Bedienungsanleitung

Instruction Leaflet

KK-Matchgewehr Biathlon

Small Bore Biathlon Rifle

Mod. 1827 ANSCHÜTZ Fortner

03/04

Bitte sorgfältig lesen, bevor Sie

dieses Gewehr zusammenbauen

oder benutzen.

Please read carefully before you

assemble or operate this rifle.

Index

Definitions ..................................................... S.03

Preface .......................................................... S.21

Safety instructions ........................................ S.21

General handling of rifles ........................... S.22

Ear and eye protection ................................ S.24

Laws .............................................................. S.24

Liability .......................................................... S.24

Technical data .............................................. S.25

Assembly, fitting the ANSCHÜTZ

barreled action ............................................. S.25

Cocking, loading and safety operation ..... S.25

Unloading ..................................................... S.26

Magazine ..................................................... S.26

Bolt ................................................................ S.26

Trigger ........................................................... S.27

Trigger adjustments ...................................... S.27

Dry firing device ........................................... S.32

Sight set ......................................................... S.34

Cleaning, maintenance, care, lubrication .. S.34

Accessories ................................................... S.35

Warranty....................................................... S.36

Copyright ...................................................... S.36

Drawings / Spare parts .............................. S.38

Warranty card.............................................. S.47

2

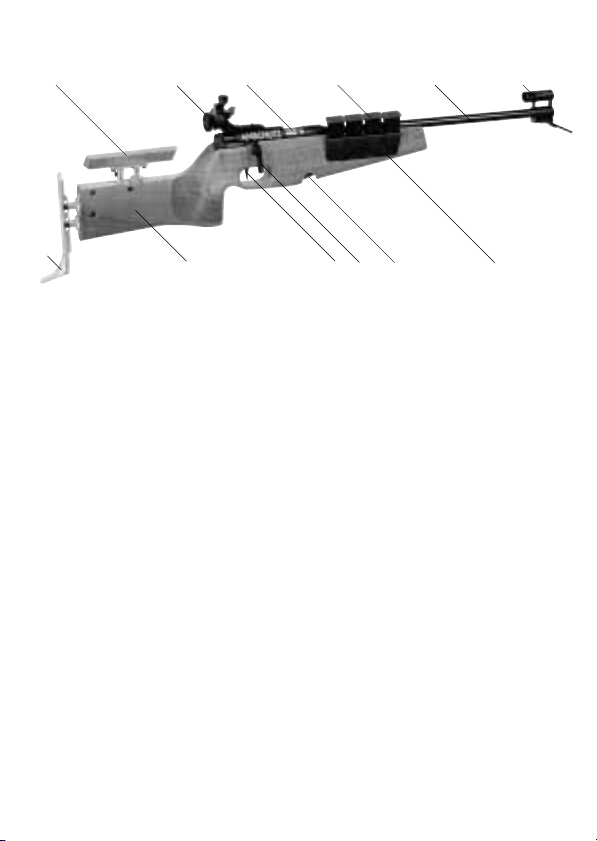

Begriffsbestimmungen / Definitions

1

8

1Schaftbacke

2Biathlondiopter

3 Patronenauswurf

4 Biathlon Magazin

5 Spezial Biathlonlauf

6 Korntunnel mit Schneeklappe

7 Mündung

8 Biathlonkappe

9 Biathlonschaft

10 Abzug

11 Geradezugverschluss

12 Magazinschacht

13 Magazinhalter

2

3

9

4 5

10

11 12

1 Cheek piece

2 Biathlon rear sight

3 Ejection

4 Biathlon magazine

5 Special Biathlon barrel

6 Front sight with snow cover

7 Muzzle

8 Biathlon butt plate

9 Biathlon stock

10 Trigger

11 Straight pull action

12 Magazine well

13 Magazine holder

6

7

13

3

Preface

Dear Friends of ANSCHÜTZ,

You have made a good choice, now that

you have decided to buy an ANSCHÜTZ

product. The many great results obtained

with ANSCHÜTZ rifles by target shooters,

participants in the Olympic Games as well

as in World and European championships

throughout the world made your choice

easy, as your rifle has benefited from our

great experience of making fine sporting

and target rifles since 1856. World-wide,

ANSCHÜTZ rifles are respected because

of their fine accuracy, impeccable design

and immaculate workmanship. Should you

still be unaware, they include:

The famous ANSCHÜTZ small bore target

rifles, target air rifles and target air pistols,

small bore biathlon rifles and repeating

summer biathlon air rifles, hunting rifles and

shotguns in diverse calibers, small bore

single loaders and repeaters, Flobert rifles,

silhouette pistols, silhouette rifles and

Varmint rifles.

