Antunes STS-200 Service Manual

180 Kehoe Blvd.

Carol Stream, Illinois 60188 USA

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL P/N 1060010

LAST UPDATED 9-7-04

1

STS-200 STEAMER/SCALE

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

2

STS-200 STEAMER/SCALE

SECTION

PAGE #

•Warranty 4

•Specifications 5

•Steamer Scale warnings 7

•Steamer Scale installation 11

•Technical theory of operation 27

•Steamer Scale operating instructions 30

•Component description & functions 33

•Tools required 40

•Steamer Scale maintenance 41

•Troubleshooting 47

•Assembly Removal Instructions

• Instructions to remove base assembly (weighing module) 59

• Instructions to remove generator assembly 62

• Instructions to remove electrical panel 69

•Parts testing & replacement 75

•Thermistor resistance chart 98

•Wiring diagrams 99

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

3

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

4

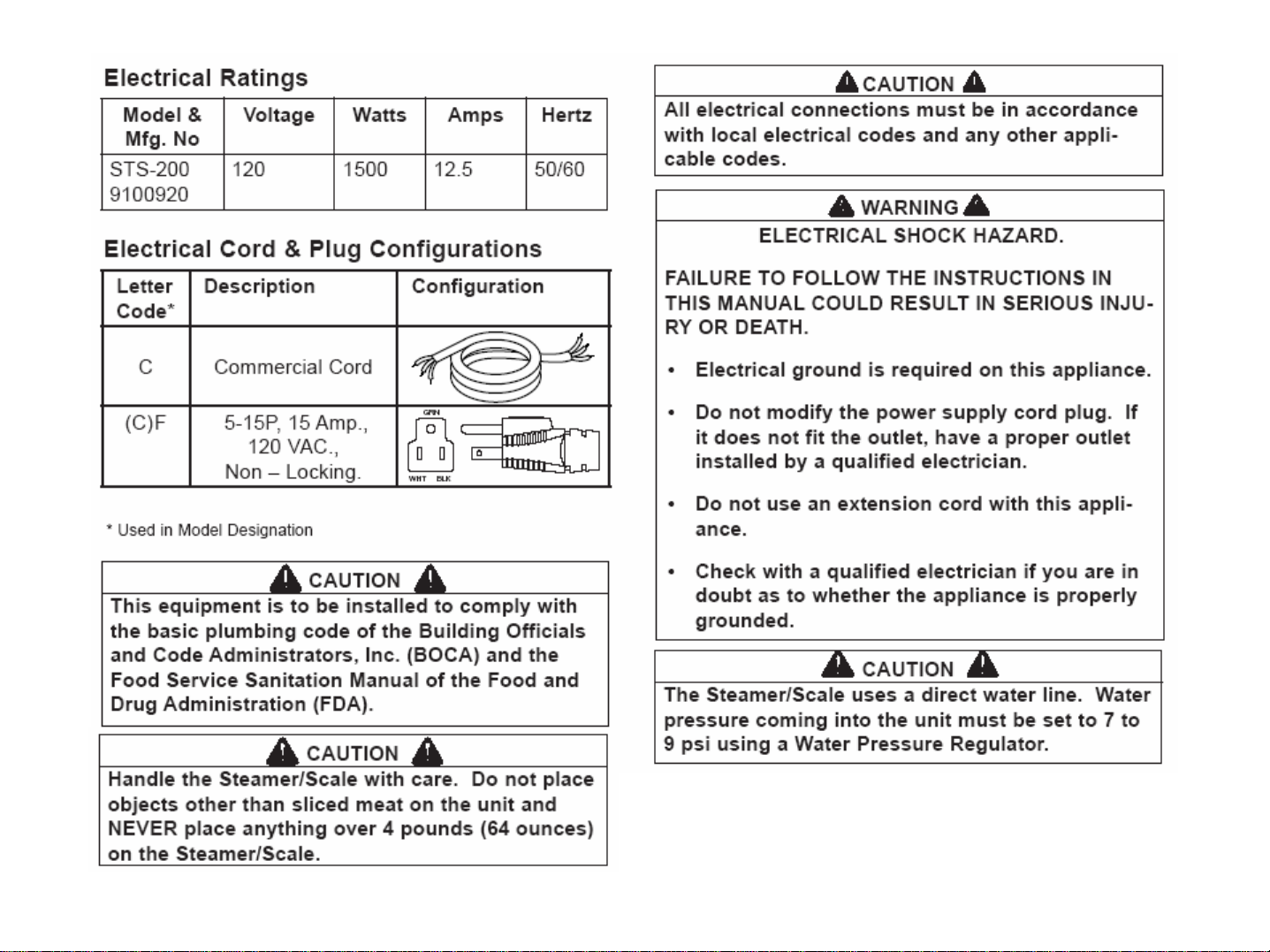

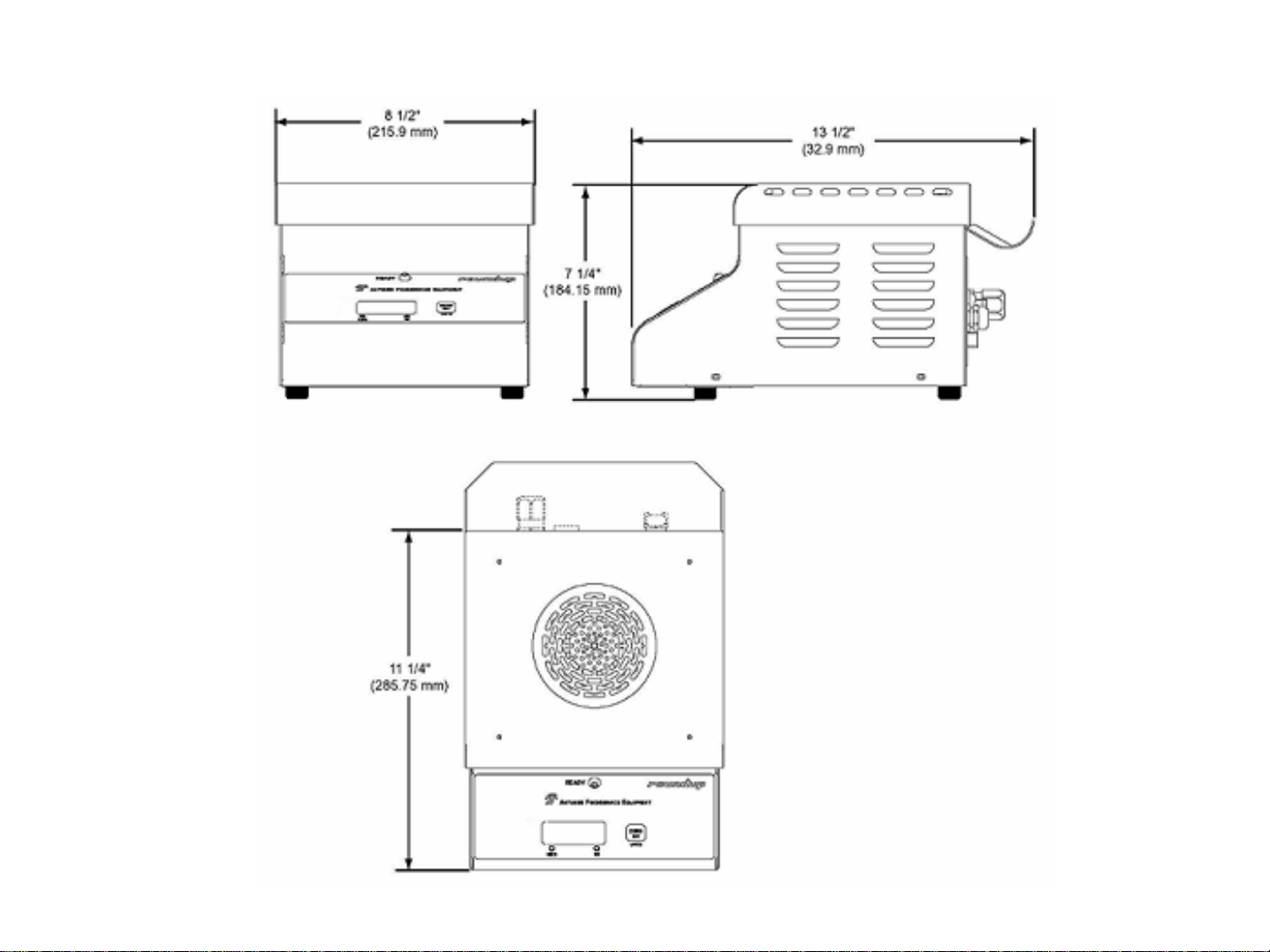

