Page 1

AOC 15/50 Wind Turbine Generator

User Manual

DOC012R02 Nov 2001

U.S. $55.00

Atlantic Orient Corporation Tel: 802-649-5446

Farrell Farm Road, Rt 5 North Fax: 802-649-5404

P.O. Box 1097 AOC@Vermontel.net

Norwich, VT 05055 www.aocwind.net

Page 2

Page 3

i

Table of Contents

WARNING...........................................................................................iv

DISCLAIMER...................................................................................... v

Part I.......................................................................................................1

1.0 Introduction........................................................................................ 3

1.1 Manual Use.................................................................................................................4

1.2 Cautionary Icons ......................................................................................................... 5

1.2.1 Warning Icon...........................................................................................................5

1.2.2 Caution Icon............................................................................................................5

1.3 Personnel Definitions..................................................................................................5

1.3.1 Installation Personnel ..............................................................................................5

1.3.2 Operational Personnel..............................................................................................5

1.3.3 Maintenance Personnel............................................................................................6

2.0 System Description..............................................................................7

2.1 General Description and Features of the Turbine.........................................................8

2.2 Control System Description .......................................................................................11

2.3 Operation Description ...............................................................................................11

3.0 Safety Guidelines............................................................................... 13

3.1 Personnel Training ....................................................................................................14

3.2 Safety Equipment......................................................................................................14

3.3 Start-up and Shut-down Safety Procedures................................................................15

3.4 Securing Machine for Maintenance and Repair..........................................................15

3.5 Climbing Safety ........................................................................................................16

3.6 Electrical Safety........................................................................................................17

3.7 Weather Related Safety.............................................................................................17

3.8 Emergency Procedure................................................................................................18

Part II ...................................................................................................21

4.0 Planning and Installation Checklist.....................................................23

4.1 Siting Factors............................................................................................................24

4.2 Utility Factors ...........................................................................................................24

4.3 Permits and Approvals ..............................................................................................25

4.4 Plans and Drawings...................................................................................................25

4.5 Construction Planning Considerations.......................................................................26

4.6 Electrical Planning Considerations ............................................................................27

4.7 Installation Tools and Equipment ..............................................................................27

4.8 Installation Personnel Considerations........................................................................28

4.9 General Installation/Commissioning Timeline...........................................................28

5.0 Site Preparation................................................................................31

5.1 Site Access................................................................................................................32

5.2 Foundation Installation..............................................................................................32

5.3 Receiving the Wind Turbine at the Site .....................................................................33

6.0 Tower and Wind Turbine Generator Installation ................................. 35

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 4

6.1 Tower Assembly .......................................................................................................36

6.2 Tower Erection..........................................................................................................37

6.3 Wind Turbine Component Preparation ......................................................................38

6.3.1 Tip Brake Installation............................................................................................38

6.4 Blade Installation ......................................................................................................41

6.5 Lift Preparation.........................................................................................................46

6.6 Lifting and Securing the Wind Turbine......................................................................50

ii

7.0 Electrical Installation.........................................................................53

7.1 Electrical Interface to Utility .....................................................................................54

7.2 Wiring and Cable Requirements................................................................................56

7.2.1 Power and Control Cable.......................................................................................56

7.3 Control Box Connections ..........................................................................................59

7.4 Twist Cables and Junction Box..................................................................................60

8.0 Function Tests and Commissioning ..................................................... 61

8.1 Function Tests and Commissioning...........................................................................62

8.2 Generator Test ...........................................................................................................63

Part III.................................................................................................. 65

9.0 Wind Turbine Operation ................................................................... 67

9.1 Normal Operation......................................................................................................68

9.1.1 Turbine TEST/OFF/ON .........................................................................................69

9.1.2 Heater ON.............................................................................................................70

9.1.3 Parking Brake Release...........................................................................................70

9.1.4 Rotor Jog ...............................................................................................................72

9.1.5 Dynamic Brake......................................................................................................72

9.1.6 Operator Interface Indicating Lights......................................................................72

9.1.7 PLC Description....................................................................................................72

9.1.7.1 PLC Inputs............................................................................................................76

9.1.7.2 PLC Outputs..........................................................................................................77

9.1.8 Control Systems Options.......................................................................................77

9.2 Emergency Operation................................................................................................77

9.3 Test Operation ...........................................................................................................78

9.3.1 Power Up ..............................................................................................................78

9.3.2 Parking Brake Release Test...................................................................................78

9.3.3 Rotor Jog Test.......................................................................................................79

9.3.4 Dynamic Brake Test..............................................................................................79

9.3.5 Anemometer Signal Test .......................................................................................79

9.3.6 Speed Sensor Signal Test.......................................................................................80

9.3.7 Normal Start-up/Shut-down Test...........................................................................80

9.3.8 Emergency Shut down Test...................................................................................80

9.3.9 Low Wind Shut Down Test ...................................................................................80

9.4 Environmental Considerations ...................................................................................80

9.4.1 Corrosion ..............................................................................................................80

9.4.2 Lightning...............................................................................................................81

9.4.3 Ice and Snow.........................................................................................................81

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 5

9.4.4 Temperature and Elevation....................................................................................82

9.4.5 Acoustics...............................................................................................................83

iii

10.0 System Monitoring ..........................................................................85

10.1 Kilowatt-Hour Meter Applications ............................................................................86

10.2 Anemometers............................................................................................................86

10.3 Output Analysis.........................................................................................................86

10.4 Output Analysis Worksheet.......................................................................................86

10.5 Wind Energy Data Sheet ...........................................................................................87

11.0 Maintenance ................................................................................... 89

11.1 Rotor Assembly.........................................................................................................90

11.2 Tower Assembly .......................................................................................................91

11.3 Drive Train Assembly ...............................................................................................91

11.4 Power Distribution System/Controls..........................................................................92

11.5 Maintenance Schedule ...............................................................................................93

12.0 Troubleshooting .............................................................................. 95

12.1 Braking System.........................................................................................................96

12.2 Generator ................................................................................................................100

12.3 Gearbox ..................................................................................................................100

12.4 Blades.....................................................................................................................100

12.5 Twist Cable.............................................................................................................100

12.6 Yaw Bearing ...........................................................................................................102

12.7 Troubleshooting Summary ......................................................................................102

13.0 Spare Parts ................................................................................... 105

Appendix A: Specifications ................................................................... 107

Appendix B: Turbine Assembly Drawings.............................................. 113

Appendix C: Assembly Drawings for 24.4 m (80 ft) Tower.......................119

Appendix D: Assembly Drawings for 30.5 m (100 ft) Tower..................... 127

Appendix E: Crate Dimensions and Weights .......................................... 135

Appendix F: Foundation Loads and Details............................................ 139

Appendix G: Installation Records..........................................................149

Appendix H: Maintenance Records........................................................ 155

Appendix I: Tools and Equipment ......................................................... 161

Appendix J: Wire, Cable and Bolt Specifications ....................................165

Appendix K: Planning ..........................................................................171

Appendix L: 50Hz Electrical Schematics................................................175

Appendix M: 60 Hz Electrical Schematics .............................................. 203

Appendix N: Hand Signals for Crane Operators..................................... 231

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 6

iv

WARNING

THE INSTALLATION OF A WIND TURBINE GENERATOR REQUIRES SPECIALIZED

SKILLS, EQUIPMENT AND EXPERIENCE. INFORMATION SUPPLIED BY ATLANTIC

ORIENT CORPORATION AND ITS SUPPLIERS, FOR THE PURPOSES OF INSTALLING,

OPERATING AND MAINTAINING ALL EQUIPMENT, ASSUMES THAT PERSONNEL HAVE

THE SKILLS, EXPERIENCE AND EQUIPMENT NEEDED. NO ONE SHOULD ATTEMPT TO

CLIMB TOWERS AND OPERATE OR MAINTAIN WIND TURBINES WITHOUT THE

NECESSARY SKILLS, EXPERIENCE, TOOLS AND SAFETY EQUIPMENT.

