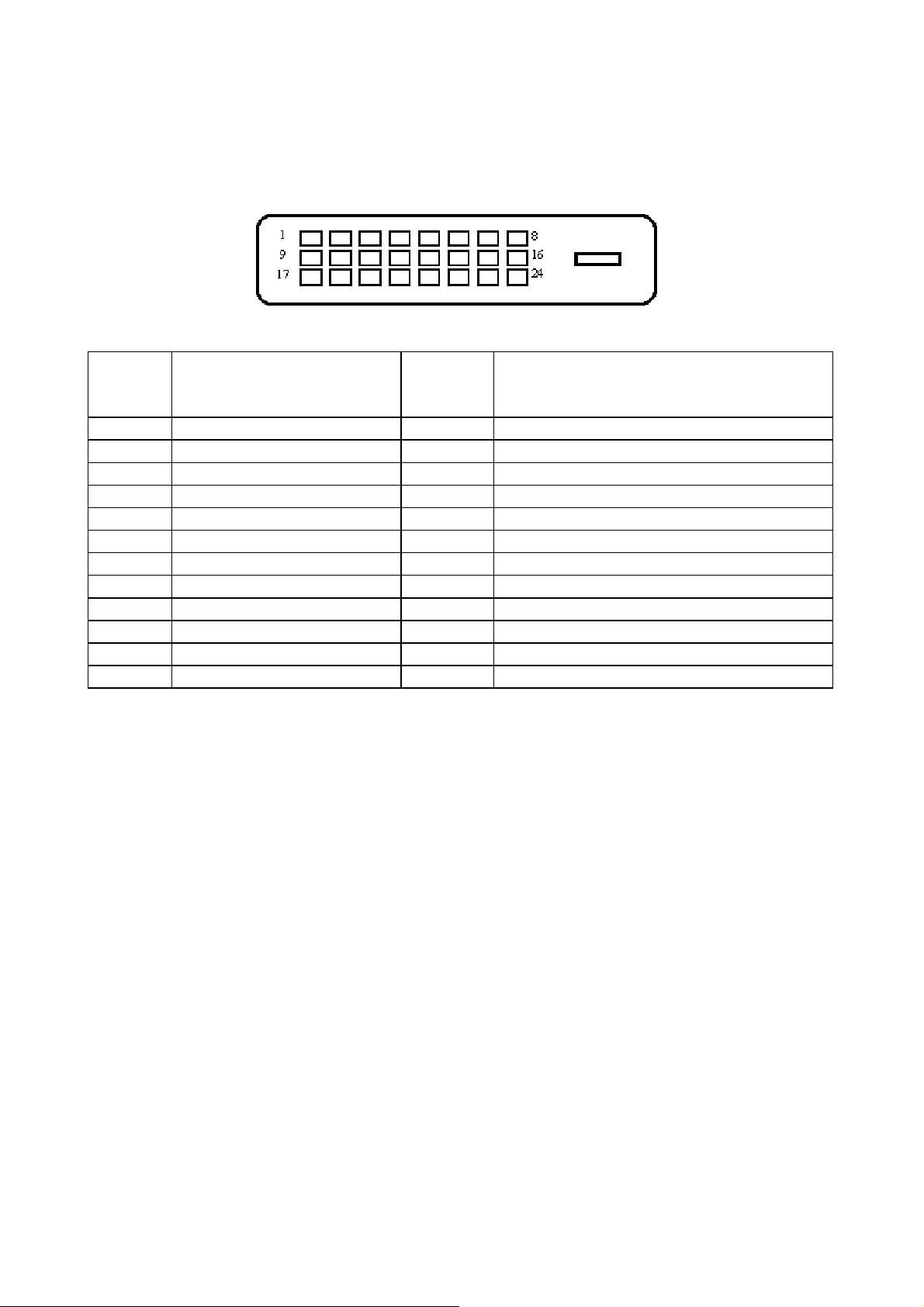

3. Connect the 24-pin color display shielded DVI-DVI signal cable to your signal

system device and lock both screws on the connector to ensure firm grounding.

The connector information is as follow:

15 - Pin Color Display Signal Cable

PIN NO.

DESCRIPTION

PI N NO.

DESCRIPTION

1. TMDS Data 2- 13. TMDS Data 3+

2. TMDS Data 2+ 14. +5V Power

3. TMDS Data 2/4 Shield 15. Ground (for+5V)

4. TMDS Data 4- 16. Hot Plug Detect

5. TMDS Data 4+ 17. TMDS Data 0-

6. DDC Clock 18. TMDS Data 0+

7. DDC Data 19. TMDS Data 0/5 Shield

8. N.C. 20. TMDS Data 5-

9. TMDS Data 1- 21. TMDS Data 5+

10. TMDS Data 1+ 22. TMDS Clock Shield

11. TMDS Data 1/3 Shield 23. TMDS Clock +

12. TMDS Data 3- 24. TMDS Clock -

4. Apply power to the display by pressing the power key for about 2 second

consecutively and allow about several seconds for Panel warm-up. The PowerOn indicator lights up when the display is on.

5. With proper signals feed to the display, a pattern or data should appear on the

screen, adjust the brightness and contrast to the most pleasing display, or press

auto-key to get the factory preset best picture-quality.

6. This monitor has power saving function following the VESA DPMS. Be sure to

connect the signal cable to the PC.

7. If your LCD monitor requires service, it must be returned with the power cord &

Adapter.

10

Page 12

4. ADJUSTMENT

4-1 ADJUSTMENT CONDITIONS AND PRECAUTIONS

Adjustments should be undertaken only on following function: Contras, Brightness,

Black level, Phase, Clock, H/V-position, Languages, Color- (C2, C1, User), Auto level, ,

Languages, Reset, RGB level, input selected, scaling mode

- Power Button:

When pressed, the monitor enters the off mode, and the LED turns blank. Press again

to restore normal status.

- Left / Right Button:

The Left/Right Button is used to control the monitor functions. Press to switch

functions or adjust settings.

- Auto Adjust Key:

The Auto Adjust Key is used to automatically set the H Position, V Position, Clock and

Phase.

- Power Indicator:

Green — Power On mode.

orange — Power Saving mode.

Blank —Power Off Mode.

4-2 ADJUSTMENT METHOD AND DESCRIPTION

4-2-1 White-Balance, Luminance adjustment

Approximately 30 minutes should be allowed for warm up before proceeding white

balance adjustment.

Before start adjusting white balance, please set Chroma-7120 MEM. Channel 1 to C2

color and MEM. channel 2 to C1 color, (our C2 parameter is x = 296 ±20, y = 311 ±20,

Y = 220 and C1 parameter is x = 313 ±20, y = 329 ±20, Y = 220)

How to setting MEM. channel you can reference to chroma 7120 user guide or simple

use “ SC” key and “ NEXT” key to modify x,y,Y value and use “ID” key to modify the

TEXT description

Following is the procedure to do white-balance adjustment:

Press MENU button during 1 seconds along with plug in the DC-power cord will

activate the factory mode, and the OSD screen will located at left top of the panel.

Alignment Procedure

1.) Pattern generator Output: Timing 1280x1024@60hz, Pattern 32 Gray Scale, Analog.

2.) Connect Alignment Tool JP2 with Chroma 7120, JP3 with Monitor Analog

Connector, JP4 with Pattern Generator.

3.) Press Menu and Select Button, then Power on Monitor to enter Factor Mode.

4.) Press [SW1] at Alignment Tool.

5.) Change Pattern Generator Pattern to Full White Pattern.

6.) Press [SW2] at Alignment Tool.

7.) Wait LED from OK -> BUSY -> OK.

8.) Press [SW3] once to verify 7800 color temperature.

9.) Press [SW3] once to verify 6500 color temperature.

10.) If there is error at step 7 to 8, repeat step 4 to 9.

4-2-2 OSD adjustments

11

Page 13

Turn the POWER-button off to on to quit from factory mode (in USER-mode, the

OSD window location was placed at the middle of the screen) Press MENU

button to activate OSD Menu or make a confirmation on desired function, Press

Left/Right button to select the function or done the adjustment.

1. Clock adjustment

Set the Chroma at pattern 63 (cross-talk pattern) or WIN98/95 shutdown mode

(dot-pattern).

Adjust until the vertical-Stripe-shadow as wide as possible or no visible.

This function is adjust the PLL divider of ADC to generate an accurate pixel clock

Example: Hsyn = 31.5KHz Pixel freq. = 25.175MHz (from VESA spec)

The Divider number is (N) = (Pixel freq. x 1000)/Hsyn

From this formula, we get the Divider number, if we fill this number in ADC

register (divider register), the PLL of ADC will generate a clock which have same

period with above Pixel freq. (25.175MHz) the accuracy of this clock will effect the

size of screen. (This clock was called PIXEL-CLOCK)

2. Focus adjustment

Set the Chroma at pattern 63 (cross talk pattern) or WIN98/95 shut down mode

(dot-pattern).

Adjust the horizontal interference as less as possible

This function is adjusting the phase shift of PIXEL-CLOCK to acquire the right

pixel data.

If the relationship of pixel data and pixel clock not so match, we will see the

horizontal interference on screen, we only find this phenomena in crosstalk

pattern or dot pattern, other pattern the affect is very light

3. H/V-Position adjustment

Set the Chroma to pattern 1 (crosshatch pattern) or WIN98/95 full-white pattern

confirm above item 2 & 3 functions (clock & focus) was done well, if that 2

functions failed, the H/V position will be failed too. Adjust the four edges until all

four-edges are visible at the edge of screen.

4. Language function

There have 5 languages for selection, presses “MENU” to select and confirm,

press “UP” or “ DOWN” to change the kind of language (English, Deutch,

Francais, Espanol, Italian)

5. Reset function

Clear each old status of auto-configuration and re-do auto-configuration (for all

mode)

This function also recalls C2 color-temperature.