SPECIFICATIONS

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

5

SPECIFICATIONS

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

6

WARNINGS

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

7

WARNINGS

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

8

WARNINGS

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

9

WARNINGS

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

10

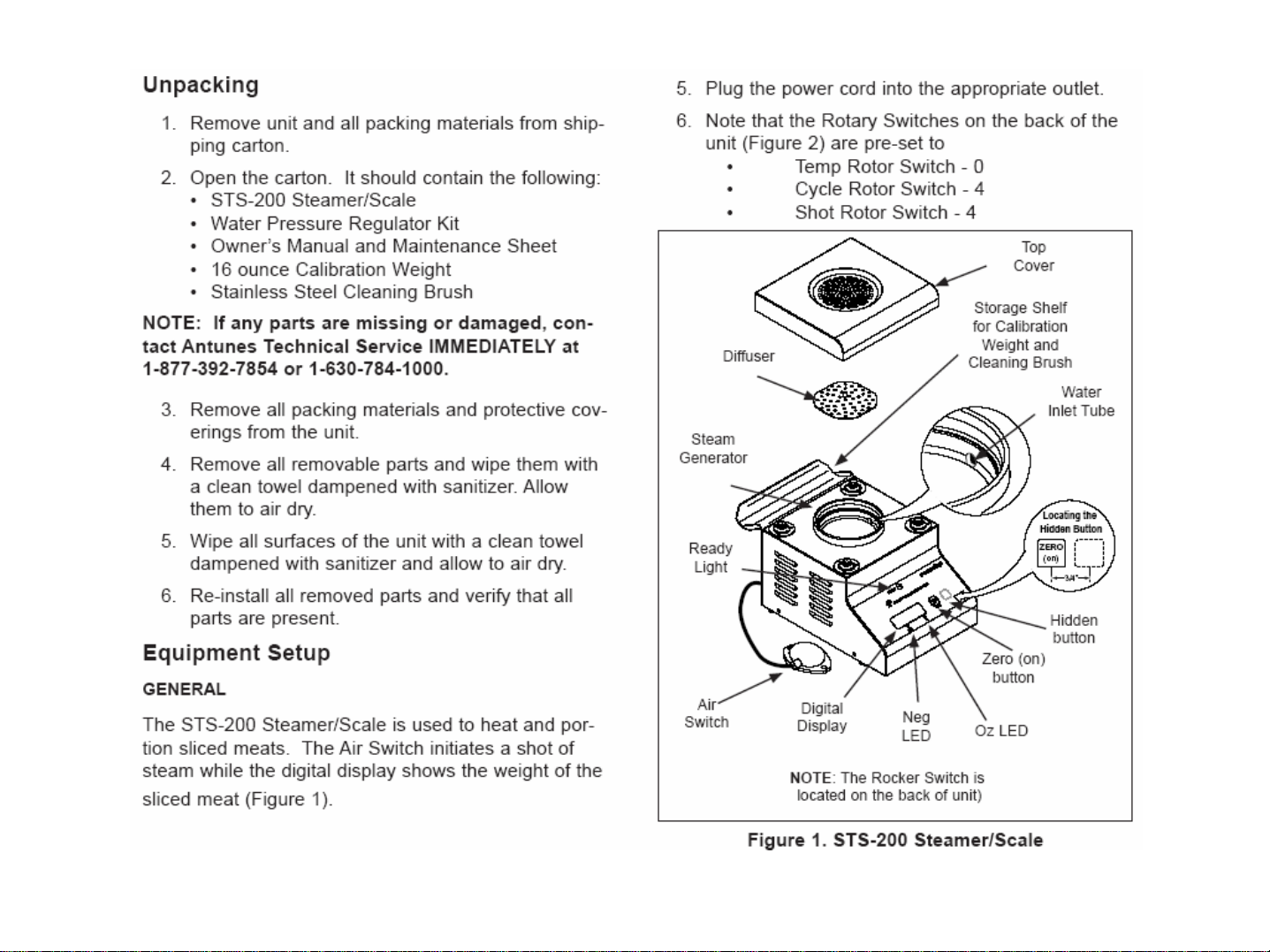

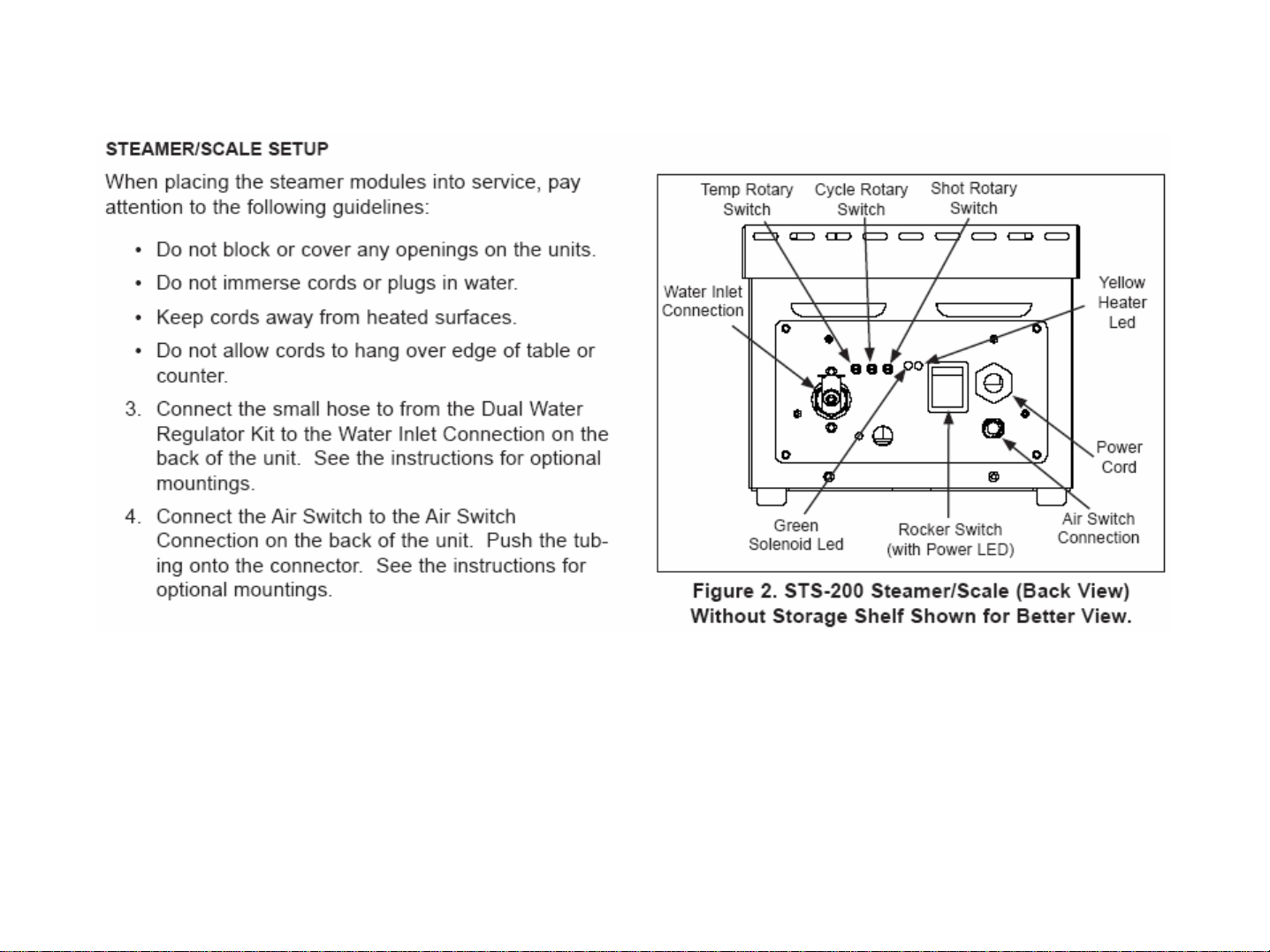

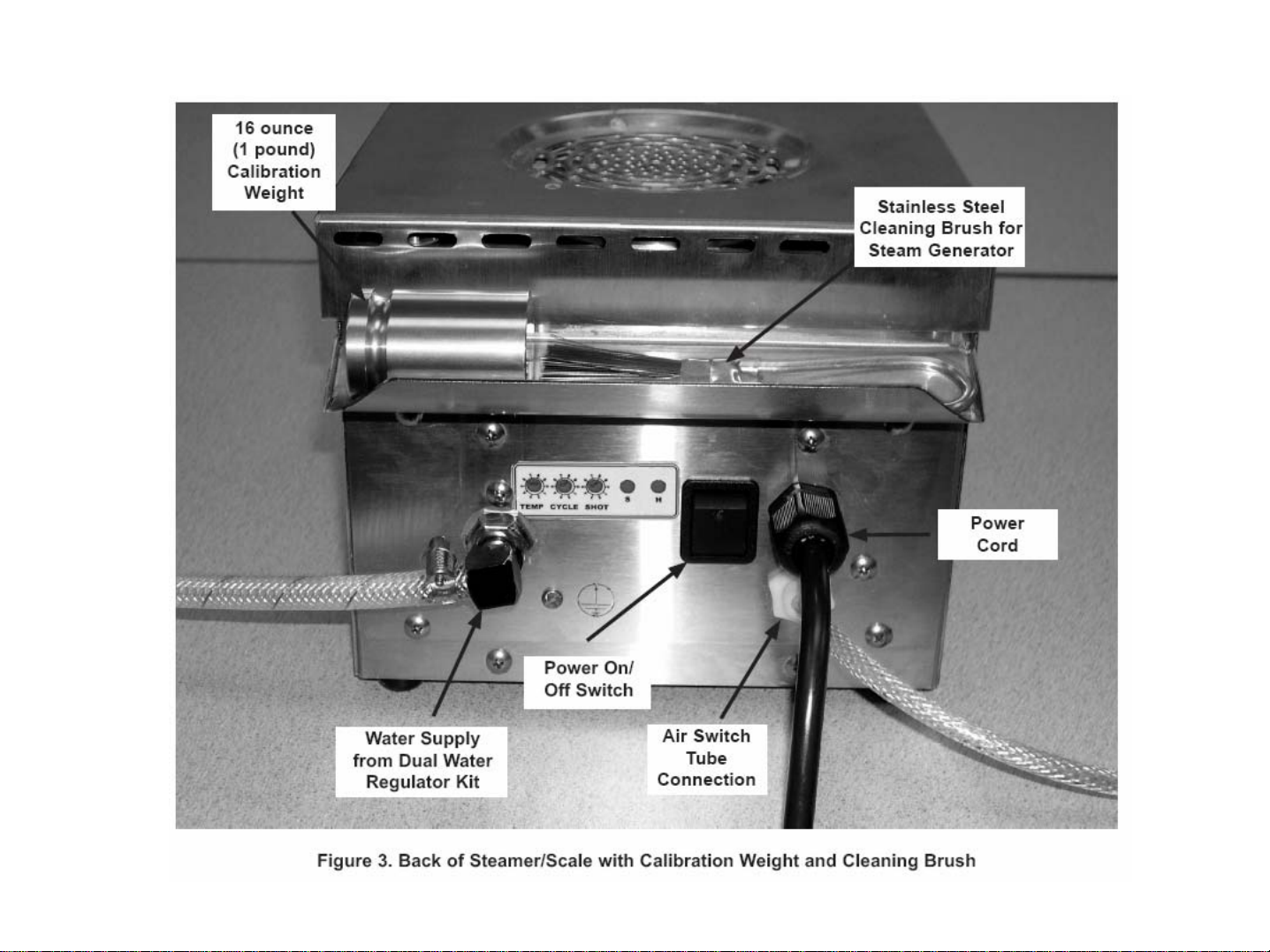