ATLANTIC ORIENT CORPORATION ASSUMES NO DIRECT OR CONSEQUENTIAL

LIABILITY IF FAULTY OR DANGEROUS INSTALLATION OR MAINTENANCE

PRACTICES ARE USED. TRAINED AND EXPERIENCED PERSONNEL ARE AVAILABLE

TO ASSIST IN INSTALLATION, OPERATION, MAINTENANCE AND TROUBLE

SHOOTING. CONTACT ATLANTIC ORIENT CORPORATION OR ITS AUTHORIZED

REPRESENTATIVE IF CONSULTATION OR ASSISTANCE IS REQUIRED.

ATLANTIC ORIENT CORPORATION AND ITS SUPPLIERS RECOMMEND RESTRICTING

ACCESS, WITH ANTI-CLIMB SECTIONS OR FENCES FOR ALL TOWERS, TO PREVENT

UNAUTHORIZED PERSONS FROM CLIMBING THEM. APPROPRIATE WARNING SIGNS

SHOULD ALSO BE PLACED ON EACH TOWER.

THE AOC 15/50 IS CONSIDERED A HEAVY DUTY INDUSTRIAL MACHINE AND SHOULD

BE SITED ACCORDINGLY. ATLANTIC ORIENT CORPORATION RECOMMENDS AN

EXCLUSION ZONE CONTROLLING PUBLIC ACCESS. ALL MOVING PARTS SHOULD BE

CONSIDERED DANGEROUS.

TOWERS SHOULD NOT BE INSTALLED NEAR UNPROTECTED POWER LINES. ALL

ELECTRIC WIRES AND CABLES SHOULD BE CONSIDERED DANGEROUS.

To ensure optimal performance, all wind turbine installations should be thoroughly inspected by

qualified personnel within 60 days of their completion, as well as at least biannually and after

any major windstorm, earthquake or other severe event. The inspection and service intervals

identified by Atlantic Orient Corporation must be followed for any Atlantic Orient Corporation

warranty to remain valid.

Atlantic Orient Corporation

P.O. Box 1097

Norwich, Vermont 05055 USA

Phone: 802-649-5446

Fax: 802-649-5404

e-mail: AOC@Vermontel.Net

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 7

v

DISCLAIMER

This manual is intended as a guide only. It should not be considered as a replacement for

professional services or as a definitive text for assembling and installing wind turbine

generating systems.

Atlantic Orient Corporation, its affiliates and representatives make no warranties either

expressed or implied that the information contained herein is accurate or complete.

Atlantic Orient Corporation makes no warranties of merchantability or fitness for a

particular purpose and/or site. Atlantic Orient Corporation will not be responsible for any

direct or consequential damages, or any incidental expense.

All instructions and diagrams are believed to be accurate at the time of publishing. Note

that success and safety in working with tools depend greatly on individual accuracy, skill

and caution. For this reason, Atlantic Orient Corporation or its affiliates are not able to

guarantee the result of any procedure contained herein, nor can they assume responsibility

for any damage to property or injury to persons resulting from the procedures contained in

this manual. Persons engaging in the procedures do so at their own risk.

Actual wind resources and site conditions impact on energy production, which will vary

with wind turbine maintenance, altitude, temperature, topography and the proximity to

other structures. Therefore, Atlantic Orient Corporation makes no representation or

warranties regarding energy production.

Atlantic Orient Corporation is constantly striving to improve its products and, therefore,

the information contained within this manual is subject to change without notice.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 8

vi

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 9

Part I

1

Part I

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 10

Part I

2

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 11

Photo Courtesy of

3

1.0 Introduction

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

DOC012R02 AOC 15/50 User Manual Nov 2001

KOTZEBUE ELECTRIC ASSOCIATION WIND FARM

on page v of this document.

KEA

Page 12

1.0 Introduction

4

1.1 Manual Use

This manual has been developed for use by qualified technicians for the operation and

maintenance of the wind turbines manufactured by Atlantic Orient Corporation (AOC). The

information provided specifically applies to the AOC 15/50 wind turbine and is valid for both the

50 Hz and the 60 Hz versions, unless otherwise stated.

It is essential for the reader to become familiar with the manual prior to preparing the site,

installing equipment, operating the system or servicing any equipment. The site should be

prepared, maintained, operated and managed to allow work to be performed safely and

efficiently. Special consideration should be given to installing, operating and maintaining

the wind turbine system under unusual conditions such as lightning, high winds or icing

(where applicable). For any operation or service related questions, please contact AOC for

clarification.

Many of the safety guidelines in this manual are based on recommendations made in the

International Electro-technical Commission’s Wind Turbine Generator Systems Part I: Safety

Requirements, Second edition, 1999, 61400-1 or its latest edition. In case of questions or doubts

concerning a potentially hazardous or harmful situation, please contact AOC for assistance. The

following standards were considered in the design of the controller and selection of components:

US National Electrical Code 196 DFPA 70, Canadian Electrical Code, Part I, 1994,

International Electro-technical Commission IEC TC88 – Safety of Wind Turbine Generators

1400-1 or the latest edition.

If there are any questions that are not adequately addressed in this manual, please contact AOC

at its corporate headquarters in NORWICH, VERMONT, USA or one of its authorized

representatives. Improvements or suggestions from field experience are always welcome.

The content of this document is the property of Atlantic Orient Corporation. Any

unauthorized use or reproduction by any means is strictly prohibited.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 13

1.0 Introduction

1.2 Cautionary Icons

1.2.1 Warning Icon

1.2.2 Caution Icon

5

The warning icon denotes actions or procedures that may lead to

equipment failure or death to personnel, if not carried out correctly.

The caution icon denotes actions or procedures that may lead to

severe equipment damage or injury to personnel, if not carried out

correctly.

1.3 Personnel Definitions

1.3.1 Installation Personnel

Installation personnel are defined as technical staff with training and/or experience in climbing

towers and the use of safety equipment, as well as rigging and lifting heavy industrial machinery.

ONLY TRAINED AND QUALIFIED TECHNICIANS SHOULD ATTEMPT TO CLIMB

A WIND TURBINE TOWER AND SHOULD USE OSHA/ANSI APPROVED PRACTICE

AND EQUIPMENT.

1.3.2 Operational Personnel

Operational personnel are defined as persons trained and qualified to operate a wind turbine’s

control panel. They are responsible for monitoring the wind turbine’s mechanical and

production performance, as well as for performing routine visual inspections of all equipment.

See Chapter 10 for the parameters to be monitored. The operation personnel should also ensure

that proper maintenance is routinely performed as described in Chapter 11.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 14

1.0 Introduction

6

1.3.3 Maintenance Personnel

Maintenance personnel are defined as technical staff with training and/or experience in climbing

towers and the use of safety equipment, as well as a firm understanding of the wind turbine’s

mechanical and control system. Knowledge of rigging and lifting heavy industrial machinery

may also be necessary. ONLY TRAINED AND QUALIFIED TECHNICIANS SHOULD

ATTEMPT TO CLIMB A WIND TURBINE TOWER AND SHOULD USE OSHA/ANSI

APPROVED PRACTICE AND EQUIPMENT.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 15

Photo Courtesy of

7

2.0 System Description

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

DOC012R02 AOC 15/50 User Manual Nov 2001

KEA

ALASKA FIELD SERVICE

on page v of this document.

Page 16

2.0 System Description

8

The following sections provide a general description of the AOC 15/50 and its control system.

