Anthony 1000R Service Manual

Model 1000, 1000R & 1200R

Doors

(Including Pass-Thru Door Models

2500/2700/3000)

Service & Installation

November, 2012

99-20439-I001

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 2 of 76

Table of Contents

1. Model 1000 Door (Non-Reversible) (Prior to 7/83) ............................................................ 5

1.1. Drawings & Schematics .......................................................................................... 6

1.1.1. Product Prior to 1987................................................................................. 6

1.1.2. Prior to 1984 .............................................................................................. 6

1.1.3. Torque Assembly (Prior to 1983)............................................................... 7

1.1.4. Model 100-100F (Prior to 1983) ................................................................ 7

1.1.5. Joining Two Frame Sections ..................................................................... 8

1.1.6. Brackets .................................................................................................... 8

2. Model 1000 Door (Non-Reversible) (7/83 to 1/87)............................................................. 9

3. Model 1000 Non-Reversible Door Installation (Prior to 1983).......................................... 10

4. Model 1000 Non-Reversible Door Handle Replacement ................................................. 11

5. Model 1000 Non-Reversible Door Handle Replacement ................................................. 11

6. Model 1000R Door (Reversible) (1987 to 1991) .............................................................. 12

7. Model 1200R Door (Reversible) (Start 10/89) ................................................................. 13

8. Model 1000, 1000R, 1200R Frame (Reversible) ............................................................. 14

9. Models 2500, 2700, 3000 – Pass-Thru Doors (Start 1987) ............................................. 15

10. Models 1000R, 1200R (Reversible) Frames – End & Center Sections, Full Flange

Construction .................................................................................................................... 16

10.1. Flange Placements ............................................................................................... 16

10.2. Finished Frame Width Dimensions ....................................................................... 17

10.3. Finished Frame Width Dimensions ....................................................................... 17

11. Frame Installation ............................................................................................................ 17

12. Reversible/Cordless Door & Hold-Open Installation ........................................................ 19

13. Hold-Open Replacement (Prior to 1987) ......................................................................... 21

14. Hold-Open Replacement (1987 to 1990) ......................................................................... 22

15. Hold-Open Replacement (1987 to 1990) ......................................................................... 22

16. Hold-Open Replacement (1987 to 1990) ......................................................................... 23

17. Models 2500, 2700 & 3000 Pass-Thru Door Installation ................................................. 23

18. Pass-Thru Identification ................................................................................................... 24

19. Pass-Thru Wiring Schematics ......................................................................................... 24

20. Reversing Frame Hardware (1987 to Present) ................................................................ 24

21. Door Reversing Instructions (1987 to 1990) .................................................................... 25

22. Door Reversing Instructions (1991 to Present)................................................................ 28

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 3 of 76

23. Wiring Instructions (1991 to Present) .............................................................................. 29

24. Frame Sill Plastic Protector Installation ........................................................................... 30

25. Ordering Replacement Doors .......................................................................................... 30

26. Torquemaster and/or Torque Casting Replacement........................................................ 31

27. Door Plastic (Cover) Replacement .................................................................................. 31

28. Door Handle Replacement .............................................................................................. 32

29. Side Access Plate Replacement...................................................................................... 33

30. Door Heater and/or Door Plug Replacement (Prior to 1987) ........................................... 33

31. Door Heater Replacement (1987 to 1991)....................................................................... 34

32. Door Heater Replacement (1987 to 1991)....................................................................... 35

33. Frame Single Station Socket Replacement ..................................................................... 35

34. Hinge Pin Replacement (1987 to 1991)........................................................................... 36

35. Torque Rod Replacement (1987 to 1991) ....................................................................... 37

36. Torque Rod Replacement (1991 to Present) ................................................................... 38

37. Front Bumper Bar Field Installation ................................................................................. 38

38. Flush Mount Lock Field Installation ................................................................................. 39

39. Door Cylinder Lock Replacement or Repair .................................................................... 39

40. P.O.M. Lock Installation................................................................................................... 40

41. P.O.M. Lock Retrofit Installation ...................................................................................... 41

42. Ordering Replacement Frames ....................................................................................... 42

43. Glass Replacement (Reglazing) ...................................................................................... 44

44. Frame Gasket Replacement – Models 1000, 2500, 3000 (Before 1981)......................... 46

45. Frame Gasket Replacement – Models 1000R, 1200R, 2500, 2700 (1981 to Present).... 47

46. Frame Junction Box Wiring (Standard Production).......................................................... 47

47. Heater Wire Diagram: Models 1000, 1000R, 1200R, 2500, 2700, 3000.......................... 48

48. “Boost & Buck” Transformer Wiring Diagram................................................................... 48

49. Pre-Wired Ballast Replacement (8G-4039W-02) (1984 to Present) ................................ 49

50. Raceway Clip Installation or Replacement (Start 1/1/93) ................................................ 50

51. Ballast, Lamp & Heater Wiring Diagram Models 1000R, 1200R (120 Volt) (1984 to

Present) ........................................................................................................................... 51

52. Ballast Wiring Diagram Models (Prior to 1984)................................................................ 52

52.1. Model 1000 Coolmaster™ Normal Temp (Also Model 100 Normal Temp) ........... 52

52.2. Model 1000 Coolmaster™ Normal Temp (Also Model 100 Normal Temp) ........... 52

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 4 of 76

53. Ballast Wiring Diagram for One- and Two-Light Ballasts (Prior to 1984) ......................... 53

53.1. Model 1000 Frame and Door Wiring Diagram ...................................................... 53

53.2. Model 1000 Light Wiring Diagram for One- and Two-Light Ballast ....................... 53

54. Light Bulb Replacement................................................................................................... 54

55. Light Channel Replacement ............................................................................................ 54

56. Light Socket Replacement............................................................................................... 55

57. Lamp Location: Reversible Models 1000R, 1200R (Prior to 1986).................................. 55

58. Lamp Locations: Cooler Door Lighting (1986 to Present) Models 1000R, 1200R ........... 56

59. Lamp Locations: Cooler Door Lighting (1986 to Present) Models 1000R, 1200R ........... 57

60. Model 1000R, 1200R Shelf Assembly ............................................................................. 58

61. Model 4000 Shelf Assembly ............................................................................................ 59

62. Shelving Installation and/or Replacement (Prior to 1984)................................................ 59

63. Four-Post Stabilizer Bar Installation ................................................................................ 61

64. Four-Post Shelving System Installation (After 1984) ....................................................... 62

65. Plastic Tag Molding Installation ....................................................................................... 63

66. Humastat Installation Procedure...................................................................................... 64

67. Electrical Information for Model 1000R Normal Temp Doors, Frames & Light Fixtures

(Heater Amperages @ 120 Volts).................................................................................... 66

68. Heat Load in BTU/Hr for Glass, Door Rail, Frame Heaters and Lights (Per Door, with

Doors Closed @ 75°F Store Ambient)............................................................................. 69

69. Electrical Information for Model 1200 Normal Temp Doors, Frames & Light

Fixtures (Amperages @ 120 Volts).................................................................................. 71

70. Heat Load in BTU/Hr for Glass, Door Rail, Frame Heaters and Lights (Per Door, with

Doors Closed @ 75°F Store Ambient)............................................................................. 72

71. Troubleshooting............................................................................................................... 73

72. Safety Precautions .......................................................................................................... 74

73. Tips.................................................................................................................................. 75

74. Dew Point Chart .............................................................................................................. 75