INSTALLATION

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

11

INSTALLATION

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

12

INSTALLATION

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

13

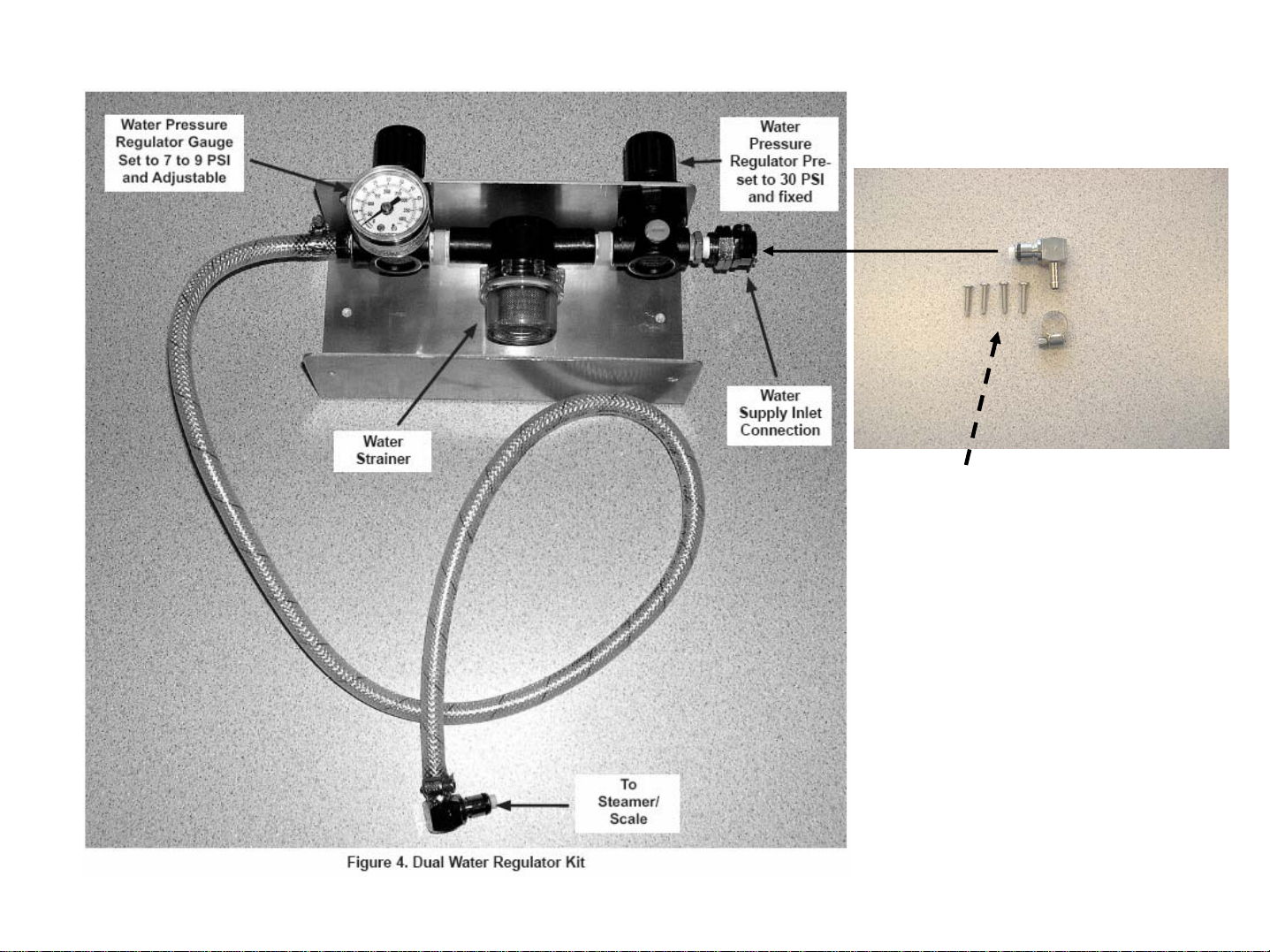

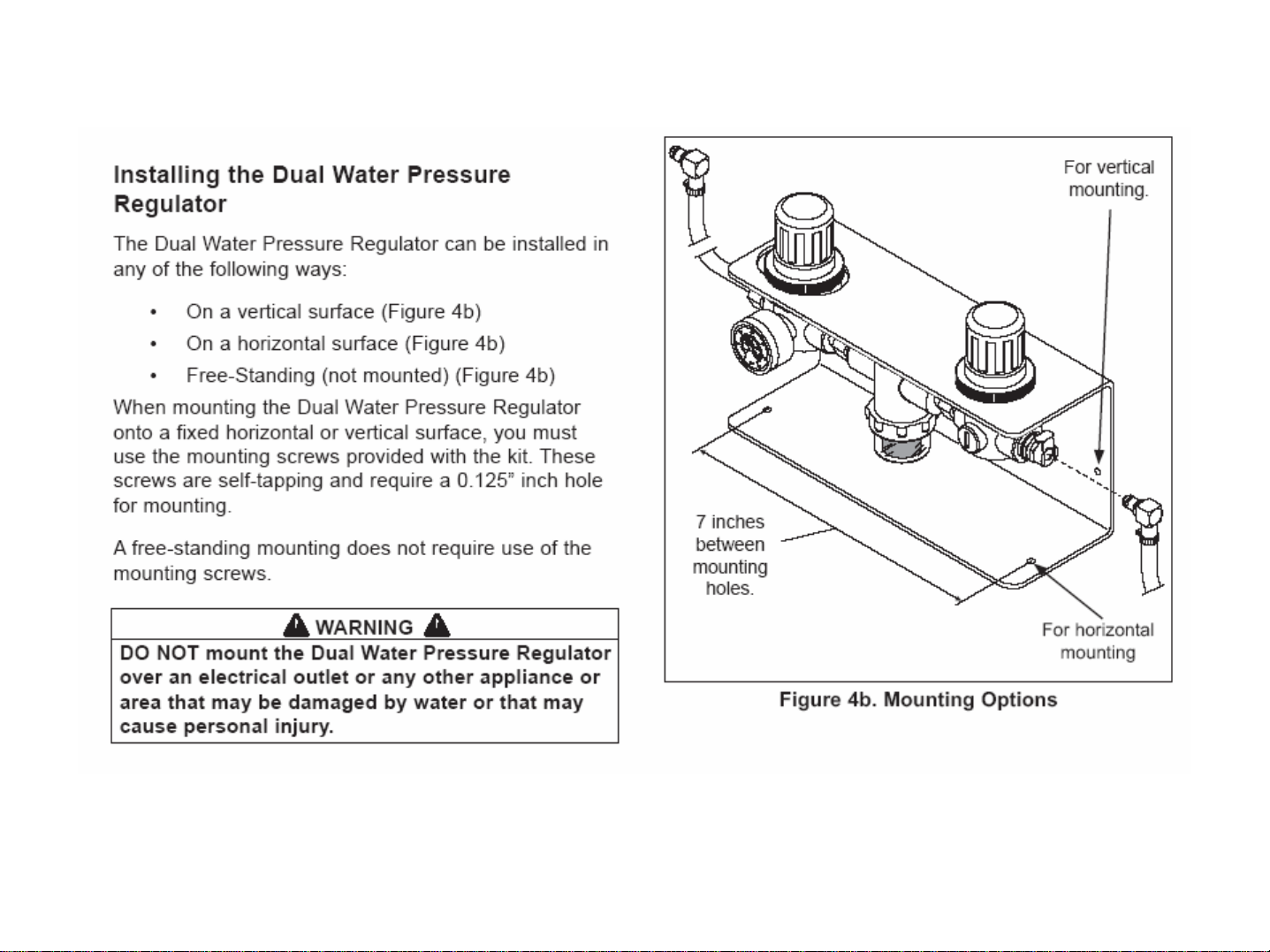

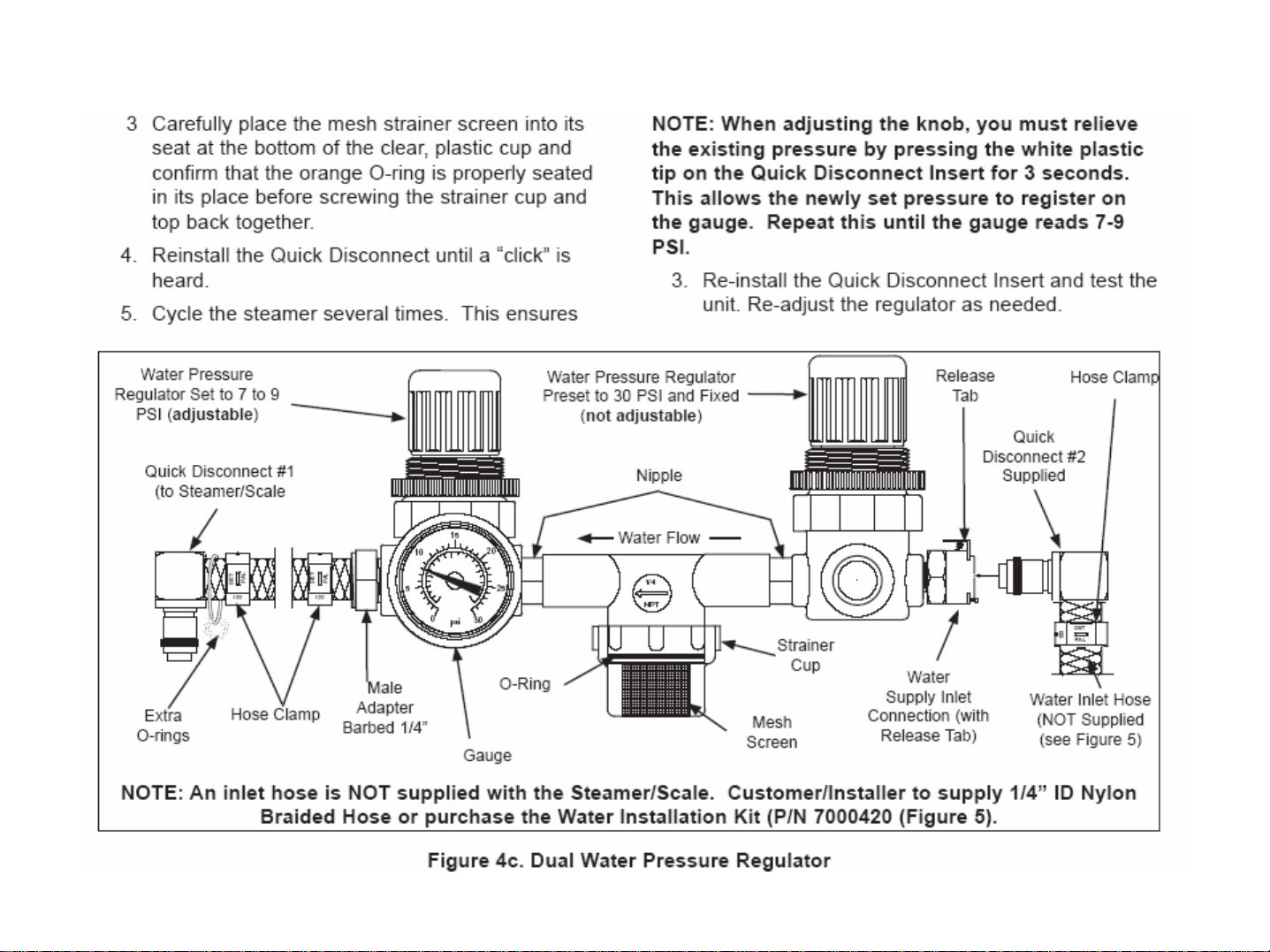

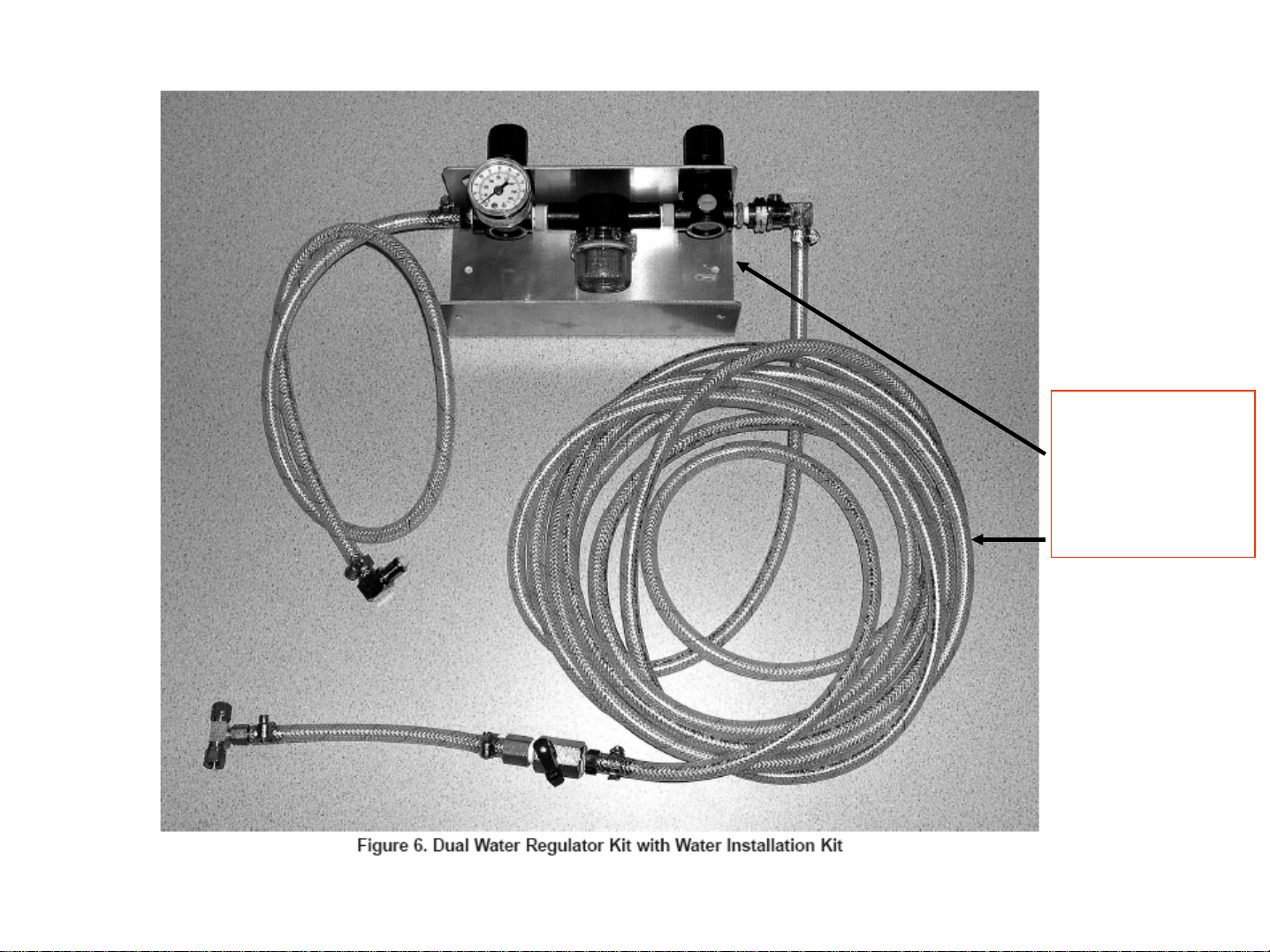

DUAL WATER REGULATOR

¼” Quick connect, 4 screws &

hose clamp are included

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