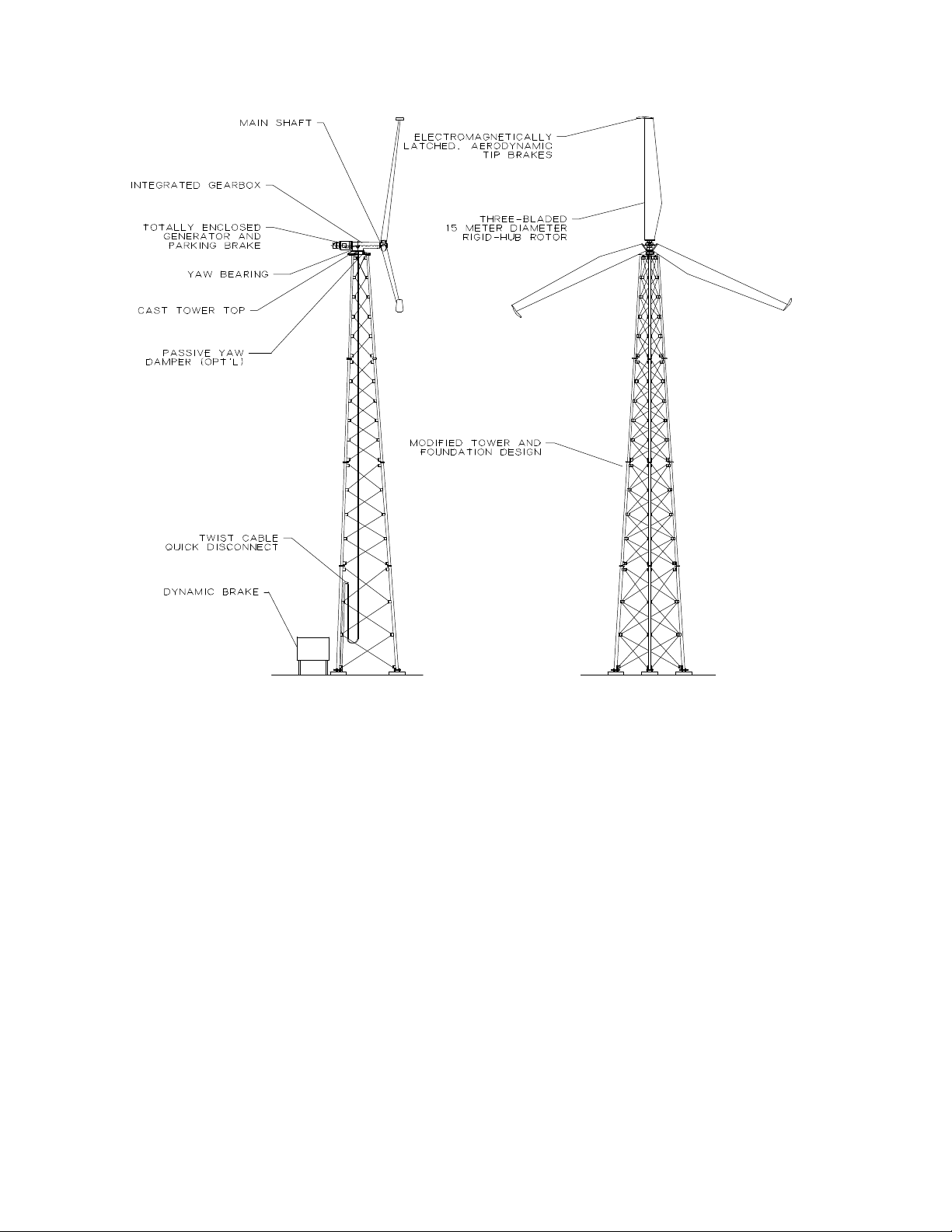

2.1 General Description and Features of the Turbine

The designation 15/50 refers to the 15 m diameter wood/epoxy or fibreglass rotor and its

projected rated output of 50 kW. This rated output is achieved at 12 m/s (26.8 mph) by the 50 Hz

version and at 11.3 m/s (25.3 mph) by the 60 Hz one.

The AOC 15/50 includes the following design features:

• Advanced NREL thick series airfoils

• High strength to weight ratio wood/epoxy or fiberglass blades

• Electro-magnetically/actively controlled tip brakes

• Single piece hub casting

• Rotary transformer to power the tip brake magnets

• Integrated planetary gearbox

• Induction generator

• Single piece cast tower top with turn table yaw bearing

• Uniformly tapered lattice tower

• Dynamic brake

• PLC based controller with adaptive features

• Optional tilt-up lattice tower

Both turbine versions are designed to cut in at 4.6 m/s (10.2 mph). The 50 Hz version reaches its

peak continuous output of 55 kW at 15 m/s (34 mph); the 60 Hz one achieves its peak of 65 kW

(60 Hz) at 16 m/s (36 mph). Assuming 100% availability and average wind speeds of 8 m/s (18

mph), the 50 Hz wind turbine is calculated to produce approximately 190,000 kWh per year and

the 60 Hz one, 215,000 kWh. In average wind speeds of 6.7 m/s (15 mph), the 50 Hz version

produces approximately 145,000 kWh annually and the 60 Hz one, 153,000 kWh.

NOTE: Energy production is site specific and varies with altitude, temperature,

topography, climate and the wind turbine’s proximity to other structures, as well as its

maintenance condition.

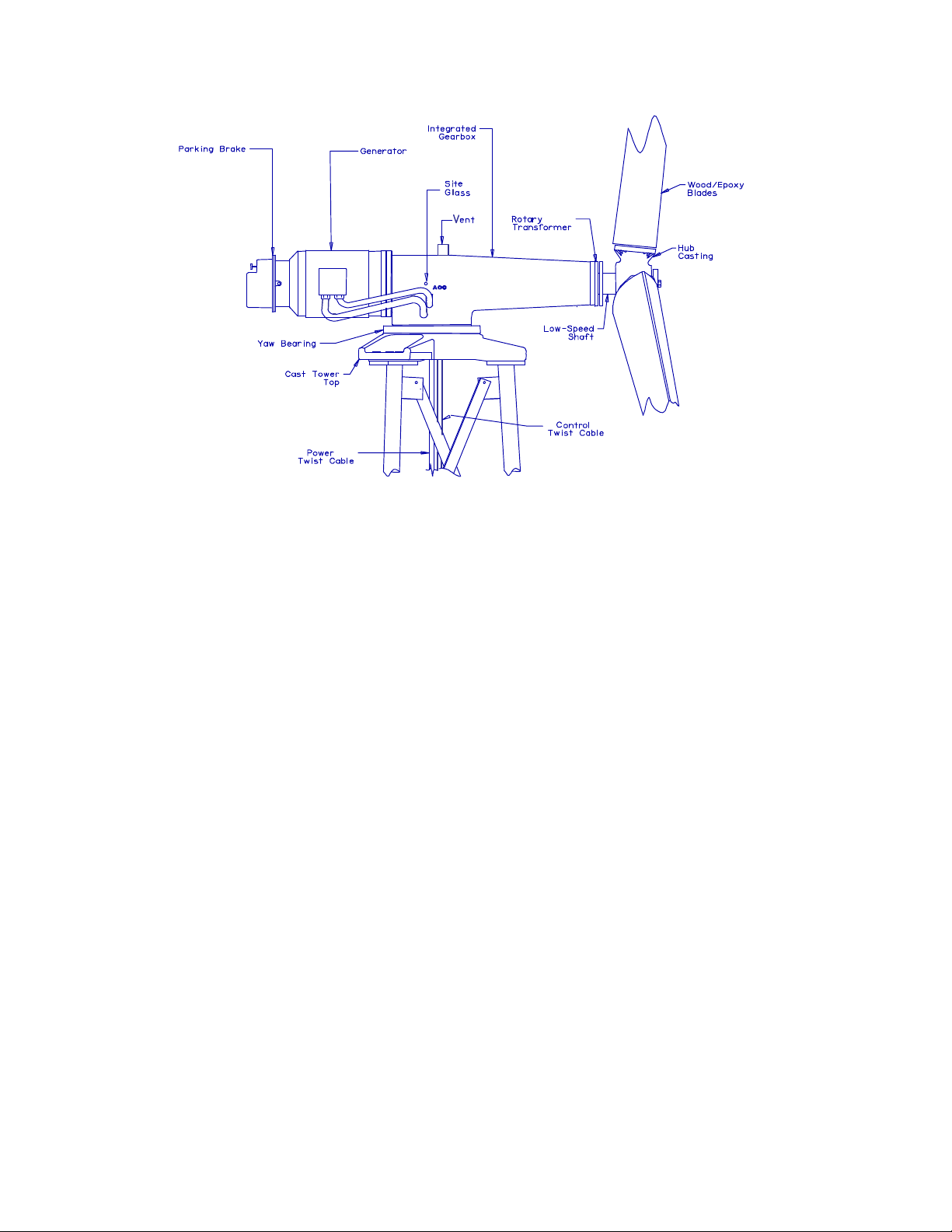

The standard tower is a 24.4 m (80 ft) tall, self-supporting lattice structure. The gearbox is

integrated in the single piece cast housing. See Figure 2-2 for a more detailed view of the drive

train assembly. The generator is flange mounted to the planetary gearbox, with the parking

brake coupled directly to the generator.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 17

2.0 System Description

9

Figure 2-1 AOC 15/50 Wind turbine

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 18

2.0 System Description

Figure 2-2 AOC 15/50 Wind turbine assembly, drive train detail

10

Figure 2-3 AOC 15/50 Drive train assembly

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 19

2.0 System Description

2.2 Control System Description

The following parameters are monitored by the wind turbine’s control system. It initiates

shutdowns when faults have been detected to protect the wind turbine from mechanical and

electrical damage.

