APW7212

1MHz, High-Efficiency, Step-Up Converter with Load Disconnection

Features

• Wide 0.8V to V

• Low 1.05V (typical) Start-Up Voltage

• Low 40µA No Load Bias Current

• 100mA Output from a Single AA Cell Input

• 250mA Output from a Dual AA Cell Input

• Internal Synchronous Rectifier

• Up to 92% Efficiency

• <1µA Quiescent Current during Shutdown

• Current-Mode Operation with Internal Compen-

sation

- Stable with Ceramic Output Capacitors

- Fast Line Transient Response

• Fixed 1MHz Oscillator Frequency

• 1.2A Current-Limit Protection

• Built-In Soft-Start

• Over-Temperature Protection with Hysteresis

• Available in a 2mmx2mm TDFN2x2-8 and TSOT-

23-6A Packages

• Halogen and Lead Free Available

(RoHS Compliant)

Input Voltage Range

OUT

Applications

• Cell Phone and Smart Phone

• PDA, PMP, and MP3

• Digital Camera

• Boost Regulator

General Description

The APW7212 is a synchronous rectifier, fixed switching

frequency (1MHz typical), and c urrent-mode step-up

regulator. The devic e allows use of small inductors and

output capacitors for portable devices. The current-mode

control sc heme provides fast transient response and

good output voltage accuracy.

At light loads, the APW7212 will automatically enter in

pulse frequency modulation(PFM) operation to reduce

the dominant switching losses. During PFM operation,

the IC consumes very low quiescent current and maintains high efficiency over the complete load range. The

device has a 1.05V start-up voltage and can operate with

input voltage down to 0.8V after start-up.

The APW7212 also includes current-limit and over-temperature shutdown to prevent damage in the event of an

output overload.

The APW7212 is available in 2mmx2mm TDFN2x2-8 and

TSOT-23-6A packages.

