Anycubic 13 mega User guide

www.anycubic3d.com

Facebook group

Youtube channel

Thank you for choosing ANYcUBIC products.

Please read the user manual carefully.

Please visit www.anycubic3d.com for more information.

Email us on support@anycubic3d.com or james@anycubic3d.com for

technical support.

If you experience any issues with this product, or the performance is not what you

had expected, please contact us first. We are here to solve any problems for you.

Team ANYcUBIC

Safety Instructions

Please carefully read the safety instructions before get started.

ANYcUBIC 3D printer generates high temperature. Do not reach inside of the

printer during operation. Allow time for the printer to cool down after printing.

Contact with extruded materials may cause burns. Wait for printed objects to cool

before removing them from the build platform.

ANYcUBIC 3D printer includes moving parts that can cause injury.

Vapors or fumes may be irritating at operating temperature. Always use the

ANYcUBIC 3D printer in an open, well ventilated area.

Be cautious when using the scraper. Never direct the scraper towards your hand.

ANYcUBIC 3D printer MUST NOT be exposed to water or rain.

ANYcUBIC 3D printer is designed to be used within ambient temperature ranging

8ºC-40ºC, and humidity ranging 20%-50%. Working outside those limits may

result in low quality printing.

It is recommended to use protection glasses when cleaning/sanding the printed

models to avoid small particles contacting eyes.

In case of emergency, immediately turn off the ANYcUBIC 3D printer and contact

us or consult for professional advice.

Never leave the ANYcUBIC 3D printer unattended during operation.。

Contents

1. Product overview ......................................................................................................... 1

2. Part list ............................................................................................................................ 4

3. Assembly instruction .................................................................................................. 5

4. Leveling ........................................................................................................................... 9

5. Software installation ................................................................................................ 15

5.1 Driver installation .............................................................................................. 15

5.2 Cura Installation ................................................................................................ 17

6. Printing .......................................................................................................................... 26

7. Manual filament change ......................................................................................... 28

8. Resume from outage ................................................................................................ 29

9. Trouble shooting ........................................................................................................ 32

Technical Specification

Printing

Technology: FDM (Fused Deposition Modeling)

Build Size: 210×210×205 (mm3)

Layer Resolution: 0.05-0.3 mm

Positioning Accuracy: X/Y 0.0125mm,Z 0.002mm

Extruder Quantity: Single

Nozzle/Filament Diameter: 0.4 mm/1.75mm

Print Speed: 20~100mm/s (suggested 60mm/s)

Travel Speed: 100mm/s

Supported Materials: PLA, ABS, HIPS, Wood

Temperature

Ambient Operating Temperature: 8°C - 40°C

Operational Extruder Temperature: max 260°C

Operational Print Bed Temperature: max 110°C

Software

Slicer Software: Cura

Software Input Formats: .STL, .OBJ, .DAE, .AMF

Software Output Formats: GCode

Connectivity: SD card; USB port(expert users only)

