Page 1

Equipment: Vertical Contact Toaster Model VCT-2010

VCT-2010

Preventative Maintenance

Precaution:

During these checks, hot surfaces will be exposed.

Hazard Communication Standard (HCS) – The procedures on this card include the use of

chemical products. These chemical products will be highlighted with bold face let-

ters followed by the abbreviation (HCS) in the tools portion of the procedure. See

the Hazard Communication Standard (HCS) Manual for the appropriate Material Safety

Data Sheet(s) (MSDS).

PICTURES AND ADDITIONAL INFORMATION: In The Corresponding Chapter of Equipment Manual.

Daily Clean the VCT-2010

Tools: Clean white towels; three 1/6-size, 6-inch deep s/s pans; 1/6-size Cambro pan; Sanitizer;

Heavy Duty Multipurpose Sink Detergent or Powersink Detergent; Dishwashing sink.

Clean the VCT-2010

WARNING

Turn the power off, unplug the power cord, and allow

the unit to cool down 30 minutes before performing any

service or maintenance.

CAUTION

To prevent damage to the unit, do NOT use abrasive

cleaners on the Release Sheet or Silicone Belt.

CAUTION

Do NOT submerse the Butter Wheel Heated Base in

water. Do NOT wash this item with a water jet. Do NOT

spray cleansers directly on this item.

AT CLOSE

• Turn the unit OFF and unplug at the outlet. Allow unit to

cool.

• Remove the Butter Wheel and Pan. Pour the remaining

butter into a clean 1/6-sized Cambro pan. Cover with solid

lid and place on dry storage shelf. Mark side of pan “use

first”. NOTE: Only butter that is clear and debris-free can

be held over.

• Take Butter Wheel and Pan to the dishwashing sink. Hand

wash, rinse; then sanitize for a minimum of 60 seconds.

Allow to air dry. Return to service line; set aside for reassembly at open.

AT OPEN

• Make sure unit is off and unplugged at the outlet.

• Take Heat Shield off; then, remove Release Sheets.

• Fill a full-sized pan with hot Detergent Solution and place

both Release Sheets into pan to soak.

• Remove Butter Wheel Heated Base and clean on-line

when cleaning the Silicone Belt. Do NOT submerge.

• Remove Heat Shield, Front and Back Conveyor Covers,

and Bun Chute and take to dishwashing sink.

NOTE: Do NOT place parts into the powerwash sink.

• Pre-rinse, hand wash, rinse, and sanitize parts. Return

parts to service line.

• Fill a clean 1/6-sized, 6-inch deep s/s pan with hot

Detergent Solution; a second pan with clean rinse water;

and a third pan with Sanitizer Solution. Place a clean,

white towel in each pan and place near toaster.

• Wipe the Butter Pan Heater.

• Wipe both sides of the Silicone Belts (side facing out first)

with a clean, white towel and hot Detergent Solution. Rinse

with a clean, white towel and clean rinse water. Sanitize

using a clean, white towel and Sanitizer Solution.

• Rotate Belt around so the side facing inward is facing out,

exposing the soiled areas of the Silicone Belt. Wash, rinse,

and sanitize following the above step.

• Remove Release Sheets that have been soaking and take

to dishwashing sink. Hand wash, rinse, and sanitize both

sides. Return to service line.

• Wipe outside of toaster with a clean, white towel and hot

Detergent Solution.

• Reinstall the Bun Chute, Front and Back Conveyor Cover,

and Butter Wheel Heated Base.

• Install the Release Sheet. NOTE: Rotate sheet daily from

silver to black side.

• Install the Heat Shield. Plug unit in.

• Turn toaster and Butter Pan Holder ON 30 minutes prior to

opening.

NOTE: Line 2 toaster in modern restaurants can be

cleaned during slow periods of the day.

NOTE: Make sure the Heat Shield is activating the

Conveyor Safety Interlock Switch. The unit will not function unless the Heat Shield is in place and the Conveyor

Safety Interlock Switch is activated.

NOTE: Check the Release Sheet to make sure it is not

caught in the Conveyor. Additional Release Sheets can be

purchased under P/N 7000625 (3-Pack).

CAUTION

Failure to use Release Sheets may result in damage to

the unit and loss of warranty coverage.