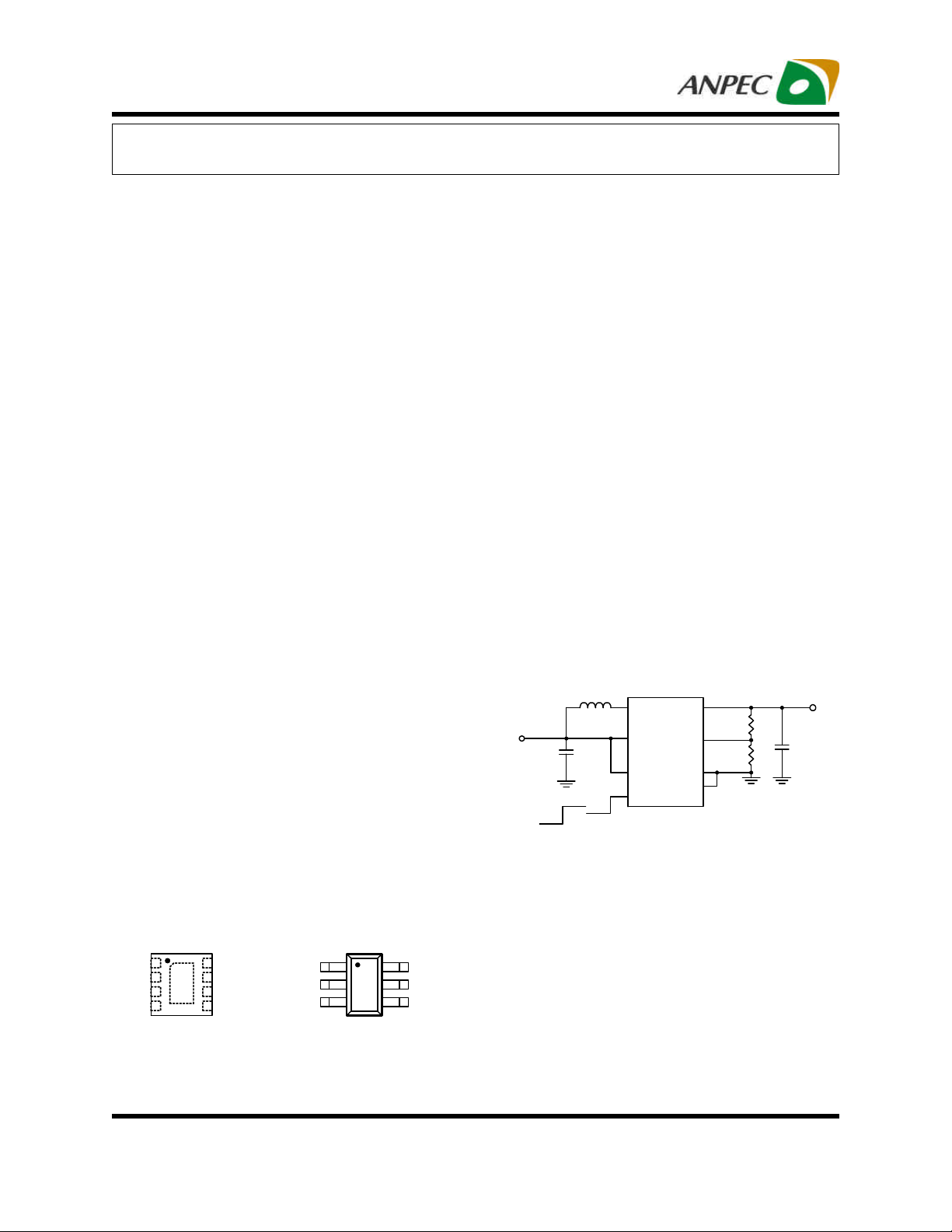

Simplified Application Circuit

V

C2

22µF

OUT

V

IN

0.8V to V

OUT

PFM/

PWM

C1

4.7µF

PWM

L1

4.7µH

8

SW

1

VIN

APW7212

3

EN

5

PS

VOUT

FB

GND

GND

2

R1

4

R2

6

7

Pin Configuration

1

VIN

2

VOUT

3

EN

FB

TDFN2x2-8

(Top View)

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and

advise customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

87SW

GND

6

GND

54

PS

SW 1

GND 2

FB 3

6 VIN

5 VOUT

4 EN

TSOT-23-6A

(Top View)

www.anpec.com.tw1

APW7212

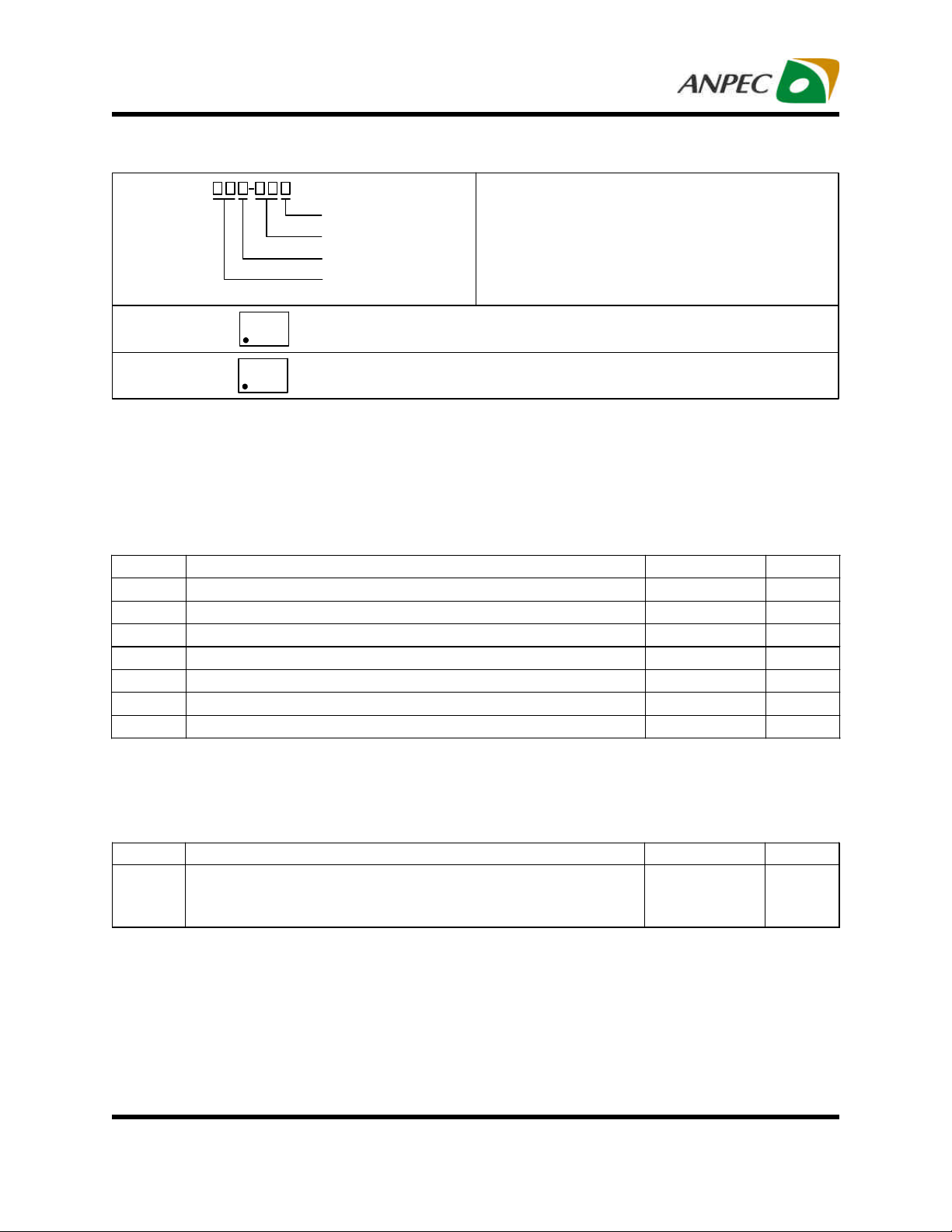

Ordering and Marking Information

APW7212

Assembly Material

Handling Code

Temperature Range

Package Code

APW7212 QB:

APW7212 CT: W12X

Note: ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate termination finish; which

are fully compliant with RoHS. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J-STD-020D for

MSL classification at lead-free peak reflow temperature. ANPEC defines “Green” to mean lead-free (RoHS compliant) and halogen

free (Br or Cl does not exceed 900ppm by weight in homogeneous material and total of Br and Cl does not exceed 1500ppm by

weight).

7212

X

Package Code

QB : TDFN2x2-8 CT : TSOT-23-6A

Operating Ambient Temperature Range

I : -40 to 85oC

Handling Code

TR : Tape & Reel

Assembly Material

G: Halogen and Lead Free Device

X - Date Code

X - Date Code

Absolute Maximum Ratings (Note 1)

Symbol

VIN VIN Supply Voltage (VIN to GND) -0.3 ~ 7 V

V

VOUT to GND Voltage -0.3 ~ 7 V

OUT

VSW SW to GND Voltage -0.3 ~ 7 V

FB, EN and PS to GND Voltage -0.3 ~ 7 V

TJ Maximum Junction Temperature 150 °C

T

Storage Temperature -65 ~ 150 °C

STG

T

Maximum Lead Soldering Temperature, 10 Seconds 260 °C

SDR

Note 1: Absolute Maximum Ratings are those values beyond which the life of a device may be impaired. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Parameter Rating Unit

Thermal Characteristics

Symbol

Thermal Resistance -Junction to Ambient

θJA

Note 2: θJA is measured with the component mounted on a high effective thermal conductivity test board in free air. The exposed pad

of package is soldered directly on the PCB.

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

Parameter Typical Value Unit

(Note 2)

TDFN2x2-8

TSOT-23-6A

85

220

°C/W

www.anpec.com.tw2

APW7212

Recommended Operating Conditions (Note 3)

Symbol

VIN VIN Input Voltage 0.8 ~ V

EB, EN and PS to GND Voltage -0.3 ~ V

Parameter Range Unit

V

OUT

+0.3 V

OUT

L Inductor 1.5 ~ 10

CIN Input Capacitor 4.7 ~

C

Output Capacitor 3.7 ~

OUT

TA Ambient Temperature -40 ~ 85 °C

TJ Junction Temperature -40 ~ 125 °C

Note 3: Refer to the application circuit for further information.

