Antunes UTX-200L Service Manual

A. J. ANTUNES & CO.

Systems Testing

PRGM

MOTOR

PLTN

UT

I/R

NEXT PREV

SELECT

BREAKFAST/LUNCH

ADJUST

180 Kehoe Blvd., Carol Stream, Illinois 60188

UTX-200 DIAGNOSTIC SERVICE MODE

CAUTION

To avoid possible personal injury and/or damage to the unit, all inspections, tests, and repair of electrical equipment

should be performed by QUALIFIED SERVICE PERSONNEL. The unit MUST be completely shut down and unplugged

before servicing, except when electrical tests are required. Use extreme care during electrical circuit tests. Live

circuits will be exposed.

TOOLS: None.

AFFECTED PRODUCTS: All UTX-200 units.

Diagnostic Service Mode

The Service Mode of the UTX-200 is used to test all the

functional areas of the toaster one at a time. While not

meant as a detailed troubleshooting guide, the Service

Mode is a built-in tool that can be used to track down the

source of a problem.

Service Mode can be used to test the following areas of the

UTX-200 system:

● Cooling Fans ● Convection Blower

● Motor & Conveyors ● Contactor (Main)

● Top Infrared (IR) Heater

System

● Platen Heaters ● Thermocouple

Generally, if the diagnostic testing does not indicate a problem, the issue is NOT likely to be the Control Circuit Boards

and other problem areas should be explored.

● Bottom Infrared (IR)