UTILITY NETWORK:

• Over/under voltage

• Phase loss

• Phase reversal

• Over/under frequency (optional)

TURBINE:

• Generator temperature

• Rotor speed

• Power (derived from rotor speed)

• Parking brake current

SYSTEM:

• Wind speed (redundant anemometers)

• Ambient temperature switch (optional)

11

2.3 Operation Description

The AOC 15/50 is a downwind turbine, i.e. its blades rotate downwind of the drive train

assembly. Furthermore, it has no active yaw control and depends on its blades to track the wind.

In winds outside of the required wind band, the PLC (Programmable Logic Controller)

disconnects the wind turbine from the grid and parks it; the wind turbine is brought to a complete

stop. The parking brake remains applied, thereby preventing the blades from rotating. However,

they will still track the wind and the wind turbine will pivot about its yaw bearing accordingly.

The AOC 15/50 has three main modes of operation: test, off and on. The setting of the

TEST/OFF/ON switch determines the parameters monitored by the PLC and which other

switches can be activated. When the turbine TEST/OFF/ON switch is set to OFF, the PLC only

monitors grid faults.

Once the turbine TEST/OFF/ON switch is set to ON, the PLC starts evaluating the wind speed

data which, together with the generator rotor speed, is the most important source of input data to

the PLC; grid related parameters and thermal relays play a secondary role.

The wind speed is measured using two cup anemometers. For the wind turbine operation the

wind speed has to fall within the specified speed band of 3.6-22.3 m/s (8-50 mph). The cut-in

speed of 4.9 m/s (11 mph) is slightly higher than its minimum operational speed because of the

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 20

2.0 System Description

12

inertia of the rotor and drive train that must be overcome initially. Once the wind speed

conditions are met, the parking brake is released and the generator starts rotating, at which point

PLC starts monitoring the generator rotor speed.

Once the parking brake has released and the rotor speed is in band,the wind turbine is connected

to the grid automatically. The wind turbine will then stay on-line until wind conditions fall

outside the operating band or until a fault or shutdown is registered. The generator shaft speed is

measured using two speed sensors from which the PLC can tell whether the shaft speed falls

within the required range. Since power produced is proportional to rotor speed, the rotor speed is

also used to check for excessive power generation.

Whenever the wind and/or shaft speeds deviate from the specified values the PLC initiates a

shutdown of the wind turbine system. In order to avoid unnecessary shutdowns, each fault is

monitored for a set period to confirm that it is not due to a temporary deviation but to a definite

change in the operating conditions. Since faults impact on the system with varying degrees of

severity, in terms of possible electrical or mechanical damage, the time delays after which a

shutdown is initiated differ.

Should the PLC register a fault that requires the wind turbine to be shut down, it does so in a set

sequence. The tip brakes and dynamic brake are deployed immediately. The parking brake is

then deployed after a variable time delay, generally set to 4 seconds. Following any deployment

of the brakes the wind turbine enters a cooling cycle, generally set to 15mins. The turbine will

not be available to comeback on line until the end of the cooling cycle to prevent overheating of

the brake components.

The dynamic and parking brakes can be tested individually when their test switches are set to ON

and the TEST/OFF/ON switch is set to TEST. See section 9.1 for a more detailed description of

the individual switches.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 21

Photo Courtesy of

13

3.0 Safety Guidelines

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

DOC012R02 AOC 15/50 User Manual Nov 2001

BED

TOWER ERECTION AT BURLINGTON ELECTRIC DEPARTMENT

on page v of this document.

Page 22

3.0 Safety Guidelines

14

This section covers the safety information needed by a technician to install, operate and

maintain the AOC 15/50 safely. Special safety considerations for specific circumstances are

highlighted throughout this manual.

CAUTION

THE RESPONSIBILITY FOR SAFE CONDUCT AND

OPERATION ULTIMATELY RESTS WITH THE OPERATOR/

TECHNICIAN.

3.1 Personnel Training

It is essential that installation, operation and maintenance personnel be instructed in the safe

operation procedures outlined in this section. Standard safety procedures should be established

and a program of regular safety training should be carried out to ensure consistent information,

regularized safety habits and efficient communication while working at the wind turbine site(s).

3.2 Safety Equipment

AOC recommends the use of approved safety equipment for any work carried out within 30.5 m

(100 ft) of an AOC 15/50.

For climbing and positioning on the erected wind turbine, an ANSI approved full body harness

should be used. AOC also recommends using a Rohn-Loc Climbing System. Positioning

lanyards are usually necessary for turbine installation and maintenance and should be ANSI

approved. AOC recommends the use of fall arresting lanyards in conjunction with positioning

lanyards, as the latter are not designed for fall protection. The fall arresting lanyards should be

no longer than 1.8 m (6 ft) and incorporate deceleration devices. All connections and anchor

points should be capable of supporting 2,270 kg (5,000 lbs.). Self-locking snap hooks and selflocking carabiners are required.

Equipment should be visually inspected for excessive wear and abrasion before each use. All

damaged or questionable equipment should be discarded immediately. Any equipment, which

has been subject to a fall, should be removed from service and discarded.

When working on electrical equipment and/or wiring, technicians must wear protective gloves

rated for the voltage level involved or be certain that the system is not, and will not, be

energized by employing a visual open/lockout process. Whenever any hazard exists,

appropriate safety glasses/shields must be worn.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 23

3.0 Safety Guidelines

15

3.3 Start-up and Shut-down Safety Procedures

Prior to starting up a wind turbine, the operator should warn any personnel in the area that it will

be started and to visually inspect the area to ensure that they are clear of it. In addition, the

operator should ensure that there are no visual signs indicating problems with the wind turbine.

During a shutdown sequence, no personnel should approach the wind turbine, until it has come

to a complete stop.

3.4 Securing Machine for Maintenance and Repair

The wind turbine should be switched off and the yaw lock engaged before any maintenance is

performed. The parking brake automatically engages whenever the wind turbine is shut down,

preventing the rotor from turning. The yaw lock must be engaged manually and once engaged

prevents the wind turbine from yawing, providing a safe working environment. To engage it,

trained personnel must climb the tower to immediately below the tower top. The yaw lock bolt

must be screwed clockwise until its top endplate engages the yaw bearing between two of the

yaw bearing’s interfacing bolts.

Figure 3-1 Yaw lock

If personnel safety or environmental conditions warrant securing the rotor or if the work carried

out requires the parking brake to be released to change the rotor position, it is recommended that

one blade be strapped to the tower or to the gearbox housing to prevent unintended rotor motion.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 24

3.0 Safety Guidelines

16

Ropes may replace straps provided care is taken not to damage the blade surface; cables or

chains should not be used.

CAUTION

NEVER USE METAL CHAINS OR CABLES TO SECURE THE

BLADE, SINCE DAMAGE TO THE BLADE IS LIKELY.

3.5 Climbing Safety

For all activities where persons could be subject to a fall of 1.8 m (6 ft) or more, appropriate fall

protection equipment should be used, which should be fastened to a secure anchor point,

preferably above the climber. Only the tower leg fitted with climbing pegs should be used for

ascending and descending the tower. Once the technician has reached the top, he/she should

attach himself to a secure anchor point. The drive train has four hoist rings that can be used as

anchor points. See Figure 3-2. Holes in the tower brace clips also provide secure anchor points.

Figure 3-2 Secure anchor points for service work

Only trained and qualified technicians should attempt to climb a wind turbine tower and should

use OSHA/ANSI approved practice and equipment. All climbers should be trained in the proper

use of fall protection equipment. AOC strongly discourages climbing when the wind turbine is

operating or when wind speeds exceed 11 m/s (25 mph).