Safety instructions

Attention:

Please read carefully the following articles

before using this rifle. It is extremely

important that you become thoroughly

familiar with this rifle and its operating

characteristics by carefully reading and

understanding the instructions in this booklet

before you attempt any use of it with

ammunition. Always remember the

sequence of disassembly. Should you still

20

have problems with the safe usage and

correct handling of your rifle or should you

have additional questions, please do not

hesitate to contact a competent gunsmith

or dealer or our factory directly. This

instruction leaflet is extraordinarily

important. Make sure that it is always with

the rifle especially when it is sold, lent or

otherwise given to a third person.

Only use as follows: Our products are

exclusively meant for target shooting. Their

use is subject to the „General Technical

Rules“ for all target shooting disciplines of

the INTERNATIONAL SHOOTING SPORT

FEDERATION (ISSF), Bavariaring 21,

80336 München, Germany or to the rules

of the INTERNATIONAL BIATHLON

UNION, Airportcenter, Postbox 1, A-5073

Wals-Himmelreich, Austria.

Additional copies of this booklet can be

ordered.

This ANSCHÜTZ firearm has been carefully

test fired and inspected before shipment

from the factory. The mechanism of this

firearm has been properly designed, tested

and fitted with the utmost attention to safety.

However, any mechanical device can fail

and no such device can prevent accidents

caused by carelessness or thoughtless

handling. ANSCHÜTZ cannot control the

handling of each firearm once they have

left the factory. Please take the time to

inspect the firearm carefully before use.

DO NOT USE ANY FIREARM WITHOUT

A COMPLETE KNOWLEDGE AND

UNDERSTANDING OF IT’S SAFE USE

AND PROPER HANDLING CHARACTERISTICS.

Warning:

This rifle can be dangerous if it is not used

correctly or if this instruction leaflet is not

observed. The privilege of ownership and

safe use of your rifle carries a personal

responsibility that no one should take lightly.

Rifle accidents would not occur if the

following rules of shooting safety were

observed.

The Ten Commandments of Firearms

Safety

•Learn the mechanical and handling

characteristics of the firearm you are

using.

•Always keep the muzzle pointed in a safe

direction.

•Firearms should be unloaded when not

in use.

•Be sure the barrel is clear of obstructions

before using.

•Be sure of your target before you shoot.

•Wear shooting glasses and ear protection

when you shoot.

•Never climb a tree or fence with a loaded firearm.

•Don’t shoot at a hard surface or at water.

•Never transport a loaded firearm.

•Avoid alcoholic beverages or drugs when

shooting or handling a gun.

Please note:

There is no substitute for personal

responsibility and common sense in the

handling, use and storage of firearms.

Securely store your unloaded guns away

from access by children or unauthorized

adults.

General handling of rifles and

pistols

Although it can be assumed that shooters

are familiar with the following rules we

would like to emphasize them once again

for reasons of safety.

All firearms are hazardous objects.

Extraordinary care has to be dedicated to

their use and storage.

1. Treat every rifle as though it was loaded.

Do not take anyone’s word or automatically

assume it is not loaded. Check your rifle

personally each time you handle it. The safe

and courteous way to carry a rifle when

you are with others is to leave the bolt open

so that they can easily see that the rifle

cannot be fired. Make sure that the rifle is

not loaded when you stop shooting. Make

sure your rifle is unloaded before every

transport. Never pick up your rifle with your

finger on the trigger or the trigger guard.

2. Whenever you pick up your rifle, point

the muzzle at the ground. Always point the

muzzle of the barrel in a safe direction.

Never pull a rifle towards you by the

muzzle.

3. Only use your rifle in approved shooting

ranges. Shoot your rifle only under good

visibility and daylight conditions. If you use

your rifle in an indoors range, make sure it

is adequately ventilated. Make sure that

there is a safe bullet trap which can be seen

from all sides and that there is no one in

the vicinity of your target. Be absolutely sure

of a safe backstop and target. Never fire

at a hard, smooth surface or water. Never

21

shoot at a skyline target or into the air. Do

not shoot at anything from which a bullet

might ricochet. Never fire your rifle with the

muzzle in the water or against any other

material to avoid an accident or damage

of your rifle.

4. Be sure that you use the correct am-

munition. The correct caliber can be seen

on your rifle. Load your rifle only when you

are at the range and ready to shoot. Use

only genuine ANSCHÜTZ magazines. Do

not exceed the stated magazine capacity.

Alterations to the rifle or the use of nonANSCHÜTZ magazines and accessories

may cause malfunctions.

5. Always keep your rifle clean. Be sure

the bore is not obstructed by dirt, water,

grease or any other foreign materials.

