Model 101 & 2100

(Including Pass-Thru Door Models 103, 105,

107, 2125, 2127, 2130)

Service & Installation

November, 2012

99-13312-S001

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 2 of 95

Contents:

1. Models 101 & 2100 Door & Frame – Reversible Parts Placement (Start 10/89) ...................6

2. Models 101 & 2100 Reversible Door Parts Placement (1989 to 1991) .................................7

3. Models 101 & 2100 Standard (Before 7/94) Frame Net Opening Widths..............................8

3.1.1. 24” Door (Catalog Size) 23-3/16” Actual Door Width ............................................. 8

3.1.2. 26” Door (Catalog Size) 26-3/8” Actual Door Width ............................................... 8

3.1.3. 30” Door (Catalog Size) 29-7/8” Actual Door Width ............................................... 8

4. Models 101 & 2100 Standard Frame Net Opening Heights ..................................................9

5. Models 101 & 2100 Frame Installation ..................................................................................9

6. Frame Divider Board Installation (Prior to 1993) .................................................................10

7. Reversible/Cordless Door & Hold-Open Installation............................................................11

8. Reversing Frame Hardware ................................................................................................12

9. Door Reversing Instructions Models 101 & 2100 (1989-1991)............................................13

10. Door Reversing Instructions (1991 to Present) ...................................................................16

11. Models 103, 105, 107, 2125, 2127 & 2130 Pass-Thru Installation ......................................17

12. Frame Sill Plastic protector Installation Models 101 & 2100................................................19

13. Contact Plate and Contact Plate Retainer Replacement.....................................................20

14. Ordering Replacement Doors..............................................................................................21

15. Torquemaster Replacement ................................................................................................22

16. Door Gasket Replacement ..................................................................................................22

17. Door Plastic (Cover) Replacement ......................................................................................23

18. Door Cut-Away & Handle Replacement ..............................................................................23

19. Side Access Plate Replacement (1989 to 1991) .................................................................24

20. Side Access Plate Replacement (1991 to Present).............................................................24

21. Door Female Plug Replacement (1989 to 1991) .................................................................25

22. Frame Female Plug and/or Socket Replacement (1991 to Present) ...................................25

23. Door Heater Replacement (1989 to 1991) Model 101 Only ................................................26

24. Door Heater Replacement (1991 to Present) Model 101 Only ............................................26

25. Hinge Pin Replacement (1989 to 1991) ..............................................................................27

26. Hinge Pin Replacement (1991 to Present) ..........................................................................27

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 3 of 95

27. Wiring Instructions, Heated & Non-Heated Glass (1991 to Present) ...................................27

28. Torque Rod Replacement (1987 to 1991) ...........................................................................28

29. Torque Rod Replacement (1991 to Present).......................................................................28

30. Front Bumper Bar Field Installation .....................................................................................28

31. Model 101 Door Cylinder Lock Replacement or Repair ......................................................29

32. P.O.M. Lock Installation ......................................................................................................30

33. P.O.M. Lock Installation ......................................................................................................31

34. Model 101 Glass Replacement (Reglazing) ........................................................................32

35. Ordering Replacement Frames ...........................................................................................35

36. Frame Heater Wire Replacement........................................................................................36

37. Models 101 & 2100 Frame Heater Schematic/Low Temp ...................................................37

38. Models 101 & 2100 Frame Heater Schematic/Normal Temp ..............................................37

39. Humastat Installation Procedure .........................................................................................38

40. Model 101 Humastat ...........................................................................................................40

41. Model 101 & 2100 Shelf Assembly Catalog Size/Shelf Size ...............................................40

42. Models 101 & 2100 Frame & Shelving with Standard Lighting............................................42

43. Models 101 & 2100 Frame & Shelving with “ELS” Electronic Lighting ................................43

44. Four-Post Stabilizer Bar Installation ....................................................................................44

45. Four-Post Shelf System Installation ....................................................................................44

46. Plastic Tag Molding Installation ...........................................................................................46

47. Model 2100 G.F.I. Location & Wiring Diagram ....................................................................47

48. Lamp Replacement .............................................................................................................47

49. Lamp Socket Replacement .................................................................................................48

50. Recessed Light Socket Replacement..................................................................................49

51. Recessed Lamp Channel Replacement with Remote Ballast .............................................49

52. Recessed Lamp Guard Replacement with Remote Ballast.................................................50

53. Recessed Lamp Replacement ............................................................................................50

54. “Boost & Buck” Transformer Wiring Diagram ......................................................................50

55. Frame Junction Box Wiring (Standard Production) .............................................................51

56. Models 101 & 2100 Light Fixture Placement (Prior to 10/93) ..............................................51

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 4 of 95

57. Models 101 & 2100 Light Fixture Placement – “Continuous” Lineup (10/93 to Present) .....52

58. Models 101 & 2100 Low Temp 120-Volt Remote Ballast and Lamp Wiring Diagram for

1-Light Systems ..................................................................................................................53

59. Models 101 & 2100 Low Temp 120-Volt Remote Ballast and Lamp Wiring Diagram for

2-Light Systems ..................................................................................................................54

60. Models 101 & 2100 Normal Temp 120-Volt Remote Ballast and Lamp Wiring Diagram

for 1- & 2-Light Systems ......................................................................................................55

61. Models 101 & 2100 Normal Temp 120-Volt Remote Ballast and Lamp Wiring Diagram

for 3-Light Systems .............................................................................................................55

62. Normal Temp & Low Temp 120-Volt Ballast and Lamp Wiring Diagram - Pre-Wired 1-

Light System .......................................................................................................................56

63. Ballast Replacement ...........................................................................................................56

64. “ELS” Lamp Socket Replacement .......................................................................................57

65. “ELS” Electronic Ballast Replacement and Wiring Instructions ...........................................59

66. T-8 Lamp Replacement Instructions....................................................................................65

67. Dew Point Chart ..................................................................................................................71

68. Electrical Information for Model 101 Low Temp Heated Doors, Frames & Standard Light

Fixtures Heater Amperages @ 120 Volts ............................................................................72

69. Electrical Information for Model 101 Normal Temp Heated Doors, Frames & Standard

Light Fixtures Heater Amperages @ 120 Volts ...................................................................73

70. Heat Load in BTU/Hr for Model 101 Low Temp Glass, Door Rail, Frame Heaters and

Standard Lighting (Per Door, with Doors Closed @ 75°F Store Ambient)...........................76

71. Heat Load in BTU/Hr for Model 101 Normal Temp Glass, Door Rail, Frame Heaters and

Standard Lighting (Per Door, with Doors Closed @ 75°F Store Ambient)...........................76

72. Heat Load in BTU/Hr for Model 2100 Low Temp Glass, Door Rail, Frame Heaters and

Standard Lighting (Per Door, with Doors Closed @ 75°F Store Ambient)...........................78

73. Electrical Information for Model 2100 Low Temp Heated Doors, Frames & Standard

Light Fixtures Heater Amperages @ 120 Volts ...................................................................79

74. Electrical Information for Model 2100 Normal Temp Doors, Frames & Standard Light

Fixtures Heater Amperages @ 120 Volts ............................................................................80

75. Heat Load in BTU/Hr for Model 2100 Normal Temp Glass, Door Rail, Frame Heaters

and Standard Lights (Per Door, with Doors Closed @ 75°F Store Ambient).......................81

76. Heat Load in BTU/Hr for Model 101 Low Temp Glass, Door Rail, Frame Heaters and

“ELS” Electronic Lighting System (Per Door, with Doors Closed @ 75°F Store Ambient) ..82

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 5 of 95

77. Electrical Information for Model 101 Low Temp Doors, Frames & “ELS Electronic

Lighting System Heater Amperages @ 120 Volts ...............................................................83

78. Electrical Information for Model 101 Normal Temp Doors, Frames & “ELS” Electronic

Lighting System Heater Amperages @ 120 Volts ...............................................................84

79. Heat Load in BTU/Hr for Model 101 Normal Temp Glass, Door Rail, Frame Heaters and

“ELS” Electronic Lighting System (Per Door, with Doors Closed @ 75°F Store Ambient) ..87

80. Electrical Information for Model 2100 Low Temp Doors, Frames & “ELS” Electronic

Lighting System Heater Amperages @ 120 Volts ...............................................................88

81. Heat Load in BTU/Hr for Model 2100 Normal Temp Glass, Door Rail, Frame Heaters and

“ELS” Electronic Lighting System (Per Door, with Doors Closed @ 75°F Store

Ambient)..............................................................................................................................89

82. Heat Load in BTU/Hr for Model 2100 Low Temp Glass, Door Rail, Frame Heaters and

“ELS” Electronic Lighting System (Per Door, with Doors Closed @ 75°F Store Ambient) ..90

83. Electrical Information for Model 2100 Normal Temp Doors, Frames & “ELS” Electronic

Lighting System Heater Amperages @ 120 Volts ...............................................................90

84. Troubleshooting ..................................................................................................................92

85. Safety Precautions ..............................................................................................................94

86. Tips .....................................................................................................................................94

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 6 of 95

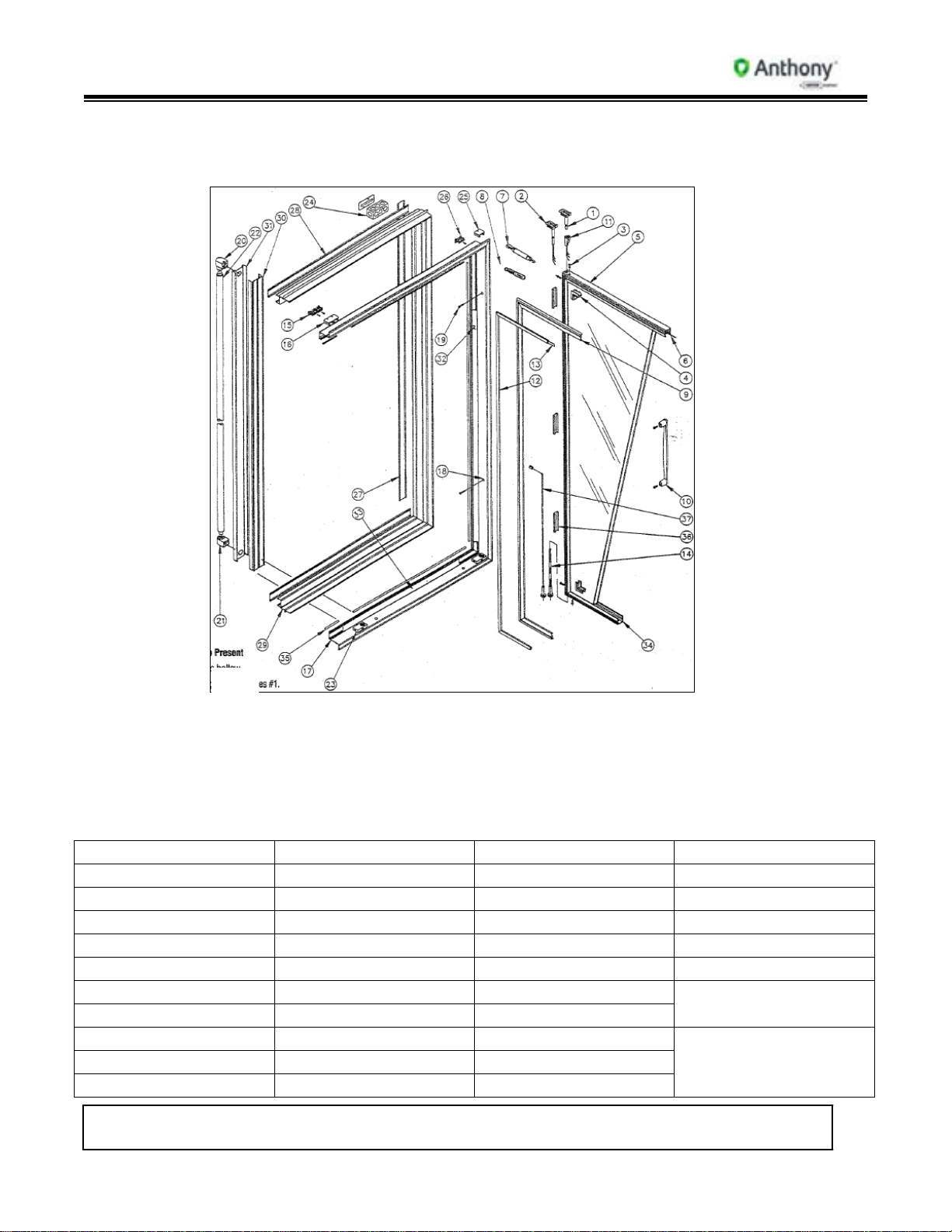

s: 199

1 to

Description

Description

Description

Description

1. Hinge Pin

11. Female Receptacle

21. Bottom Lamp Socket

31. Light Fixture

2. Molded Hinge Pin (’91)

12. Magnetic Gasket

22. Bulb

32. Contact Plate

3. Corner Screw

13. Magnet

23. Torquemaster

33. Contact Plate

4. Corner Piece

14. Torque Rod

24. Junction Box

34. Door Extrusion

5. Door Extrusion

15. Double Socket

25. Single Receptacle

35. Retainer

6. Heater Wire

16. Double Receptacle

26. Single Socket

7. Hold-Open (’86-90)

17. Frame Extrusion

27. Raceway Cover

8. Hold-Open (’90)

18. Installation Hole

28. Raceway Cover

9. Door Cover

19. Installation Screw

29. Raceway

10. Door Handle

20. Top Lamp Socket

30. Frame Mullion

1. Models 101 & 2100 Door & Frame – Reversible Parts Placement

(Start 10/89)

Change Present

1. Hinge Rail is hollow.

2. Use #2 Hinge Pin; replaces #1.

3. Delete #11 Receptacle.

4. Single hinge side Access Hole in center of Hinge Rail only. Delete #36.

36. Access Hole Cover

Plate

37. Torque Rod (Right

Angle)

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 7 of 95

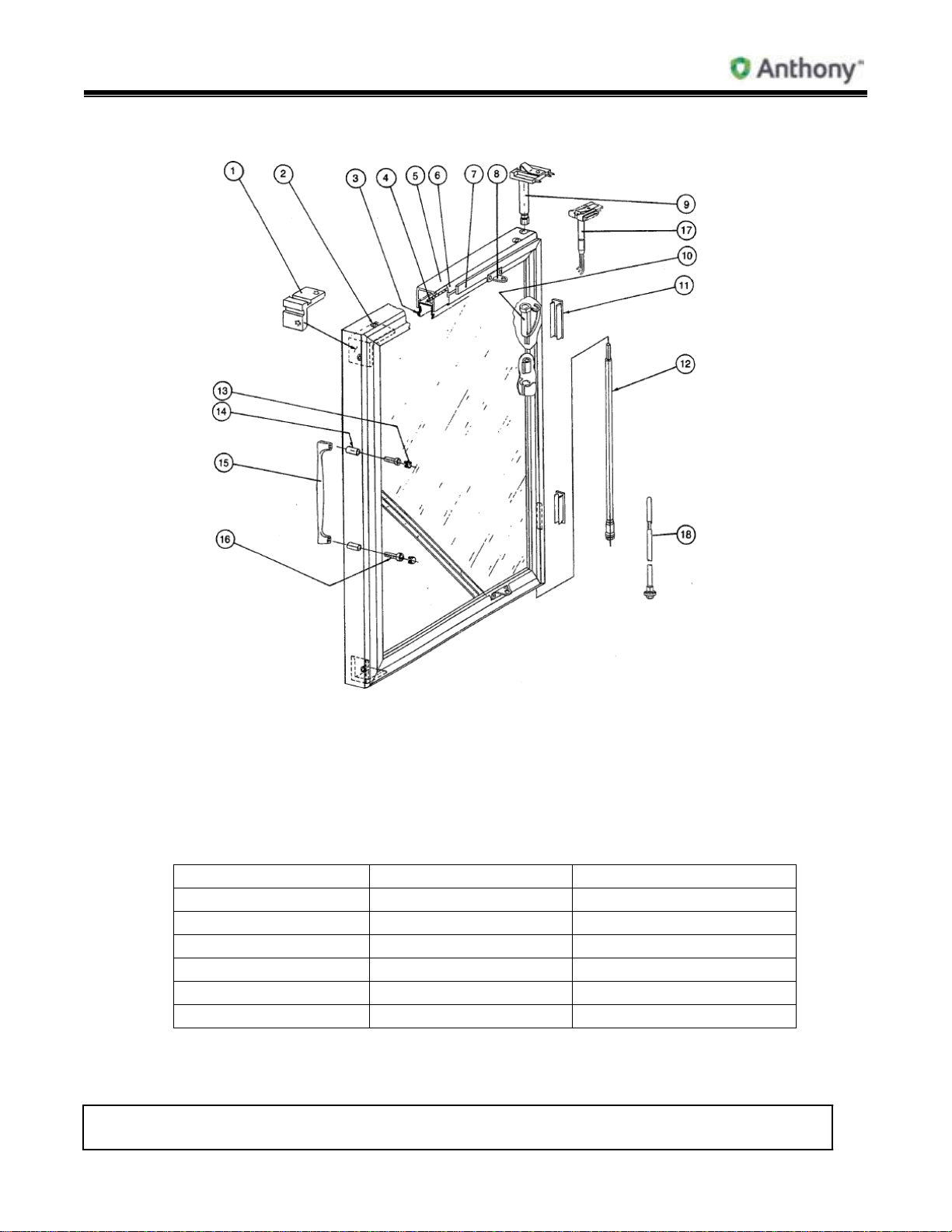

Description

Description

Description

1. Corner Piece

7. Gasket

13. Cap

2. Corner Screw

8. Camel Back

14. Access Tube

3. Glazing Channel

9. Hinge Pin

15. Handle

4. Heater Wire

10. Receptacle

16. Handle Screw

5. Door Rail

11. Cover

17. Molded Hinge Pin

6. Plastic

12. Torque Rod

18. Torque Rod

2. Models 101 & 2100 Reversible Door Parts Placement (1989 to 1991)

Changes: 1991 to Present

1. Hinge Rail is hollow.

2. Use #17 Hinge Pin; replaces #9.

3. Delete #10 Receptacle.

4. Use #18 Torque Rod; replaces #12

5. Single hinge side Access Hole in center of Hinge Rail only. Delete #11.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 8 of 95