Whenever climbing a tower or performing a service function above ground level AOC

recommends at least two service personnel working together. Wireless communication devices

(preferably hands-free) are recommended to facilitate communication between tower and

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 25

3.0 Safety Guidelines

17

ground personnel. The area around the tower should also be roped off with appropriate warning

signs indicating falling objects.

Finger rings should not be worn while climbing structures or vehicles, or while performing any

task where the ring might be caught under or snagged by a projecting or moving item.

3.6 Electrical Safety

WARNING

WHENEVER POSSIBLE, ELECTRICAL EQUIPMENT SHOULD

BE DE-ENERGIZED AND GROUNDED PRIOR TO SERVICING.

CAUTION MUST BE TAKEN TO ENSURE THAT THE DYNAMIC

BRAKE AND THE POWER FACTOR CORRECTION

CAPACITORS ARE DISCHARGED BEFORE SERVICING.

Electrical equipment should not be serviced while standing in water, on wet surfaces or during

significant precipitation. Hands must be dry. Any electrical power supply to tools and

conveniences should be grounded.

A shirt or jacket with full-length sleeves rolled down and buttoned up, as well as an electrical

safety hat should be worn when working on or near live parts.

Loose, dangling metal chains, key chains, or conductive jewelry of any kind should not be worn

while working on or near energized parts. Each employee should wear gloves suitable for the

work. Rubber glove protectors should not be used as work gloves. Wristwatches with metal

cases and watchbands should not be worn while working on or near energized equipment.

3.7 Weather Related Safety

It is important to observe weather conditions and to take appropriate action when a weather

related safety hazard arises. No service work should be performed in the presence or threat of

lightning. Wet and/or ice laden towers should not be climbed, nor should electrical equipment

be worked on during significant precipitation. Towers should not be climbed when average

wind speeds approach 11 m/s (25 mph) or wind gusts exceed 13 m/s (29 mph).

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 26

3.0 Safety Guidelines

18

WARNING

NO SERVICE WORK SHOULD BE PERFORMED ON A WIND

TURBINE IN THE PRESENCE OR THREAT OF LIGHTING. WET

AND/OR ICE LADEN TOWERS SHOULD NOT BE CLIMBED.

EXTERIOR ELECTRICAL EQUIPMENT SHOULD NOT BE

WORKED ON DURING SIGNIFICANT PRECIPITATION.

3.8 Emergency Procedure

CAUTION

WHEN A HAZARD EXISTS, PERSONNEL SAFETY MUST BE

ENSURED BEFORE ADDRESSING THE SAFETY OF THE

WIND TURBINE EQUIPMENT. IN ALL CASES, SAFE

EFFORTS SHOULD BE MADE TO BRING THE WIND

TURBINE TO A FULL STOP OR TO PREVENT OVER

SPEEDING.

AOC takes extreme care to design a safe and reliable product and the AOC 15/50 has been

designed to meet strict and extensive safety guidelines. However, due to the variety of

unpredictable and possibly extreme conditions it may experience, operators should prepare and

have on hand site-specific emergency procedures to effectively address the following hazards:

• Turbine over-speed

• Loose fasteners

• Structural damage

• Earthquakes

• Sand storms

• High vibration

• Complete braking failure

• Electric fires

• Lighting

• Hurricanes

• Blade damage/separation

• Tower damage

• Cable over-wrap and/or separation

AOC recommends the following as a generic safety plan in the unlikely case of an emergency:

1. Do not approach the AOC 15/50 or any of its components if one of the safety hazards

mentioned above is suspected. Always maintain a safe distance (at least 90 m, 300 ft)

upwind of the wind turbine.

2. If the controller area is deemed safe, depress the emergency stop button. The wind

turbine should come to a complete stop and the main contactor should de-energize.

3. Contact the local emergency officials if necessary (i.e. fire marshal, 911, utility, etc.).

4. Contact the wind turbine owner.

5. Do not attempt to operate the AOC 15/50 without first contacting AOC. It may be

necessary to schedule an inspection by AOC personnel.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 27

3.0 Safety Guidelines

DO NOT ATTEMPT TO OPERATE THE AOC 15/50 WITHOUT AOC

CONSULTATION AFTER A SERIOUS EVENT HAS OCCURRED.

AOC RECOMMENDS A COMPLETE INSPECTION OF THE

TURBINE AND ITS COMPONENTS BY TRAINED PERSONNEL

AFTER ANY SUCH EVENT. FAILURE TO DO SO MAY RESULT IN

POOR PERFORMANCE, INJURY OR DEATH.

19

WARNING

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 28

3.0 Safety Guidelines

20

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 29

Part II

21

Part II

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 30

Part II

22

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 31

Photo Courtesy of

23

4.0 Planning and Installation Checklist

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

DOC012R02 AOC 15/50 User Manual Nov 2001

KEA

SITE CONSTRUCTION AT KOTZEBUE ELECTRIC ASSOCIATION

on page v of this document.

Page 32

4.0 Planning and Installation Checklist

24

The following sections are intended to assist customers in addressing the relevant installation

details in a logical sequence. Although most points apply to both large and small projects, not

all will apply to every project. To ensure thorough planning, it is strongly recommended that

customers understand why a particular detail is or is not appropriate to their installation.

By reviewing the entire list repeatedly throughout the project, the customer should be able to

ensure that none of the details, necessary to complete it, have been overlooked.

4.1 Siting Factors

Site selection has a significant effect on annual energy production. It is, therefore, worth the

additional time and effort to locate the most suitable site to ensure optimal energy production

and maximize the wind turbine’s lifespan. When selecting a site, the following factors should

be considered:

• Wind resource characteristics

§ Average wind speed

§ Makeup of wind speed average (frequency and duration of power producing winds)

§ Prevailing wind direction(s)

§ Turbulence

§ Peak wind speeds

• Height and location of obstructions

• Distance from utility service point

• Local restrictions relative to height, proximity to boundaries, etc.

• Tower height

• Proximity to other wind turbines

• Site accessibility and its effect on construction and maintenance costs

• Safety zone preventing public access

4.2 Utility Factors

The AOC 15/50 includes an induction generator, which depends on the interfacing electrical

system for excitation. Each wind turbine has a fixed set of power factor correction capacitors

installed in the dynamic brake capacitor box. To ensure a safe and efficient installation, the

following utility related factors should be considered:

• Buy back rates, contract options, green pricing and net billing

• Available line capacity (in kVA)

• Available fault current

• Voltage and phase configuration of the primary circuit and the local utility line

• Distance to nearest substation

• Size and winding configuration of the step down transformer required at the site (in

kVA)

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 33

4.0 Planning and Installation Checklist

25

• Line protection required

• Cogeneration standards for small power producers

• Interconnection hardware and wiring standards

• System operation requirements:

§ Voltage regulation

§ Power factor

§ Protective devices

§ Utility/wind turbine interface responsibilities

To interface with the utility network correctly all power factor correction capacitors or

unique loads connected to the utility system need to be identified by the customer.

Furthermore, the Required Customer Power Grid Information sheet should be completed to

assist AOC in designing the most suitable interface. See Appendix K.

4.3 Permits and Approvals

Local authorities often require a wind turbine operator to obtain permits or approvals, some of

which have been identified below. It is important to determine which of these apply to a site

and whether any independent inspections are required.

Issuing Authority:

• Municipality or local council

• Country

• State or Province

• Federal (FAA, FCC, etc.)

• Commission (energy, conservation, historic, etc.)