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 5 of 76

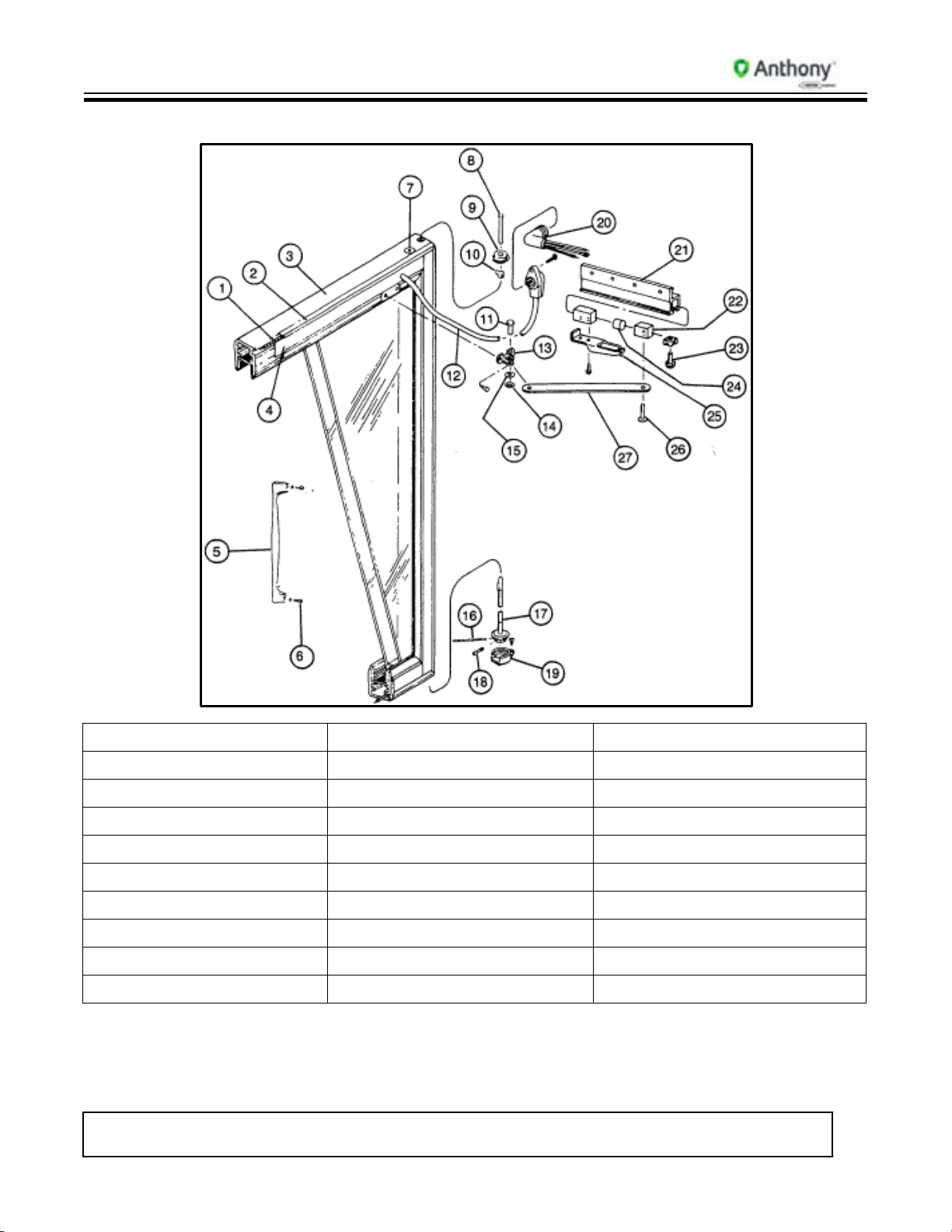

1. Model 1000 Door (Non-Reversible) (Prior to 7/83)

Description

Description

Description

1. Heater Wire 10. Safety Clip 19. Torque Casting

2. Plastic 11. Camel Back Hinge Pin 20. Female Plug

3. Door Rail 12. S.J. Cord 21. Door Stop Assembly

4. Contact Plate 13. Camel Back Hinge 22. Door Stop Sliding Block

5. Handle 14. Camel Back Hinge Pin Holder 23. Door Stop Nut & Bolt

6. Handle Screw 15. Camel Back Washer 24. Slide Stop Bumper

7. Corner Screw 16. Adjustment Pin 25. Hold-Open

8. Top Hinge Pin 17. Torque Rod 26. Door Stop Sliding Block Screw

9. Top Hinge Pin Holder 18. Set Pin 27. 10” Door Stop Arm

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 6 of 76

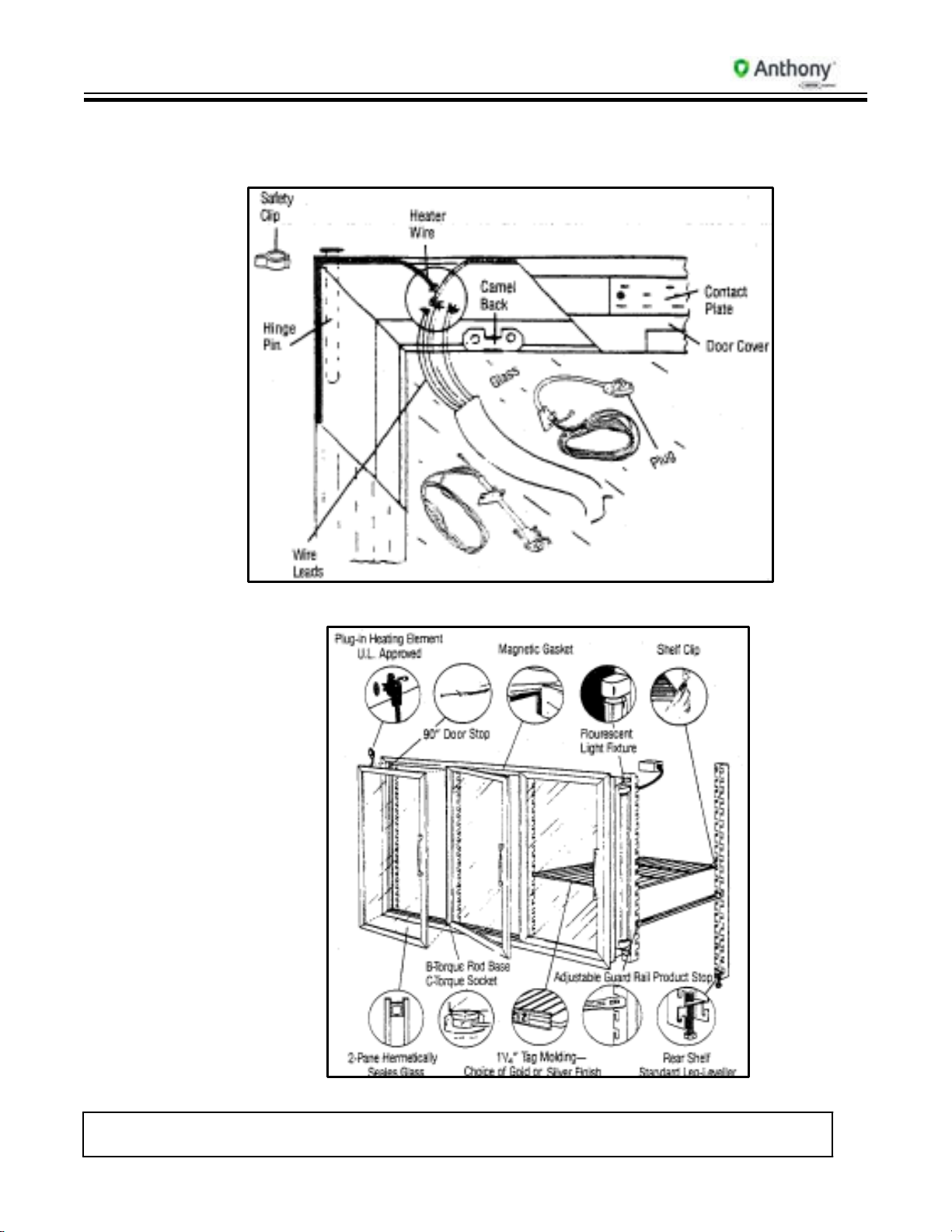

1.1. Drawings & Schematics

1.1.1. Product Prior to 1987

1.1.2. Prior to 1984

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 7 of 76

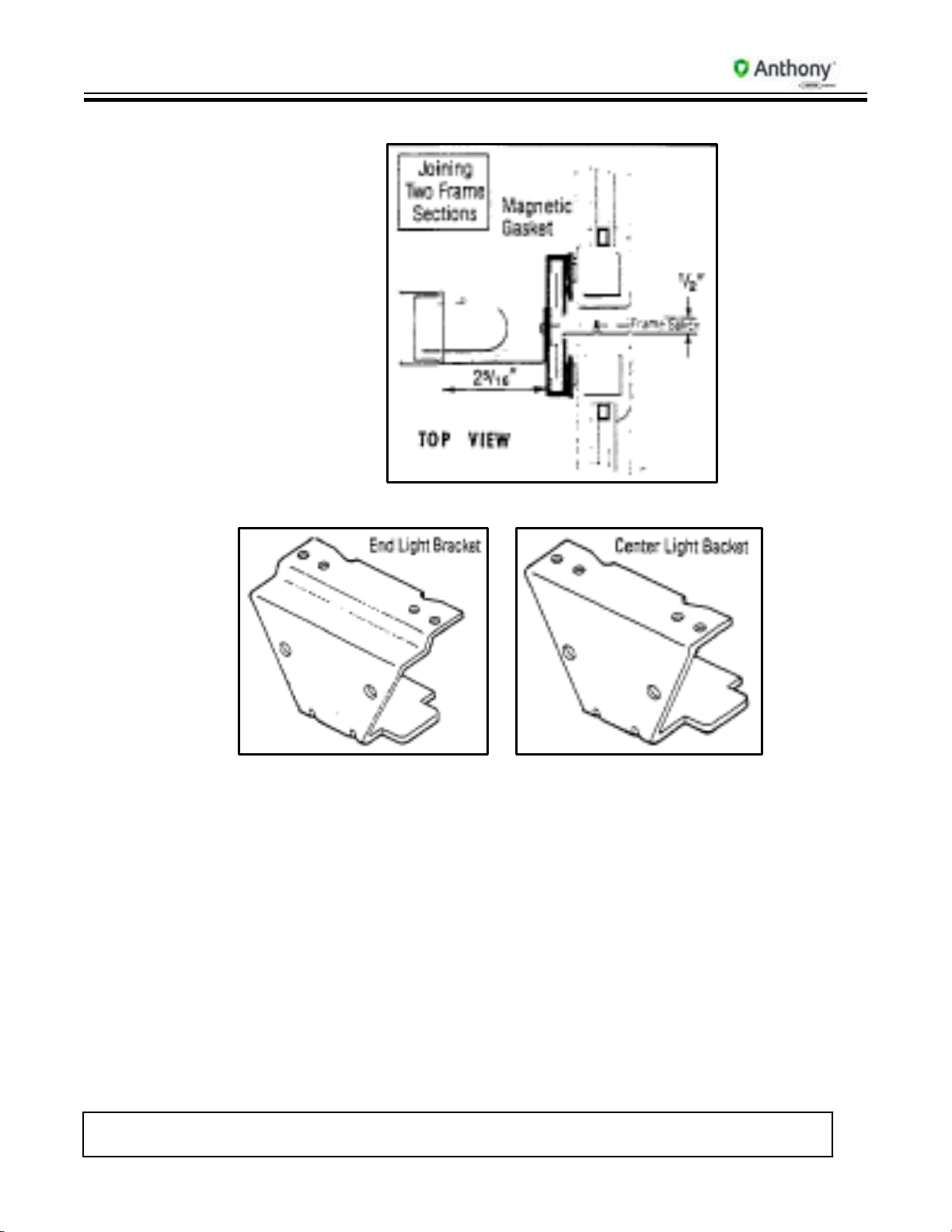

1.1.3. Torque Assembly (Prior to 1983)

1.1.4. Model 100-100F (Prior to 1983)