Never try to shoot out any obstruction.

6. Serious injury and damage can result

from the use of the wrong ammunition, bore

obstructions, or incorrect cartridge components.

7. Place the safety fully into „S“ or „F“

position - never inbetween. Always keep

safety in full „safe“ position until ready to

fire. Do not put your finger on the trigger

when operating the safety or whenever you

are not ready to shoot.

8. When not in use your rifle should be

stored in a locked and secure place

accessible only to you. Check first to make

sure it is unloaded. Store the rifle with

uncocked trigger. Store ammunition in a

separate and secure place. It is your special

responsibility to make sure that at all times

and especially when you are not present

your rifle is well secured, out of any reach

of children and other unauthorized persons

and in no way accessible to them. For the

safe storage of your rifle even in a locked

cabinet or safe the use of an additional

trigger lock is recommended.

Only give your rifle to authorized persons.

Never let your rifle be used by anyone who

is not familiar with the safe handling of a

rifle and these instructions. This rifle must

only be used by a responsible adult or

under his or her supervision.

9. Watch for any change in the operation

of your rifle which might impair its safety.

The safety is only guaranteed as long as

the firearm is in faultless condition. If you

suspect or note a defect or malfunction, stop

using it immediately, unload the rifle, make

sure that it is not under pressure and send it

to a competent gunsmith, the factory or its

recommended repair station for inspection.

Note: Apart from normal cleaning the rifle

must only be disassembled by an

authorized gunsmith. Please note that your

firearm must also be checked by an

authorized gunsmith when it has been

impaired by external conditions such as

corrosion etc. or when it dropped. When

you assemble or disassemble your firearm,

never try to do it by force. Unqualified

handling or disassembly can cause injuries

or irreparable damage of the rifle.

10. Your rifle should always be handled

with extreme care. Make sure that it is never

dropped or placed in such a way that it

can fall. For transport purposes your rifle

should be dry and clean. We recommend

an approved protective gun case.

22

11. You must be in good physical condition

and mental health and not under the

influence of any substance (drugs, alcohol)

which might impair vision, dexterity or

judgement. Do not use your rifle when you

are tired. Tiredness may result in a loss of

control.

12. Clean your hands carefully after

shooting and cleaning your ANSCHÜTZ

product. Residues of bullets, powder or oil

might impair the health of your skin.

13. Your ANSCHÜTZ rifle has been

carefully built and inspected by skilled

technicians to provide maximum efficiency.

The service life depends on the owner’s

care and on cleaning following this

instruction leaflet.

Ear and eye protection

You should always use approved hearing

protection and approved shatterproof eye

protection while shooting. Please remember

persons near you to also wear hearing

protection and approved shatterproof eye

protection.

Laws

Please observe the corresponding

regulations and laws for the use of firearms

in your country. Please also observe the

corresponding safety rules of sports

shooting.

Liability

1. ANSCHÜTZ does not assume any

responsibility or payment of damage claims

for damages of any kind resulting from the

disregard of these instructions, non-qualified

treatment or repair, the use of non-original

ANSCHÜTZ spare parts, incorrect handling

or care, negligence, removal of the knot

varnish or unauthorized modifications.

2. The wood of the stock or grip as well as

the PRO grip equipment have been very

carefully checked by factory inspectors

prior to shipment and has been determined

to be free of defects. Certain kinds of abuse,

such as a dropping or falling down can

cause damage to the wood for which the

owner is solely responsible. We also

assume no responsibility for defects resulting

from inappropriate transportation (mail,

plane, etc.). Please immediately contact

your forwarder in such a case.

3. Changes, alterations or manipulations to

this product or any of its parts are prohibited

and might infringe firearms regulations.

Such changes or alterations can

significantly impair the safe use of our

product and can lead to accidents involving

severe or even fatal bodily injuries. Any

product warranty will automatically lapse

in case changes or alterations are

implemented. Users are requested to

carefully inspect the product with regard to

possible changes and alterations before

use. In case of doubt you should contact us

for further information.

23

KK-Biathlon

Small bore target rifle

Mod. 1827 ANSCHÜTZ Fortner

Technical Data:

1827 ANSCHÜTZ Fortner

Caliber: .22 l.r.

Barrel length: 55 cm / 21.6“

Rifling: 55 cm / 21.6“

Total length: 104 cm / 40.9“

Total length

barreled action: 73 cm / 28.7“

Weight approx.: 4,0 kg / 8.8 lbs

Version: Repeater

1827 ANSCHÜTZ Fortner Sprint nitride

Caliber: .22 l.r.