The descriptions for function control LEDS is as following list

12

Page 14

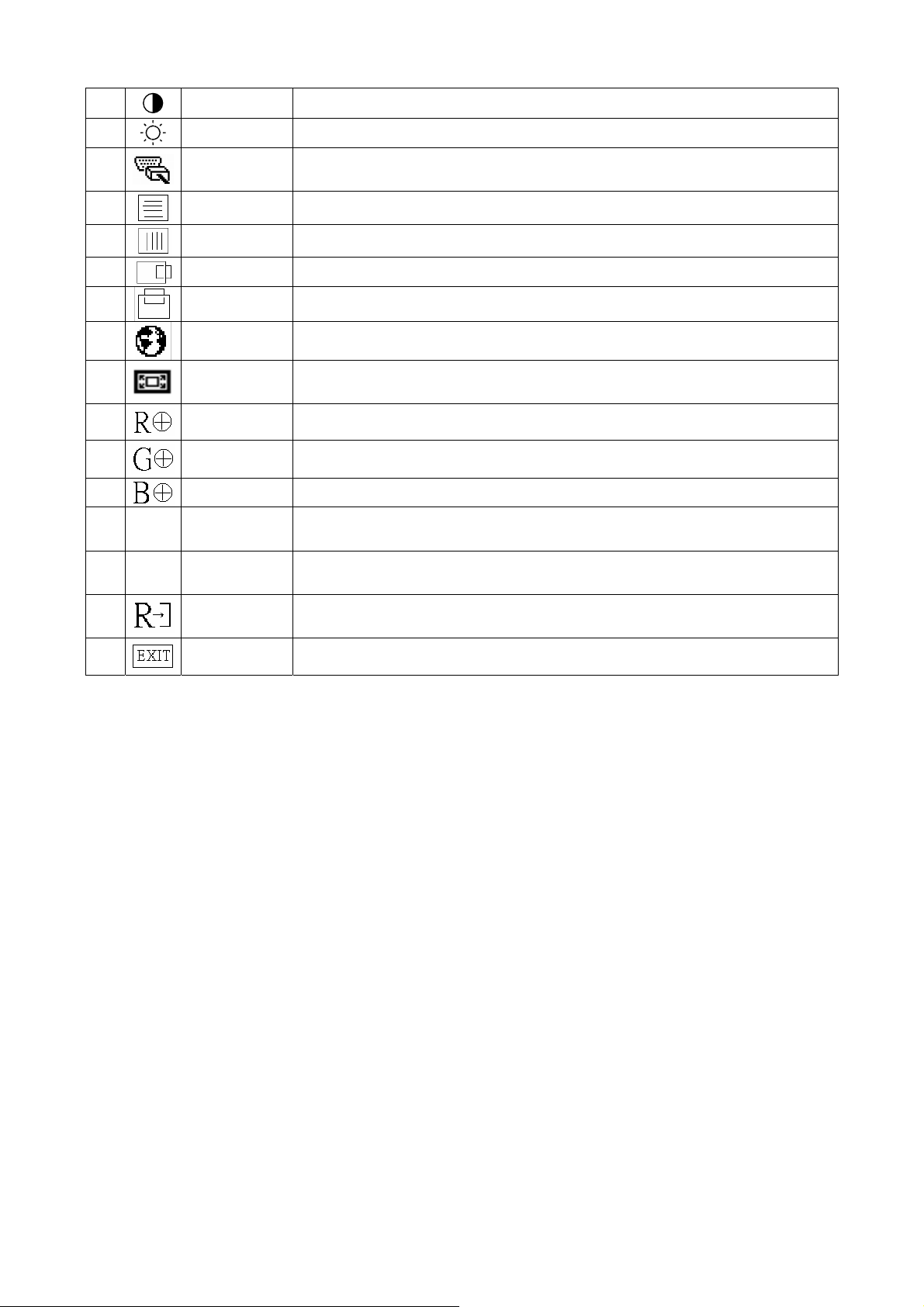

1.

2.

3.

Contrast Adjust the picture contrast.

Brightness Adjust the picture brightness.

Input

Selected

Input Signal source selected (select Analog or Digital input

source)

4.

5.

6.

7.

8.

9.

10.

11.

12.

13 C1

15. C2

16.

17.

Focus Adjust picture Focus.

Clock Adjust picture Clock.

H- Position Adjust the horizontal position of the picture.

V- Position Adjust the vertical position of the picture.

Language Multi-Language selection

Scaling

Mode

Red Adjusts Red intensity.

Green Adjusts Green intensity.

Blue Adjusts Blue intensity.

(6500K)

Color

(7800K)

Color

Reset

Exit Save user adjustment and OSD disappear.

Stretch the picture to fit full screen, screen size ratio or native

size.

The color temperature for 6500°K is x=0.313, y=0.329.

The color temperature for 7800°K is x=0.296, y=0.311.

Clear each old status of Auto-configuration and re-do auto-

configuration and set the color temperature to 7800°K.

13

Page 15

555 55 BLOCK DIAGRAM

6655-1 SPECIAL FUNCTION WITH PRESS-KEY

Press menu button during 2 seconds along with plug-in the DC Power cord:

That operation will set the monitor into “Factory- mode”, in Factory mode we can

do the White balance adjustment with RS232 .In Factory mode, OSD-screen will

locate in left top of screen. Press POWER-button off to on once will quit from

factory mode and back touser-mode. The OSD-index explanation is as following:

1. No signal: No signal input (Signal-cable not connected).

2. Input not supported:

a. Input frequency out of range: H > 92kHz, v > 85Hz or H < 31kHz, v < 55Hz

b. Input frequency out of VESA-spec. (Out of tolerance too far)

5-2 CIRCUIT FUNCTION DESCRIPTION

5-2-1 main board

1. U600, scaler IC gm5020 (all-in-one chip solution for ADC, OSD, scalar and

interpolation):

USE for computer graphics images to convert analog RGB data to digital data with

interpolation process, zooming, generated the OSD font, perform overlay function

and generate drive timing for LCD-PANEL.

2. U502, W78E65 (WINBOND- MCU, type 8052 series with 64k Rom-size and 512

byte ram):

Use for calculate frequency, pixel-dot, detect change mode, rs232-communication,

power-consumption control, OSD-index warning, …etc.

3. U301,ATMEL12524C02N

EEPROM type, 1K ROM-SIZE, for saving Digital DDC-CONTENT.

4. U302, MIRCOCHIP24LC21A

EEPROM type, 1K ROM-SIZE, for saving Analog DDC-CONTENT.

4. U501, 24C16 (ATMEL IC):

EEPROM type, 16K ROM-SIZE, for saving AUTO-config data, White-balance data,

and Power-key status and Backlight-counter data.

5. U901,SI8050(switching regulator 12V to 5V with 3A load current) .

6. U904,AIC 1084-33CM (AIC brand linear regulator 5V to 3.3V)

7. U902,RT9164(Linear regulator 5V to 2.5V)

8. U201,U202,LVDS ( use NOVATEK NT7181F)

Convert the TTL signal to LVDS signal , the advantage of LVDS signal is : the

wire can be lengthen and eliminate wire number , low EMI .LVDS signal is high

frequency but low voltage, only 0.35 VPP ,the frequency is seven times higher than

