Page 1

23.6" LCD Monitor AOC e2436Vwa

Service

Service

Service

Horizontal Frequency

30- 80kHz

Table of Contents

Description Page Description Page

Table of Contents…………………..…………………..…...1

Revision List.…...................................................……......2

Important Safety Notice.….….............................……......3

1.Monitor Specification..............................………............4

2.LCD Monitor Description……….…………………….......6

3.Operation Instruction.…………...................……...........8

3.1.General Instructions....................................…...........8

3.2.Control Buttons and Connections...............................8

3.3.OSD Setting…..........................................................10

4.Input/Output Specification...............……………….......26

4.1.Input Signal Connector...............………..................26

4.2.Preset Display Modes……..........................27

4.3.Panel Specification…………..………………………..27

5.Block Diagram….........................................................30

5.1.Main Board…..….............................................30

5.2.Power Board…………..…………………………......31

6.Schematic…………..….........................................32

6.1.Main Board..…….…...........................................32

6.2.Power Board..……….........................................36

7.PCB Layout..………..............................................39

7.1.Main Board………..…........................................39

7.2.Power Board….…..............................................40

7.3.Key Board………..…..........................................42

7.4.USB Board………..….........................................43

8.Maintainability………............................................44

8.1.Equipments and Tools Requirement…...............44

8.2.Trouble Shooting…..………...............................45

9. FOS Testing………………………………………49

10.Firmware and DDC Instruction……………….….53

11.White-Balance,Luminance Adjustment…............66

12.Mechanical Instructions …............ ..............68

13.Monitor Exploded View……................................72

14.BOM List…………..……………………….............73

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE

CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING

ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFOMER FOR THIS UNIT WHEN SERVICING

1

Page 2

Revision List

Version Release Date Revision History TPV Model Name

A00 Sep.-07-2010

Initial release TD92A8NB6WA1PNE

2

Page 3

Important Safety Notice

Proper service and repair is important to the safe, reliable operation of all AOC Company Equipment. The service

procedures recommended by AOC and described in this service manual are effective methods of performing service

operations. Some of these service operations require the use of tools specially designed for the purpose. The

special tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to understand that these CAUTIONS and NOTICES ARE

NOT EXHAUSTIVE. AOC could not possibly know, evaluate and advise the service trade of all conceivable ways in

which service might be done or of the possible hazardous consequences of each way. Consequently, AOC has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not

recommended by AOC must first satisfy himself thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

Hereafter throughout this manual, AOC Company will be referred to as AOC.

WARNING

Use of substitute replacement parts, which do not have the same, specified safety characteristics may create shock,

fire, or other hazards.

Under no circumstances should the original design be modified or altered without written permission from AOC.

AOC assumes no liability, express or implied, arising out of any unauthorized modification of design.

Servicer assumes all liability.

FOR PRODUCTS CONTAINING LASER:

DANGER-Invisible laser radiation when open AVOID DIRECT EXPOSURE TO BEAM.

CAUTION-Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

CAUTION -The use of optical instruments with this product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR PART NUMBERS IN THE PARTS LIST SECTION OF

THIS SERVICE MANUAL.

Take care during handling the LCD module with backlight unit

-Must mount the module using mounting holes arranged in four corners.

-Do not press on the panel, edge of the frame strongly or electric shock as this will result in damage to the screen.

-Do not scratch or press on the panel with any sharp objects, such as pencil or pen as this may result in damage to

the panel.

-Protect the module from the ESD as it may damage the electronic circuit (C-MOS).

-Make certain that treatment person’s body is grounded through wristband.

-Do not leave the module in high temperature and in areas of high humidity for a long time.

-Avoid contact with water as it may a short circuit within the module.

-If the surface of panel becomes dirty, please wipe it off with a soft material. (Cleaning with a dirty or rough cloth may

damage the panel.)

3

Page 4

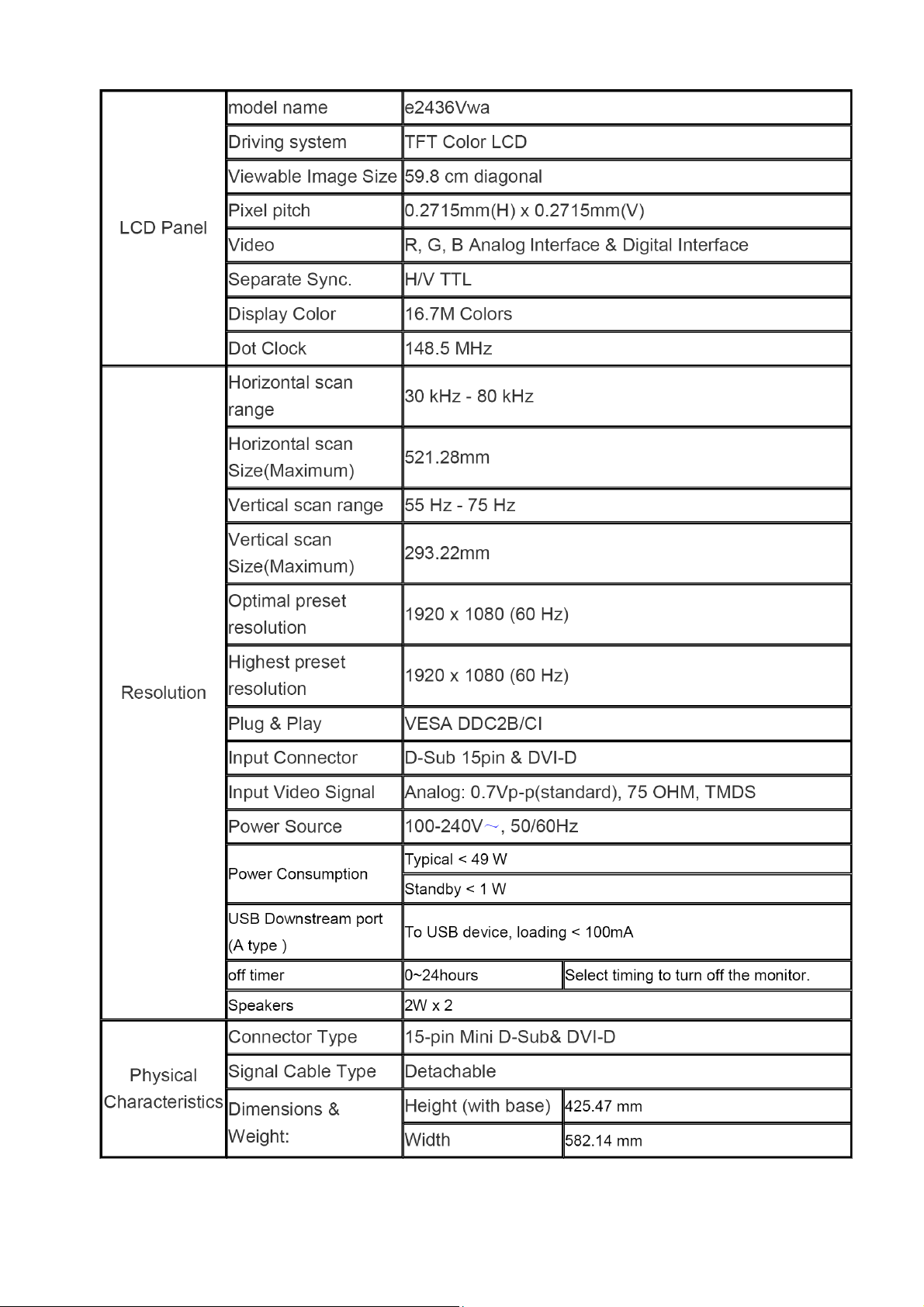

1.Monitor Specifications

4

Page 5

5

Page 6

A

2.LCD Monitor Description

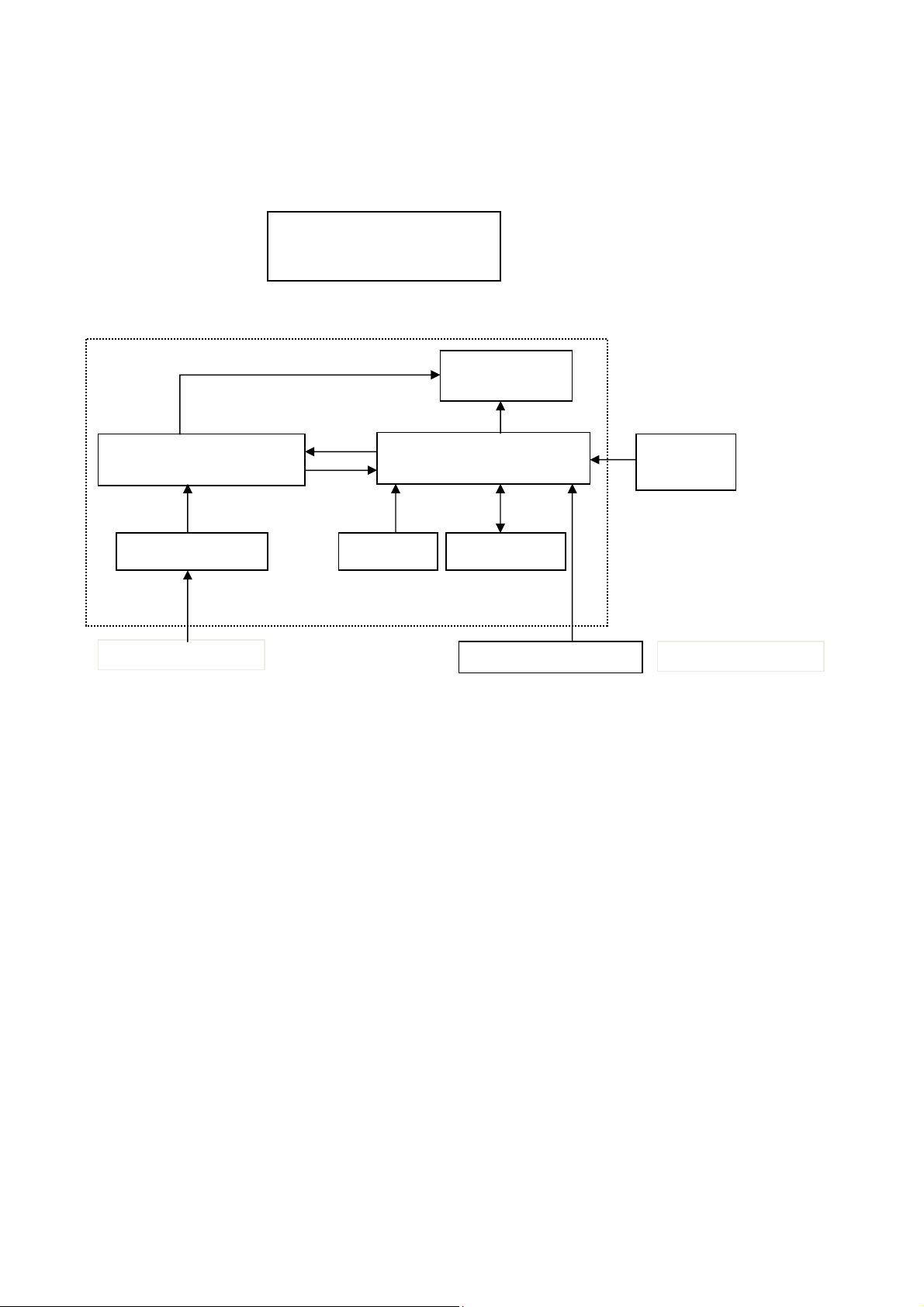

The LCD monitor will contain a main board, an adapter board, a converter board ,a key board and two USB

boards.The main board houses the flat panel control logic, brightness control logic and DDC.

The adapter board will provide AC to DC Inverter voltage to drive the backlight of panel and the main board chips

each voltage.

LED Drive

Monitor Block Diagram

Flat Panel and

LED backlight

Converter Board

Adapter Board

C-IN 90~264V

Key Board

Main Board

USB Board*2

HOST Computer

DVI-D

D-SUB

Video signal, DDC

6

Page 7

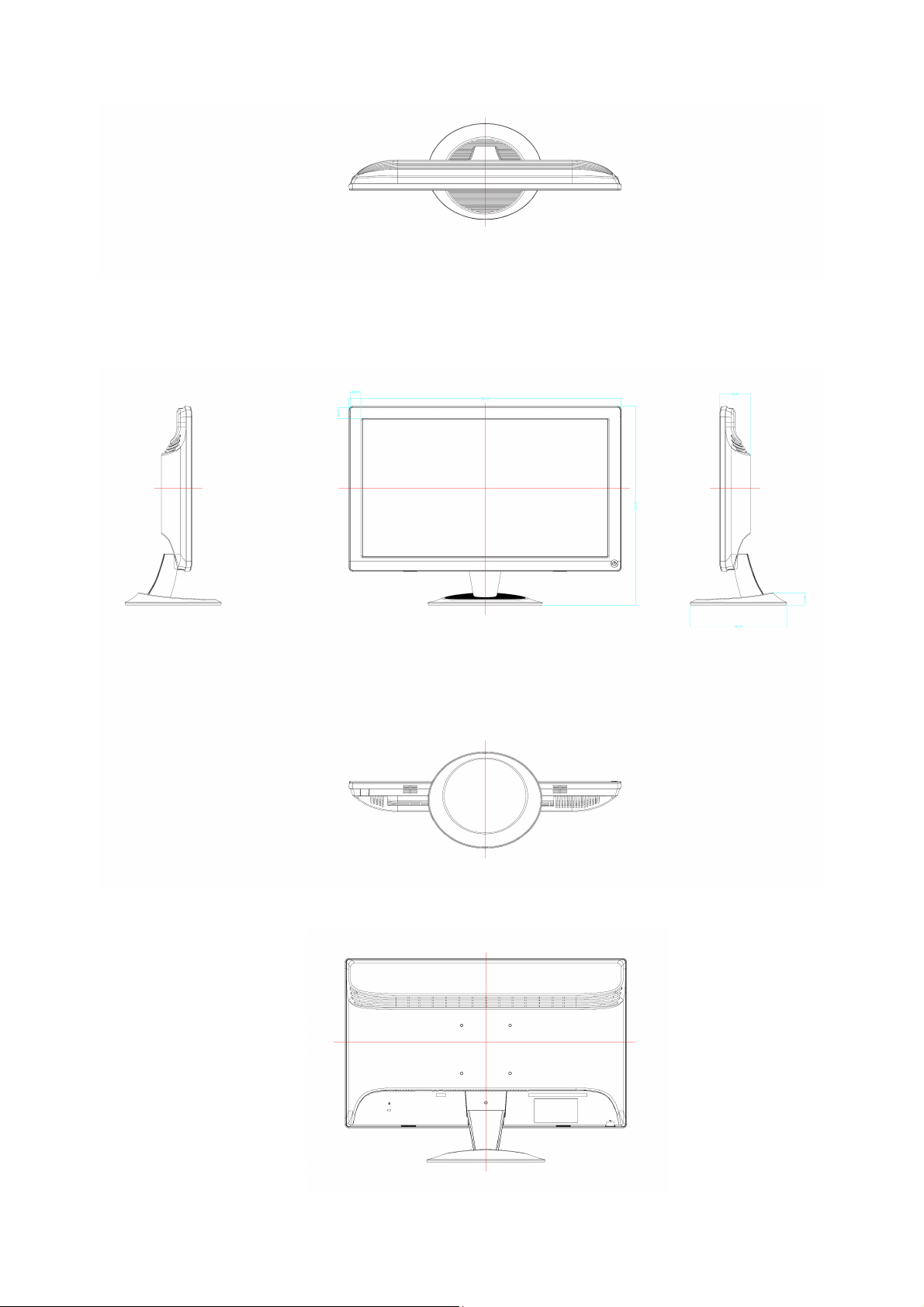

View and Dimension

7

Page 8

3. Operating Instructions

3.1 General Instructions

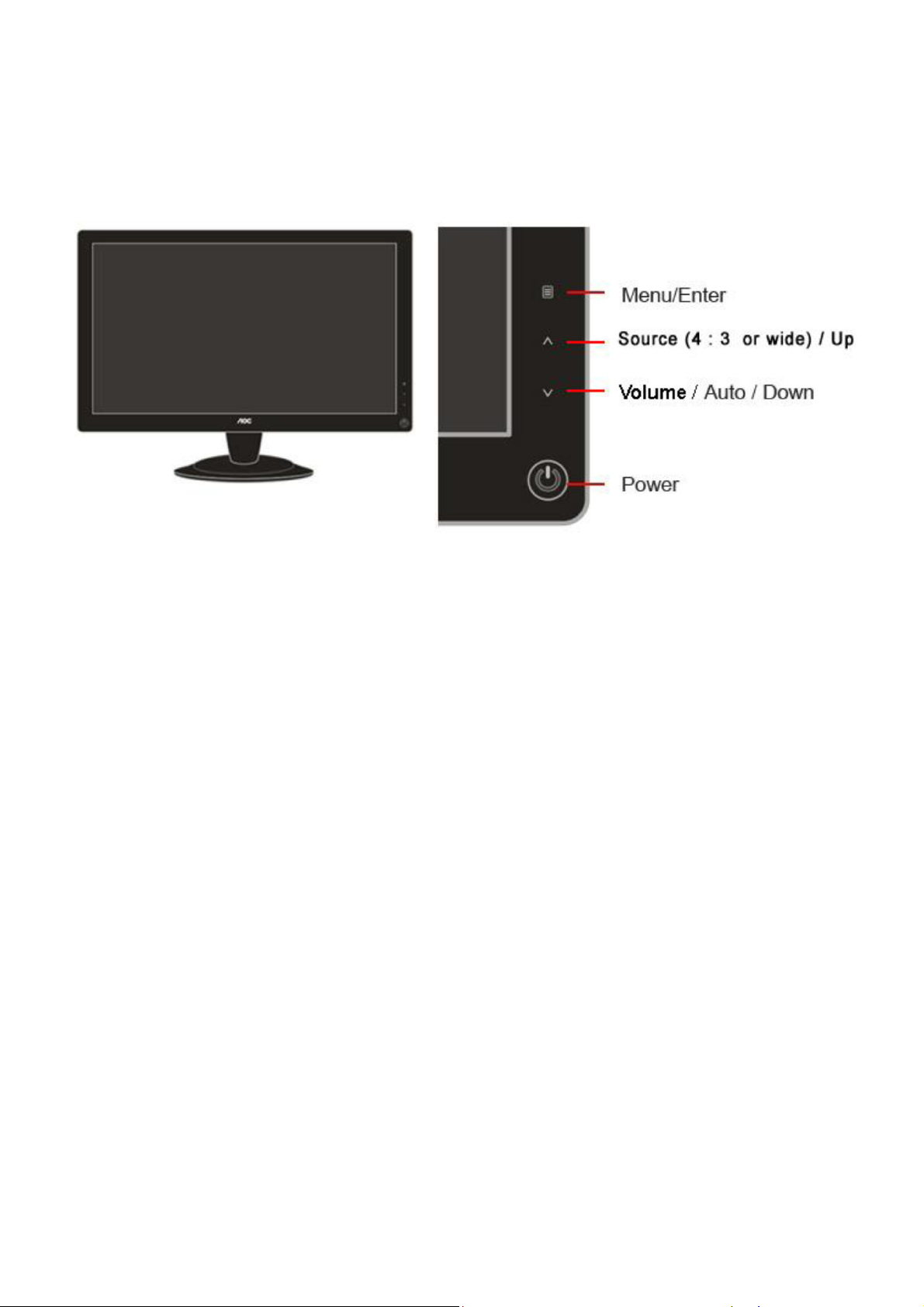

Press the power button to turn the monitor on or off. The other control knobs are located at front panel of the monitor

(See Figure ). By changing these settings, the picture can be adjusted to your personal preferences.

