Page 1

MANUFACTURING

A

S

D

L

I

S

T

E

CM

O

I

N

N

I

T

A

T

C

T

I

S

L

US

E

D

NUMBERS:

910 0 922

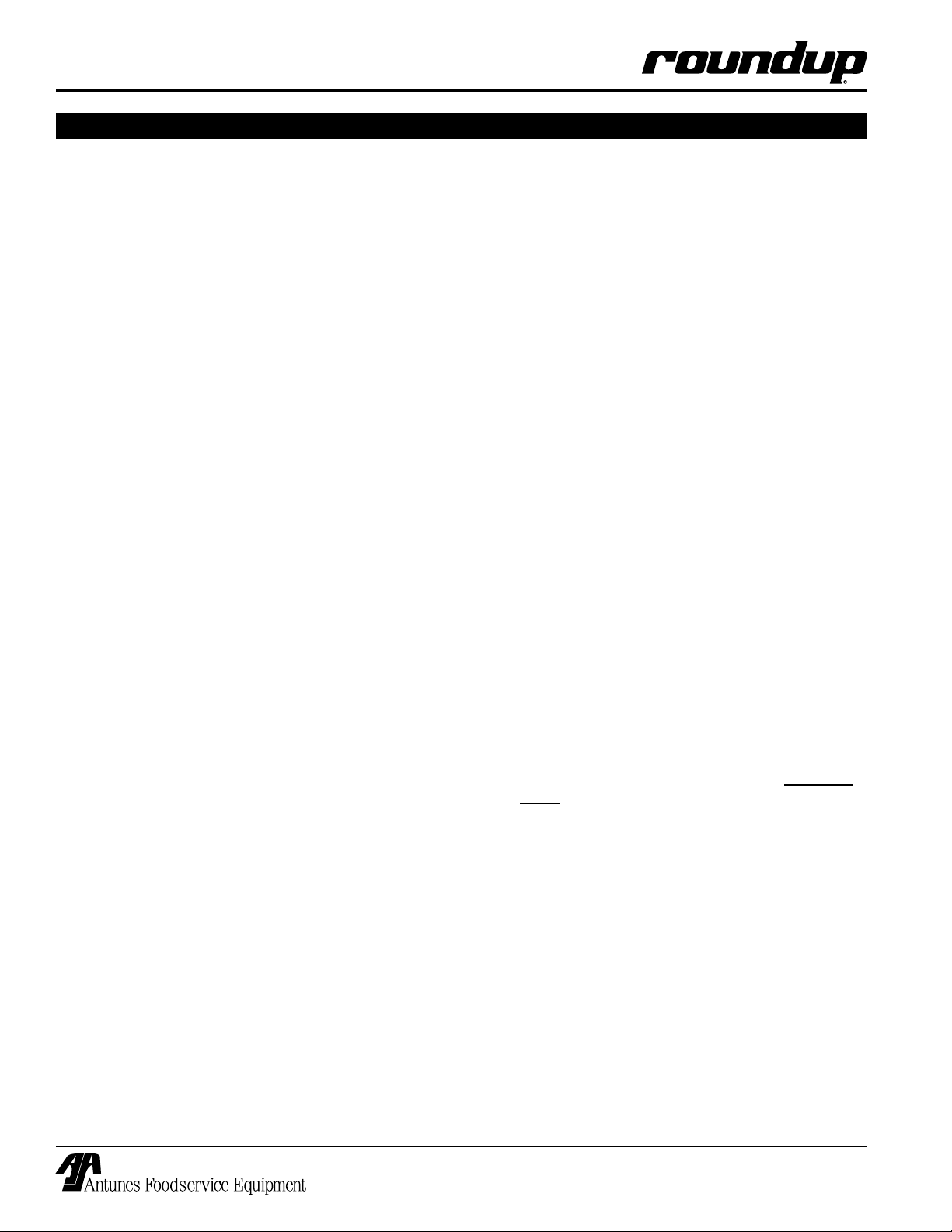

STEAMER/SCALE

Model STS-200

P/N 1010929 03/06

Owner’s Manual

Page 2

STS-200 STEAMER/SCALE

TABLE OF CONTENTS

Owner Information .....................................................2

General ......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ....................................3

Important Safety Information ....................................3

Specifications ............................................................5

Electrical Ratings .......................................................5

Electrical Cord & Plug Configurations .......................5

Model Designation .....................................................5

Dimensions ................................................................6

Installation ...................................................................7

Unpacking ..................................................................7

Equipment Setup .......................................................7

Installation Instructions

for Dual Water Pressure Regulator Kit P/N 7000418 9

General ......................................................................9

Installing the Dual Water Pressure Regulator ...........9

Checking and Cleaning the Water Strainer ............ 10

Adjusting the Water Pressure Regulator ................ 10

Installation Instructions

Optional Water Installation Kit P/N 7000420 ..........12

General ................................................................... 12

Installation .............................................................. 12

Installation Instructions

for Air Bulb Switch Kit P/N 7000419 .......................14

General ................................................................... 14

Replacing the Air Bulb Switch ................................ 14

Operation ...................................................................16

Operating Instructions ............................................ 16

Calibrating the Steamer/Scale ................................ 16

Rotary Switch Settings ........................................... 17

Maintenance .............................................................. 18

Cleaning the STS-200 During Daily Use ................ 18

Cleaning the STS-200 Steamer/Scale Daily .......... 19

Weekly Maintenance .............................................. 19

Cleaning the Water Inlet Tube ................................ 20

Checking/Cleaning the Water Strainer Monthly ..... 20

Weekly- Testing the STS-200

for Weighing Accuracy ............................................ 21

Troubleshooting .......................................................21

Message Codes ...................................................... 21

Error Codes ............................................................ 22

Technical Theory of Operation ...............................26

Technical Theory of Operation ............................... 26

Replacement Parts ...................................................28

Wiring Diagram .........................................................36

NOTES .......................................................................37

LIMITED WARRANTY ............................... Back Cover

OWNER INFORMATION

General

The STS-200 Steamer/Scale produces steam using

plain tap water for quick steaming of sliced meats.

Simple push button action delivers a consistent impulse

of steam. Because the amount of steam is consistent,

it removes the guesswork and produces a uniform finished product from one operator to the next.

This manual provides the safety, installation, and operating procedures for the Steamer/Scale. We recommend that all information contained in this manual be

read prior to installing and operating the unit.

Your Steamer/Scale is manufactured from the finest

materials available and is assembled to Roundup’s

strict quality standards. This unit has been tested at

the factory to ensure dependable trouble-free operation.

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

IMPORTANT! Keep these instructions for future reference. If the unit changes owner-

ship, be sure this manual accompanies the equipment.

If the unit arrives damaged, contact the carrier immediately and file a damage claim with them. Save all

packing materials when filing a claim. Freight damage

claims are the responsibility of the purchaser and are

not covered under warranty.

The warranty does not extend to:

• Damages caused in shipment or damage as

result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

• Damage caused by abuse or careless handling.

• Moisture damage to electrical components.

• Damage from tampering with, removal of, or

changing any preset control or safety device.

2

P/N 1010929 03/06

Page 3

STS-200 STEAMER/SCALE

OWNER INFORMATION (continued)

Service/Technical Assistance

If you experience any problems with the installation

or operation of your unit, contact your local Roundup

Authorized Service Agency. They can be found in the

service agency directory packaged with the equipment.

Fill in the information below and have it handy when

calling your authorized service agency for assistance.

The serial number is on the specification plate located

on the rear of the unit.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

Refer to the service agency directory and fill in the

information below:

IMPORTANT SAFETY INFORMATION

Authorized Service Agency

Name:

Phone No.:

Address:

Use only genuine Roundup replacement parts in this

unit. Use of replacement parts other than those supplied by the manufacturer will void the warranty. Your

Authorized Service Agency has been factory trained

and has a complete supply of parts for this unit.

You may also contact the factory at 1-877-392-7854 or

1-630-784-1000 if you have trouble locating your local

authorized service agency.

Throughout this manual, you will find the following safety words and symbols that signify important safety issues with

regards to operating or maintaining the Miracle Steamer.

WARNING

GENERAL WARNING. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment and/or

severe bodily injury or death.

CAUTION

GENERAL CAUTION. Indicates information important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment.

ELECTRICAL WARNING. Indicates information relating to possible shock hazard.

Failure to observe may result in damage

to the equipment and/or severe bodily

injury or death.

HOT SURFACE WARNING. Indicates

information important to the handling of

equipment and parts. Failure to observe

caution could result in personal injury.

WARNING

WARNING

P/N 1010929 03/06

3

Page 4

STS-200 STEAMER/SCALE

IMPORTANT SAFETY INFORMATION (continued)

In addition to the warnings and cautions in this manual,

use the following guidelines for safe operation of the

unit.

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with

a properly grounded cord connector. Do not

attempt to defeat the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual. Do not use

corrosive chemicals in this equipment.

• Do not operate this equipment if it has a damaged cord or plug, if it is not working properly, or

if it has been damaged or dropped.

• This equipment should be serviced by qualified

personnel only. Contact the nearest Roundup

authorized service facility for adjustment or repair.

• Do not block or cover any openings on the unit.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge of table or

counter.

The following warnings and cautions appear

throughout this manual and should be carefully

observed.

• Turn the unit off, disconnect the power source

and allow unit to cool down before performing

any service or maintenance on the unit.

• The equipment should be grounded according to local electrical codes to prevent the

possibility of electrical shock. It requires a

grounded receptacle with separate electrical

lines, protected by fuses or circuit breaker of

the proper rating.

• All electrical connections must be in accordance with local electrical codes and any

other applicable codes.

• WARNING ELECTRICAL SHOCK HAZARD.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR

DEATH.

- Electrical ground is required on this appliance.

- Do not modify the power supply cord plug.

If it does not fit the outlet, have a proper

outlet installed by a qualified electrician.

- Do not use an extension cord with this

appliance.

- Check with a qualified electrician if you

are in doubt as to whether the appliance is

properly grounded.

• This equipment is to be installed to comply with the basic plumbing code of the

Building Officials and Code Administrators,

Inc. (BOCA) and the Food Service Sanitation

Manual of the Food and Drug Administration

(FDA).

• If the supply cord is damaged, it must be

replaced by the manufacturer or its service

agent, or a similarly qualified person.

• Do not clean this appliance with a water jet.

• Do not use a sanitizing solution or abrasive

materials. The use of these may cause damage to the stainless steel finish.

• To ensure proper steaming characteristics,

some mineral deposits must be present on

generator surface. If, during cleaning, the

surface does become free of mineral deposits, one approved method is to add plain tap

water to the generator surface and allow it

to boil off. This will ensure proper steaming

characteristics by creating a thin layer of mineral deposits on the casting.

• Chlorides or phosphates in cleansing agents

(e.g. bleach, sanitizers, degreasers or detergents) could cause permanent damage to

stainless steel equipment. The damage is

usually in the form of discoloration, dulling

of metal surface finish, pits, voids, holes or

cracks. This damage is permanent and not

covered by warranty.

NOTE: This may require repeating several times.

4

P/N 1010929 03/06

Page 5

STS-200 STEAMER/SCALE

WHT

BLK

GRN

IMPORTANT SAFETY INFORMATION (continued)

• The following tips are recommended for maintenance of your stainless steel equipment,

- Always use soft, damp cloth for cleaning,

rinse with clear water and wipe dry. When

required, always rub in direction of metal

polish lines.