TTL

14

Page 16

5-2-2 adapter/inverter

1. ADAPTER: CONVERSION-module to convert AC 110V-240V to 12VDC, with 5

AMP

2. INVERTER: CONVERSION-module to convert DC 12V to High-Voltage around

1650V, with frequency 30K-80Khz, 5mA-13mA

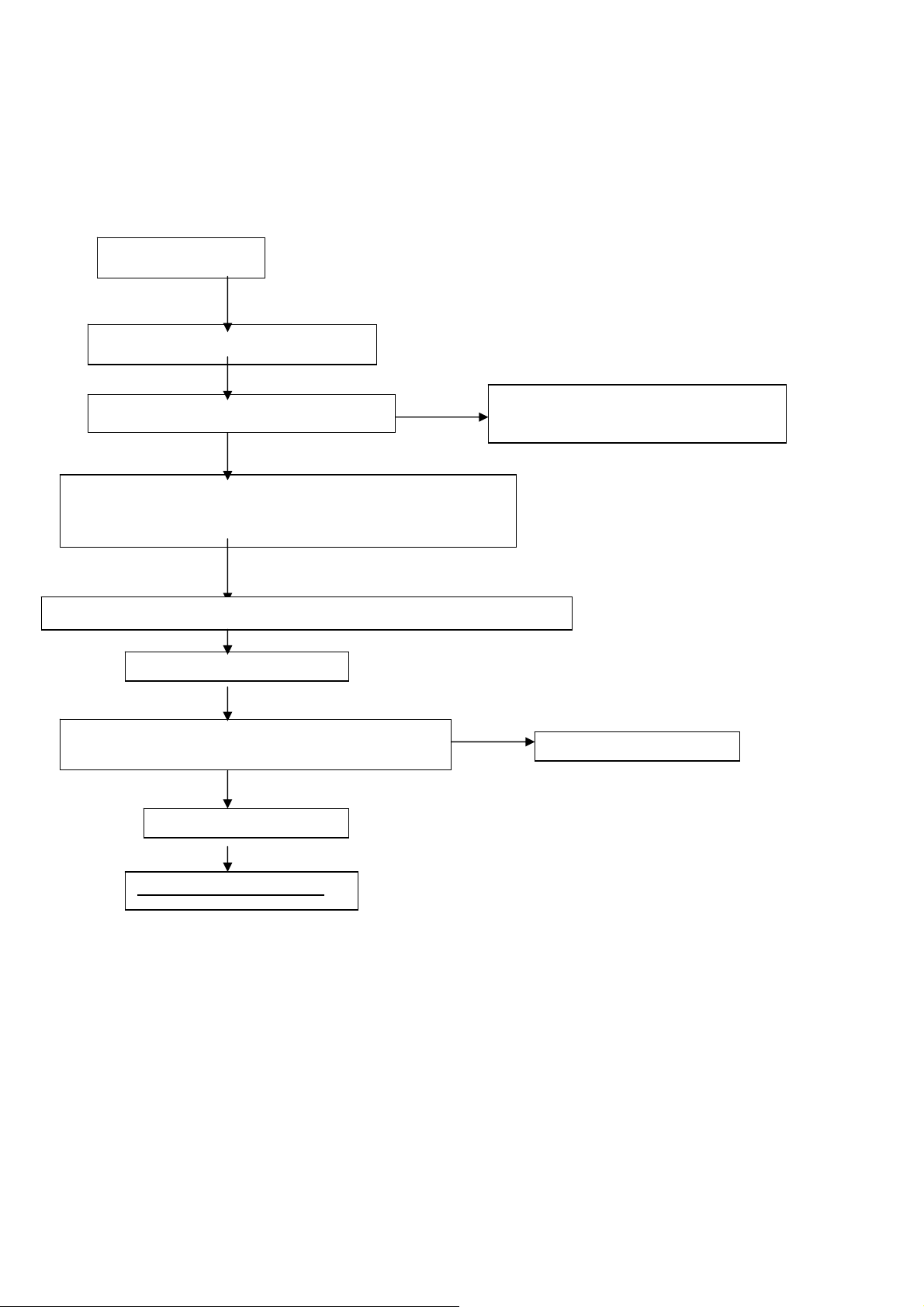

5-3 SOFTWARE FLOW CHART

POWER-ON START

Initial MCU I/O, Interrupt vector & Ram

Check Eeprom is empty?

Check White-balance data (C1 & C2) same with the backup data?

Check POC (backlight counter) data same with the backup data?

IF not same, overwrite the data with backup value.

Check Previous power-switch status from Eeprom, & other system status

Initial gm5020

Check if in Factory mode? (When power-on, press the

MENU Button will be in FACTORY mode)

Clear factory mode flag

MAIN-SUBROTINE LOOP

Initial 1.POC (backlight counter)

2. Clr all mode value

SET factory mode flag

15

Page 17

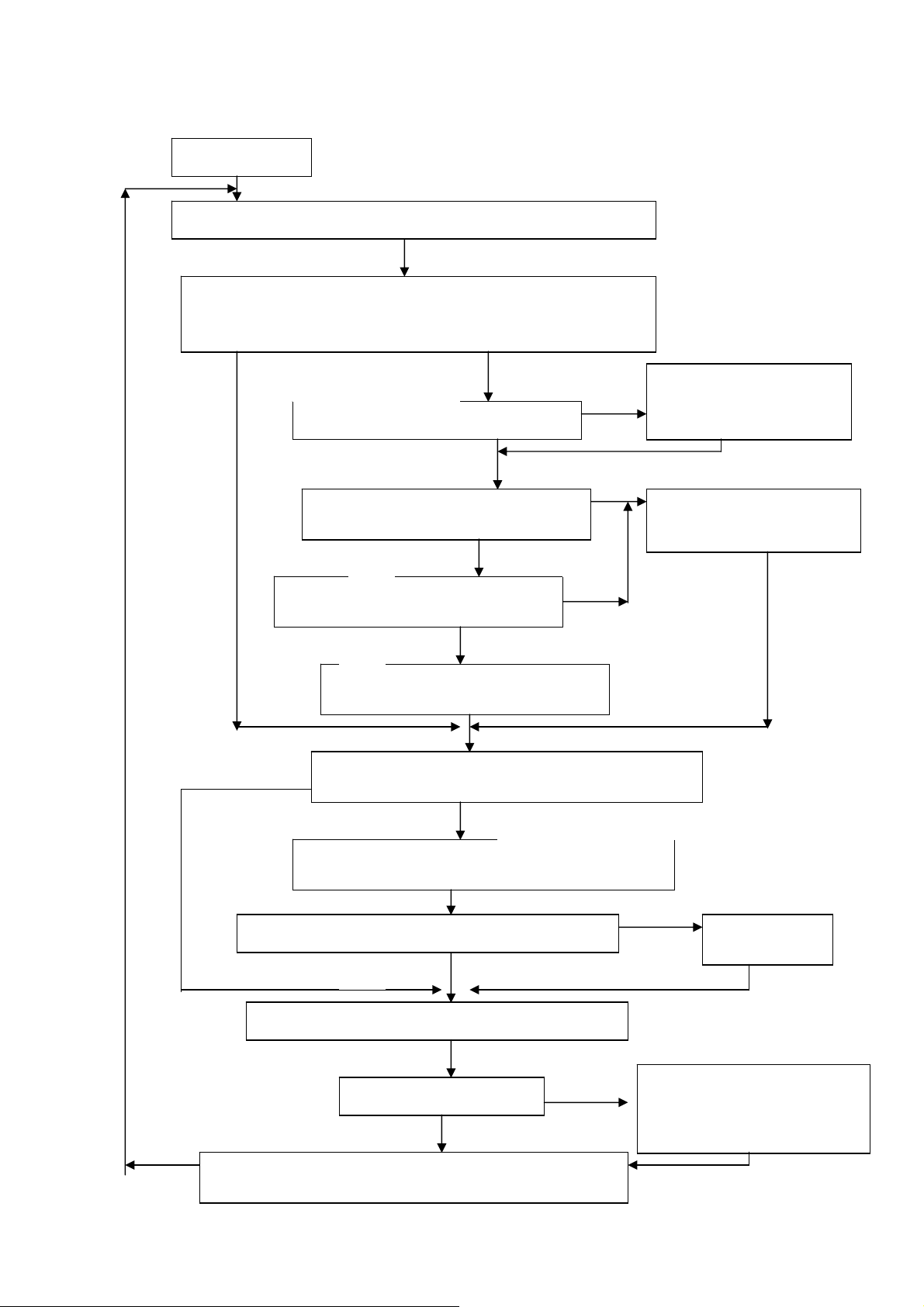

Main subroutine loop

Main loop start

Process Power-saving status (according to below flow-chart result)

Check gm5020 IFM status .is change or not.

And check Signal cable status (cable not connected or not)

** IFM is the register, which measured the HSYN & Vsyn status

Check the IFM result is in the user mode

table?

Check Auto-config mode flag already been set?

Read Key status and Process on OSD-screen

Monitoring the time-out of osd status (if no key input persist for

10 sec, the osd time-out counter will trigger)

)

Yes, IFM have change

Is current system status in Power-saving?

Check the IFM result is in the standard

Mode table?

Out of range (input not support) be

confirm

Confirm the frequency (Hsyn or Vsyn) from IFM already

been changed? (Check the change mode flag)

Process (turn off OSD, setting GM5020according to

above parameter, set LED status, set backlight status)

Check Factory mode flag= 1

Wake-up gm5020

(Because gm5020 was in

partial sleeping state)

Set mode index & parameter

Set change mode flag

Do Auto-config

automatically

If the RS232 buffer is full,

process the command (while

adjust white-balance in factory

mode)

16

Page 18

6.MAINTAINABLITY

6-1. EQUITMENTS AND TOOLS REQUIRED

1.) Voltmeter.

2.) Oscilloscope.

3) Pattern Generator.

4) DDC Tool with a personal computer

5) Alignment Tool.

6) LCD Color Analyzer.

7) Service Manual.

8)User Manual.

6-2 TROUBLE SHOOTING

6-2-1 interface board trouble shooting chart

*Use the PC Win 98 white pattern, with some icon on it, and Change the Resolution to

640x480 60 Hz / 31 KHz

**NOTICE: The free-running freq. of our system is 48 KHz / 60 Hz, so we recommend to

use another resolution to do trouble shooting, this trouble shooting is proceed with

640x480 @60Hz 31Khz

17

Page 19

g

k

K

,

K

,

I. No screen appear

No

Measured Input DC-voltage (J1)= 12 V?

Measured U901 SI-8050 pin4=5V?

Measured U904 AIC 1084 pin 2 = 3.3V?

Measured U903 AIC1117 pin 2= 3.3V?

Measured U902 RT9164 pin 2=2.5v

Measured U905 AIC 1084 pin2=2.5V

DC-Power Part

Check Correspondent component.

Is there any shortage or cold solder?

Disconnected the Signal cable (Loose the

Signal cable), Is the screen show “No

”

No, nothing is show

Connected the Signal cable again,

Check LED status.

Check the Wire-Harness from CN201

Was tight enough?

Check the Wire connection to panel side too

Led Green

Yes, all DC level exist

Led Orange

OK, Keyboard no stuc

Connected the Signal cable again,

Check LED status.

Check Power switch is in Power-on

status, and check if Power switch had

been stuck?

Led orange

Measured RGB (r302, r304, r306) H, V Input at

nal input pin13, 15 was there signal?

si

NG

O

OK, Wire tight

Check Panel-Power Circuit Block

input

Measured Oscillator Block

Crystal X501

Check U600 Data-output Block

OK, Panel Power OK

O

clock

Check communication pin between U600 &

MCU pin 2,6,7. , Is it have transition?

OK, U600 data OK

OK, Mcu have transition

NG, no transition

Replace Inverter and Check

Inverter control relative circuit

Re-do White balance adjust

Replace U600 (Gm5020)

Replace U502 (MCU)

& Check Reset pin 10

Must be change from High to

low when first AC power plugin

OK

OK

Note: 1. If Replace “Main board”, Please re-do“DDC-content”programmed & “White-balance”.

2. If Replace “ Inverter” only, Please re-do “ White-Balance”

Led Green

Replace MCU

Check Correspondent

component short/open

(Protection Diode)

and Signal cable bad?

18

Page 20

PANEL-POWER CIRCUIT

p

OK, & Re

Check U

Check R202 should have response from 0V to 5V

When we switch the power switch from off to on

Measured the U203 pin 5,6,7,8= 5 V?