* The power cord should be connected.

* Press the power button to turn on the monitor. The power indicator will light up.

3.2 Control Buttons and Connections

Power Press to turn on or turn off the monitor.

Source (4 : 3 or wide)/ Up

Press∧key to change the screen aspect ratio between standard 4:3 format or Wide format. When the input

resolution is wide format, the aspect ratio hotkey is disabled. When the main menu or sub-menu is active, the∧ key

functions as to select up or increase value.

Source hot key : When the OSD is closed, press button will be Source hot key function (Only for the models with

dual or more inputs) .Press Source button continuously to select the input source showed in the message bar , press

Menu/Enter button to change to the source selected.

Menu / Enter

Press to activate OSD, then press Up or Down to navigate through the functions. Once the desired function is

highlighted, press the Menu button to activate the submenu. In sub-menu, Press Up or Down to navigate through

the functions. Once the desired function is highlighted, press Up or Down button to change the setting. Select Exit

icon then press Menu button to return to superior menu.

Volume(Auto) / Down

When there is no OSD, press the key to activate Volume and auto function, then press Up or Down to select

Volume or Auto configure function. Once the Volume icon is selected, press Menu button to activate it, and press Up

or Down to change the setting, press Menu button for confirmation and exit OSD . Once the Auto icon is selected,

press Menu button to do auto configure and exit OSD . If the product has no speaker built-in, to press the Down key

is to do auto configure directly. When it is DVI or HDMI input, auto configure function is disabled and the auto icon is

gray.

8

Page 9

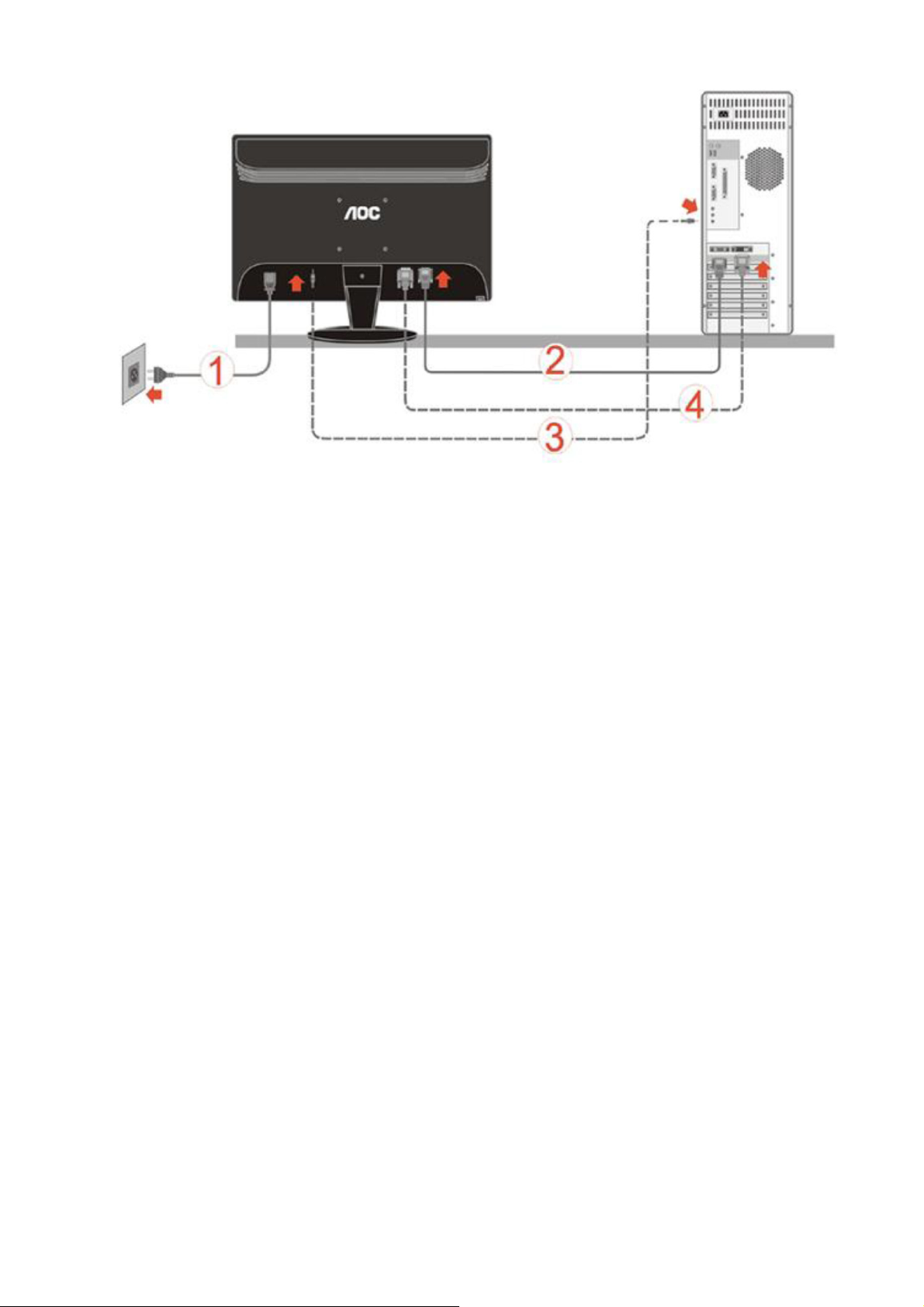

1. Power

2. Analog (DB-15 VGA cable)

3.Audio

4.DVI

To protect equipment, always turn off the PC and LCD monitor before connecting.

1 Connect the power cable to the AC port on the back of the monitor.

2 Connect one end of the 15-pin D-Sub cable to the back of the monitor and connect the other end to the computer's

D-Sub port.

3 Connect the audio cable to audio in port on the back of the monitor.

4 (Optional – Requires a video card with DVI port) - Connect one end of the DVI cable to the back of the monitor and

connect the other end to the computer‟s DVI port.

5 Turn on your monitor and computer.

If your monitor displays an image, installation is complete. If it does not display an image, please refer

Troubleshooting.

9

Page 10

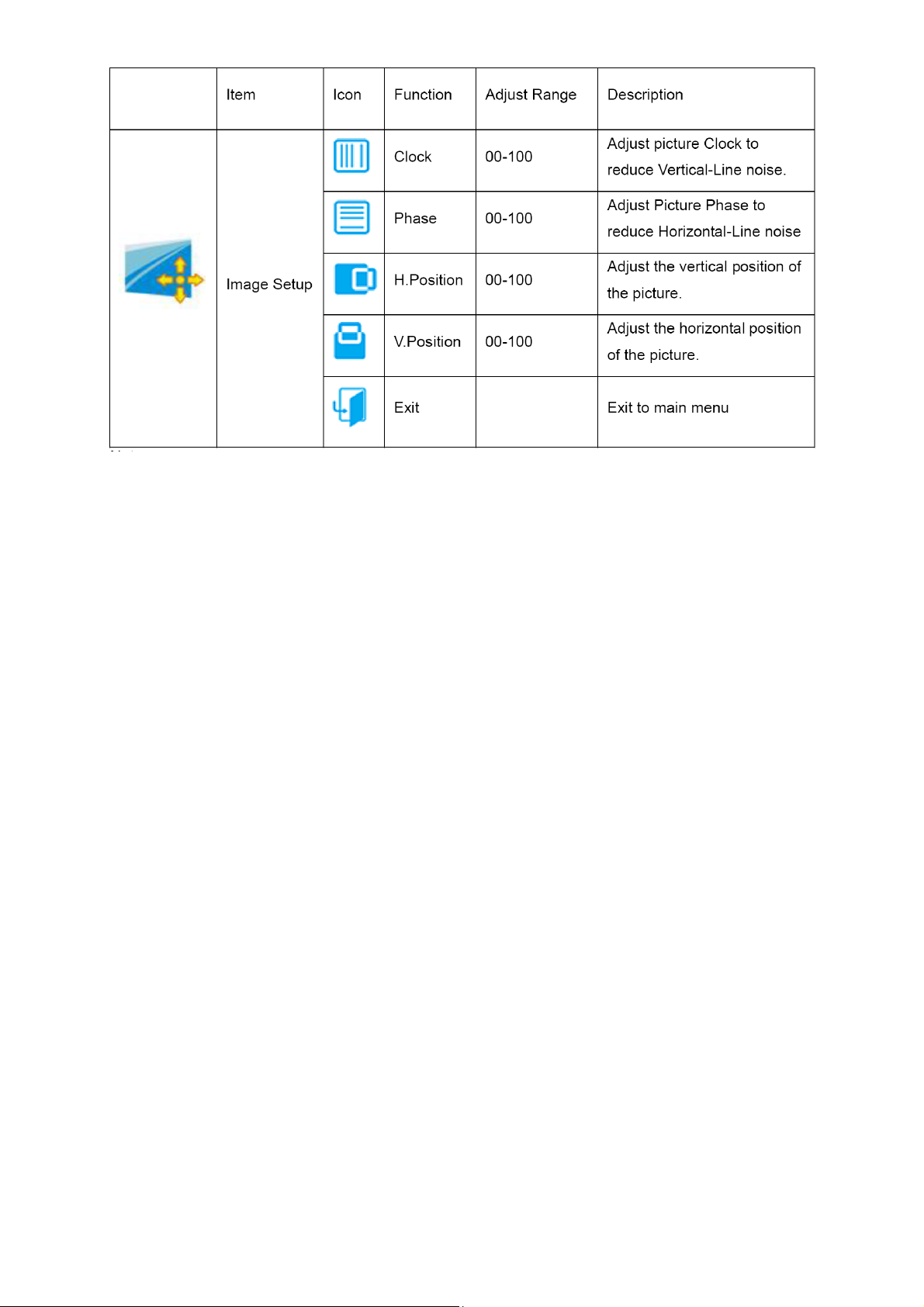

3.3 OSD Setting

Basic and simple instruction on the control keys.

When you press the MENU button on the front control of your monitor, the On DOWN Screen Display (OSD) Main

Controls window will pop up and you can then start making adjustments to your monitor's various features. Use the

UP or DOWN keys to make your adjustments. Follow the steps below to activate the adjustment.

1) Press the MENU key to activate the OSD window.

2) Press UP or DOWN to navigate through the functions. Once the desired function is highlighted, press the MENU

key to activate it. If the function selected has a sub-menu, press UP or DOWN again to navigate through the

sub-menu functions. Once the desired function is highlighted, press MENU key to activate it.

3) Press UP or DOWN to change the settings of the selected function. Press MENU key to exit and save, select the

exit function. If you want to adjust any other function, repeat steps 2-3.

4) OSD Lock Function: To lock the OSD, press and hold the MENU key while the monitor is off and then press

power button to turn the monitor on. To unlock the OSD, press and hold the MENU key while the monitor is off and

then press power button to turn the monitor on.

10

Page 11

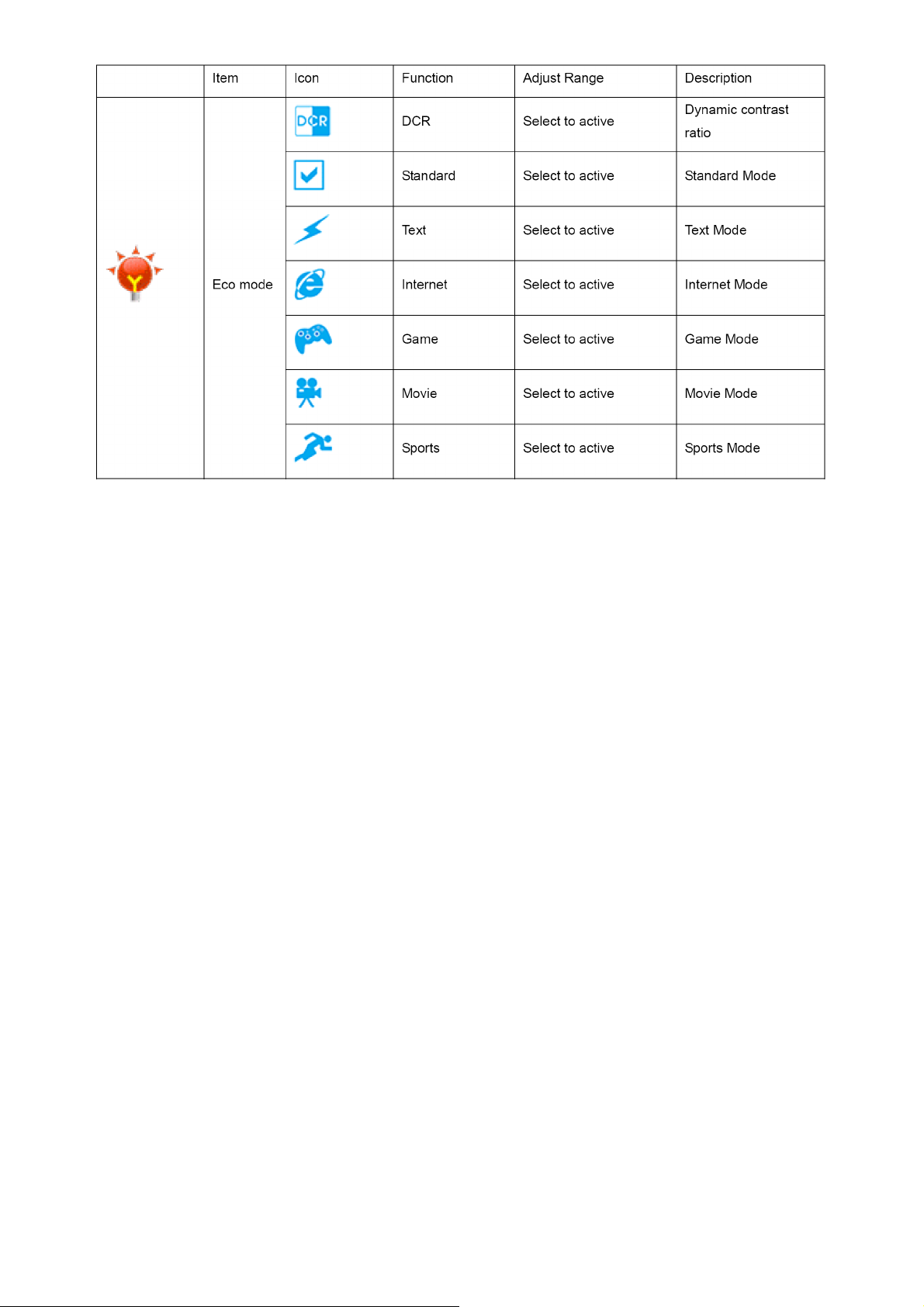

Eco mode

11

Page 12

Notes :

When Eco mode is not set as “Standard”, Contrast and Brightness can not be adjusted; When DCR is set as “On”,

Contrast, Brightness, Eco mode and Gamma can not be adjusted.