• Utility

Type:

• Construction

• Foundation engineering

• Electrical works

• Interconnection

• Zoning

• Communication interference

• Aviation interference

• Environmental impact

4.4 Plans and Drawings

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 34

4.0 Planning and Installation Checklist

26

The following list contains suggested documentation to prepare in advance and have on hand to

ensure efficient and proper site development, as well as for submittal for the necessary

approvals:

• Plot plan

• Site layout

• Tower foundation drawing

• Tower assembly drawing

• Site wiring layout

• Control house interior wiring (if applicable) diagram

• Control house physical layout (if applicable)

• Utility interface - single line drawing

• Utility interface - three line drawing

• Wind turbine generator to control box wiring schematic

• Wind turbine generator wiring diagram

4.5 Construction Planning Considerations

To reduce delays later and to minimize cost, the following items should be considered during

the planning process:

• Subcontractor roles and responsibilities

• Cable trenches (type, length and depth)

• Control enclosure design

• Site specific weather extremes

• Tower foundation type

• Foundation forming details

• Site accessibility and road conditions

• Crane availability and cost

• Concrete availability and cost

• Backhoe availability and cost

• Concrete reinforcing bar availability and cost

• Labor skills and related costs

• Soil characteristics

§ Soil stability

§ Depth to water table

§ Depth to significant frost

§ Allowable bearing capacities

• Blasting needs

• Tripod or backhoe for tower assembly

• Availability of hand tools

• Concrete working tools

• Anchor bolt template and verification of proper placement

• Fencing materials and security

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 35

4.0 Planning and Installation Checklist

27

4.6 Electrical Planning Considerations

The local wiring inspector should review the design of the electrical installation before work

starts at the site. The following items should be considered in the design/installation of the

electrical system:

• Wire sizes, length and type as described in Appendix M

• Conduit type and size

• Service entrance hardware

• Revenue meter specifications

• Protective hardware required by the interfacing utility

• Distribution panel(s) with properly sized circuit protection

• Single phase power for control house lights and receptacles

• Step down transformer characteristics

• Control house interior wire ways

• Control house junction box(es)

• Multiple unit control for wind power stations

• Twist cable termination box

• Foundation/conduit interfaces

4.7 Installation Tools and Equipment

The installation of the AOC 15/50 requires specific tools and equipment (see Appendix I).

Below is a breakdown of steps to take or equipment to have on hand for the three main

installation phases.

For tower assembly:

• Tower manufacturer’s assembly drawings

• Checklist of tower parts, hardware and tools

• Torque specifications

• Tripod, bucket, backhoe or boom truck

• Personnel for lifting and assembly

• Anemometer boom and brackets

To prepare machine:

• If wind turbine generator was shipped in a crate, remove from crate

• Check components

• Open blade crate

For installation:

• Slings, ropes, buckets and tools

• Adequately trained personnel

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 36

4.0 Planning and Installation Checklist

28

• Platform or bucket for blade installation

• Appropriate safety equipment

• Crane

• Forklift or boom truck

4.8 Installation Personnel Considerations

The installation and maintenance of a wind turbine requires specialized skills, equipment and

experience. AOC assumes that all installation and operation personnel will have these skills,

experience and equipment. Only trained and qualified technicians should attempt to climb a

wind turbine tower and should use OSHA/ANSI approved practice and equipment. It is highly

recommended that a trained AOC representative be present for the erection and assembly of the

wind turbine (see Section 4.9). The following personnel should also be present, as and when

required, during installation:

• One to two qualified technicians trained in climbing safety to erect and install wind

turbine

• Qualified crane operator to operate the crane during tower and wind turbine lifting

• Certified electrician and/or utility personnel to install cables and wire controllers

• Additional labor for non-technical tasks such as tower assembly

4.9 General Installation/Commissioning Timeline

The following timeline represents the minimum installation schedule for one wind turbine under

ideal circumstances. Three to five days is usually a reasonable estimate. Poor weather

conditions, logistic problems and poor planning may extend the timeline considerably.

Site Preparations and Construction:

• Pour foundation

• Create cableways, wiring, power cables

• Install and wire control boxes, capacitor, and dynamic brakes

• Inspect wind turbine and hardware

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 37

4.0 Planning and Installation Checklist

Day 1:

• Plan and prepare erection

• Assemble tower

• Test generator and use it as a motor to test drive train

• Clean blades and install tip brake cable

• Prepare tip brake studs and cavity

• Prepare blade bolt inserts

• Attach twist cable

• Install two of three blades if time permits (fork lift, boom truck, etc.)

Day 2:

• Lift and install tower on foundation (crane)

• Install blades on hub

• Install tip brakes on blade ends

• Lift and mount machine onto the tower

• Torque tower top fasteners

• Torque all tower bolts and add pal nuts

Day 3:

• Install and wire anemometers

• Wire twist cable junction box and disconnect (if applicable) at tower base

• Grout tower legs

• Mount warning signs as required

• Troubleshoot and commission

Day 4:

• Complete any further installation details

• Carry out final QA check

• Monitor performance (wind permitting)

29

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 38

4.0 Planning and Installation Checklist

30

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 39

of

31

5.0 Site Preparation

Photo Courtesy

BED

FOUNDATION CONSTRUCTION AT THE BURLINGTON ELECTRIC DEPARTMENT PROJECT

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 40

5.0 Site Preparation

32

WARNING

DURING THE INSTALLATION OF A WIND TURBINE, THE SITE

SHOULD BE MAINTAINED SO THAT IT DOES NOT PRESENT A

SAFETY RISK/HAZARD TO PERSONNEL.

The following sections discuss some of the siting factors, which must be considered before the

wind turbine arrives.

5.1 Site Access

Access to the site is a prime consideration when installing a wind turbine. Limitations in site

access will determine the type of installation and equipment that can be used. Potentially

limiting factors include:

• Roadways (existence, permits, size, surface, restricted use, weight bearings)

• Bridges (size, load capacity, width and height clearances)

• Physical clearances (overhead wires, lamp posts, turning radii, grade)

• Traffic (movement to and at the site)

• Lay down area (space to assemble the tower and locate components prior to installation)

5.2 Foundation Installation

Foundation types and installation approaches are site specific and the foundations must be

designed for the load conditions expected at the site in question. Refer to IEC Standards for

Wind Turbines for additional information. Since AOC offers a standard and tilt-up tower, it

should be noted that the chosen configuration will affect the position of the anchor bolts. For

planning purposes regarding the tilt-up towers, it should be remembered that AOC only supplies

the hinges not the erection equipment.

See Appendix F for foundation loads and details. The civil engineer responsible for the

foundation design should consider site specific conditions.

Each tower leg should be grounded as per EIA standards. Rohn recommends using three 5/8”

galvanized ground rods, 8 feet long and mechanically connected to each leg using #4 gage wire.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 41

5.0 Site Preparation

It may be advisable to excavate trenches for power and control cables at the time of digging the

foundations. For wire and cable information, refer to Appendix M.

CAUTION

CAREFUL MEASUREMENT AND USE OF AN

ACCURATE ANCHOR BOLT TEMPLATE BEFORE,

DURING AND AFTER CONCRETE POURING CAN

MINIMIZE ALIGNMENT PROBLEMS OR

FOUNDATION REPAIRS.

5.3 Receiving the Wind Turbine at the Site

Wind turbines are often installed on uneven terrain. Moving components and assembling them

is easier on level ground. It is, therefore, suggested that a level lay-down area is either

excavated (taking care to prevent erosion) or built, on which the wind turbine can be assembled

and erected. Items such as blades may need to be anchored and covered if the site experiences

strong winds or other hazardous environmental conditions.

The wind turbine will normally be shipped in four crates. Their nominal weights and sizes are

listed in Appendix E. For containerized shipping please note that both the tower sections and

the blades are too long to fit a 20 ft container.

Once the shipment has been offloaded from the truck:

• The packing list should be checked to confirm that all items have been received. The

items should be inspected for damage and if any damage is suspected the shipping

company should be contacted regarding claims procedures. AOC should also be

notified of the parts needed. Particular care should be taken to inspect the twist cable

and the blade surfaces.

• Any scratches obtained during transit should be touched up. CRC Industrial SP

Corrosion Inhibitor or an equivalent can be used as an anticorrosive on any bare metal

surface. Failure to properly coat bare metal may result in significant corrosion.

• With the wind turbine on level ground, the oil level in the gearbox sight glass should be

checked. See Figure 2-2 for the sight glass location. It should be half way up the sight

glass.

• All grease fittings should be intact. These are located on the generator housing, yaw

bearing, yaw lock.

The checklist is provided in Appendix G.