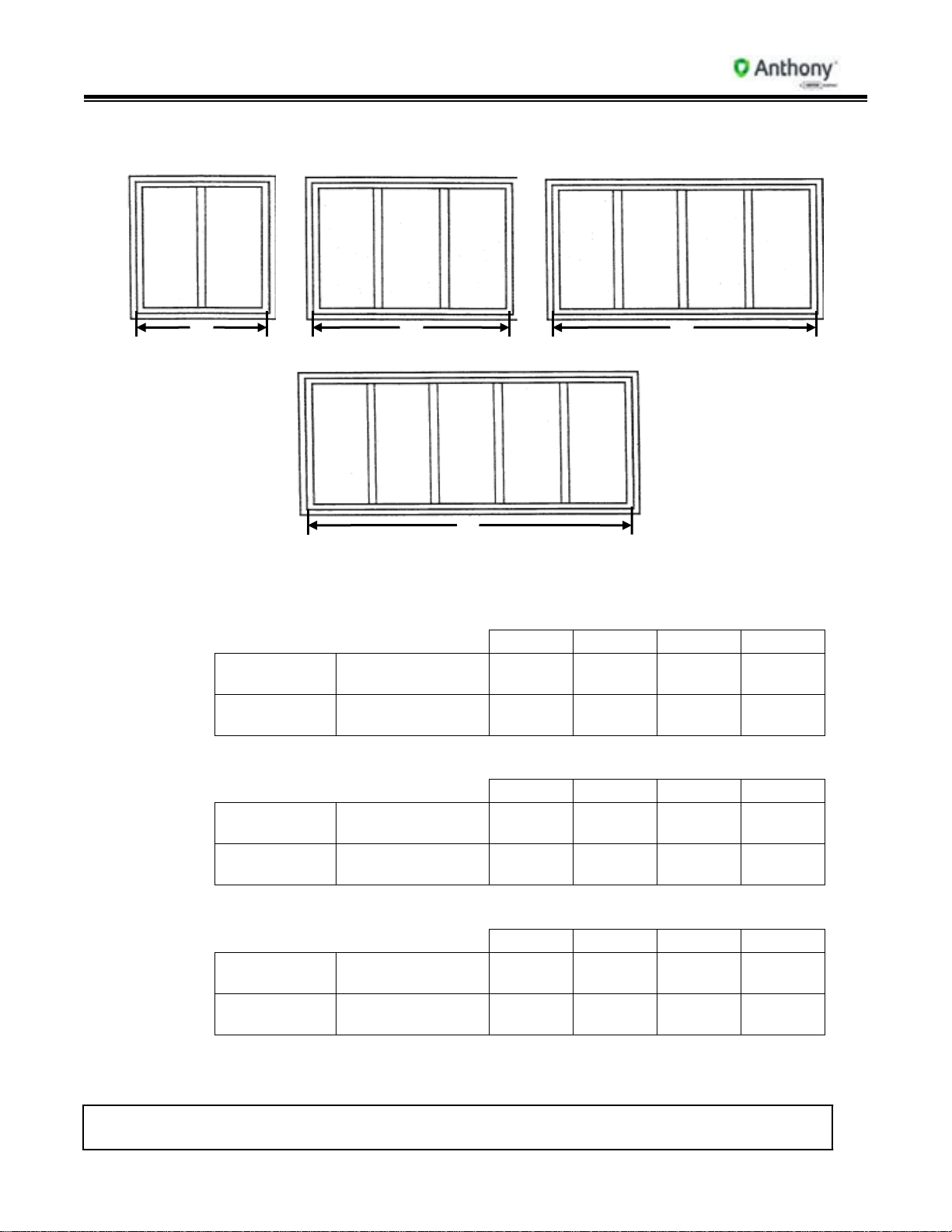

A B C D

MULLION

NET OPENING

FLANGE

NET OPENING

A B C D

MULLION

NET OPENING

FLANGE

NET OPENING

A B C D

MULLION

NET OPENING

FLANGE

NET OPENING

3. Models 101 & 2100 Standard (Before 7/94) Frame Net Opening Widths

A B C

TWO-DOOR FRAME THREE-DOOR FRAME FOUR-DOOR

FRAME

3.1. Frame Width Data

FIVE-DOOR

3.1.1. 24” Door (Catalog Size) 23-3/16” Actual Door Width

ENDLESS

FINISHED FRAME

D

FRAME

48-5/8” 72-3/8”

96-1/8” 119-7/8”

FULL

3.1.2. 26” Door (Catalog Size) 26-3/8” Actual Door Width

FINISHED FRAME

48-7/8” 72-5/8”

96-3/8” 120-1/8”

ENDLESS

FULL

FINISHED FRAME

FINISHED FRAME

55-1/4” 82-3/16” 109-1/8” 136-1/16”

55-1/2” 82-7/16” 109-3/8” 136-5/16”

3.1.3. 30” Door (Catalog Size) 29-7/8” Actual Door Width

ENDLESS

FULL

FINISHED FRAME

FINISHED FRAME

62”

92-7/16” 122-7/8” 153-5/16”

62-1/4” 92-11/16” 123-1/8” 153-9/16”

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 9 of 95

CATALOG DOOR HEIGHT

75” 73” 67” 63”

FINISHED FRAME

74-13/16”

72-13/16”

66-13/16”

64-9/16”

NET OPENING HEIGHT

75” 73” 67”

64-3/4”

CATALOG WIDTH

CATALOG HEIGHT

24” 26” 30” 75” 73” 67” 63”

ACTUAL SIZE

23-3/16”

26-3/8”

29-7/8”

73-1/16”

71-1/16”

65-1/16”

62-13/16”

4. Models 101 & 2100 Standard Frame Net Opening Heights

4.1. Frame Height Data

4.2. Door Size

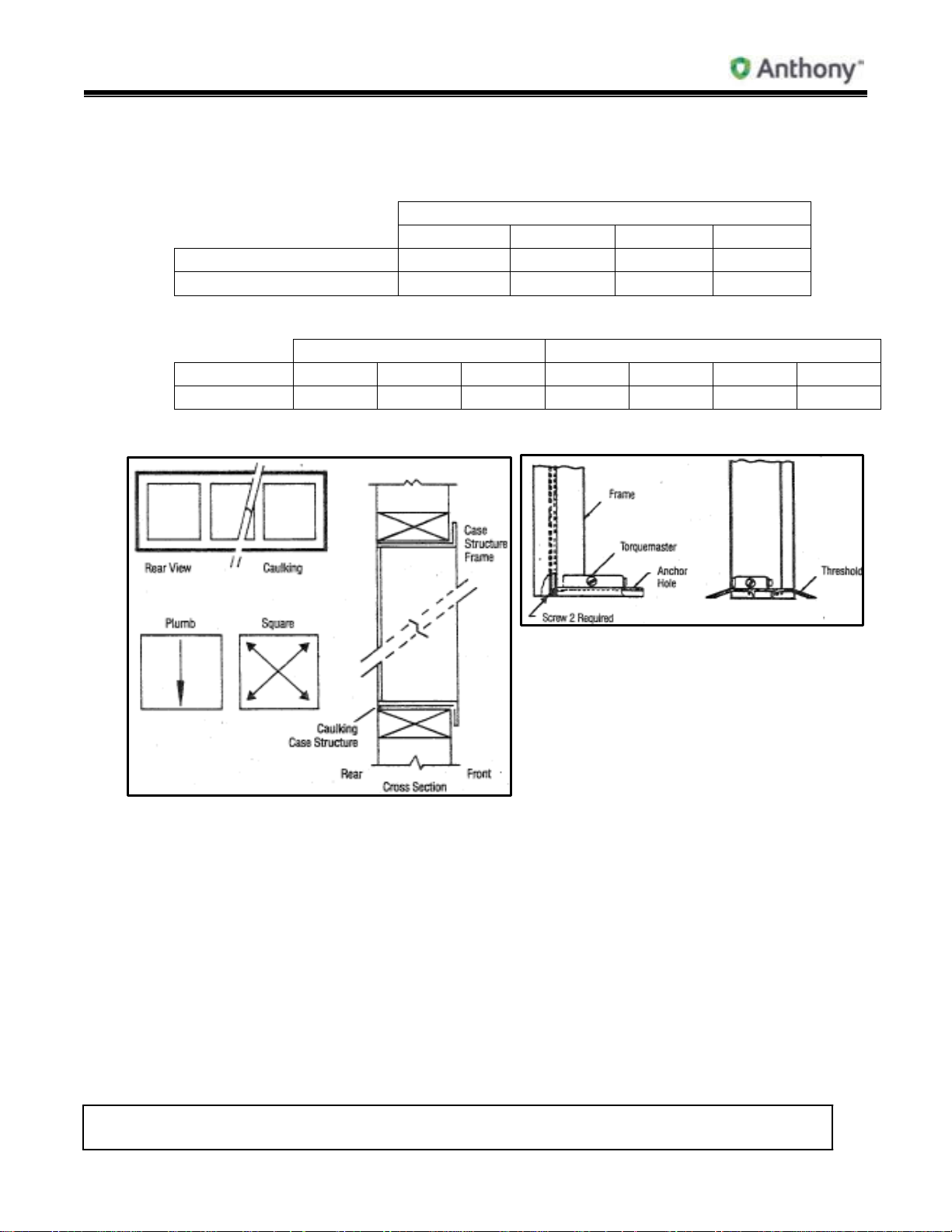

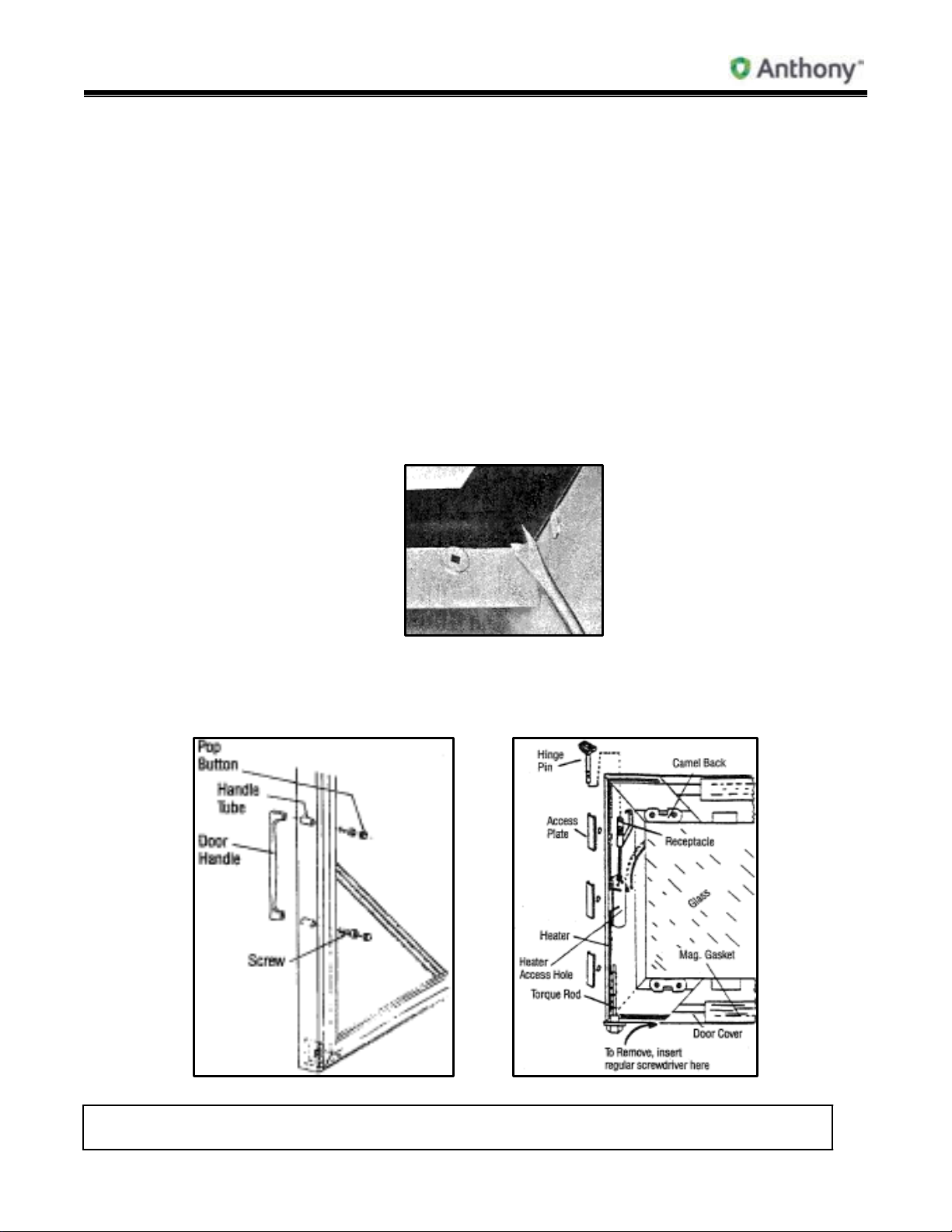

5. Models 101 & 2100 Frame Installation

1. Read instructions completely before installing frames.

2. Openings must conform to net openings listed in Price Book or other.

3. Check size of finished frame to net opening.

4. Do not force frame into tight opening.

5. Check net opening for plumb and square as shown. Sill must be level left to right and

front to back.

a. Jambs, header and sill should be wood for a secure installation

b. Anthony door frame needs a sill of at least 1-1/2” for proper installation.

Frame Installation Pass-Thru Cross Section (w/wo Threshold)

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 10 of 95

6. Set frame in net opening. For safety, partially install wood screws in top of frame. Do

not tighten. Torquemaster (silver rectangular box) goes at bottom of frame; hinge pin

to top of frame.

7. Check frame for square, as shown. Shim as necessary. Ensure that shims are placed

as close to installation holes as possible. When shimming is necessary, shim top and

bottom and/or left end of frame and right end of frame to maintain square of frame in

net opening.

Continuous Lineup Frames:

8. Set next frame into case opening and snug frame against right side of first frame.

9. Square and plumb second frame. For safety, partially install wood screws in top of

frame.

10. Insert sex bolts through right side of first frame, into left side of second frame.

Tighten until frames are pulled together.

11. From inside of case, caulk all four sides of frame, between frame and opening.

12. Starting with frame sill, install mounting screws and tighten, then do sides and top.

Do not over-tighten top screws, as this will bow frame.

13. From inside the case, re-check caulking.

6. Frame Divider Board Installation (Prior to 1993)

Instructions are for multiple full flange frame lineups.

Frames are shipped with divider board taped to end of frame.

Divider board is pre-cut to given net opening height. For example, a 75” net opening will

get a 75” divider board, and a 67” net opening will get a 67” divider board.

If net opening height varies, make up the difference with a solid shim.

1. Set frame into case opening and push frame tight against left side of opening. Square

and plumb frame. Install installation screws on bottom of frame, left end of frame and

top of frame.

2. Insert divider board behind flange on right side of frame. Toenail divider board to sill

and header, if possible. (Metal cover plate is on customer side.) Screw right end of

frame to divider board.

3. Set next frame into net opening and snug frame against divider board. Install screws

through left side of frame into divider board.

4. When adding divider boards and frame sections, always make sure frames are plumb

and square.