Heater System

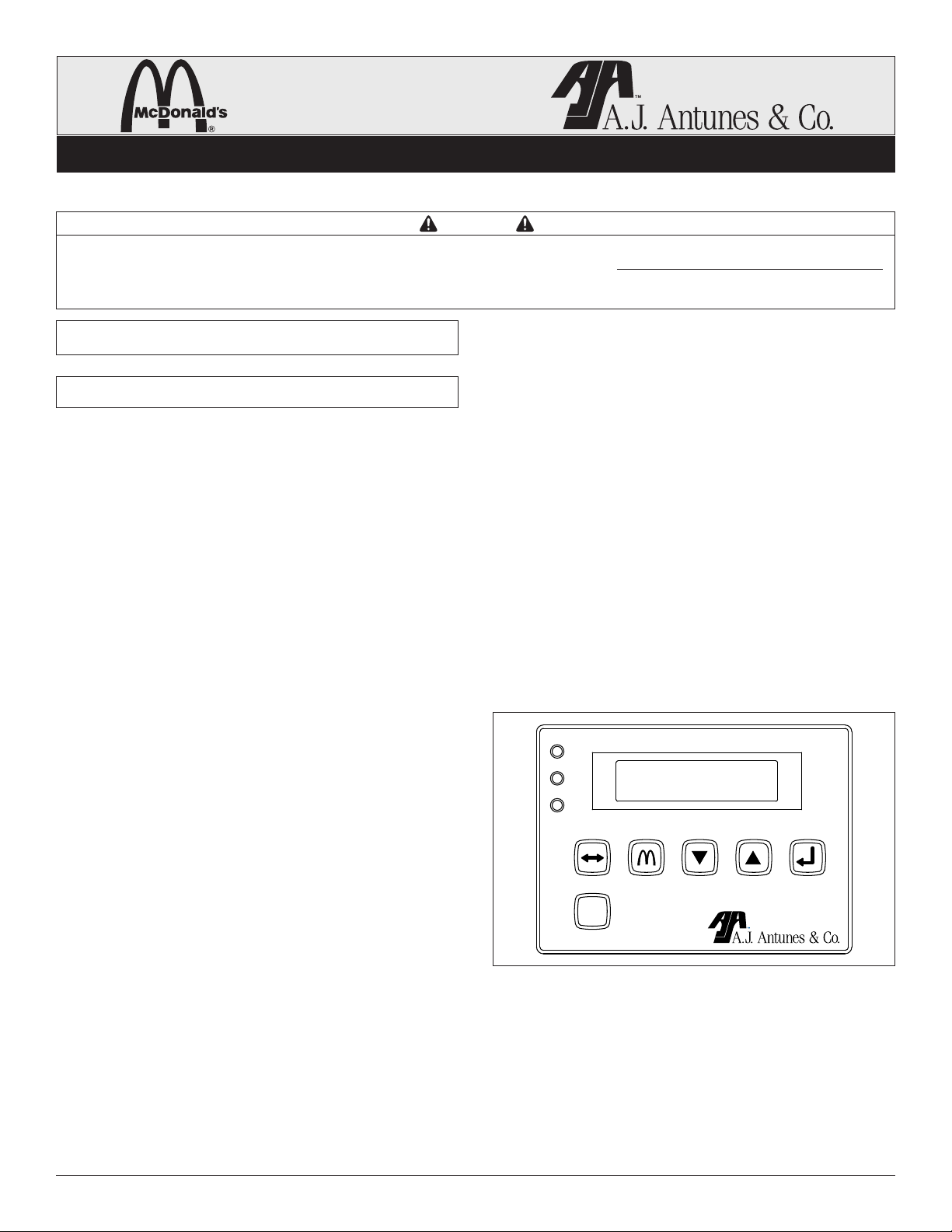

Entering Service Mode

1. Turn the power off. The unit should enter Cool Down

mode.

2. Turn the power back on and listen for the unit to click

three times.

3. During the 20-second countdown, press and hold the

ADJUST and UT buttons (Figure 1) for approximately

5 seconds until it enters Service Mode.

4. Press the NEXT (Figure 1) button twice.

5. The unit will display “Systems Testing”. Press the

SELECT button, then press the NEXT button

(Figure 1).

6. The unit will display “All Systems Are Off”.

7. All toaster functions should now be turned off. No

motors, heaters, or fans should be running. The

Contactor and less than 1.0 Amp. should be flowing in

the main wires (L1, L2, L3).

8. Press the NEXT button to continue with the tests.

NOTE: The Service Mode will automatically switch to the

Fan Speed Test after 5 minutes of inactivity to prevent

any of the systems being tested from overheating.

NOTE: Error codes will NOT be signaled or recorded by

the toaster while in Service Mode.

NOTE: The NEXT and PREV buttons can be used to scroll

through the various test modes.

1-877-392-7854 Fax: 630-784-1655 P/N 1011010 11/08

Figure 1. UTX-200 Control Panel

Page 1 of 4

McDonald’s

A. J. ANTUNES & CO.

Fan Speeds % of normal

L:100 C:100 R:100

PRGM

MOTOR

PLTN

UT

I/R

NEXT PREV

SELECT

BREAKFAST/LUNCH

ADJUST

Speed Motor SetPt

96 500 100

PRGM

MOTOR

PLTN

UT

I/R

NEXT PREV

SELECT

BREAKFAST/LUNCH

ADJUST

Is the contactor on?

Are all SSRs off?