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 8 of 76

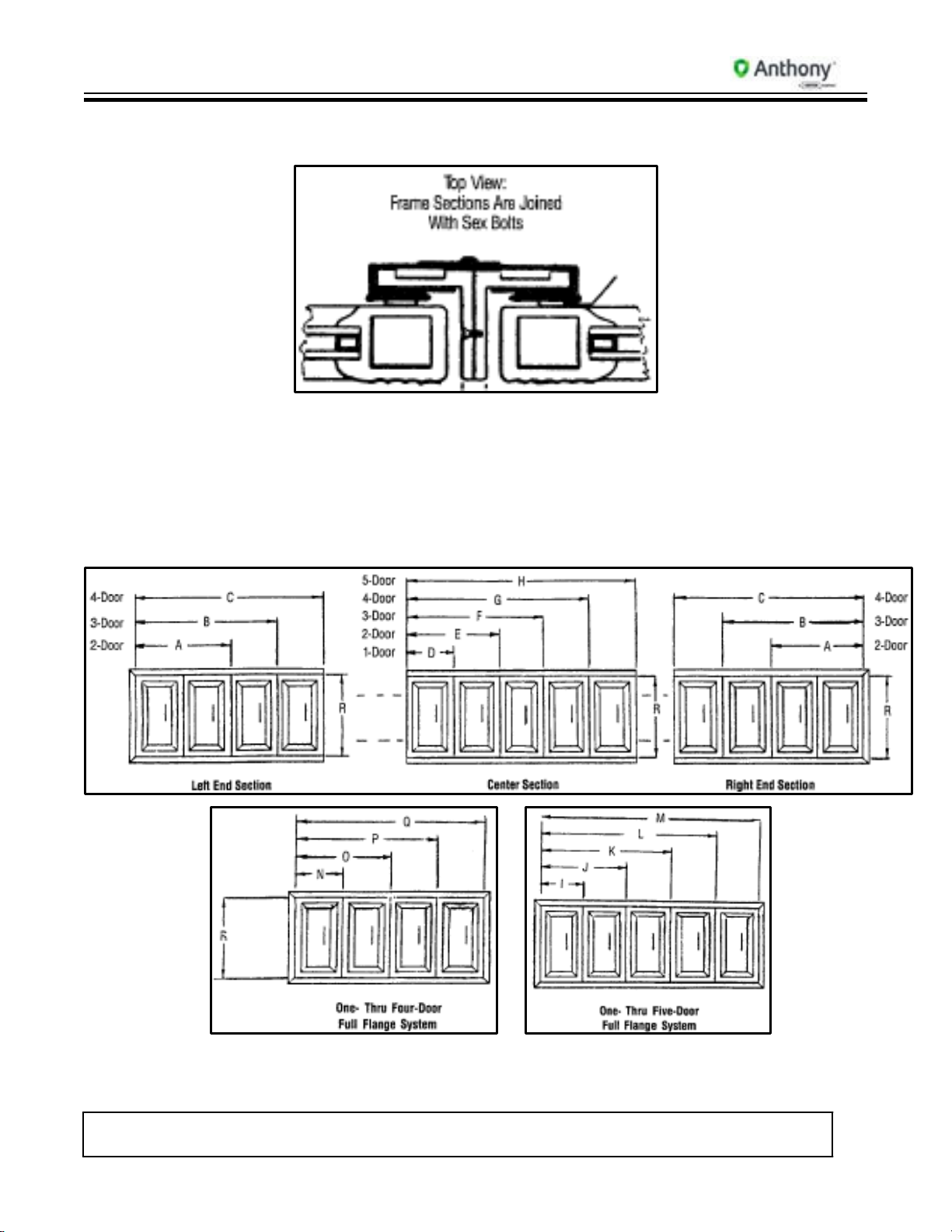

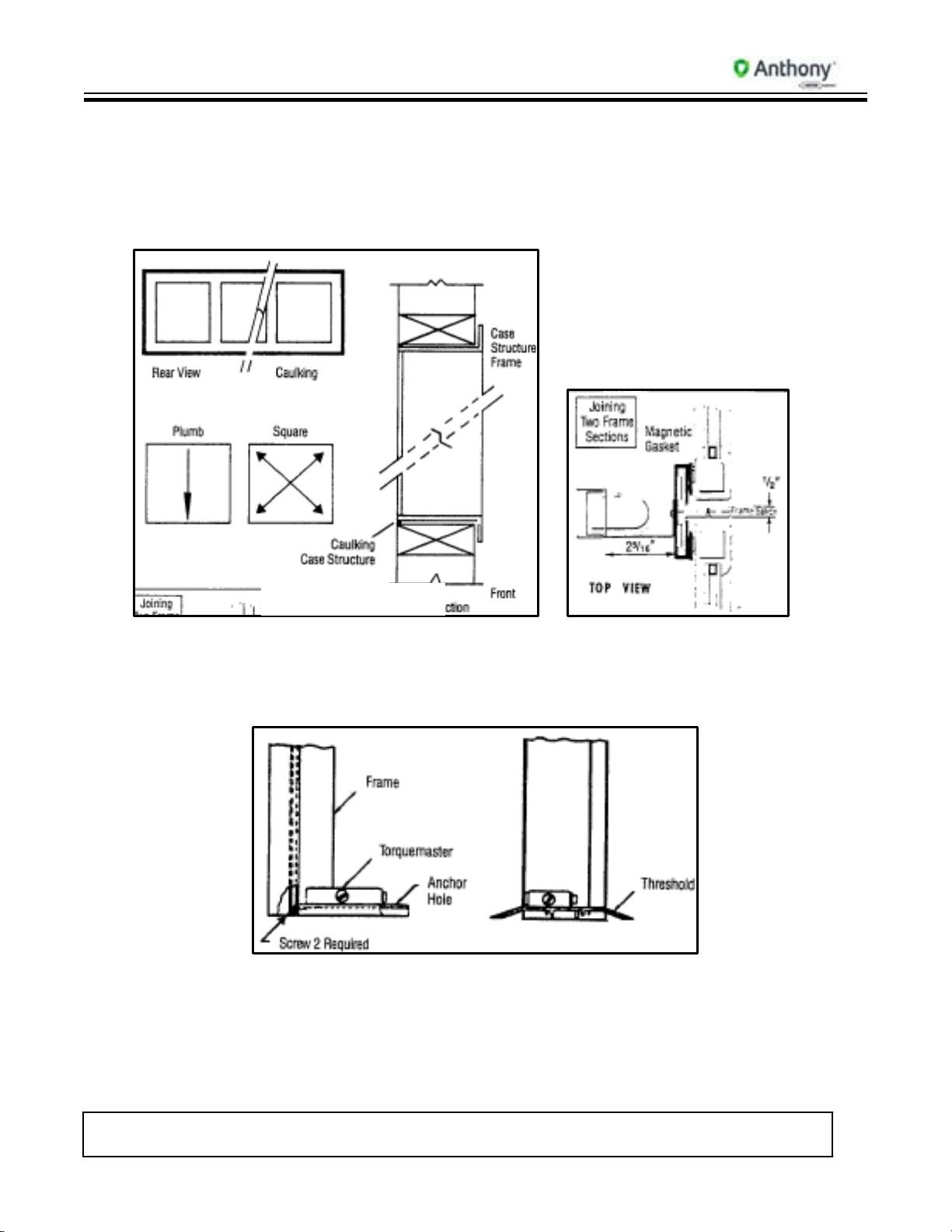

1.1.5. Joining Two Frame Sections

1.1.6. Brackets

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 9 of 76

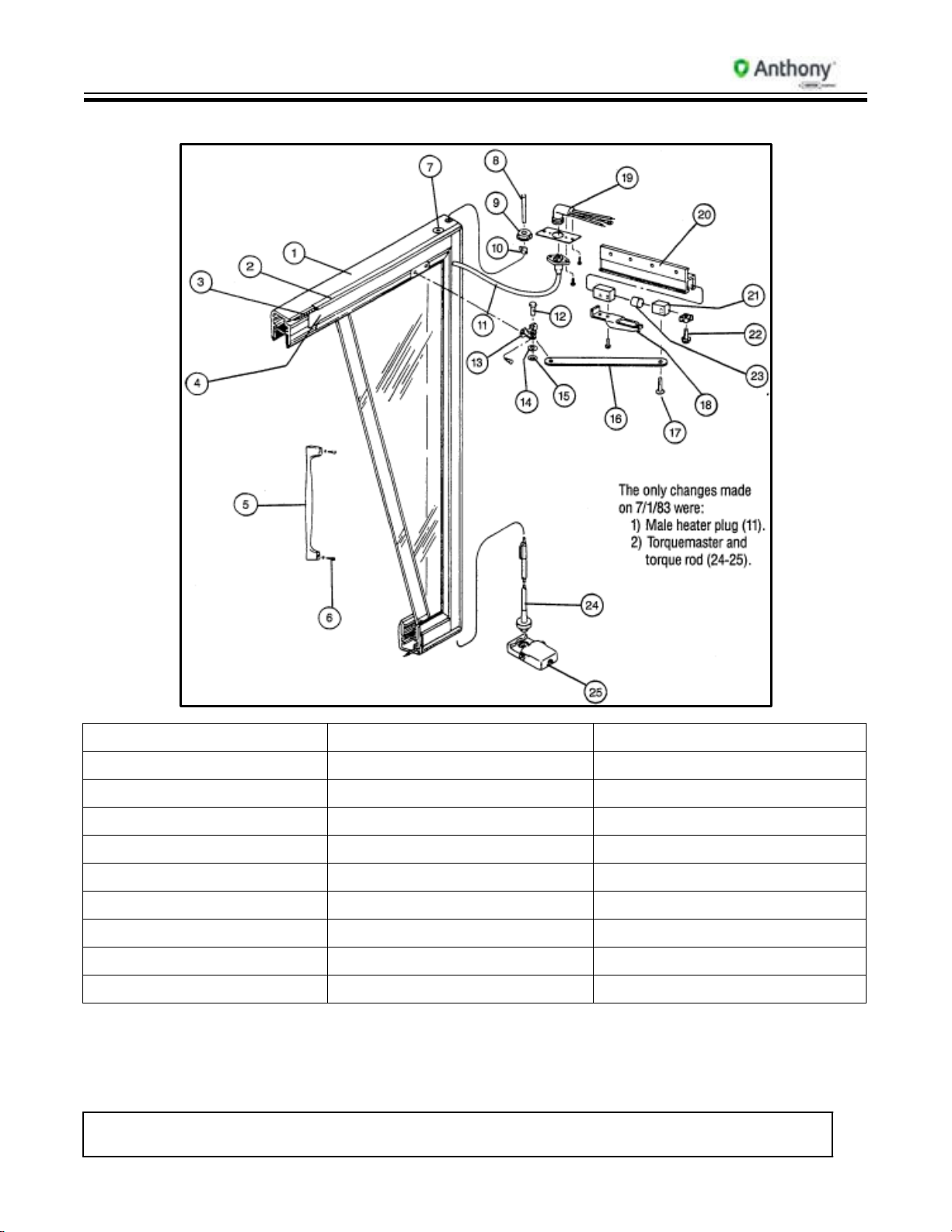

2. Model 1000 Door (Non-Reversible) (7/83 to 1/87)

Description

Description

Description

1. Door Rail 10. Safety Clip 19. Female Plug

2. Plastic 11. Male Plug 20. Door Stop Assembly

3. Heater Wire 12. Camel Back Hinge Pin 21. Door Sliding Block

4. Contact Plate 13. Camel Back Hinge 22. Door Stop Nut & Bolt

5. Handle 14. Nylon Washer 23. Bumper

6. Handle Screw 15. Camel Back Hinge Pin Holder 24. Torque Rod

7. Corner Screw 16. 10” Door Arm 25. Torquemaster

8. Hinge Pin 17. Block Screw

9. Pin Holder 18. Hold-Open

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 10 of 76

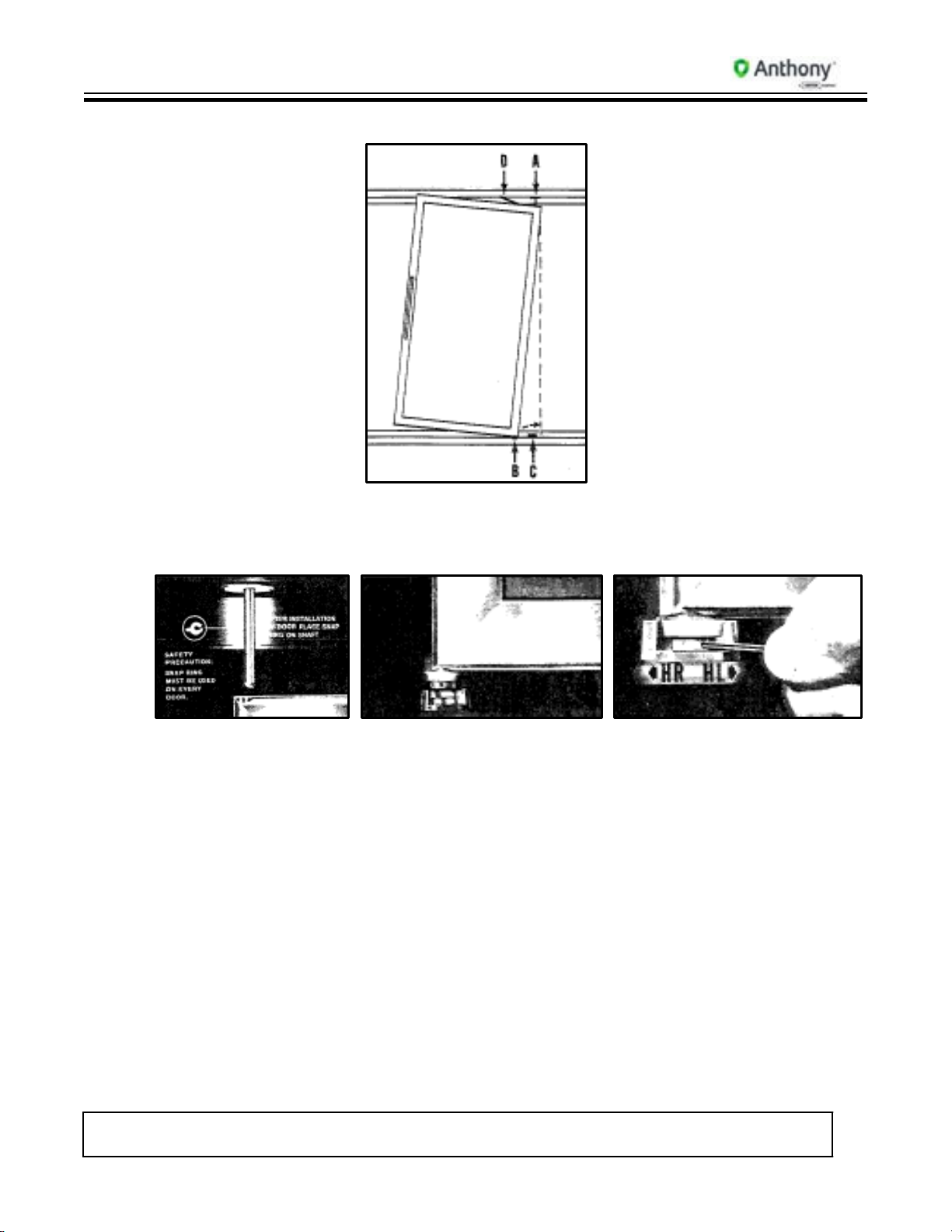

3. Model 1000 Non-Reversible Door Installation (Prior to 1983)

1. Insert top of door into top hinge pin “A”.

Safety Precaution: Snap ring must be used on every door. Place snap ring on top