Barrel length: 55 cm / 21.6“

Rifling: 55 cm / 21.6“

Total length: 104 cm / 40.9“

Total length

barreled action: 73 cm / 28,7“

Weight approx.: 3,7 kg / 8.2 lbs

Version: Repeater

Assembly, fitting the

ANSCHÜTZ barreled action

The stock and the barreled action are

packed separately for shipment and need

to be assembled. However, do not do this

until you have followed all the procedures

listed below.

•Wipe away excess oil from the surface

of the barreled action.

•Remove the magazine and the two screws.

•Insert the barreled action into the barrel

channel in the stock. To do this the groove

24

at the bottom of the receiver must be

attached to the iron abutment of the stock.

The receiver must not touch the abutment,

however.

•Screw in the bedding screws with the

enclosed screw driver and tighten uniformly

step by step.

For a correct adjustment we recommend to

use the torque wrench Model No. 4405

(Item No. 7006180), which is to be

adjusted to 5 Nm (50 cmkp). An audible

and sensible click shows you that the

adjusted value has been reached.

After the first assembly there might be a

warping of the wood. We would therefore

recommend to loosen and tighten the

bedding screws again after some time.

Check the tight fit of the screws before every

shooting.

Cocking, loading and safety

operation

•Degrease the bolt and the interior of the

barrel without leaving lint.

•Then insert the filled magazine into the

magazine well until you hear that it caught

the magazine holder.

•Now close the bolt and push it forward

to the stop.

•Thus the first cartridge from the magazine

is fed into the barrel and the firing pin is

cocked.

•The rifle is now ready for firing.

•After firing, open t he bolt handle and pull

it fully to the rear.

•When the bolt is closed again a new

cartridge will be loaded.

•The rifle is ready for firing again.

There is a safety lever at the left side, which

deactivates the safety mechanism in the

front position.

The rifle is

•safe, when the „S“ (safe) is visible but the

„F“ (fire) is covered.

•ready for shooting when the „F“ (fire) is

visible but the „S“ (safe) is covered.

Please note:

The safety lever must latch properly and

audibly, never between the two positions.

Unloading

For safety reasons the rifle must immediately

be unloaded if you intend to stop shooting.

Remove the magazine and operate the

bolt. This will eject the cartridge. Please also

see safety instructions for the handling of

rifles and pistols.

Magazine

•Remove the magazine from the magazine

well.

•Push the cartrige with the head first between the lateral cavities at the back of

the magazine.

•Insert the filled magazine into the

magazine well until you hear that it caught

the magazine holder.

•Now open the bolt completely, push it

forward and lock it. Thus the first cartridge

of the magazine is fed into the barrel, the

firing pin is cocked. The rifle is now ready

for shooting.

The bottom of the magazine can be pushed

forward to accept further cartridges. Fill in

cartriges one after the other.

25

Bolt

To remove the Fortner bolt

•Pull back the bolt (1).

•Pull back the thumb spring (22) a little

and turn it to the right until the groove is

in line with the breech wedge (24).

•Remove the breech wedge by pulling it

backwards.

•Screw off the breech (23).

•Pull back the bolt handle (15) and hold it

under tension. By holding the bolt handle

the locking balls (12) are free of load.

•Remove bolt by pulling it backwards.

To disassemble the Fortner bolt

Attention:

This should only be done by an authorized

expert!

•Screw off screwed conduit sleeve until it

is possible to separate front and rear part.

Do not warp the two bolt parts opposite

to each other.

•Remove spring support and firing pin

spring.

•Remove retaining collar with safety pin

by pulling it upwards.

•Pull bolt handle (15) to the stop.

•Pull bolt clamping sleeve out of the rear

bolt part. To do this you have to overcome

a considerable resistance.

•Press out the locking balls (12) to the

inside.

•Press plunger out of the bolt clamping

sleeve.

•Remove driving pin out of the bolt

clamping sleeve by pulling it upwards.

•Remove firing pin by pulling it backwards.

•Screw off thumb spring (22).

•Pull nut plate and spring for thumb spring

out of lateral groove.

To reassemble the Fortner bolt

The bolt is reassembled in reverse

sequence. The following points have to be

26

considered. (Note: the sequence and

position of the parts can be seen from the

drawing)

grease them a little they will not fall out).

•To reassemble the bolt parts attach the

screwed conduit sleeve with its teeth

opposite to the direction of fire to the rear

bolt part thus connecting it to the chamber.

•The screwed conduit sleeve has two

opposing threads each of which is

connected to the referring bolt part.

Tighten screwed conduit sleeve manually

until it is no longer possible to turn the

chamber.

•The tip of the firing pin must protrude over

the action face of the chamber.

To insert the Fortner bolt

The Fortner bolt is inserted into the receiver

in reverse sequence of the removal.