- Routine cleaning should be done daily

using soap, and water.

SPECIFICATIONS

Electrical Ratings

Model &

Mfg. No

STS-200

9100922

Electrical Cord & Plug Configurations

Letter

Code*

C

(C)F 5-15P, 15 Amp.,

* Used in Model Designation

This equipment is to be installed to comply with

the basic plumbing code of the Building Officials

and Code Administrators, Inc. (BOCA) and the

Food Service Sanitation Manual of the Food and

Drug Administration (FDA).

Handle the Steamer/Scale with care. Do not place

objects other than sliced meat on the unit and

NEVER place anything over 4 pounds (64 ounces)

on the Steamer/Scale.

Voltage Watts Amps Hertz

120 1500 12.5 50/60

Description Configuration

Commercial Cord

120 VAC.,

Non – Locking.

CAUTION

CAUTION

- Stains and spots should be sponged using

a vinegar solution as required.

- Finger marks and smears should be

rubbed off using soap and water.

- Hard water spots should be sponged using

a vinegar solution.

CAUTION

All electrical connections must be in accordance

with local electrical codes and any other applicable codes.

WARNING

ELECTRICAL SHOCK HAZARD.

FAILURE TO FOLLOW THE INSTRUCTIONS IN

THIS MANUAL COULD RESULT IN SERIOUS INJURY OR DEATH.

• Electrical ground is required on this appliance.

• Do not modify the power supply cord plug. If

it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

• Do not use an extension cord with this appliance.

• Check with a qualified electrician if you are in

doubt as to whether the appliance is properly

grounded.

CAUTION

The Steamer/Scale uses a direct water line. Water

pressure coming into the unit must be set to 7 to

9 psi using a Water Pressure Regulator.

Model Designation

STS-200XX

TYPE OF POWER CORD

C = COMMERCIAL

TYPE OF PLUG

F = NEMA 5-15P

P/N 1010929 03/06

5

Page 6

STS-200 STEAMER/SCALE

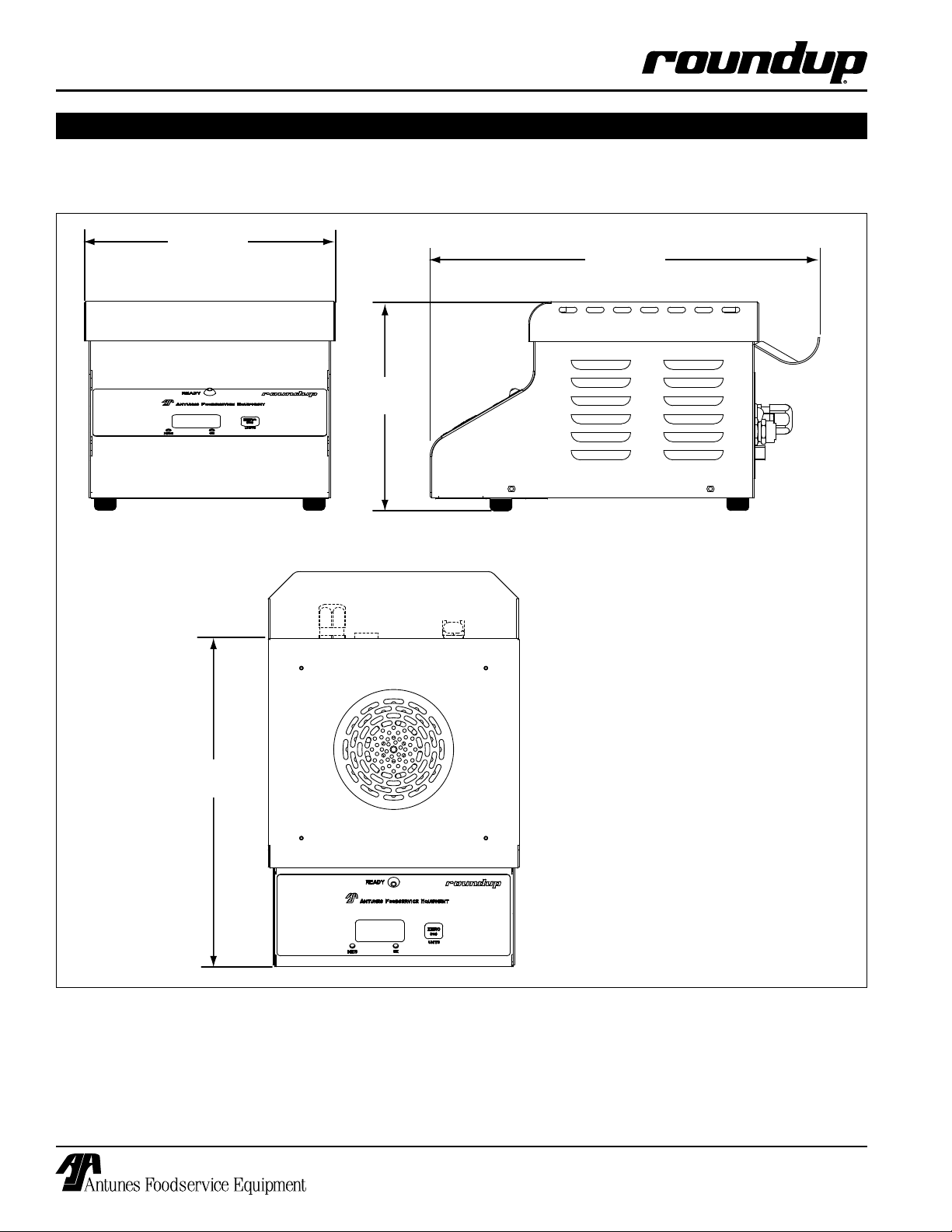

11 1/4"

(285.75 mm)

8 1/2"

(215.9 mm)

7 1/4"

(184.15 mm)

13 1/2"

(32.9 mm)

SPECIFICATIONS (continued)

Dimensions

6

P/N 1010929 03/06

Page 7

ZERO

(on)

3/4"

Locating the

Hidden Button

INSTALLATION

STS-200 STEAMER/SCALE

Unpacking

1. Remove unit and all packing materials from shipping carton.

2. Open the carton. It should contain the following:

• STS-200 Steamer/Scale

• Water Pressure Regulator Kit

• Owner’s Manual and Maintenance Sheet

• 16 ounce Calibration Weight

• Stainless Steel Cleaning Brush

NOTE: If any parts are missing or damaged, contact Antunes Technical Service IMMEDIATELY at

1-877-392-7854 or 1-630-784-1000.

3. Remove all packing materials and protective coverings from the unit.

4. Remove all removable parts and wipe them with

a clean towel dampened with sanitizer. Allow

them to air dry.

5. Wipe all surfaces of the unit with a clean towel

dampened with sanitizer and allow to air dry.

6. Re-install all removed parts and verify that all

parts are present.

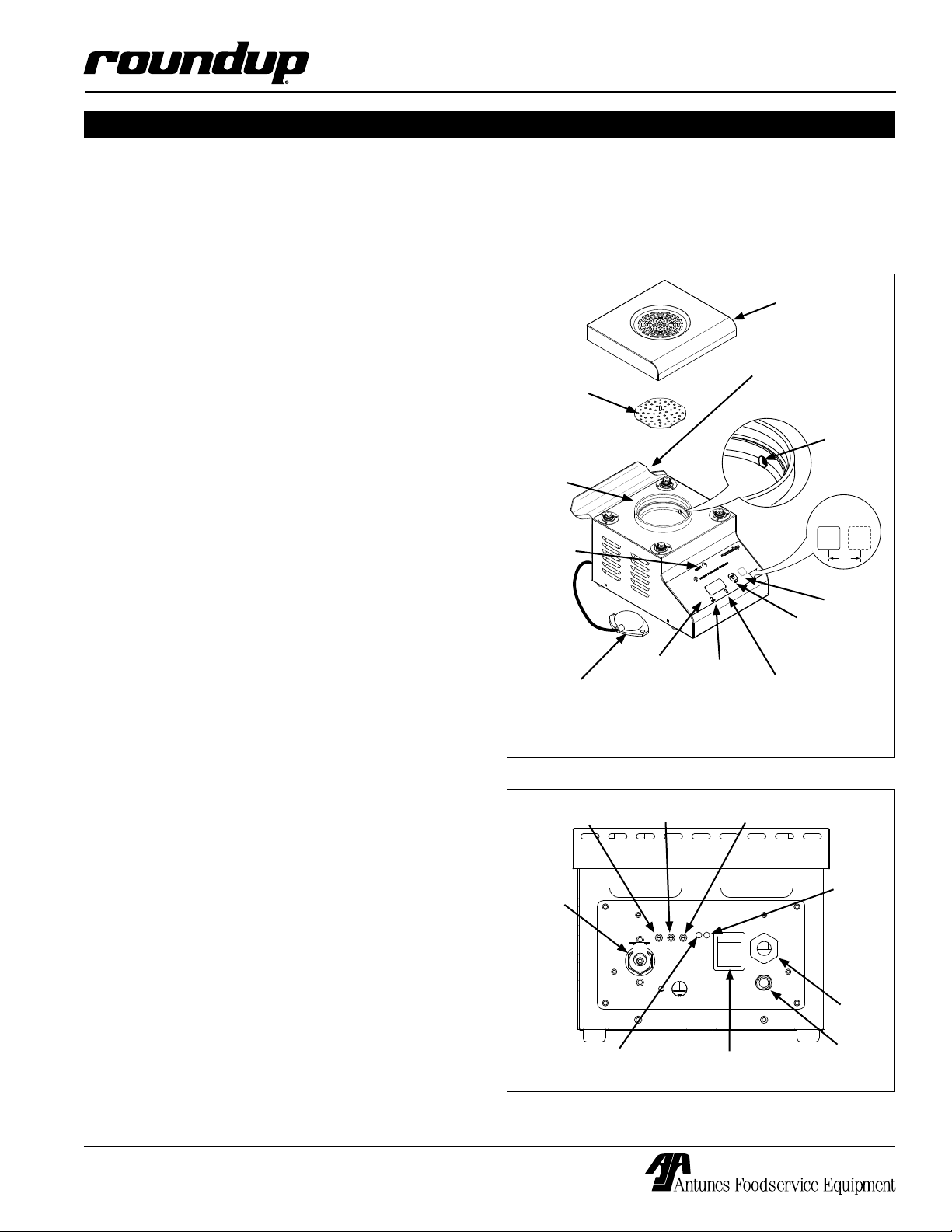

Equipment Setup

GENERAL

The STS-200 Steamer/Scale is used to heat and portion sliced meats. The Air Bulb Switch initiates a shot

of steam while the digital display shows the weight of

the sliced meat (Figure 1).

5. Plug the power cord into the appropriate outlet.

6. Note that the Rotary Switches on the back of the

unit (Figure 2) are pre-set to

• Temp Rotor Switch - 0

• Cycle Rotor Switch - 4

• Shot Rotor Switch - 4

Top

Cover

Storage Shelf for

Calibration Weight

Diffuser

Steam

Generator

Ready

Light

Ai Bulb

Switch

with

Tubing

Digital

Display

NOTE: The Rocker Switch is

located on the back of unit)

Neg

LED

and Cleaning Brush

Water

Inlet Tube

Hidden

button

Zero (on)

button

Oz LED

STEAMER/SCALE SETUP

When placing the Steamer/Scale into service, pay

attention to the following guidelines:

• Do not block or cover any openings on the units.