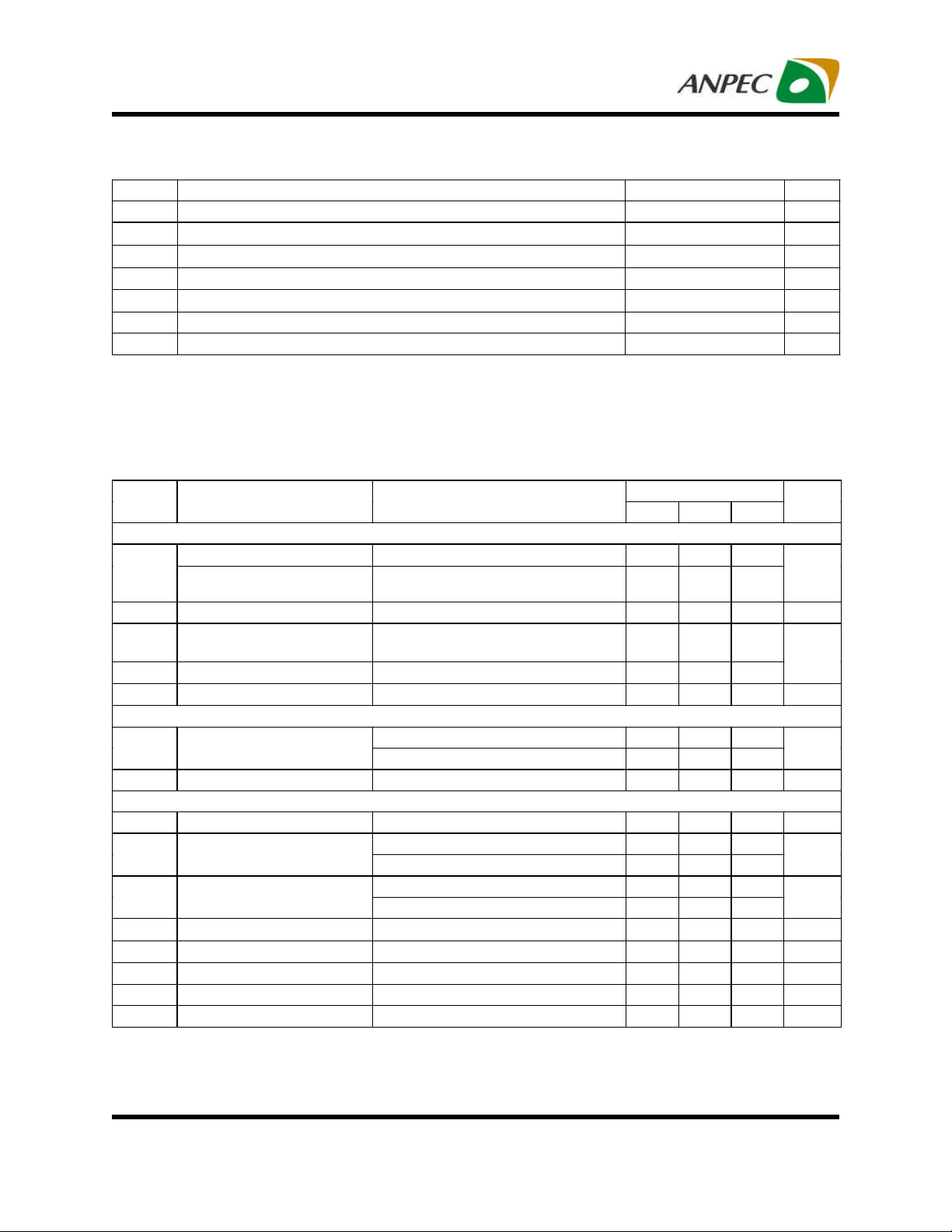

Electrical Characteristics

Refer to the typical application circuits. These specifications apply over VIN = 1.2V, V

otherwise noted. Typical values are at TA = 25°C.

Symbol

Parameter Test Conditions

SUPPLY VOLTAGE AND CURRENT

Minimum Start-up Voltage

VIN

Minimum Operating Voltage after

Stat-up

V

Output Voltage Range 1.8 - 5.5 V

OUT

I

No Switching Quiescent Current

DD1

I

VIN Quiescent Current Measured from VIN, VIN = 1.2V, TA=25°C - 0.5 1

DD2

RL = 3kΩ

VEN = VIN - 0.8 0.9

Measured form VOUT, VFB = 1.3V,

V

= 3.3V, TA=25°C

OUT

ISD Shutdown Current VEN = GND, VIN = 1.2V - 0.1 1

REFERENCE AND OUTPUT VOLTAGES

V

Regulated Feedback Voltage

REF

TA = 0 ~ 85°C -1.5% 1.23 +1.5%

TA = -40 ~ 85°C -2% - +2%

IFB FB Input Current VFB = 1.3V -50 - 50 nA

INTERNAL POWER SWITCH

FSW Switching Frequency FB = GND 0.75

V

= 3.3V - 0.35

R

N-FET Switch On Resistance

N-FET

R

P-FET Switch On Resistance

P-FET

OUT

V

= 5V - 0.3 -

OUT

V

= 3.3V - 0.6 -

OUT

V

= 5V - 0.55

OUT

N-FET Switch Leakage Current VSW = 5V - 0.05

P-FET Switch Leakage Current VSW = 0V, V

I

N-FET Switch Current-Limit 0.9 1.2 - A

LIM

Dead-Time

D

SW Maximum Duty Cycle 80 85 95 %

MAX

(Note 4)

= 5V - 0.05

OUT

= 3.3V, I

OUT

= 0mA, TA = -40°C to 85°C, unless

OUT

APW7212

Min. Typ. Max.

- 1.05 1.15

- 40 60

1 1.25 MHz

-

1

1

- 10 - ns

µH

µF

µF

Unit

V

µA

µA

V

Ω

Ω

µA

µA

Copyright ANPEC Electronics Corp.