•When the thumb spring is screwed in

(approx. 4 turns) make sure that the nut

plate is vertical to the set screw.

•Before assembling the rear bolt part and

the bolt clamping sleeve insert the balls

into the rear bolt part from inside (If you

27

et

i

pa sd f

uo

r

Trigger

Warning:

Your ANSCHÜTZ target rifle offers you a

versatility of individual adjusting properties.

Please make sure that your rifle always is

unloaded when carrying out adjustments.

The trigger adjusted by the factory

guarantees utmost safety. Please observe

the general safety use when using your rifle.

Trigger adjustments

1. Trigger weight

Adjust the trigger weight with set screw

No. 10 (silver screw):

changed there will always be a corresponding change of the other as well.

To move trigger cam No. 11:

•lowest position of the trigger cam:

lowest trigger weight

•highest position of the trigger cam:

highest trigger weight

If the trigger weight is to be more than 200 g,

the trigger cam No. 11 must be adjusted to

the highest position (turn it by 180° and fix

it then). To do this you need a 2 mm hex

key and perhaps tweezers.

•if you turn it to the left:

You release the screw

•if you turn it to the right:

You tighten the screw

Attention:

Please ensure the trigger cam is positioned

correctly. Be very careful tightening the

small cam screw as it is easily broken!

Please check the sear engagement according to paragraph No. 3 when you have

finished this process. It might have to be

adjusted as well. The precise adjustments

of the trigger weight and first stage weight

are carried out with the set screws No. 10

(trigger weight) and No.9 (first stage weight).

•if you turn it to the right:

trigger weight is increased (+)

•if you turn it to the left:

trigger weight is decreased (-)

Trigger weight and first stage weight

depend on each other with regard to the

mechanic mechanism. If one of them is

28

2. First stage weight (only for two-stage

triggers)

Adjust first stage weight with set screw

No. 9 (black screw):

•if you turn it to the right:

first stage weight is increased (+)

•if you turn it to the left:

first stage weight is decreased (-)

Trigger weight and first stage weight

depend on each other with regard to the

mechanic mechanism. If one of them is

changed there will always be a corresponding change of the other as well.

Attention:

Do not reduce either trigger weight screw

to zero or lower as the trigger pull may

become erratic.

3. Sear engagement

The sear engagement is the distance between the second stage and the release of

the trigger.

Important note:

To protect your precise trigger and to

guarantee perfect operation you should

always close the action carefully. If the sear

engagement of single stage triggers is too

small and the trigger weight is too low or if

the first stage of two-stage triggers is too

short, the trigger might release inadvertently

by a sudden impact or too powerful closing

of the action if the rifle is loaded and not in

the ”safe“ position.

Adjustment of the sear engagement for two-

stage triggers with set screw No. 5:

•if you turn it to the right:

sear engagement is shortened

•if you turn it to the left:

sear engagement is extended

Adjustment of an optimum sear engagement:

Make sure your rifle is not loaded. Cock

your rifle and release the trigger. Check if

the trigger releases as desired.

The sear engagement is too long:

There is a small distance between the

second stage and the release of the trigger.

•Turn set screw No. 5 clockwise after

cocking and releasing (approximately

1/8 turn each).

•Repeat this process until you do not feel

the second stage anymore. Then turn

1/5 turn back to the left. Thus the optimum

sear engagement is adjusted.

The sear engagement is too short:

There is no second stage. The trigger

releases un-defined without second stage.

•Turn set screw No. 5 counter-clockwise

for at least 1/4 turn after cocking. Then

release the trigger and check if there is a

second stage. If not, repeat this procedure until you feel a second stage.

•As soon as you feel a second stage

proceed according to the points of the

paragraph „The sear engagement is too

long“ to obtain an optimum sear

engagement.

For the adjustment of the sear engagement

for single stage triggers with set screw

No. 5 see point 7:

4. First stage (only for two-stage

triggers):

The single stage is the distance between

the trigger blade from zero position to the

second stage.

29

•if you turn it to the left:

overtravel is extended

Attention:

The trigger stop set screw No. 8 can be

turned over the second stage or first stage

function. Malfunction (the trigger does not

release)!

6. Adjustment of the trigger blade

r

uo

et

Adjustment of first stage with set screw No. 4:

•if you turn it to the right:

first stage is shortened

•if you turn it to the left:

first stage is extended

Attention:

Set screw No. 4 (first stage) can be turned

past the second stage function. In this case

the trigger does not work anymore.

Danger! Do not under no circumstances

remove the first stage completely in order

to change the two-stage trigger into a single stage trigger.

5. Trigger stop:

The trigger stop is the distance from the second stage to the stop of the trigger blade.