OK

INVERTER Control Relative Circuit

Measured the inverter connector CN502

Pin 1,2=12V, pin 3 on/off control=5V (on)

Replace INVERTER to new-one, and

Check the screen is normal??

OSCILLATOR BLOCK

Measured X501 Oscillator output 24MhZ?

Measured X600 Crystal output 24 KHz?

OK, R202 have

-do white

OK

NG, no Voltage

U600-DATA OUTPUT

Measured DCLK, DHS, DVS, DEN (pin G20,

F20, F19, F18 from U600)

Is there have any transition?

Pclk around 47MHz to 57MHZ, PVS=60.09Hz,

PHS around 67 KHz?? (Refer to input

signal=640x480@60 Hz 31k, and LED is green)

OK

Check the PPWR panel power relative circuit,

R201, R202, Q201, U203 (pin 5,6,7,8)

In normal operation, when LED =green, R223

Should =0 v,

If PPWR no-response when the power switch

Turn on and turn off, replace the U600-GM5020

Check U203 pin 1,3= 5V

Replace U203 (Nmos, SI9953)

NG

502 pin18

Check the Bklt-On relative circuit, R520, Q503, R519,

In normal operation, when LED =green,

R520 Bklt-On should =0 v,

If Bklt-On no-response when the power switch turn on-off,

Re

lace the MCU

Replace Oscillator X501

Replace Crystal X300

Replace GM5020 (U600) or replace

main board

If Main Board being replace, please

do the DDC – content

19

Page 21

p

II (a) the screen is abnormal, stuck at white screen, OSD window can’t appear,

but keyboard & LED is normal operation.

At general, this symptom is cause by missing panel data or panel power, so we must

check our wire-harness, which connected to panel or the panel power controller (U203)

Check if the Wire harness from CN201 loose?

Check the wire on both Panel-side and Main board side.

Tighten it.

Yes, tight enough

Check the Panel-Power circuit as above (page 20)

U203 pin 5,6,7,8, must be 5V

Yes, Voltage normal

Check the LVDS-Power L904= 3.3V?

Yes, Voltage normal

Check both U201 & U202 LVDS-Input pin 31= 45mhz –

65mhz, and pin 28 = Vsyn freq, pin 27 = 45khz- 65 kHz

Yes, Frequency normal

Replace both LVDS chip (U601 & U602)

Check U903, which convert the 5V to

3.3V

Check U600 DATA-OUPUT block as

above (page 20)

NG, no data output

Check OSCILLATOR Block as

above (page 20)

OK, all clock is normal

Replace U502 MCU and check it RESET

pin 10, must be turn high to low when first

AC

ower-on

OK, reset is normal

Check U600 DATA-OUTPUT block again

NG, still no data out

Replace U600 GM5020

20

Page 22

II. (B) The screen had the Vertical Straight Line, may be stuck in Red, Green or Blue

That symptom is cause by bad Panel issue (might be the Source IC from Panel is cold

soldered or open looped) so replace the panel and try it.

III.ALL SCREEN HAS INTERFERENCES OR NOISE, CAN’T BE FIXED BY AUTO KEY

** NOTE: There are so many kinds of interferences,

1). One is caused by some VGA-CARD that not meet VESA spec or power grounding too

bad that influence the circuit.

2). Other is cause by external interferences, move the monitor far from electronic

equipment. (Rarely happened)

Use DOT-pattern, or win98/99 shutdown

mode pattern, press “AUTO” key, was the

interferences disappear??

Adjust “FOCUS” step by step, until the

horizontal interferences disappear

Does your signal-cable have an additional

cable for extension??

Does your noise only exist in one mode only?

(Ex: only at 1280x1024 @ 85 Hz, other is normal)

That was caused by you VGA-CARD setting, your VGA

card timing back porch / front porch exceed vesa timing

too far, for some new AGP-VGA-CARD such situation

always happened

So in your control-panel icon, select monitor, setting,

advance, screen-adjust, at

Size icon, increase step by step slowly, and press,

“AUTO” key every step you increase the SIZE repeat

the procedure (increase/decrease SIZE one-step and press

AUTO) until the interferences disappear, press

“APPLY” to save in your VGA

No additional extension cable

Yes, only happened on one mode

Yes, has extension

END

END

Put away the additional cable

May be the additional cable grounding is

not quite good.

Change the Signal-cable to new one or

Try other brand VGA-CARD

(Make sure just only that brand VGACARD has this problem)

21

Page 23

III There is interferences in DOS mode

NOTE: the criteria of doing AUTO-CONFIGURATION: must be a full-size screen, if the

screen not full, the auto-configuration will fail. So in DOS mode, just set your “CLOCK” in

OSD-MENU to zero or use some EDITOR software which can full fill the whole screen (ex:

PE2, HE) and then press “AUTO” Or you can use “DOS1.EXE” which attached in your

Driver disk to optimize DOS mode performance.

IV The panel luminance is down

Use white pattern and resolution 1280x1024 @ 60Hz, CHROMA 7120 measured the

center of panel

Set Contrast, brightness =maximal, RGB= 50

Quit from OSD-screen, measured Y (luminance)

With chroma 7120, check Y= 230±10 cd/m2?

If Y can reach >240 cd/m2 that means

The lamp still working well, so we just re-do the

white-balance process

As following procedure

If the Y less than 200 cd/m2 (after the contrast,

brightness = max) then change the LAMP of panel

Use white-pattern, press MENU button along

with AC power-plug in (you will in factory

mode) The OSD-menu will be at left top of

screen,

Press AUTO button to automatically adjust black

level value, you will see the sign PASS

Follow White-Balance, Luminance adjustment

as above, method to more detail procedure

For do a white-balance adjust

6-2-2 INVERTER –MODULE TROUBLE SHOOTING CHART

**Note: the Waveform of U901 pin 2 can determined the power situation

1. Stable rectangle waveform with equal duty, freq around 150K-158KHz

that means all power of this interface board is in normal operation

, And all status of 5V & 3.3V is working well

2. Unstable or uneven rectangle waveform without same duty, that means

ABNORMAL operation was happened, check 3.3V or 5V, if short-circuit or bad

component

3. Rectangle waveform with large spike & harmonic pulse on front side means all

3.3v is no load, U600 Gm5020 was shut-down, and only U502 MCU still working,

that means the monitor is in power saving status, all power system is working

well.

22

Page 24

Check IC1 pin9=12V

pin9=12vvoltage of

C905(+)

Check C1 (+) =12V

NG

OK

Check ON/OFF signal

NG

OK

NG

Check the pin1 of IC1 have saw tooth wave

OK

Check F1/ D1/Q3/Q4or

D2/Q9/Q10

Check Interface board

CheckQ1 or Q2

OK

NG

Change IC1

Check MOSFET Q5/Q8 if has the output of square wave.

OK

NG

Check Q6/Q7//D3 or

Q11/Q12 /D4

Check the resonant wave of pin2 & pin5 for T1/T2

OK

NG

Check Q6/Q7/C5 or

Q11/Q12/C19

Check the output of T1/T2

OK

NG

Change T1or T2

Check connecter & lamp

END

23

Page 25

6-2-3 KeyPad Board module trouble-shooting chart

I

OSD is unstable or not working

Is KeyPad Board connecting normally?

Y

Is Button Switch normally?

Y

Is KeyPad Board Normally?

Y

N

N

N

Connect KeyPad Board

Replace Button Switch

Replace KeyPad Board

Check Main Board

24

Page 26

,

r

II

Check U502 MCU pin 43,42,41,40,39 at

High state (5V)? without press any key

Press power key and check U502 pin 43

= low (0V)?

Check U502 pin 37 (LED green) will have

transition from hi to low or low to hi when we

press the power key??

Check U502 pin 20= 24MHz? And pin 44

(VDD)=5V? And pin 10 (reset)=0V ? At norm al

condition

Without press key and change mode, Check U502

pin 16,17(SDA, SCL)= hi 5V? Or keep

transition?

Replace U502 MCU

NG, MCU no response

NG

Mechanical stuck, Check!

Check main board PR505 shortage?

Replace Tact-switch SW105 at keyboard if still

no work replace U302 MCU at main-board and

check MCU relative reset circuit, and crystal

If still no Led green indicator, check LED at

keyboard !! cold solder or bad

If one of these items was NG, check the relative

circuit

Keep transition that means eeprom no response

Check U501 eeprom 24LC16 relative circuit,

check U600 pin 7 = low?