hinge pin after installation of every door.

2. Lift up door and insert torque shaft “B” into socket “C”. Using two (2) long pins,

adjust torque to desired tension and set with one (1) short pin. Both long and short

pins are provided.

Note: Do not over-adjust door as this will cause door to slam.

3. Connect 90° door stop arm “D” to slide block on frame. Secure with screw

provided.

4. Reverse instructions to remove door.

Caution: Before removing door, extract torque set pin and safety snap ring

with a pair of pliers.

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 11 of 76

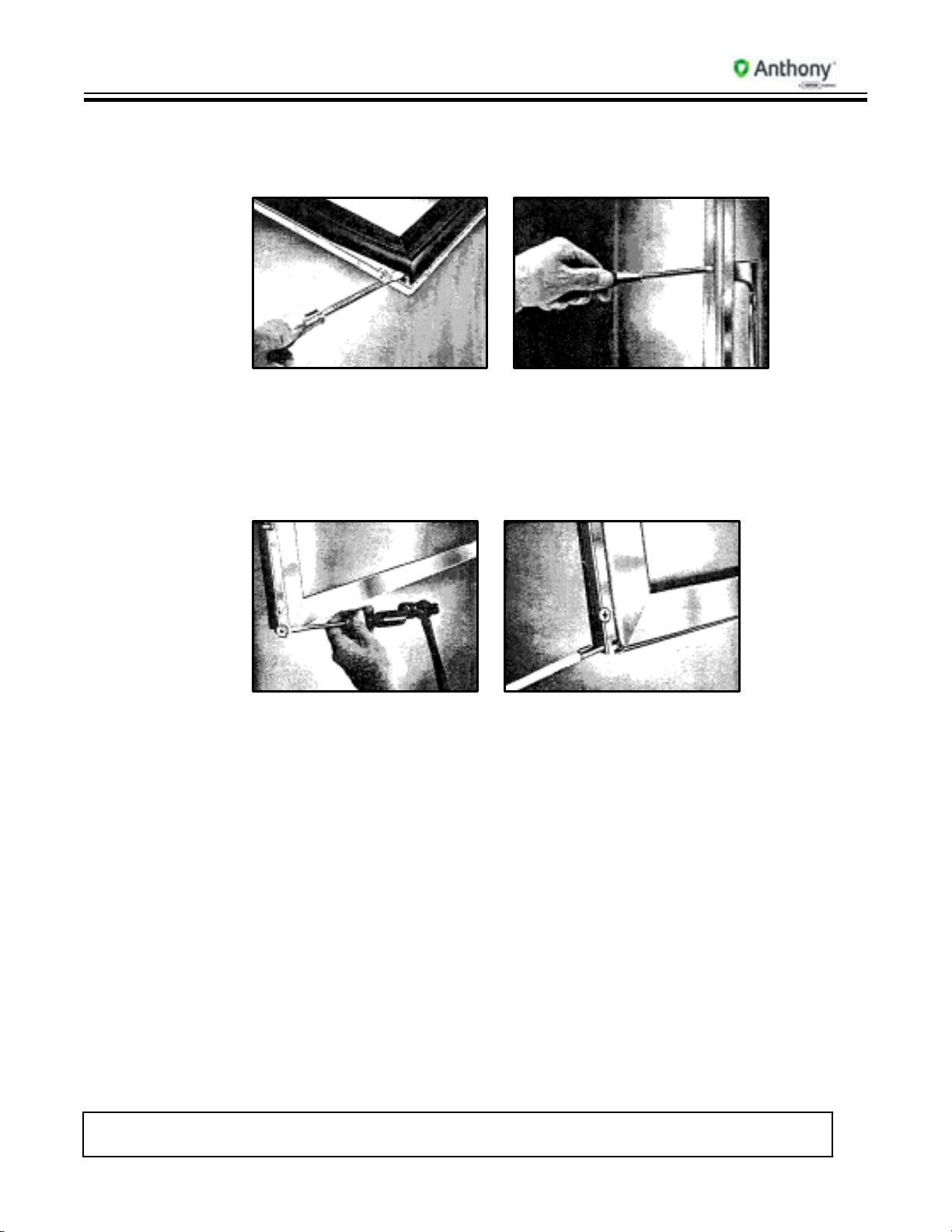

4. Model 1000 Non-Reversible Door Handle Replacement

1. To remove handle, insert 5/32” Allen wrench through back side of door frame. Handle

screws are contained in door frame.

5. Model 1000 Non-Reversible Door Handle Replacement

1. Door does not have to be disassembled to replace torque rod. Drive tapered shaft of

torque rod as shown below.

2. To replace new torque rod, align torque shaft with key way in door. Tapered shaft

must be driven flush with bottom of door.