14

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

15

INSTALLATION (continued)

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

16

INSTALLATION

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

17

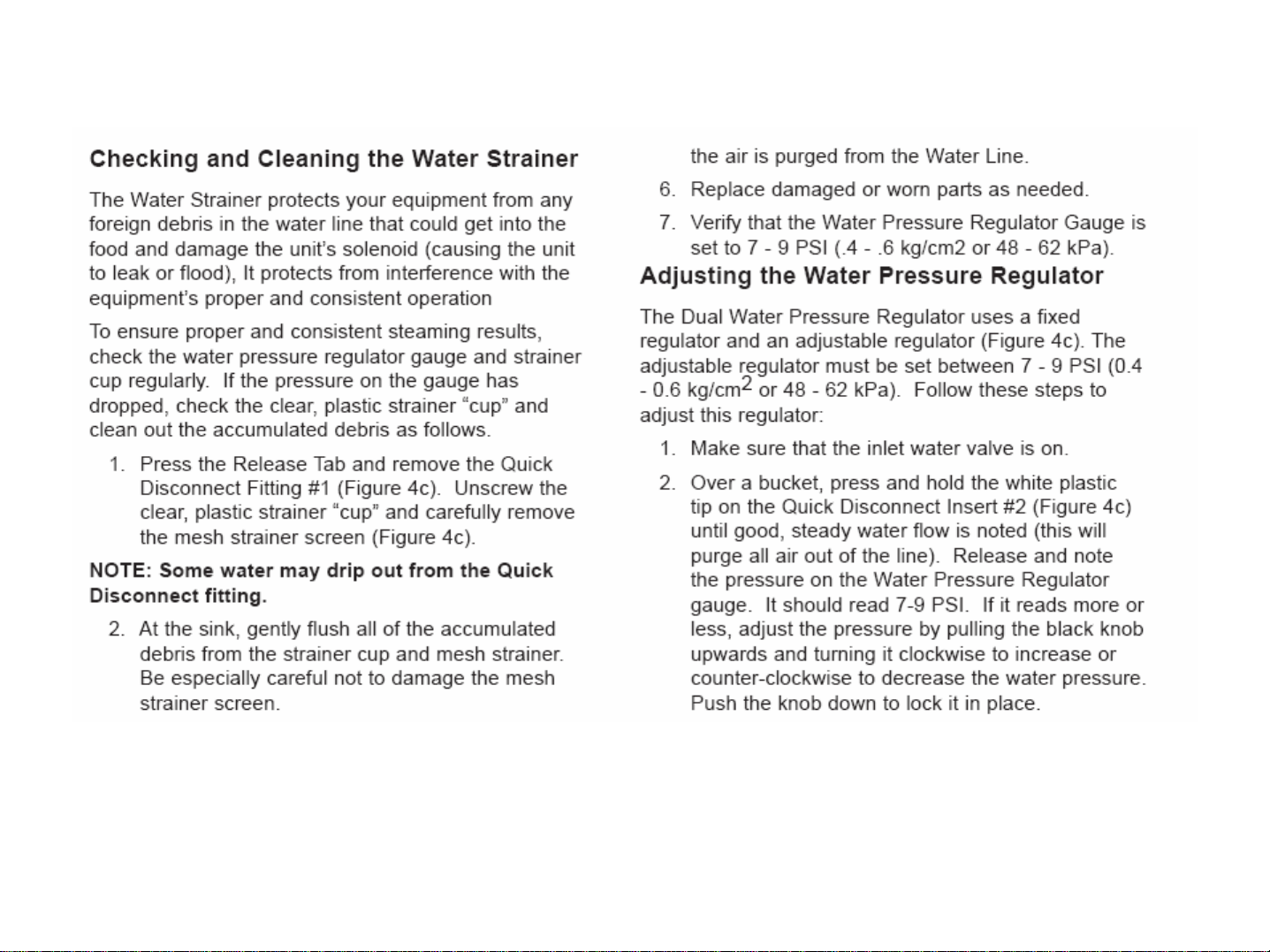

CHECKING CLEANING (CONTINUED)

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

18

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

19

INSTALLATION (continued)

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

20

INSTALLATION (CONTINUED)