33

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 42

5.0 Site Preparation

34

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 43

Photo Courtesy of

35

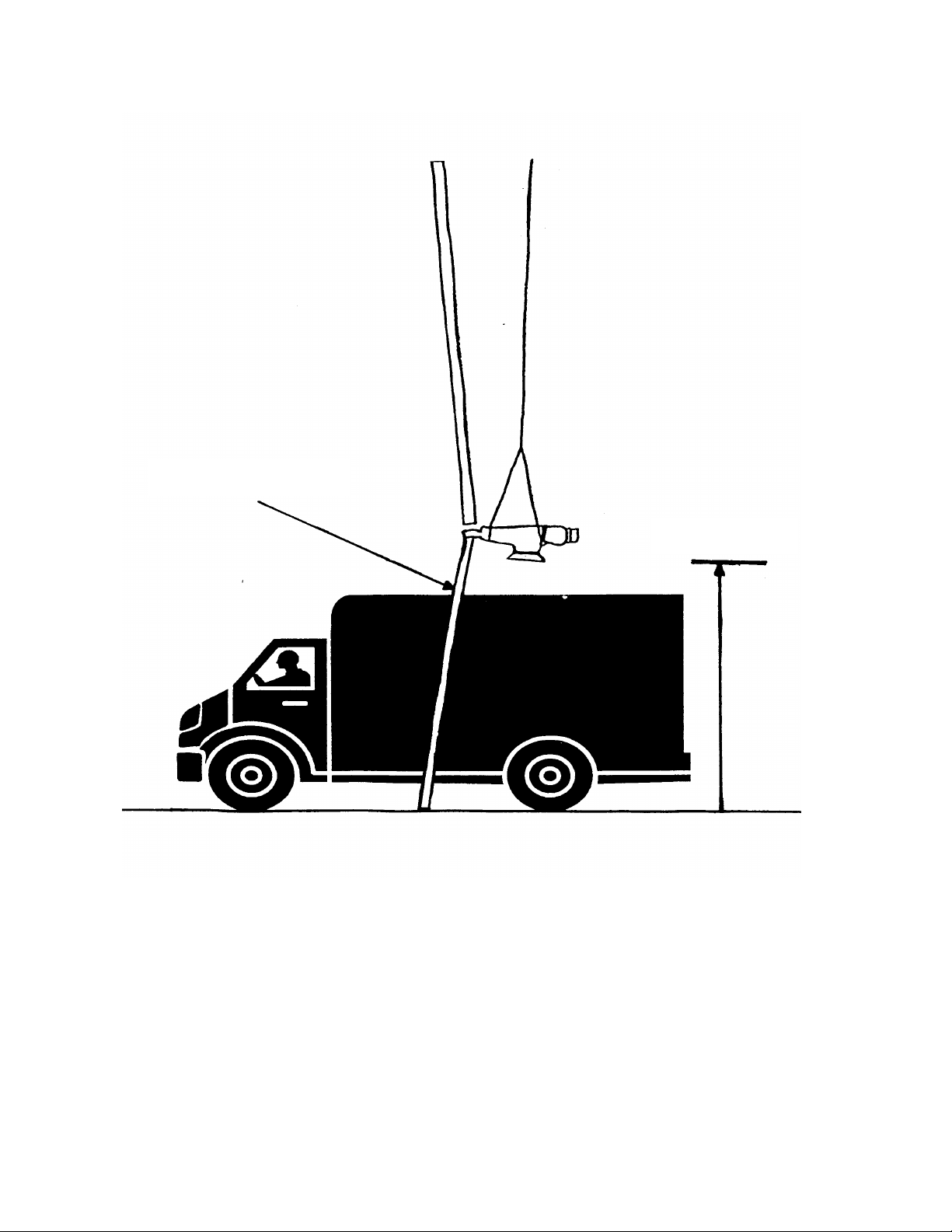

6.0 Tower and Wind Turbine Generator Installation

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

DOC012R02 AOC 15/50 User Manual Nov 2001

BED

TOWER ASSEMBLY AT THE BURLINGTON ELECTRIC DEPARTMENT PROJECT

on page v of this document.

Page 44

6.0 Tower and Wind Turbine Generator Installation

36

The following sections describe the assembly of the tower, as well as its erection and the

installation of the wind turbine generator.

6.1 Tower Assembly

For the assembly details refer to the manufacturer’s instruction packet shipped with the tower.

The tower assembly drawings for the standard 24.4 m (80 ft) tower are supplied in Appendix C;

for those of the 30.5 m (100 ft) tower see Appendix D.

The tower will generally be assembled horizontally with two of its three legs near the ground.

Blocks should be used to support these two legs at several locations along their length. The

height of the blocks should be chosen to ensure that the tower is straight and to allow crossbraces to be bolted to the legs. The blocks must have sufficient strength and stability for the

tower to be worked on safely.

After laying out the tower leg sections, the braces should be matched to their respective brace

clips on the legs. Braces and legs are clearly stamped with their part numbers and are referenced

in the tower drawings (see Appendix C or D). The bottom leg flanges of the bottom tower

section and the upper leg flanges of the topmost tower section are angled. This ensures that they

are parallel to the foundation and the turbine tower top casting once the tower is vertical.

The cross-braces between two legs from each section should be installed. The third leg then has

to be lifted above the two lower legs for the remaining cross-braces to be installed. The leg can

be raised using a bucket loader, fork lift or similar aid.

The open angle on the cross-braces should face towards the tower base, to shed any water. The

longer distance between the middle and the outer bolt hole in the cross-brace should also be

positioned facing down, towards the base. This configuration should be repeated down the tower

and around its sides. The top braces of each section start in the top hole of the brace clips, and

the bottom braces of each section terminate at the bottom hole of the brace clips. The crossbrace holes may not line up with the brace clip hole easily but they can be aligned using a pair of

drift pins and two vise grips to hold the brace in place while a bolt is inserted.

Brace bolts should be installed with the head on the inside of the tower and the nut on the

outside. Flange bolts should be inserted from the bottom up, with the nut on the flange top. The

flange bolts on the top and bottom most sections should be left slightly loose until the tower is in

place, as should the cross-brace bolts on these sections. It is helpful to use templates on the top

and bottom sections when assembling the tower. This ensures a better fit when the tower is

erected on the foundation. The bolts on the middle sections may be tightened to their required

torques after the tower has been completely assembled.

The 1” flange bolt nuts should be torqued to 340 Nm (250 ft-lbs) and the 5/8” nuts on the braces,

to 200 Nm (150 ft-lbs). Pal nuts should be placed snug tight on every bolt after the nut has been

torqued, thereby indicating that the bolt has been torqued to specification.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 45

6.0 Tower and Wind Turbine Generator Installation

37

NOTE: A template identical to the anchor bolt template can be bolted to the bottom leg

flanges during tower assembly to insure a proper fit during the tower erection. Using both

templates should theoretically allow all bolts to be torqued before erection.

6.2 Tower Erection

Appendix G contains the Installation QA checklist that should be used during the installation

process.

Much time can be saved if a crane capable of lifting the tower as one complete unit is used.

When considering crane capacity, the erection load and local wind conditions should be taken

into account. The centerline of the drive train is approximately 1.2 m (4 ft) above the chosen

tower height. The 24.4 m (80 ft) tower weighs approximately 3,180 kg (7,000 lbs) and the 30.5

m (100 ft) tower, approximately 4,550 kg (10,000 lbs). The wind turbine generator weighs

approximately 2,480 kg (5,450 lbs). See Appendix E. The length of the crane ball, lifting sling

and the height lost due to boom angle reach should also be taken into account.

Before the tower is set on the foundation, an anchor nut should be placed on each anchor bolt to

serve as a base for the tower flanges to rest upon. These nuts should be leveled before the tower

is placed on them, using a survey transit and straight rod or a long straightedge with a bubble

level, for example. Tolerance is not important initially, as the nuts may need to be adjusted in

order to level the gearbox.

The tower can be lifted using three appropriately rated, separate slings or cables of equal length,

each of which is hooked to the crane ball at one end and to the tower, near the top of its top

section legs, at the other. The lifting devices should be inspected for correct attachment

before raising the tower. Special care should be taken not to damage the lifting webbing on

sharp edges. The tower should be lifted slowly and set on the anchor bolts carefully. The tower

base flanges may not fit the anchor bolts precisely, especially if a base template was not used.