www.anpec.com.tw3

Rev. A.2 - Feb., 2011

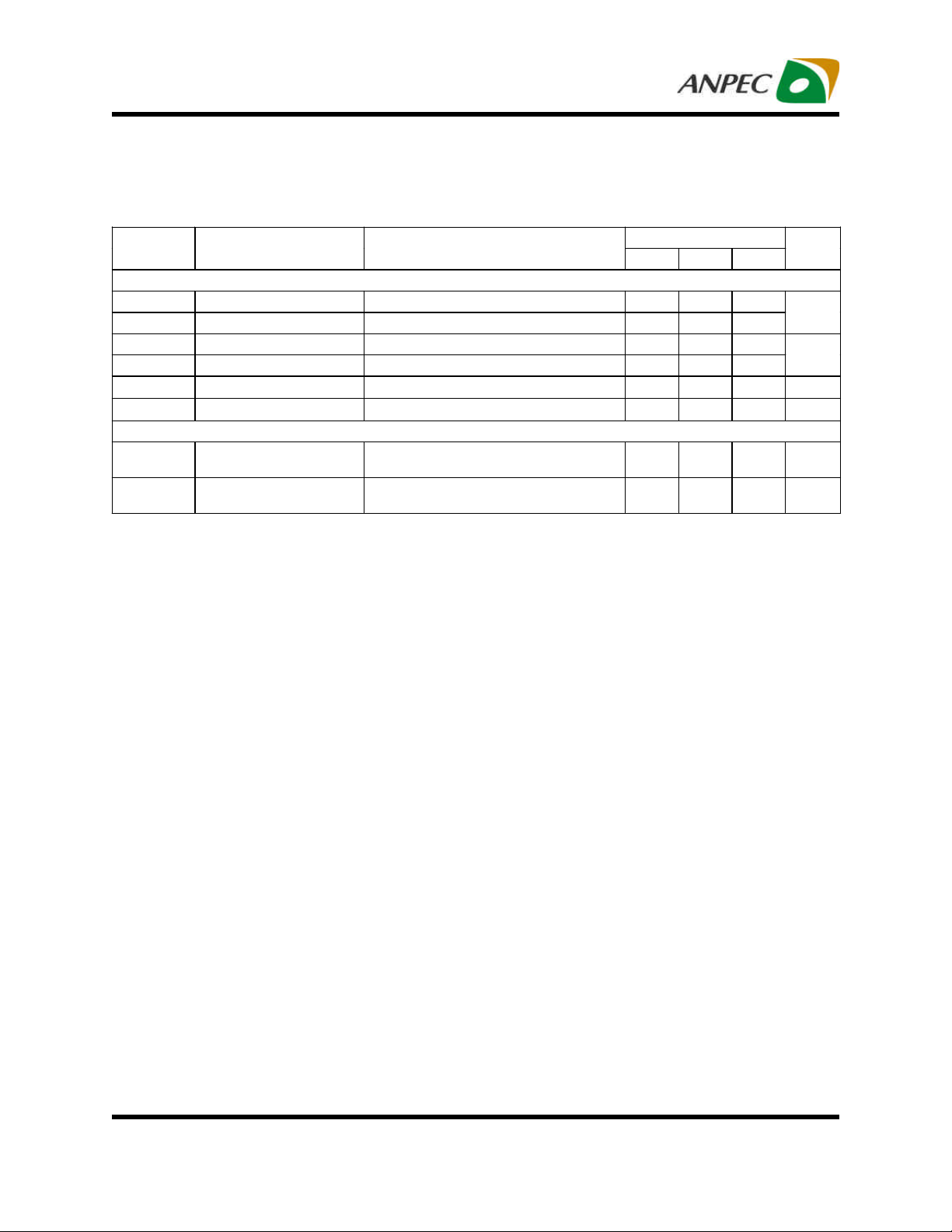

APW7212

Electrical Characteristics (Cont.)

Refer to the typical application circuits. These specifications apply over VIN = 1.2V, V

otherwise noted. Typical values are at TA = 25°C.

= 3.3V, I

OUT

= 0mA, TA = -40°C to 85°C, unless

OUT

Symbol Parameter Test Conditions

APW7212

Min. Typ. Max.

CONTROL STAGE

EN EN Input Low Threshold - - 0.4

EN Input High Threshold 1 - -

PS PS Input Low Threshold - - 0.4

PS Input High Threshold 1 - IEN EN Input Leakage Current VEN = 5V or GND - 0.4 1

IPS PS Input Leakage Current VPS = 5V or GND - 0.1 1

OVER-TEMPERATURE PROTECTION

T

OTP

Note 4: Guaranteed by design, not production tested.

Over-Temperature

Protection

Over-Temperature

Protection Hysteresis

(Note 4)

(Note 4)

TJ Rising - 150 - °C

- 30 - °C

Unit

V

V

µA

µA

Copyright ANPEC Electronics Corp.