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 12 of 76

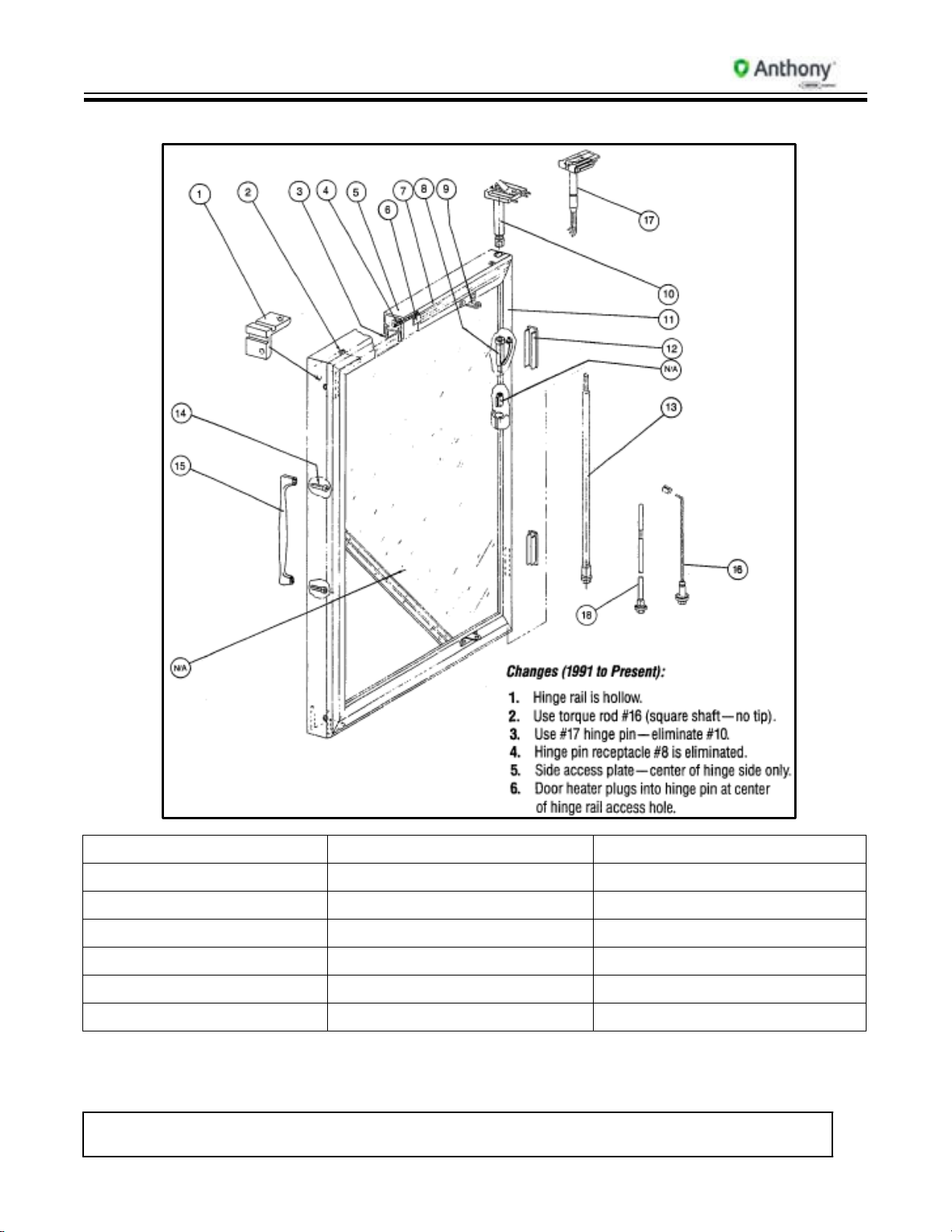

6. Model 1000R Door (Reversible) (1987 to 1991)

Description

Description

Description

1. Corner Piece 7. Door Plastic 13. Torque Rod

2. Corner Screw 8. Receptacle 14. Handle Screw

3. Glazing Channel 9. Camel Back 15. Handle

4. Heater Wire 10. Hinge Pin 16. Torque Rod (1987-1991)

5. Door Rail 11. Door Plastic 17. Hinge Pin (1991 to Present)

6. Contact Plate 12. Access Cover 18. Torque Rod (1991 to Present)

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 13 of 76

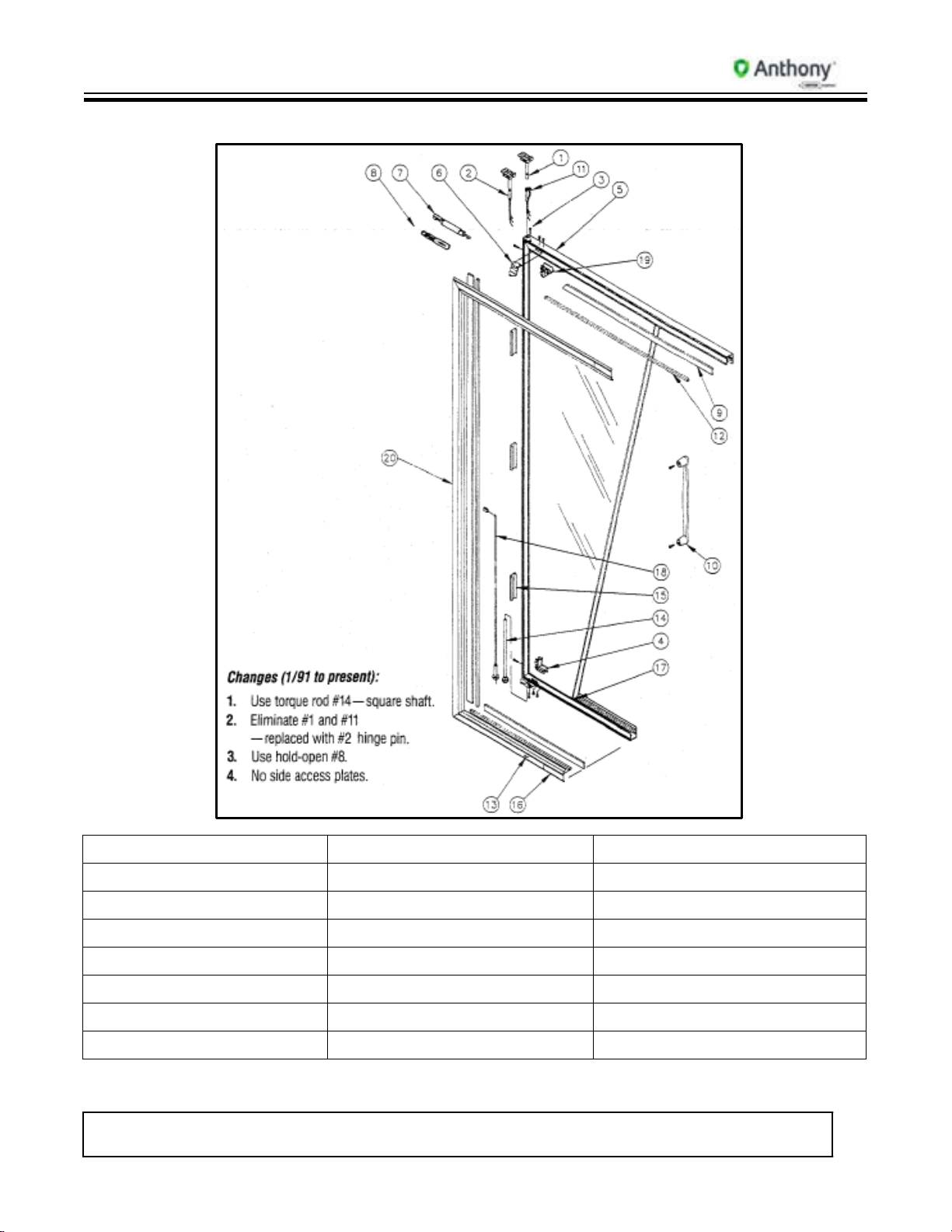

7. Model 1200R Door (Reversible) (Start 10/89)

Description

Description

Description

1. Hinge Pin 8. New Hold-Open 15. Access Hole Cover

2. Molded Hinge Pin 9. Door Foam 16. Contact Retainer

3. Corner Screw 10. Handle 17. Glazing Channel

4. Corner Piece 11. Female Receptacle 18. Torque Rod

5. Door Extrusion 12. Door Foam 19. Corner Piece

6. Camel Back 13. Contact Plate 20. Door Cover (Hinge Side)

7. Old Hold-Open 14. Torque Rod

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 14 of 76

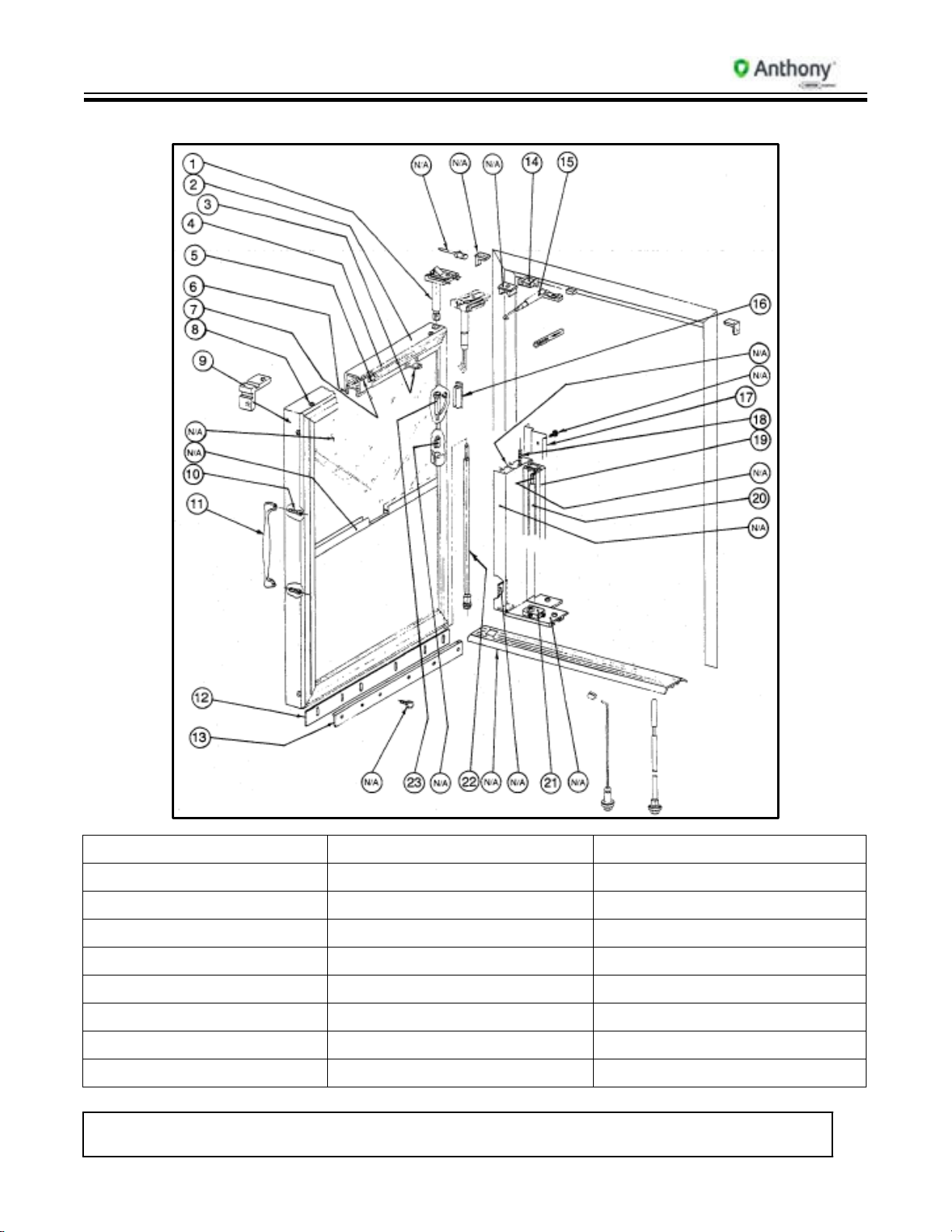

8. Model 1000, 1000R, 1200R Frame (Reversible)

Description

Description

Description

1. Safety Cover 8. End Bracket 15. Hole Plug

2. Socket 9. Ballast 16. End Caps

3. Light Socket 10. Raceway Cover 17. Socket

4. Hold-Open 11. Bulb 18. Torquemaster

5. Gasket 12. Center Bracket 19. Heater

6. Frame Cover 13. Screw 20. Center Fixture

7. End Light 14. Installation Screw

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 15 of 76

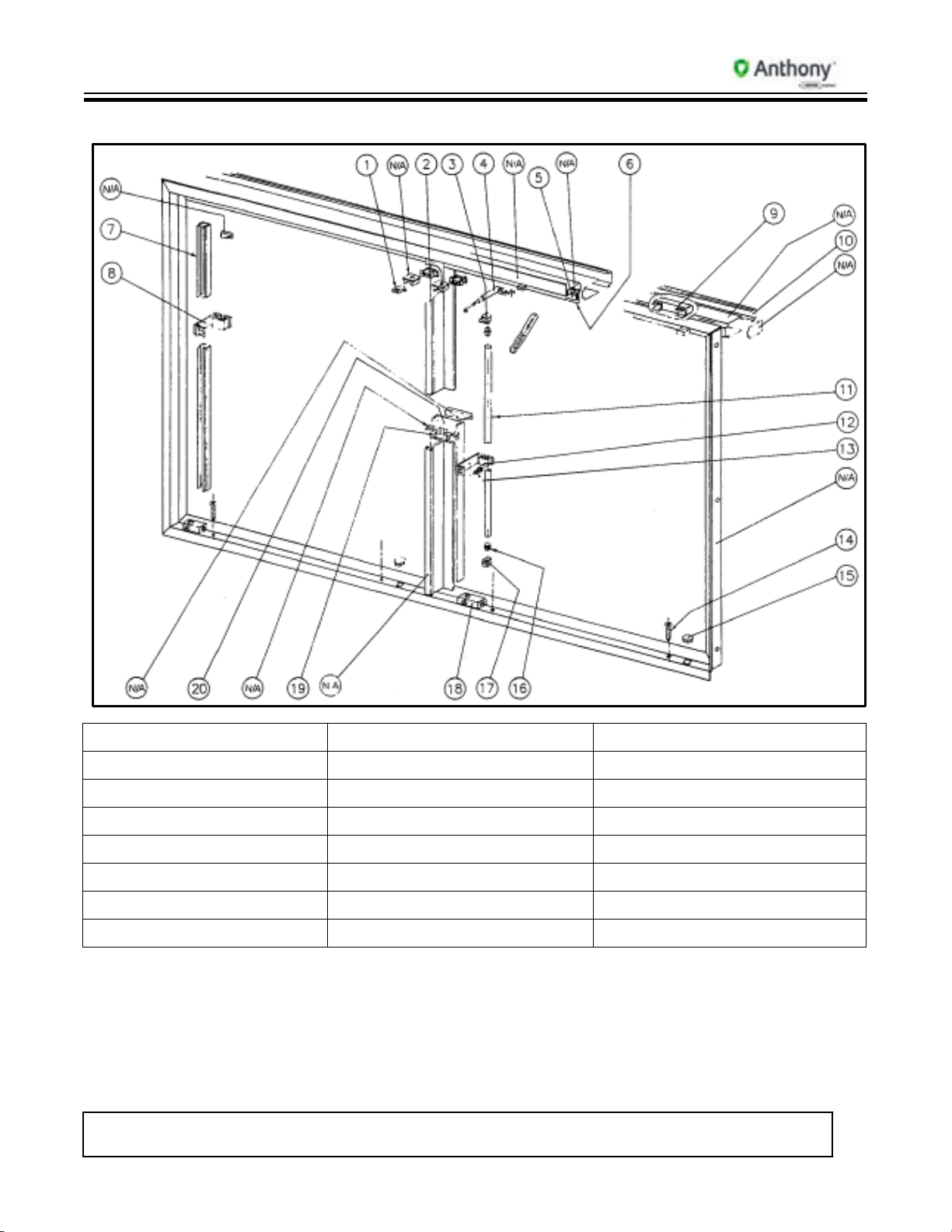

9. Models 2500, 2700, 3000 – Pass-Thru Doors (Start 1987)

Description

Description

Description

1. Hinge Pin 9. Corner Piece 17. Screw

2. Door Rail 10. Handle Screw 18. Heater