5. Continue adding frames and divider boards to complete line-up.

6. Divider boards must be snug between sill and header.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 11 of 95

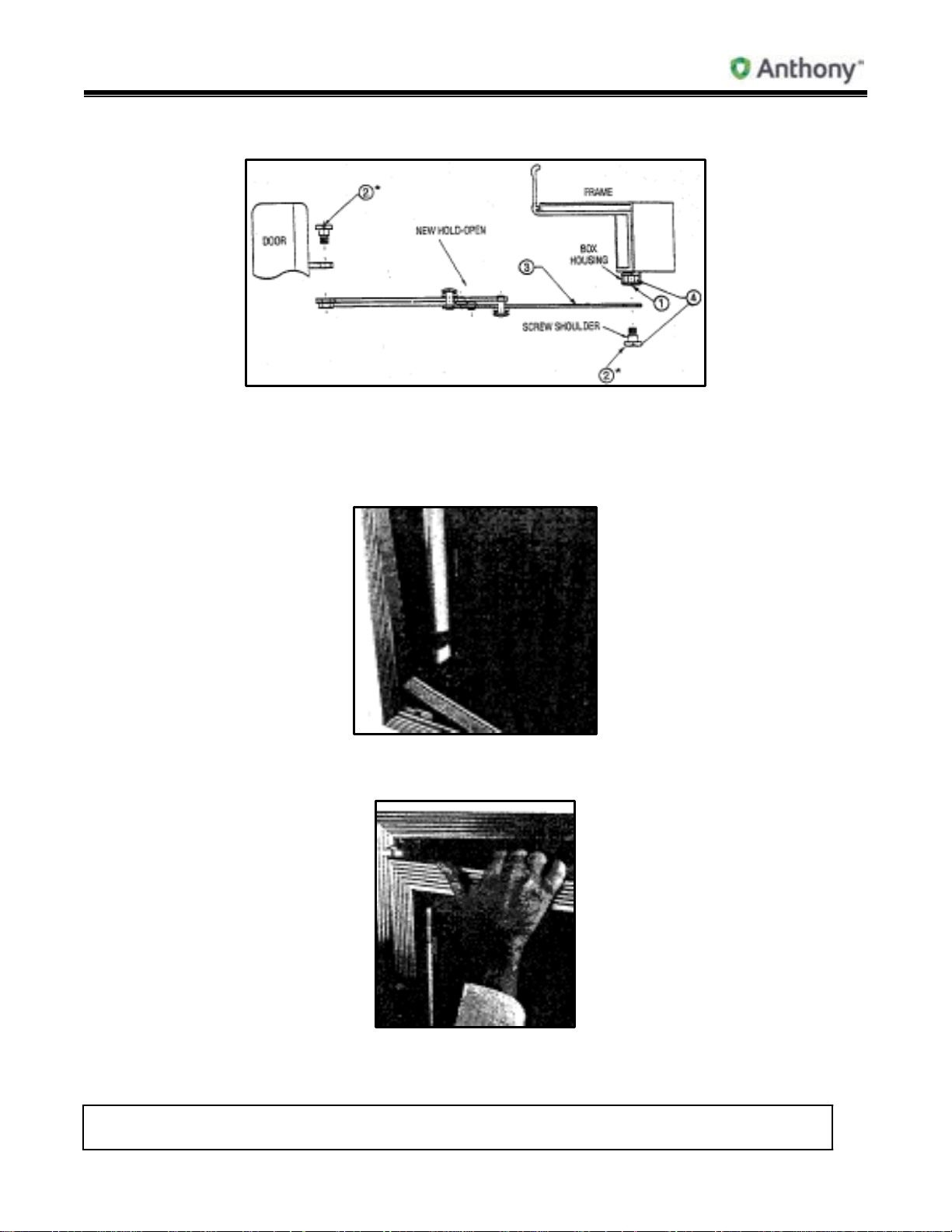

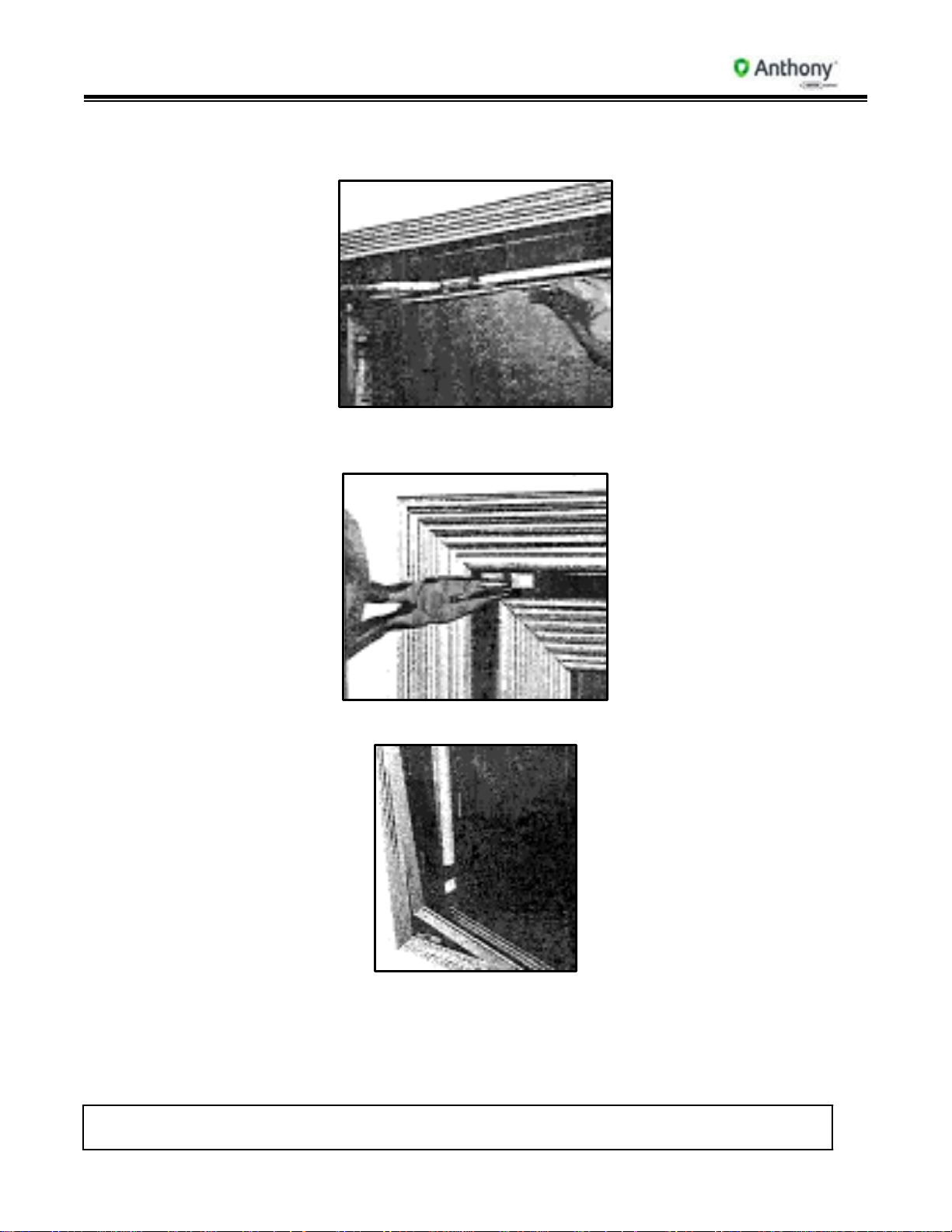

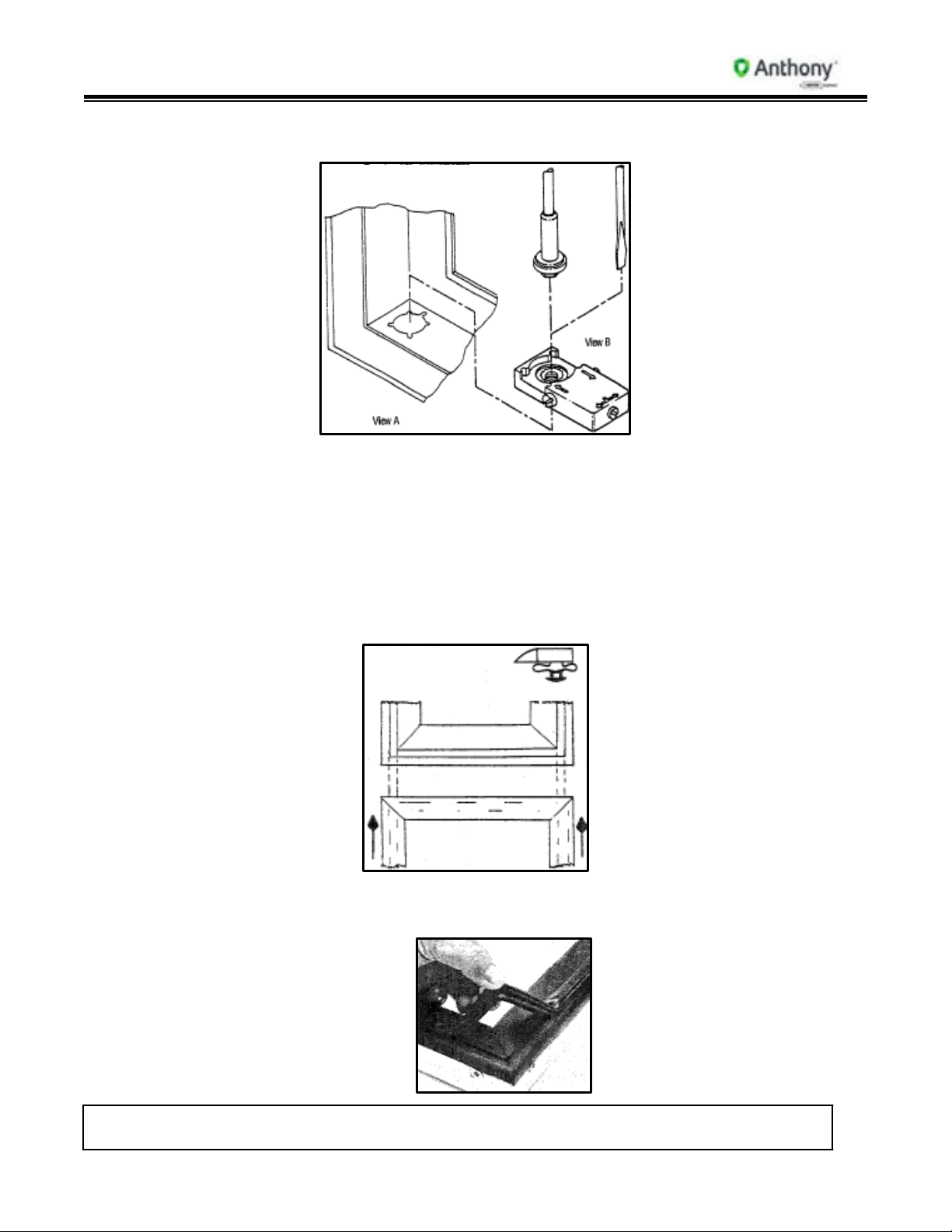

7. Reversible/Cordless Door & Hold-Open Installation

Model 101 and 2100 Hold-Open

Note: Replace spare shoulder screw (#2) in spare box housing nut (#4) when

installing or reversing a door.

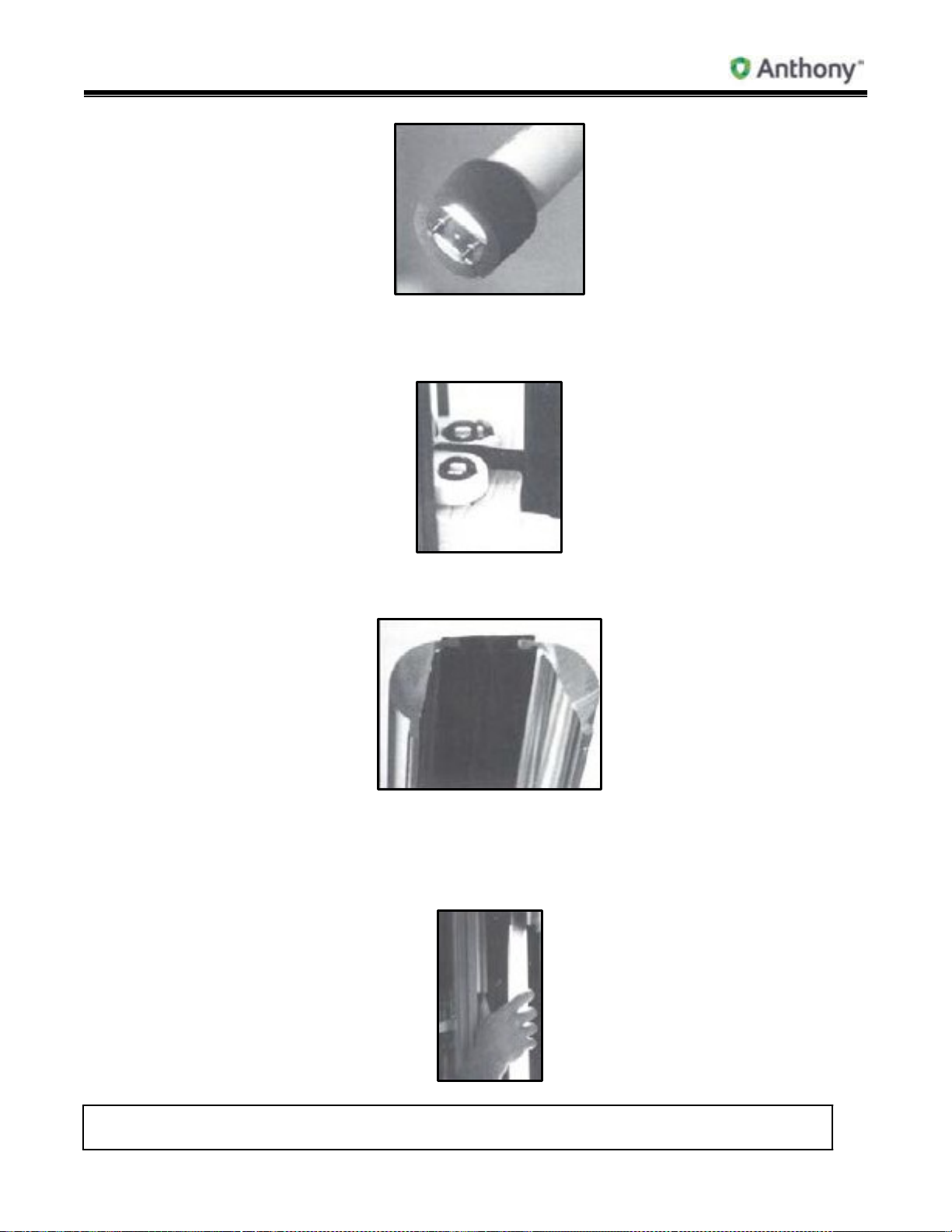

1. Align door with torque rod and insert into the Torquemaster socket at base of door.

2. Engage door with hinge pin plug inserted into hinge pin plug receptacle at top of

frame.

Instructions

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 12 of 95

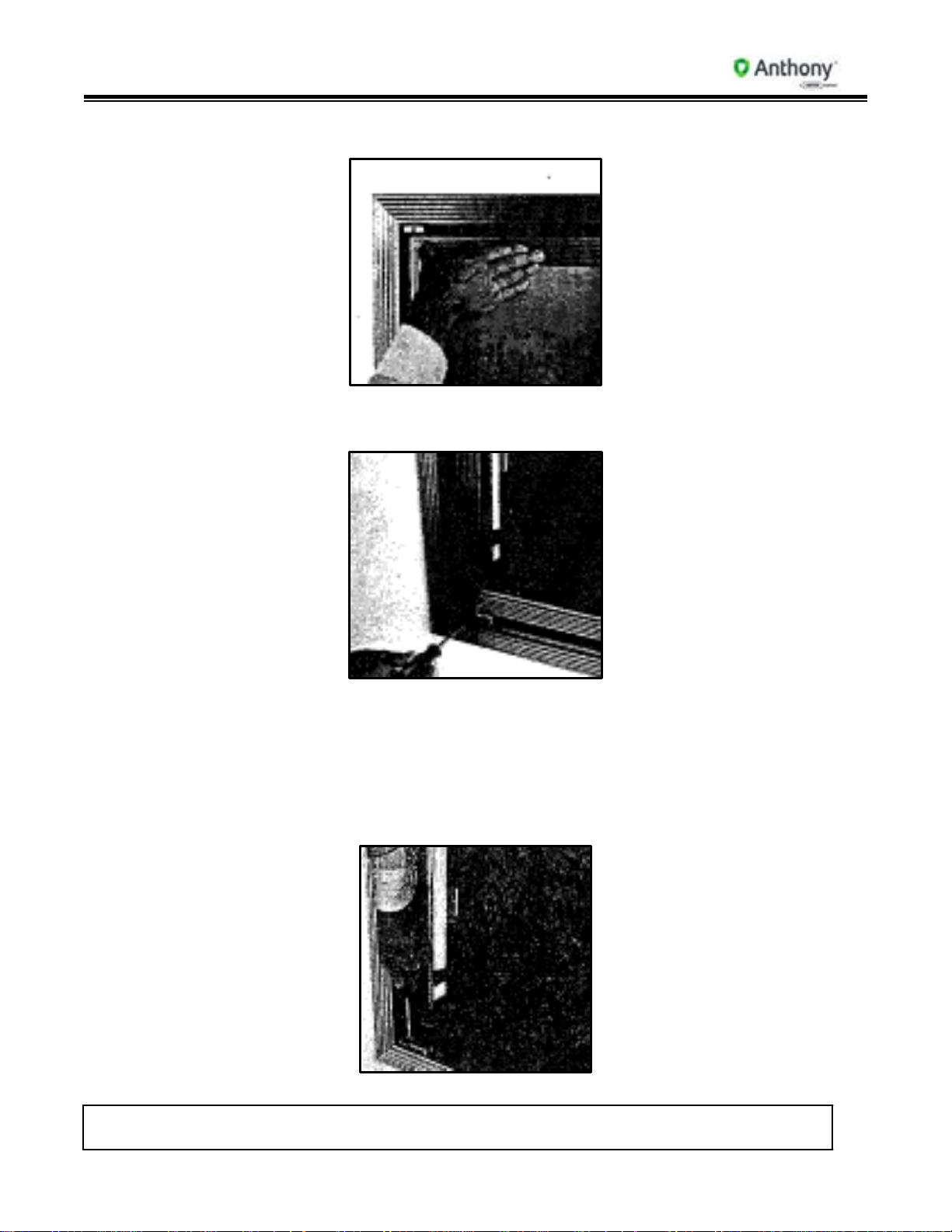

3. Push door into top frame with thumb until hinge pin plug snaps into place.

4. Adjust closing force by turning the screw on the front of the Torquemaster with a flathead screwdriver. Turn counter-clockwise to tighten, clockwise to loosen.

5. If necessary to square door in frame opening, turn end screw on Torquemaster

(marked SAG ADJ) with a flat-head screwdriver.

6. Do not use power tools for installation or removal.

8. Reversing Frame Hardware

1. Remove Torquemaster by turning center screw counter-clockwise.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 13 of 95

2. Remove back cover plate with flat-head screwdriver and insert into opposite

Torquemaster hole. Replace and re-install Torquemaster in new position.

3. Insert back safety cover plate into opposite side hinge receptacle.

4. Do not use power tools for installation or removal.

9. Door Reversing Instructions Models 101 & 2100 (1989-1991)

1. Release tension on Torquemaster by turning front screw clockwise.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 14 of 95

2. On Hold-Open (1990 to Present), remove shoulder screw from camel back hinge on

back of door (Model 101 and 2100 Hold-Open Instructions).

3. Remove hinge pin plug from frame by inserting needle-nose pliers into hinge pin plug

1/8” hole. Compress and pull hinge pin plug away from frame.

4. Lift door out of Torquemaster. Lean door on its side against a stable surface.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 15 of 95

5. Remove hinge pin plug access cover from hinged side of door.

6. Disengage safety snap from female plug, remove male plug from door and insert in

opposite end of door.

7. Remove torque rod by sliding it out bottom of door and insert in opposite end of door.

8. Model 101 & 2100 have only one female receptacle. When reversing door, also

reverse receptacle. Pull receptacle from one end and feed back down through

opposite end.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 16 of 95

9. Carefully replace hinge pin access covers.

10. Do not use power tools for installation or removal.

11. See Model 101 & 2100 torque rod below.

10. Door Reversing Instructions (1991 to Present)

Door Quick Disconnect and

1. Reverse door hardware.

a. Remove cover plate from center hinge side of door.

b. Disconnect hinge pin connectors from door heater and/or glass heater connectors.

c. Pull hinge pin out through top of door.

Reversing

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 17 of 95

d. Remove torque rod from bottom of door; pull rod down and out.

e. Insert torque rod in opposite end of door.

f. Insert hinge pin in opposite end of door.

g. Plug in hinge pin connectors to door heaters and/or glass heaters.

2. Wiring Instructions:

Heated Glass:

a. If glass is heated, unplug Black and White lead wires from glass.

b. To re-connect heated glass, plug in Black and White lead wires coming off heater

loom to Black and White lead wires from glass.