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

21

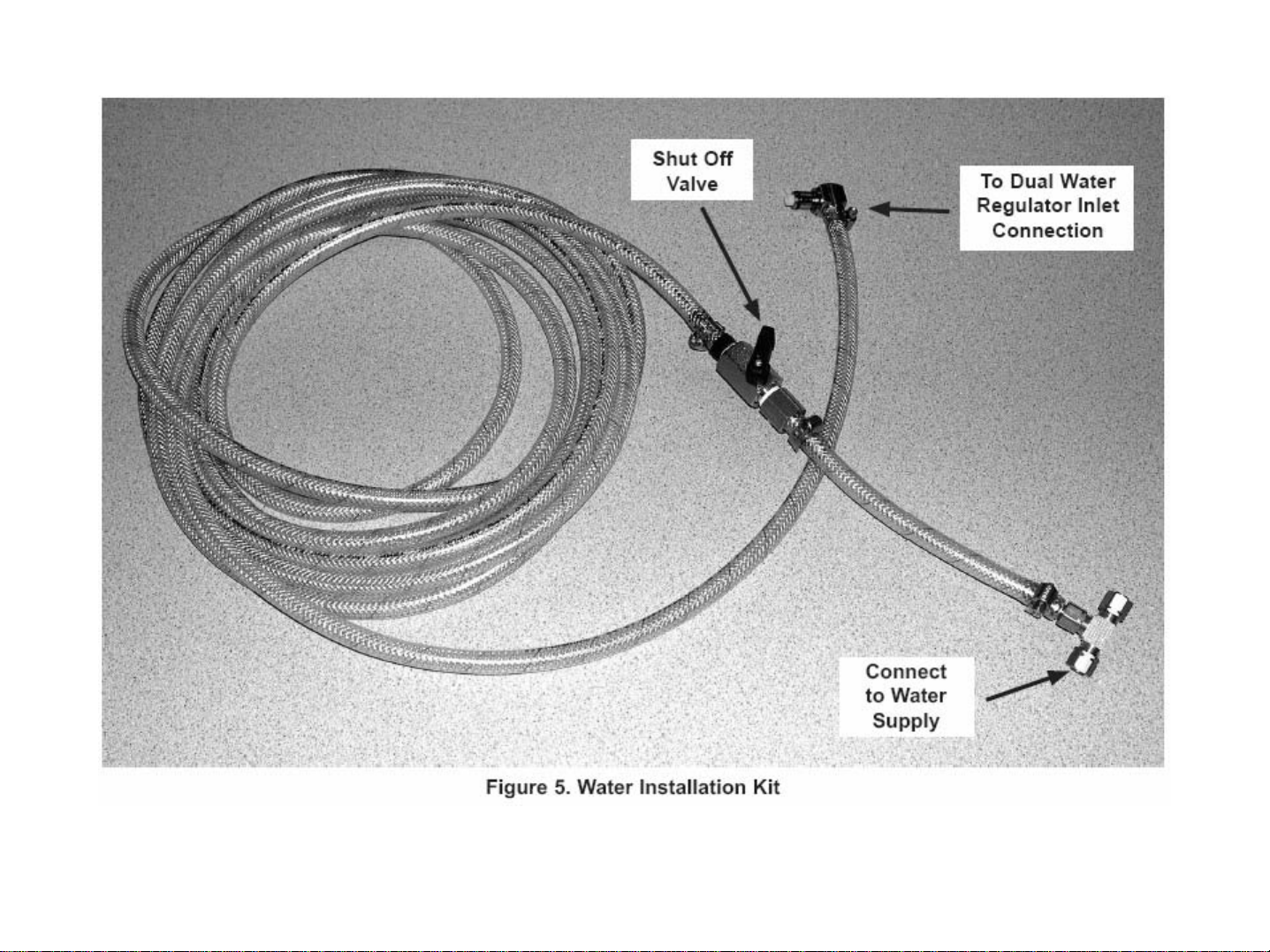

INSTALLATION

Dual water

regulator kit

#(7000418)

with OPTIONAL

water installation

kit #(7000240)