WARNING

DO NOT HAMMER OR BEND ANCHOR BOLTS TO FIT THE

TOWER BASE. THIS MAY CAUSE CATASTROPHIC

STRUCTURAL FAILURE AND RESULT IN SEVERE INJURY OR

DEATH.

The tower legs may have to be twisted along their axes, to obtain the correct alignment between

the flange holes and the anchor bolts. This can be done using a come-along and pry-bar. As the

tower is lowered onto the base nuts, the top locking nuts should be placed on the anchor bolts as

soon as the first threads protrude from the flanges. The nuts should be tightened incrementally

as the tower is lowered. Once the tower is in place, the lock nuts should be tightened hand snug,

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 46

6.0 Tower and Wind Turbine Generator Installation

38

after which the tension on the crane cable can be relaxed. A technician should verify that the

tower top is level by climbing the tower. Any adjustments required to level the tower top should

be made by adjusting the anchor nuts.

The 1½ “ anchor bolt nuts should be torqued to AISC snug tight standards after the tower has

been erected; snug tight being defined as the tightness needed to bring all plies in a joint into

firm contact. This may be obtained by a few impacts of an impact wrench or the full effort of a

man using an ordinary spud wrench. Following this, the tower grounding rods should be

connected (see Section 5.2) and the slings released.

WARNING

ONLY TRAINED AND QUALIFIED TECHNICIANS SHOULD

ATTEMPT TO CLIMB A WIND TURBINE TOWER AND SHOULD

USE OSHA/ANSI APPROVED PRACTICE AND EQUIPMENT. ANY

ACTIVITIES WHERE PERSONS COULD BE SUBJECT TO A FALL

OF SIX FEET OR MORE SHOULD BE PERFORMED USING

APPROPRIATE FALL PROTECTION EQUIPMENT FASTENED

TO A SECURE ANCHOR POINT. SEE APPENDIX S FOR A

DESCRIPTION OF SAFETY EQUIPMENT AND SECURE ANCHOR

POINTS.

A DESIGNATED PERSON SHOULD BE CLEARLY IDENTIFIED

AS THE LIFT COORDINATOR. THE LIFT COORDINATOR

SHOULD DIRECT ALL EQUIPMENT AND PERSONNEL DURING

THE LIFT. HAND SIGNALS (APPENDIX R) MUST BE

CAREFULLY COORDINATED WITH THE CRANE OPERATOR IN

ADVANCE. SUPPLEMENTARY RADIO CONTACT IS STRONGLY

RECOMMENDED.

6.3 Wind Turbine Component Preparation

6.3.1 Tip Brake Installation

After removing the top of the blade crate, the blade tips should be slid on to the edge of the crate

end. The blades should then be pulled out of their crate completely, inspected for damage and

laid on support blocks. The foam packing inserts can be used to separate and support the blades.

Both conduit ends should be free of debris and epoxy!

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 47

6.0 Tower and Wind Turbine Generator Installation

39

CAUTION

THE BLADES SHOULD NOT BE SCRATCHED OR GOUGED

DURING SITE HANDLING AS THIS CAN CAUSE A LOSS OF

ROTOR PERFORMANCE AND/OR BLADE DEGRADATION

FROM ENVIRONMENTAL EFFECTS.

The string in the conduit should be used to pull a #10 gage wire through the conduit. The blade

cable should then be attached to the wire (with tape, for example) and pulled through the blade

conduit, with the molded 3-pin connector at the root end of the blade. Lubricating the blade

cable facilitates this operation. Female connectors should be crimped to the black and red wires

and a fork-tongue connector to the blue wire. The female connectors should be connected to the

rectifier and the fork-tongue connector to the ground point on the damper bracket (see Figure 6-

2).

To avoid damaging the tip brakes during blade installation, it is preferable to install them once

the blades have been attached to the hub. Till then, the blade ends should be protected with foam

to prevent damage, should they strike the ground or any hard object.

After connecting the electromagnet, the tip brake assembly should be inserted carefully into the

end of the blade without pinching the electromagnet wires. Each tip brake should be bolted to its

blade using low profile nylon-insert lock nuts over the blade end studs. The lock nuts should be

torqued to 14.8 Nm (11 ft-lbs) for the 5/16" studs and 24 Nm (18 ft-lbs) for the 3/8" studs, using

½" and 9/16" socket wrenches, respectively. It is recommended to step torque each nut to

distribute the force over all studs.

CAUTION

FORCING THE TIP BRAKE INTO THE BLADE CAVITY CAN

DAMAGE BOTH THE BLADE AND THE TIP BRAKE. TIP

BRAKES SHOULD SLIDE INTO THE BLADE CAVITY

EASILY.

After the tip brake has been mounted on the blade and wired, the blade should be positioned so

that the tip brake can open and close freely. The tip brake should be opened and let go; it should

close completely.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 48

6.0 Tower and Wind Turbine Generator Installation

Figure 6-1 Parking brake manual release

40

Figure 6-2 Tip brake installation

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 49

6.0 Tower and Wind Turbine Generator Installation

41

6.4 Blade Installation

This procedure should be carried out by a minimum of three technicians. Each blade weighs 135

kg (300 lbs) and can be lifted by a crew of three or four or using equipment such as a back hoe or

a boom truck fitted with nylon slings or ropes. Metal slings or chains should never be used to

move a blade.

CAUTION

NICKS OR GOUGES IN THE BLADE SURFACE CAN

AFFECT THE PERFORMANCE AND THE EXPECTED LIFE

OF THE BLADE SIGNIFICANTLY. TAKE EVERY

PRECAUTION TO PROTECT THE BLADE SURFACE

DURING HANDLING AND INSTALLATION.

The first two blades should be installed with the machine still set on the ground. The yaw lock

should be engaged, to restrict the turbine from rotating about the yaw axis. See Figure 6-4 for

the yaw locking position. The parking brake is released by pulling on the manual release, after

which the hub can be rotated so that a blade can be mounted with its tip or tip brake supported

above the ground (see Figure 6-1). The blade should rest on a piece of packing foam to prevent

surface damage. A drift pin or bolt placed in a blade bolt hole on the hub will help align the

blade with the hub.

WARNING

BLADE WASHERS SHOULD LIE FLAT AGAINST THE HUB

COUNTERBORE. FAILURE TO INSTALL WASHERS PROPERLY

CAN RESULT IN LOOSENING AND FAILURE OF FASTENERS.

THIS MAY RESULT IN BLADE DETACHING, SEVERELY

DAMAGING THE MACHINE AND CAUSING SERIOUS INJURY

OR DEATH.

The red protective plugs should be removed from the blade inserts in the root end. The blade

should be slid onto the hub, with the concave (upwind) side of the blade towards the machine.

The tip brake wire, which exits the trailing edge of the blade near the root, must not be damaged.

It is helpful to tape this down to the blade during assembly.

Note: The concave ('bottom' of the airfoil) MUST face the machine. Only the blade bolt

washers supplied with the wind turbine should be used. These washers are oval shaped and

designed for the blade mounting. The washer must be oriented in the correct position for the

required pitch, as the washers are not symmetric. It is extremely important that the

washers are seated entirely in the hub slot counter bores and rest flat on the bottom of

these counter bores. If the washers are even slightly misaligned, the bolts and washers

should be reassembled.

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 50

6.0 Tower and Wind Turbine Generator Installation

42

DO NOT SUBSTITUTE BOLTS. Only the AOC supplied Grade 8, fine thread bolts, 5/8" x

3", should be used to secure the blades to the hub. The tip brakes can be unlatched or

removed (if necessary) to prevent damage during the mounting process.

The four corner bolts on the blade should be installed, initially without the washers, to hold the

blade in place. The pitch tool should be inserted first, in slot #1 (see Figure 6.10), and secured

with a bolt inserted snug tight.

Unlock

Lock

Yaw Lock

Bottom View

Figure 6-4 Yaw lock on tower top

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 51

6.0 Tower and Wind Turbine Generator Installation

Figure 6-5 Yaw lock

43

Figure 6-6 Tower top casting

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

Page 52

6.0 Tower and Wind Turbine Generator Installation

Blade #1

Figure 6-7 Positioning the blade for attachment

44

Turbine on pallet

Ground level