12

Page 13

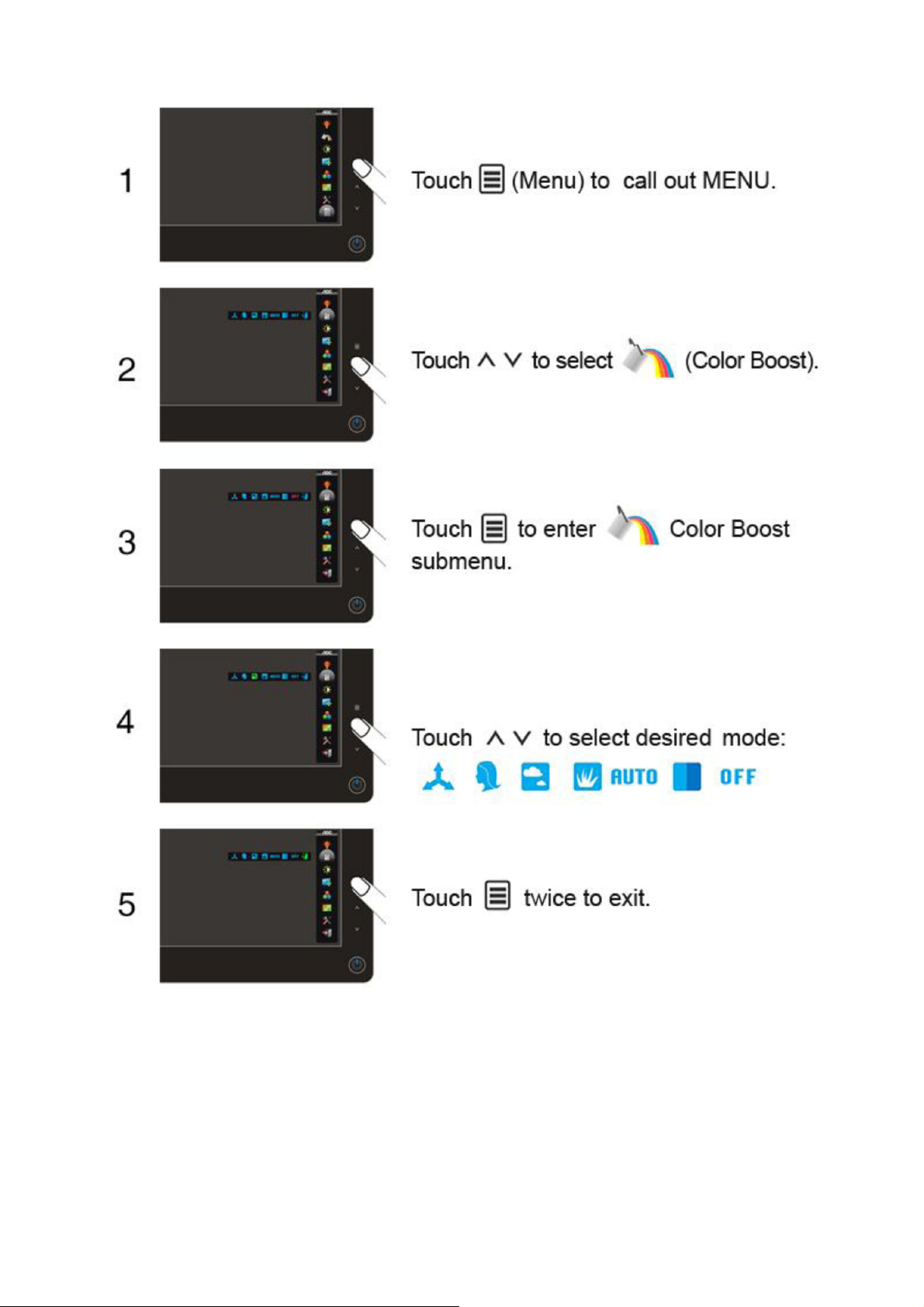

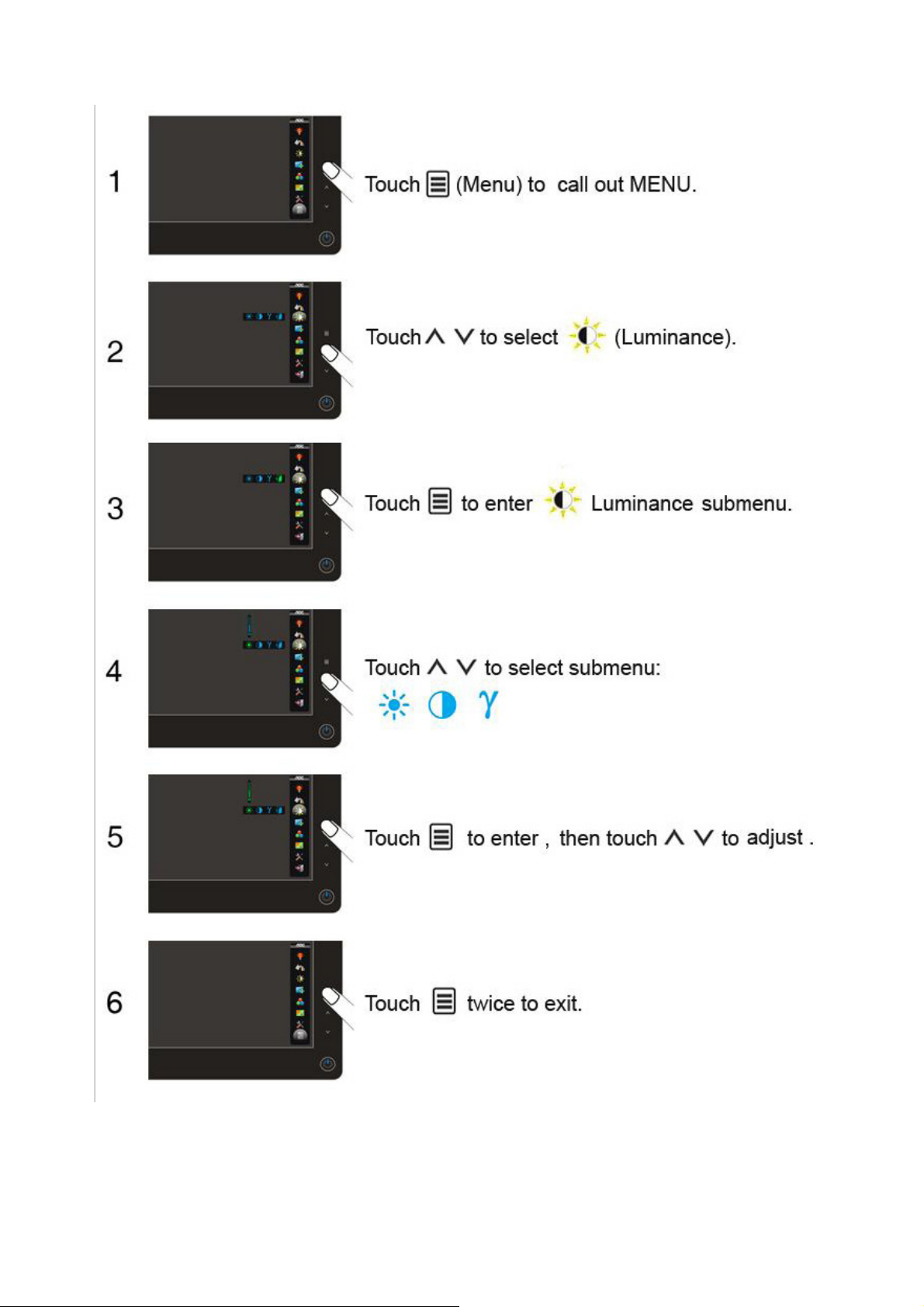

Color Boost

13

Page 14

Notes :

Full Enhance: Total color saturation is enhanced, suitable for vivid pictures.

Natural Skin: Suitable for human portrait.

Green Field: Suitable for large area of green.

Sky Blue: Suitable for sky or ocean scene.

Auto Detect: Suitable for outdoor or garden.

Demo: Screen divided into two for comparison purpose.

14

Page 15

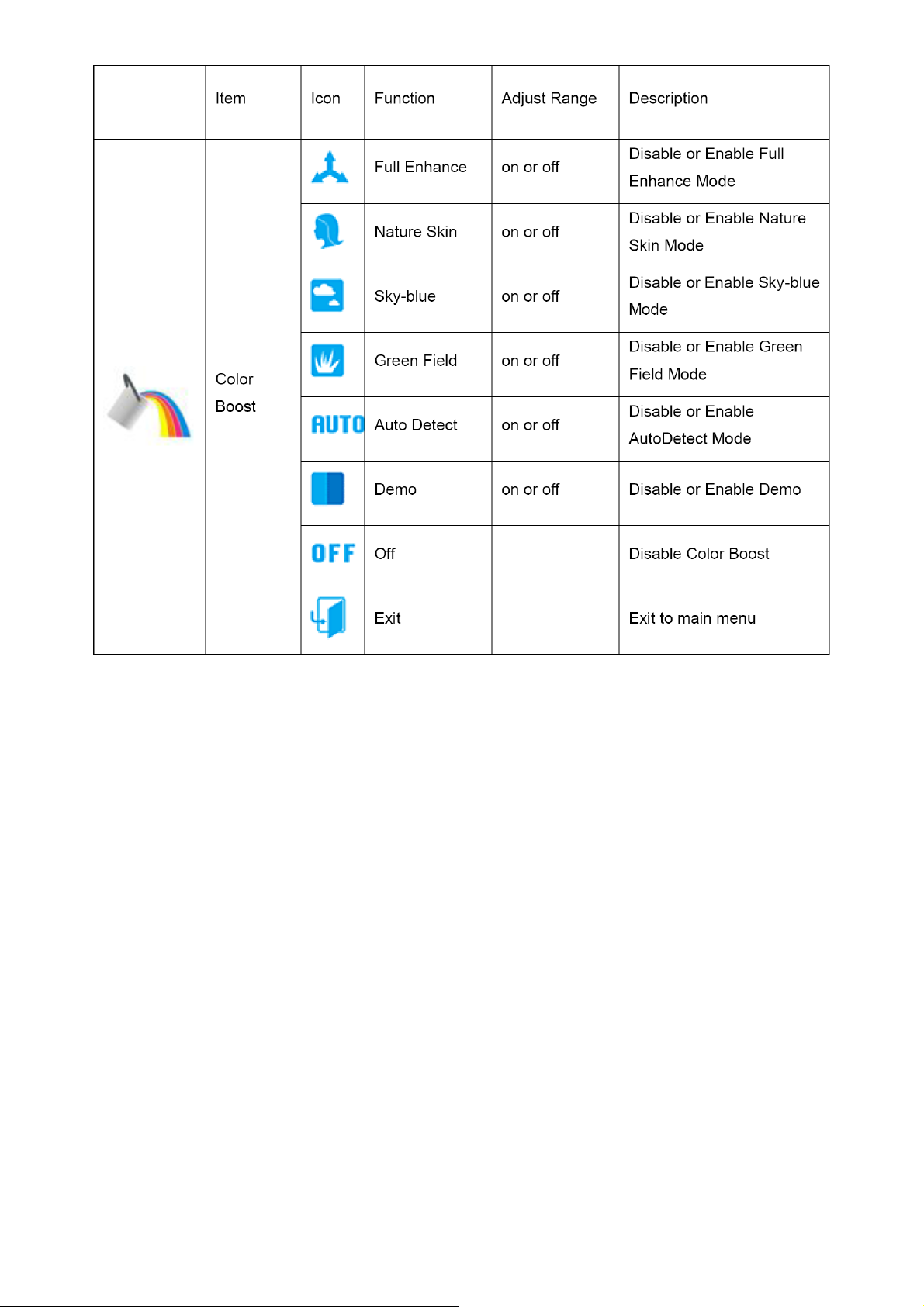

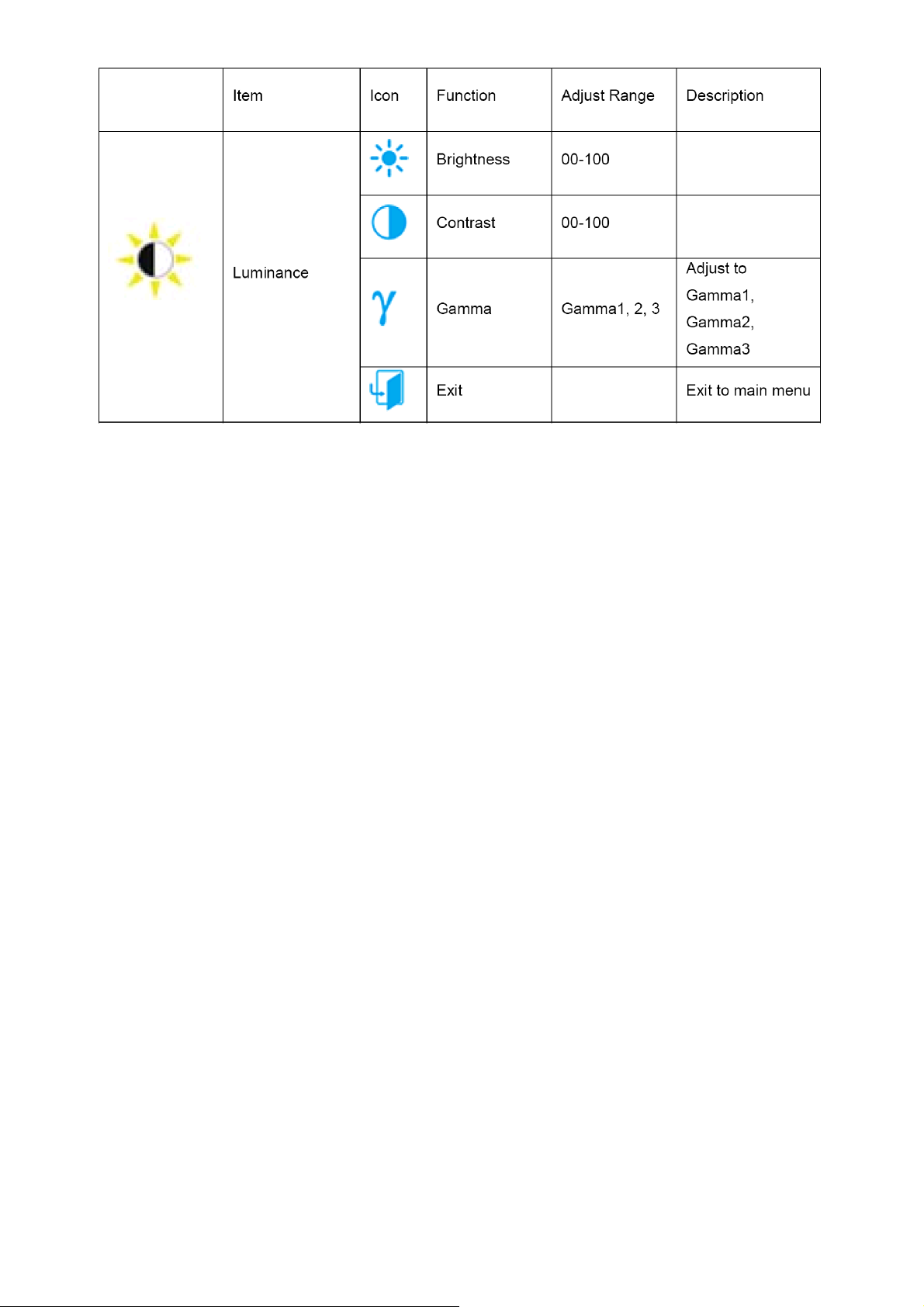

Luminance

15

Page 16

Notes :

When Eco mode is not set as “Standard”, Contrast and Brightness can not be adjusted; When DCR is set as “On”,

Contrast, Brightness, Eco mode and Gamma can not be adjusted.

16

Page 17

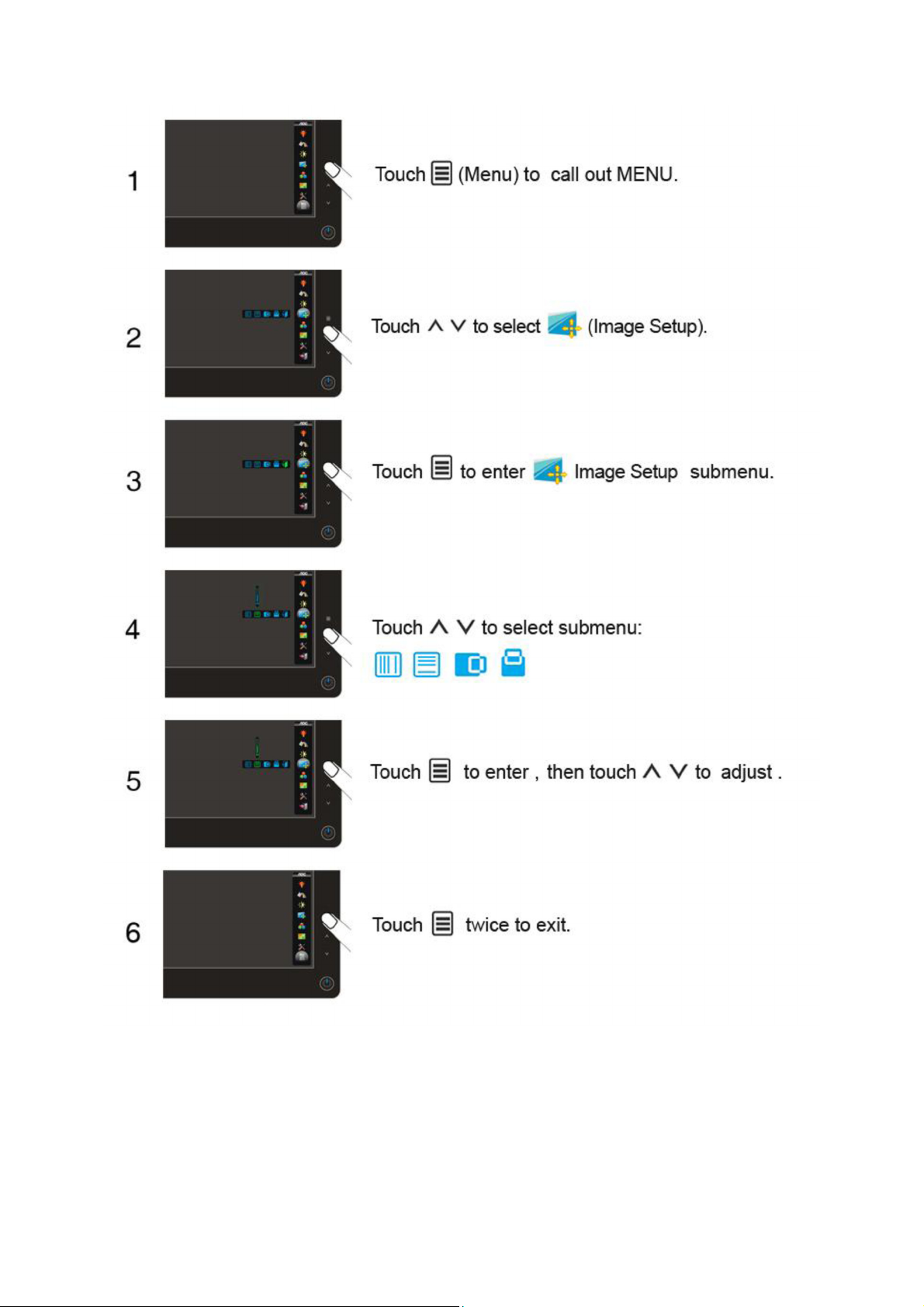

Image Setup

17

Page 18

Notes :

When the input source is digital signal like DVI or HDMI, Image Setup can not be adjusted.