3. Camel Back Hinge 11. Handle 19. Mullion

4. Door Plastic 12. Rubber Flap 20. Frame Gasket

5. Contact Plate 13. Retainer 21. Torquemaster

6. Glazing Channel 14. Single Station Socket 22. Torque Rod

7. Door Heater 15. Hold Open 23. Female Receptacle

8. Corner Screw 16. Access Hole Cover

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 16 of 76

10. Models 1000R, 1200R (Reversible) Frames – End & Center Sections, Full Flange

Construction

10.1. Flange Placements

a. Left End Section from customer side has no flange on right end of frame.

b. Center Section from customer side has flanges on neither side.

c. Right End Section from customer side has no flanges on left end of frame.

d. Full Flange Frames have flanges on all four (4) sides.

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 17 of 76

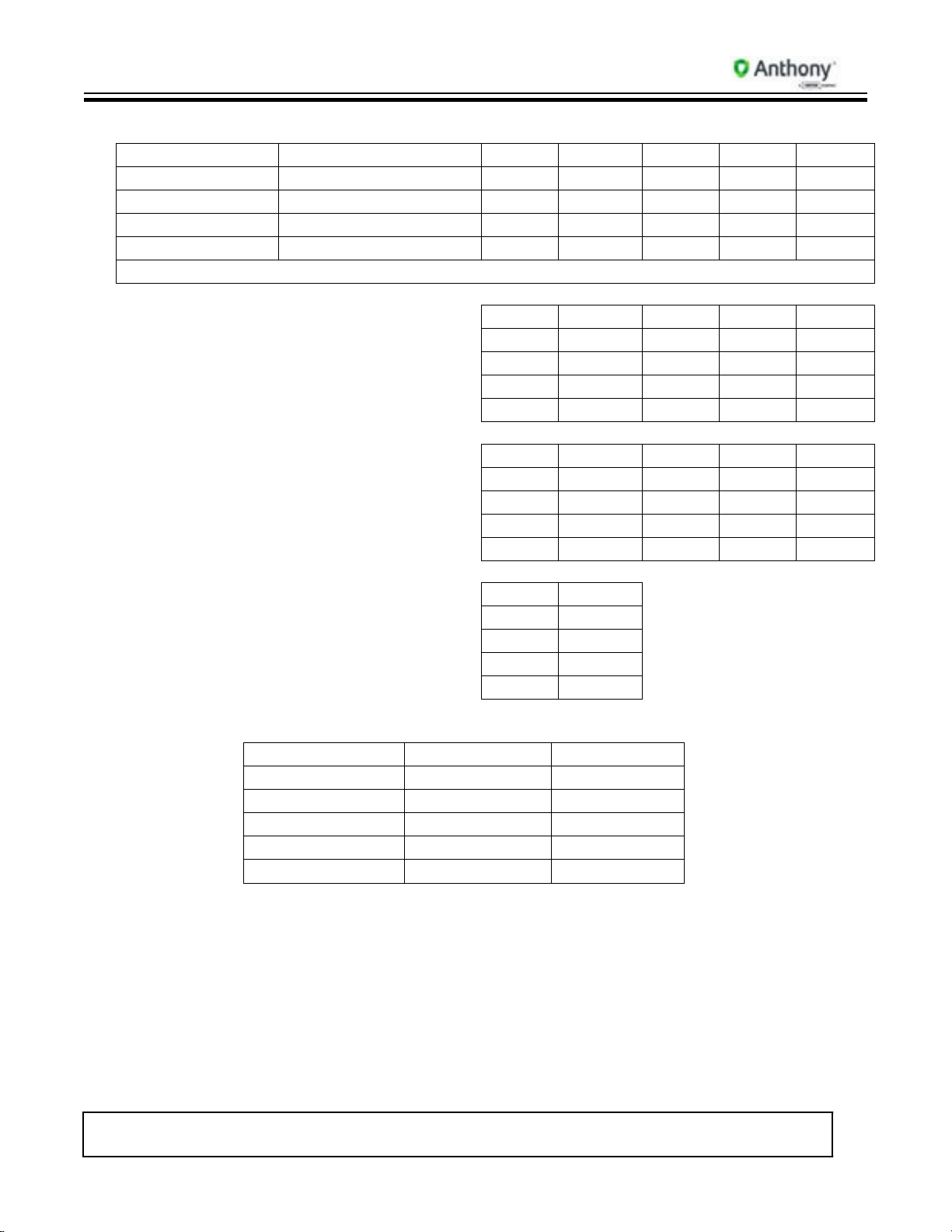

Actual Door Width

Catalog Size

A B C D E

21-5/8” 23”

C-C

46-1/2”

69-1/2”

92-1/2”

23” 46” 25-3/8”

26-3/4” C-C

54”

80-3/4”

107-1/2”

26-3/4”

53-1/2”

27-3/8”

28-3/4” C-C

58”

86-3/4”

115-1/2”

28-3/4”

57-1/2”

28-7/8”

30-1/4” C-C

61”

91-1/4”

121-1/2”

30-1/4”

60-1/2”

NOTE: C-C: Center-To-Center Dimension

F G H I J

69” 92” 115”

24” 47”

80-1/4””

107”

133-3/4”

27-3/4”

54-1/2”

86-1/4”

115”

143-3/4”

29-3/4”

58-1/2”

90-3/4”

121”

151-1/4”

31-1/4”

61-1/2”

K L M N O

70” 93” 116”

24” 47”

81-1/4””

108”

N/A

27-3/4”

54-1/2”

87-1/4”

116”

N/A

29-3/4”

58-1/2”

91-3/4”

122”

N/A

31-1/4”

61-1/2”

P Q

70” 93”

81-1/4””

108”

87-1/4”

116”

91-3/4”

122”

Actual Door Height

Catalog Size

R

51” 54”

53-13/16”

64” 67”

66-13/16”

70” 73”

72-13/16”

72” 75”

74-13/16”

76” 79”

78-13/16”

10.2. Finished Frame Width Dimensions

10.3. Finished Frame Height Dimensions

Notes: 1. Features A Thru Q denote actual finished frame dimensions.