Non-Heated Glass:

a. Connect Black or Red lead wires from hinge pin to Black or Red door heater lead.

b. Connect White lead wire from hinge pin to White door heater lead.

4. Re-install door.

3. Replace hinge side cover plate.

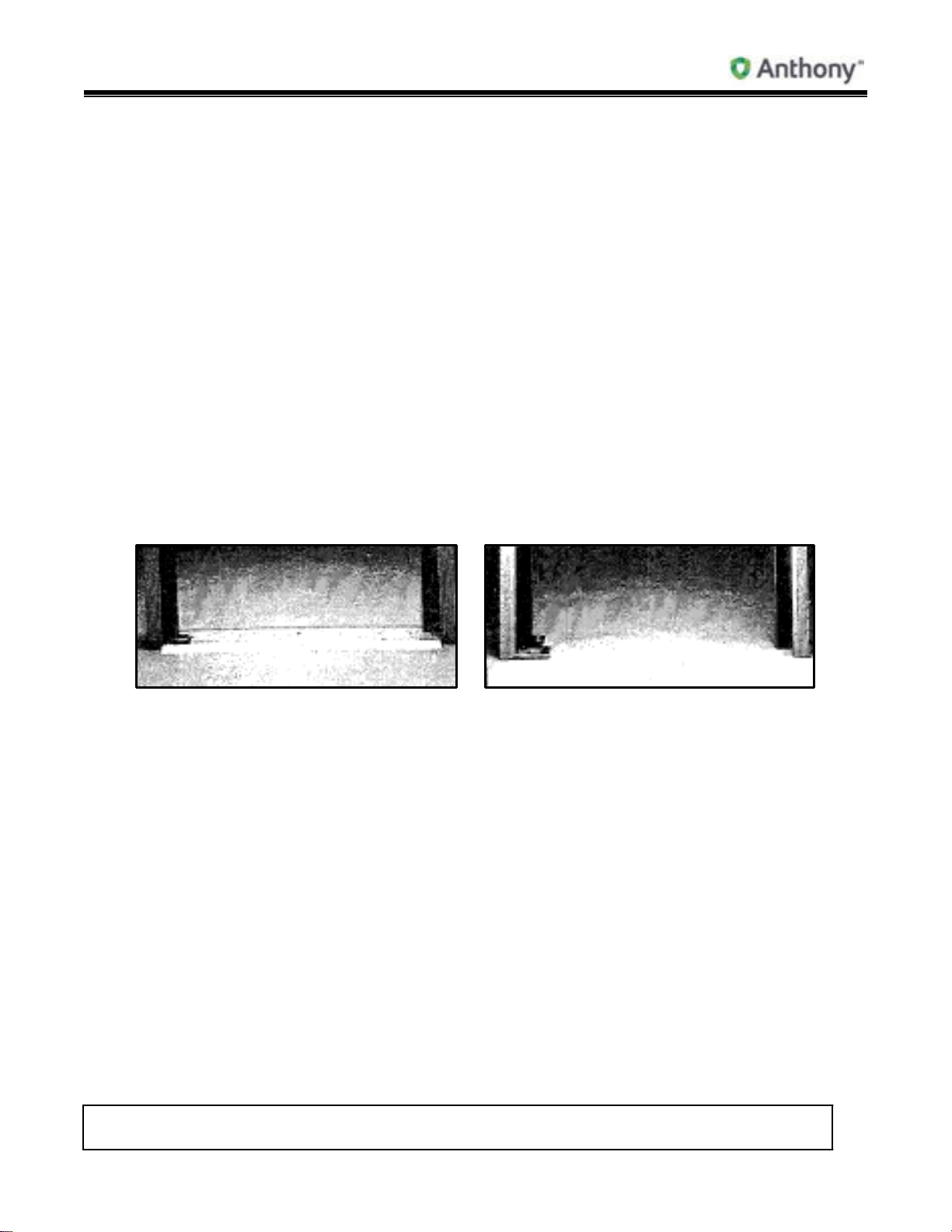

11. Models 103, 105, 107, 2125, 2127 & 2130 Pass-Thru Installation

With Threshold Without

Note: If a roll-a-way cart is included in order, it must be behind the door before

installing frame.

1. Refer to Frame Installation instruction to install frame.

2. When threshold is desired, drill and tag on pre-drilled mounting holes only.

3. For installation of door and hold-open, use Reversible/Cordless Door & Hold-Open

Installation instructions.

4. With door in closed position, adjust floor wiper seal to fit flush with door and/or slab.

Turn screws clockwise to tighten and counter-clockwise to loosen.

Threshold

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 18 of 95

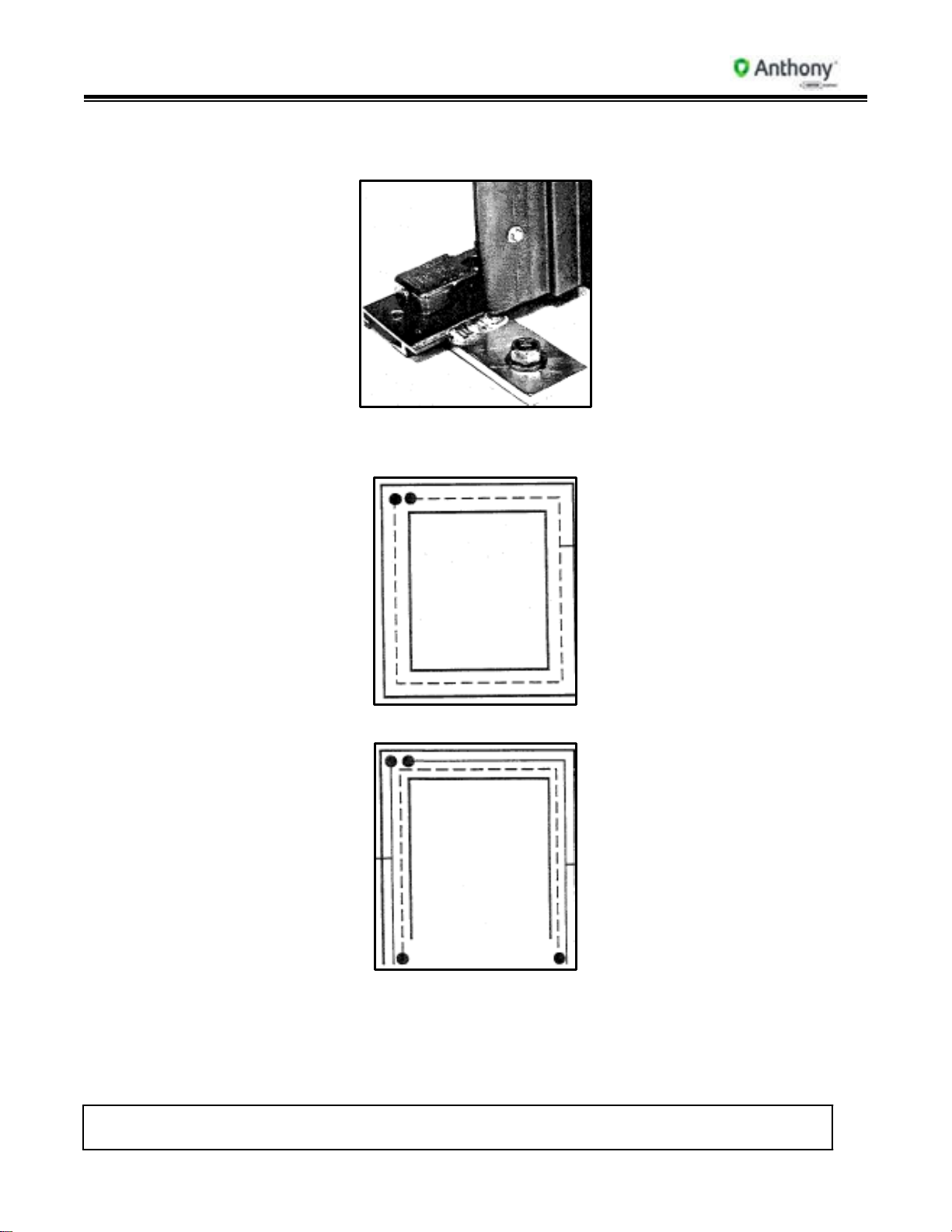

5. For additional bottom support, Anthony Pass-Thrus are equipped with a base plate

and two special floor anchor bolts.

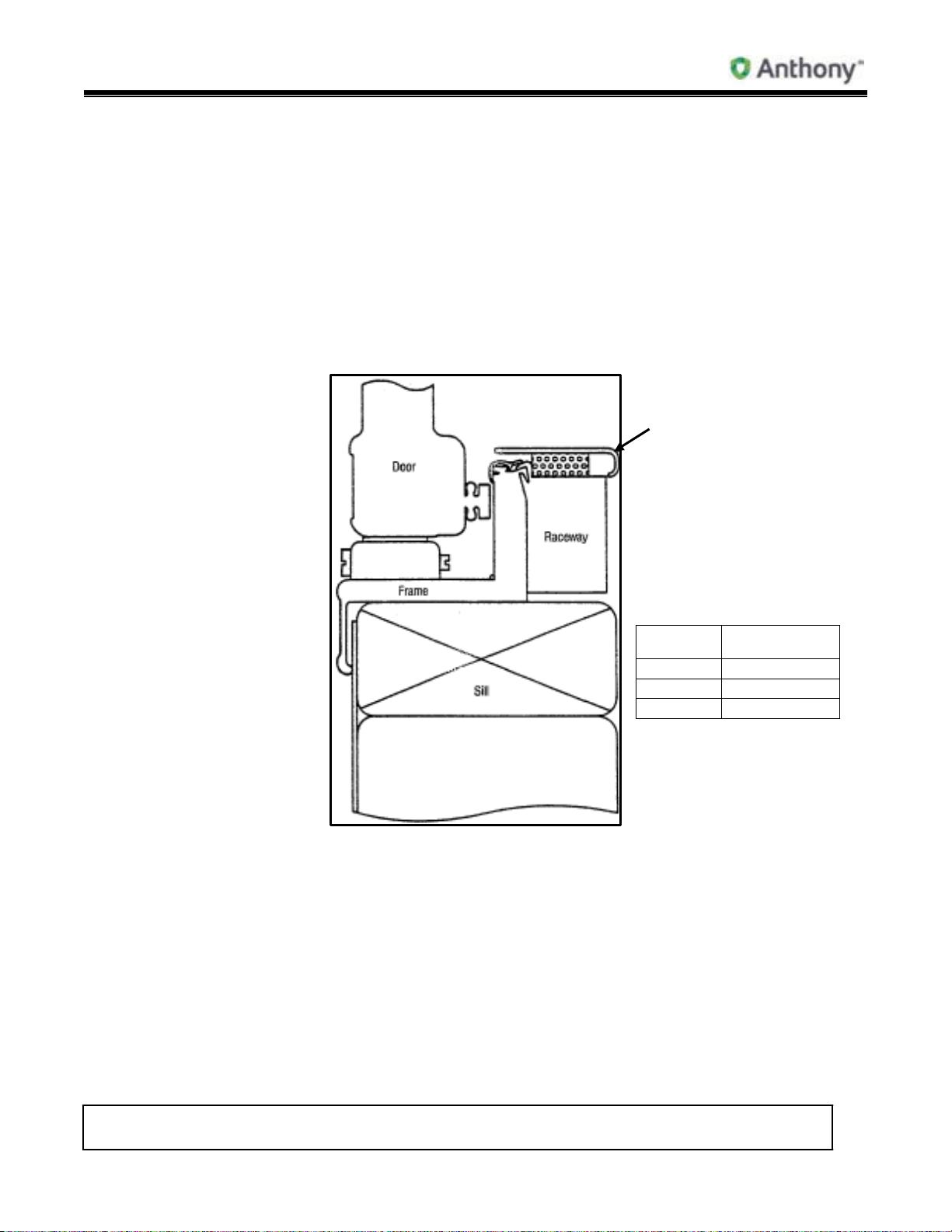

6. Pass-Thru Frame Wiring Diagrams

a. With Threshold

Heater Wire

b. Without Threshold

White

Lead Wire

Black

Lead Wire

11.1. Pass-Thru 101 Model Numbers

1. Model 103: All glass or all solid panel.

2. Model 105: 1/3 glass, 2/3 solid panel.

3. Model 107: All glass with Roll-A-Way cart.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 19 of 95

DOOR SIZE

30”

26-3/4”

11.2. Pass-Thru 2100 Model Numbers

1. Model 2130: All clear glass with colored border, or all glass with solid color.

2. Model 2125: 1/3 clear glass, 2/3 solid color glass.

3. Model 2127: All clear glass with colored border, and Roll-A-Way cart.

12. Frame Sill Plastic protector Installation Models 101 & 2100

1. Set metal protector on sill inside of case between clear opening of frame, with curved

edge over bottom sill plastic.

2. Stick frame guard to top of bottom raceway with two-way tape provided.

Frame Guard

TA0432D

CATALOG

GUARD LENGTH

24” 19-1/2”

26” 23-1/4”

NOTE: Foam 5/16” x 3/4” Polyethelene #8302 unless otherwise specified.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 20 of 95

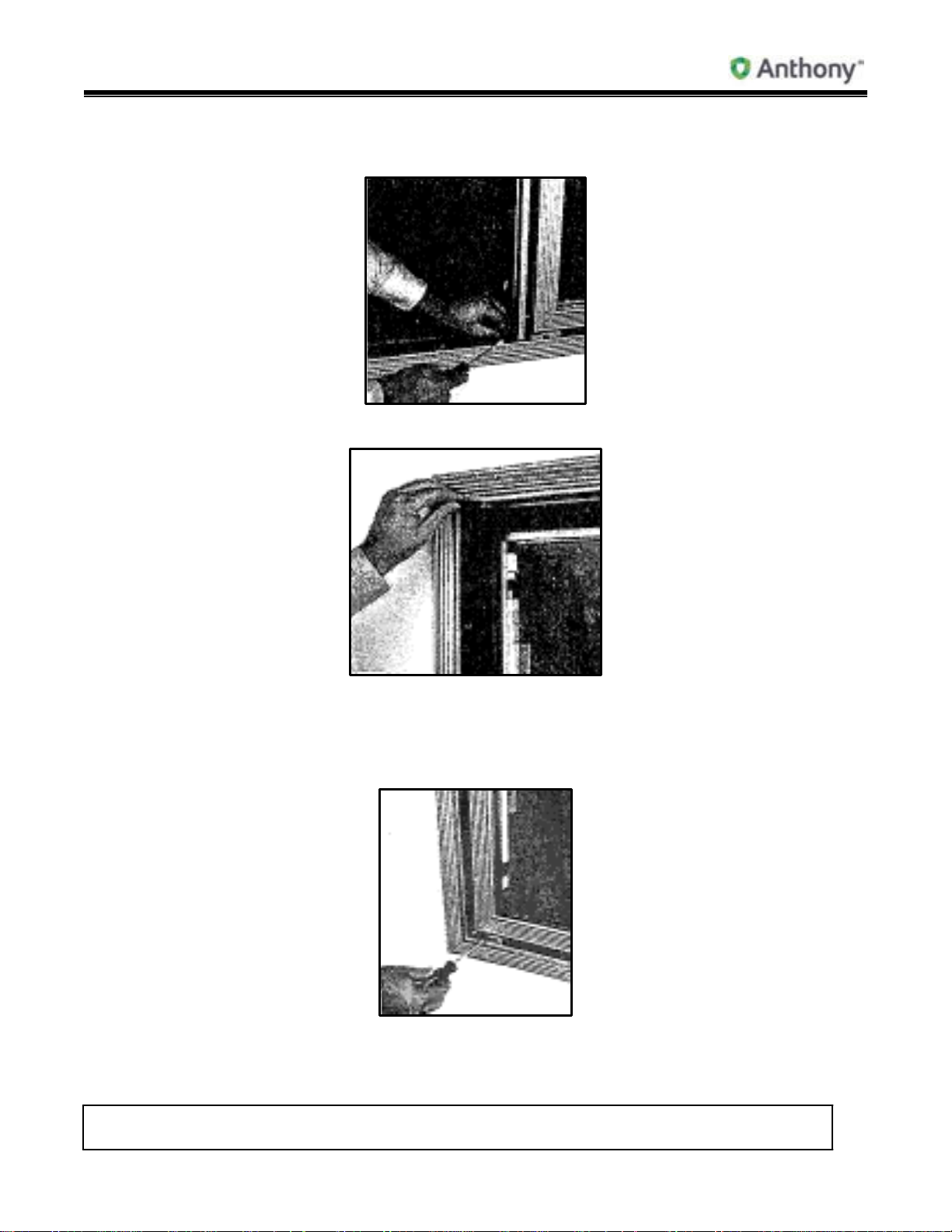

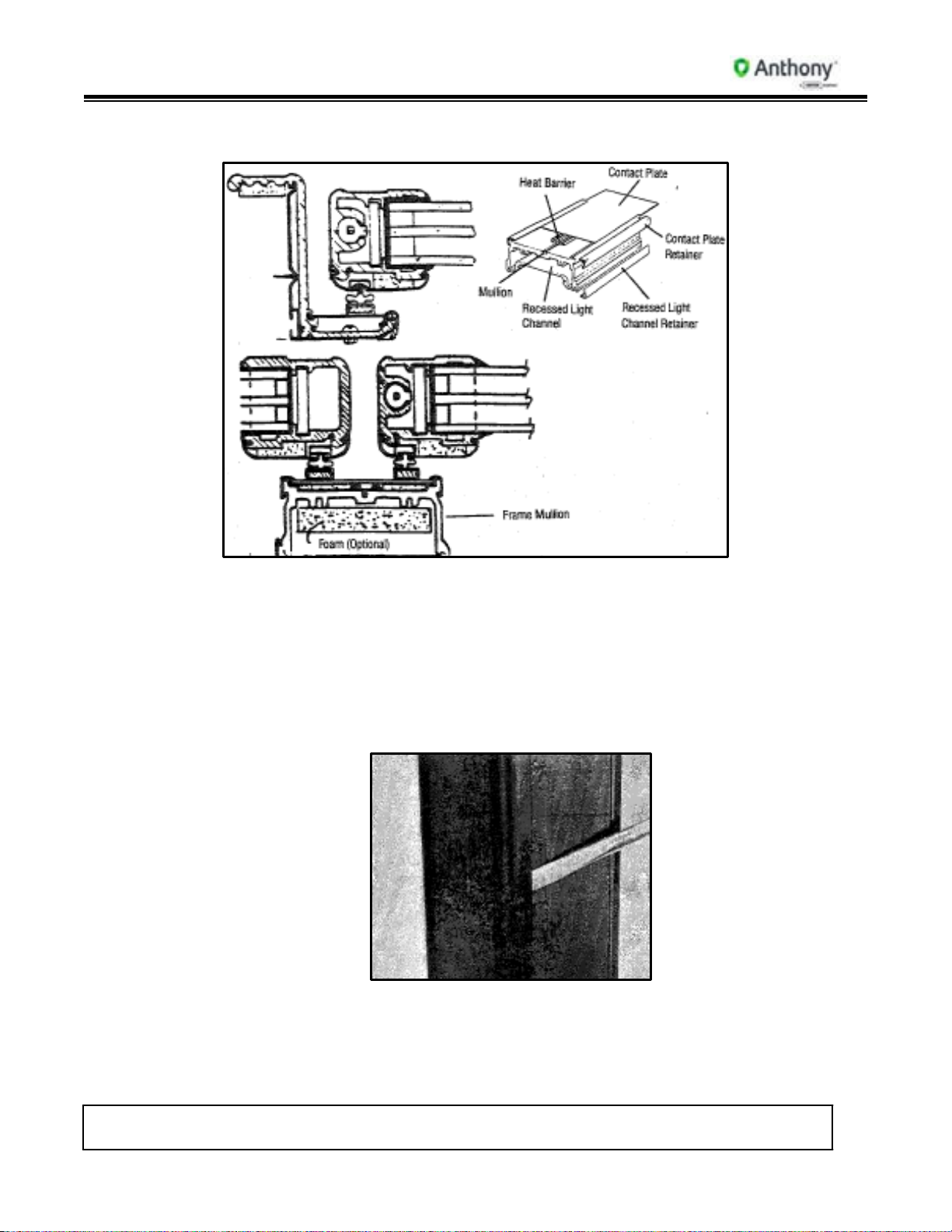

13. Contact Plate and Contact Plate Retainer Replacement

Note: In the illustration above, Model 100R is shown. Model 100FR is the same

except for the mullion and mullion contact plate. Model 101 is the same except

for the mullion cover as shown in Door Quick Disconnect and Reversing.