18

Page 19

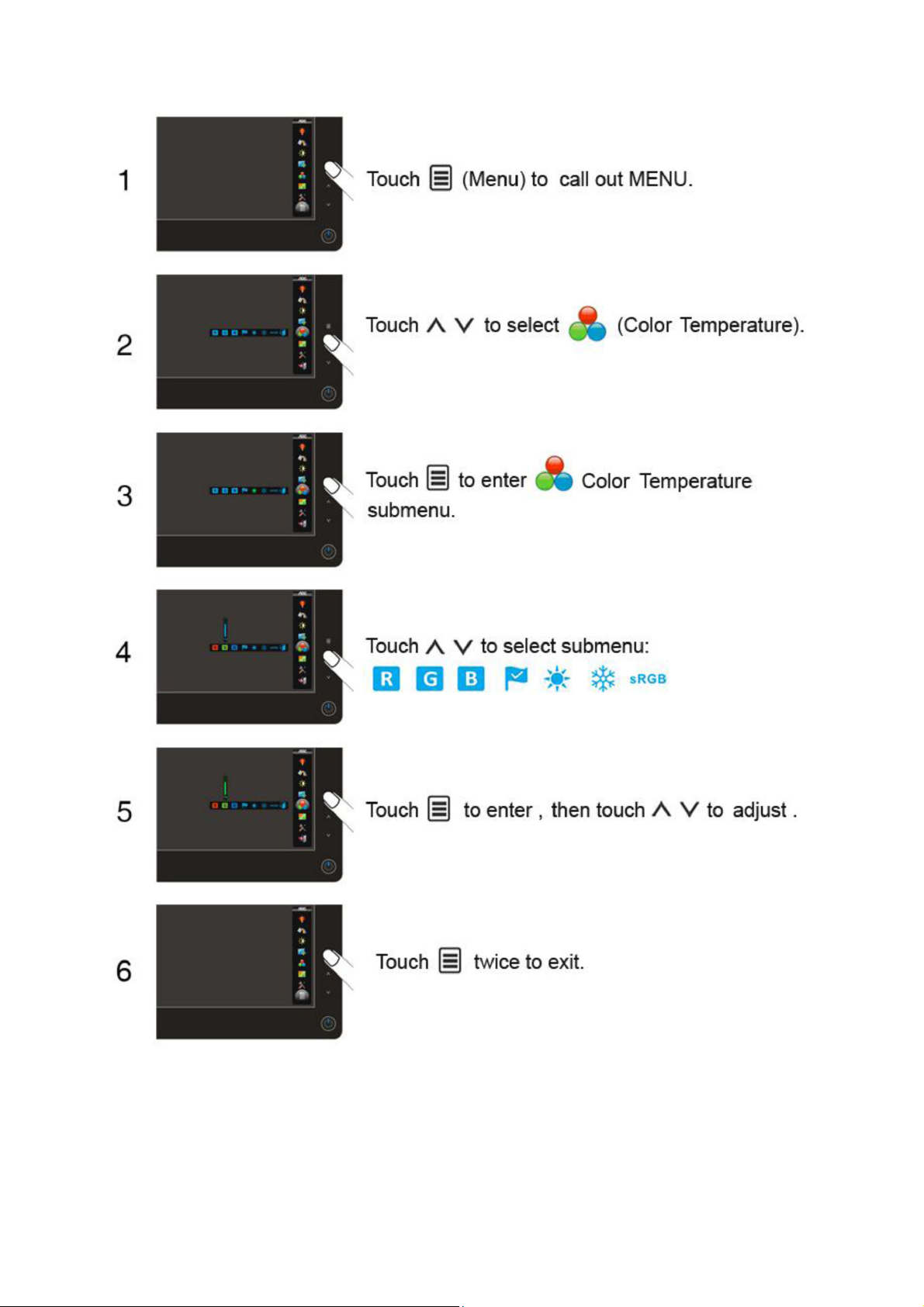

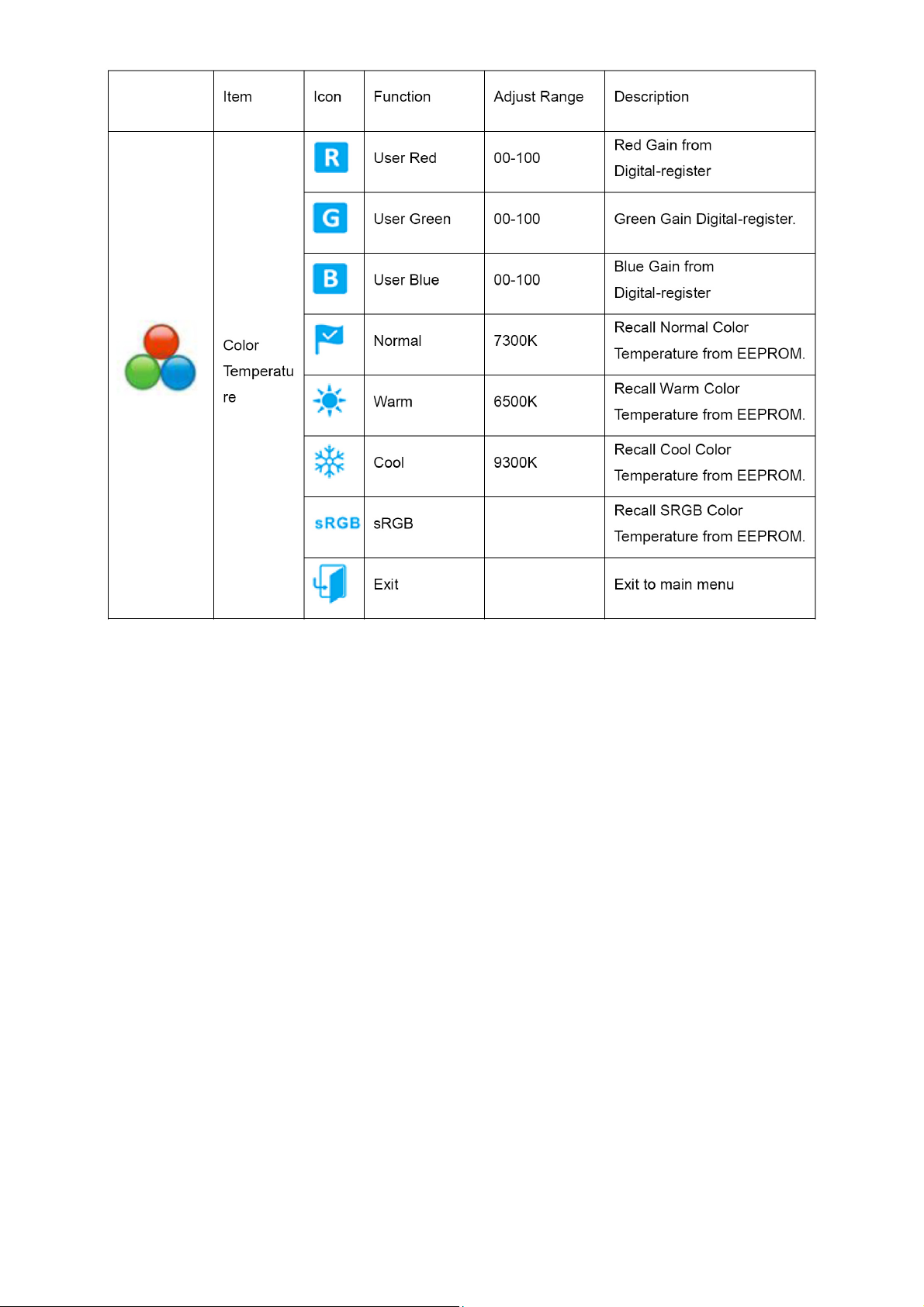

Color Temperature

19

Page 20

20

Page 21

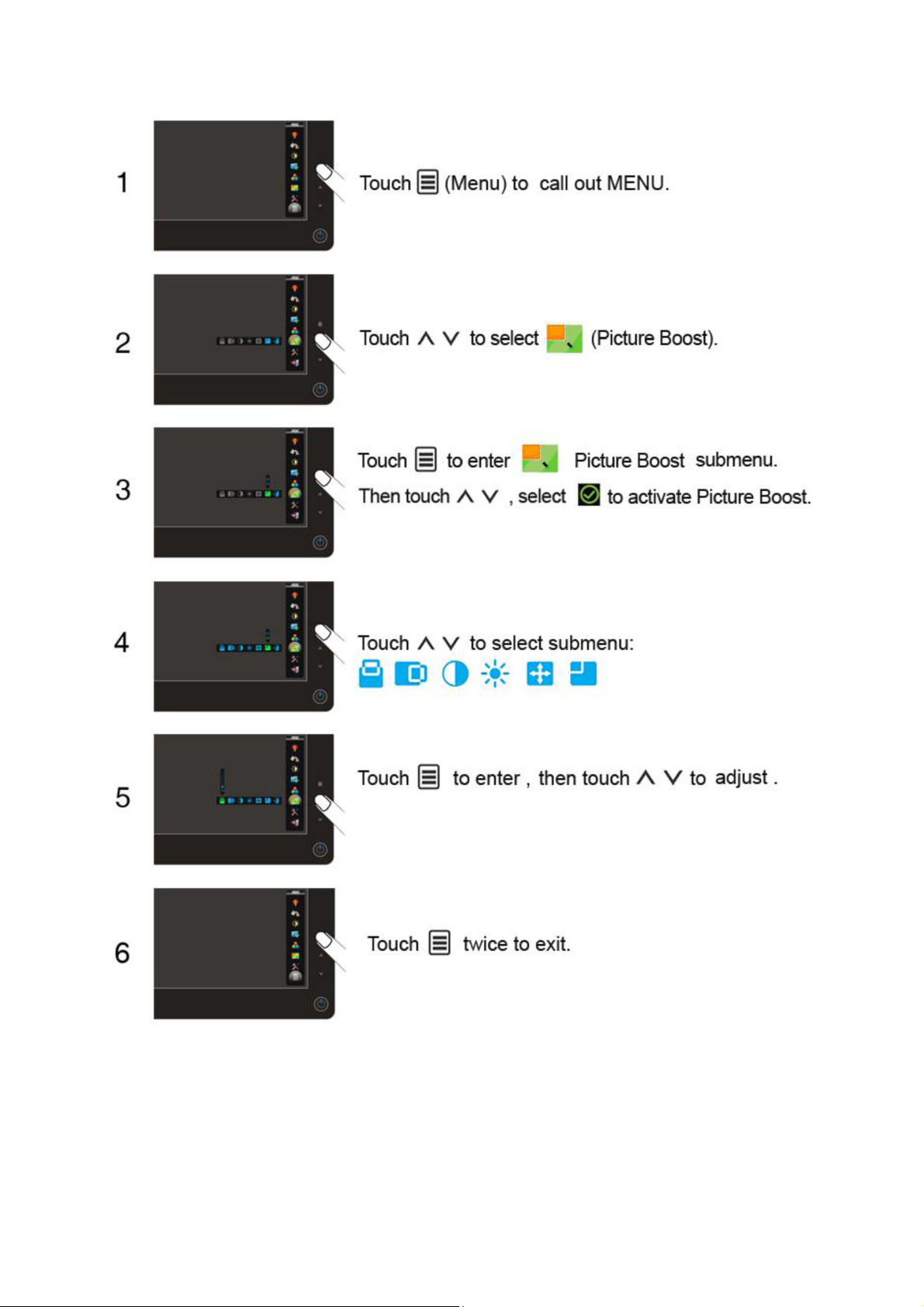

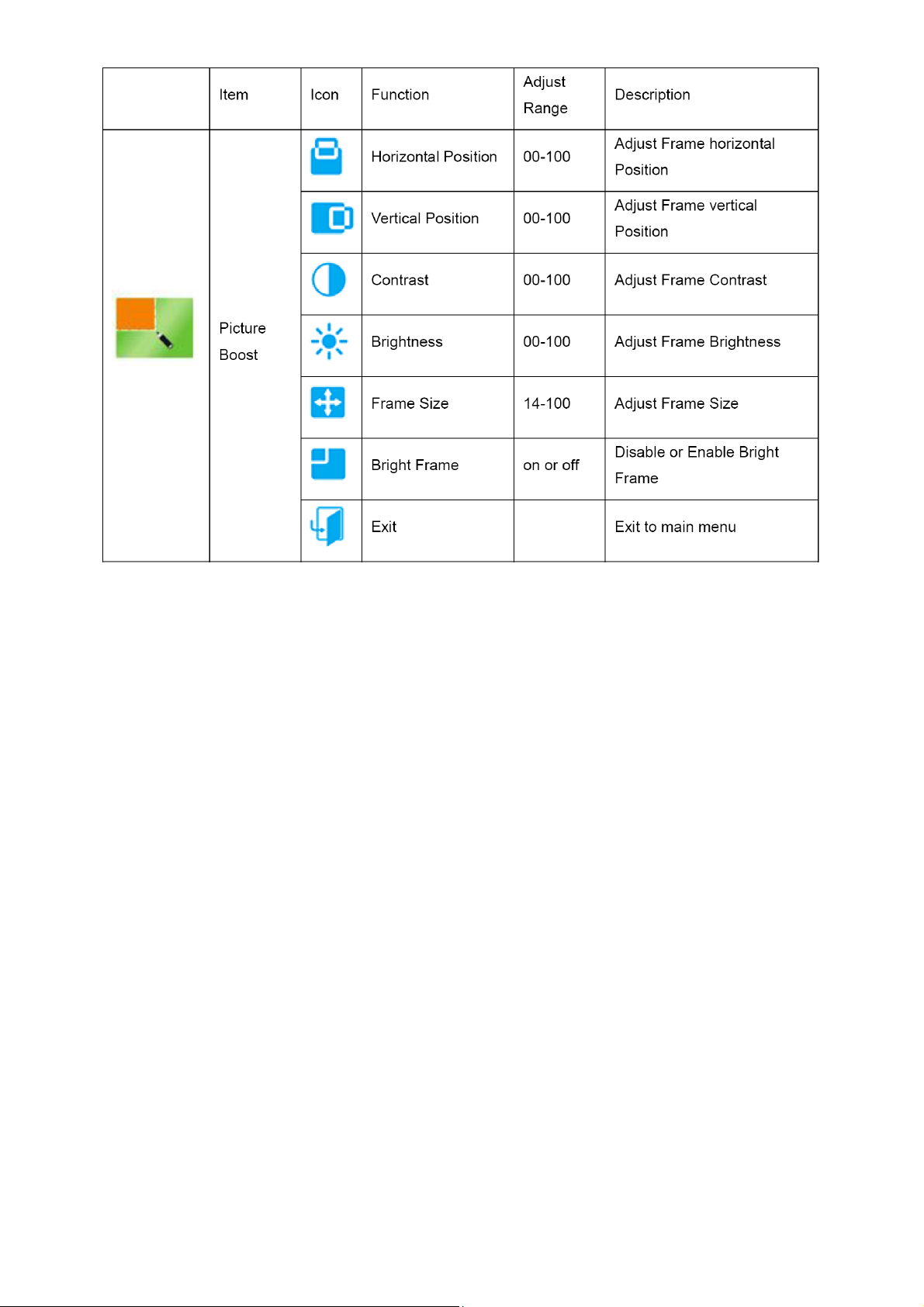

Picture Boost

21

Page 22

Notes :

One of DCR, Color Boost, and Picture Boost functions is active, the other two function is turned off accordingly.