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

22

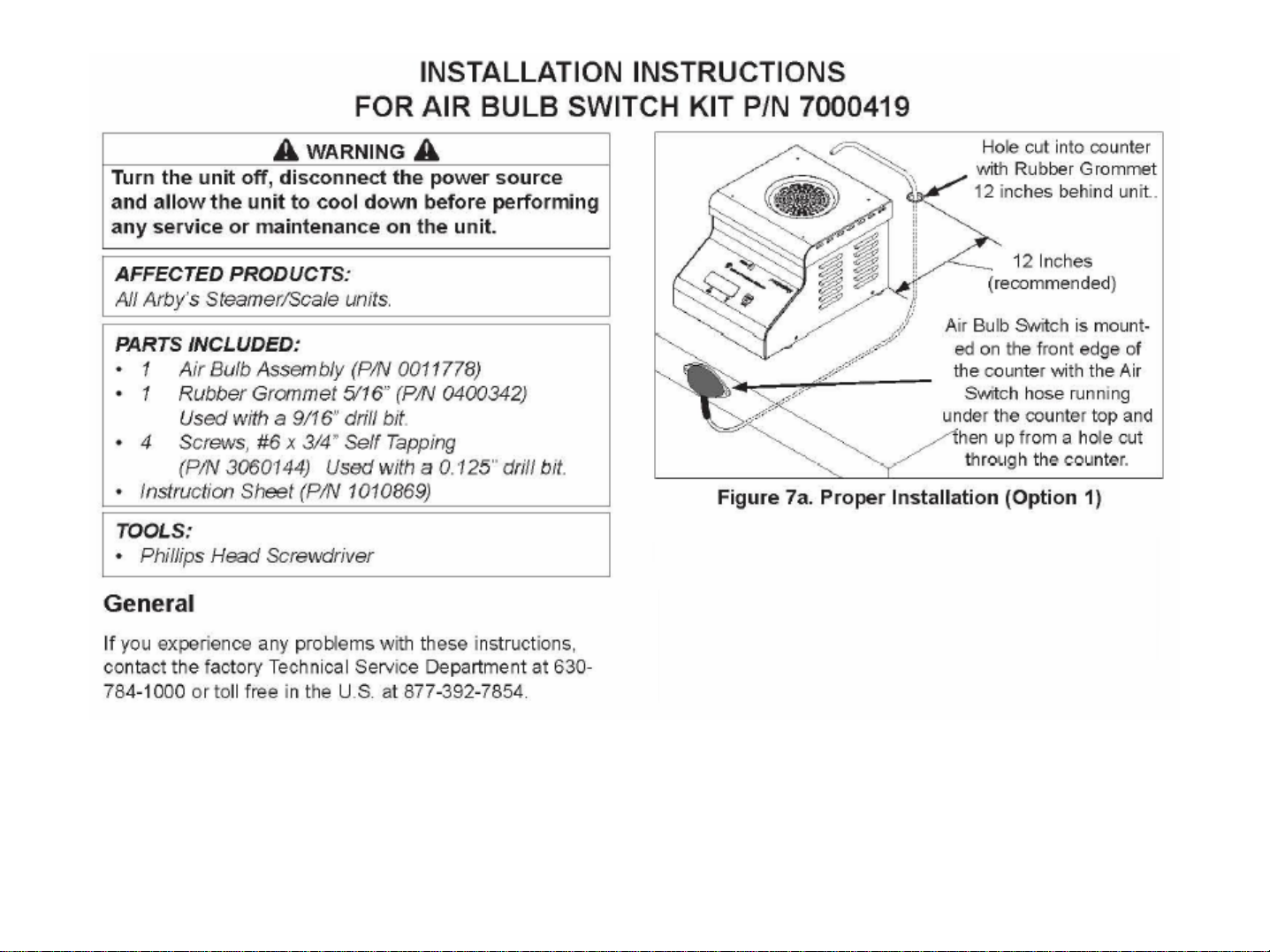

AIR BULB ASSEMBLY

9/9/2004

Mounting Holes

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

23

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

24

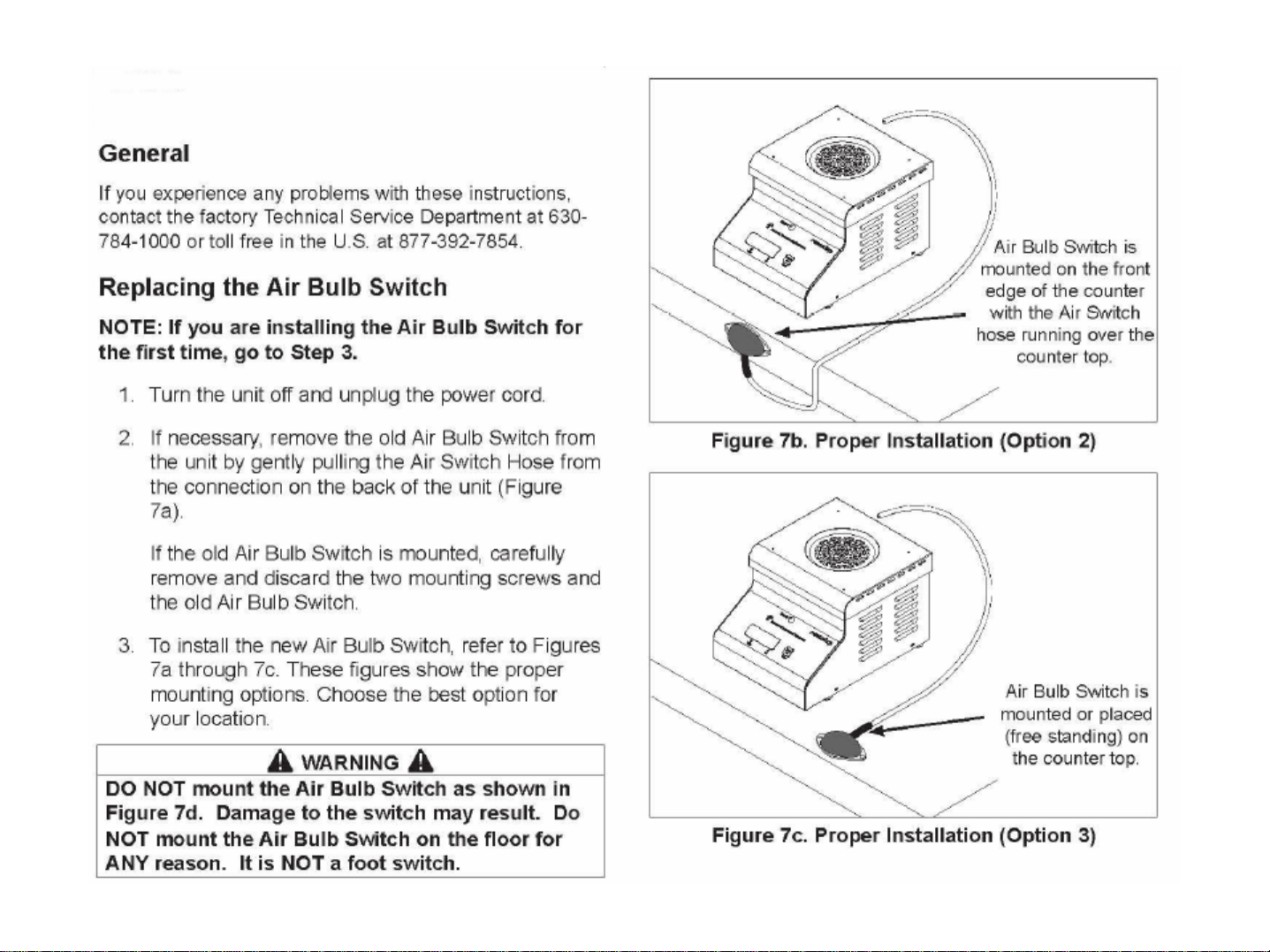

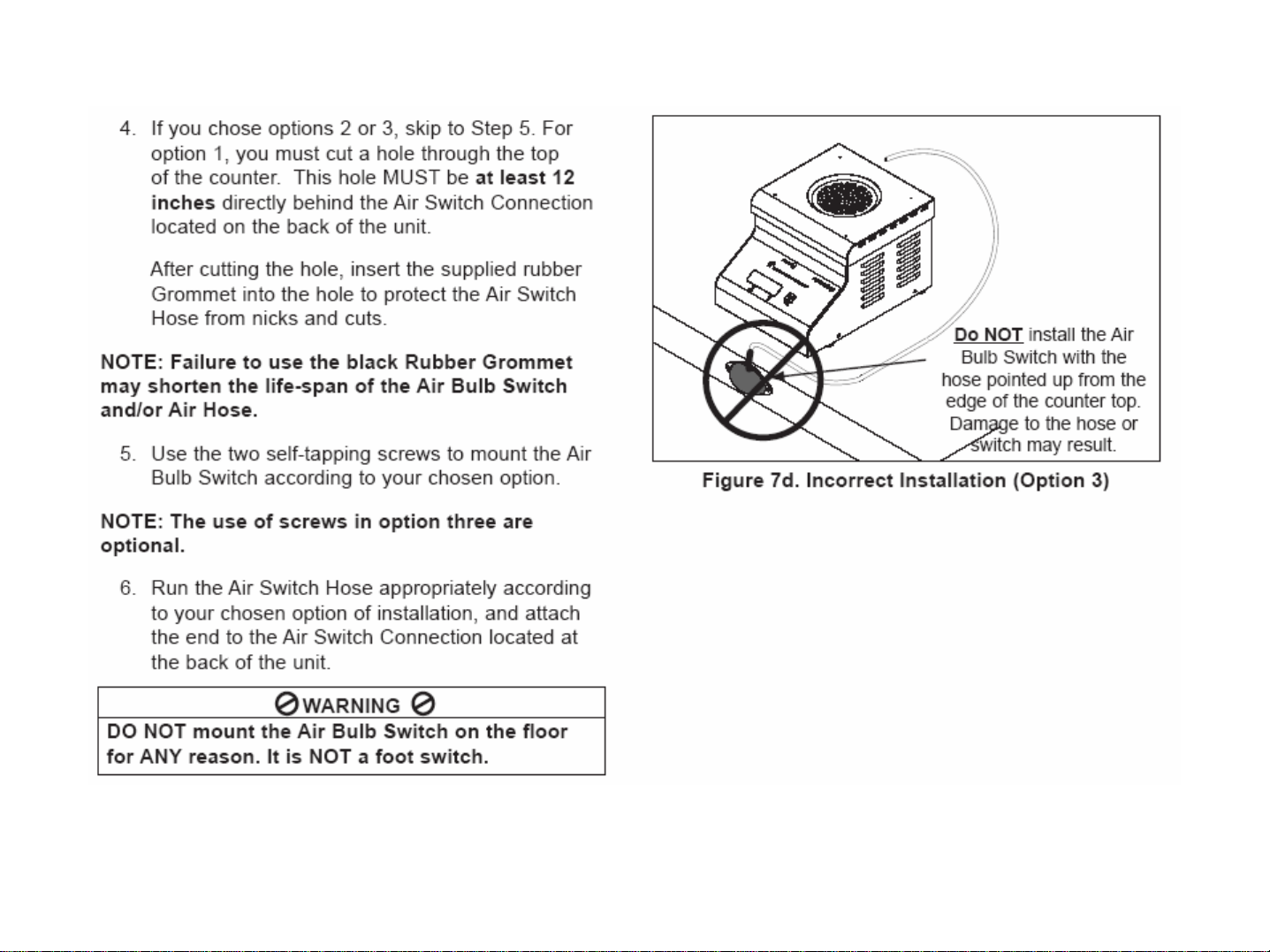

INSTALLATION (AIR BULB)

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

25

INSTALLATION (AIR BULB)

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

26

TECHNICAL THEORY OF OPERATION

STS-200 TEMPERATURE / STEAMING THEORY

When the power switch is on, line voltage flows to the primary side of the step down transformer. The transformer’s

secondary side supplies 12 VAC to the multifunctional temperature control board terminals T1 & T2. Once powered,

& provided that the generator surface temperature is below 375°F (190° C), the multifunctional temperature control

board calls for heat by energizing its onboard mechanical relay. Once energized, the mechanical relay closes its

contacts which allows line voltage to flow to the generator. As the generator begins to heat up, a 100 K ohm

thermistor monitors the internal generator temperature. As the heat continues to increase, the thermistor’s ohms

begin to decrease. As the generator’s temperature approaches 375-390° (190-198° C), the thermistor is generating

approximately 790-665 ohms. The multifunctional temperature control board receives these ohms & proceeds to deenergize the mechanical relay since the heating circuit has now become satisfied. Then, the mechanical relay

contacts open up, and the generator stops heating. The heating circuit will cycle on & off as needed, even at idle.