www.anpec.com.tw4

Rev. A.2 - Feb., 2011

APW7212

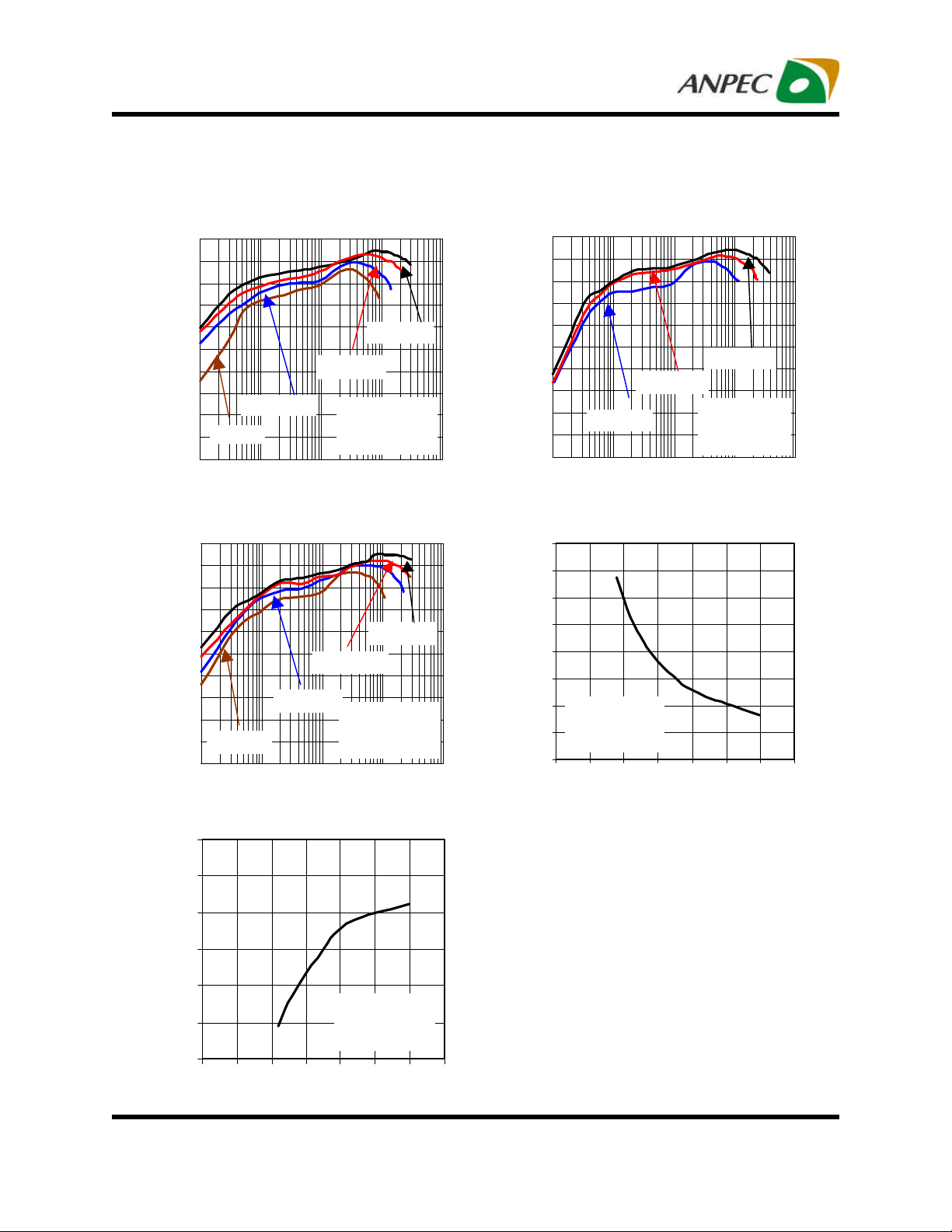

Typical Operating Characteristics

(Refer to the application circuit in the section"Typical Application Circuits", VIN=1.5V, V

otherwise specified )

100

90

80

70

60

50

40

Efficiency (%)

30

20

VIN=0.9V

10

0

0.1 1 10

100

90

80

70

60

50

40

Efficiency (%)

30

20

VIN=1.2V

10

0

0.1 1 10 100 1000

Start-up Voltage vs. Load Current

300

Efficiency vs. Load Current

VIN=2.4V

VIN=1.8V

.

VIN=1.2V

V

OUT

L = 4.7µH

C

OUT

= 3.3V

= 22µF

100

Load Current, I

OUT

(mA)

Efficiency vs. Load Current

VIN=3.6V

VIN=2.4V

VIN=1.8V

V

OUT

L = 4.7µH

C

= 22µF

OUT

Load Current, I

OUT

(mA)

= 5V

1000

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

400

350

(uA)

300

IN

250

200

150

100

No Load Input Current, I

50

Efficiency vs. Load Current

VIN=1.2V

0.1

1 10 100 1000

Load Current, I

No Load Input Current vs. Supply

V

= 3.3V

OUT

L = 4.7µH

C

= 22µF

0

OUT

0 0.5 1 1.5 2 2.5 3 3.5

Supply Voltage, VIN(V)