22

Page 23

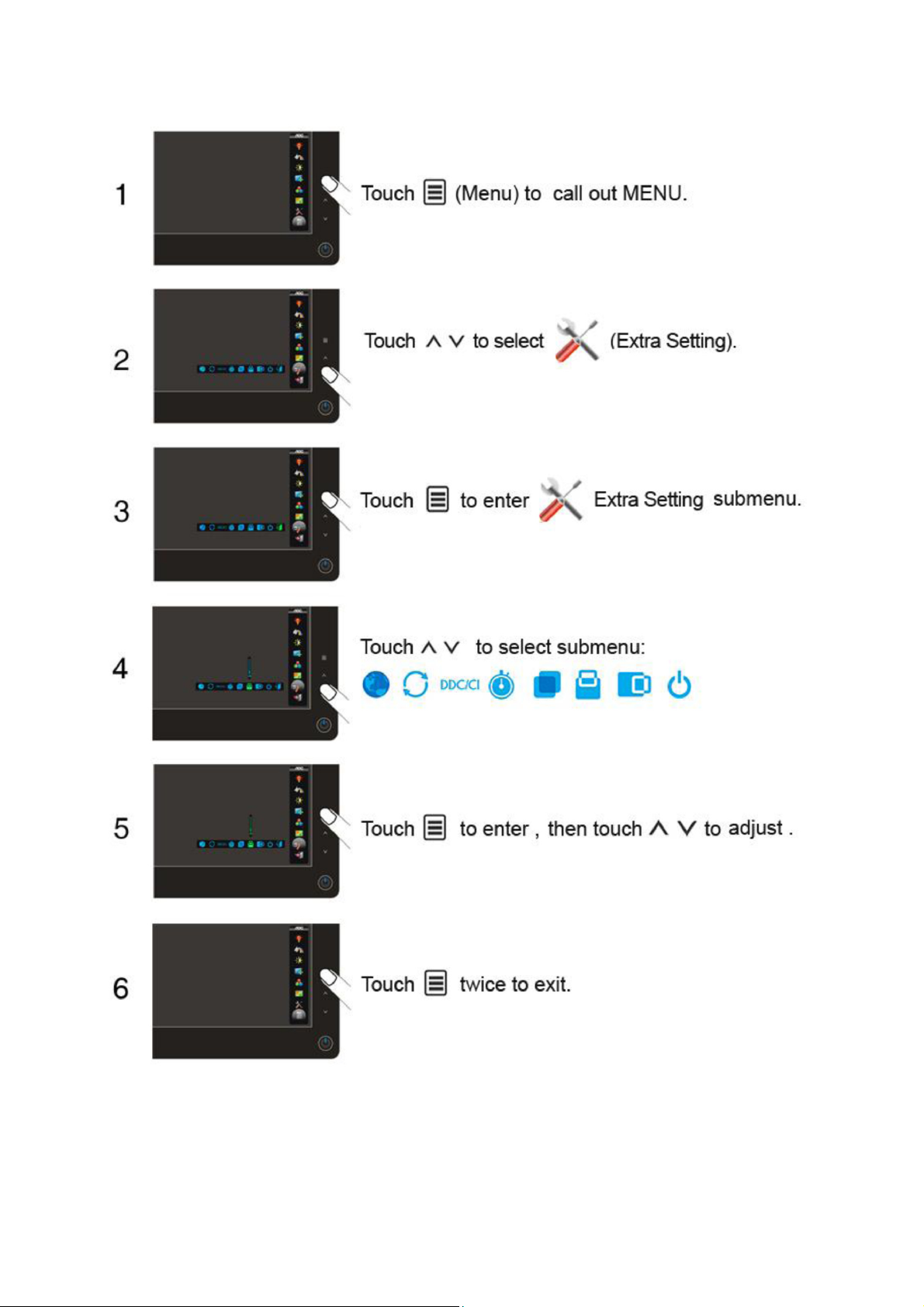

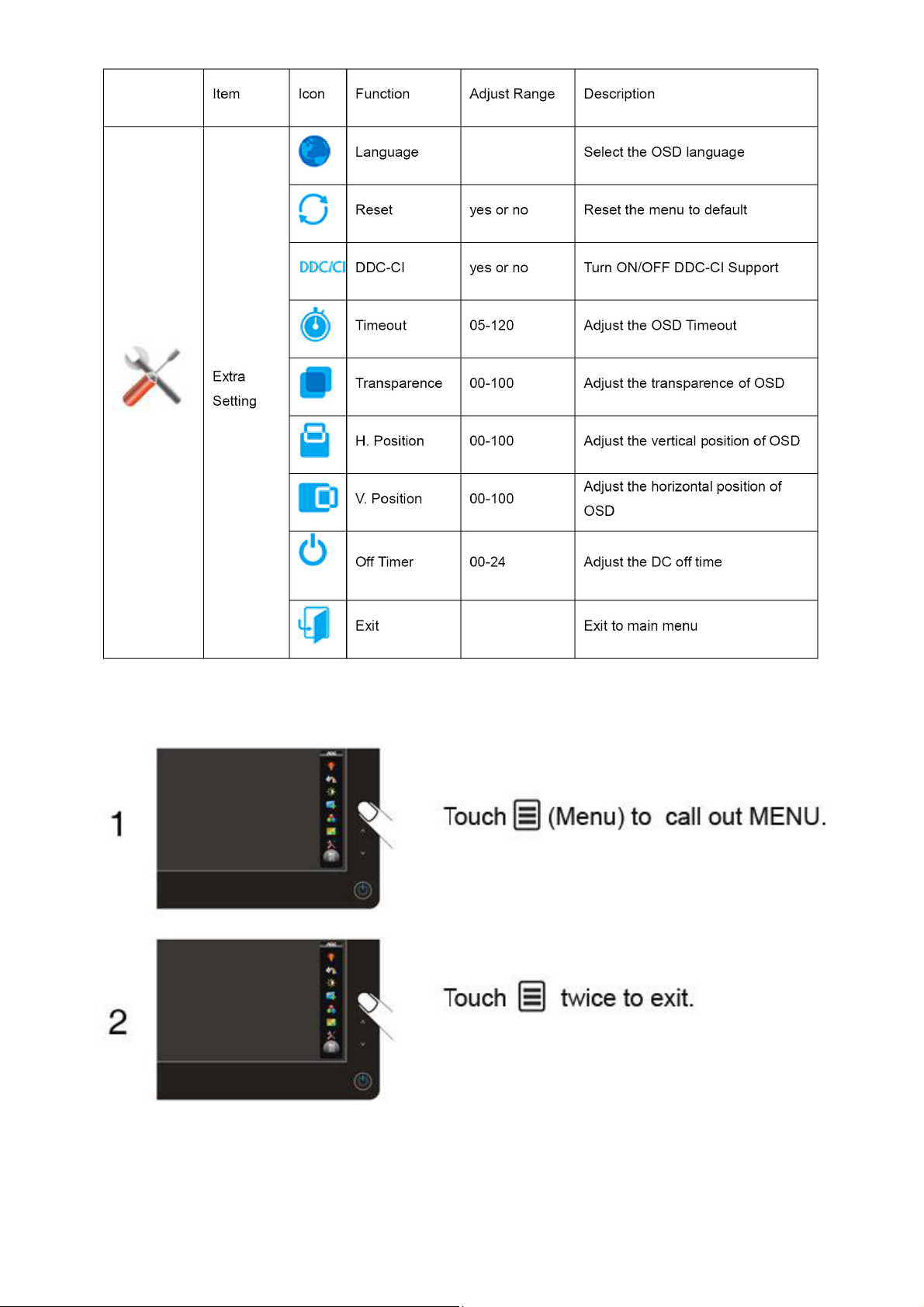

Extra Setting

23

Page 24

Exit

24

Page 25

LED Indicators

Status LED Color

Full Power Mode Blue

Active-off Mode Orange

25

Page 26

4. Input/Output Specification

4.1 Input Signal Connector

Analog connector

Pin Number 15-Pin Side of the Signal Cable

DVI connector

1 Video-Red

2 Video-Green

3 Video-Blue

4 N.C.

5 Detect Cable

6 GND-R

7 GND-G

8 GND-B

9 +5V

10 Ground

11 N.C.

12 DDC-Serial data

13 H-sync

14 V-sync

15 DDC-Serial clock

Pin

No.

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 0-

2 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4 Shield 11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

4 TMDS Data 4- 12 TMDS Data 3- 20 TMDS Data 5-

5 TMDS Data 4+ 13 TMDS Data 3+ 21 TMDS Data 5+

6 DDC Clock 14 +5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground(for+5V) 23 TMDS Clock +

8 N.C. 16 Hot Plug Detect 24 TMDS Clock -

Signal Name Pin No. Signal Name

Pin

No.

Signal Name

26

Page 27

4.2 Preset Display Modes

STANDARD RESOLUTION

VGA 640×480 @60Hz 31.469 59.940

VGA 640×480 @67Hz 35.000 66.667

VGA 640×480 @72Hz 37.861 72.809

VGA 640×480 @75Hz 37.500 75.000

Dos-mode 720×400 @70Hz 31.469 70.087

SVGA 800×600 @56Hz 35.156 56.250

SVGA 800×600 @60Hz 37.879 60.317

SVGA 800×600 @72Hz 48.077 72.188

SVGA 800×600 @75Hz 46.875 75.000

SVGA 832×624 @75Hz 49.725 74.550

XGA 1024×768 @60Hz 48.363 60.004

XGA 1024×768 @70Hz 56.476 70.069

XGA 1024×768 @75Hz 60.023 75.029

XGA 1024×768 @75Hz 60.241 74.927

*** 1280×960 @60Hz 60.000 60.000

SXGA 1280×1024 @60Hz 63.981 60.02

SXGA 1280×1024 @75Hz 79.976 75.025

WXGA+ 1440×900 @60Hz 55.935 59.887

WSXGA 1680X1050 @60Hz 65.290 59.954

HD 1920×1080@60Hz 67.500 60.000

HORIZONTAL

FREQUENCY(kHZ)

VERTICAL

FREQUENCY(Hz)

4.3 Panel Specification

4.3.1 General Features

M236H3-L02 is a 23.6” TFT Liquid Crystal Display module with WLED Backlight unit and 30 pins 2ch-LVDS

interface. This module supports 1920 x 1080 Full HD mode and can display up to 16.7M colors. The converter

module for Backlight is not built in.

Features

–Extra-wide viewing angle. -High contrast ratio.

-Fast response time. -High color saturation.

-Full HD (1920 x 1080 pixels) resolution.

-DE (Data Enable) only mode.

-LVDS (Low Voltage Differential Signaling) interface.

RoHS compliance.

4.3.2 GENERAL SPECIFICATIONS

27

Page 28

4.3.3 Electrical Characteristics

1.TFT LCD Module

Vcc = 5.0 V, Ta = 25 ± 2℃, fv = 60Hz

2.Back Light Unit(LED matrix is 12S8P)

Ta = 25 ± 2℃

Note (1)LED can work normally if the PWM dinming ratio range is from 0% to 100% and the operation current

Is 25mA

Note (2) PLED = (ILED×8) ×VLED, LED matrix is 12S8P.

Note (3)The lifetime of LED is defined as the time when it continues to operate under the conditions at

Ta = 25 ± 2℃ and I = 25 mA(Per EA) until the brightness becomes ≤50% of its original value.

28

Page 29

4.3.4 Optical Characteristics

Ta = 25 ± 2℃,Ha =50±10 %RH, VCC =7V

29

Page 30

5. Block Diagram

5.1 Main Board

Keypad Interface Panel Interface

(CN402) (CN301)

Flash IC EN25F20 Scaler IC TSUMU58EHL-L Crystal

(U402) (Include ADC.OSD.MCU) NXS14.31818

(U401) (X401)

EEPROM EEPROM

AT24C02BN AT24C02BN

(U101) (U102)

DDC1-SCL DDC2-SCL

DDC1-SDA DDC2-SDA

D-Sub Connector DVI Connector

(CN101) (CN102)

30

Page 31

5.2 Power Board

Adapter

AC input Bridge Rectifier Transformer Rectifier 16V

EMI filter and Filter (T901) diodes

5V

Start Resistor

(R904,R905)

PWM Control Power Switch Feedback

LD7576(IC901) (Q901) Circuit

Photocoupler Regulator

(IC903) (IC904)

Audio

CN601(PHONE JACK)

Audio Power Amplifier

5V APA2069JITUL CN602

(IC601)

Converter

Boost Circuit 12V

LED

OVP Circuit Setup-up Controller

Panel DIM

IC TA9690G

Current Feedback (IC801,IC802) ENA

31

Page 32

6. Schematic

6.1 Main Board

715G3329 1 2

DDC1_SCL5

DDC1_SDA5

DDC 1_SCL

DDC 1_SDA

CN102

SYN C GND

JACK

GND POW ER

100R 1/16W 5%

VSYNC

DDC SCL

DDC SDA

+5V

HPD

1/3shiel d

2/4shiel d

0/5shiel d

clk shield

DAT0+

DAT0DAT1+

DAT1DAT2+

DAT2DAT3+

DAT3DAT4+

DAT4DAT5+

DAT5-

clk+

clk-

GND

GND

26

25

R101

R113

100R 1/16W 5%

8

15

DVI_HPD

6

7

14

16

11

3

19

22

18

17

10

9

2

1

13

12

5

4

21

20

23

24

DGND

H_Sync

R102 0R05 1/ 10W 5%

V_Sy nc

15

DSUB_SCL

14

13

DSUB_SDA

12

11

U107

AZC199-04S

1

I/O1

I/O4

2

GND

VDD

3 4

I/O2 I/O3

R106

2K2 1/16W 5%

CN101

17 16

ESD_VCC 1

6

5

候綼

10

5

9

4

8

3

7

2

6

1

U107

VGA_PLUG

DVI_5V

C120

NC

R107

2K2 1/16W 5%

VGA_BVGA_B+

ZD104

VGA_G-

RLZ5.6B

VGA_G+

VGA_RVGA_R+

R120 10K 1/16W 5%

C115

0.1uF/ 16V

U105

AZC199-04S

1

I/O1

I/O4

2

GND

VDD

3 4

I/O2 I/ O3

ESD_VCC 1

FB110

300 OHM

R103 1K 1/16W 5%

R104 1K 1/16W 5%

C103

C104

22pF

22pF

DSUB_SCL

DSUB_SDA

DSUB_5V

6

5

C124

0.1uF/ 16V

VGA_G+

VGA_R+

R118 100R 1/16W 5%

R119 100R 1/16W 5%

R126 10R 1/16W 5%

R127 10R 1/16W 5%

R128 10R 1/16W 5%

R129 10R 1/16W 5%

R130 10R 1/16W 5%

R131 10R 1/16W 5%

C118

NC

U105

ESD_VCC 2

U106

AZC199-04S

1

I/O1

I/O4

2

GND

VDD

3 4

I/O2 I/ O3

ESD_VCC 1 ESD_VCC 1

候綼

DSUB_H 5

DSUB_V 5

U104

AZC199-04S

1

I/O1

I/O4

2

GND

VDD

3 4

I/O2 I/O3

U103

AZC199-04S

1

I/O1

I/O4

2

GND

VDD

3 4

I/O2 I/O3

DDC2_SCL

DDC2_SDA

RX0P

RX0N

RX1P

RX1N

RX2P

RX2N

R132 10R 1/ 16W 5%

R134 10R 1/ 16W 5%

6

5

C119

NC

候綼

U106

6

5

6

5

DDC2_SCL 5

DDC2_SDA 5

RX0P 5

RX0N 5

RX1P 5

RX1N 5

RX2P 5

RX2N 5

H_Sync

V_Sy nc

VGA_PLUG

VGA_B+

RXCP

RXCN

ESD_VCC

候綼

ESD_VCC

候綼

R122

NC

DVI_HPD

VGA_PLUG

VGA_B+

VGA_B-

VGA_G+

C112

NC

U103

C101

NC

U101

DVI 1_5V

R140

NC

R121

NC

Q101

NC

RXCP 5

RXCN 5

R135

10K 1/16W 5%

6K8 1/16W 5%

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

Date

VGA_G-

VGA_R+

VGA_R-

HDCP_CTRL 5

VCC3.3

R133

10K 1/16W 5%

DET_CABLE 5R139

G3329-C-2-X-2-090401

2.0.I NPUT

FB102

1 2

BEAD

FB103

1 2

BEAD

FB101

1 2

BEAD

4K7 1/16W 5%

DDC1_SCL

DDC1_SDA

DDC_WP5

100R 1/16W 5%

R105

R108

75R 1/16W 5%

R112

75R 1/16W 5%

R116

75R 1/16W 5%

ESD_VCC

R124

R125

4K7 1/16W 5%

CMVCC1

4K7 1/16W 5%

FB104

300 OHM

C121

1000pF

ESD_VCC1

R137

DDC2_SCL

DDC2_SDA

DDC_WP5

OEM MO DE L Si ze

TPV MO DEL

PCB NAME

Sheet

C105

5pF/50V

100R 1/16W 5%

R109

470R 1/16W 5%

R110

R111

100R 1/16W 5%

C109

5pF/50V

100R 1/16W 5%

R114

100R 1/16W 5%

R115

C113

5pF/50V

R117

100R 1/16W 5%

CMVCC13,4

R123

4K7 1/16W 5%

2

3

R138

4K7 1/16W 5%

NEW R SERIES

AOC 2236VWA B

25Wednesday , June 10, 2009

of

1

D108

BAV70

R136

4K7 1/16W 5%

8

7

6

C114

8

7

6

C111

0.047uF

VCC

WP

SCL

C102

0.047uF

C106

0.047uF

C107

C108

0.047uF

C110

0.047uF

0.047uF

DVI 1_5V

VCC

WP

SCL

1000pF

CMVCC1

DSUB_5V

1

2

3

U101

1

A0

2

A1

3

A2

45

GNDSDA

AT24C02BN-SH-T

FB105

300 OHM

U102

A0

A1

A2

GNDSDA

AT24C02BN-SH -T

Rev

称爹

DSUB_B+ 5

DSUB_B- 5

DSUB_SOG 5

DSUB_G+ 5

DSUB_G- 5

DSUB_R+ 5

DSUB_R- 5

D104

BAV70

C116

0.22uF16V

DVI_5V

C122

1000pF

C117

0.22uF16V

1

2

3

45

B

称爹

>

<

32

Page 33

PA[0.. 9]5

PPWR_ON #5

PA[0.. 9]

R303

4K7 1/16W 5%

PA0

LVA3P

LVA3M

PA1

LVACKP

PA2

LVACKM

PA3

PA4

LVA2P

LVA2M

PA5

LVA1P LVBCKM

PA6

PA7

LVA1M

LVA0P

PA8

PA9

LVA0M

CMVCC12,4

R304

22K 1/16W 5%

C304

0.1uF /16V

PB[0.. 9]5

CMVCC1

R305

10K 1/16W 5%

Q302

2N3904S-RTK/PS

PB[0.. 9]