1. Remove door.

2. To remove contact plate and contact plate retainer, insert flat-head screwdriver under

side back edge of retainer plastic.

Pull up to unsnap retainer from mullion and perimeter of frame. Remove contact plate.

Frame heaters are now exposed.

End and Center Mullion (1987 to Present)

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 21 of 95

3. To replace retainer and contact plate, lay contact plate flat on frame rail, insert top

front leg edge of retainer between the contact plate and the mullion. Snhap retainer on

back edge of mullion and perimeter of frame.

4. Contact plate for prewired ballast frame is 3-7/16” wide. Contact plate for nonprewired frames is 2-1/2” wide.

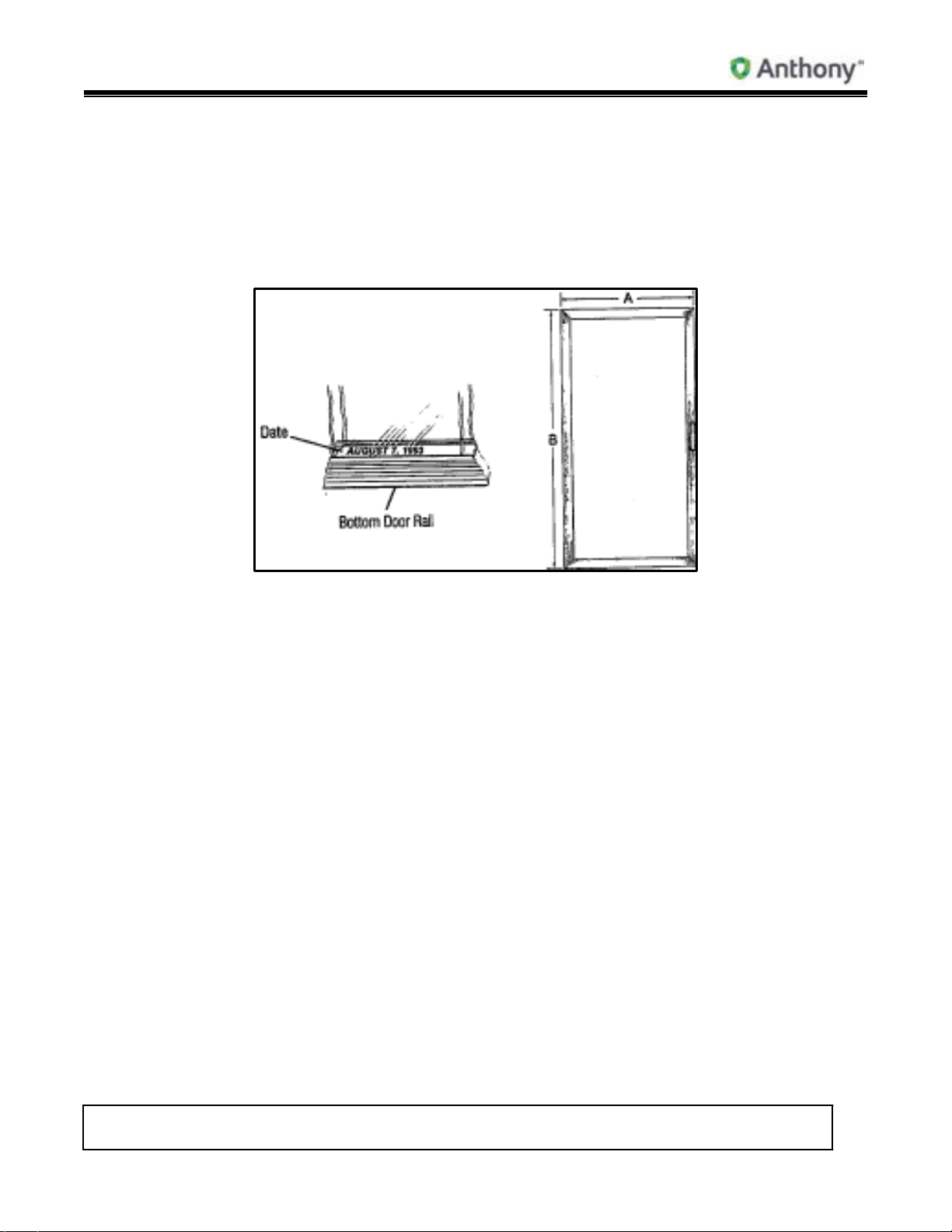

14. Ordering Replacement Doors

Replacement Doors (All Swing Door

1. Specify outside dimensions of door (measure to nearest 1/16”).

2. With or without heaters?

3. Hinge swing; left or right?

4. Specify model: Cooler or Freezer?

5. Specify finish.

6. Specify any custom items in the original order.

7. Specify date of original order and/or Anthony confirmation/invoice number. (Original

manufacture date is stamped on metal spacer bar between panes of glass, as shown

above.

8. With or without locks?

9. Specify voltage.

Models)

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 22 of 95

15. Torquemaster Replacement

Torquemaster

1. Torquemaster is used on all standard production frames.

2. To remove, insert flat-head screwdriver into top center cutout in Torquemaster and turn

screw 1/8” turn. If necessary, insert small flat-head screwdriver between edge of

Torquemaster and frame and gently pry up.

3. Reverse instructions to replace.

16. Door Gasket Replacement

Door

Gasket

1. Remove old gasket by starting in corner, gently pulling gasket away from plastic.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 23 of 95

2. Model 101 To replace gasket, remove top and bottom door plastic and slide the

gasket up the two verticals. Slide top and bottom plastic onto gasket and

replace top and bottom plastic on door rail. Tuck in corners of gasket with

a flat-head screwdriver.

Model 2100 Lay new gasket over track in back of door rail. With a single-edged plastic

roller, roll in the outside edge of door gasket first, then the inside edge.

Tuck in all four corners.

3. Reverse instructions to replace.

17. Door Plastic (Cover) Replacement

1. Starting in corner, gently pull rubber gasket away from door plastic.

2. With gasket removed, insert flat-head screwdriver under outside edge of plastic and

gently pry up. At either end of plastic, run screwdriver the complete length and width of

door rail. With outside edge of plastic released, push plastic toward glass to remove.

3. To replace, insert inside edge of plastic into inside door rail groove. Snap outside edge

of plastic over outside edge of door rail.

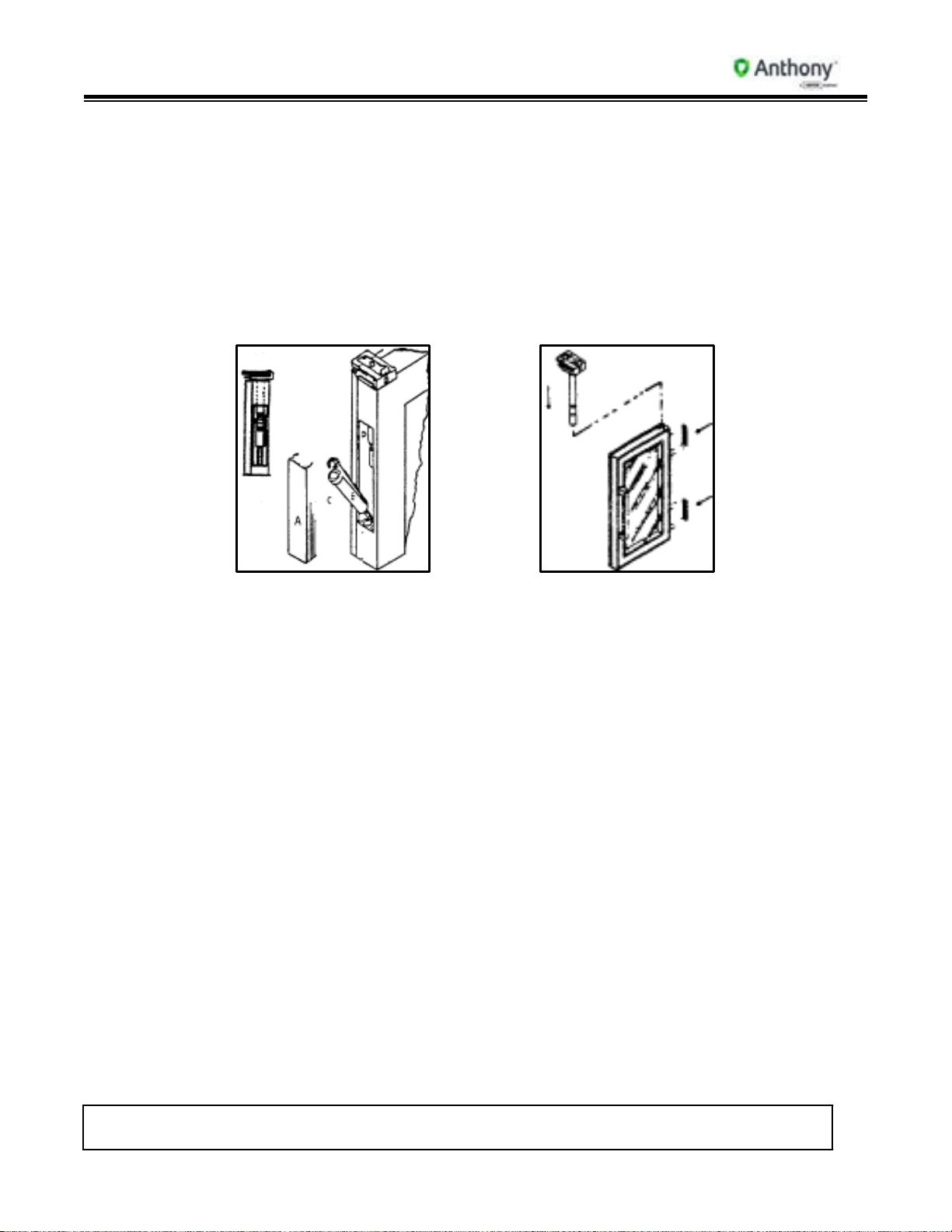

18. Door Cut-Away & Handle Replacement

Handle Replacement Door Cut-Away

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 24 of 95

1. Model 101 Remove plastic hole plug from back of door plastic.

2. Insert 5/32” Allen wrench into access holes and turn screws counter-clockwise to

remove.

3. Reverse instructions to replace handle.

4. Model 2100 Remove screws on side of door rail

5. Reverse instructions to re-install.

19. Side Access Plate Replacement (1989 to 1991)

Hinge Pin and Cover Plate Hinge Pin Removal

Note: Lead Wires: Heater (Black, White), Receptacle (Black, White, Green), Glass

(Black, White).

1. Side access plate is located at top side of door.

2. To remove, insert flat-head screwdriver under edge of cover and lift up.

3. Snap plate into door extrusion to replace.

20. Side Access Plate Replacement (1991 to Present)

1. Access plate is located on the center of the hinge rail (Door Quick Disconnect and Reversing).

2. To remove side access plate, insert small flat-head screwdriver under edge of cover

and lift up.

3. Snap plate into door extrusion to replace.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 25 of 95

21. Door Female Plug Replacement (1989 to 1991)

1. Model 101 Only – Gently insert flat-head screwdriver under edge of top side access

plate and pull up to remove (Hinge Pin and Cover Plate/Door Cut-Away).

2. Unsnap hinge pin from female receptacle.

3. Female plug is installed with additional lead wire. Pull female plug out through access

hole and cut Black, White and Green/Yellow lead wires.

4. Reverse instructions to replace door female plug. Re-wire Black to Black, White to

White and Green/Yellow to ground.

5. Replace side access plate.

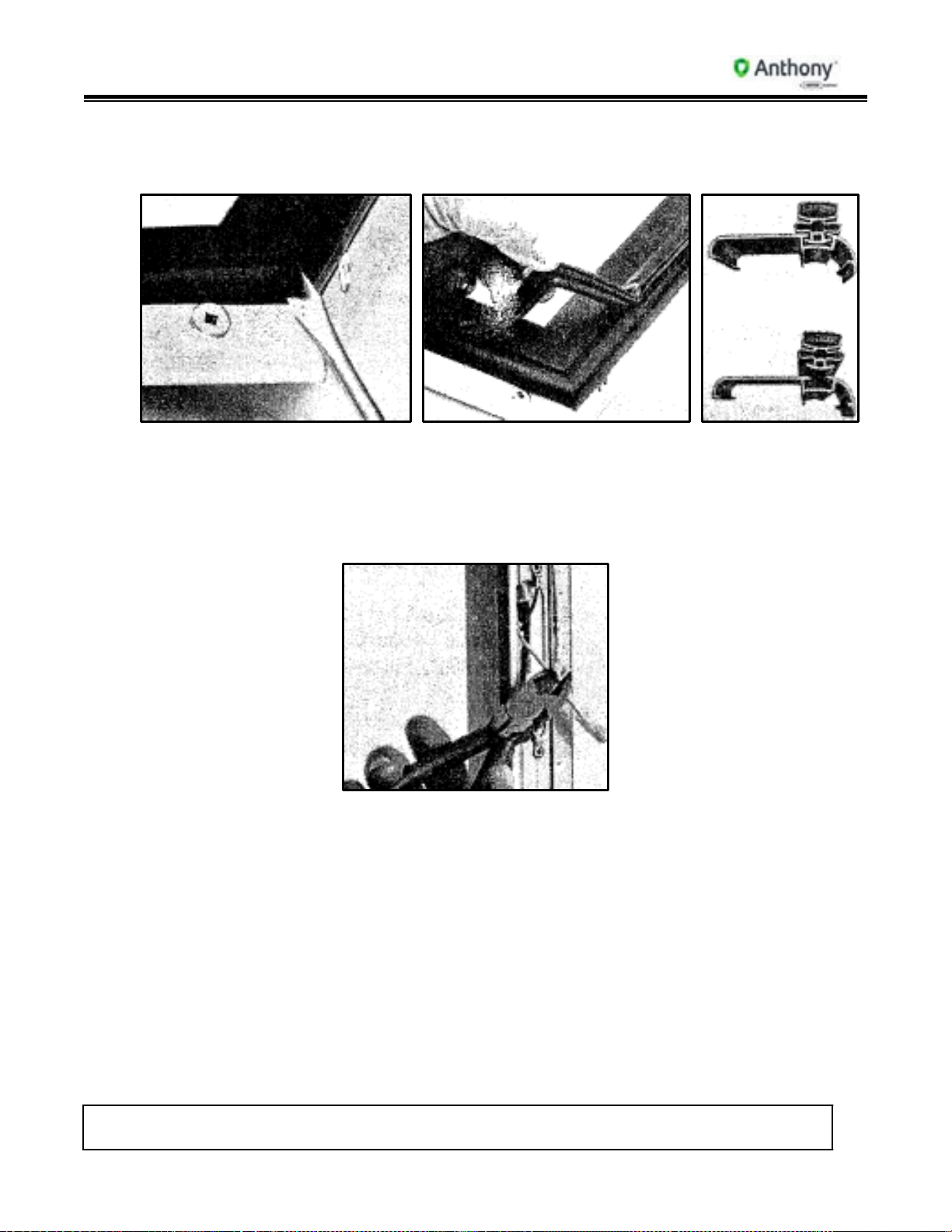

22. Frame Female Plug and/or Socket Replacement (1991 to Present)

Double Station Socket Single Station

Model 100R, 100FR, 101 (1989) Model 100R, 100FR, 101 (1987 to Present)

Note: Double Station Socket Wire Leads – 2 Reds, 2 Whites, 2 Greens

1. Model 101 Only – Frame female plug is removed through front side of frame.

2. Insert small Phillips-head screwdriver into round access hole in face of female plug, and

turn screw counter-clockwise to remove. For double station socket replacement,

remove two screws out through front.

3. Female plug has extra length wire leads in raceway for easy placement.

4. Pull plug out front and cut lead wires: Black-White, and Green/Yellow.

5. Reverse instructions to re-wire: Black to Black, White to White and Green/Yellow to

ground.