Once the generator is up to temperature (Indicated by a steady “Blue” light), & if the pneumatic air bulb is pressed

& released (To initiate a steam cycle), it rapidly directs air through the pneumatic hose which then activates a

pneumatic switch. Once activated, the pneumatic switch contacts momentarily close to complete a circuit to terminal

J4 on the multifunctional temperature control board. Simultaneously, the “Blue” light turns off, & the multifunctional

control board supplies line voltage to the solenoid valve coil for a split second. The solenoid valve opens, and allows

approximately 2-3 tablespoons of water to be disbursed onto the generator surface for steaming. The water flashes

into steam immediately then rises up through the steam ports and steams the product. After approximately 4

seconds, the “Blue” light turns back on to indicate that the unit is ready to run another steam cycle. The

multifunctional control board incorporates two status Leds detailed below. If the heating circuit continues to call for

heat and the generator overheats, an automatic resetting hi-limit thermostat will trip and open the generator circuit &

transformer circuit at approximately 450-470° F (232-243° C).

NOTE: If this condition should repeat, the root cause must be determined & corrected.

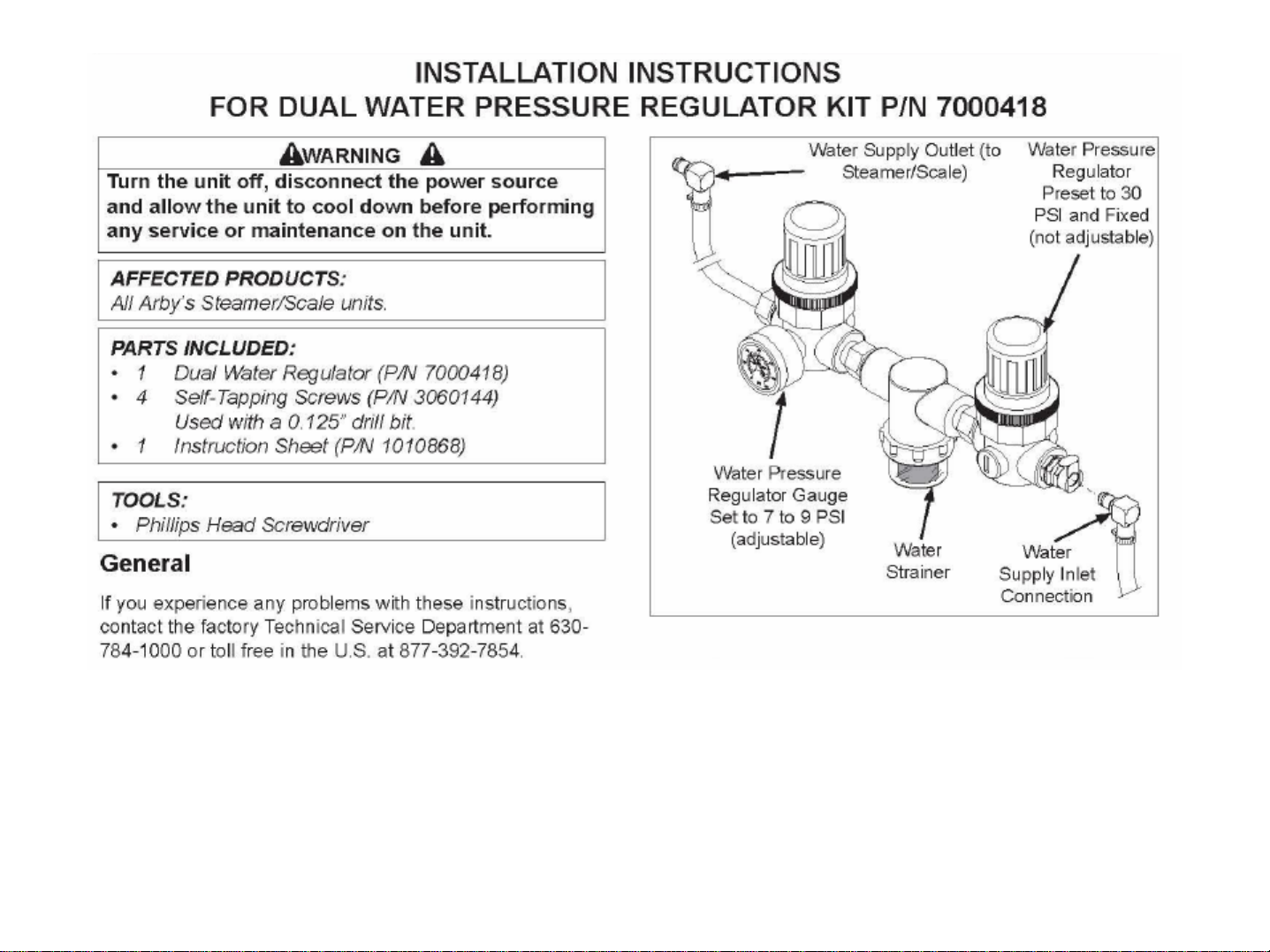

NOTE: The STS-200 scale/steamer is shipped with a dual water pressure regulator assembly. The primary

water pressure regulator is fixed at 30 PSI & is not adjustable. The secondary water pressure regulator is

factory set & should remain set between 7-9 PSI. It should only be momentarily adjusted if required as per

the maintenance section.

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

27

WEIGHT SCALE THEORY

As previously stated, when the power switch is on, line voltage flows to the primary side of the step down transformer.

The transformer’s secondary side supplies 12 VAC to the multifunctional temperature control board terminals T1 &

T2. Once powered, terminal J1 on the multifunctional temperature control board supplies 8-10 VDC to terminal J1 of

the scale control board by means of a wiring harness. Once powered, the scale control board illuminates its display.

In addition, the two outer pins of the scale control board’s J2 terminal powers up the load cell. These two outer pins

supply 4-5 VDC to the load cell’s “Green” & “Black” wires. The two center pins receive a signal from the load cell’s

“Red” & “White” wires. NOTE: The load cell is manufactured with an integrated wiring harness. The loose

end of this harness plugs into the scale control board. The removable top platform sits on 4 floating steel pegs.

The steel pegs are attached to a floating steel cage (Spider). The steel cage is attached to the load cell. The Scale’s

maximum operating weight capacity is 4 lbs. The scale weighs in .1 oz increments.

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

28

Led Function

(The following LED’S are viewed from the rear of the unit)

Yellow (Heat): When lit, it indicates that the unit is in heat mode. During this time, line voltage is being supplied to the

generator. When off, it indicates that the generator is up to operating temperature.

NOTE: This led will cycle on & off even at idle.

Green (Solenoid Valve): When lit, it indicates that line voltage is momentarily being supplied to the solenoid valve coil.

NOTE: This LED is only lit for a split second.

The following provides unique features involving the “Blue” light. These are handy for troubleshooting

purposes. Also see “Components Description & Function” for additional details.

During cold start up, the “Blue” light remains off (Indicating that the generator is not up to temperature). During this time,

the solenoid valve circuit is disabled & the unit will not initiate a cycle even if the air bulb is pressed. Within 5 minutes after cold

start up, the “Blue” light will turn on steady (Indicating that the generator is now up to operating temperature). During this

time, the solenoid valve circuit is enabled. NOTE: The unit should always be preheated for 30 minutes before use.

Blue light blinking codes

Also See “Troubleshooting Section” & “Parts Testing & Replacement Procedures”

Rapid Flashing: Under this condition, the generator may, or may not get hot. The solenoid valve circuit is disabled until the

cause is corrected. Possible Cause(s): An open thermistor or loose, burnt, broken wiring in heating circuit or one of the two

generator heaters is open, or faulty temperature control board.

Slow Flashing (1 second on & 1 second off): Under this condition, the generator surface temperature has dropped below

280° F (137° C). The solenoid valve circuit is disabled until the temperature rises above 280° F (137° C) & re aches proper

operating temperature. Possible Cause(s): The water pressure regulator is improperly set or rotary switches are not correctly

set or one of the two generator heaters is open or faulty temperature control board.

Slow Flashing (1 second on & 3 seconds off): Under this condition, the electrical compartment temperature has exceeded

155° F (68° C). The solenoid valve circuit is disabled until the electrical compartment temperature drops below 155° F (68° C).

Possible Cause(s): Insufficient ventilation around the unit or faulty temperature control board.

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

29

OPERATION

9/9/2004

STS-200 STEAMER / SCALE TECHNICAL MANUAL

LAST UPDATED 9-7-04

30

Loading...

Loading...