PRGM

MOTOR

PLTN

UT

I/R

NEXT PREV

SELECT

BREAKFAST/LUNCH

ADJUST

180 Kehoe Blvd., Carol Stream, Illinois 60188

UTX-200 DIAGNOSTIC SERVICE MODE

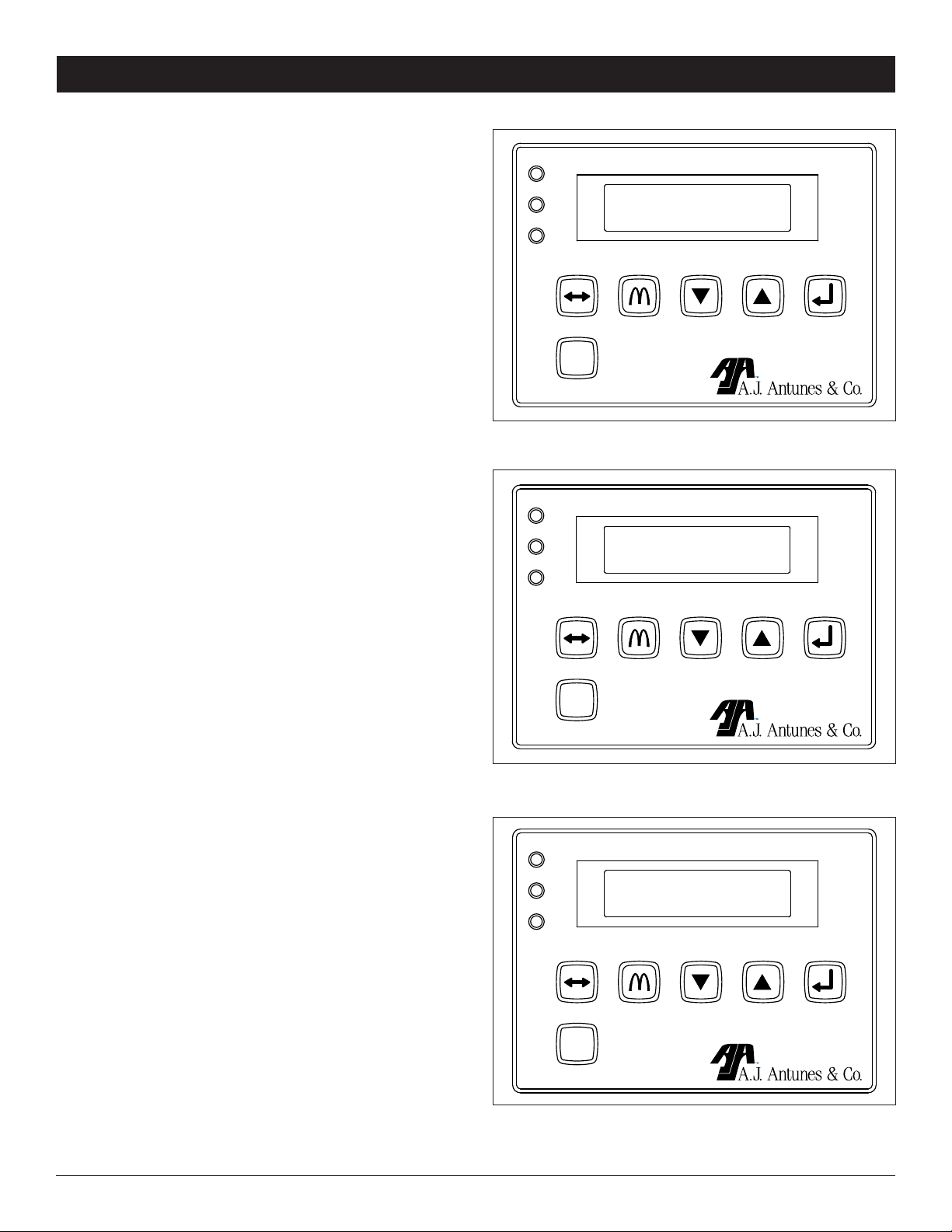

Testing the Fan Speed

The Fan Speed Test turns on the three Cooling Fans – left,

center, and right – as well as the Main Blower. The Cooling

Fan speeds should be greater than 70% (Figure 2). A fan

running between 70% and 95% may need to be carefully

cleaned of buildup.

The Main Blower speed is not monitored but can be seen by

using a flashlight to look into the rectangular holes below the

Control Panel.

To continue to the next test, press the NEXT button.

Testing the Conveyor Motor

The Conveyor Motor Test checks the Conveyor Motor as well

as the two Conveyor Drive Systems. Pressing the UT button

will set the motor to the minimum speed of 160. Pressing the

UT button again will set the motor to the lunch mode maximum speed of 6480. Pressing the UT button a third time will

stop the motor and the values will read “0”. Press the

UT button again to restart the process.

Figure 2. Fan Speed Test

NOTE: Pressing the ADJUST button will increase the

speed by increments of 100.

The Speed value and Set Point value (Figure 3) should be

within 10% of one another after a few minutes. If the Speed

value is not within 10% of the Set Point value, there is a

problem in the mechanical drive system (Bearings, Drive

Chain Sprockets, Vertical or Horizontal Conveyor Belts, etc.).

The Motor value (Figure 3) indicates how hard the motor

needs to work to maintain its speed. Typical values should

range from 400 to 600. Higher values may indicate friction or

drag somewhere in one or both Conveyor Drive Systems. If

the Motor value remains at 999 and the motor stops turning,

then there is a problem with the Mechanical Conveyor Drive.

The Conveyor Motor and Conveyor Drive Systems should

run smooth with no clunking or hesitation, and they should

maintain their speed.

To continue to the next test, press the NEXT button.

Testing the Contactor

This test should energize the Contactor, which you should

then hear close. If needed, press the PREV button to try it

again.

All other power devices should be off except for the Cooling

Fans. The current flow in L1, L2, and L3 should be less than

1.0 Amp. If not, one of the Solid State Relays may be shorted and can’t turn off. This will also result in an “SSR Failure

System Stopped” message after the 20-second self-test

when the unit is turned on.

To continue to the next test, press the NEXT button.

Figure 3. Conveyor Motor Test

Figure 4. Contactor Test

1-877-392-7854 Fax: 630-784-1655 P/N 1011010 11/08

Page 2 of 4

McDonald’s

Loading...

Loading...