Electrical

Input rating: 110V/220V AC, 50/60Hz

Working Voltage: 12V DC

Physical Dimensions

Printer Dimensions: 405mm×410mm×453mm

Net Weight: ~11kg

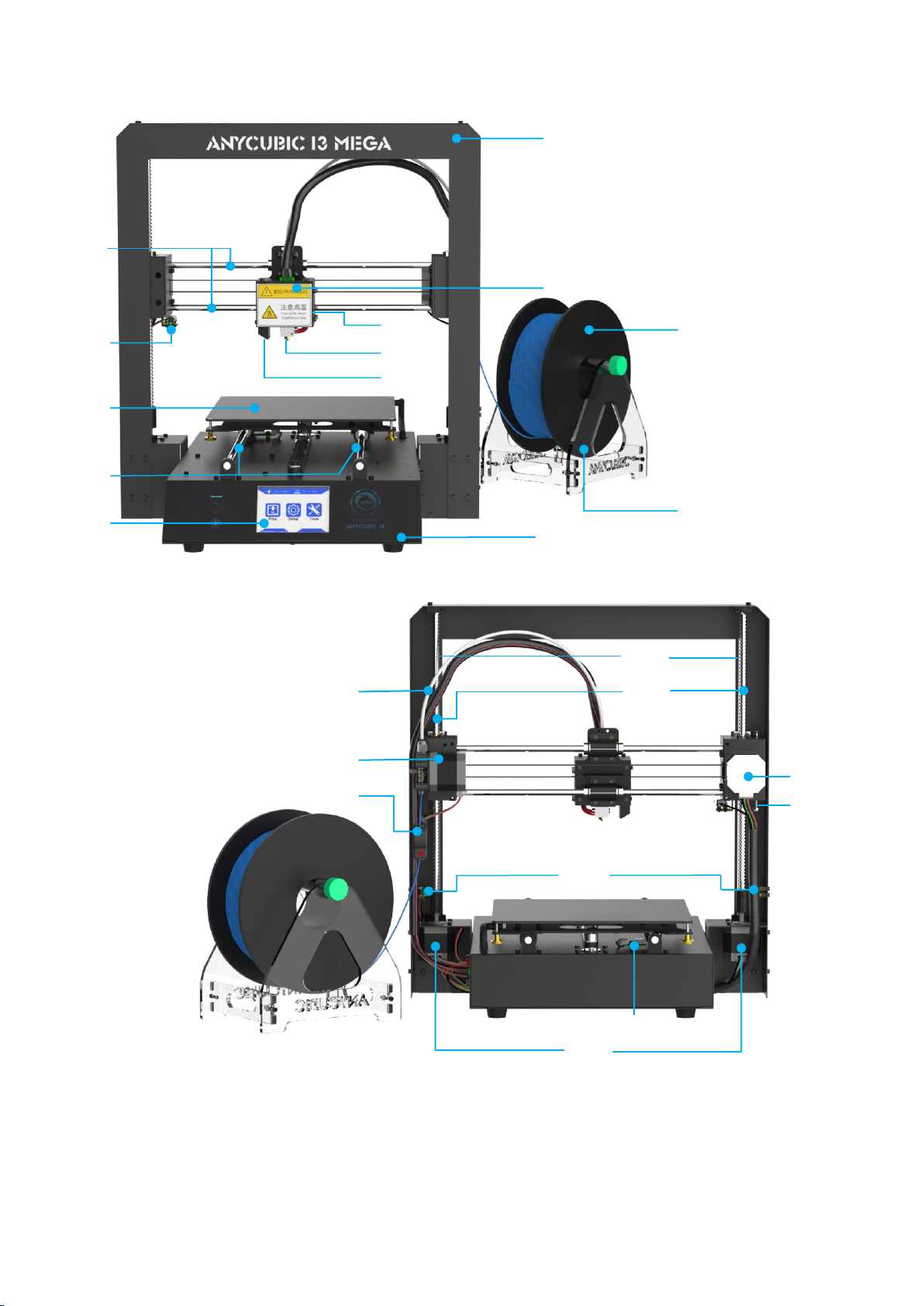

1. Product overview

⑹ ⑻ ⑴

⑵

⑷

⑸ ⑿ ⒀ ⑾ ⑼

⑽

⑺ ⒁ ⒂

(22)

⒃

⑴Frame ⑵Print head ⑶Hotend cooling fan ⑷Nozzle ⑸Model cooling fan ⑹Base ⑺X smooth

rods ⑻X end stop ⑼Print platform ⑽Y smooth rods ⑾Touch screen ⑿Filament spool ⒀Spool

holder ⒁Z smooth rods ⒂Z lead screw ⒃X motor ⒄Z adjustable nut ⒅Z end stop ⒆Y end stop ⒇

Z motors (21)Teflon tubing (22) Extruder (23) Filament sensor

(21)

⒆ ⒇ ⒅

⑶

(23)