Adjustment of the trigger stop with set screw

No. 8:

•if you turn it to the right:

overtravel is shortened

i

pa sd f

30

•Loosen hex screw No. 7

•Trigger blade No. 6 can be moved in the

longitudinal guide and can be tilted

laterally.

7. Change of two-stage trigger into

single stage trigger

Adjusting process:

•Turn first stage weight screw No. 4 clockwise until you have reached the maximum

first stage.

•Cock the rifle.

•Turn set screw No. 5 (first stage) counterclockwise until the trigger releases.

•Turn set screw No. 5 from this position

approx. 1/4 turn clockwise.

The trigger is now adjusted to single stage

operation, there is no more first stage.

Warning:

Single stage triggers are very sensitive and

must be operated with special care.

The sear engagement of 5/

tained after the action is closed. In combination with a minimum trigger weight

mm is ob-

100

there might be a malfunction and an

increased risk (inadvertent shot

release).

8. Change of single stage trigger into

two-stage trigger

•Turn trigger stop set screw No. 8 approx.

2 1/2 turns to the left (adjust max. trigger

stop longer).

•Release the safety of the trigger and cock

the rifle.

•Turn set screw No. 5 approx. 2 1/2 turns

counter-clockwise.

•You should now feel a second stage

•To adjust the optimum sear engagement

proceed according to paragraph 3.

•Perhaps you have to adjust the first stage

according to paragraph 4, the trigger

stop according to paragraph 5, the

trigger weight according to paragraph 1

and the first stage weight according to

paragraph 2 to the desired values.

9. Malfunctions of the trigger due to

wrong adjustment procedure

is attached correctly.

•The trigger stop set screw No. 8 is

screwed in too much. Turn it a few turns

to the left until the cocking piston or firing

pin will release again.

The trigger does not catch the cocking

piston or firing pin:

•Set screw No. 4 (first stage) is screwed

in too much.

•Check to see if the spring is correctly

attached and not defective.

The first stage trigger is adjusted too

tightly:

•Turn set screw No. 5 stepwise 1/4 turn to

the right until the firing pin is caught.

Catch rebound spring is too weak or

defective:

•Send your trigger to the factory or your

service center for inspection.

10. Safety

If the trigger is not adjusted correctly malfunctions may occur. Tampering with the

trigger adjustments will not result in any

success. Therefore proceed as follows:

After every change the function of the

trigger must be checked. When the

malfunction is removed check the desired

trigger values and adjust them again if

necessary.

The trigger catches the firing pin, but the

trigger does not release:

•Make sure that the safety of the trigger is

released.

•Check if there is a trigger cam and that it

On the left side of the trigger there is a

safety lever. Please see chapter „Cocking,

loading and safety operation“.

11. Maintenance

Please see chapter „Cleaning, maintenance, care, lubrication“.

Important note:

To protect your highly accurate trigger and

to maintain perfect functioning always close

the bolt carefully.

31

Attention:

Please attach as follows:

If you change the trigger remove the bolt

from the receiver when fitting the trigger as

otherwise the trigger will be damaged.

Dry firing device

The length of the firing pin is adjusted so

that it definitely ignites the cartridg es. If there

is no cartridge or cartridge case in the

chamber, the firing pin as well as the rim of

the chamber may be damaged when

dryfiring for a longer period. In order to

prevent any possible damage use either a

cartridge case (after about 5 practice shots

insert a different case) or preferably a tone

down disc 1927F-40. With this device you

can practice under competition conditions

without having to use ammunition.

Illustration Dry firing device

•Screw off breech1827F-24.

•Remove the Fortner action.

•Screw off screwed conduit sleeve

1827F-8.

•Pull off chamber 1827F-5 from the rear

bolt part.

•Attach tone down disc to firing pin.

•Screw together chamber1827F-5 and

rear bolt part with the help of screwed

conduit sleeve1827F-8.

•Cock Fortner bolt and insert it again.

Do not forget to remove the tone down disc

for live firing.

32

Sight Set

Assembly

The rear sight is pushed onto the rail of

11 mm width and fixed with the 2 screws

(tighten manually).

Vertical and horizontal adjustment

The screws for vertical and horizontal

adjustment have clicks. The impact point

changes from click to click.

•Shots are too high:

Turn knob into „H“ direction

•Shots are too low:

Turn knob into „T“ direction

•Shots are too far at the right:

Turn knob into „R“ direction

•Shots are too far at the left:

Turn knob into „L“ direction

Zeroing

After test firing of the rifle both screws

should be brought into the „0“ position.

•Loosen threaded pins in the knob.

•Bring knobs into the „0“ position.

•Tighten threaded pins in the knob

manually.