=3.3V, TA=25oC unless

OUT

VIN=2.4V

VIN=1.8V

V

= 4V

OUT

L = 4.7µH

C

= 22µF

OUT

(mA)

OUT

Voltage

250

(mA)

200

OUT

150

100

Load Current, I

50

0

0 0.5 1 1.5 2 2.5 3 3.5

Start-up Voltage, V

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

V

OUT

L = 4.7µH

C

OUT

(V)

IN

= 3.3V

= 22µF

www.anpec.com.tw5

APW7212

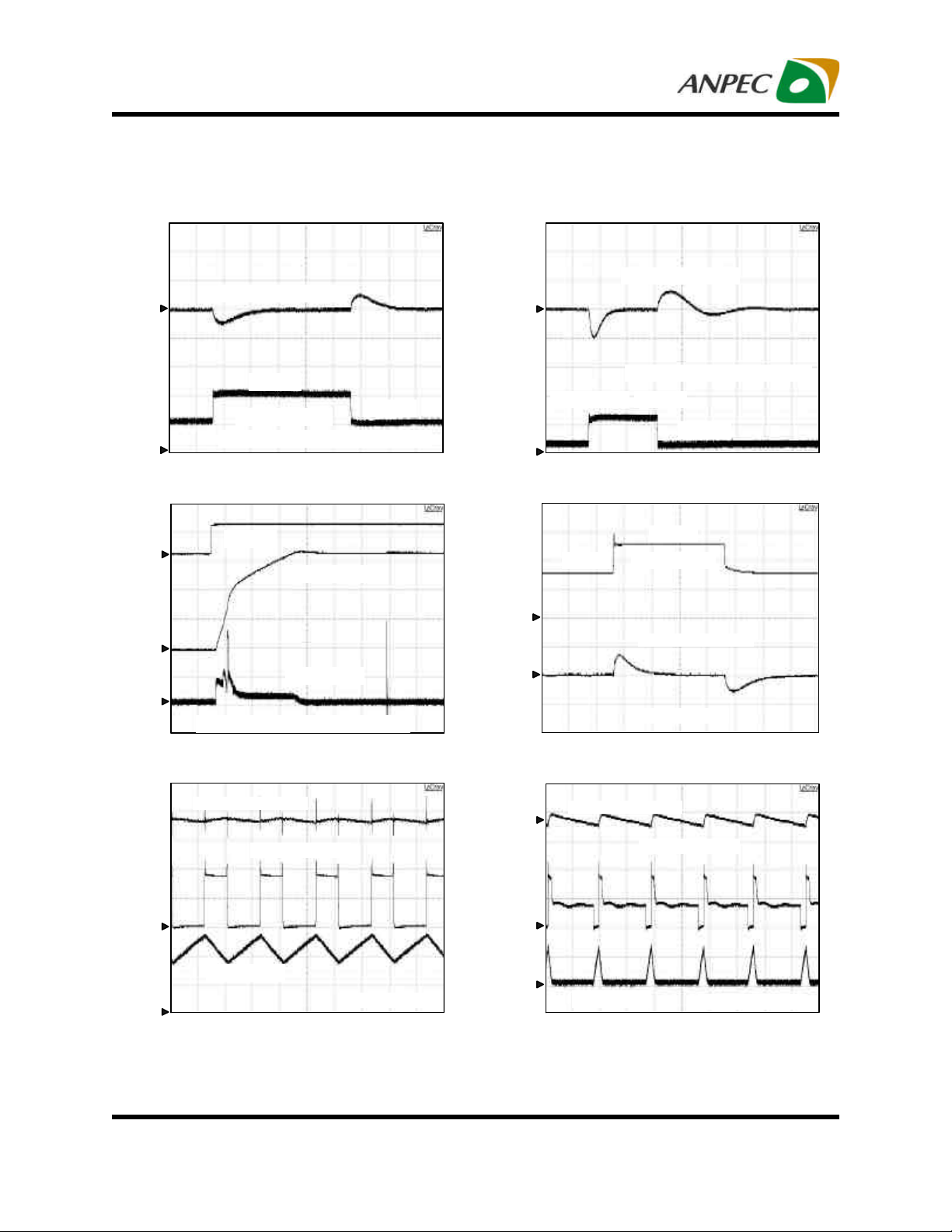

Operating Waveforms

(Refer to the application circuit in the section “Typical Application Circuits”, VIN=1.5V, V

otherwise specified)