• Do not immerse cords or plugs in water.

• Keep cords away from heated surfaces.

• Do not allow cords to hang over edge of table or

counter.

3. Connect the outlet hose/fitting from the Dual

Water Regulator Kit to the Water Inlet Connection

at the rear of the unit (Figures 3 and 4a).

4. Connect the Air Bulb Switch tubing to the

Connection on the back of the unit (figure 3).

Push the tubing onto the connector. See the

instructions for optional mountings.

P/N 1010929 03/06

Connection

7

Figure 1. STS-200 Steamer/Scale

Temp Rotary

Switch

Water Inlet

Cycle Rotary

Switch

Green

Solenoid Led

Shot Rotary

Switch

Rocker Switch

(with Power LED)

Connection

Figure 2. STS-200 Steamer/Scale (Back View)

Without Storage Shelf Shown for Better View.

Yellow

Heater

Led

Power

Cord

Air Hose

Page 8

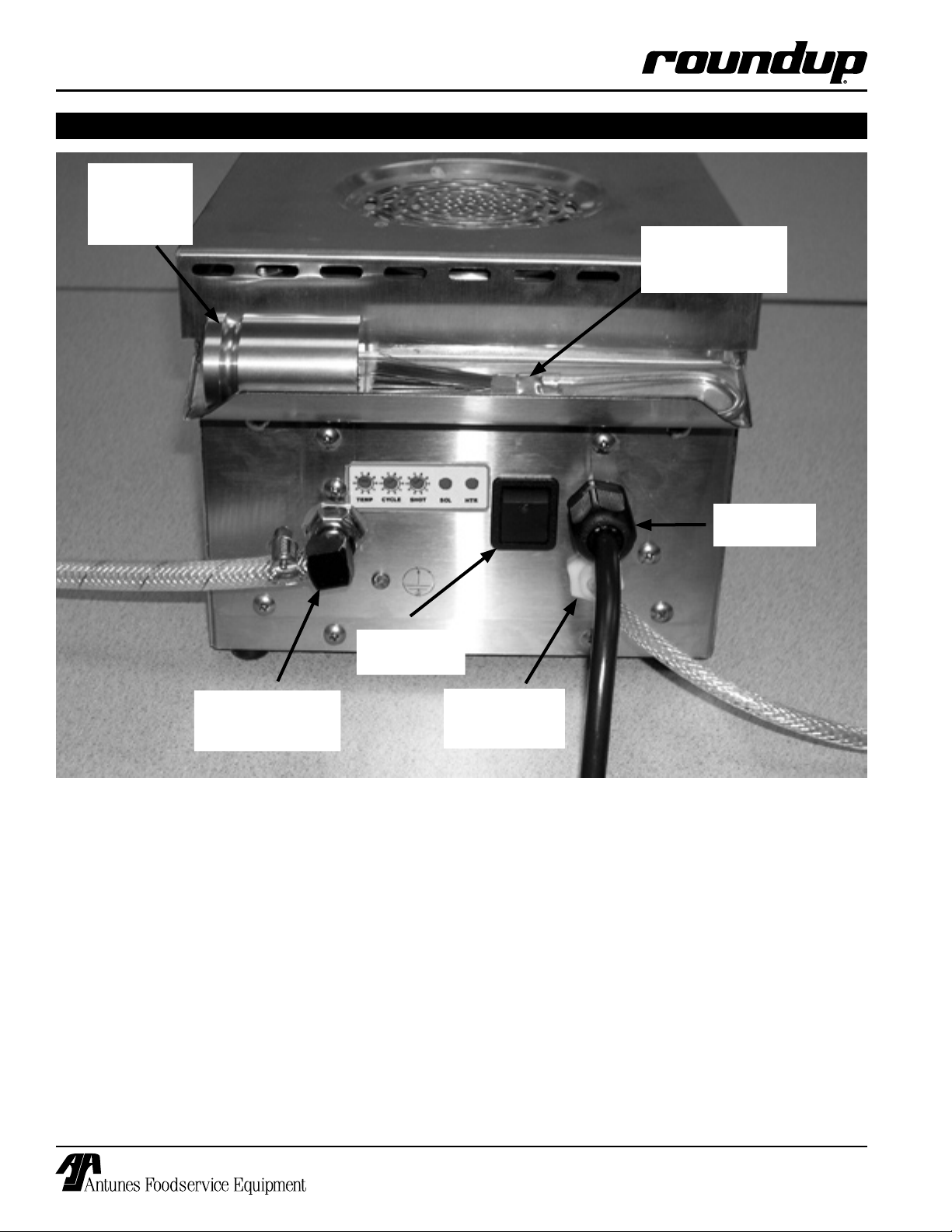

STS-200 STEAMER/SCALE

INSTALLATION (continued)

16 ounce

(1 pound)

Calibration

Weight

Stainless Steel

Cleaning Brush for

Steam Generator

Power

Cord

Power On/

Off Switch

Water Supply

from Dual Water

Regulator Kit

Figure 3. Back of Steamer/Scale with Calibration Weight and Cleaning Brush

Air Bulb

Switch Tubing

Connection

8

P/N 1010929 03/06

Page 9

STS-200 STEAMER/SCALE

INSTALLATION (continued)

INSTALLATION INSTRUCTIONS

FOR DUAL WATER PRESSURE REGULATOR KIT P/N 7000418

WARNING

Turn the unit off, disconnect the power source

and allow the unit to cool down before performing

any service or maintenance on the unit.

AFFECTED PRODUCTS:

All A.J. Antunes Steamer/Scale units.

PARTS INCLUDED:

• 1 Dual Water Regulator Assy. (P/N 7000418)

• 4 Self-Tapping Screws (P/N 3060144)

Used with a 0.125” drill bit.

• 1 Instruction Sheet (P/N 1010868)

TOOLS:

• Phillips Head Screwdriver

General

If you experience any problems with these instructions,

contact the factory Technical Service Department at 630784-1000 or toll free in the U.S. at 877-392-7854.

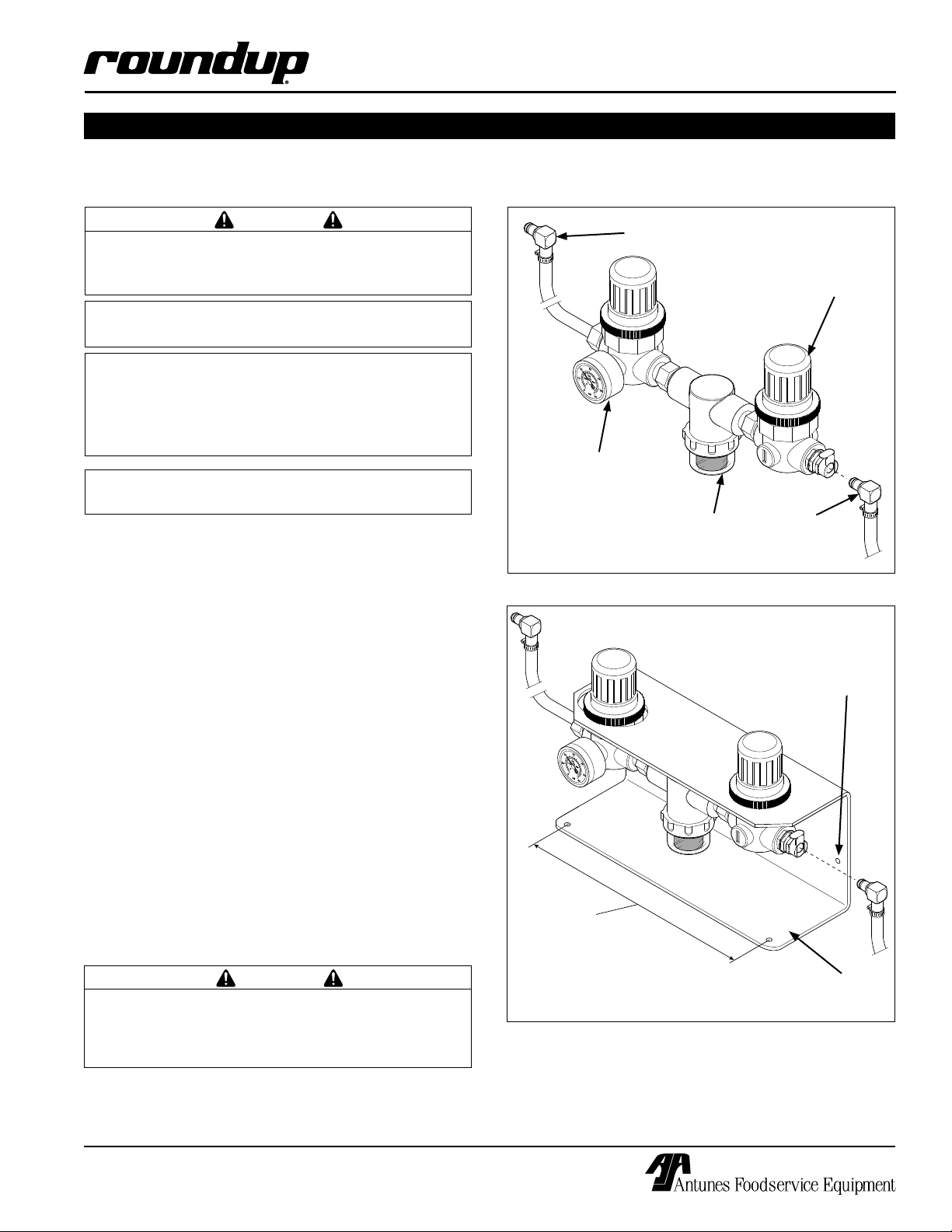

Installing the Dual Water Pressure Regulator

The Dual Water Pressure Regulator can be installed in

any of the following ways:

Water Supply Outlet (to

Water Pressure

Regulator Gauge

Set to 7 to 9 PSI

(adjustable)

Steamer/Scale)

Water

Strainer

Water Pressure

Regulator

Preset to 30

PSI and Fixed

(not adjustable)

Water

Supply Inlet

Connection

Figure 4a. Dual Water Pressure Regulator

Holes for verti-

cal mounting

(7 inches

apart).

• On a vertical surface (Figure 4b)

• On a horizontal surface (Figure 4b)

• Free-Standing (not mounted) (Figure 4b)

When mounting the Dual Water Pressure Regulator

onto a fixed horizontal or vertical surface, you must

use the mounting screws provided with the kit. These

screws are self-tapping and require a 0.125” inch hole

for mounting.

A free-standing mounting does not require use of the

mounting screws.

WARNING

DO NOT mount the Dual Water Pressure Regulator

over an electrical outlet or any other appliance or

area that may be damaged by water or that may

cause personal injury.

P/N 1010929 03/06

7.5 inches

between

mounting

holes.

For horizontal

mounting

Figure 4b. Mounting Options

9

Page 10

STS-200 STEAMER/SCALE

INSTALLATION (continued)

Checking and Cleaning the Water Strainer

The Water Strainer protects your equipment from any

foreign debris in the water line that could get into the

food and damage the unit’s solenoid (causing the unit

to leak or flood), It protects from interference with the

equipment’s proper and consistent operation

To ensure proper and consistent steaming results,

check the water pressure regulator gauge and strainer

cup regularly. If the pressure on the gauge has

dropped, check the clear, plastic strainer “cup” and

clean out the accumulated debris as follows.