Check the relative

power circuit, was

there 5v input

Check U501 pin 8

(vdd)= 5V, and check

R501

R503 cold solde

Replace eeprom

OK

25

Page 27

7.MECHANICAL OF CABINET FRONT DIS-ASSEMBLY

26

Page 28

8.POWER SYSTEM AND CONSUMPTION CURRENT

(

(

(

)

)

ADAPTER MODULE

Input AC 110V, 60Hz/240V, 50Hz

Output DC 12V 5A

SI-8050SD, 12V to 5V (5A SPEC)

5V

AIC1084

5V to 3.3V

5A SPEC)

3.3V

For GM5020 and

USB hub consumption

Main board power system

To CPU, Eeprom, 24c21, control-inverter-on.off,

and USB hub

860mA when Cable not connected

841mA when Normal operation

AIC1084

5V to 2.5V

800mA SPEC

2.5V

2.5V

For GM5020

Consumption

INVERTER MODULE

Input DC 12V

Output AC 1500V/30K-80KHz

Current 14mA

RT9164

5V to 2.5V

(1000mA

SPEC

For gm5020

consumption

AIC1117

5V to 3.3V

800mAspec)

3.3V

For LVDS consumption

27

Page 29

9. MAIN BOARD SCHEMATIC

Page 30

Sheet 3

3.Input Connectors

Sheet 4

HDATAF[0..3]

RED+

GREEN+

GREEN-

BLUE+

BLUE-

RXC+

RXCRX2+

RX1+

RX0+

DDC_SCL

DDC_SDA

/RESET

GPIO[0..7]

HCLK

/PANEL_EN

LVDS_EN

RED-

RX2-

RX1-

RX0-

HFS

/IRQ

Sheet 5

RED+

REDGREEN+

GREENBLUE+

BLUE-

RXC+

RXCRX2+

RX2RX1+

RX1RX0+

RX0-

HS

VS

HS

VS

DDC_SCL

DDC_SDA

/RESET

GPIO[0..7]

HDATAF[0..3]

HFS

HCLK

/IRQ

/PANEL_EN

LVDS_EN

RED+

REDGREEN+

GREENBLUE+

BLUE-

RXC+

RXCRX2+

RX2RX1+

RX1RX0+

RX0-

HS

VS

DDC_SCL

DDC_SDA

/RESET

GPIO[0..7]

HDATAF[0..3]

HFS

HCLK

/IRQ

FSDATA[0..47]

FSADDR[0..13]

DCLK

DARED[0..7]

DAGRN[0..7]

DABLU[0..7]

DBRED[0..7]

DBGRN[0..7]

DBBLU[0..7]

FSCLK

FSCKE

FSRAS

FSCAS

FSWE

FSDQM0

FSDQM1

FSDQM2

FSDQM3

DVS

DHS

DEN

DCLK

DVS

DHS

DEN

DARED[0..7]

DAGRN[0..7]

DABLU[0..7]

DBRED[0..7]

DBGRN[0..7]

DBBLU[0..7]

/PANEL_EN

LVDS_EN

FSDATA[0..47]

FSADDR[0..13]

FSCLK

FSCKE

FSRAS

FSCAS

FSWE

FSDQM0

FSDQM1

FSDQM2

FSDQM3

Sheet 6

DCLK

DVS

DHS

DEN

DARED[0..7]

DAGRN[0..7]

DABLU[0..7]

DBRED[0..7]

DBGRN[0..7]

DBBLU[0..7]

/PANEL_EN

LVDS_EN

6.Display Interface

Sheet 7

FSDATA[0..47]

FSADDR[0..13]

FSCLK

FSCKE

FSRAS

FSCAS

FSWE

FSDQM0

FSDQM1

FSDQM2

FSDQM3

7.Frame Store

Sheet 8

4.MCU

5.Gm5020

8.Power

AOC (Top Victory) Electronics Co., Ltd.

Title

Size Document Number Rev

A

Date: Sheet

Tuesday, October 01, 2002

Top Level

974-G-SAMSUNG.DSN

28

of

29

A

Page 31

D302

SOT23B

AGND

RX2-

RX2+

GND

RX4-

RX4+

SCL

SDA

VS

RX1-

RX1+

GND

RX3-

RX3+

5V

GND

HP

RX0-

RX0+

GND

RX5-

RX5+

GND

RXC+

RXC-

3

84

VCCGND

VCLK

BAV70

SDA

SCL

AGND

+5V

12

5

6

7

RX2-IN

1

RX2+IN

2

3

4

5

SCL_IN

6

7

SDA_IN

VS_DVI

8

RX1-IN

9

RX1+IN

10

11

12

13

14

15

16

RX0-IN

17

RX0+IN

18

19

20

21

22

RXC+IN

23

RXC-IN

24

VGA_5V

C308

0.1uF

AGND

U302

1

NC

2

NC

3

NC

24LC21A

910917 Compatibility

CN302

DVI-D

R321

47K

D307

5.6V

R327 0R

R328

0R(NC)

DVI_5V

HOT_PLUG

GND

R301 10K

SHEET 4.MCU

SHEET 4.MCU

R322

47K

VGA_SDA

VGA_SCL

D308

5.6V

VS

GND

RX2- SHEET 5.Gm5020

RX2+ SHEET 5.Gm5020

R313 100R

R314 100R

RX1- SHEET 5.Gm5020

RX1+ SHEET 5.Gm5020

RX0- SHEET 5.Gm5020

RX0+ SHEET 5.Gm5020

RXC+ SHEET 5.Gm5020

RXC- SHEET 5.Gm5020

TXD

RXD

CN301

1

11

R319 100R

R320 100R

+5V

R335

R336

1K(NC)

1K(NC)

R317

R318

2.2K

2.2K

AGND

R311

47K

D303

5.6V

GND

910917 EEPROM Option

6

2

12

7

3

13

8

4

14

9

5

15

10

DB15HD

R315 100R

R316 100R

+5V

R312

47K

D304

5.6V

D305

5.6V

AVDD_3.3

2

VGA_5V

VGACON

AGND

3

Signal Cable the same as T541

D306

C309

5.6V

47pF

DVI_5V

D301

SOT23B

3

R331

R333

10K(NC)

10K(NC)

R332

0R

U301

0R

84

1

NC

2

NC

3

NC

VCLK

GND

911002 DVI Detected

VCCGND

SDA

SCL

D310

BAV99

1

BAV70

AGND

12

5

6

7

+5V

VSYNC

HSYNC

C310

47pF

2

VGACON

R324 0RR334

R325

0R(NC)

GND

3

GND

D311

BAV99

1

AGND

C307

0.1uF

24C02

AGND

R308

75R

D309

5.6V

4.MCU

/V_CON (R323---U502.24)

5.Gm5020

RED- (C301---U601.E1)

RED- (C302---U601.E2)

GREEN+ (C303---U601.D2)

GREEN- (C304---U601.D1)

BLUE+ (C305---U601.C1)

BLUE- (C306---U601.C2)

VS (U303.8---U601.K1)

HS (U303.4---U601.L2)

R309

75R

D312

BAV99

2

1

AGND

R302 100R

3

R303 100R

R304 100R

R305 100R

R306 100R

R307 100R

R310

75R

C301 0.01uF

C302 0.01uF

C303 0.01uF

C304 0.01uF

C305 0.01uF

C306 0.01uF

RED+ SHEET 5.Gm5020

RED- SHEET 5.Gm5020

GREEN+ SHEET 5.Gm5020

GREEN- SHEET 5.Gm5020

BLUE+ SHEET 5.Gm5020

BLUE- SHEET 5.Gm5020

RX2- (CN302.1---U601.D10)

AGND

+5V

R326

10K

VSYNC

HSYNC

VS_DVI

DVI_5V

C311

1000pF

AGND

R337 1K

R323 100R

GND

V_CON SHEET 4.MCU

U303E

11 10

74LVT14_ADC(NC)

U303A

1 2

74LVT14_ADC(NC)

DVI_PLUG SHEET 4.MCU

R338

10K

R330

0R

9 8

R329 0R

3 4

U303D

74LVT14_ADC(NC)

U303B

74LVT14_ADC(NC)

AOC (Top Victory) Electronics Co., Ltd.

Title

Size Document Number Rev

B

Tuesday, October 01, 2002

Date: Sheet of

RX2+ (CN302.2---U601.C10)

RX1- (CN302.9---U601.D9)

RX1+ (CN302.10---U601.C9)

RX0- (CN302.17---U601.D8)

RX0+ (CN302.18---U601.C8)

RXC- (CN302.24---U601.D6)

RXC+ (CN302.23---U601.C6)

VS

AGND

AGND

C312

100 pF

C313

100 pF

C314

0.1uF

HS

VS SHEET 5.Gm5020

+5V

AGND

HS SHEET 5.Gm5020

Input Conecotors

974-G-SAMSUNG.DSN

38

A

30

Page 32

C511

0.1UF

_IRQ SHEET 5.Gm5020

HCLK SHEET 5.Gm5020

HFS SHEET 5.Gm5020

5

6

7

8

5

6

7

8

R527 0R(op)

+A5V

C512

470uF/16V

876

123

代刚筁

R520

4.7K

+5V

R522

620R

5

4

RP506

10K(8P4R)

MMBT3904

R521 1K

876

5

123

4

+5V

R519

3

Q503

1

2

GND

C508

22uF

GND

2

RP507

10K(8P4R)

1

8

MMBT3904

1

Q501

3

4327

CP502

1000P

5

6

910917 ESD

10K

ON/OFF

AD

C523

0.1uF/16V

GND

910918 EMI

5.Gm5020

HDATAF[0..3](U502.26,27,28,29---U601.R2,R1,P4,P3)

HCLK (U502.30---U601.P1)

HFS (U502.31---U601.P2)

/IRQ (U502.14---U601.R3)

RESET_FW (U502.25---R906)

PWM0 (U601.N1---R527)

PWM1 (U601.M4---R528)

3.Input Connectors

TXD (U502.13---CN301.4)

RXD (U502.11---CN301.11)

VGA_CON (U502.24---CN301.5)

6.Display Interface

PANEL_EN (U502.18---R201)

LVDS_EN (U502.36---U201.32,U202.32)

+5V

GND

0.1uF/16V

R531 220R

CN501

9

8

7

6

5

4

3

2

1

Pitch 2.0mm

C929

GND

C522

0.1uF/16V

GND

1

4327

568

GND

代刚筁

2

MMBT3904

Q502

3

1

+12V

CN502

12

34

56

78

910

11 12

HEADER 6X2

GND

LED GREEN

LED AMBER

AUTO KEY

KEY ENTER

KEY LEFT

KEY RIGHT

POWER

CP501

1000P

ON/OFF

AD

910918 EMI

GND

P1

DOS

R525

R526

0R(op)

0R(op)

GND

GND

P2

R524

0R(op)

GND

+5V

+5V

+5V

C502

C501

22uF

16V

GND

R528 0R(NC)

PWM1SHEET 5.Gm5020

0.1uF

KEY/SH

+5V

R514

10K

GND

+5V

R529

620R(NC)

+5V

D501

1N4148

1 2

R509

10K

GND

P_S_ENSHEET 8.Power

_PANEL_ENSHEET 6.Display Interface

RESET_FW SHEET 5.Gm5020

R523

0R(op)