⒄

1

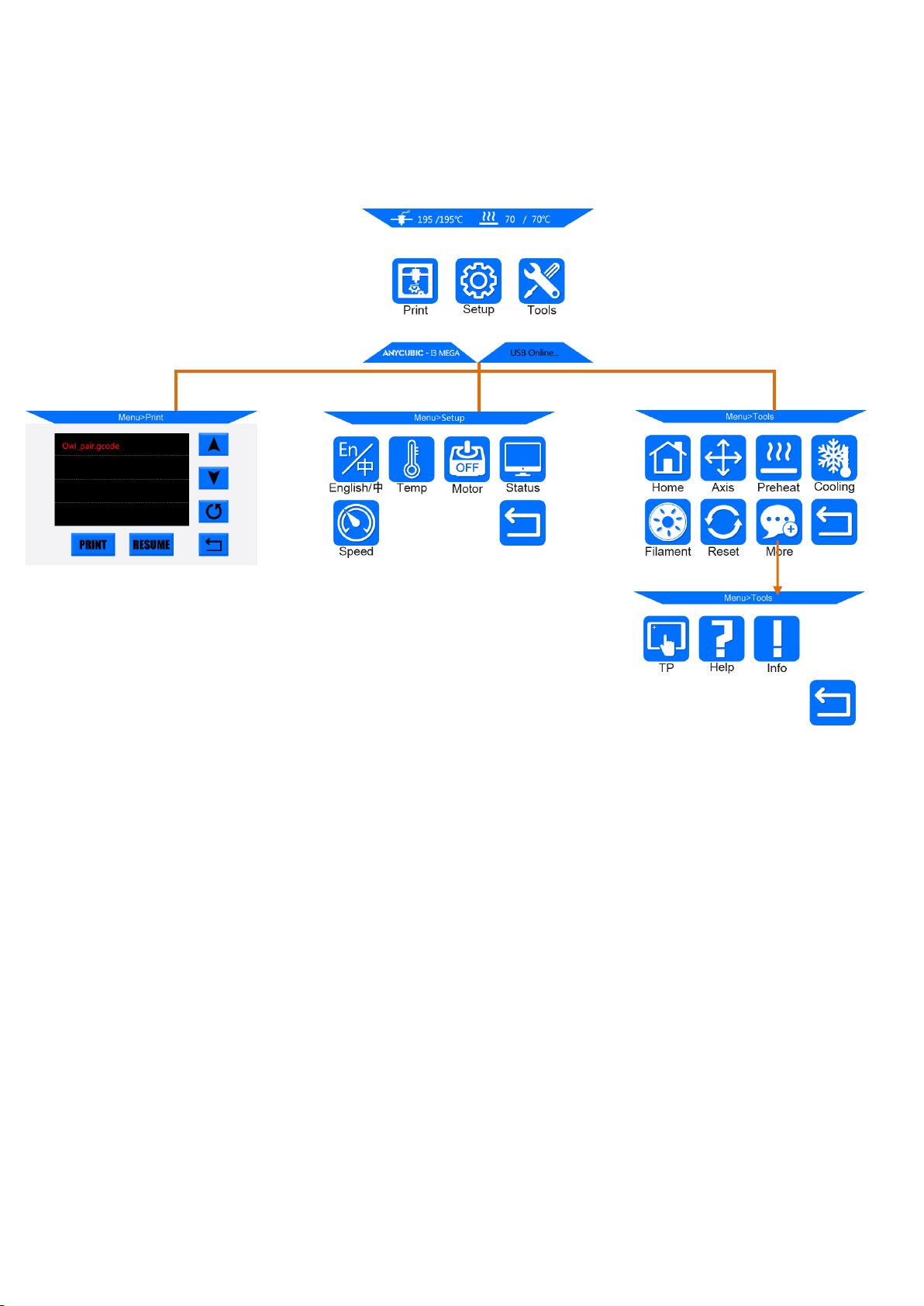

Menu Directory

Home Menu

Print

Tools

Setup

Home menu

Print: enter the print list

Setup: enter the setup menu

Tools: enter the tools menu

(Other information: ①nozzle temperature ②heated bed temperature ③printer status)

Print

Print: print the selected files in SD card

Resume: Resume from outage (only valid for offline print via SD card)

(Other information: ①Page up and down ②Refresh the list ③Return to the home menu)

Setup

En/中: Change language (English/Chinese)

2

Temp: Enter the menu to adjust ① E0 (hotend) Temp (170-260°C) ②Bed Temp (0-120°C)

Motor: Disable all motors (only valid when machine is not printing)

Status: Enter the sub-menu with Print/Pause/Resume icon (only valid for offline print)

(Other information: ①Files ②Print Rate ③Time ④Progress ⑤E0 Temp ⑥Bed Temp ⑦

coordinates for X/Y/Z axis ⑧Return to previous menu)

Speed: Enter the menu to adjust ①Fan speed (0-100) ②Print Rate (50-999)

Return: Return to Home Menu

Tools

Home: ①Home X ②Home Y ③Home Z ④Home All ⑤Return (only valid when machine is not

printing)

Axis: ① Home all axis ②Move X/Y/Z axis by 0.1/1/10 ③Speed mode for axis move

Low/Medium/High (only valid when machine is not printing)

Preheat: ①Preheat PLA ②Preheat ABS (only valid when machine is not printing)

(Other information: ①E0 Temp ②Bed Temp)

Cooling: Cut off the power of hotend and heated bed (only valid when machine is not printing)

Filament: ①Filament In ②Filament Remove (will automatically heating to 200°C for filament in

or remove) ③ Stop (only valid when on print job)

Reset: Popup window to decide if reboot the mainboard

More: Enter the next page of Tools sub-menu

TP: Touch panel alignment(click on the cue points)