1. Press the Release Tab and remove the Quick

Disconnect Fitting #2 (Figure 4c). Unscrew the

clear, plastic strainer “cup” and carefully remove

the mesh strainer screen (Figure 4c).

NOTE: Some water may drip out from the Quick

Disconnect fitting and Strainer Cup.

2. At the sink, gently flush all of the accumulated

debris from the strainer cup and mesh strainer.

Be especially careful not to damage the mesh

strainer screen.

3 Carefully place the mesh strainer screen into its

seat at the bottom of the clear, plastic cup and

confirm that the orange O-ring is properly seated

in its place before screwing the strainer cup and

top back together.

4. Reinstall the Quick Disconnect until a “click” is

heard.

5. Cycle the steamer several times. This ensures

the air is purged from the Water Line.

6. Replace damaged or worn parts as needed.

7. Verify that the Water Pressure Regulator Gauge

is set to 7 - 9 PSI (.4 - .6 kg/cm2 or 48 - 62 kPa).

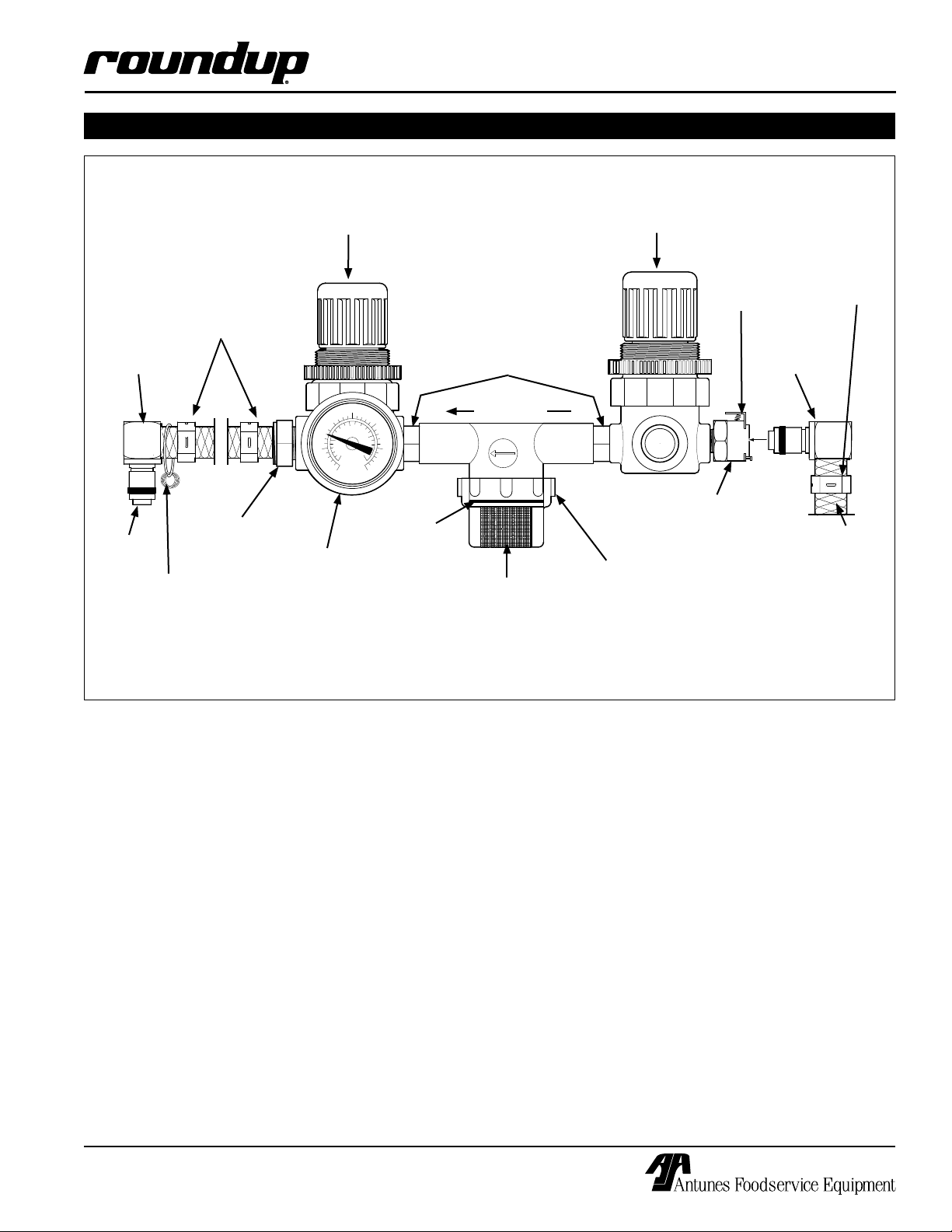

Adjusting the Water Pressure Regulator

The Dual Water Pressure Regulator uses a fixed

regulator and an adjustable regulator (Figure 4c). The

adjustable regulator must be set between 7 - 9 PSI (0.4

- 0.6 kg/cm2 or 48 - 62 kPa). Follow these steps to

adjust this regulator:

1. Make sure that the inlet water valve is on.

2. Over a bucket, press and hold the white plastic tip

on the Quick Disconnect #1 (Figure 4c) until good,

steady water flow is noted (this will purge all air

out of the line). Release and note the pressure

on the Water Pressure Regulator gauge. It should

read 7-9 PSI. If it reads more or less, adjust the

pressure by pulling the black knob upwards and

turning it clockwise to increase or counter-clockwise to decrease the water pressure. Push the

knob down to lock it in place.

NOTE: When adjusting the knob, you must relieve

the existing pressure by pressing the white plastic

tip on the Quick Disconnect Insert for 3 seconds.

This allows the newly set pressure to register on

the gauge. Repeat this until the gauge reads 7-9

PSI.

3. Re-install the Quick Disconnect until it “clicks” into

place and test the unit. Re-adjust the regulator as

needed.

10

P/N 1010929 03/06

Page 11

psi

5

0

10

25

30

20

1/4

NPT

DET

PAL

133

DET

PAL

133

15

DET

PAL

133

INSTALLATION (continued)

Water Pressure

Regulator Set to 7 to 9

PSI (adjustable)

STS-200 STEAMER/SCALE

Water Pressure

Regulator Preset to

30 PSI and Fixed

(not adjustable)

Release

Hose Clamp

Tab

Quick

Disconnect #1

(to Steamer/

Scale

Hose Clamp

Nipple

Quick

Disconnect #2

Supplied

Water Flow

Water

Supply Inlet

Connection (with

Release Tab)

Water Inlet Hose

(NOT Supplied

(see Figure 5)

White

Plastic Tip

Extra

O-rings

Male

Adapter

Barbed 1/4”

Gauge

O-Ring

Mesh

Screen

Strainer

Cup

NOTE: An inlet hose is NOT supplied with the Steamer/Scale. Customer/Installer to supply 1/4” ID Nylon

Braided Hose or purchase the Water Installation Kit (P/N 7000420 (Figure 5).

Figure 4c. Dual Water Pressure Regulator

P/N 1010929 03/06

11

Page 12

STS-200 STEAMER/SCALE

INSTALLATION (continued)

INSTALLATION INSTRUCTIONS

OPTIONAL WATER INSTALLATION KIT P/N 7000420

WARNING

Turn the unit off, disconnect the power source

and allow the unit to cool down before performing

any service or maintenance on the unit.

AFFECTED PRODUCTS:

All A.J. Antunes Steamer/Scale units.

PARTS INCLUDED:

• Water Installation Kit (P/N 7000420)

TOOLS:

• General Tools as Required.

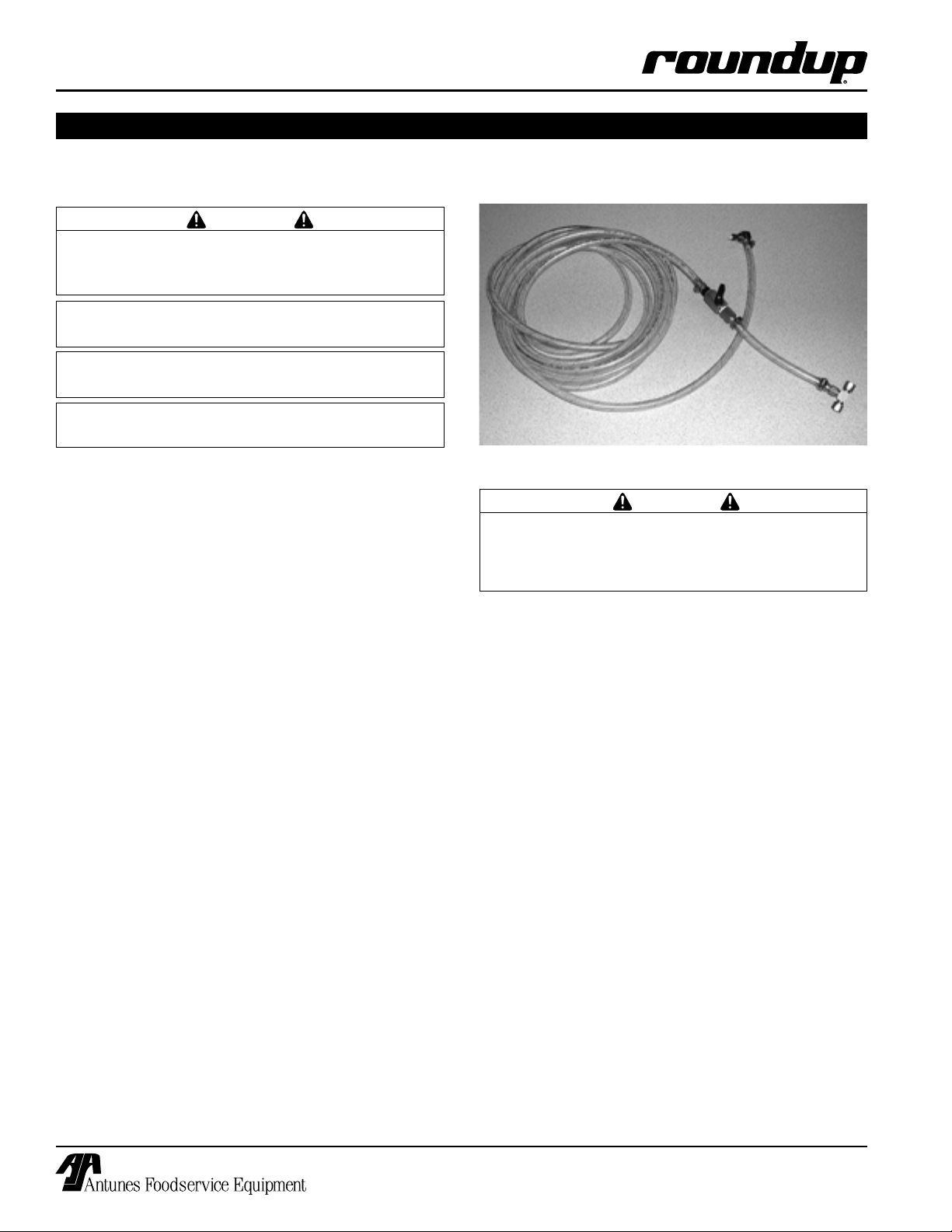

General

Figure 5. Water Installation Kit

If you experience any problems with these instructions,

contact the factory Technical Service Department at 630784-1000 or toll free in the U.S. at 877-392-7854.

Installation

The optional Water Installation Kit is used in conjunction with the Dual Water Pressure Regulator for the

STS-200.