R530

1K(NC)

GND

RP503

10K(8P4R)

1 8

2 7

3 6

C505

22uF

D502

1N4148(NC)

1 2

GND

RXD

RXDSHEET 3.Inout Connectors

TXD

TXDSHEET 3.Inout Connectors

WP

R515 10K

X501 24MHz

C504

22pF

+5V

+12V

C521

C516

22uF(NC)

C520

0.1uF/16V

0.1uF/16V

GND GND

GND

910918 EMI

RP502

10K(8P4R)

1 8

2 7

3 6

4 5

4 5

C503

22pF

C519

0.1uF/16V

GND

GND

0.1uF/16V

C518

GND

RP501

1 8

2 7

3 6

4 5

R505 33R

R506 33R

DOS

P1

P2

KEY/SH

STDBY

MUTE

RXD

TXD

_IRQ

SDA

SCL

_BKLT_ON

XTAL2

C517

0.1uF/16V

GND

33R(8P4R)

10

11

13

14

15

16

17

18

19

20

21

22

12

23

34

U502

2

P1.0/T2

3

P1.1/T2EX

4

P1.2/ECI

5

P1.3/CEX0

6

P1.4/CEX1

7

P1.5/CEX2

8

P1.6/CEX3/WAIT#

9

P1.7/CEX4/A17/W

RST

P3.0/RXD

P3.1/TXD

P3.2/INT0#

P3.3/INT1#

P3.4/T0

P3.5/T1

P3.6/WR#

P3.7/RD#/A16

XTAL2

XTAL1

VSS

1

NIC

NIC

NIC

NIC

W78E62BP-40

STDBY

MUTE

VOL

HDATAF3

HDATAF2

HDATAF1

HDATAF0

A8/P2.0

A9/P2.1

A10/P2.2

A11/P2.3

A12/P2.4

A13/P2.5

A14/P2.6

A15/P2.7

PSEN#

ALE/PROG#

AD7/P0.7

AD6/P0.6

AD5/P0.5

AD4/P0.4

AD3/P0.3

AD2/P0.2

AD1/P0.1

AD0/P0.0

VCC

EA#/VPP

Internal Program Memory

GND

CN503

1

2

3

4

5

6

HEADER 6

24

25

26

HDATA0

HDATA1

27

HDATA2

28

29

HDATA3

30

HCLK/SCL

HFS/SDA

31

32

33

36

37

38

39

40

41

42

43

44

R516

35

10K

U501

1

A0

VCC

2

A1

WP

3

A2

SCK

4 5

VSS SI

24LC16B

911002 DVI Detected

+5V

R532

10K

+A5V

+5V

R501

10K

+A5V

8

7

6

L502

CHOKE

C509

C510

0.1UF

100uF

GND

HDATAF[0..3] SHEET 5.Gm5020

R508

R507

47R

47R

C514

100PF

GND

V_CON SHEET 3.Input Connectors

DVI_PLUG SHEET 3.Input Connectors

LVDS_EN SHEET 6.Display Interface

4

3

2

1

4

3

2

1

RP504

330R(8P4R)

RP505

330R(8P4R)

910917 ESD

R510

10K

R503

WP

10K

R504

10K

SCL

SDA

R502

10K

GND

PWM0SHEET 5.Gm5020

C515

100PF

_BKLT_ON

AOC (Top Victory) Electronics Co., Ltd.

Title

Size Document Number Rev

C

Tuesday, October 01, 2002

Date: Sheet of

MCU

974-G-SAMSUNG.DSN

48

A

31

Page 33

DVDD_3.3

C601

C602

0.1uF

0.1uF

C620

C621

22uF

0.1uF

10V

C639

C640

0.1uF

0.1uF

C649

C648

0.1uF

0.1uF

C659

C660

0.1uF

0.1uF

C667

C668

22uF

22uF

10V

10V

DVDD_2.5

AVDD_2.5

AVDD_3.3

PVDD_3.3

DVDD_3.3

C600

0.1uF

C619

22uF

10V

C638

0.1uF

C647

0.1uF

0.1uF

C666

22uF

10V

3.Input Connectors

RED- (C301---U601.E1)

RED- (C302---U601.E2)

GREEN+ (C303---U601.D2)

GREEN- (C304---U601.D1)

BLUE+ (C305---U601.C1)

BLUE- (C306---U601.C2)

VS (U303.8---U601.K1)

HS (U303.4---U601.L2)

RX2- (CN302.1---U601.D10)

RX2+ (CN302.2---U601.C10)

RX1- (CN302.9---U601.D9)

RX1+ (CN302.10---U601.C9)

RX0- (CN302.17---U601.D8)

RX0+ (CN302.18---U601.C8)

RXC- (CN302.24---U601.D6)

RXC+ (CN302.23---U601.C6)

C604

C603

0.1uF

0.1uF

C623

C622

0.1uF

0.1uF

C642

C641

220pF

0.1uF

C650

C651

0.1uF

0.1uF

C661

C662

0.1uF

220pF

GND

4.MCU

6.Display Interface

7.Frame Store

FSADDR[0..13] (U601---U801,U802,U803)

FSDATA[0..47] (U601---U801,U802,U803)

FSCLK (U601.T3---U801.35,U802.35,U803.35)

FSCKE (U601.U1---U801.34,U802.34,U803.34)

FSRAS (U601.V1---U801.17,U802.17,U803.17)

FSCAS (U601.U3---U801.16,U802.16,U803.16)

FSWE (U601.U2---U801.15,U802.15,U803.15)

FSDQM0 (U601.W8---U801.14)

FSDQM1 (U601.Y8---U801.36)

FSDQM2 (U601.V12---U802.14,U802.14)

FSDQM3 (U601.W12---U802.36,U803.36)

C608

C605

0.1uF

C624

0.1uF

C643

220pF

C652

220pF

C663

220pF

C606

0.1uF

C625

0.1uF

C644

220pF

C653

220pF

C664

220pF

AVDD_2.5

AGND

PVDD_3.3

PGND

C607

0.1uF

C626

0.1uF

C645

220pF

C654

220pF

C665

220pF

0.1uF

C627

0.1uF

C655

220pF

AVDD_3.3

AGND

C609

0.1uF

C628

0.1uF

C656

220pF

C610

220pF

C629

220pF

C611

220pF

C630

220pF

GNDC658

Join Grounds

GNDGND

PGND

HDATAF[0..3](U502.26,27,28,29---U601.R2,R1,P4,P3)

HCLK (U502.30---U601.P1)

HFS (U502.31---U601.P2)

/IRQ (U502.14---U601.R3)

RESET_FW (U502.25---R906)

PWM0 (U601.N1---R527)

PWM1 (U601.M4---R528)

DARED[0..7] (U601---U201)

DAGRN[0..7] (U601---U201)

DABLU[0..7] (U601---U201)

DBRED[0..7] (U601---U201)

DBGRN[0..7] (U601---U201)

DBBLU[0..7] (U601---U201)

DCLK (U601.G20---U201.31,U202.31)

DHS (U601.F20---U201.27,U202.27)

DVS (U601.F19---U201.28,U202.28)

DEN (U601.F18---U201.30,U202.30)

AGND

SHEET 4.MCU

RESET_FW

R603

10K(NC)

910917

DVDD_3.3

GND

穦 耑

C612

220pF

C631

220pF

C671

22pF

R602

10K(NC)

C932

22uF

GND

C613

220pF

C632

220pF

C672

22pF

D904

1N4148(NC)

1 2

D905

1N4148(NC)