Socket

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 26 of 95

23. Door Heater Replacement (1989 to 1991) Model 101 Only

1. Remove door gasket and plastic.

2. Remove side access plate (Door Cut-Away).

3. Unsnap hinge pin from female receptacle.

4. Wiring for the door is done in the center side of hinge rail.

5. To remove heater, cut solid lead wires: Black, White and Green/Yellow (ground).

6. Heater wire lies in track on the back outside edge of door. Pull heater out.

7. If glass is heated, cut Black and White lead wires from glass.

8. Reverse instructions to replace door heater. Wire Black to Black, White to White and

Green/Yellow to ground. If heated glass is used, reconnect glass Black and White lead

wires to heater Black and White lead wires.

24. Door Heater Replacement (1991 to Present) Model 101 Only

1. Remove door plastic and door gasket.

2. Remove center side access plate (Door Quick Disconnect and Reversing).

3. To remove heater, unplug solid lead wires: Black or Red, White and Yellow/Green

(ground).

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 27 of 95

4. If glass is heated, unplug Black and White solid wires from glass.

5. Heater wire lies in track on the back outside edge of door. Pull heater out.

6. Reverse instructions to replace door heater. Plug in Black or Red lead wire from hinge

pin to Black or Red lead wire from heater, White lead wire from hinge pin to White

heater lead and Green/Yellow lead from hinge pin to ground.

Note: If glass is heated, plug in Black and White lead wires coming off heater loom to

Black and White lead wires from glass.

7. Replace side access plate.

8. Replace door plastic and gasket.

25. Hinge Pin Replacement (1989 to 1991)

1. Model 101 - Remove top side access plate (Door Cut-Away).

Note: Lead Wires: Heater (Black, White), Receptacle (Black, White, Green), Glass

(Black, White).

2. Unsnap female receptacle from hinge pin and remove hinge pin out through top door

rail.

3. Reverse instructions to replace.

26. Hinge Pin Replacement (1991 to Present)

1. Model 101 & 2100 - Remove center hinge side access plate (Door Quick Disconnect and

Reversing

).

2. Unplug Black or Red lead wire from hinge pin from Black solid heater wire lead.

3. Unplug White lead wire from hinge pin from White solid heater wire lead.

4. Unplug Green/Yellow (ground) lead wire.

5. If glass is heated, unplug Black and White lead wire on heater loom from Black and

White lead wire from glass.

6. Pull hinge pin out through top of door.

7. Reverse instructions to replace.

27. Wiring Instructions, Heated & Non-Heated Glass (1991 to Present)

1. Heated Glass – Connect Black or Red lead wire from hinge pin to Black lead wire from

glass and Red or Black lead wire from door heater (Door Quick Disconnect and Reversing).

2. Connect White heater lead wire from hinge pin to glass White lead wire.

3. Non-Heated Glass – Connect Black or Red lead wire from hinge pin to Black or Red

door heater lead.

4. Connect White lead wire from hinge pin to White door heater lead.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 28 of 95

5. Replace hinge side cover plate.

6. Re-install door.

28. Torque Rod Replacement (1987 to 1991)

1. To remove torque rod, use flat-head screwdriver. Catch edge of torque rod shaft and

tap rod down and out through bottom of door.

2. Reverse instructions to replace.

29. Torque Rod Replacement (1991 to Present)

1. To remove torque rod, use flat-head screwdriver. Catch edge of torque rod shaft with

screwdriver and tap rod down into place (Door Quick Disconnect and Reversing).

2. To replace, slide end of rod up hinge rail, then insert square shaft of torque rod into

square hole in door rail. Tap into place.

Note: Torque rod has no tip.

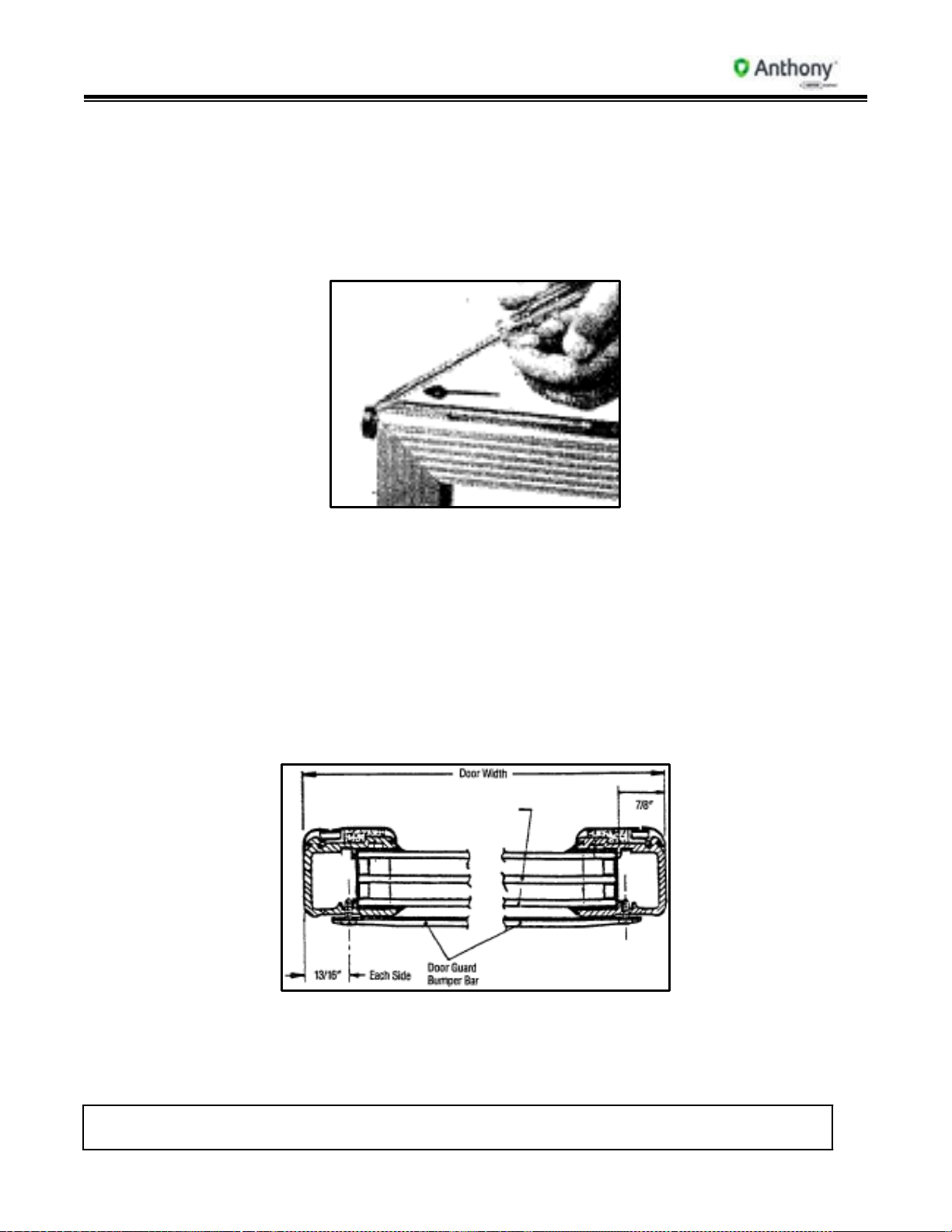

30. Front Bumper Bar Field Installation

Front Bumper

1. Order door guards 1” smaller than actual door width.

2. Specify finish (Gold/Silver).

Bar

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 29 of 95

3. Anthony provides pre-drilled screw holes in bar. Customer must drill a #30 or 1/8” hole

in door rail 13/16” from each side of door rail.

4. Screws for mounting bar are self-tapping. Screws are not to exceed 3/8” in length.

5. Mount bar at desired vertical height to protect door glass.

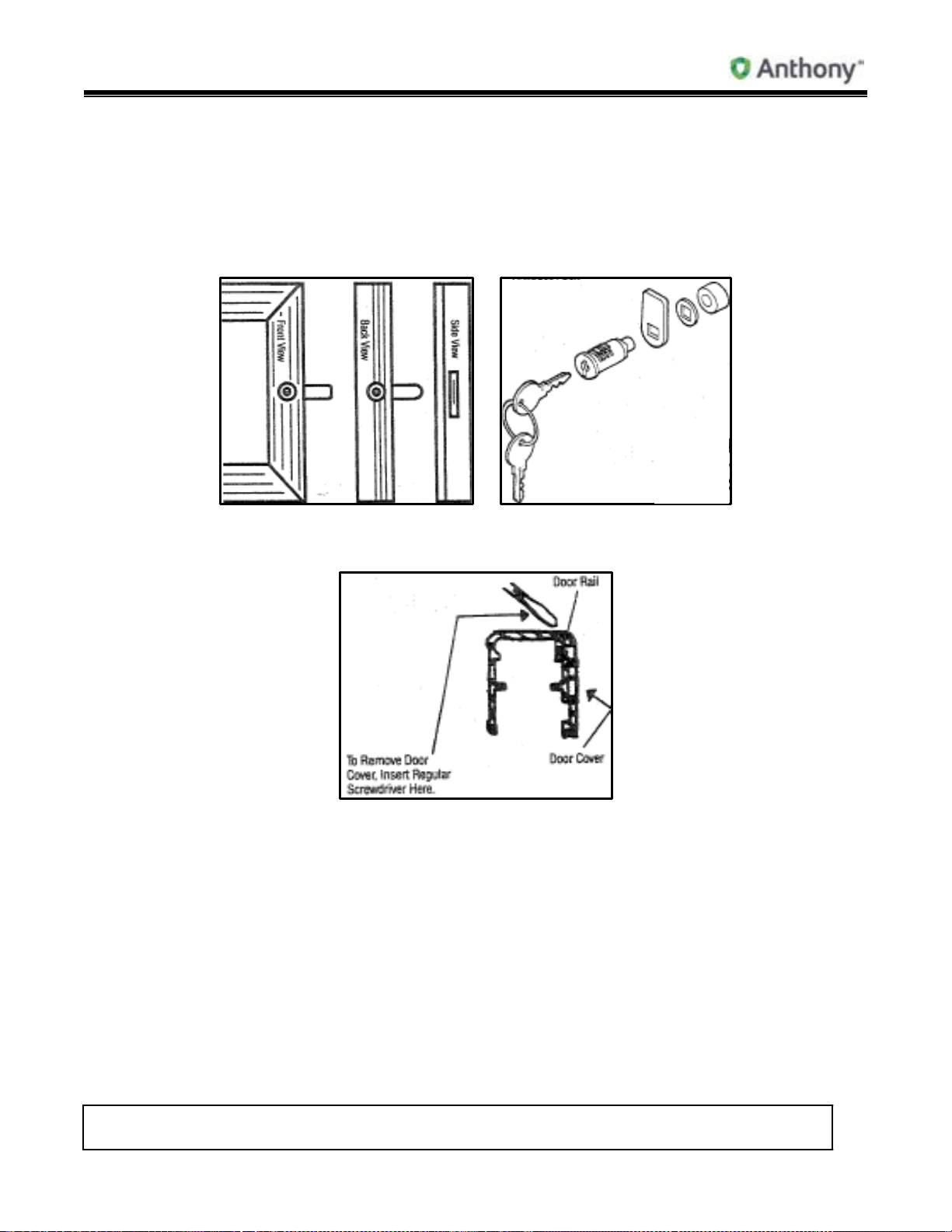

31. Model 101 Door Cylinder Lock Replacement or Repair

Cylinder

1. If lock arm is bent or damaged, remove door plastic from back of door.

2. Insert Allen wrench in lock access hole and remove screw.

3. Pull washers out, then lock arm and replace.

4. Reverse instructions to replace.

5. If cylinder lock is defective, follow instruction #2 above. Insert key into lock and pull lock

out through front of door.

6. Reverse instructions to replace.

Lock

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 30 of 95

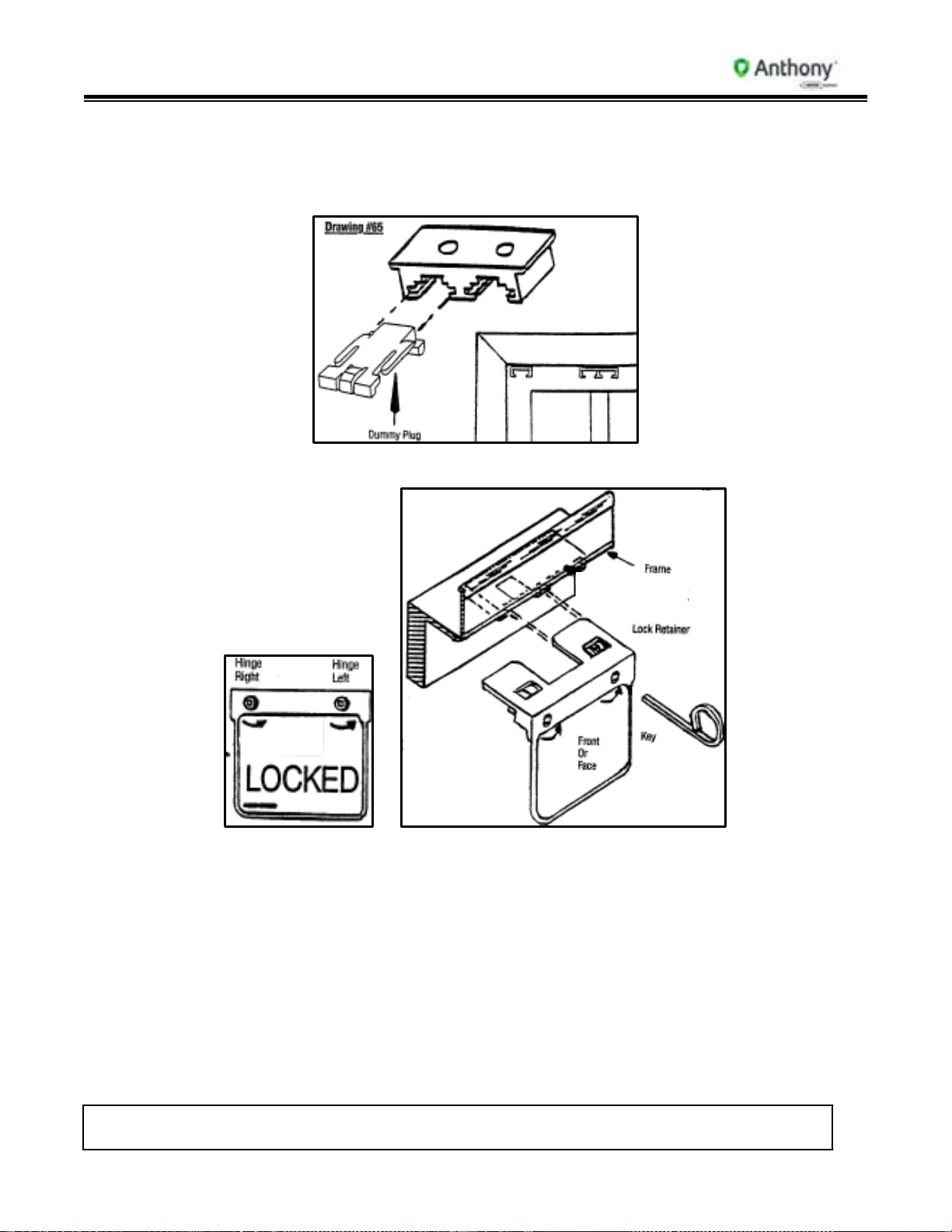

32. P.O.M. Lock Installation

1. Remove dummy plug from hinge pin access plate on top of frame on handle side of

door.

2. The P.O.M Lock inserts into a hinge pin access plate.

3. Insert key into P.O.M Lock’s square keyhole and turn key counterclockwise to lock.

4. Remove key.

5. To remove P.O.M. Lock, insert key into square hole and turn key clockwise.

6. Pull straight out to remove lock.

7. Replace dummy plug.

8. Lock only side that inserts into hinge access plate.

9. Facing doors, the lock on the right side is for left-hinged doors and the lock on the left

side is for right-hinged doors.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 31 of 95

10. The P.O.M. Lock is manufactured to install in frame on top of handle rail side of door.

11. For retrofitting the P.O.M. Lock on existing doors in the field, contact Anthony

Customer Service or the local Sales Representative for information and instructions.

33. P.O.M. Lock Installation

1. To install the retrofit retainer, measure in 1-1/2” from the edge of door (handle side) and

mark frame above the door.

2. Place template provided on frame, with the right edge of the template on the mark

previously made on the frame.

3. Mark the frame through the five (5) holes on the template with a pencil. Remove

template and center punch the marks on the frame.

4. Drill the four (4) outboard holes with an 11/64” drill, the center hole with a 5/8” drill and

deburr holes.