It allows you to easily connect your existing water supply to the STS-200 Steamer/Scale. It is equipped with

quick disconnect attachments for easy installation and

also has a water shut-off valve for maintenance

(Figure 5).

To install, follow these steps:

1. Make sure that the Water Shut-off Valve is

closed.

2. Attach the T-Fitting to your existing water supply.

NOTE: The T-Fitting is for 1/4” O.D. Tubing

3. Attach the Quick Disconnect fitting to the inlet

connection of the Dual Water Pressure Regulator.

WARNING

Make sure that the water hoses are not kinked or

bent. This could result in poor steaming performance.

12

P/N 1010929 03/06

Page 13

STS-200 STEAMER/SCALE

INSTALLATION (continued)

Dual Water

Regulator Kit

(P/N 7000418)

From Cold

Water Supply

Main Shut

Off Valve

To STS-

200

Optional Water

Installation Kit

(P/N 7000420)

Figure 6. Dual Water Regulator Kit (P/N 7000418) with optional Water Installation Kit (P/N 7000420)

P/N 1010929 03/06

13

Page 14

STS-200 STEAMER/SCALE

INSTALLATION (continued)

INSTALLATION INSTRUCTIONS

FOR AIR BULB SWITCH KIT P/N 7000419

WARNING

Turn the unit off, disconnect the power source

and allow the unit to cool down before performing

any service or maintenance on the unit.

AFFECTED PRODUCTS:

All A.J. Antunes Steamer/Scale units.

PARTS INCLUDED:

• 1 Air Bulb Assembly (P/N 0011778)

• 1 Rubber Grommet 5/16” (P/N 0400342)

Used with a 9/16” drill bit.

• 4 Screws, #6 x 3/4” Self Tapping

(P/N 3060144) Used with a 0.125” drill bit.

• Instruction Sheet (P/N 1010869)

TOOLS:

• Phillips Head Screwdriver

General

If you experience any problems with these instructions,

contact the factory Technical Service Department at 630784-1000 or toll free in the U.S. at 877-392-7854.

Replacing the Air Bulb Switch

NOTE: If you are installing the Air Bulb Switch for

the first time, go to Step 3.

Hole cut into counter

with Rubber Grommet

12 inches behind unit..

12 Inches

(recommended)

Air Bulb Switch is mount-

ed on the front edge of

the counter with the Air

Switch hose running

under the counter top and

then up from a hole cut

through the counter.

Figure 7a. Proper Installation (Option 1)

Air Bulb Switch is

mounted on the front

edge of the counter

with the Air Switch

hose running over the

counter top.

1. Turn the unit off and unplug the power cord.

2. If necessary, remove the old Air Bulb Switch from

the unit by gently pulling the Air Switch Hose from

the connection on the back of the unit

(Figure 7a).

If the old Air Bulb Switch is mounted, carefully

remove and discard the two mounting screws and

the old Air Bulb Switch.

3. To install the new Air Bulb Switch, refer to Figures

7a through 7c. These figures show the proper

mounting options. Choose the best option for

your location.

WARNING

DO NOT mount the Air Bulb Switch as shown in

Figure 7d. Damage to the switch may result. Do

NOT mount the Air Bulb Switch on the floor for

ANY reason. It is NOT a foot switch.

14

Figure 7b. Proper Installation (Option 2)

Air Bulb Switch is

mounted or placed

(free standing) on

the counter top.

Figure 7c. Proper Installation (Option 3)

P/N 1010929 03/06

Page 15

INSTALLATION (continued)

4. If you chose options 2 or 3, skip to Step 5. For

option 1, you must cut a hole through the top

of the counter. This hole MUST be at least 12

inches directly behind the Air Switch Connection

located on the back of the unit.

After cutting the hole, insert the supplied rubber

Grommet into the hole to protect the Air Switch

Hose from nicks and cuts.

NOTE: Failure to use the black Rubber Grommet

may shorten the life-span of the Air Bulb Switch

and/or Air Hose.

5. Use the two self-tapping screws to mount the Air

Bulb Switch according to your chosen option.

NOTE: The use of screws in option three are

optional.

6. Run the Air Switch Hose appropriately according

to your chosen option of installation, and attach

the end to the Air Switch Connection located at

the back of the unit.

STS-200 STEAMER/SCALE

Do NOT install the Air

Bulb Switch with the

hose pointed up from the

edge of the counter top.

Damage to the hose or

switch may result.

Figure 7d. Incorrect Installation (Option 3)

WARNING

DO NOT mount the Air Bulb Switch on the floor

for ANY reason. It is NOT a foot switch.

P/N 1010929 03/06

15

Page 16

STS-200 STEAMER/SCALE

OPERATION

CAUTION

Handle the Steamer/Scale with great care. Do not

place objects other than sliced meat on the unit

and NEVER place anything over 4 pounds (64

ounces) on the Steamer/Scale. Damage to the

unit may result due to careless handling or misuse.

IMPORTANT

Handle the Top Cover with care. If the Top Cover

is bent, dented, or damaged, it may not sit properly on the Steamer/Scale resulting in inaccurate

weight measurements.

Operating Instructions

1. Turn the Rocker Switch (power On/Off) to ON

(Figure 2).

2. Allow the unit to preheat for approximately 30

minutes. The yellow Heater LED, located on the

back of the unit, will illuminate during the time

that the heating element is heating up. When the

unit is ready for operation, the blue Ready light

on the front of the unit will turn on and remain

lit. The unit will display 0.0. If it displays anything

besides 0.0, zero the scale by pressing the “Zero”

button once. If the display still does not read 0.0,

perform the procedures in the “Calibrating the

Steamer Scale” section of this manual.

NOTE: Do NOT press any buttons or use the scale

until it has warmed up and the Blue Ready LED is

ON.

3. Place the sliced meat onto the center of the

Steamer/Scale surface. At the same time, press

the Air Switch (Figure 1). The Steamer/Scale will

initiate a shot of steam.

4. The Blue LED will also turn off for 4 seconds.

This is the timer cycle.

5. Note the weight of the sliced meat and adjust

according to serving requirements.

IMPORTANT

Weight readings are accurate at the center of the

scale surface ONLY. Do not weigh sliced meat on

the edges or corners of the Steamer/Scale.

6. When the blue LED turns on, another steam/time

cycle can be initiated.

7. Remove steamed product and complete the

assembly of the sandwich.

Calibrating the Steamer/Scale

If the Steamer/Scale displays anything other than 0.0

during operation, first zero the scale. If the Steamer/

Scale still does not display 0.0 after it has been zeroed,

you must calibrate it as follows:.

1. Turn the unit on and allow it to warm up for 30

minutes.

2. Turn the unit off and wait for 20 seconds.

3. Ensure nothing is on the Steamer/Scale surface

and that the Top Cover is seated correctly.

4. Directly to the right of the Zero (on) button is the

Hidden button used to adjust the scale (Figure 1).

Simultaneously press and hold both the Zero (button) and the Hidden button and then turn the unit

on. Continue holding the buttons. The system

displays 888, 93, r 1.8, and then rb. At this point,

release both buttons. The unit will then display

C0. If the unit does not display C0, repeats Steps 2

through 4.

5. Press and release the Zero (on) button. Wait for

10 seconds. Do NOT bump the unit, counter,

or touch the Steamer/Scale during this 10

second period! The unit will then display C

and then C1.

6. Place a 1 pound (16 oz.) calibration weight on the

center of the scale surface. Press and release

the Zero (on) button. Wait 10 seconds. Do NOT

bump the unit, counter, or touch the Steamer/

Scale during this 10 seconds! During this 10

second time frame, the unit will display C, don, Sav,

and then 15.9, 16.0, or 16.1.

Remove the 1 pound (16 oz.) calibration weight.

The unit should read 0.0. If it does not, repeat

Steps 2 though 6.

16

P/N 1010929 03/06

Page 17

STS-200 STEAMER/SCALE

HTRSOL

7

3

6

5

4

8

2

9

1

0

7

3

6

5

4

8

2

9

1

0

7

3

6

5

4

8

2

9

1

0

CYCLETEMP

SHOT

OPERATION (continued)

Rotary Switch Settings

At the back of the STS-200 unit are three Rotary

Switches: Temp, Cycle, and Shot.

The Temp Rotary Switch sets the operating temperature

of the unit. The Cycle Rotary Switch sets the length of

a steam cycle in seconds. The Shot Rotary Switch sets

the amount of water used in each cycle of operation.

The standard settings and other possible settings are

listed in the following table.

Setting Temp/F° Cycle/sec Shot/Sec

0 375* 10.0 1.0

9 370 9.0 0.9

8 365 8.0 0.8

7 360 7.0 0.7

6 355 6.0 0.6

5 350 5.0 0.5

4 345 4.0* 0.4*

3 340 3.0 0.3

2 355 2.0 0.2

1 330 1.0 0.1

* These are the Standard Settings for the STS-200.

P/N 1010929 03/06

17

Page 18

STS-200 STEAMER/SCALE

MAINTENANCE

Precaution:

During these checks, hot surfaces will be exposed.

Hazard Communication Standard (HCS) – The procedures on this card include the use of

chemical products. These chemical products will be highlighted with bold face letters fol-

lowed by the abbreviation (HCS) in the tools portion of the procedure. See the Hazard

Communication Standard (HCS) Manual for the appropriate Material Safety Data Sheet(s)

(MSDS).

WARNING

Turn the unit off, disconnect the power source and

allow the unit to cool down before performing any service or maintenance on the unit.

The table below describes the types of cleansers and

detergents used during maintenance of the Steamer/

Scale.

IMPORTANT

Read ALL instructions on the cleaning products used.

Follow all instructions regarding the proper cleaning

product to use as well as the proper mixture and/or

handling of the cleaning product.

You MUST use the appropriate cleanser for the task

based on the appropriate supplier.

Document

Term

General

Detergent

Cleaner (HCS)

Steam

Generator

Cleaner (HCS)

Delimer/Scale

Remover

(HCS)

Sanitizer

Solution (HCS)

Proctor & Gamble

Product Name

Dawn™ Detergent

Solution

Spic and Span® Multisurface Cleaner (the

Green Liquid)

DCT-Delimer Solution

Clean Quick Sanitizer Ster-O-Kem® #15

Damon

Product Name

Lark® Detergent

Solution

SF-77®

Degreaser

Detergent.

---

Sanitizer

CAUTION

Chlorides or phosphates in cleansing agents (such

as bleach, sanitizers, degreasers or detergents) could

cause permanent damage to stainless steel equipment.

The damage is usually in the form of discoloration, dulling of metal surface finish, pits, voids, holes or cracks.

This damage is permanent and not covered by warranty.

NOTE: Frequency of cleaning is determined by water

conditions, usage and water filter systems.

Cover

Water Inlet

Diffuser

Steam

Generator

Steamer/

Scale

Figure 8. Steamer/Scale Components

Tube

Hidden

button

Zero (on)

button

Cleaning the STS-200 During Daily Use

CAUTION

The Top Cover, Diffuser, and Steam Generator are HOT

when performing the following procedures.

During the day’s use, there is a build up of meat and

meat juices on the Top Cover, Diffuser, and in the

Steam Generator.

This should be cleaned throughout the day. To do so,

remove the Top Cover and Diffuser and clean them with

a damp cloth (not dripping).

Using the damp cloth, wipe out the Steam Generator to

remove any meat and/or juices.