1 2

C614

220pF

C633

220pF

X600

24MHz

C615

220pF

C634

220pF

DVDD_3.3

C616

220pF

C635

220pF

TCLK

XTAL

PWM1SHEET 4.MCU

PWM0SHEET 4.MCU

HDATAF[0..3]SHEET 4.MCU

HFSSHEET 4.MCU

HCLKSHEET 4.MCU

_IRQSHEET 4.MCU

DVDD_2.5

GND

RED+SHEET 3.Input Connectors

RED-SHEET 3.Input Connectors

GREEN+SHEET 3.Input Connectors

GREEN-SHEET 3.Input Connectors

BLUE+SHEET 3.Input Connectors

BLUE-SHEET 3.Input Connectors

RXC+SHEET 3.Input Connectors

RXC-SHEET 3.Input Connectors

RX0+SHEET 3.Input Connectors

RX0-SHEET 3.Input Connectors

RX1+SHEET 3.Input Connectors

RX1-SHEET 3.Input Connectors

RX2+SHEET 3.Input Connectors

RX2-SHEET 3.Input Connectors

VSSHEET 3.Input Connectors

HSSHEET 3.Input Connectors

C617

220pF

C636

220pF

AVDD_3.3

C618

AVDD_2.5

220pF

GND

AVDD_3.3

AGND

PVDD_3.3

PGND

ADC_TEST

TP600

CLKOUT

TP601

VBUFC

TP602

R601

REXT

1.00K

1%

TP603

TP604

HDATAF3

HDATAF2

HDATAF1

HDATAF0

XTAL

TCLK

ANTEST

VDACP

GND

A6

A7

A8

A9

A10

A11

B2

B6

B7

B8

B9

B11

C3

D3

E3

A2

A3

A4

B1

B3

B4

C4

C5

C7

C11

D4

D5

D7

D11

E4

F2

F4

G1

G3

H1

J1

J3

F3

G2

G4

H2

H3

J2

K3

E1

E2

D2

D1

C1

C2

C6

D6

C8

D8

C9

D9

C10

D10

A5

B5

B10

H4

J4

K1

L2

F1

K2

L3

A12

B12

C12

A13

B13

C13

A14

B14

C14

G19

G18

L1

M1

M2

M3

M4

N1

P3

P4

R1

R2

P2

P1

R3

R4

T1

T2

N2

N3

DVDD_2.5

U600

AVDD_2.5

AVDD_2.5

AVDD_2.5

AVDD_2.5

AVDD_2.5

AVDD_2.5

AVDD_3.3

AVDD_3.3

AVDD_3.3

AVDD_3.3

AVDD_3.3

AVDD_3.3

AVDD_3.3

AVDD_3.3

AVDD_3.3

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

PLLVDD_3.3

PLLVDD_3.3

PLLVDD_3.3

PLLVDD_3.3

PLLVDD_3.3

PLLVDD_3.3

PLLVDD_3.3

PLLGND

PLLGND

PLLGND

PLLGND

PLLGND

PLLGND

PLLGND

RED+

REDGREEN+

GREENBLUE+

BLUEADC_TEST

RXC+

RXCRX0+

RX0RX1+

RX1RX2+

RX2-

CLKOUT

VBUFC

REXT

XTAL

TCLK

VSYNC

HSYNC

ANTEST

VDACP

EXTCLK

VCLK

YUV7

YUV6

YUV5

YUV4

YUV3

YUV2

YUV1

YUV0

GPIO7/DOVL

GPIO6/DFSYNCn

GPIO5/TXD

GPIO4/RXD

GPIO3/T1

GPIO2

GPIO1/PWM1

GPIO0/PWM0

HDATA3

HDATA2

HDATA1

HDATA0

HFS/SDA

HCLK/SCL

IRQn

IRQINn

RESETn

SCAN_TEST

DDC_SCL

DDC_SDA

gm5020

GM5020

D12

DVDD_2.5

DGND

H8

GND

D17

F17

K17

D14

DVDD_2.5

DVDD_2.5

DVDD_2.5

Analog Input

TMDS Receiver

PLL and DDS

Video Input

Host Interface

HDCP

DGND

DGND

DGND

H11

H9

H10

H12

DVDD_2.5

DGND

DVDD_3.3

DGND

D13

K13

D15J9E17

DVDD_3.3

DVDD_3.3

DGND

DGND

L8L9L10

R17

J17

N17

D16

L17

G17

U17

DVDD_3.3

DVDD_3.3

DVDD_3.3

DVDD_3.3

DVDD_3.3

DVDD_3.3

DVDD_3.3

DGND

DGND

DGND

DGND

DGND

DGND

DGND

L11

L12

L13M8M9

M10

U15

U12

U13

DVDD_3.3

DVDD_3.3

DVDD_3.3

DVDD_3.3

Display Port

Frame Store

Interface

DGND

DGND

DGND

DGND

M11

M12

M13

L4

U10

U8

U5

U6

DVDD_3.3

DGND

DVDD_3.3

DGND

DVDD_3.3

DGND

T4

G20

DCLK

F20

DHS

F19

DVS

F18

DVDD_3.3

DVDD_3.3

DVDD_3.3

DEN

DARED0

K18

DARED0

DARED1

DARED2

DARED3

DARED4

DARED5

DARED6

DARED7

DAGRN0

DAGRN1

DAGRN2

DAGRN3

DAGRN4

DAGRN5

DAGRN6

DAGRN7

DABLU0

DABLU1

DABLU2

DABLU3

DABLU4

DABLU5

DABLU6

DABLU7

DBRED0

DBRED1

DBRED2

DBRED3

DBRED4

DBRED5

DBRED6

DBRED7

DBGRN0

DBGRN1

DBGRN2

DBGRN3

DBGRN4

DBGRN5

DBGRN6

DBGRN7

DBBLU0

DBBLU1

DBBLU2

DBBLU3

DBBLU4

DBBLU5

DBBLU6

DBBLU7

FSDATA0

FSDATA1

FSDATA2

FSDATA3

FSDATA4

FSDATA5

FSDATA6

FSDATA7

FSDATA8

FSDATA9

FSDATA10

FSDATA11

FSDATA12

FSDATA13

FSDATA14

FSDATA15

FSDATA16

FSDATA17

FSDATA18

FSDATA19

FSDATA20

FSDATA21

FSDATA22

FSDATA23

FSDATA24

FSDATA25

FSDATA26

FSDATA27

FSDATA28

FSDATA29

FSDATA30

FSDATA31

FSDATA32

FSDATA33

FSDATA34

FSDATA35

FSDATA36

FSDATA37

FSDATA38

FSDATA39

FSDATA40

FSDATA41

FSDATA42

FSDATA43

FSDATA44

FSDATA45

FSDATA46

FSDATA47

FSADDR0

FSADDR1

FSADDR2

FSADDR3

FSADDR4

FSADDR5

FSADDR6

FSADDR7

FSADDR8

FSADDR9

FSADDR10

FSADDR11

FSADDR12

FSADDR13

FSDQM0

FSDQM1

FSDQM2

FSDQM3

DGND

DGND

DGND

N11N9N13N8N10

N12

DARED1

J20

J19

DARED2

DARED3

J18

H20

DARED4

H19

DARED5

DARED6

H18

H17

DARED7

DAGRN0

M18

DAGRN1

M19

DAGRN2

M20

L18

DAGRN3

DAGRN4

L19

DAGRN5

L20

DAGRN6

K20

DAGRN7

K19

DABLU0

R19

DABLU1

R20

DABLU2

P18

P19

DABLU3

DABLU4

P20

DABLU5

N18

DABLU6

N19

DABLU7

N20

DBRED0

B17

DBRED1

A17

DBRED2

C16

DBRED3

B16

A16

DBRED4

C15

DBRED5

DBRED6

B15

DBRED7

A15

B20

DBGRN0

B19

DBGRN1

A20

DBGRN2

A19

DBGRN3

DBGRN4

C18

B18

DBGRN5

A18

DBGRN6

DBGRN7

C17

DBBLU0

E20

DBBLU1

E19

E18

DBBLU2

D20

DBBLU3

DBBLU4

D19

D18

DBBLU5

C20

DBBLU6

C19

DBBLU7

FSDATA0

V6

FSDATA1

W6

FSDATA2

Y6

FSDATA3

V7

W7

FSDATA4

FSDATA5

Y7

V8

FSDATA6

FSDATA7

V9

W9

FSDATA8

FSDATA9

Y9

FSDATA10

V10

W10

FSDATA11

FSDATA12

Y10

FSDATA13

Y11

W11

FSDATA14

FSDATA15

V11

Y12

FSDATA16

Y13

FSDATA17

W13

FSDATA18

V13

FSDATA19

FSDATA20

Y14

FSDATA21

W14

V14

FSDATA22

FSDATA23

Y15

W15

FSDATA24

FSDATA25

V15

Y16

FSDATA26

W16

FSDATA27

FSDATA28

V16

FSDATA29

Y17

W17

FSDATA30

FSDATA31

V17

Y18

FSDATA32

FSDATA33

W18

V18

FSDATA34

Y19

FSDATA35

FSDATA36

W19

Y20

FSDATA37

FSDATA38

W20

FSDATA39

V19

V20

FSDATA40

U18

FSDATA41

FSDATA42

U19

U20

FSDATA43

FSDATA44

T18

T19

FSDATA45

FSDATA46

T20

R18

FSDATA47

FSADDR0

Y5

FSADDR1

W5

V5

FSADDR2

FSADDR3

Y4

W4

FSADDR4

V4

FSADDR5

Y3

FSADDR6

W3

FSADDR7

FSADDR8

V3

FSADDR9

Y2

W2

FSADDR10

FSADDR11

Y1

W1

FSADDR12

FSADDR13

V2

T3

FSCLK

U1

FSCKE

V1

FSRAS

U3

FSCAS

U2

FSWE

W8

Y8

V12

W12

AOC (Top Victory) Electronics Co., Ltd.

Title

Size Document Number Rev

C

Tuesday, October 01, 2002

Date: Sheet of

DCLK SHEET 6.Display Interface

DHS SHEET 6.Display Interface

DVS SHEET 6.Display Interface

DEN SHEET 6.Display Interface

DARED[0..7] SHEET 6.Display Interface

DAGRN[0..7] SHEET 6.Display Interface

DABLU[0..7] SHEET 6.Display Interface

DBRED[0..7] SHEET 6.Display Interface

DBGRN[0..7] SHEET 6.Display Interface

DBBLU[0..7] SHEET 6.Display Interface

FSDATA[0..47] SHEET 7.Frame Store

FSADDR[0..13] SHEET 7.Frame Store

FSCLK SHEET 7.Frame Store

FSCKE SHEET 7.Frame Store

FSRAS SHEET 7.Frame Store

FSCAS SHEET 7.Frame Store

FSWE SHEET 7.Frame Store

FSDQM0 SHEET 7.Frame Store

FSDQM1 SHEET 7.Frame Store

FSDQM2 SHEET 7.Frame Store

FSDQM3 SHEET 7.Frame Store

Gm5020

974-G-SAMSUNG.DSN

58

A

P17

M17

T17

U14

U16

U11

U9N4U7

U4A1K4

DVDD_2.5

DVDD_2.5

DVDD_2.5

DVDD_2.5

DVDD_2.5

DVDD_2.5

DVDD_2.5

DVDD_2.5

DVDD_2.5

DVDD_2.5

DVDD_2.5

gm5020

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

J8

H13

J10

K10

K12

K11

J12

K9

J13K8J11

32

Page 34

DVDD_3.3

L201

BEAD (0)

A1= EVEN B1=ODD

C201

100uF

GND

910918 EMI

C202

0.1uF

L3.3V

FUJITSU㎝SAMSUNG

SHEET 5.Gm5020

DARED[0..7]

L3.3V

C220

0.1uF

SHEET 5.Gm5020

DAGRN[0..7]

SHEET 5.Gm5020

DABLU[0..7]

SHEET 5.Gm5020

DBRED[0..7]

SHEET 5.Gm5020

DBGRN[0..7]

SHEET 5.Gm5020

DBBLU[0..7]