5. Place retrofit retainer bracket over the holes with the rectangular notch out. Use #10-32

x 5/16” screws provided and mount retainer bracket to frame.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 32 of 95

6. Insert P.O.M. Lock into access plate and turn key to lock.

7. Remove key.

8. To remove P.O.M. Lock, insert key into square lock hole and turn the key clockwise.

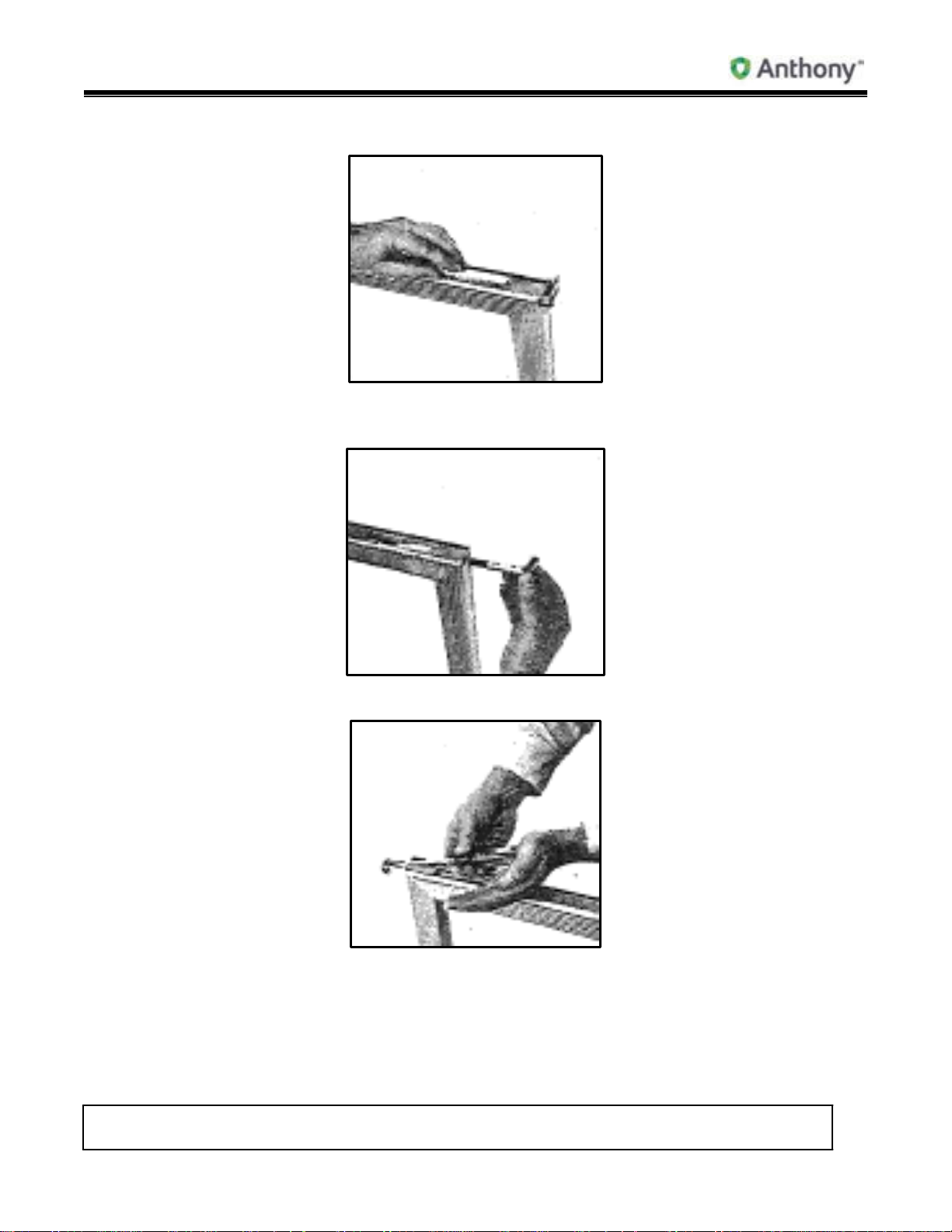

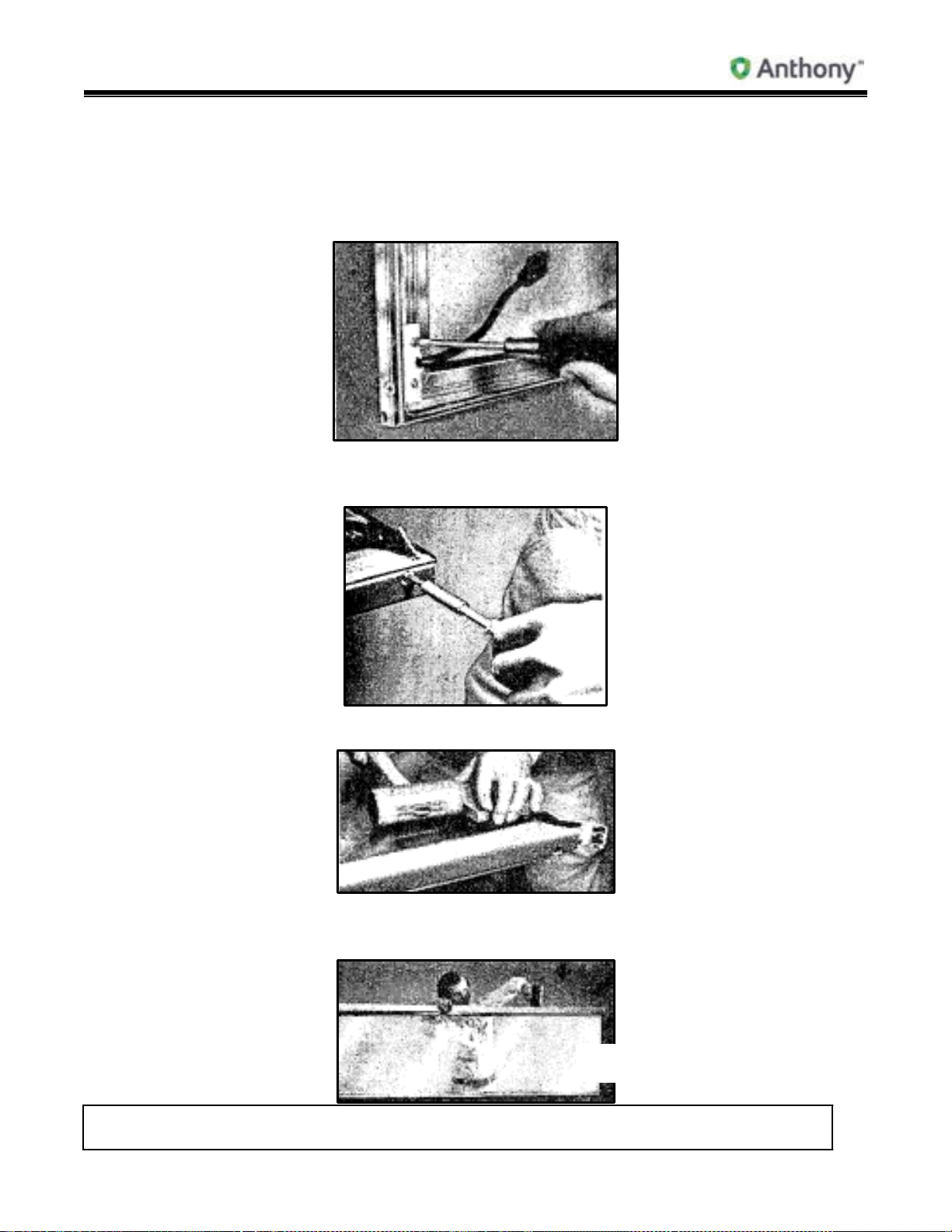

34. Model 101 Glass Replacement (Reglazing)

1. To remove torque rod from door, drive tapered shaft of torque rod from door.

2. Starting at corner of door, remove gasket and plastic from all four sides of door.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 33 of 95

3. For models prior to 1987, unscrew SJ cord retainer to expose heating element wires.

For models after 1987, remove top or center access plate. Unsnap hinge pin from

female socket and remove, or unplug hinge pin lead wires to remove hinge pin. If

heated glass is used, cut Black and White lead wires to glass. Remove heating element

from door.

4. Using a square-head or clutch-head driver, remove screws on both side rails only.

Remove top and bottom door rails first.

5. Drive rails from glass, using mallet and block, always starting at corner of door.

6. Once rails have been removed from glass, re-insert new friction-fit glazing channel on

new glass and drive rails onto glass.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 34 of 95

7. After both long rails have been affixed to glass, re-insert friction-fit glazing channel on

top and bottom and tighten miters with square-head or clutch-head driver.

Glazing

Channel

Square

Head

Screw

Clutch

Head

Screw

8. Once all four (4) door rails have been affixed to glass, measure diagonally to make sure

door is in square.

9. After replacing the glass unit, and when door rails are in square, re-insert heating

element wires in door rail channels and repeat process. Replace gasket and retainer

strips.

To re-install torque rod, align torque shaft with key way in door and drive tapered shaft

flush with bottom of door rail.

Note: If heated glass is used, when disassembling door, cut Black and White lead wires

to glass. When rebuilding door, pull glass heater leads out through heater access

hole before assembling top or side door rails. Re-connect Black and White lead

wires to heater wire Black and White lead wires. On newer models, re-connect

hinge pin to heater receptacle or heater lead wires.

10. When replacing heated glass, bus bars on glass (colored bars on top and bottom of

glass or up and down the sides) must go to the front of door, or customer side. This is

the heated side.

11. For questions about glass replacement, call Anthony’s Customer Service or local

Sales Representative.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 35 of 95

35. Ordering Replacement Frames

1. Specify outside tip-to-tip dimensions of frame. Measure to nearest 1/16”.

2. Specify date of original manufacture and/or Anthony confirmation/invoice number.

3. Specify Cooler or Freezer.

4. Specify door size (width and height).

5. Specify finish (smooth/serrated/gold/silver/black, etc.).

6. Specify Model number.

7. Specify left or right hinge swing.

8. With or without heaters?

9. With or without lights?

10. With or without locks?

11. Specify any custom items on original order.

Replacement Frames (All Swing Doors)

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 36 of 95

36. Frame Heater Wire Replacement

1. Remove door from frame, following previous instructions for door removal.

2. Insert small flat-head screwdriver under back side edge of contact plate retainer and lift

up to remove.

Mullion Front

and Retainer

3. Remove contact plate to expose heater wires.

4. See following page for frame heater schematics.

5. Cut heater at the lead wire and pull heater out of track.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 37 of 95

6. When ordering replacement heaters, specify which heater needs replacing: top, bottom,

end or center mullion heater. This varies depending upon the particular frame make-up..

7. Reverse instructions to re-install heater.

37. Models 101 & 2100 Frame Heater Schematic/Low Temp

Heater Wire Layout:

3-Door Frame (Typical for 2 Thru 5 Doors)

Bottom and End – Perimeter –

Center Top Supplement – Bottom Supplement.

Note: Top Heater to be installed before door sockets are set in place.

38. Models 101 & 2100 Frame Heater Schematic/Normal Temp

Heater Wire Layout:

3-Door Frame (Typical for 2 Thru 5 Doors)

Bottom and End – Perimeter and Center

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 38 of 95

39. Humastat Installation Procedure

1. Install Humastat Power Junction Box before refrigerator door power wiring, on the inside

wall of refrigerator.

2. Remove wiring compartment covers by removing four (4) sheet metal screws.

3. Connect heater hot wire to Red wire from control unit.

4. Connect input power hot wire to Black wire from control unit.

5. Connect all White wires, including common side of power line, line load and control unit

White wire.

6. Connect Green Ground wire from control unit to Green Ground wire at frame and to

incoming Ground wire (if furnished).

7. Replace the Wiring Compartment Cover with the sheet metal removed in No. 2 above.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 39 of 95

8. Install Humastat Sensor on the outside wall of refrigerator above the door frame, within

three feet of power junction box.

120 VAC 50/60 Hz, 20 Amperes Maximum

a. Drill a 1/4” diameter hole through refrigerator wall directly above the door frame.

b. Use the wood probe supplied with the sensor to feed the sensor wire through the

refrigerator wall.

c. Apply permagum to back of sensor around the wire. Pull the wire through the hole

until the sensor makes close contact with the wall and secure it to the wall with the

9. Remove wood probe from sensor connector by holding the body of connector securely

10. Insert the sensor plug into the sensor jack on the outside end of the power junction

11. Set the heater control knob for the lowest value which keeps the door free of

screws provided Seal the probe wire with the permagum on inside of wall.

and pulling off the probe.

box.

undesirable moisture.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 40 of 95

12. Red light indicates when heaters are functioning.

Control Panel End

Switch shall remain in Position “A” for normal operation

View

40. Model 101 Humastat

1. Sensor is prewired in frame mullion.

2. For Low Temp applications, see Sensor Part #F-161.

3. For Normal Temperature applications, see Sensor Part #F-1649.

41. Model 101 & 2100 Shelf Assembly Catalog Size/Shelf Size

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 41 of 95

Shelf Tabulation

Catalog Size

Shelf Size

24”

23 5/16” x 27”

30”

29 13/16” x 27”

NOTE:

For 24” 1- and 2-Door

Frames, use shelf

size 22 9/16” x 27”

26” 26 5/16” x 27”

For 3 Doors or more,

use 23 5/16” x 27”

"""

TITlE:

99-13312-8001Mode

101/2100

Doors

Ser..tce &

hstallation

B

Page 42of

95

=-,

>

,,.,,

1

21

•

• <

O Anth

ony·

42. Models 101 & 21

i -i;

.,..,i

oo

Frame &

i

I

5r

Qr

, '/

J

I

._::-r

.

F

shelving

l

_J

==i

.

-'

with Standard

($

M"

!. l

.

J\,

.

M

I I\

J

•

••

':)

Lighting

j

1"'1

<

I

.

••

ti

J

j

., {

'

!' l

!

s

f-

f-

;

•

<

;;

-

•

.

TITlE:

43. Models 101 & 21

oo

Frame &

shelving

with "ELS"

•'

O Anthony·

Electronic

Lighting

'

1---lf-

• fi

1-

-

-t-1--

-

-

·-

-

-'

--

--1

-1

"""

TITlE:

99-13312-8001Mode

101/2100

Doors

Ser..tce &

hstallation

B

Page 42of

95

99-13312-8001Mode

101/2100 Doors Ser..tce &

hstallation

"B""

Page 43of

95

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 44 of 95

44. Four-Post Stabilizer Bar Installation

1. The four-post stabilizer is designed to help support the posts during installation and

stabilize the system while in use.

2. Insert the forked end of stabilizer bar into the elongated holes in post.

3. Install the post stabilizers on the top and bottom of all posts, front to rear, before

installing shelves.

45. Four-Post Shelf System Installation

1. Attach post to inside frame by inserting post key into frame retaining bracket.

2. Before installing shelves, adjust all front posts to equal heights with leg leveling bolts at

bottom of posts.

.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 45 of 95

3. Insert front of shelf in front post at angle as shown, then position rear shelf posts.

4. Drop rear of shelf down and pull back in slot on rear posts. Continue to add shelves

behind each door, spacing for desired product merchandising.

5. After installing shelves, adjust rear post leveling bolts to level. The Four-Post Shelf

System is now ready for merchandising.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 46 of 95

46. Plastic Tag Molding Installation

1. Tag molding is the exact length of the shelf’s upper front bar. Center tag molding on

front of shelf. Hook bottom of tag molding under shelf across entire width of shelf.

Spread thumbs across tag molding and push up.

2. Snap top corner of tag molding strip onto shelf front. Apply even pressure across top of

tag molding as it is fed onto top horizontal bar on shelf front.

3. For replacement tag molding, specify width of shelf when ordering.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 47 of 95

47. Model 2100 G.F.I. Location & Wiring Diagram

48. Lamp Replacement

1. Lift lamp up into top plunger socket, then out at bottom to remove.

2. Pull end caps off end of light shield, then remove bulb from shield.

3. To replace bulb, insert new bulb into lamp shield and snap in end caps. To replace

lamp, lift bulb up into top plunger socket, then set into bottom socket. Do not install

lamps without lamp shield.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 48 of 95

49. Lamp Socket Replacement

1. To replace sockets, remove lamp, then pull top socket down and pull out of “D” hole. To

replace bottom socket, pull socket up and out of “D” hole. Extra lead wire is left in the

mullion for easy replacement.

2. Pull sockets out, then cut lead wires.

3. Reverse instructions to replace.

4. To re-install sockets, insert top front metal tab into “D” hole and snap socket up. For

bottom socket, insert metal tab into “D” hole and snap socket down to install.

5. Replace lamps.

6. For safety and efficiency, lamps should never be installed without shields.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 49 of 95

50. Recessed Light Socket Replacement

1. Remove safety clips and light guard.

2. To remove top socket (plunger socket), pull socket down then out.

3. To remove bottom socket, pull up then out.

4. Mullion contains excess socket lead wire. Cut lead wires to sockets.

5. Re-wire new socket in place.

6. To re-install sockets, reverse above instructions.

7. Replace bulbs and lamp guards.

51. Recessed Lamp Channel Replacement with Remote Ballast

1. Insert flat-head screwdriver under back edge of light channel retainer to remove.

2. To replace, lay light channel into mullion, then snap on retainer as shown.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 50 of 95

52. Recessed Lamp Guard Replacement with Remote Ballast

1. Compress metal safety clips on each end and in the center of light guard to remove.

2. Lift light guard up to release from lower shield clip, drop down to release guard from top

clip.

3. To replace, insert guard into bottom clip first, then into top clip. Compress metal safety

clips when they’re put into recessed channel. Release to let clip seat into groove in

recessed channel.

4. To replace end plastic clips, compress sides and pull out.

5. To replace end clips, compress new end clip and insert into access groove in light

channel.

53. Recessed Lamp Replacement

1. Remove light guard per previous instructions.

2. Lift bulb up into top plunger socket and pull bulb out and down at bottom to remove.

3. To replace bulb, insert bulb into top light socket and set into bottom socket.

4. Re-install light guard and clips.

54. “Boost & Buck” Transformer Wiring Diagram

1. Recommended wiring for 110/120 volt applications.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 51 of 95

2. Transformer, wired as follows, will increase the 115 volt line voltage by 10% and the

applied heat by 20%.