If the Water Inlet Tube becomes clogged so that water

cannot flow onto the Steam Generator, refer to the section titled “Cleaning the Water Inlet Tube” in this document.

18

P/N 1010929 03/06

Page 19

STS-200 STEAMER/SCALE

MAINTENANCE (continued)

Cleaning the STS-200 Steamer/Scale Daily

IMPORTANT

Turn the Rocker Switch (power On/Off) to OFF, unplug

the unit and allow it to cool down before proceeding.

1. Check the water quick disconnect fitting and all

hose clamp connections for leakage. If leakage

is apparent, tighten all clamps or replace part if

required.

2. Remove the Top Cover and Diffuser and wash in

a solution of Steam Generator Cleaner (HCS).

Use a wire brush to clean/remove the meat residue from the Top Cover and Diffuser. Rinse in

Sanitizer Solution (HCS) and then with clear

water. Allow to air dry.

3. To clean the Steam Generator, wipe out any meat

and meat juices. Pour some Steam Generator

Cleaner (HCS) into the Steam Generator.

Wait 15 minutes and then use the wire brush to

clean the Steam Generator.

Weekly Maintenance

IMPORTANT

Turn the Rocker Switch (power On/Off) to OFF, unplug

the power cord and allow the unit to cool down before

proceeding.

The STS-200 Steamer/Scale utilizes an open Steam

Generator. Water sprayed into the Steam Generator surface

flashes into steam immediately, but the minerals in the water

do not steam, they stay on the Steam Generator surface and

accumulate. A small amount of mineral deposits are needed

for proper operation, but a build-up of excessive mineral

deposits causes poor steaming efficiency, excessive moisture

(wet steam) and will eventually severely retard the steaming

action completely.

CLEANING STEAM GENERATOR

1. Perform the Daily Maintenance first.

2. Remove the Top Cover from unit.

3. Remove the Steam Diffuser.

4. Clean Steam Generator free of any product spills.

NOTE: If the mineral deposits come off in “flakes” or in

layers, build-up is excessive.

CAUTION

Observe all instructions, precautions, and warnings on

cleaning product labels .

Make sure to remove all meat and meat juices.

Rinse the Steam Generator using Sanitizer

Solution (HCS) and then clear water. If the

Steam Generator is not clean, repeat this step.

4. In this step, the cloths are to be damp, NOT

dripping wet. Clean the Steamer Scale base

using a damp soft cloth and General Detergent

Cleaner (HCS). Rinse using a soft cloth with

Sanitizer Solution (HCS) and then a soft cloth

dampened with clear water.

5. Re-install the Diffuser and Top Cover and plug the

power cord into the appropriate outlet.

6. Turn the Steamer/Scale on, allow the unit to

preheat for 30 minutes, and “zero” it by pressing

“zero” button/switch on the front of the unit

(Figure 8).

7. If the Water Inlet Tube becomes clogged so that

water cannot flow onto the Steam Generator,

refer to the section titled “Cleaning the Water Inlet

Tube” in this document.

5. Use a stainless steel wire brush to loosen and

remove excessive deposits from the Steam

Generator surface. Next, reinstall the Steam

Diffuser.

6. Pour Delimer/Scale Remover (HCS) so that it

just covers the top of the Diffuser. Be sure to follow the delimer manufacturer’s directions for proper mixture and use; it must be safe to be used on

aluminum. Wait one hour.

7. Remove the Delimer/Scale Remover (HCS) from

the Steam Generator and rinse with clear water

to remove all traces of Delimer/Scale Remover

(HCS). Repeat Steps 3 through 7 if needed to

remove mineral deposits.

8. Clean the Cover and Diffuser in a hot solution of

General Detergent Cleaner (HCS) and water,

then rinse in clear water and allow to air dry.

9. Clean unit surface with a hot, clean, damp cloth

(not dripping wet) and wipe dry. Re-install all

parts.

IMPORTANT: To ensure proper steaming characteristics,

some mineral deposits must be present on the Steam

Generator surface. If during cleaning, the surface does

become free of mineral deposits (bare aluminum), add

plain tap water to the surface and allow it to boil off.

P/N 1010929 03/06

19

Page 20

STS-200 STEAMER/SCALE

MAINTENANCE (continued)

IMPORTANT: In soft water areas, it may be necessary to

add a small amount of lime to the Steam Generator surface to “season” it.

This will ensure proper steaming characteristics by

producing a thin coating of mineral deposits on the surface. To season the Steam Generator, Mix 1 teaspoon of

Baking Soda with 3 ounces of water.

Pour the seasoning mixture onto hot Steam Generator.

After mixture is converted to steam, the remaining loose

powder can be removed.

10. Plug the power cord into the appropriate outlet

and connect the water line. Turn the Steamer/

Scale on, allow the unit to preheat for 30 minutes,

and “zero” the unit.

11. If the Water Inlet Tube becomes clogged so that

water cannot flow onto the Steam Generator,

refer to the section titled “Cleaning the Water Inlet

Tube” in this document.

Figure 9. Dirty Steam Generator

Figure 10. Clean Steam Generator

Cleaning the Water Inlet Tube

Sometimes when cleaning the Steam Generator, small

particles may be pushed into the Water Inlet Tube causing it to become clogged.

In a clogged state, the unit is unable to spray water into

the Steam Generator. Follow these steps to clean the

Water Inlet Tube and to restore the unit to proper operating condition:

1. With the unit heated, insert a straightened paper

clip SLIGHTLY into the Water Inlet Tube opening

(Figure 1) and rotate in a circular motion

NOTE: Do NOT shove the paper clip into the tube,

otherwise you may further clog the tube.

2. After cleaning the Water Inlet Tube, remove the

paper clip and cycle the unit several times to flush

out any particles. If the water sprays, the unit is

ready for use. If the water does NOT spray, follow

Steps 3 through 5.

3. Set the adjustable Water Pressure Regulator

(Figure 4c) between 20-25 PSI.

4. Next, cycle the unit several times to flush out any

particles.

5. Once the water sprays, set the water pressure

back to 7-9 PSI.

NOTE: Cycle the Steamer several times while

adjusting the water pressure regulator knob until

the water pressure gauge reads between 7-9 PSI.

Checking/Cleaning the Water Strainer Monthly

GENERAL

The Water Strainer (Figure 4c) protects the unit from

any foreign debris in the water line that could get into

the food, damage the unit’s solenoid (causing the unit

to leak or flood), or interfere with the equipment’s proper and consistent operation.

To ensure proper and consistent steaming results,

visually check the water pressure regulator gauge and

strainer cup regularly. If the pressure on the gauge has

dropped, visually check the clear plastic strainer “cup”

and clean out the accumulated debris as follows.

1. Remove the Quick Disconnect #2 (Figure 4c) from

the incoming water supply or shut off the water

supply valve to the unit. Unscrew the clear plastic strainer “cup” and carefully remove the mesh

strainer screen.

2. Take the strainer cup and mesh strainer to the

sink and gently flush all the accumulated debris

out of them, be especially careful not to damage

the mesh strainer screen.

20

P/N 1010929 03/06

Page 21

STS-200 STEAMER/SCALE

MAINTENANCE (continued)

3. Carefully place the mesh strainer screen into its

seat at the bottom of the clear plastic cup and

verify that the orange O-ring is properly seated in

its place before screwing the Strainer cup and top

back together.

4. Reinstall the quick disconnect until it “clicks” into

place.

5. Purge the air out of the strainer by cycling the unit

through several steam cycles.

6. Replace damaged or worn parts as needed.

NOTE: Refer to the Replacement Parts section of

this manual for a complete list of parts.

Weekly- Testing the STS-200 for Weighing Accuracy

1. Turn the unit on and allow it to warm up for 30

minutes.

TROUBLESHOOTING

Message Codes

2. Ensure nothing is on the Steamer/Scale surface

and that the Top Cover is seated correctly.

3. Press the “Zero” button once. The display should

now read 0.0.

4. Place the certified 16 ounce (1 pound) calibration

weight in the center of the scale surface.

5. The display should register 15.9 to 16.1 ounces

(452.67 to 458.36 grams). If it does, the Steamer/

Scale is weighing properly, and does not need

calibrating.

If the unit does not register 15.9, 16.0, or 16.1

ounces (452.67 to 458.36 grams), you must calibrate the scale according to the Operating section

of this manual.

The table below lists the possible message codes displayed by the unit during operation. Contact the factory

if you have any questions about these message codes.

Message

Code

888

93

r0.3

Ld0

don

SAv

Unt

Int

r b

Display test, all digits on.

Software part number, DSW0093.

Software revision.

Loading zero, shown on start up.

Indicates that calibration is complete.

Indicates that the current values are saved into memory.

Display Units (toggles between ounces or grams).

Initialize or reset all scale settings in memory.

Release button. Prompts user to release the Zero (On) or hidden buttons.

Description

P/N 1010929 03/06

21

Page 22

STS-200 STEAMER/SCALE

TROUBLESHOOTING (continued)

Error Codes

The table below lists the possible error codes displayed by the unit when an error occurs.

NOTE: If any of these errors appear on the Steamer/Scale display, contact the factory.

Error Code Description and Corrective Action

“E1” Program

Rom Error

“E2” Gross

Overload

“E3” Scale

Overload

“E4” Calibration

Span Error

“E5” EEPROM

Error

“E6” Calibration

Range Error

“E7 A/D Failure The scale has detected a failure in A/D circuit. Have the Steamer/Scale serviced by a qualified

The program memory in the Steamer/Scale has become corrupted. Have the Steamer/Scale serviced by a qualified Scale Repair Technician.

The Steamer/Scale is in gross overload. The load exceeds the scale’s input range and might

result in damage to the Load Cell. Remove excess weight immediately or Load Cell connections

may be wired in wrong. Ignore this message for the first 5 seconds after powering the Steamer/

Scale.

The Steamer/Scale is in overload. The load on the scale exceeds capacity by more than 103%.

Remove excess weight from the Steamer/Scale.

The Calibration Span is out of range, refer to A/D Ranging section for additional information.

The setup parameters loaded in nonvolatile memory have been corrupted. The Have the

Steamer/Scale re calibrated by a qualified Steamer/Scale Technician.

The “zero” Calibration is out of range. Refer to the A/D Ranging section for additional information.

Steamer/Scale Repair Technician.

22

P/N 1010929 03/06

Page 23

STS-200 STEAMER/SCALE

TROUBLESHOOTING (continued)

Problem Possible Cause(s) Corrective Action

The unit heats up and steams but

the front display is blank.

Unit operates, but the front display intermittently goes blank then

comes back on after several minutes.

NOTE: The generator surface

temperature is in excess of

375° F. The hi-limit will trip at

450-470° F.

No heat, the front display is blank,

and the light on the power switch

is “Off”

No heat, the front display is on,

and the “Blue” ready light is on

steady.

“Blue” ready light flashes rapidly. Thermistor is open. Contact your maintenance person

No heat, front display is blank, but

the light on the power switch is

ON.

The “Blue” ready light repeatedly

flashes 1 second on 3 seconds off

NOTE: The electrical compartment temperature has exceeded

155° F.

The “Blue” ready light intermittently

flashes 1 second on 1 second off

during normal use.

NOTE: The generator surface

temperature has dropped below

280° F. Proper operating temperature is 375° F.

Faulty scale Control Board. Contact your maintenance person

Faulty temperature Control Board.

Disconnected/Loose wiring harness.