© 2011 1 of 4 P/N 1011110 Rev. C 04/11

Page 2

Every 3-5 Weeks Replace the Release Sheet

INCORRECT

CORRECT

Tools: Heat-Resistant Gloves

VCT-2010

Preventative Maintenance

Replace the Release Sheet

IMPORTANT

Turn the power off, unplug the power cord and allow the

unit to cool down before proceeding.

NOTE: Depending on toaster usage and on how well it

is cleaned daily, the Release Sheet should last between

21–35 days. Additional Release Sheets can be purchased

under P/N 7000625 (3-Pack).

1. Turn the power off to the unit and the Butter Wheel

Heated Base. Unplug the power cord.

2. Put on heat-resistant gloves and remove the Heat

Shield.

3. Remove and discard the Release Sheet.

4. Lay a new Release Sheet on a clean, dry surface and

fold it in half lengthwise. Then gently crease it at the fold

using only your fingers.

5. Install the new Release Sheet by draping it over both sides

of the Platen with the crease centered on the Platen.

6. Reinstall the Heat Shield with the Release Sheet retainer

clips securely over the Release Sheet and Platen.

7. Plug in the power cord and test the unit before returning

it to service.

NOTE: Make sure the Heat Shield is activating the

Conveyor Safety Interlock Switch. The unit will not function

unless the Heat Shield is in place and the Conveyor Safety

Interlock Switch is activated.

NOTE: Check the Release Sheet to make sure it is not

caught in the Conveyor.

CAUTION

Failure to use Release Sheets may result in damage to

the unit and loss of warranty coverage.

Every 2-4 Months Replace the Silicone Belts

Tools: Heat-Resistant Gloves

Replace the Silicone Belts

NOTE: The Silicone Belts should last 2‒4 months.

Additional Silicone Belts may be purchased under P/N

7000626 (2-Pack).

1. Turn the power off, unplug the power cord, and allow the

unit to cool.

2. Unplug and remove the Butter Wheel Assembly, and

Heat Shield. Set the Bun Thickness Compression Knobs

to 6 and 6.