56K 1/16W 5%

1

G

R306

3

PB0

LVB3P

PB1

LVB3M

PB2

LVBCKP

LVBCKM

PB3

PB4

LVB2P

PB5

LVB2M

PB6

LVB1P

PB7

LVB1M

PB8

LVB0P

PB9

LVB0M

080912

R307

NC

D

2

S

C302

0.22uF16V

FB301

1 2

120 OHM

Q301

AO3401

C303

1uF/25V

LVB0M

LVB1M

LVB2M

LVBCKM

LVB3M

LVA0M

LVA1M

LVA2M

LVACKM

LVA3M

PANEL_VCC

C305

+

100UF25V

5

D

G

4

RXO0RXO1RXO2RXOCRXO3RXE0RXE1RXE2RXECRXE3-

876

U301

DDD

NC/ AO4411

SSS

123

R308

10K 1/16W 5%

LVB0M

RXO0-

LVB0P

CN302

9

7

5

3

1

CONN

CMVCC1

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

RXO0+

RXO1+

RXO2+

RXOC+

RXO3+

RXE0+

RXE1+

RXE2+

RXEC+

RXE3+

LVB0P

LVB1P

LVB2P

LVBCKP

LVB3P

LVA0P

LVA1P

LVA2P

LVACKP

LVA3P

PANEL_VCC

PANEL_VCC

R301

220 OHM 1/4W

R302

220 OHM 1/4W

29

27

25

23

21

19

17

15

13

11

LVB1M

LVB1P

LVB2M

LVB2P

LVBCKP

LVB3M

LVB3P

LVA0M

LVA0P

LVA1M

LVA1P

LVA2M

LVA2P

LVACKM

LVACKP

LVA3M

LVA3P

RXO0+

RXO1RXO1+

RXO2RXO2+

RXOCRXOC+

RXO3RXO3+

RXE0RXE0+

RXE1RXE1+

RXE2RXE2+

RXECRXEC+

RXE3RXE3+

C301

0.1uF/ 16V

AO3401L

CN301

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

NC

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

G3329-C-2-X-2-090401

3.0.OU TPUT

Date

OEM MODEL Size

TPV MO DEL

PCB NAME

Sheet

NEW R SERIES

AOC 2236VWA

of

35Wednesday , June 10, 2009

Rev

称爹

33

B

B

<

称爹

>

Page 34

CMVCC1 2,3

CN701

9

8

7

6

5

4

3

2

1

CONN

lock type

CMVCC1

CMVCC1

BKLT-VBRI

PANEL_ID #

Volume#

Mut e1

DGND 2,3,5

BKLT-VBRI

BKLT-EN

C702

0.1uF/ 16V

R710 NCBKLT-EN

Volume# 5

C701

0.1uF/ 16V

CMVCC1

R702

10K 1/16W 5%

Q701

2N3904S-RTK/PS

C712

0.1uF/ 16V

R704

22K 1/16W 5%

VCC3.3

R705

1K 1/16W 5%

VCC3.3

R703

10K 1/16W 5%

R706

100R 1/16W 5%

R709

NC

PANEL_ID # 5

Mute 5

on_BACKLIGH T 5

adj_BACKLIGH T 5

Both 223 and 252

foot-print

CMVCC1

R708

3.3OHM 2W

R701

NC

C713

0.1uF/ 16V

SOT 252

C708

0.1uF/ 16V

U704

NC/ AP1117E18LA

3 2

VI VO

GND

4

1

4

U703

AZ1117D-1. 8-E1

OUTIN

GND

1

ADJ(GND )

VOUT

VIN

123

SOT 223

VOUTVI N

VSS

1

U701

AP1117E33LA

SOT 223

23

U702

NC/ AP1117D33L-13

23

C705

0.1uF/ 16V

C709

0.1uF/ 16V

VCC1. 8

+

VCC3.3

C707

+

100UF25V

C704

100UF25V

T P V ( Top Victory Electronics Co . , Ltd. )

Date

G3329-C-2-X-2-090401

4.0.POW ER

絬 隔 瓜 絪 腹

Key Component

OEM MODEL Size

TPV MODEL

PCB NAME

NEW R SERIES

AOC 2236VWA B

of

45Wednesday , June 10, 2009

Sheet

Rev

称爹

34

B

称爹

>

<

Page 35

VDVI

AVDD

CMVCC1

0.22uF16V

MSCL

MSDA

VCC3.3

C401

R412

10K 1/16W 5%

C419

+

10UF50V

NC

SST

Eon

SST

010A

020A

Eon

020

AVDD

U402

1

8

CS#

VCC

2

7

DO

HOLD#

WP

3

6

WP#

CLK

4 5

VSS DI

U402

U402

U402

C420 47pF

C421 47pF

8

7

NC

PPWR_ON#3

U403

NC

VCC

E1

WC

E2

SCL

VSSSDA

EN25F20-100GCP

R421

100K 1/16W 5%

R442

R441NCR440

NC

EE_WP

For user data, WB, EDID,

HDCP are saved in

Flash.

Befor AOC ID2007 OSD

For ID2008 ID2009

For All model

DSUB_R+2

DSUB_R-2

DSUB_G+2

DSUB_G-2

DSUB_SOG2

DSUB_B+2

DSUB_B-2

DSUB_H2

DSUB_V2

DDC1_SDA2

DDC1_SCL2

RX2P2

RX2N2

RX1P2

RX1N2

RX0P2

RX0N2

RXCP2

RXCN2

DDC2_SDA2

DDC2_SCL2

R401 390 OHM 1/16W

0.1uF/16V

C417

R423

0R05 1/16W

X401

14.31818MHz

1 2

R428 100R 1/16W 5%

C422 0.1uF/16V

VCC3.3

1

2

3456

VMPLL

VPLL

8

14

98163249668234

23

RIN0P

AVDD_33

AVDD_33

AVDD_33

22

RIN0M

20

GIN0P

19

GIN0M

21

SOGIN0

18

BIN0P

17

BIN0M

27

HSYNC0

28

VSYNC0

30

DDCA_SD A/RS 232_TX

31

DDCA_SCL/rs232_R X

3

RX2P

4

RX2N

6

RX1P

7

RX1N

9

RX0P

10

RX0N

12

RXCKP

13

RXCKN

100

DDCD_SDA

1

DDCD_SCL

15

REXT

TSUMU58EHL-LF-1

26

REFP

25

REFM

37

SDO

38

SCZ

39

SCK

40

SDI

48

GPIO_P45/PWM1

84

RST

96

XOUT

97

XIN

80

BYPASS

52

MODE[ 0]

53

MODE[ 1]

GND

2

5

X'TAL

Normal Function : CL = Cs + ((Cg*Cd)/(Cg+Cd))

C423

P.S : Assume Cs = 4 pF

NC

蔼

瑉红

U403

C423

R429

R430

R440

R442

VDDC

VDDP

24

56

51

75

VDDP

VDDP

VDDP

VDDP

AVDD_33

AVDD_33

LVDS

GND

GND

GND

GND

GND

GND

GND

GND

GND

112933

5057767983

X401

(93G 22-53B-H)

(93G 22-53-J)

For NVRAM

M24C04-WMN6TP R419

0.22uF16V

100R 1/16W 5%

100R 1/16W 5%

10K 1/16W 5%

10K 1/16W 5%R441

10K 1/16W 5%

VDDC

VDDC

VDDC

VDDC

LVACKP

LVACKM

LVBCKP

LVBCKM

GPIO_P23

GPIO_P43

GPIO_P42

GPIO_P47

GPIO_P46

GPIO_P22/PWM0

PWM2/GPIO_P24

GPIO_P25

PWM3/GPIO_P27

GPIO_P00/SAR0

GPIO_P01/SAR1

GPIO_P02/SAR2

GPIO_P03/SAR3

GPIO_P07

GPIO_P15

PWM1/GPIO_P16

GPIO_P12

GPIO_P13

GPIO_P14/PWM0

GPIO_P10/I2C_MCL

GPIO_P11/I2C_MDA

Without NVRAM

NC

NC

NC

NC

NC

NC

NC

81

VCTRL

54

LVA3P

55

LVA3M

58

59

60

LVA2P

61

LVA2M

62

LVA1P

63

LVA1M

64

LVA0P

65

LVA0M

67

LVB3P

68

LVB3M

69

70

71

LVB2P

72

LVB2M

73

LVB1P

74

LVB1M

77

LVB0P

78

LVB0M

36

45

46

41

42

35

47

85

86

87

88

89

90

91

92

93

94

95

99

44

43

CL of SPEC

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PA8

PA9

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PB8

PB9

R425 NC

R445 NC

R409 100R 1/16W 5%

R415 100R 1/16W 5%

R416 100R 1/16W 5%

R417 100R 1/16W 5%

R419 0R05 1/16W

R420 NC

R424 100R 1/16W 5%

R426 NC

R429 NC

R430

NC

18 pF

32 pF

PA[0..9]

PA[0..9] 3

PB[0..9]PB0

PB[0..9] 3

POWER_KEY#

EE_WP

PANEL_ID# 4

WP

on_BACKLIGHT 4

adj_BACKLIGHT 4

KEY1

KEY2

DET_CABLE 2

LED G_B

LED O

HDCP_CTRL 2

27 pF

56 pF

Indirect LED

10K 1/16W 5%

10K 1/16W 5%

0R 1/16W 5%

2.2K 1/16W 5%

NC

0R 1/16W 5%

2.2K 1/16W 5%

NC

2N3906S

2N3906S

Mute 4

BUZZER

MSCL

MSDA

Cs and Cd (C420, C421)

R420

R453

R455

R461

R457

R459

R462

Q407

Q408

R402

1K 1/16W 5%

R404 1K 1/16W 5%

100R 1/16W 5%

Max condition for LED:

1. Vcc = 3.3 V

2. Current = 12 mA

FW need to be

modified.

Direct LED

100R 1/16W 5%

100R 1/16W 5%

0R 1/16W 5%

0R 1/16W 5%

DVI 1_5V

R447

NC

CMVCC1

R422

NC

NC

NC

NC

NC

NC

1

For detect function,

depend on FW

R446

NC

R406

22K 1/16W 5%

R427

NC

R434

0R05 1/16W

R451 NC

R452 0R05 1/16W

23

Q405

2N3906S-RTK/PS

R405 0R05 1/10W 5%

CMVCC1

VCC3.3

R407

10K 1/16W 5%

C438

NC

LED G_B

CN401

NC/CONN

CN402

CONN

6

5

4

3

2

1

7

6

5

4

3

2

1

LF_B

Volume# 4

C416

0.1uF 16V

R455 NC

R461

0R05 1/10W 5%

Q401

LMBT3904LT1G

Q407

NC

NC/CONN

DDC_WP 2

R453 NC

R454 NC

R456

22R 1/16W 5%

2

4

6

8

NC/CONN

CN405

CN403

CN404

NC/CONN

VCC3.3

LED_GRN/BLUE

1

3

5

7

1

2

3

4

5

6

1

2

3

4

5

6

7

VCC3.3

VCC3.3

CMVCC1 2

CMVCC1

TOUCH_POWER

FB402

300OHM

R408

R411

R414

0R05 1/16W

LED_ORANGE

R418

0R05 1/16W

FB404

300OHM

0.1uF/16V

VCC3.32,4

NC

NC

LED_GRN/BLUE

R435

VPLL

VCC3.3

AVDD

FB401

300OHM

C408

0.1uF/16V

VMPLL

C413

VCC3.3

VCC1.84

R459 NC

LED O

POWER_KEY#

C431

NC

NC

R436

10K 1/16W 5%

VCC3.3

FB405

NC

LF_B

C436

1uF 10V

VCC1.8

C402

4.7uF/10V

R462

NC

C407

0.1uF/16V

VCC3.3

VDVI

FB410

300OHM

C415

C414

0.1uF/16V

0.1uF/1 6V

VDDP

VDDC

C433

0.1uF/16V

0.1uF/16V

R457 NC

R458 NC

R460

NC

NC

NC

NC

C406

C404

C405

0.1uF/16V

0.1uF/16V

C412

C409

0.1uF/16V

C411

C410

0.1uF/ 16V

0.1uF/16V

CMVCC1

VCC3.3

LED_ORANGE

VCC3.3

R433

R432

3.9K OHM +-1% 1/16W

3.9K OHM +-1% 1/16W

KEY1

KEY2

C435

C434

ZD401

BUZZER

CMVCC1

NC

CN406

1

2

3

NC/CONN

NC

For BUZZER control board

or Touch Panel

C403

0.1uF/16V

Q408

NC

R431

C432

0.1uF/16V

T P V ( Top Victory Electronics Co . , Ltd. )

G3329-C-2-X-2-090401

絬 隔 瓜 絪 腹

Key Component

5.0.SCALER

Date

OEM MOD EL Si ze

NEW R SERIES

TPV MODEL

AOC 2236VWA B

PCB NAME

of

Sheet

55Wednesday, J une 10, 2009

Custom

Rev

称爹

>

<

称爹

35

Page 36

6.2 Power Board

Adapter

715G2824P01010001S

1

BD901

+

!

-

4

C904

0.22UF 275V

2

3

L901

27mH

1

4

C903

0.22UF 275V

1 MOHM +-5% 1/4W

!

C901

1000pF

3

12

2

GBU408

R901

!

1

2

GND1

GND

!

!

67G315Z12115K

120uF450V

12

t

F901

FUSE

!

3

!

!

R902

1 MOHM +-5% 1/4W

!

C902

1000pF

CN901

SOCKET

GND2

GND

1

2

NR901

NTCR

C905

C940

47nF 50V

+

1500PF2KV

C928

10nF 50V

HS3

HEAT SINK(D906)

1

2

C938

NC

IC901

1

CT

2

COMP

3

CS

4 5

GNDOU T

LD7576

CN801

5

4

3

2

1

CONN

VCC

+

C918

680uF25V

L904

Coil

L903

R924

100 OHM 1/8W

C934

1000uF25V

Coil

C915

+

470UF M 16V

L905

Coil

+

OEM MOD EL Size

TPV MOD EL

PCB NAME

Sheet

R918100 OHM 1/4W

R919100 OHM 1/4W

R920100 OHM 1/4W

!

FB902

0R05 4A 1/4W

R904

8.2K 1/4W

R905

8.2K 1/4W

C907100N 50V

8

HV

7

NC

6

+16V

+

DIM

ON/OF F

CN802

5

4

3

2

1

CONN

HS2

HEAT SINK(D908)

1

2

+

D903 1N4148

R910

10 OHM 1/4W

R912

220 OHM 1/4W

C909

220pF 50V

+16V

C910

100uF 50V

C906

1500PF2KV

C908

22uF 50V

STP10NK70ZF P

NC

1

2

D901

FR103

Q901

R938

10KOHM +-5% 1/8W

R914

0.39 OHM 2W +-5%

CN903

1

2

3

4

CONN

HS1

HEAT SINK(Q90 1)

R903

100KOHM +-5% 2WS

R909

3.3 OHM 1/4 W

D900

FR107

C937

100PF1KV

!

+5V

DIM

ON/OF F

PID

VOL

MUTE

+5V1

4

POWER X'FMR

5

6

1

3

!

C921

1000pF

C900

3300pF 250V

T901

IC903

PC123X2YFZOF

43

C931

100N 50V

8

7

9

10

12

11

1K 1/8W

12

R925

C924

100N 50V

IC904

KIA431A-AT/P

12

R926

1K 1/10W

C912

1000pF630V

D906

2

FMX-12SL

3

R935 100 OHM 1/4W

R961 100 OHM 1/4W

R962 100 OHM 1/4W

D909

31DQ06FC3

D907

31DQ06FC3

FB901

BEAD

R949 100 OHM 1/4W

R950 100 OHM 1/4W

R951 100 OHM 1/4W

2

3

CN902

1

2

3

4

5

6

7

8

9

10

11

12

13

Wire Harness

C917

+

680uF25V

1

C929

1000pF630V

+

C939

1000uF M 16V

C935

1000pF630V

1

D908

MBRF1060CT

+

C916

NC

T P V ( Top Victory Electronics Co . , Ltd. )

G2824-P0A-010-0010-1-091028

絬 隔 瓜 絪 腹

Key Component

03.POWER

Date

820 OHM 2W

R947

C932

1N 50V

ZD902

TZX18B

R943

470OHM +-5% 1/8W

R939

1K 1/8W

L906

2.2uH

C930

100N 50V

R927

10K +-1% 1/10W

R930

9.1KOHM +-1% 1/10W

F902

FUSE

Rev

称爹

R946

820 OHM 2W

Q903

KTD1028

e2436vwa

ADPC91603H D1 1

715G2824-P0A-010-0010

of

23Wednesday , Oct ober 28, 2009

R940

NC

+16V

F903

FUSE

+5V1

Custom

OD M MOD EL

+5V

36

Page 37

+5V1

C603 0.47uF 16V

+

LOUT-

VDD

LOUT+

GND

GND

ROUT+

VDD

ROUT-

C602 0.47uF 16V

4

3

2

1

CN602

CONN

10

11

12

13

14

15

16

LOUT+

LOUT-

ROUT-

ROUT+

CN601

PHONEJ ACK

+5V1

VOL

4

Lin

5

3

2

1

R604 10K 1/10W 5%

Rin

R605 10K 1/10W 5%

R602

10K 1/10W

R603

10K 1/10W

C609

1U 25V

C601 0.47uF 16V

C606 0.47uF 16V

10K 1/10W

R609

+5V1

C604

100uF 25V

IC601

8 9

SE/BTL

7

VOLUME

6

LIN -

5

GND

4

GND

3

RIN-

2

BYPASS

1

SHUTDOWN

APA2069JI TUL

R608

0R051/8W

FB602

1 2

BEAD

HS4

HEAT SINK(I C601)

1

2

C610100pF 50V

C612

6.2K 1/10W

R606

6.2K 1/10W

R607

C611100pF 50V

MUTE

R612

D601

10 OHM 1/10W

1N4148

1K 1/10W

C613

+

100uF 25V

R613

Q607

PMBS3906

Q608

10K 1/10W

R610

R611

56K1/10W

MMBT 3904

100N16V

R601

10K 1/10W

C614

100N16V

C608

1U25V

IC with Heat-sink(90G6295-3)