Cleaning and care

Your ANSCHÜTZ rear sight is a highly

accurate device of utmost quality and

therefore needs special handling. Good

care and maintenance guarantee perfect

functionning. Protect your rear sight from

dust and dirt. Guides and spindles must

not be oiled or greased.

Attention:

Your ANSCHÜTZ rear sight has been

adjusted carefully and without play with the

help of special tools. It has been checked

several times and therefore does not require

any additional adjustments. Therefore only

operate the screws for vertical and horizontal adjustments as described above. Do not

turn the screws beyond their stop as this

would cause a permanent damage to the

screw and thread. In order not to endanger

your right of warranty, please contact your

dealer or our repair service in case any

malfunctions might occur.

Cleaning, Maintenance, Care,

Lubrication

Even after considerable use, your

ANSCHÜTZ small bore match rifle will not

require much attention - a tribute to its solid

design, first class materials, well proven

ANSCHÜTZ workmanship and precision.

If you follow the recommendations below,

you will help maintain the excellent

performance of your rifle for a long time.

If the rifle comes from the cold into warmth

after test firing or after competition,

condensed water is deposited especially on

metal parts and in the interior of the barrel.

If this condensed water is not removed

quickly, rust might occur. Rust makes the

interiour of the barrel rough and the

shooting performance will decrease.

Before initial shooting:

•Carefully deoil the rifle. Deoiling should

be carried out at room temperature as too

33

many residues would remain in the barrel

at low temperatures.

After initial shooting:

•Dry clean (remove powder residues).

•Leave the rifle locked and the snow cap

closed, do not take into a warm room.

After competition:

•Warm up rifle with opened bolt and snow

cover to room temperature.

•Carefully remove condensed water on the

external parts.

•Disassemble bolt and also remove condensed water from the individual parts.

Oil with a suitable gun oil.

•Carefully clean the interior of the barrel

with a cleaning rod to remove condensed

water and residues of firing. Then oil the

interior of the barrel with a resin and acid

free oil.

Maintenance of the trigger:

•Lubricate the bearings slightly with cold

resistant molybdenum disulphide grease

once a year.

•Spot a small amount of oil into the bearing

parts using a needle.

•The internal parts should not be washed

with spray or oil to avoid resin or other

residues in the trigger.

is horizontal or even with the stock up to

avoid any contamination of the trigger

mechanism.

Protect your rifle against dust, sand,

humidity, heat and other harmful influences.

Vacuum clean your gun case or soft gun

case once a month to remove dust and lint.

Gun cases and soft gun cases should have

a smooth and dust rejecting inner lining.

Leave your gun case or soft gun case open

when you store them at home so that

possible humidity can escape.

Adding a humidity absorber reduces the

development of humidity. A slight oil film

on the steel parts additionally protects your

rifle against corrosion. Be aware of other

possible changes or damage. In such a

case take your rifle to an authorized

gunsmith for checking or send it to our

factory.

To reduce the risk of damage in transit, we

recommend the disassembly of the barreled

action from the stock, especially on flights.

Accessories

Please ask for our catalog or take a look at

our website under www.anschuetzsport.com

Attention:

When cleaning the rifle no dirt, residues of

solvents, grease or non-suitable oils must get

into the trigger mechanism. We therefore

recommend either to use our cleaning rod

guide or to clean your gun in a way that it

34

Warranty

A warranty of 2 years will be issued. Parts

which are subjected to wear are not part

of this warranty. In the case of warranty we

substitute the defective parts free of charge.

Cases of warranty will only be accepted if

the article in question and the corresponding purchase receipt plus filled-in

warranty card are presented. Warranty will

not be accepted if changes or repair works

have been carried out by persons who are

not authorized, if the rifle is not used

correctly or if non-ANSCHÜTZ original

parts were used.

In addition a damage to your firearm is not

subject to warranty if it is due to an

ignorance of this instruction leaflet or

improper care or treatment.

We wish you much pleasure and success

with your ANSCHÜTZ product and would

be pleased if you could let us have your

ideas on our products and the design of

this instruction leaflet.

Copyright

Product specifications, design and model

changes are subject to change without prior

notice. Dimensions and colors are subject

to change. With reservation of misprints and

errors. Goods are subject to prior sale.

Delivery subject to the presentation of the

referring license for the purchase of

firearms.

All rights of this instruction leaflet reserved.

The use of the instruction leaflet, also in

excerpts, is not allowed without the

permission of J.G. ANSCHÜTZ GmbH &

Co. KG and otherwise is punishable. This

is especially applicable for unauthorized

copying, translations and read-ins in

electronic systems.