Help: Basic description of the Menu

Info: Information about the product

Return: Return to Home Menu

3

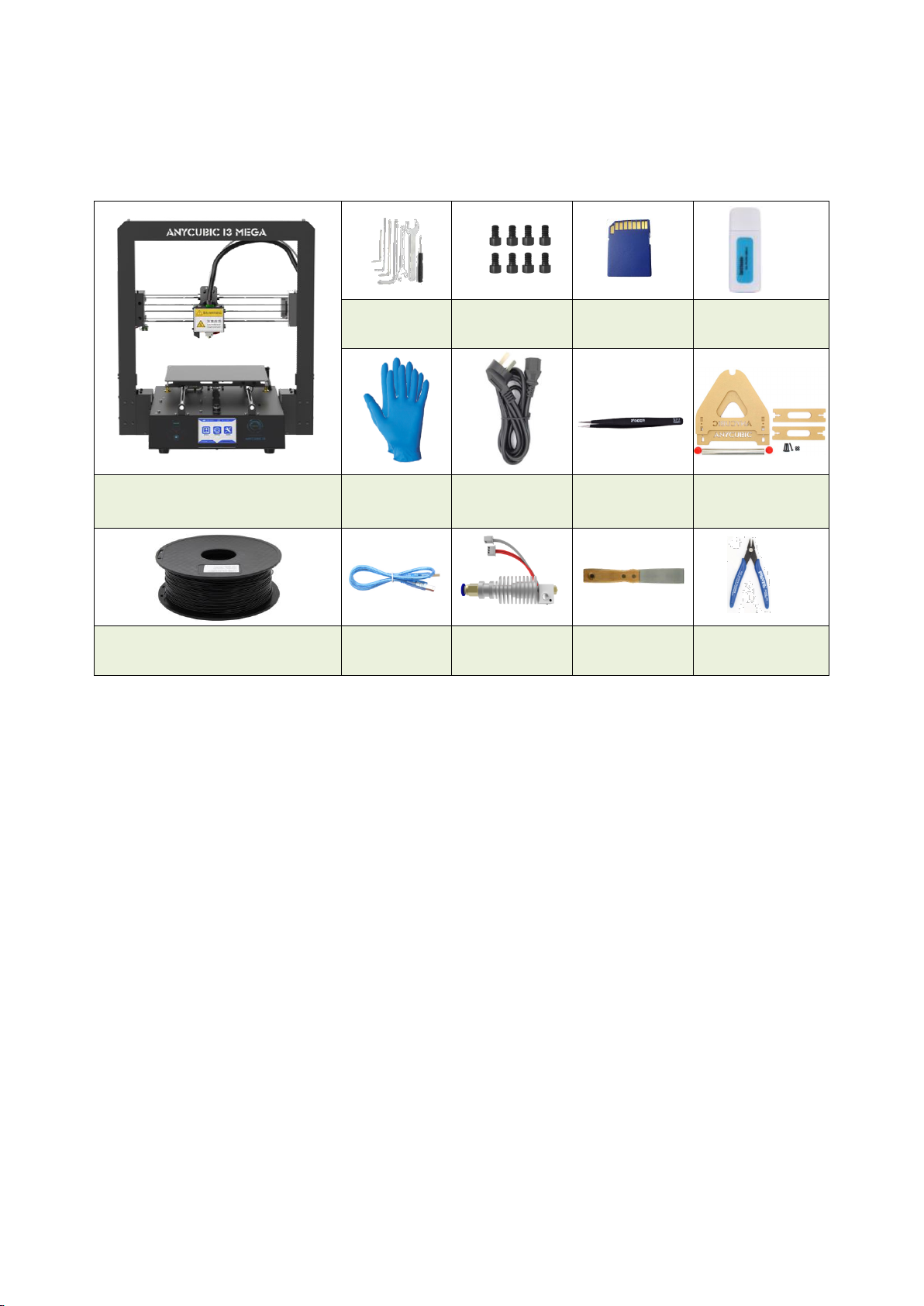

2. Packing list

Tool kit

M5*8 screws

SD card

SD Card reader

ANYcUBIC 3D printer

Gloves

Power cord

Tweezer

Spool holder

PLA filament (Random color)

USB cable

Extra hotend

Scraper

Plier

4

3. Assembly instruction

Frame

Base

①

②

③

Step 1. Unpack and take out the printer and accessories.

Wear gloves because the smooth rods and lead screw may be greased in factory.

Step 2. Follow ① ② ③ in Fig. 1. Carefully lift the base to fit into the frame and fix them by

8 pieces of M5*8mm hex cap screws. The screw locations are indicated by red

squares in ③. The screws can be installed in diagonal order and can be tightened

after all screws installed in place.