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

Date

G2824-P0A-010-0010-1-091028

03.AUDIO

OEM MODEL Size

TPV MODEL

PCB NA ME

Sheet

e2436vwa

ADPC91603H D1 1

715G2824-P0A-010-0010

of

33Wednesday , October 28, 2009

Rev

称爹

Custom

OD M MO D EL

37

Page 38

Converter

715G3918P03000004C

CN801

CONN

CN802

CONN

5

4

3

2

1

1

2

Τэ

OVP2

OVP1

+12V

DIM

ENA

Vout

R822

1M 1/10W 5%

R823

4.7K 1/ 10W

R824

43KOHM +-1% 1/10W

F801

100N 50V

R825

0R05 1/4W

FUSE

C801

0.15 OH M +-1% 1/4W

R844 NC

+

C813

100uF 50V

R801

C812

100p 50V X7R

Iout

R804

R842

R815

R843

L801

22uH

1

2

3

4 5

APM8005KCTRG

25mA

20mA

56K

27K

56K

150K

56K

27K

56K

150K

C811 NC

S1

D1

G1

D1

S2

D2

G2 D2

Q801

100 OHM 1/10W

R802

NC

8

7

6

R845

ZD801

B360B

C803

100N 50V

10K 1/10W 5%

10K 1/10W 5%

100uF 50V

C814

100P 50V

R806

R817

+

C804

+

C810

100uF 50V

R804

30K +-1% 1/10W

N.C

R842

R815

30K +-1% 1/10W

R843 N.C

R816 160KOH M +-1%1/10W

T P V ( Top Victory Electronics Co . , Ltd. )

絬 隔 瓜 絪 腹

Key Component

Date

OVP1

R805 160KOH M +-1%1/10W

10R 1/ 10W 5%

OVP2

G3918-P0E-000-0040-1-091215

02.CON VERTER

1

PWM

STATUS

2

ISEN1

3

ISEN2

SSTCMP

4

ISEN3

5

6

7

8

9

10

11

12 13

R807

1

2

3

4

5

6

7

8

9

10

11

12 13

COMP

ISEN4

GNDA

ISEN8

GNDP

ISEN6

VREF

ISEN7

OVP

ISEN5

ISET

RT ENA

IC801

TA96 90G N

R814

10 OHM 1/10W

PWM

STATUS

ISEN1

ISEN2

SSTCMP

ISEN3

COMP

ISEN4

GNDA

ISEN8

GNDP

ISEN6

VREF

ISEN7

OVP

ISEN5

ISET

RT ENA

IC802

TA9690GN

LDR

ISW

LDR

ISW

R833 1 OH M 1/10W

R832 1 OH M 1/10W

R831 1 OH M 1/10W

R830 1 OH M 1/10W

R829 1 OH M 1/10W

R813 10K 1/10W 5%

R812

C805

0.47uF 16V

1K 1/10W 5%

R808

NC

C808

0.47uF 16V

R803

1K 1/10W 5%

R818

NC

C809

2.2U 16V

R828 1 OH M 1/10W

R827 1 OH M 1/10W

R826 1 OH M 1/10W

R810

C807

2.2U 16V

R809

100K 1/10W 5%

R839 1 OH M 1/10W

R838 1 OH M 1/10W

R837 1 OH M 1/10W

R836 1 OH M 1/10W

R835 1 OH M 1/10W

R834 1 OH M 1/10W

24

23

NC

22

21

20

SEL

19

VIN

18

17

16

15

14

24

23

NC

22

21

20

SEL

19

VIN

18

17

16

15

14

OEM MO DE L Size

TPV MODEL

PCB NAME

Sheet

100 OHM 1/10W

C806

2U2 25V

R811

0R05 1/ 10W

R821 10K 1/ 10W 5%

100 OHM 1/10W

AOC E2436VWA

LNPC9D432MHD 1

715G3918-P0E-000-0040

22Wednes day , D ecem ber 16, 2009

of

R820

R841 1 OH M 1/10W

R840 1 OH M 1/10W

R819

100K 1/10W 5%

Rev

称爹

Vout

CN803

CONN

A4

ver.E

ODM MODEL

CN805

NC

CN804

CONN

10

9

8

7

6

5

4

3

2

1

11 12

12

11

10

9

8

7

6

5

4

3

2

1

13 14

10

9

8

7

6

5

4

3

2

1

11 12

38

Page 39

7. PCB Layout

7.1 Main Board

715G3329 1 2

39

Page 40

7.2 Power Board

Adapter

715G2824P01010001S

40

Page 41

41

Page 42

Converter

715G3918P03000004C

7.3 Key Board

715G3371 2

42

Page 43

7.4 USB Board

715G3501 2

715G2663 2

43

Page 44

8. Maintainability

8.1 Equipments and Tools Requirement

1. Voltmeter.

2. Oscilloscope.

3. Pattern Generator.

4. DDC Tool with an IBM Compatible Computer.

5. Alignment Tool.

6. LCD Color Analyzer.

7. Service Manual.

8. User Manual.

44

Page 45

8.2 Trouble Shooting

1. No Power

No power

Check power cable is

tightened?

OK

Check Power “On/Off”

is “On”?

OK

Check the LED

indicate is OK?

NG

Re-plug the power cable

NG

Turn on the Power “On/Off” switch

NG

Check the AC power

OK

Replace the converter board

NG

Replace main board and check connections

NG

Replace key board and check connections

45

Page 46

2. No Video (Power LED Blue)

No Video (Power LED Blue)

Press the power

button is OK?

OK

Replace the converter

board

NG

Replace the main

board and connection

NG

Replace the main board

OK

The end

OK

The end

NG

Check the LVDS/FFC

cable or panel

NG

Replace the key board

OK

Replace the LVDS/FFC

cable or panel

46

Page 47

3. DIM

DIM (image overlap, focus or flicker)

Reset in factory mode

NG

OK

The end

Set to the optimal

frequency, select the

recommended frequency

NG

Readjust the phase and pixel

clock in the user mode

NG

Pull out signal cable and

check “Self Test Feature

Check” is ok?

OK

The end

OK

The end

OK

Check the signal cable

and the PC

NG

Replace the main board

NG

Replace the panel

OK

NG

OK

The end

47

Page 48

4. Color is not optimal

Miss color

Replace the signal cable

NG

Pull out the signal cable

and check the screen

color display is normal?

NG

Replace the main board

Replace the signal cable or PC

Color is not optimal

OK

The end

OK

Color shift

Reset the factory mode

NG

In the user mode, set the” color

settings” until customer satisfy

NG

48

Page 49

9. FOS Testing

9.1 Brightness Measurement

Max. Brightness>250 cd/㎡(typ).

Test conditions:

- Center of display

- Video input (RGB) = 0,700V for Analog Input

- Brightness control is set to max

- Contrast control is set to max.

Min. brightness measurement:

< 45% of Max luminance (max luminance = max contrast + max brightness)

Test conditions: - Center of display

- Video input (RGB) = 0.700V for Analog Input

- Brightness control is set to min.

- Contrast control is set to min.

9.2 Patterns Testing

Condition

Item

(Resolution, Commended

test paten)

Normal picture Abnormal Picture

Waterwave

noise

Mura

LCD

bubble

1. 1920 x 1080 (60 Hz)

2. White pattern

1. 1920 x 1080 (60 Hz)

2. Black pattern or White

pattern.

1. 1920 x 1080 (60 Hz)

2. Black pattern or White

pattern

49

Page 50

Cross line

Half line

1. 1920 x 1080 (60 Hz)

2. Black pattern

1. 1920 x 1080 (60 Hz)

2. Black pattern or White

pattern

H-Line

V-Line

1. 1920 x 1080 (60 Hz)

2. Black pattern, Red

pattern, Green pattern or

Blue pattern.

1. 1920 x 1080 (60 Hz)

2. Black pattern or White

pattern

H-Strip

1 1920 x 1080 (60 Hz)

2. Black pattern, Gray scale

pattern, Red pattern, Green

pattern or blue pattern .

50

Page 51

V-St rip

1. 1920 x 1080 (60 Hz)

2. Black pattern, Gray scale

pattern, Red pattern, Green

pattern or blue pattern .

Abnormal

display

Gray defect

1. 1920 x 1080 (60 Hz)

2. Gray scale pattern

1. 1920 x 1080 (60 Hz)

2. Gray scale pattern

Video noise

Color tint

1. 1920 x 1080 (60 Hz)

2. Gray scale pattern

1. 1920 x 1080 (60 Hz)

2. Gray scale pattern

51

Page 52

Gray scale

failure

Light

leakage

Fuzzy

video

1. 1920 x 1080 (60 Hz)

2. Gray scale pattern

1. 1920 x 1080 (60 Hz)

2. Black pattern or White

pattern

1. 1920 x 1080 (60 Hz)

2. Pane picture

52

Page 53

10. Firmware and DDC Instruction

10.1Firmware Instruction(TSUM IC ISP for exemple TSUMO58GDJ)

1. OPERATION CONDITIONS:

1) An i486 (or above) personal computer or compatible.

2) Microsoft operation system Windows XP.

3) “MSTAR ISP Tool V4.5.0.7.7”programs.

4) Printer cable and VGA cable.

5) ISP board (PN: 715GT039-A).

2. Connection:

1) LPT cable connect PC and ISP board ;

2)VGA cable connect monitor and ISP board ;

3)Reference picture as below

ISP Board (TPV P/N:715GT039-A)

3.Software list:

1)LPT driver:

2)MSTAR ISP TOOL:

Eg: TSUMO58GDJ_LGLM215WF4_20100518_V005_8143.BIN

3)Setup LPT driver:run Port95nt icon:

4)USB driver install

53

Page 54

4 .Program:

1)Run MSTAR ISP Tool V4.5.0.7.7,interface as below:

2) Choose CONFIG icon ,interface as below :

Setting as :

Port type :LPT1

Speed :50KHZ

54

Page 55

3)Choose DEVICE,and choice WP Pin pull to high during ISP :

4)Choose CONNECT icon ,and interface show Device type , PC and monitor communications successful, click

“OK”.

55

Page 56

5)Click “Read”, show as follow picture, then choose correct software to click “open.

PS:For exemple TSUMO58GDJ_LGLM215WF4_20100518_V005_8143.BIN

6 )Then ,as below :

7.

56

Page 57

7) Show the interface as follows after press the AUTO button

8).Then , press Run icon ,as below,Show Blank OK, Program OK, Verify OK, It’s successfully if interface show

PASS.

57

Page 58

9) AC off, wait about one minute, after the elextricity large capacitance of power board release, then AC on,

otherwise, the key button and power button cann't work.

5.Check Software Version and auto color and reset:

You should check the program code is right in factory mode ;(about the method of enter factory mode ,pls reference

the service manual )

5.1Auto level :

1)Monitor display gray pattern ;

2)Enter the factory mode ;

3)Choise the AUTO LEVEL icon and run it.

4)Check the gray pattern is clear ;

5)Change to full black pattern , and check the display there is no noise .

5.2Reset

Monitor would change to default setting after reset .

5.3power off

Monitor must be turned off after rework code.

58

Page 59

10.2 DDC Instruction(For exemple:Philips 201B)

General

DDC Data Re-programming

In case the main EEPROM with Software DDC which store all factory settings were replaced because a defect

repaired monitor’ the serial numbers have to be re-programmed.

It is advised to re- soldered the main EEPROM with Software DDC from the old board onto the new board if circuit

board have been replaced, in this case the DDC data does not need to be re-programmed.

Additional information about DDC (Display Data Channel) may be obtained from Video Electronics Standards

Association (VESA). Extended Display Identification Data (EDID) information may be also obtained from VESA.

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98/2000/XP.

3. “PORT95NT.exe, TPVDDC5.6.exe” program.

4. EDID Board (715GT034-B) x1,

5. Printer cablex1, VGA cable x 1, DVI-D cable x 1, 12V DC power source

6. EDID data

10.2.1. Install the “PORT95NT.EXE”, and restart the computer.

The process of installing “PORT95NT” has been specified in, so it will not be specified again. If you have any

problem, please read it.

10.2.2.Connect the EDID Board as follow:

Note: when update, should make sure the LCD AC on, DC on.

Note:

If the VGA can not write successfully, please try to cut off the 5th and 9th pin of the VGA connector.

If the DVI can not write successfully, please try to cut off the 14th pin of the DVI connector.

59

Page 60

1. Rename the EDID data to “wa”, “wd”.

2. Put the “wa” and “wd” into a new folder, and then create another new folder named “ddc” (It must be “ddc” instead

of other names).

Step1: Must put the “ddc” folder and “TPVDDC6.0.exe” into the same folder.

Step2: Must copy the folder which contains EDID data and “config” to “ddc” folder.

60

Page 61

3. Double-click

,and choose the “Analog and DVI”, it will show the picture as follow:

4. Click “LoadFile”, it will show the picture as follow:

61

Page 62

5. Click “OK”, it will show the picture as follow:

6. Key in the same 14 numbers in the Input SN and Verify SN.

62

Page 63

7. Click “Program”, if it shows the below mistake, please try to write again.

63

Page 64

8. If it shows the below picture, it means the write is successful.

9. Click “ReadBoth”, if the DDC Write is OK, it will show the picture as follow:

64

Page 65

10. Click “program”, if the 12V connector is not OK, it will show the picture as follow:

11. Click “program”, if the cable connector is not OK, it will show the picture as follow:

65

Page 66

11.White- Balance, Luminance Adjustment

Approximately 30 minutes should be allowed for warm up before proceeding white balance adjustment.

How to setting MEM channel you can reference to chroma 7120 user guide or simple use “SC” key and

“NEXT” Key to modify xyY value and use “ID” key to modify the TEXT description Following is the procedure to do

white-balance adjust .

1. Setting the color temp.

A. MEM.CHANNEL 3 (Warm color):

Warm color temp. parameter is x=313±30 ,y=329±30

B. MEM.CHANNEL 4 (Normal color):

Normal color temp. parameter is x=302±30 ,y=318±30

C. MEM.CHANNEL 9(Cool color):

Cool color temp. parameter is x=283±30,y=297±30

D. MEM.CHANNEL 10 (sRGB color):

sRGB color temp. parameter is x=313±30 ,y=329±30

2. Enter into the factory mode:

Turn on power, press the power button, then press key and the key at the same time, the next, press the ∧∨

power button. You will enter into the factory mode.

3. Bias adjustment:

Set the Contrast

to 50; Adjust the Brightness to 90.

4. Gain adjustment:

A. Adjust Warm (6500K) color-temperature

1. Switch the chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 3 (with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x=313±30 ,y=329±30

4. Adjust the RED on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN on factory window until chroma 7120 indicator reachedthe value G=100

6. Adjust the BLUE on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item4, 5, 6) until chroma 7120 RGB value meet the tolerance =100±2

B. Adjust Normal (7300K) color-temperature

1. Switch the chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 4(with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x=302±30 ,y=318±30

4. Adjust the RED on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN on factory window until chroma 7120 indicator reachedthe value G=100

6. Adjust the BLUE on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4, 5, 6) until chroma 7120 RGB value meet the tolerance =100±2

66

Page 67

C. Adjust Cool (9300K) color-temperature

1. Switch the Chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM. Channel to Channel 9 (with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x=283±30,y=297±30

4. Adjust the RED on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN on factory window until chroma 7120 indicator reached the value G=100

6. Adjust the BLUE on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4, 5, 6) until chroma 7120 RGB value meet the tolerance =100±2

D. Adjust sRGB color-temperature

1. Switch the chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 10 (with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x=313±30 ,y=329±30

4. Adjust the RED on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN on factory window until chroma 7120 indicator reachedthe value G=100

6. Adjust the BLUE on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4, 5, 6) until chroma 7120 RGB value meet the tolerance =100±2

E. Turn the Power-button off to quit from factory mode.

67

Page 68

12.Mechanical Instructions

1.Put the monitor on the EPE pad.

2.Lay down the monitor, then use cross screwdriver or the expert tools leave off the stand while press the Push area

of the back cover.

3.Overturn the monitor and the top towards to us.

68

Page 69

4.Take apart the front frame with hands on the label area.

5.As the center of one side of USB connector, take apart 3 sides and stop. Attention: Do not break off the key pc

side, or pull the front frame forcibly, to avoid the keypad peel off.

6.Overturn the monitor, on the USB connector area, one hand press the Panel, and use the other to undrawn the

back cover.

69

Page 70

7.Make the notice that the front frame of the key pc side should be separated at last.

8. In turn to take apart the key pc connect PIN (A&B), lamp line (C&D), peel off the aluminum foil (E&F), draw off the

FFC pin (G), if there is defect with main pc, need leave of f the six-angle screw (H).

9.Withdraw the front frame from the Panel side. Use screwdriver to take off the screw which used to fix the iron

frame and Panel, and then take apart them.

70

Page 71

10. According to the different defective area, take off the screws ABCDE to get the relevant part to maintain. Before

take apart the POWER pc should take off the AC iron piece first.

11. Use little screwdriver to peel off the key pc from the front frame when need maintain it.

71

Page 72

13. Monitor Exploded Views

72

Page 73

14. BOM List

Note: The parts information listed below are for reference only, and are subject to change without notice. Please go

to http://cs.tpv.com.cn/hello1.asp

TD92A8NB6WA1PNE

Location Part No. Description Remark

050G 600 1 W WHITE STRAP (1G004991)

052G 1186 SMALL TAPE

052G 1211 B Conductive Tape 85mm *40mm *0.09mm

HDCP-L 070GHDCP500HDC NO-SUGGEST HDCP CODE

E07801 078G0020 2 V SPEAKER 4 OHM 2 W 430/230mm 40X20mm

E08904 089G 173 56 4B AUDIO CABLE

E08905 089G 175 8 C USB CABLE A+B 1.8M

E08902 089G 715HAAE01 SIGNAL CABLE

E08901 089G404A15N IS POWER CORD

E09504 095G176J 10E07 FFC CABLE 10PIN P0.5MM 370MM

E09514 095G176J 10E08 FFC CABLE 10PIN P0.5MM 325MM

E09503 095G8014 7TE05 HARNESS 7P-6P 350MM

0D1G1730 6120 SCREW

0D1G1730 8120 SCREW

0M1G 130 6120 SCREW M3X6

705GH934026 24"LCD STAND-BASE ASS'Y

E750 750GLV236H3211N000 PANEL M236H3-L02 C1A FQ TPV

A15G0556502 mainframe

A34G1062AEDD2B0130 BEZEL

A34G1063AEDA5S0100 REAR COVER

A85G0140201 AC Shield

ADPC91603HD1 ADAPTER BOARD

H26G 800504 2A barcode

H40G 18N61525B e936Swa EU ID LABEL

H40G 58161569A USB LABEL

H40G 58261537A e936Vw POP LABEL

H40G 58261569A CARTON LABEL

H40G 58361560A SRS WIN7 GOLD EPA LABEL

H41G780961518B QSG

H44GD027102 EPS

H44GD027202 EPS

H44GD027615 5B CARTON

H45G 77 6 PE PACKING

H45G 87 1 20 EPE COVER

H52G 1250006 Conductive Tape 100mm*50mm*0.08mm

H52G6029 1 TAPE-INSULATION

H70G200961544B CD MANUAL

KEPC9HAB KEY BOARD

Q45G 76 28 H A PE BAG FOR MANUAL

Q45G 76 28V13 A PE BAG

Q50G 4 10 TIE (Y1900221)

Q52G 1185 99 big carton tape for aoc

E08907 S89G179T30N522 FFC CABLE 30P 275mm P1.0MM

USB9HA3 USB BOARD

USBAHA5 USB BOARD

0Q1G1040 10120 SCREW

A34G1064AED 1S0100 Stand-Front

A34G1065ABJ 1S0100 Stand-Back

A34G1066AED 2S0130 BASE_AOC_2436

for the latest information.