The automatic resetting hi-limit is tripping due to the generator overheating.

Faulty temperature Control board.

Faulty thermistor.

Power cord not plugged into the

appropriate outlet.

Circuit breaker is off or tripped. Verify circuit breaker is on.

Faulty power cord. Contact your maintenance person

Faulty terminal block.

Faulty power switch.

Thermistor is shorted. Contact your maintenance person

Faulty temperature Control Board.

Loose, burnt, or broken wiring in heating circuit.

One of the two generator heaters is

open.

Faulty temperature Control Board.

Faulty transformer. Contact your maintenance person

Faulty temperature Control Board.

Loose or broken wiring in circuit.

Insufficient ventilation around unit. Turn unit off and let cool down. If

Faulty Temperature Control Board

Water pressure regulator is improperly

set.

Rotary switches are not correctly set Set switches to the proper settings

One of the two generator heaters is

open

Faulty Temperature Control Board.

or an Authorized Service Agency for

service.

Contact your maintenance person

or an Authorized Service Agency for

service.

Verify that the power cord is plugged

into the appropriate outlet.

or an Authorized Service Agency for

service.

or an Authorized Service Agency for

service.

or an Authorized Service Agency for

service.

or an Authorized Service Agency for

service.

the problem persists, Contact your

maintenance person or an Authorized

Service Agency for service.

Adjust regulator to 7-9 PSI.

shown under the “Equipment Setup”

section in the manual.

Contact your maintenance person

or an Authorized Service Agency for

service.

P/N 1010929 03/06

23

Page 24

STS-200 STEAMER/SCALE

TROUBLESHOOTING (continued)

Problem Possible Cause(s) Corrective Action

Scale is not weighing properly and/or behaves

erratically

Unit heats, does not steam,

but the green LED at the

rear of the unit DOES turn

on for a split second as the

air bulb is pressed

Unit heats, does not steam,

but the green LED at the

rear of the unit DOES NOT

turn on for a split second

as the air bulb is pressed

Scale requires calibration. Calibrate scale according section titled

Interference/binding with the floating

“Spider” (refer to part number 0504087 on

page 30 in the Replacement Parts section

of this manual.)

Faulty load cell. Contact your maintenance person or an

Faulty scale Control Board. Contact your maintenance person or an

The water valve is in the OFF position. Verify water valve is ON.

The quick disconnect fitting is not fully

inserted into the inlet side of the Water

Pressure Regulator.

The quick disconnect fitting is not fully

inserted into the rear of the scale/steamer.

The water regulator strainer screen is

clogged.

The generator’s water inlet tube is clogged. Clean the inlet tube according to the

Faulty solenoid valve. Contact your maintenance person or an

Air Bulb Hose is not properly connected to

the rear of the unit.

Air Bulb Hose is damaged. Replace Air Bulb or hose if damage is

Air Bulb is damaged.

Faulty Air Bulb Switch. Contact your maintenance person or an

“Calibrating the Steamer Scale” in the

Operation section of this manual.

If unit was recently disassembled and/or

serviced, some possible wiring or component may be interfering / binding with

the floating spider.

Authorized Service Agency for service.

Authorized Service Agency for service.

Remove and reinsert the quick disconnect fitting until a “click” is heard.

Clean the strainer according to the

Maintenance section of this manual.

Maintenance section of this manual.

Authorized Service Agency for service.

Remove and reattach the Air Bulb

Hose.

apparent.

Authorized Service Agency for service.

24

P/N 1010929 03/06

Page 25

STS-200 STEAMER/SCALE

TROUBLESHOOTING (continued)

Problem Possible Cause(s) Corrective Action

The unit is not

steaming the product

properly and/or the

product requires

re-steaming.

The generator surface

continuously fills with

water ONLY when the

power switch is OFF.

The generator surface

continuously fills with

water ONLY when the

power switch is turned

ON.

No heat and the rear

LEDS are off but the

front display is on.

The Water Pressure Regulator is improperly set.

The water regulator strainer screen is

clogged.

Rotary switches are not correctly set. Set switches to the proper settings shown in

The generator water inlet tube is clogged. Clean the inlet tube according to the

The generator needs cleaning. Clean the generator according to the

The unit is not being cleaned as required. Clean the unit according to the Daily, Weekly,

The generator surface is not hot enough. Preheat the unit and verify that the generator

The solenoid valve is leaking due to

debris trapped within its plunger and seat.

The Solenoid Valve is not installed

correctly.

Faulty temperature Control Board Contact your maintenance person or an

Faulty Temperature Control Board. Contact your maintenance person or

Adjust regulator to 7-9 PSI. Refer to the section titled “Adjusting the Water Pressure

Regulator” in this manual.

Clean the strainer according to the

Maintenance section of this manual.

the “Equipment Setup” section of this manual.

Maintenance section of this manual.

Maintenance section of this manual.

& Monthly cleaning procedures found in the

Maintenance section of this manual.

surface temperature is at least 375° F.

Attempt to flush the debris out by increasing

the water regulator to 30 PSI & cycling the

unit several times. Reset the regulator back to

7-9 PSI. If the problem persists. Contact the

Authorized Service Agency for service

If the Solenoid Valve was replaced, verify that

the “IN” and “OUT” labels on the valve correspond to the water flow.

Authorized Service Agency for service.

Authorized Service Agency for service.

P/N 1010929 03/06

25

Page 26

STS-200 STEAMER/SCALE

TECHNICAL THEORY OF OPERATION

Technical Theory of Operation

TEMPERATURE/STEAMING THEORY

When the Rocker Switch (Power On/OFF) is ON, line

voltage flows to the primary side of the step down

transformer. The transformer’s secondary side supplies

12 VAC to terminals T1 and T2 of the multifunctional

temperature Control Board.

Once powered, and provided that the generator surface

temperature is below 375º F (190º C), the multifunctional temperature Control Board calls for heat by energizing its on board mechanical relay. Once energized, the

mechanical relay closes its contacts, which allows line

voltage to flow to the generator.

As the generator begins to heat up, a 100 K ohm

thermistor monitors the internal generator temperature.

As the heat continues to increase, the thermistor’s

ohms begin to decrease. As the internal generator temperature approaches 375-390º (190-198º C), the thermistor is generating approximately 790-665 ohms.

The multifunctional temperature Control Board receives

these ohms and then de-energizes the mechanical

relay since the heating circuit is satisfied. Then, the

mechanical relay contacts open, and the generator

stops heating.

The heating circuit cycles on and off as needed, even

at idle. Once the generator is up to temperature (a state

indicated by a steady “Blue” light), and if the pneumatic

Air Bulb Switch is pressed and released to initiate a

steam cycle, air is directed rapidly through the pneumatic hose which then activates a pneumatic switch.

Once activated, the pneumatic switch contacts momentarily close to complete a circuit to terminal J4 on the

multifunctional temperature Control Board.

Simultaneously, the “Blue” light turns off, and the multifunctional Control Board supplies line voltage to the

Solenoid Valve Coil for a split second. The Solenoid

Valve opens, and allows approximately 2-3 tablespoons

of water to be disbursed onto the Generator surface for

steaming. The water flashes into steam immediately

then rises up through the steam ports and steams the

product.

The multifunctional Control Board incorporates two status LEDs detailed below. If the heating circuit continues

to call for heat and the Generator overheats, an automatic resetting Hi-Limit Thermostat will trip and open

the generator circuit and transformer circuit at approximately 450-470º F (232-243º C).

NOTE: If this condition should repeat, the root

cause must be determined and corrected.

NOTE: The STS-200 Scale/Steamer is shipped with

a dual water pressure regulator assembly. The primary water pressure regulator is fixed at 30 PSI

and is not adjustable. The secondary water pressure regulator is factory set and should remain

set between 7-9 PSI. It should only be momentarily

adjusted if required as per the maintenance section.

WEIGHT SCALE THEORY

As previously stated, when the power switch is on,

line voltage flows to the primary side of the step down

transformer. The transformer’s secondary side supplies 12 VAC to the multifunctional temperature Control

Board terminals T1 and T2.

Once powered, terminal J1 on the multifunctional temperature Control Board supplies 8-10 VDC to terminal

J1 of the scale Control Board by means of a wiring

harness. Once powered, the scale Control Board illuminates its display. In addition, the two outer pins of the

scale Control Board’s J2 terminal powers up the load

cell. These two outer pins supply 4-5 VDC to the load

cell’s “Green” and “Black” wires. The two center pins

receive a signal from the load cell’s “Red” and “White”

wires.

NOTE: The load cell is manufactured with an

integrated wiring harness. The loose end of this

harness plugs into the scale Control Board. The

removable top platform sits on 4 floating steel

pegs. The steel pegs are attached to a floating steel

cage (known as a Spider). The steel cage is attaches to the load cell. The Scale’s maximum operating

weight capacity is 4 lbs. The scale weighs in .1 oz

increments.

After approximately 4 seconds, the “Blue” light turns

back on to indicate that the unit is ready to run another

steam cycle.

26

P/N 1010929 03/06

Page 27

STS-200 STEAMER/SCALE

TECHNICAL THEORY OF OPERATION (continued)

LED FUNCTION

(The following LEDs are viewed from the rear of the

unit)

Yellow (Heat): When lit, it indicates that the unit is in

heat mode. During this time, line voltage is being supplied to the generator. When off, it indicates that the

generator is up to operating temperature.

NOTE: This led will cycle on and off even at idle.

Green (Solenoid Valve): When lit, it indicates that line

voltage is momentarily being supplied to the solenoid

valve coil.

NOTE: This LED is only lit for a split second.

THE FOLLOWING PROVIDES UNIQUE FEATURES

INVOLVING THE “BLUE” LIGHT. THESE ARE HANDY FOR

TROUBLESHOOTING PURPOSES.

During cold start up, the “Blue” light remains off (indicating that the generator is not up to temperature).

During this time, the solenoid valve circuit is disabled

and the unit will not initiate a cycle even if the air bulb is

pressed.

Within 5 minutes after cold start up, the “Blue” light will

turn on steady (indicating that the generator is now up

to operating temperature). During this time, the solenoid

valve circuit is enabled.

BLUE LIGHT BLINKING CODES (REFER ALSO TO THE

TROUBLESHOOTING SECTION)

Rapid Flashing: Under this condition, the generator

may, or may not get hot. The solenoid valve circuit is

disabled until the cause is corrected.

Possible Cause(s): An open thermistor or loose, burnt,

broken wiring in heating circuit or one of the two generator heaters is open, or faulty temperature Control

Board.

Slow Flashing (1 second on and 1 second off):

Under this condition, the generator surface temperature

has dropped below 280º F (137º C). The solenoid valve

circuit is disabled until the temperature rises above 280º

F (137º C) and reaches proper operating temperature.

Possible Cause(s): The water pressure regulator is

improperly set or rotary switches are not correctly set or

one of the two generator heaters is open or faulty temperature Control Board.

Slow Flashing (1 second on and 3 seconds off):

Under this condition, the electrical compartment temperature has exceeded 155º F (68º C). The solenoid

valve circuit is disabled until the electrical compartment

temperature drops below 155º F (68º C).

Possible Cause(s): Insufficient ventilation around the

unit or faulty temperature Control Board.

NOTE: The unit should always be preheated for 30

minutes before use.