DHSSHEET 5.Gm5020

DVSSHEET 5.Gm5020

DENSHEET 5.Gm5020

DCLKSHEET 5.Gm5020

DARED0

DARED1

DARED2

DARED3

DARED4

DARED5

DARED6

DARED7

DAGRN0

DAGRN1

DAGRN2

DAGRN3

DAGRN4

DAGRN5

DAGRN6

DAGRN7

DABLU0

DABLU1

DABLU2

DABLU3

DABLU4

DABLU5

DABLU6

DABLU7

DBRED0

DBRED1

DBRED2

DBRED3

DBRED4

DBRED5

DBRED6

DBRED7

DBGRN0

DBGRN1

DBGRN2

DBGRN3

DBGRN4

DBGRN5

DBGRN6

DBGRN7

DBBLU0

DBBLU1

DBBLU2

DBBLU3

DBBLU4

DBBLU5

DBBLU6

DBBLU7

逼 抖 ぃ 妓

EVEN

51

52

54

55

56

3

50

2

4

6

7

11

12

14

8

10

15

19

20

22

23

24

16

18

25

27

28

30

31

GND

51

52

54

55

56

3

50

2

4

6

7

11

12

14

8

10

15

19

20

22

23

24

16

18

25

27

28

30

31

GND

U201

DS90CF383MTD

TSSOP56

TXIN0

TXIN1

TXIN2

TXIN3

TXIN4

TXIN6

TXIN27

TXIN5

TXIN7

TXIN8

TXIN9

TXIN12

TXIN13

TXIN14

TXIN10

TXIN11

TXIN15

TXIN18

TXIN19

TXIN20

TXIN21

TXIN22

TXIN16

TXIN17

TXIN23

TXIN24

TXIN25

TXIN26

TXCLKIN

ODD

U202

DS90CF383MTD

TSSOP56

TXIN0

TXIN1

TXIN2

TXIN3

TXIN4

TXIN6

TXIN27

TXIN5

TXIN7

TXIN8

TXIN9

TXIN12

TXIN13

TXIN14

TXIN10

TXIN11

TXIN15

TXIN18

TXIN19

TXIN20

TXIN21

TXIN22

TXIN16

TXIN17

TXIN23

TXIN24

TXIN25

TXIN26

TXCLKIN

1917

1917

VVV

VVV

C204

C205

C203

0.1uF

0.1uF

26

V

PWRDWN

TXOUT0-

TXOUT0+

TXOUT1-

TXOUT1+

TXOUT2-

TXOUT2+

TXCLKOUT-

TXCLKOUT+

TXOUT3-

TXOUT3+

LVDSVCC

LVDSGND

LVDSGND

LVDSGND

PLLVCC

PLLGND

PLLGND

GND

GND

GND

GND

GND

C211

C210

0.1uF

0.1uF

26

V

PWRDWN

TXOUT0-

TXOUT0+

TXOUT1-

TXOUT1+

TXOUT2-

TXOUT2+

TXCLKOUT-

TXCLKOUT+

TXOUT3-

TXOUT3+

LVDSVCC

LVDSGND

LVDSGND

LVDSGND

PLLVCC

PLLGND

PLLGND

GND

GND

GND

GND

GND

C206

0.1uF

0.1uF

GND

32

48

TXE0

47

TXE1

46

TXE2

45

TXE3

42

TXE4

41

TXE5

40

TXE8

39

TXE9

38

TXE6

37

TXE7

44

49

43

36

34

35

33

53

29

21

13

5

GND

C212

C213

0.1uF

0.1uF

GND

32

TXO0

48

TXO1

47

46

TXO2

TXO3

45

42

TXO4

41

TXO5

TXO8

40

TXO9

39

TXO6

38

TXO7

37

44

49

43

36

34

35

33

53

29

21

13

5

GND

TX0-E

TX0+E

TX1-E

TX1+E

TX2-E

TX2+E

TX3-E

TX3+E

TXCK-E

TXCK+E

C207

C208

0.1uF

22uF

C209

0.1UF

L3.3V

TX0-O

TX0+O

TX1-O

TX1+O

TX2-O

TX2+O

TX3-O

TX3+O

TXCK-O

TXCK+O

C215

C214

0.1uF

22uF

C216

0.1UF

L203

BEAD (120)

L202

BEAD (120)

L204

BEAD (120)

L205

BEAD (120)

L3.3V

L3.3V

LVDS_EN

L3.3V

L3.3V

_PANEL_ENSHEET 4.MCU

DARED[0..7] (U601---U201)

DAGRN[0..7] (U601---U201)

DABLU[0..7] (U601---U201)

DBRED[0..7] (U601---U201)

DBGRN[0..7] (U601---U201)

DBBLU[0..7] (U601---U201)

DCLK (U601.G20---U201.31,U202.31)

DHS (U601.F20---U201.27,U202.27)

DVS (U601.F19---U201.28,U202.28)

DEN (U601.F18---U201.30,U202.30)

4.MCU

PANEL_EN (U502.18---R201)

LVDS_EN (U502.36---U201.32,U202.32)

CN201

TX0-E

TXE0

TXE2

TXE4

TXE8

TXE6 TXE7

TXO0

TXO2

TXO4

TXO8

TXO6

PANEL-VCC

C221

0.1uF

GND

910918 EMI

LVDS_EN SHEET 4.MCU

/PANEL_EN

TX1-E

TX2-E

TX3-E

TXCK-E

TX0-O

TX1-O

TX2-O

TX3-O

TXCK-O

HEADER 12X2 (Pitch 2.0mm)

+12V

C219

100uF

GND

R201

10K

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

GND

+12V

JP201

0R(OP)

R202

4.7K

Q201

MMBT3904

GND

TXE1

TXE3

TXE5

TXE9

TXO1

TXO3

TXO5

TXO9

TXO7

+5V

JP202

0R

C217

22uF

16V

GND

1

2

3

4

TX0+E

TX1+E

TX2+E

TX3+E

TXCK+E

TX0+O

TX1+O

TX2+O

TX3+O

TXCK+O

U203

S1

G1

S2

G2

SI9933ADY

BEAD (600(1206))

L206

8

D1

7

D1

6

D2

5

D2

C218

0.1uF

GND

PANEL-VCC

R203

1K(NC)

5.Gm5020

AOC (Top Victory) Electronics Co., Ltd.

Title

Size Document Number Rev

C

Date: Sheet of

Display Interface

Tuesday, October 01, 2002

974-G-SAMSUNG.DSN

68

A

33

Page 35

DVDD_3.3

910918 EMI

U801

U802

U803

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

CLK

CKE

/CS

/RAS

/CAS

/WE

LDQM

UDQM

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

CLK

CKE

/CS

/RAS

/CAS

/WE

LDQM

UDQM

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

CLK

CKE

/CS

/RAS

/CAS

/WE

LDQM

UDQM

F3.3V

25713

VSS VCC

26 1

504104147

F3.3V

25713

VSS VCC

26 1

504104147

F3.3V

25713

VSS VCC

26 1

504104147

VCC

VSS

VCC

VSS

VCC

VSS

38

44

DQ0

VCCQ

VCCQ

VCCQ

VCCQ

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

NC

VSSQ

VSSQ

VSSQ

VSSQ

K4S161622

GND

910918 EMI

38

44

DQ0

VCCQ

VCCQ

VCCQ

VCCQ

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

NC

VSSQ

VSSQ

VSSQ

VSSQ

K4S161622

GND

910918 EMI

38

44

DQ0

VCCQ

VCCQ

VCCQ

VCCQ

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

NC

VSSQ

VSSQ

VSSQ

VSSQ

K4S161622

GND

910918 EMI

FSDATA0

2

FSDATA1

3

5

FSDATA2

FSDATA3

6

8

FSDATA4

9

FSDATA5

FSDATA6

11

12

FSDATA7

FSDATA8

39

FSDATA9

40

FSDATA10

42

43

FSDATA11

FSDATA12

45

FSDATA13

46

FSDATA14

48

FSDATA15

49

37

FSDATA16

2

FSDATA17

3

FSDATA18

5

FSDATA19

6

FSDATA20

8

9

FSDATA21

FSDATA22

11

FSDATA23

12

FSDATA24

39

FSDATA25

40

FSDATA26

42

43

FSDATA27

45

FSDATA28

46

FSDATA29

FSDATA30

48

FSDATA31

49

37

F3.3V

C801

C802

22uF

0.1uF

GND

F3.3V

C809

C808

0.1uF

22uF

GND

F3.3V

C815

C816

22uF

0.1uF

GND

2

FSDATA32

3

FSDATA33

5

FSDATA34

6

FSDATA35

8

FSDATA36

9

FSDATA37

11

FSDATA38

12

FSDATA39

39

FSDATA40

40

FSDATA41

42

FSDATA42

43

FSDATA43

45

FSDATA44

46

FSDATA45

48

FSDATA46

49

FSDATA47

37

FSDATA[0..47]SHEET 5.Gm5020

FSADDR[0..13]SHEET 5.Gm5020

FSADDR0

FSADDR1

FSADDR2

FSADDR3

FSADDR4

FSADDR5

FSADDR6

FSADDR7

FSADDR8

FSADDR9

FSADDR10

FSCLKSHEET 5.Gm5020

FSCKESHEET 5.Gm5020

FSRASSHEET 5.Gm5020

FSCASSHEET 5.Gm5020

FSWESHEET 5.Gm5020

FSDQM0SHEET 5.Gm5020

FSDQM1SHEET 5.Gm5020

FSDQM2SHEET 5.Gm5020

FSDQM3SHEET 5.Gm5020

FSADDR11

FSADDR0

FSADDR1

FSADDR2

FSADDR3

FSADDR4

FSADDR5

FSADDR6

FSADDR7

FSADDR8

FSADDR9

FSADDR10

FSADDR11

FSADDR0