73

Page 74

A37G0108 2 HINGE

H01G6006 1 Screw

756GH9CB A2015 MAIN BOARD-CBPC9A8A1H1

SMTCR-U402 100GAMMD003W11 MCU ASS'Y-056G1133129

GND1 009G6005 1 GROUND TERMINAL

CN602 033G3802 4 WAFER 2.0MM 4P

040G 45762412B CBPC LABEL

IC903 056G 139 7 1 IC EL817MA M-TYPE

NR901 061G 58809MEN RST NTCR 8OHM £«£20£¥ 4A XIANZHENG

R946 061G152M561 64 SY RST MOFR 560 OHM +-5% 2WS FUTABA

R947 061G152M561 64 SY RST MOFR 560 OHM +-5% 2WS FUTABA

C903 063G107K224AUM CAP X2 0.22uF 10% 305V

C901 065G305M1022BP CAP Y2 1000PF M 250VAC

C902 065G305M1022BP CAP Y2 1000PF M 250VAC

C921 065G306M1022BP Y1 1000PF M 250VAC

C900 065G306M3322BP Y1 CAP 3300PF M 250VAC

C910 067G 4151017KV EC 100uF 50V ED 8*12

C918 067G215D6814KV CAP 105C 680uF M 25V 10*20

C917 067G215D6814KV CAP 105C 680uF M 25V 10*20

C939 067G215S1023KV 105C 1000uF M 16V

C934 067G215S1024KV EC 1000UF 20% 25V 12.5*20

C915 067G215S4713KV

EC 105℃ CAP 470UF M 16V

C905 067G315Z12115K EC 120UF 20% 450V 20*40

L905 073G 253 91 L CHOKE BY LI TA

L904 073G 253 91 L CHOKE BY LI TA

L903 073G 253 91 L CHOKE BY LI TA

CN901 087G 501 32 DL AC SOCKET DIP 3PIN+2PIN GROUND

CN601 088G 30214K DC PHONE JACK 5P GREEN -

D907 093G3006 1 1 31DQ06FC3 NIHON INTER

CN902 095G 82013WE03 harness 13p-9p 200mm

705GQ857026 Q901 ASS'Y

705GQ893039 D908 ASS'Y

705GQ893040 D906 ASS'Y

AD91603HD1SMT ADAPTER BOARD FOR SMT

LNPC9D432MHD1 CONVERTER BOARD

HS4 Q90G6295 3 HEAT SINK

L901 S73G17465V2 Transformer Ass'Y

T901 S80GL22T3V1 XFMR POWER 490uH TPV-PT

IC601 056G 616 34 IC APA2069JITUL 2.6W*2 PDIP-16

BD901 093G 50460911 BRIDGE GBU406 4A/800V

CN402 033G3802 7B Y L CONNECTOR 7P 2.0

CN701 033G3802 9B Y L CONN 2.0 9P

CN301 033G801930F CH JS CONNECTOR

040G 45762412B CBPC LABEL

R708 061G152M33964L RST MOFR 3.3 OHM +-5% 2WS

CN101 088G 35315F XH D-SUB 15PIN VERTICAL CONN WITH SCREW

CN102 088G 35424F D DVI 24PIN CONN F ATTACHED SCREW

X401 093G 2253B J NXS14.31818AC32F-KAB10

E09513 095G8022 6D504 HARNESS 6P-6P 200MM

A33G0564 2 1L0100 Key-Guide

Q52G 3 75 3M DOUBLE FACE TAPE

CN511 033G3802 5 BH L CONNECTOR 5PIN

CN512 088G 352 2 XH USB CONN

715G2663 2 USB BOARD PCB

CN501 033G3802 5B Y L CONNECTOR 5P 2.0

74

Page 75

CN502 088G 351 2B XH USB CONN

E09508 095G8014 5DH09 HARNESS 5P(PH)-5P(PLUG) 180MM

Q901 057G 667 21 NO-SUGGEST STP10NK70ZFP

0M1G 930 8120 SCREW

HS1 Q90G6263 6 HEAT SINK

D908 093G 60278 DIODE SP1060 ITO-220 SECOS

0M1G 930 8120 SCREW

HS2 Q90G6263 6 HEAT SINK

D906 093G 52 66 DIODE FMX-12SL 10A/200V TO-220

0M1G 930 8120 SCREW

HS3 Q90G6264 5 HEAT SINK

IC901 056G 379128 IC LD7576 GS SOP-8

Q607 057G 417517 Tra LMBT3906LT1G -200mA/-40V SOT-23 LRC

Q608 057G 417518 TRA LMBT3904LT1G 200mA/40V SOT-23 LRC

R612 061G0603100 JT RST CHIP 10R 1/10W 5% TZAI YUAN

R926 061G06031001FT RST CHIP 1K 1/10W 1%

R927 061G06031002FT RST CHIP 10K 1/10W 1%

R613 061G0603102 JT RST CHIP 1K 1/10W 5% TZAI YUAN

R604 061G0603103 JT RST CHIP 10K 1/10W 5% TZAI YUAN

R605 061G0603103 JT RST CHIP 10K 1/10W 5% TZAI YUAN

R609 061G0603103 JT RST CHIP 10K 1/10W 5% TZAI YUAN

R601 061G0603103 JT RST CHIP 10K 1/10W 5% TZAI YUAN

R602 061G0603103 JT RST CHIP 10K 1/10W 5% TZAI YUAN

R603 061G0603103 JT RST CHIP 10K 1/10W 5% TZAI YUAN

R610 061G0603103 JT RST CHIP 10K 1/10W 5% TZAI YUAN

R611 061G0603563 JT RST CHIPR 56KOHM +-5% 1/10W TZAI YUAN

R606 061G0603622 JT RST CHIPR 6.2KOHM +-5% 1/10W TZAI YUAN

R607 061G0603622 JT RST CHIPR 6.2KOHM +-5% 1/10W TZAI YUAN

R930 061G06039101FT RST CHIP 9K1 1/10W 1%

R608 061G0805000 JT RST CHIPR 0 OHM +- 5% 1/8W TZAI YUAN

JR903 061G0805000 JT RST CHIPR 0 OHM +- 5% 1/8W TZAI YUAN

JR601 061G0805000 JT RST CHIPR 0 OHM +- 5% 1/8W TZAI YUAN

R924 061G0805101 JT RST CHIP 100R 1/8W 5% TZAI YUAN

R939 061G0805102 JT RST CHIPR 1K OHM +- 5% 1/8W TZAI YUAN

R925 061G0805102 JT RST CHIPR 1K OHM +- 5% 1/8W TZAI YUAN

R938 061G0805103 JT RST CHIPR 10K OHM +- 5% 1/8W TZAI YUAN

R943 061G0805471 JT RST CHIPR 470OHM +-5% 1/8W TZAI YUAN

JR902 061G1206000 JT RST CHIPR MAX0R05 1/4W TZAI YUAN

JR901 061G1206000 JT RST CHIPR MAX0R05 1/4W TZAI YUAN

FB902 061G12060004JT RST CHIPR 1206 MAX0R05 4A 1/4W TZAI YUAN

R910 061G1206100 JT RST CHIPR 10 OHM +-5% 1/4W TZAI YUAN

R962 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R961 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R951 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R950 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R949 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R935 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R920 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R919 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R918 061G1206101 JT RST CHIPR 100 OHM +-5% 1/4W TZAI YUAN

R901 061G1206105 JT RST CHIPR 1MOHM +-5% 1/4W TZAI YUAN

R902 061G1206105 JT RST CHIPR 1MOHM +-5% 1/4W TZAI YUAN

R912 061G1206221 JT RST CHIPR 220 OHM +-5% 1/4W TZAI YUAN

R909 061G1206339 JT RST CHIPR 3.3 OHM +-5% 1/4W TZAI YUAN

R905 061G1206822 JT RST CHIPR 8.2 KOHM +-5% 1/4W TZAI YUAN

75

Page 76

R904 061G1206822 JT RST CHIPR 8.2 KOHM +-5% 1/4W TZAI YUAN

C610 065G060310131J A CAP CHIP 0603 100PF J 50V NPO SAMSUNG

C611 065G060310131J A CAP CHIP 0603 100PF J 50V NPO SAMSUNG

C932 065G060310232K A CAP CHIP 0603 1000pF K 50V X7R

C614 065G060310412K A NO-SUGGEST 0603 0.1uF K 16V X7R SAMSUNG

C612 065G060310412K A NO-SUGGEST 0603 0.1uF K 16V X7R SAMSUNG

C601 065G060347412K T CAP CHIP 0603 0.47UF K 16V X7R

C602 065G060347412K T CAP CHIP 0603 0.47UF K 16V X7R

C603 065G060347412K T CAP CHIP 0603 0.47UF K 16V X7R

C606 065G060347412K T CAP CHIP 0603 0.47UF K 16V X7R

C928 065G080510332K F CAP 0805 10NF K 50V X7R

C907 065G080510432K A CAP CHIP 0805 0.1UF K 50V X7R

C924 065G080510432K A CAP CHIP 0805 0.1UF K 50V X7R

C930 065G080510432K A CAP CHIP 0805 0.1UF K 50V X7R

C931 065G080510432K A CAP CHIP 0805 0.1UF K 50V X7R

C608 065G080510522K T CAP 0805 1UF 10% 25V X7R

C609 065G080510522K T CAP 0805 1UF 10% 25V X7R

C909 065G080522131J F CAP CHIP 0805 220PF J 50V NPO

C940 065G080547332K F CAP CHIP 0805 47NF K 50V X7R

C935 065G1206102B2K T CAP CHIP1206 1000PF K 630V X7R

C929 065G1206102B2K T CAP CHIP1206 1000PF K 630V X7R

C912 065G1206102B2K T CAP CHIP1206 1000PF K 630V X7R

AD91603HD1AI ADAPTER BOARD FOR AI

040G 45762412B CBPC LABEL

C813 067G 4151017LV EC 100uF 20% 50V RZY 8*11.5

C804 067G 4151017LV EC 100uF 20% 50V RZY 8*11.5

CN802 311GB254B04AAL PIN HEADER 2.54MM 4P 2P7.2MM/2P4.0MM

CN801 311GB254B07AAL PIN HEADER 2.54MM 7P 5P7.2MM/2P4.0MM

LN9D432MHD1SMT CONVERTER BOARD FOR SMT

C419 067G 3151007KB EC 10uF M 50V 5*11mm

C704 067G 3151014KB EC LOW ESR 100UF M 25V 6.3*11mm

C305 067G 3151014KB EC LOW ESR 100UF M 25V 6.3*11mm

C707 067G 3151014KB EC LOW ESR 100UF M 25V 6.3*11mm

U401 056G 562574 NO-SUGGEST IC TSUMU58EHL-LF-1 PQFP100

U703 056G 563 31 IC AZ1117D-1.8-E1

U701 056G 585 4A IC AP1117E33L-13

U103 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U104 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U105 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U106 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U107 056G 662502 IC ESD AZC199-04S.R7G SOT23-6L

U402 056G1133129 IC EN25F20-100GCP 2Mb SOP-8

U102 056G1133918 NO-SUGGEST AT24C02BN-SH-T 2kb SO-8

U101 056G1133918 NO-SUGGEST AT24C02BN-SH-T 2kb SO-8

Q302 057G 417 12 T KEC 2N3904S-RTK/PS

Q701 057G 417 12 T KEC 2N3904S-RTK/PS

Q405 057G 417 13 T KEC 2N3906S-RTK/PS

Q401 057G 417518 TRA LMBT3904LT1G 200mA/40V SOT-23 LRC

Q301 057G 763 1 AO3401 SOT23 BY AOS

R452 061G0402000 RST CHIP MAX 0R05 1/16W

R434 061G0402000 RST CHIP MAX 0R05 1/16W

R423 061G0402000 RST CHIP MAX 0R05 1/16W

R419 061G0402000 RST CHIP MAX 0R05 1/16W

R418 061G0402000 RST CHIP MAX 0R05 1/16W

R414 061G0402000 RST CHIP MAX 0R05 1/16W

76

Page 77

R134 061G0402100 RST CHIPR 10 OHM +-5% 1/16W

R132 061G0402100 RST CHIPR 10 OHM +-5% 1/16W

R131 061G0402100 RST CHIPR 10 OHM +-5% 1/16W

R130 061G0402100 RST CHIPR 10 OHM +-5% 1/16W

R129 061G0402100 RST CHIPR 10 OHM +-5% 1/16W

R128 061G0402100 RST CHIPR 10 OHM +-5% 1/16W

R127 061G0402100 RST CHIPR 10 OHM +-5% 1/16W

R126 061G0402100 RST CHIPR 10 OHM +-5% 1/16W

R119 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R409 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R415 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R416 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R417 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R422 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R424 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R428 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R706 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R118 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R117 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R115 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R114 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R113 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R111 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R109 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R105 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R101 061G0402101 RST CHIPR 100 OHM +-5% 1/16W

R705 061G0402102 RST CHIPR 1 KOHM +-5% 1/16W

R404 061G0402102 RST CHIPR 1 KOHM +-5% 1/16W

R402 061G0402102 RST CHIPR 1 KOHM +-5% 1/16W

R104 061G0402102 RST CHIPR 1 KOHM +-5% 1/16W

R103 061G0402102 RST CHIPR 1 KOHM +-5% 1/16W

R703 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R702 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R436 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R412 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R407 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R308 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R305 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R135 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R133 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R120 061G0402103 RST CHIPR 10 KOHM +-5% 1/16W

R421 061G0402104 RST CHIPR 100 KOHM +-5% 1/16W

R106 061G0402222 RST CHIPR 2.2 KOHM +-5% 1/16W

R107 061G0402222 RST CHIPR 2.2 KOHM +-5% 1/16W

R704 061G0402223 RST CHIPR 22 KOHM +-5% 1/16W

R406 061G0402223 RST CHIPR 22 KOHM +-5% 1/16W

R304 061G0402223 RST CHIPR 22 KOHM +-5% 1/16W

R401 061G0402390 0F RST CHIP 390R 1/16W 1%

R432 061G0402390 1F NO-SUGGEST RST CHIPR 3.9KOHM +-1% 1/16W

R433 061G0402390 1F NO-SUGGEST RST CHIPR 3.9KOHM +-1% 1/16W

R110 061G0402471 RST CHIPR 470 OHM +-5% 1/16W

R303 061G0402472 RST CHIPR 4.7 KOHM +-5% 1/16W

R138 061G0402472 RST CHIPR 4.7 KOHM +-5% 1/16W

R137 061G0402472 RST CHIPR 4.7 KOHM +-5% 1/16W

R136 061G0402472 RST CHIPR 4.7 KOHM +-5% 1/16W

77

Page 78

R125 061G0402472 RST CHIPR 4.7 KOHM +-5% 1/16W

R124 061G0402472 RST CHIPR 4.7 KOHM +-5% 1/16W

R123 061G0402472 RST CHIPR 4.7 KOHM +-5% 1/16W

R306 061G0402563 RST CHIP 56K 1/16W 5%

R139 061G0402682 RST CHIP 6K8 1/16W 5%

R116 061G0402750 RST CHIPR 75 OHM +-5% 1/16W

R112 061G0402750 RST CHIPR 75 OHM +-5% 1/16W

R108 061G0402750 RST CHIPR 75 OHM +-5% 1/16W

R102 061G0603000 RST CHIP MAX 0R05 1/10W

R405 061G0603000 RST CHIP MAX 0R05 1/10W

R461 061G0603000 RST CHIP MAX 0R05 1/10W

R456 061G0603220 RST CHIPR 22 OHM +-5% 1/10W

R301 061G1206221 NO-SUGGEST RST CHIPR 220 OHM +-5% 1/4W

R302 061G1206221 NO-SUGGEST RST CHIPR 220 OHM +-5% 1/4W

C122 065G0402102 32 1000PF +-10% 50V X7R

C121 065G0402102 32 1000PF +-10% 50V X7R

C107 065G0402102 32 1000PF +-10% 50V X7R

C412 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C413 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C414 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C415 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C417 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C422 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C432 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C701 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C702 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C705 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C708 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C709 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C712 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C713 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C416 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C115 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C124 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C301 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C304 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C403 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C404 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C405 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C406 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C407 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C408 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C409 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C410 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C411 065G040210412K A CAP CHIP 0402 100nF K 16V X7R

C436 065G0402105 A5 NO-SUGGEST CAP 0402 1UF K 10V X5R

C104 065G0402220 31 CHIP 22PF 50V NPO

C103 065G0402220 31 CHIP 22PF 50V NPO

C116 065G0402224 17 NO-SUGGEST MLCC 0402 0.22UF Z 16V Y5V

C117 065G0402224 17 NO-SUGGEST MLCC 0402 0.22UF Z 16V Y5V

C302 065G0402224 17 NO-SUGGEST MLCC 0402 0.22UF Z 16V Y5V