P/N 1010929 03/06

27

Page 28

STS-200 STEAMER/SCALE

See Page 29

See Page 30

See

Page 31

See

Page 32

See

Page 33

REPLACEMENT PARTS

28

P/N 1010929 03/06

Page 29

STS-200 STEAMER/SCALE

7

8

1

3

5

4

2

9

11

REPLACEMENT PARTS (continued)

Item Part Description Qty.

No.

1 7000424 Generator Kit 1

(Incl. 2, 4, 5, 7, 8, & 10)

0100245** Generator Machined 1

4050228** Probe, Thermistor 1

0011787** Cartridge Heater Assy. w/ Term. 2

3080192** Set Screw, 8-32 x 3/8 Cup Point 3

2 0400343 Insulation, Generator 1

3 0200242 O-Ring 1

4 2120168 Spacer, #6 4

5 306P101 Nut, Hex #6-32 1

7 7000438 Generator Elbow Kit (Incl. 3) 1

2020117** Tube, Silicone 1

2190142** Elbow 1/8”* 1

Item Part Description Qty.

No.

8 7000458 Hi-Limit Thermostat Kit* 1

4030373** Thermostat 1

3040114** Screw #4-40 x 1/4 2

2140119** Therm Paste 1

9 0504053 Retainer, Insulation 1

10 7000356 Silicone Sealer Kit (Not Shown) 1

11 306P102 Internal Tooth Lock Washer #6 1

* These Parts to be Assembled onto the Generator

Assembly

** The Part Numbers in grey are NOT available for

P/N 1010929 03/06

29

Page 30

STS-200 STEAMER/SCALE

2

3

2

4

5

6

7

8

9

1

10

7

2

REPLACEMENT PARTS (continued)

Item Part Description Qty.

No.

1 308P189 Screw 8-32 x 1/4” (10 pack) 1

2 310P170** Nut, #10-32 NY-Lock (10 pack) 1

3 800P007** Screw, M6 x 16 mm 1

Hex Head

4 0504087** Spider 1

5 0504122** Spacer, Load Cell 2

6 4030367** Load Cell 1

Includes item #5, 3, and 2

7 310P146** Nut, Hex “KEPS” #10-32 1

8 0504082** Plate, Base 1

9 310P180** Screw, Mach. 1

#10-32 x 1-3/4” Lg. (10 pack)

10 0504119 Brace, Spider 1

11 7000459 Base/Load Cell Assembly Kit 1

(Includes Items 1 through 10

assembled)

12 7000460 Load Cell Test Kit (not shown) 1

** The part numbers in grey are NOT available for

individual purchase. You must use item #11 in

their place. Item #11 consists of all of the items

shown.

11

30

P/N 1010929 03/06

Page 31

STS-200 STEAMER/SCALE

8

8

2

1

9

11

10

7

6

5

3

4

12

13

13

REPLACEMENT PARTS (continued)

Item Part Description Qty.

No.

1 0504057 Housing, Steamer 1

2 4060386 Indicator, LED Blue 1

3 1001140 Label, Control Panel 1

4 7000439 Membrane Switch (Incl. #3) 1

5 0504080 Plate, Cover 1

6 7000436 Leg Kit (Pack of 4) 1

7 7000421 Scale Control Board 1

Item Part Description Qty.

No.

8 2120168 Spacer #6 8

9 0504123 Bracket, Terminal Mounting 1

10 4060387 Terminal, Double Row x 2 Con 1

11 306P130 Nut, Hex KEPS #6-32 1

12 7000427 Water Tube with Quick 1

Disconnect Kit (Female)

13 306P102 Internal Tooth Lock Washer #6 1

(pack of 10)

P/N 1010929 03/06

31

Page 32

STS-200 STEAMER/SCALE

33

34

14

26

20

21

23

25

24

22

15

12

11

13

29

30

31

7

2

8

3

5

6

9

28

16

17

18

19

10

1

1

NOTE: Item 8 can be

purchased separately in

kit #7000429

32

27

REPLACEMENT PARTS (continued)

Item Part Description Qty.

No.

1 7000425 Solenoid Assy. (incl. Items 2-9) 1

2 4040175 Solenoid Valve 1

3 0504089 Plate, Solenoid 1

5 3620102 Lock Washer 5/8” Int. 1

6 2080117 Quick Disconnect 1/8” NPT 1

7 2190143 Barb 3/16” tube x 1/8” NPT 1

8 7000429 Solenoid coil 120 VAC 1

9 2020118 Tube, Silicone 3/16” I.D. x 3/8”

O.D. x 10 “ Lg. 1

10 2080124 Elbow, Quick Disconnect 1/8” 1

11 0504072 Panel, Control 1

12 0504071 Housing, Electrical 1

13 3080143 Nut, Hex KEPS #8-32 2

14 4060304 Terminal Block, 3-Pole 1

15 306P101* Nut, Hex #6-32 2

16 300P102* NU, Speed #8-32 “U” 2

17 4010201 Transformer 120v/12v 1

18 0400147 Bushing, Shorty 7/8” 2

19 308P104* Screw, Mach #8-32 x 3/8” Sltrshd 2

20 306P130* Nut, Hex KEPS #6-32 5

21 0504088 Plate, Control 1

22 306P123* Screw, Mach #6-32 x 7/8” Sltrshd 2

Item Part Description Qty.

No.

23 306P105* Screw, Mach #6-32 x 1/2” Sltrshd. 5

24 040P119* Bushing, Shorty 5/8” 1

25 3080189 Screw, Machine #8-32 x 1/4” 5

26 7000422 Temperature Control Board Kit 1

27 0700674 Power Cord 5-15P 120V 1

28 040K251 Strain Relief - Cord Connector 1

29 4010212 Air Switch 1

30 4010151 Switch, Rocker (25 A - 125V) 1

31 308P124* Screw, Mach One-way #8-32 5

32 7000426 Water Supply Kit

(Incl. Items #9 and 10) 1

33 4060389 Ferrite 100 Ohm/100 Mhz 1

34 4060388 Varistor (Mov) Assembly 1

35 1001141* Setting Label (Not shown) 1

36 1001153* Water Label (Not shown) 1

NOTE: Item #8 comes included in Kit 7000425 but is also

available for purchase by itself.

NOTE: Items #11 and 12 are sold as one piece ONLY.

*NOTE: Items only available in a package of 10. The part

numbers in gray are NOT available for individual purchase.

32

P/N 1010929 03/06

Page 33

STS-200 STEAMER/SCALE

7

6

5

4

3

2

1

8

REPLACEMENT PARTS (continued)

Item Part Description Qty.

No.

1 0011784 Top Cover Weldment 1

2 304P114 Screw, Machine #4-40 x 1/4” 2

(10 pack)

3 0504121 Seal Retainer 4

4 0300145 Screw, Locator (peg, steel) 4

5 2120157 Spacer 4

6 2120154 Standoff 4

7 7000423 Seal Kit, pack of 4 (Incl. #2) 4

8 0011776 Diffuser Assembly 1

P/N 1010929 03/06

33

Page 34

STS-200 STEAMER/SCALE

11

3

4

1

10

8

2

9

6

5

7

1

7

Inlet Tubing

NOT Supplied

Must use 1/4" I.D

Nylon Braided

Hose

Strainer

Screen

Strainer Cup

13

12

14

12

2

2

O-Ring

Orange

REPLACEMENT PARTS (continued)

Dual Water Pressure Regulator Kit (P/N 7000418)

Item Part Description Qty.

No.

1 7000139 Elbow, Quick Disconnect 2

(Incl 2 & 12)

2 2110160 Clamp, Ear 17/32” 3

3 2030128 Tubing - 1/4” ID PVC Brd. 30” long 1

4 2040130 Male Adaptor, Barbed - 1/4” 1

5 7000437 Gauge, Pressure (0-30 PSI) 1

6 2170122 Regulator Pressure (adjustable) 1

7 2190129 Nipple 1/4” NPT x 1/4” NPT 2

34

Item Part Description Qty.

No.

8 7000333 Strainer 1/4 FTP (includes O-Ring, 1

Strainer Screen, and Strainer Cup

9 2170124 Regulator, Pressure 1

(non-adjustable)

10 2080118 Quick Disconnect 1/4” NPT 1

11 0504195 Bracket, Regulator 1

12 020P117 O-Rings, Spare (10 Pack) 3

13 306P144 Screw- Self Tapping (10 Pack) 1

14 7000334 Screen & Gasket Kit 1

P/N 1010929 03/06

Page 35

STS-200 STEAMER/SCALE

1

1A

REPLACEMENT PARTS (continued)

Item Part Description Qty.

No.

1 7000435 Weight 1 lb (16 ounces) (Incl 1A) 1

1a 2130173 Wire Brush 1

P/N 1010929 03/06

35

Page 36

STS-200 STEAMER/SCALE

5

2

4

1

# 16 GA. TFE-200°C

UNLESS OTHERWISE SPECIFIED.

NOTE: ALL WIRES TO BE 14 GA. TFE-200°C

22 GA. TFE-200°C

GENERATOR

T4

T3

TEMP CONTROL

T1

T6

T5

SOLENOID

# BLK

THERMISTOR

GEN.

RELAY

LED

BLU

BLU

AIR SWITCH

T2

SCALE CONTROL

12VAC

120/240VAC

X-FORMER

J2

J4

J3J1

LOAD CELL

HI-LIMIT

THERMOSTAT

BLOCK #2

TERMINAL

BLK

# WHT

# BLK

4

3

ZERO/HIDDEN

SWITCH

J1

J2

J3

WHT

POWER

SWITCH

GND

TERMINAL

POWER

BLOCK

CORD

CORE

FERRITE

VARISTORS

(X3)

WIRING DIAGRAM

36

P/N 1010929 03/06

Page 37

NOTES

STS-200 STEAMER/SCALE

P/N 1010929 03/06

37

Page 38

STS-200 STEAMER/SCALE

NOTES

38

P/N 1010929 03/06

Page 39

NOTES

STS-200 STEAMER/SCALE

P/N 1010929 03/06

39

Page 40

A.J. Antunes & Co.

Headquarters/Manufacturing

180 Kehoe Boulevard

Carol Stream, Illinois 60188

USA

Phone (630) 784-1000

Toll Free (800) 253-2991

Fax: (630) 784-1650

Antunes Equipment

Manufacturing (Suzhou) Ltd.,

9 Hou Ju Road, Building #24,

S&T Park, SND

Suzhou, Jiangsu, China 215011

Phone: 86-512-6841-3637

Fax: 86-512-6841-3907

www.ajantunes.com

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed

of the finest materials available and manufactured to high quality standards. These units are warranted to be

free from mechanical and electrical defects for a period of one year from date of purchase or 18 months from

shipment from factory, whichever occurs first, under normal use and service, and when installed in accordance

with manufacturer’s recommendations.

To insure continued proper operation of the units, follow the maintenance procedure outlined in the Owner’s

Manual.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of

the Equipment. This warranty does not include overtime charges or work done by unauthorized service agencies

or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments as specified

in operating and maintenance instructions of this manual, and/or labor involved in moving adjacent objects to gain

access to the Equipment. This warranty does not cover consumable items such as Platen Release Sheet and

Conveyor Belt Wraps. This warranty does not pay travel, mileage, or any other charges for an authorized

service agency to reach the equipment location.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right is

always reserved to modify equipment because of factors beyond our control and government regulations. Changes

to update equipment do not constitute a warranty charge.

3.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should

be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt. Damage

should be reported to the carrier. This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight

and taxes are the responsibility of the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE

AND IN NO EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

Loading...

Loading...