Figure 1

5

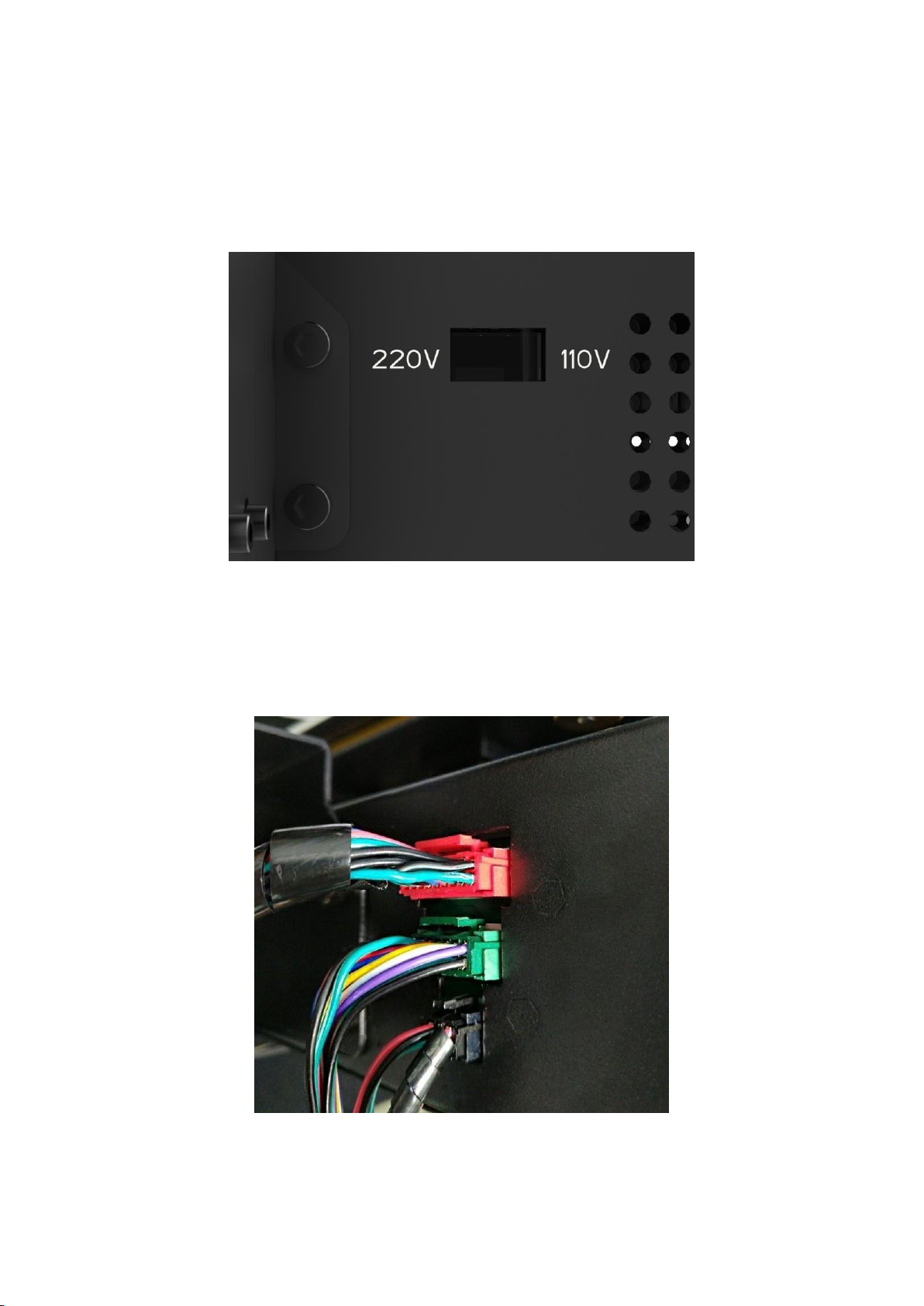

Step 3. Wiring

(Figure 3)

(Figure 2)

(1) Fig.2, select the correct voltage mode according to your local voltage ratings

(110V/220V). The switch is inside the bottom left of the base and 220V is default.

Allan keys can be used to move the switch inside.

(2) There are 3 ports with different color (Red/Green/Black) at the bottom right side of

the base, and there are 3 different color cable connectors respectively. Accordingly,

insert those connectors to the ports by the same color, as shown in Fig. 3.

> Make sure the connectors are well inserted, and no pins are bent inside.

> Wrong or loose connection would lead to malfunction of the machine.

6

Loading...

Loading...