2. For outside to outside frame flange width or height, add 1-1/8” total

11. Frame Installation

1. Read instructions completely before installing frames.

2. Openings must conform to net openings listed in Price Book or other.

3. Check size of finished frame to net opening.

for Decorator (Flat) Rail. Add 1-7/8” total for Serrated Rail.

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 18 of 76

4. Do not force frame into tight opening.

5. Check cooler opening for plumb and square as shown below. Sill must be level left

to right and front to back.

a. Jambs, header and sill should be wood for a secure installation.

b. Anthony door frame needs a sill of at least 1-1/2” for proper installation.

Frame

Installation

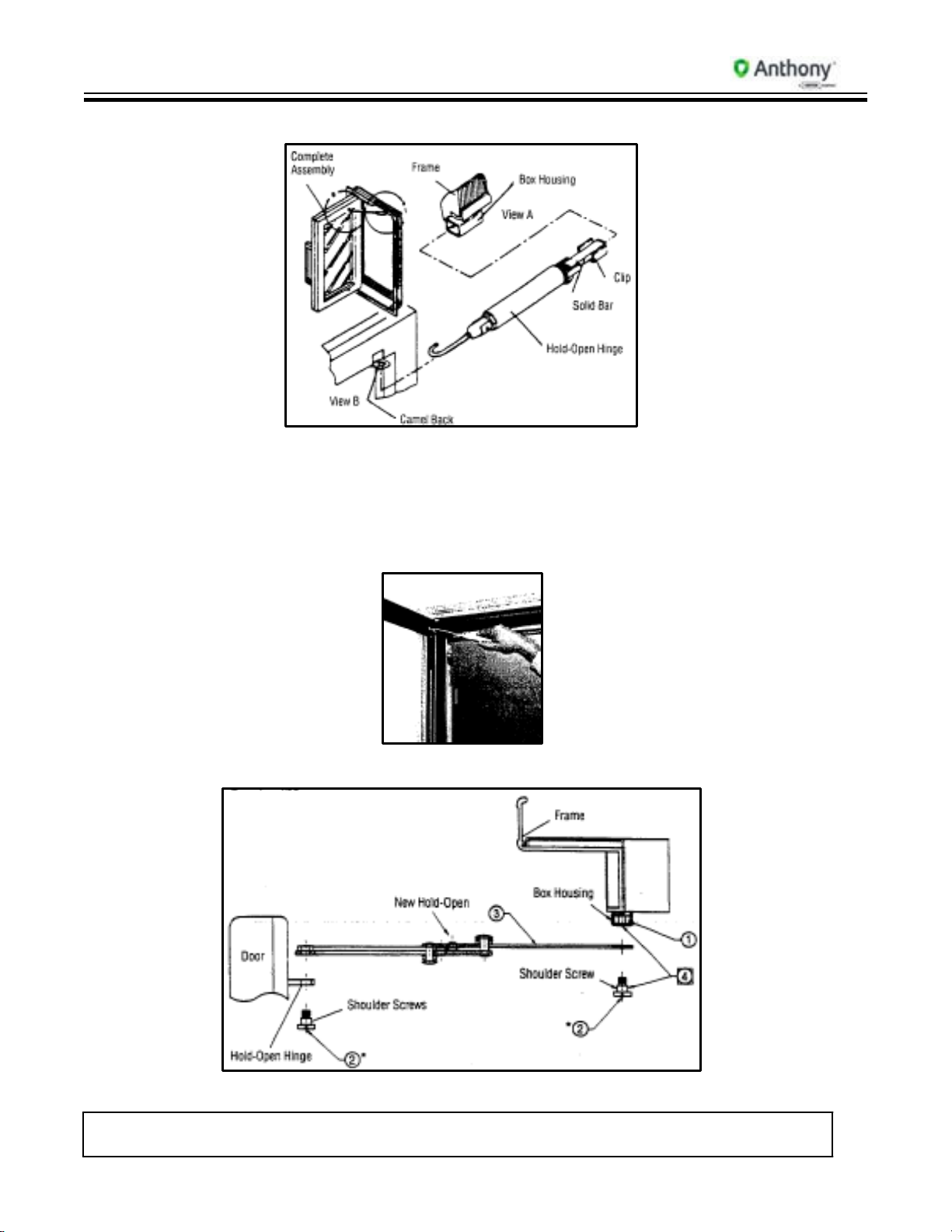

6. Set frame in opening. For safety, partially install wood screws in top of frame. Do

not tighten. Torquemaster (silver rectangular box) goes at bottom of frame. Hinge

pin to top of frame.

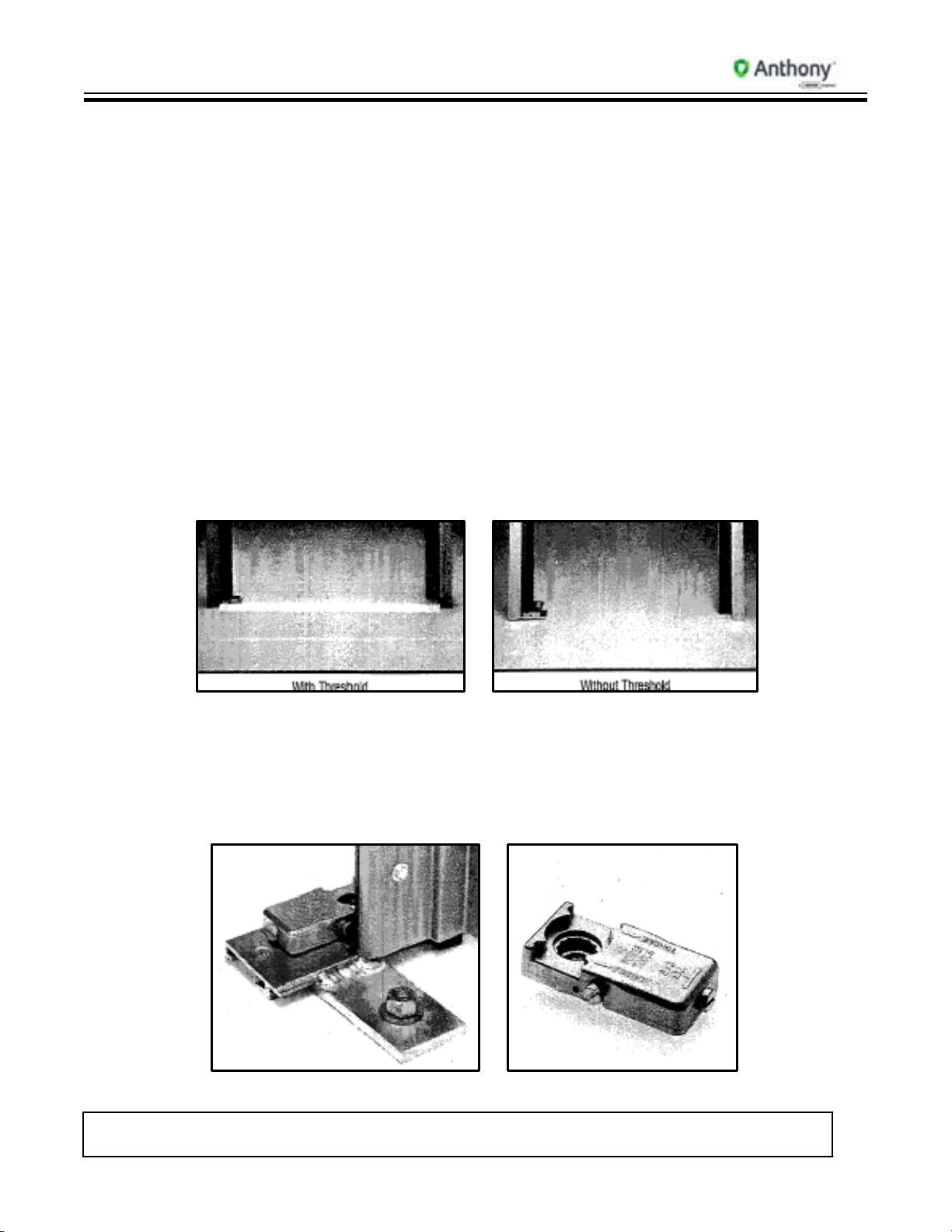

Pass-Thru Cross-Section (with/without

Threshold)

7. Check frame for square as shown. Shim as necessary. Ensure that shims are

placed as close to installation holes as possible. When shimming is necessary,

shim top to bottom and/or left end of frame and right end of frame to maintain

square of frame in net opening.

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 19 of 76

8. From the inside of case, caulk all four sides of frame between frame and case

opening, as shown above.

9. Starting with frame sill, install mounting screws and tighten; first sides, then top.

(Do not over-tighten top screws as this will bow frame.)

10. From inside the case, re-check caulking.

11. For joining frame sections without flanges on center section, or one end of left

end and one of right end of frame, align top and bottom with end sections and

join together with sex bolts provided.

12. Reversible/Cordless Door & Hold-Open Installation

1. Align door with torque rod and insert into the Torquemaster socket at base of door.

2. Engage door with hinge pin plug inserted into hinge pin plug receptacle at top of

frame.

3. Push door into top frame with thumb until hinge pin plug snaps into place.

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 20 of 76

4. Hold-Open Instructions: (1987 to 1990)

a. Hold door stop and hold-open device into camel back side of door.

Note: Change is for hook to be installed coming up from the underside of the

camel back hinge.

b. Slide hold-open bar with spring clip through box on frame until clip snaps into

place.