3. Remove both Conveyor Covers and pull the Silicone

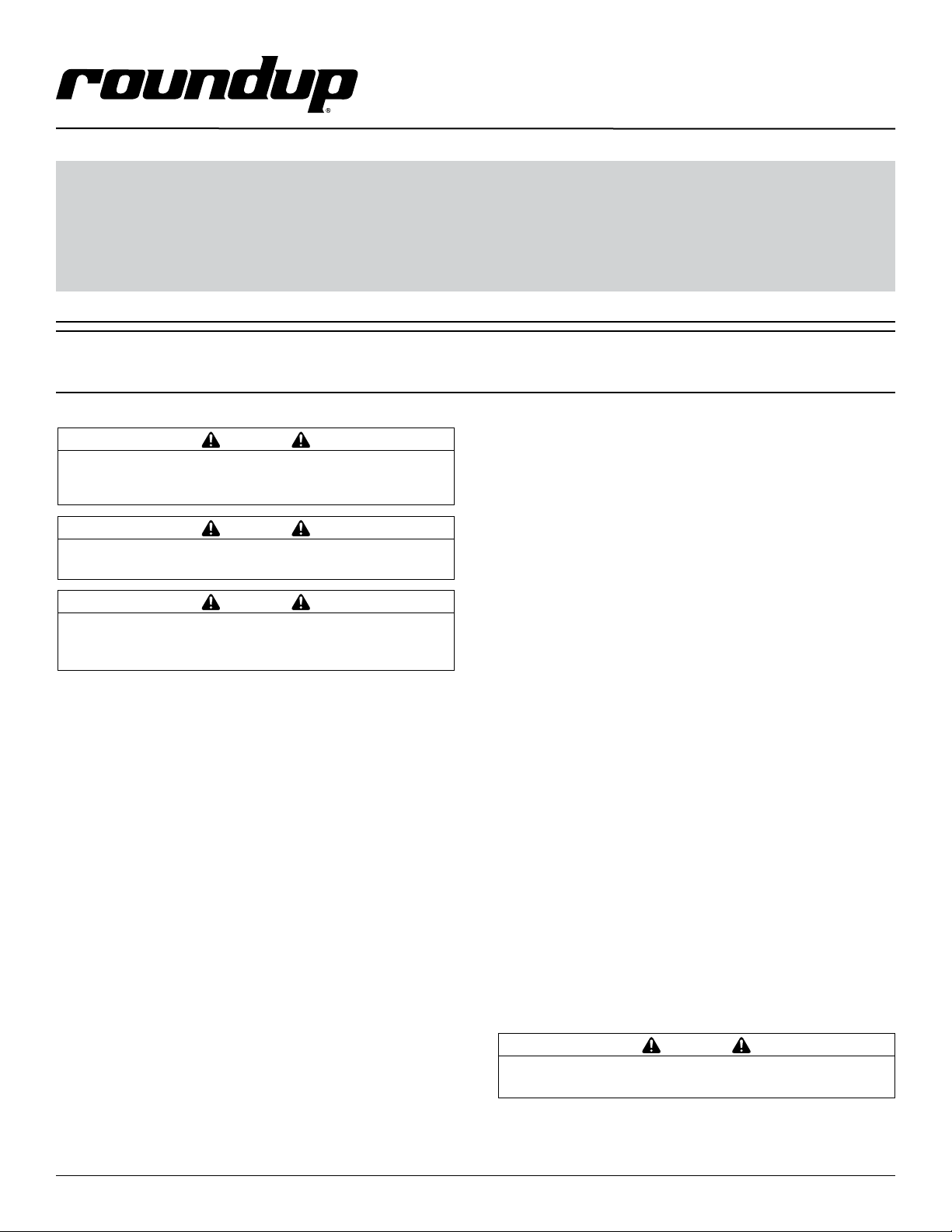

Belt Pin from the zipper on the Silicone Belts (Figure 1).

4. Remove and discard the old Silicone Belts.

5. Clean both Conveyor Belt Chains just as you would

clean the Silicone Belts during Daily Cleaning.

6. Install the new Silicone Belts around the Conveyor Belt

Chains between the yellow Upper and Lower Support Rods.

The zipper flap should be exposed and hanging down

(Figure 1).

NOTE: Make sure the Silicone Belt is only wrapped around

the Conveyor Belt Chain.

7. Install the Silicone Belt Pins in the new Silicone Belts,

ensuring the ends are properly aligned (Figure 2).

8. Set the Bun Thickness Compression Knobs to 3 and 4.

9. Reinstall the Conveyor Covers, Heat Shield and Butter

Wheel Assembly.

10. Plug in the power cord and test the unit before returning

it to service.

© 2011 2 of 4 P/N 1011110 Rev. C 04/11

Figure 1. Removing Silicone Belt

Figure 2. Aligning Belt Teeth

Silicone

Belt

Silicone Belt

Flap (down)

Silicone

Belt Pin

Page 3

Every 3-6 Months Check the Conveyor Belt Chains

Tools: Heat-Resistant Gloves, Dime

VCT-2010

Preventative Maintenance

Check the Conveyor Belt Chains

NOTE: The Bun Thickness Compression Knobs must be

set to 6 and 6 prior to measuring, removing, or installing

the Conveyor Belt Chains.

MEASURING CONVEYOR BELT CHAINS

1. Remove the Butter Wheel Assembly, Bun Chute, and

Heat Shield. Set the Bun Thickness Compression Knobs

to 6 and 6.

2. Remove the front and rear Conveyor Covers and pull

the Silicone Belt Pin out of the zipper (Figure 1).

3. Pull the Conveyor Chain away from the edge of the

toaster.

NOTE: Do NOT pull too hard on the Conveyor Chain.

Pulling too hard will compress the top shaft, which will

make the gap between the frame and the chain seem

larger than it is.

4. Hold a U.S. Dime horizontally between the frame and

the chain (Figure 3).

5. If the gap is significantly wider than the coin, REMOVE

links as described.

6. Repeat on the opposite side of the toaster.

REMOVING CONVEYOR BELT CHAIN LINKS

1. Turn the power off, unplug the power cord, and allow the

unit to cool.

2. Remove the Butter Wheel Assembly, Bun Chute, and Heat

Shield. Set the Bun Thickness Compression Knobs to 6

and 6.

3. Remove the Conveyor Cover and pull the Silicone Belt

Pin out of the zipper.