3. Hot to H1-X3.

4. Neutral to H2-X1-X3.

5. Load for heaters X2-X4.

6. Transformer is rated for an 18 Amp load.

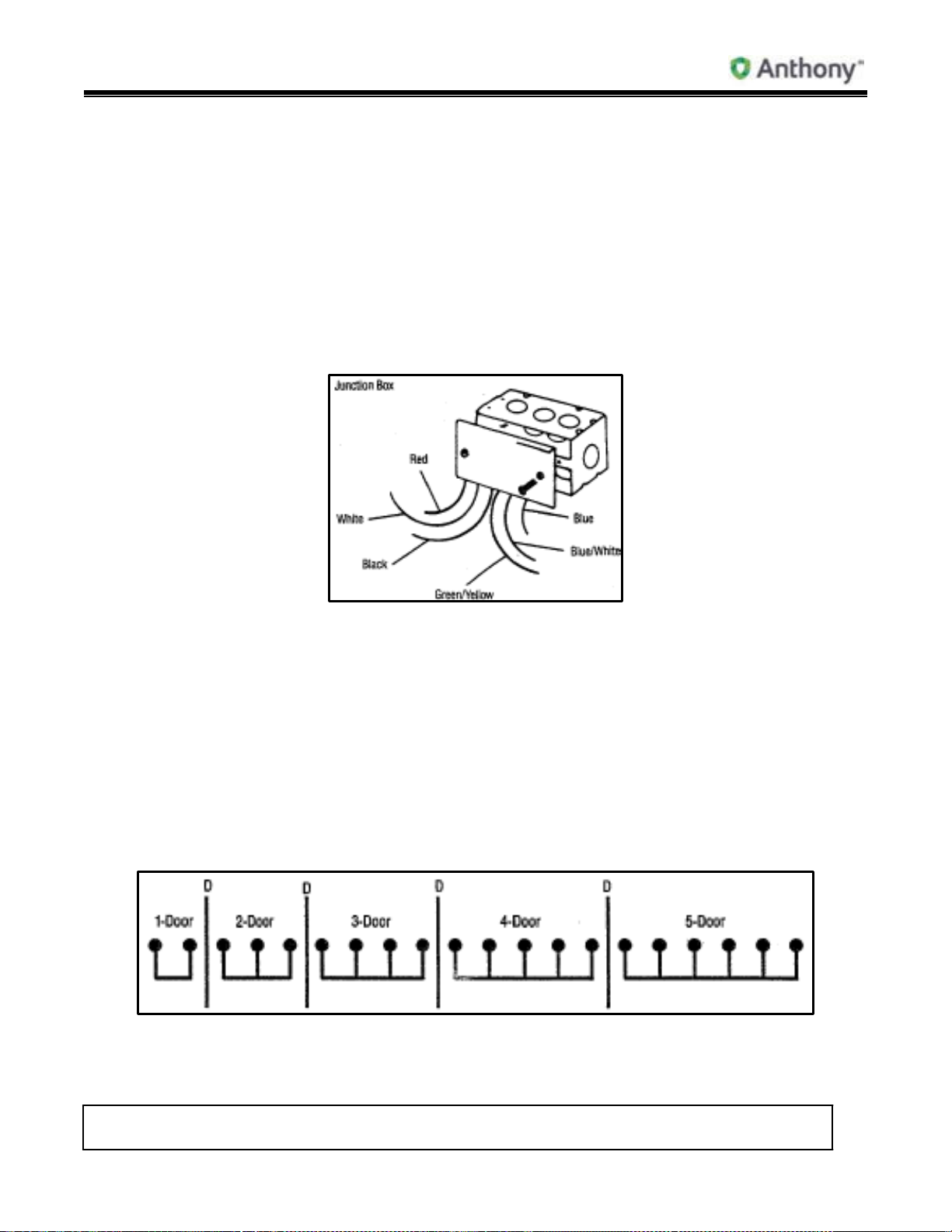

55. Frame Junction Box Wiring (Standard Production)

1. Remove cover.

2. Wires are marked as to application.

1-Black for frame heat.

1-Red for door heat.

1-White, common for Black and Red.

1-Blue for lights.

1-Blue/White common for lights.

1-Green/Yellow for ground.

56. Models 101 & 2100 Light Fixture Placement (Prior to 10/93)

Pre-wired lighting uses only 1-light ballasts. Non pre-wired uses 1- or 2-light ballasts.

Frame Breakdown – Each Frame Section with Full Flange

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 52 of 95

= Light

X = No Light

D = Wood Divider

Example: 6-Door Lineup (2 sets of 3) of Model 101 or 2100 with Full

Flange

57. Models 101 & 2100 Light Fixture Placement – “Continuous” Lineup

(10/93 to Present)

Pre-wired lighting using 1- or 2-light ballasts. Continuous lineup with “E.L.S.” lighting.

= Light

Frame breakdown: 1 set of 6 (2 sets of 3, joined with sex bolts).

Note: Lamp at each end of frame and on each mullion.

Pre-wired lighting using 1-light ballasts. Continuous lineup with standard lighting.

Frame breakdown: 1 set of 6 (2 sets of 3, joined with sex bolts).

Note: One more lamp than number of doors.

58. Models 101

& 2100 Low Temp 120-Volt Remote Ballast and

Wiring

HMPiallasl

Diagram tor

!llK

'

/IKf

BUE

BWE

UNI\Itf$i.L t'95lS·.TC-P

1-Light Systems

RED

RE:J

Kll..K\

15:»2

O Anthony·

Lamp

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 54 of 95

"""

99-13312-8001Mode

TITlE:

101/2100 Doors Ser..tce &

hstallation

Page 53of

B

95

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 55 of 95

=

59. Models 101 & 2100 Low Temp 120-Volt Remote Ballast and

>O

T

Wiring

Diagram tor

2-Light Systems

2-Lamp

83118$1

.t811

j

F60110CIINH0{6)"

F'?Z110CNNHO

vc:uow

0CIJNWO{>Iil

(7?"}

}

O

Anthony·

Lamp

KU.

KA*530-2

lJ

IL

TITlE:

99-13312-8001Mode

101/2100

Doors

Ser..tce &

hstallation

Page of

"B""

54 95

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 57 of 95

Model 101/2100 Doors Service & Installation

60. Models 101 & 2100 Normal Temp 120-Volt Remote Ballast and Lamp

Wiring Diagram for 1- & 2-Light Systems

Lighting Diagram for 1- & 2-Light

Ballast

61. Models 101 & 2100 Normal Temp 120-Volt Remote Ballast and Lamp

Wiring Diagram for 3-Light Systems

Lighting Diagram for 3-Light Ballast

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 56 of 95

62. Normal Temp & Low Temp 120-Volt Ballast and Lamp Wiring Diagram -

Pre-Wired 1-Light System

Wiring:

1. Ballast has two (2) Red wires, two (2) Blue wires, a Black and a White wire.

a. Wire two (2) Red wires to two (2) Red wires on bottom socket.

b. Wire two (2) Blue wires to two (2) Blue wires on top socket.

c. Black wire goes to hot, White wire goes to neutral.

63. Ballast Replacement

1. For replacement ballast, always use ballast number from existing ballast.

2. Remove door from frame opening.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 57 of 95

3. Insert flat-head screwdriver under back edge of contact plate retainer to remove.

4. Remove contact plate from mullion.

5. Pull heat barrier from mullion to remove.

6. The ballast has a wiring diagram on its face. To replace ballast, cut lead wires: 2-Red,

2-Blue, 1-Black and 1-White.

7. Follow color codes to rewire ballast. Reverse instructions to replace heat barrier,

contact plate and contact plate retainer.

Note: When the two (2) Blue and two (2) Red wires are connected to the top and

bottom sockets, make sure the wiring is one-to-one. Do not gang wire.

64. “ELS” Lamp Socket Replacement

WARNING: Before servicing Anthony doors make sure all power to case is off. Always

1. Remove front contact plate retainer.

2. Remove contact plate.

use a qualified electrician.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 58 of 95

3. Remove top and bottom spring steel clips. Insert small flat-head screwdriver under clip

to release clip from side of fixture. On one side at a time, pull clip out of pre-punched

holes in side of mullion.

4. Gently pull clips away from fixture and set clips aside for re-installation.

5. Remove “ELS” lens. Starting at the top, pull lens away from front of light fixture, next

to frame mullion. (If necessary, a small flat-head screwdriver can be inserted between

lens and back mullion plastic to ease lens out of groove.) There is no need to remove

lens from the bridge. (The “bridge” is the black or clear plastic piece connecting the

two lenses at the back of the fixture.)

6. Remove bulb.

7. From the front of the socket, depress both sides of socket and push socket out through

front of mullion.

8. Cut ballast lead wires to socket as close to socket as possible.

9. To replace a socket, insert socket into access hole in mullion and push until tabs on

side of socket snap in place on back side of mullion.

10. Insert ballast lead wires into socket connections.

11. Re-install bulb, lens and front contact plate.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 59 of 95

65. “ELS” Electronic Ballast Replacement and Wiring Instructions

WARNING: Before servicing Anthony doors make sure all power to case is off. Always

1. Refer to drawings on following pages for ballast location and wiring.

2. Remove door that hinges on mullion where ballast will be replaced.

3. From front of frame, remove contact plate and retainer by inserting a flat-head

screwdriver under back edge of black contact plate retainer, and gently pull to unsnap

retainer from mullion. Repeat from other side of mullion and remove contact plate.

4. With ballast now exposed, remove screw on top end of ballast. Slide ballast up and out

of punched mullion tabs.

5. Disconnect or cut all lead wires. If cut, leave enough lead wire to re-connect new ballast

with wire nut.

6. Insert bottom of new ballast in punched tabs on mullion. Re-install top screw in top end

of ballast.

use a qualified electrician.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 60 of 95

7. Re-connect new ballast lead wires using the following Wiring Diagrams:

2-Light (1-Door)

3-Light (2-Door)

4-Light (3-Door)

5-Light (4-Door)

6-Light (5-Door)

8. Lay contact plate flat on mullion. Staring at the top, insert contact plate retainer into front

edge of mullion. Snap retainer on back edge of mullion. Repeat instructions for opposite

side.

120V Electronic Ballast Wiring Diagrams

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 61 of 95

120V ELS Lighting System Component Layout

1-Door Section 2-Door Section

3-Door

Section

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 62 of 95

220V Electronic Ballast Wiring Diagrams

4-Door

5-Door

Section

Section

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 63 of 95

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 64 of 95

220V ELS Lighting System Component Layout

1-Door Section 2-Door Section

3-Door

4-Door

Section

Section

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 65 of 95

5-Door

Section

66. T-8 Lamp Replacement Instructions

CENTER MULLION FIXTURES

1. Turn light power off before start of lamp replacement.

2. Remove top and bottom spring steel clips. Insert small flat-head screwdriver under

clip to release clip from side of fixture (as shown in the following figure). On one side at

a time, pull clip out of pre-punched holes in side of mullion.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 66 of 95

3. Remove ELS lens. Starting at top, pull lens away from front of light fixture that is

attached to the frame mullion. If necessary, a small flat-head screwdriver can be

inserted between the lens and black mullion plastic, to ease the lens out of the groove.

There is no need to remove the lens from the bridge (the black or clear plastic piece

connecting the two lenses at the back of the fixture).

If pulled away from one side carefully, the lens will swing back into the case to give

access to the bulb. Otherwise, the left and right lenses and the bridge will pull away

from the fixture – in one complete section.

4. With the lens removed, hold lamp with fingers and twist bulb to line up with socket

access holes.

Remove old bulb. Remove insulator tubes from both ends of old bulb and replace on

ends of new bulb.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 67 of 95

To install new bulb, place into socket and turn two clicks. There are foam end caps

on the top and bottom of lamp sockets. End caps must be attached before lens is

replaced.

5. Be sure that both ELS lenses are snapped securely into the plastic bridge before re-

installing on the light fixture.

6. Install clip on plastic bridge, if required, before re-installing on light fixture.

7. Starting at the top on one side of the light fixture, line up the edge of the lens with the

groove in the fixture plastic. Snap lens into groove. Repeat with lens on the other side,

if removed.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 68 of 95

8. Holding lens snugly against top of light fixture, install spring steel clip over lenses. Snap

clip into pre-punched holes on each side of mullion. Move to bottom of fixture and install

bottom clip.

IMPORTANT: Bulb insulators must be on each end of bulb before lenses are re-installed.

Foam end caps should be securely attached to top and bottom of lamp

sockets. (Foam end caps are cut to fit snugly, but if they have become

dislodged, or pulled out during changes, they must be replaced!)

9. Turn light power on.

FRAME END FIXTURES

1. Turn light power off before start of lamp replacement.

2. Remove top and bottom spring steel clips. Insert small flat-head screwdriver under

flat portion of spring steel clip to remove from side of fixture (as shown in the following

figure). Swing clips to the side until re-installation.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 69 of 95

3. Remove ELS lens. Starting at top, pull lens away from inside front edge of fixture. If

necessary, a small flat-head screwdriver can be inserted between the lens and black

fixture plastic, to ease the lens out of the groove. If rear edge of lens is left in fixture

plastic, lens will swing back on flexible “hinge” to expose bulb.

4. Reaching into fixture, hold bulb with fingers and twist to line up with socket access

holes. Remove old bulb. Remove insulator tubes from both ends of old bulb and

replace on ends of new bulb.

To install new bulb, place into socket and turn two clicks. There are foam end caps

on the top and bottom of lamp sockets. End caps must be attached before lens is

replaced.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 70 of 95

5. Re-install ELS lens. If lens has been completely removed from fixture, pull grooved

plastic rear section of fixture forward, and snap rear edge of ELS Lens back into the

groove. (This part of the light fixture has a “hinge” or flexible portion, that swings away

for easy bulb access. Install clip on hinging side, if required, before re-installing the

other end of the lens. Starting at the top, snap the other side of the lens into the front

groove of the lamp fixture.

6. End clips conform to the shape of the end fixture, and can be snapped into place only

one way. The curved sides of the spring steel clip should be touching the lens. Snap

the top and bottom clips into place.

IMPORTANT: Bulb insulators must be on each end of bulb before lens is re-installed.

Foam end caps should be securely attached to top and bottom of lamp

sockets. (Foam end caps are cut to fit snugly, but if they have become

dislodged, or pulled out during changes, they must be replaced!)

7. Turn light power on.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 71 of 95

CASE TEMPERATURE

(F)

40 35 30 25 20

70 70 66 61 58 53 75 67 62 59 55 52 80 63 60 57 53 50 85 60 58 53 50 49 90 58 55 52 49 47

70 74 71 68 65 62 75 72 68 66 63 60 80 68 66 63 60 58 85 66 64 61 58 56 90 65 62 59 57 54

70 76 75 70 67 63 75 75 70 69 66 62 80 70 68 66 62 59 85 68 66 63 60 58 90 67 64 60 58 56

70 98 92 90 84 80 75 95 90 86 84 77 80 90 85 81 76 73 85 86 80 78 72 69 90 82 78 74 70 66

% REL HUMIDITY @ WHICH CONDENSATION FORMS ON GLASS

CASE TEMPERATURE

(F)

+5 0 -5

-10

-15

-20

-25

90

88

83

81

79

76

73

85

81

80

78

76

72

70

80

80

78

75

72

70

69

79

78

77

73

71

68

68

78

75

73

71

69

67

65

67. Dew Point Chart

GLASS

TYPE

TWO PANE

NHG*

THREE

PANE NHG*

REFLECTIVE

PANE

TWO

NHG*

PANE

TWO

HEATED

GLASS

*NHG = Non Heated Glass

GLASS

TYPE

ROOM TEMP

(F)

ROOM

TEMP (F)

NORMAL TEMPERATURE APPLICATIONS

LOW TEMPERATURE APPLICATIONS

THREE PANE

HEATED

REFLECTIVE

GLASS

% REL HUMIDITY @ WHICH CONDENSATION FORMS ON GLASS

Calculations make no allowance for air leaks or unusual air flow patterns within cases and are

intended to be used as guidelines only.

Model 101/2100 Doors Service & Installation

TITLE:

99-13312-S001 Model 101/2100 Doors Service &

Installation

REV.

B

Page 72 of 95

NUMBER OF DOORS:

1 2 3 4 5 6 7 8 9 10 STYLE:

APPLICATION:

24 x 36

24 x 67

24 x 75

26 x 67

26 x 75

28 x 75

28 x 79

30 x 36

30 x 67

30 x 75

30 x 79

LIGHT

24 x 36

11.79

12.78

13.93

14.92

15.99

17.04

18.11

19.26

20.25

21.32 NA

24 x 67

18.16

19.77

21.40

23.01

24.63

26.36

27.98

29.61

31.22

32.84

0.85

24 x 75

19.91

21.72

23.49

25.30

27.09

28.96

30.75

32.52

34.33

36.12

0.85

26 x 67

19.90

21.69

23.30

25.09

26.79

28.92

30.62

32.23

34.02

35.72

0.85

26 x 75

21.33

23.16

25.23

27.06

29.01

30.88

32.83

34.90

36.73

38.68

0.85

28 x 75

22.52

24.48

26.58

28.54

30.57

32.64

34.67

36.77

38.73

40.76

0.85

28 x 79

23.70

25.77

28.02

30.09

32.25

34.36

36.52

38.77

40.84

43.00

0.85

30 x 36

14.59

15.96

16.93

18.30

19.47

21.28

22.45

23.42

24.79

25.96 NA

30 x 67

21.36

23.34

24.94

26.92

28.71

31.12

32.91

34.51

36.49

38.28

0.85

30 x 75

23.18

25.23

27.18

29.23

31.23

33.64

35.64

37.59

39.64

41.64

0.85

30 x 79

24.46

26.70

28.62

30.86

32.94

35.60

37.68

39.60

41.84

43.92

0.85

68. Electrical Information for Model 101 Low Temp Heated Doors, Frames

& Standard Light Fixtures

18

19

20

AMPS PER

Heater Amperages @ 120 Volts

Low temp doors with heaters, 3-Pane Heated Reflective Glass (5.75 W/SQ. FT.)

Case Temperature -10°F, Humidity 75% or less, @ 75°F ambient.

NOTES: 1. All amperages are design amperages subject to the following tolerances: heated glass +/- 8%.

2. Although the amperages are calculated at 120 volts, all doors are designed to operate without

sweating when used within the application parameters with a voltage range of +/- 10%.

3. When calculating standard lamp amperage, add 1 lamp to the number of doors in the line-up and

multiply that number by the appropriate AMPS PER LIGHT value.

4. Design parameters do not make allowances for factors such as air leaks or unusual air flow

patterns within cases; therefore, some sweating may occur when upper limits of temperature or

humidity are encountered.

11

12

1.12 2.20 3.27 4.26 5.33 6.54 7.53 8.52 9.59 10.66

1.86 3.40 4.98 6.59 8.21 9.96 11.57 13.18 14.80 16.42

2.00 3.68 5.43 7.24 9.03 10.86 12.67 14.48 16.27 18.06

1.91 3.74 5.44 7.23 8.93 10.88 12.67 14.46 16.16 17.86

2.13 4.05 5.89 7.72 9.67 11.78 13.61 15.44 17.39 19.34

2.18 4.15 6.20 8.16 10.19 12.40 14.36 16.32 18.35 20.38

2.41 4.39 6.52 8.59 10.75 13.04 15.11 17.18 19.34 21.50

1.34 2.68 3.95 5.32 6.49 7.90 9.27 10.64 11.81 12.98

2.10 3.98 5.80 7.78 9.57 11.60 13.58 15.56 17.35 19.14

2.27 4.32 6.36 8.41 10.41 12.72 14.77 16.82 18.82 20.82

2.42 4.56 6.66 8.90 10.98 13.32 15.56 17.80 19.88 21.96