ANSCHÜTZ, the ANSCHÜTZ logo and the

ANSCHÜTZ logo in connection with the

slogan „Die Meister Macher“ (also in

modified spelling) and „Soft-Link®“ are

protected brands of J.G. ANSCHÜTZ

GmbH & Co. KG, Ulm, Germany. The

unauthorized use of this brand name is not

allowed and punishable.

35

Übergabe des Artikels vorlag. Für Mängel, die auf unsach-

gemäße Behandlung oder auf Reparaturen zurückzuführen

sind, stehen wir nicht ein. Die Garantieleistung steht in unse-

rer Wahl in Nachbesserung oder Neulieferung. Schadens-

ersatzansprüche – aus welchem Rechtsgrund auch immer

geltend gemacht – sind ausgeschlossen. Wir bitten, diese

Karte – von Ihrem Waffenfachgeschäft ausgefüllt und unter-

schrieben – mit dem Artikel an uns einzusenden.

J.G. ANSCHÜTZ GmbH & Co. KG · Jagd- und Sportwaffenfarbrik

Postfach 1128 · D-89001 Ulm/Germany · www.anschuetz-sport.com

FABRIKATIONS-NR.:

Serial-No. / Numéro de série:

DATUM DES VERKAUFS:

Date / Date d‘achat:

GEKAUFT BEI:

This item was bought from / Détaillant:

Dieser Artikel wurde zum Verkauf freigegeben, nachdem er

selbst, seine Materialien und Einzelteile strenge Kontrollen

durchlaufen haben, oder das Gewehr beim Beschuss seine

Haltbarkeit und Funktion unter Beweis gestellt hat. Wir über-

nehmen für zwei Jahre volle Garantie auf Material- oder

Bearbeitungsfehler (ausgenommen Schaft- und Federbrüche),

sofern ein Mangel nachweisbar bereits im Zeitpunkt der

<<<<GARANTIE>>>>

Stempel und Unterschrift des Fachhändlers

stamp of dealer / timbre du détaillant

✄

45

<<<<WARRANTY>>>>

After throrough testing of materials and finished parts this

item has passed a rigid final inspection as well as proof

testing or test shooting. If, despite these precautions, there

is any failure due to defective materials or workmanship

(except brocken stocks and springs) within two years the

necessary repairs will be carried out without charge, in so

far as the item was evidently defective at the time of

purchase. No claims under warranty can be accepted if

the item has been subjected to improper use or unauthorized

repair. The item will be either repaired or replaced at our

discretion. Claims for compensation – put forward for any

legal cause whatsoever – are excluded. This warranty card

– completed and stamped by your dealer – must be

<<<<GARANTIE>>>>

Cet article n‘a été mis en vente qu‘après une vérification

minutieuse des pièces et matières à tous les stades de la

fabrication ou après avoir subi un contrôle de fiabilité et

de bon fonctionnement au banc d‘épreuve. Nous la garan-

tissons pendant deux ans contre tout défaut de matière ou

vice de fabrication (sauf contre les bris de crosse ou de

ressorts) dans la mesure ou il peut être prouvé qu‘un défaut

éxistait déjà au moment de l‘achat de l‘article. Nous ne

répondons pas des défauts résultant d‘une utilisation

incorrecte ou de réparations. Nous nous réservons d‘exé-

cuter la garantie soit par remise en état soit par échange.

Les demandes en dommages-intérêts sont irrecevables quel-

le que soit la cause mise en avant. Veuillez faire remplir

46

returned with the item for repairs.

et signer cette carte par votre armurier et nous l‘adresser

avec l‘article.

J.G. ANSCHÜTZ GmbH & Co. KG · Jagd- und Sportwaffenfarbrik

Postfach 1128 · D-89001 Ulm/Germany · www.anschuetz-sport.com

J.G. ANSCHÜTZ GmbH & Co. KG · Jagd- und Sportwaffenfarbrik

Postfach 1128 · D-89001 Ulm/Germany · www.anschuetz-sport.com

✄

Fabr.-Nr.:

Serial No.:..........................................................................

Bitte hier eintragen · Please fill in here

Originalschussbild Ihres Gewehres 5 Schuss auf 50 m

Original group of your rifle 5 shots at 50 m

J.G. ANSCHÜTZ GmbH & Co. KG

Jagd- und Sportwaffenfabrik

Daimlerstrasse 12

D-89079 Ulm / GERMANY

Postfach 11 28

D-89001 Ulm / GERMANY

Telefon (++49)-(0)-731-4012-0

Telefax (++49)-(0)-731-4012-700

anschuetz-sport.com

JGA-Info@anschuetz-sport.com

DSchi · 03/04 · 1.500

Loading...

Loading...