4. Remove the Silicone Belt.

5. Locate the two Master Links as shown in Figure 4.

6. Remove the Master Link on both the left and right side

of the chain.

7. Remove one complete link from the chain.

8. Replace the Master Links on both the left and right side

of the chain. This connects the two ends of the chain

together.

NOTE: The ends of the hooks must point down.

9. Replace the Silicone Belt. Secure with Pin.

NOTE: Make sure the Conveyor Belt Chain and Silicone Belt

are installed between the yellow Upper and Lower Support

Rod.

10. Reinstall the Conveyor Covers, Butter Wheel Assembly,

Bun Chute, and Heat Shield.

11. Set the Bun Thickness Compression Knobs to 3 and 4.

12. Plug in the power cord and test the unit before returning

it to service.

© 2011 3 of 4 P/N 1011110 Rev. C 04/11

REPLACING THE CONVEYOR BELT CHAINS

1. Turn the unit off, unplug the power cord, and allow the

unit to cool.

2. Remove the Butter Wheel Assembly, Bun Chute, and Heat

Shield. Set the Compression Control Knobs to 6 and 6.

3. Remove the Conveyor Cover(s) and pull the Silicone Belt

Hinge Pin out of the zipper.

4. Pull the Conveyor Chain away from the edge of the

toaster. Remove the Silicone Belt.

5. Locate the two Master Links on the Conveyor Belt Chain

and remove both the left and the right Master Link.

6. Remove the existing Conveyor Belt Chains.

7. Place the new Conveyor Belt Chains on the top sprockets

with the hook ends down.

NOTE: The ends of the hooks must point down (Figure 4).

8. Wrap the Conveyor Belt Chain around the top and lower

sprockets and connect by replacing both the left and the

right Master Links.

9. Reinstall the Silicone Belts, Conveyor Covers, Butter

Wheel Assembly, Bun Chute, and Heat Shield.

10. Set the Bun Thickness Compression Knobs to 3 and 4.

11. Plug in the power cord and test the unit before returning

it to service.

Figure 3. Measuring Conveyor Belt Chain

Master Links

Figure 4. Removing Conveyor Belt Chain

Page 4

Every 3-6 Months Check the Roller Tensioners

Tools: Ruler, Adjustable Wrench

VCT-2010

Preventative Maintenance

Check the Roller Tensioners

MEASURING THE ROLLER TENSIONERS

1. Turn the power off, unplug the power cord, and allow the

unit to cool.

2. Remove the Butter Wheel Assembly and Heat Shield.

3. Remove the front and rear Conveyor Covers.

4. Measure the Roller Tensioner on both inner Conveyor

Covers (Figure 5).

5. The space between the inner Conveyor Cover and bottom

of the Tensioner wheel should be no larger than 1/2”.

6. Adjust or replace Tensioners as needed.

7. Reinstall the front and rear Conveyor Covers.

8. Reinstall the Heat Shield and Butter Wheel Assembly.

9. Plug in the power cord and test the unit before returning

it to service.

REPLACING/ADJUSTING THE ROLLER TENSIONERS

1. Remove the acorn nuts and old Roller Tensioner

Assembly.

2. Install the new Tensioner Assembly (Figure 6).

3. Make sure the spacers are placed inside the Tensioner

arm. The spacers allow the Tensioner to pivot freely.

4. Make sure there is 1/2” between the bottom of the

Tensioner wheel and the inside of the Conveyor Cover.

Inner Surface

of Conveyor cover

Figure 5. Measuring Roller Tensioner

Acorn Nuts

Roller

Tensioner

Assy.

Spacers

NOTE: Installation is the

same for both the Front

and Rear Conveyor Covers

Teflon

Tape

Figure 6. Roller Tensioner Assembly

Roller

Tensioner

Assy.

1/2 Inch

Rear

Conveyor

Cover

Heat Shield

Butter

Wheel

Butter

Pan

Butter Wheel

Heated Base

Conveyor

Cover (Front)

Silicone

Belt

Bun Chute

Release

Sheet

Conveyor

Chain

PROGRAM

LIGHTER

DARKER

Control Panel

and Power Switch

Belt

Roller

Tensioner

Conveyor

Cover (Rear)

Figure 7. VCT-2010 Components

© 2011 4 of 4 P/N 1011110 Rev. C 04/11

Loading...

Loading...