5. Hold-Open Instructions: (1990 to Present)

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 21 of 76

a. Insert rectangular nut provided into hold-open hinge on frame as shown below.

Note: On hold-opens starting March, 1990, the nut is affixed to hold-open arm.

b. With shoulder screws provided, mount new hold-open as shown. Tighten

screws.

c. Install thin metal slide toward top of frame.

d. Do not use power tools for installation or removal.

6. Adjust closing force by turning the screw on the front of the Torquemaster with a

flat-head screwdriver. Turn counterclockwise to tighten, clockwise to loosen. Do

not over-adjust as this will cause door to slam.

7. If necessary to square door in frame opening, turn end screw on Torquemaster

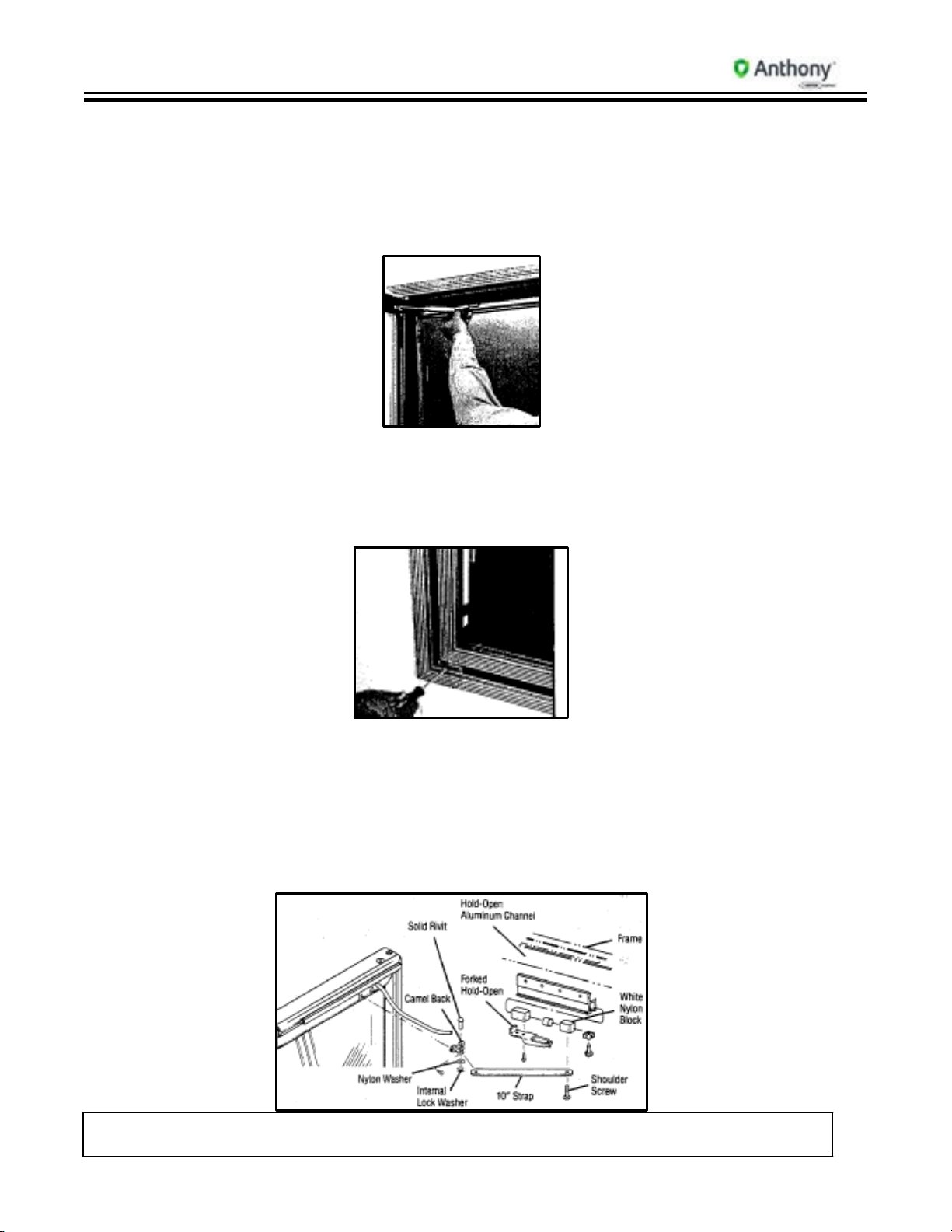

13. Hold-Open Replacement (Prior to 1987)

(marked SAG ADJ) with flat-head screwdriver.

1. To remove, insert flat-head screwdriver into shoulder screw on frame white slide

block and remove. Go to back of door and remove locking washer and solid rivet.

This will remove 10” door stop arm.

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 22 of 76

2. To remove white block inside slide channel, remove end Phillips-head screw and

slide block outside of channel.

3. To remove fork, remove two (2) Phillips-head screws. To remove complete hold-

open assembly, remove back of frame raceway for access to screws that hold

hold-open channel to frame. Remove screws.

4. Reverse instructions to replace.

14. Hold-Open Replacement (1987 to 1990)

1. Open the door and lock into hold-open position. Using a flat-head screwdriver,

release the door stop and hold-open frame attachment from slide channel as

shown below.

2. Remove door stop and hold-open device from door as shown.

3. Reverse instructions to replace.

15. Hold-Open Replacement (1987 to 1990)

1. Remove shoulder screws from both ends of slide stop arm.

Model 1000/1000R/1200R Door Service & Installation

TITLE:

99-20439-I001 Model 1000/1000R/1200R Door Service &

Installation

REV.

A

Page 23 of 76

2. With a flat-head screwdriver, turn screws counter-clockwise.

3. Reverse instructions to replace.

16. H

ld-Open Replacement (1987 to 1990)

1. Remove existing hold-open (see 15. & 16.).

2. Using a 1/4” drill, enlarge hole for hold-open on hinge side of door.

3. Insert rectangular nut provided into hold-open hinge on frame.

4. Mount new hold-open with shoulder screws provided.

5. Thin metal slide goes toward top of frame.

6. Do not over-tighten screws. (Hand tighten with hand driver only.)

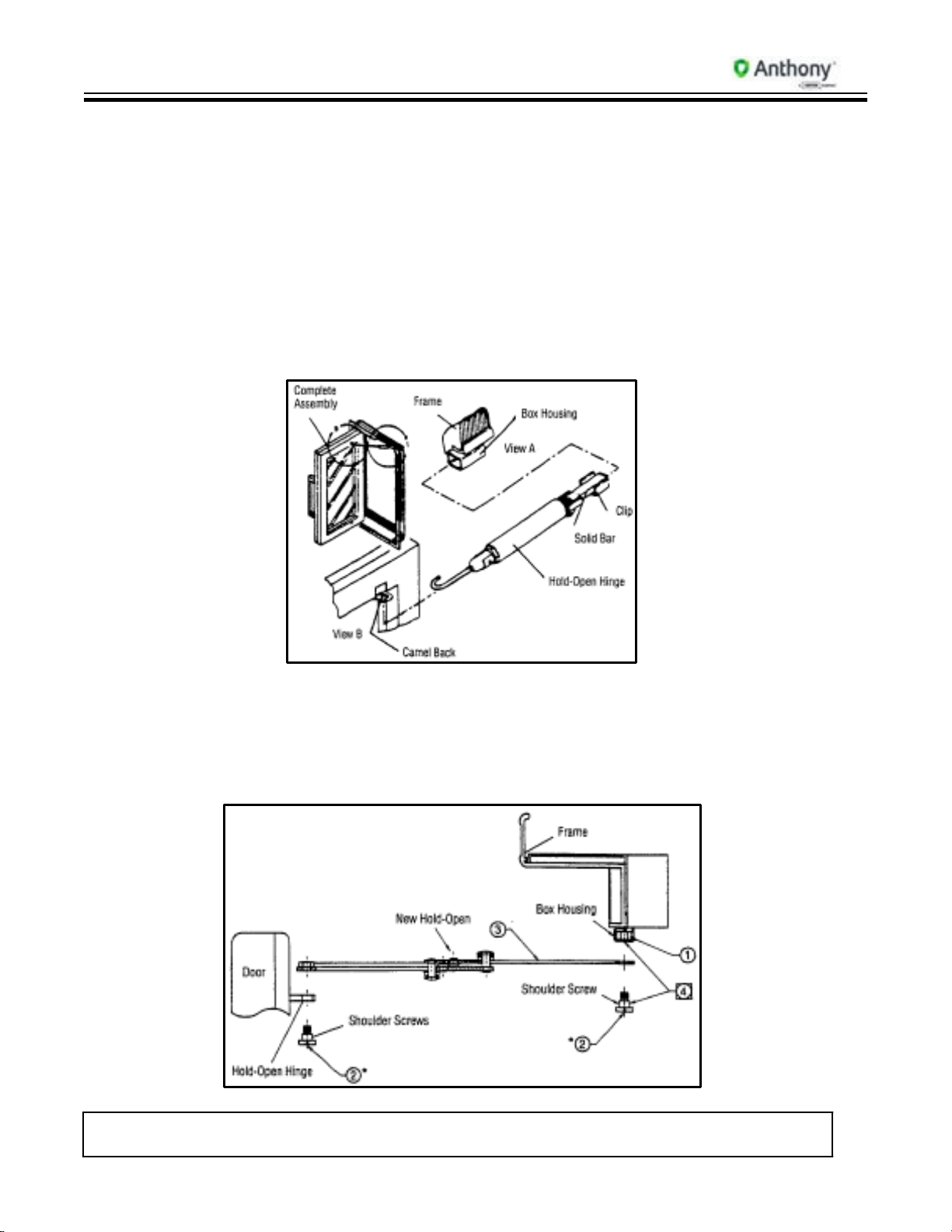

17. Models 2500, 2700 & 3000 Pass-Thru Door Installation

Note: If Roll-A-Way cart is included in order, it must be behind the door before

installing frame.

1. When threshold is desired, drill and lag on pre-drilled mounting holes only.

2. For door and hold-open installation instructions, see previous pages.

3. When door is in closed position, adjust floor wiper seal to fit flush with door slab

and screw into place.

4. For additional bottom support, Anthony Pass-Thru doors are equipped with a base

plate and two special floor anchor bolts.

Base Plate Torquemaster

Loading...

Loading...