Load Transient Response

V

,200mV/Div, AC

1

OUT

1

Load Transient Response

V

OUT

=3.3V,TA=25oC unless

OUT

,200mV/Div, AC

2

Time: 100µs/Div

1

2

3

Time: 500µs/Div

200mA

I

, 100mA/Div

OUT

L=4.7µH, VIN=1.5V, C

No Load Start-up

V

EN

V

, 1V/Div

OUT

IIN, 0.2A/Div

L=4.7µH, VIN=1.5V, I

OUT

Normal Operating Waveform

V

10mV/Div, AC

OUT,

VLX, 2V/Div, DC

100mA

=22µF

OUT

=0mA

OUT

2

Time: 100µs/Div

1

2

Time: 100µs/Div

1

L=4.7µH, VIN=1.5V, C

, 0.1A/Div

110mAI

10mA

Line Transient Response

2.5V

V

0.5V/Div1.5V

IN,

V

200mV/Div,AC

OUT,

I

= 100mA

OUT

Normal Operating Waveform

V

10mV/Div, AC

OUT,

VLX, 2V/Div, DC

OUT

=22µF

2

IL, 200mA/Div

3

Time: 500ns/Div

I

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

= 200mA

OUT

2

3

Time: 10µs/Div

IL, 500mA/Div

I

OUT

= 20mA

www.anpec.com.tw6

APW7212

Pin Description

PIN

NO.

TDFN2x2-8 TSOT-23-6A

1 6 VIN Supply Voltage Input Pin.

2 5 VOUT Converter output and control circuitry bias supply pin.

3 4 EN

4 3 FB

5 - PS

6, 7 2 GND Power and signal ground pin.

8 1 SW Switch pin. Connect this pin to inductor.

- -

NAME

Exposed

PAD

Enable Control Input. Forcing this pin above 1.0V enables the device. Forcing this

pin below 0.4V to shut it down. In shutdown, all functions are disabled to decrease

the supply current below 1µA.

Feedback Input. The device senses feedback voltage via FB and regulate the

voltage at 1.23V. Connecting FB with a resistor-divider from the output set the

output voltage in the range from 1.8 to 5.5V.

Pulse Skipping Mode Selection. Pulling this pin to logic high to force boost converter

enter PWM mode. Pulling it low to automatic switch under PFM (Pulse Frequency

Mode) and PWM mode. Do not leave this pin floating. This pin internally connects to

GND for TSOT-23-6 package.

Connected this pad to GND.

FUNCTION

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

www.anpec.com.tw7

APW7212

Block Diagram

EN

GND

Shutdown

Control

Over-

Temperature

Protection

Slope

Compensation

Oscillator

From

V

MAX

Control

Softstart

Σ

VIN

Low

Voltage

Start-up

Current-

limit

MUX

Logic Control

ICMP

COMP

V

MAX

Control

From VOUT

Error

Amplifier

EAMP

Zero-Crossing

Comparator

Gate

Control

Current Sense

Amplifier

V

REF

1.23V

PS

(APW7212CT only)

VOUT

SW

FB

Typical Application Circuit

L1

V

IN

0.8V to V

OUT

PFM/

PWM

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

4.7µH

C1

4.7µF

PWM

8

SW

1

VIN

3

EN

5

PS

VOUT

APW7212

GND

GND

FB

V

2

OUT

R1

4

R2

C2

22µF

6

7

www.anpec.com.tw8

APW7212

Function Description

Main Control Loop

The APW7212 is a c onstant frequency, synchronous

rectifier, and current-mode switching regulator. In normal

operation, the internal N-channel power MOSFET is turned

on each cycle when the oscillator sets an internal RS

latch and turned off when an internal comparator (ICMP)

resets the latch. The peak inductor current which ICMP

resets the RS latch is controlled by the voltage on the

COMP node, whic h is the output of the error amplifier

(EAMP). An external resistive divider connected between

V

and ground allows the EAMP to rec eive an output

OUT

feedback voltage VFB at FB pin. When the load current

increases, it causes a slightly decrease in VFB relative to

the 1.23V reference, which in turn causes the COMP voltage to increase until the average inductor current matches

the new load current.

Start-up

A start-up oscillator circuit is integrated in the APW7212.

When the device enables, the circ uit pumps the output

voltage high. Once the output voltage reaches 1.6V (typ),

the main DC-DC circ uitry turns on and boosts the output

voltage to the final regulation voltage.

Automatic PFM/PWM mode Switch

The APW7212 is a fixed frequency PWM peak current

modulation control step-up converter. At light loads, the

APW7212 will automatically enter in pulse frequency

modulation operation to reduce the dominant switching

losses. In PFM operation, the inductor current may reach

zero or reverse on each pulse. A zero current comparator

turns off the P-channel synchronous MOSFET, forcing

DCM(Discontinuous Current Mode) operation at light load.

These controls get very low quiescent current, help to

maintain high efficiency over the complete load range.

Synchronous Rectification

The internal synchronous rectifier eliminates the need

for an external Schottky diode, thus reducing cost and

board space. During the cycle off-time, the P-FET turns

on and shunts the FET body diode. As a result, the synchronous rectifier significantly improves efficiency without the addition of an external component. Conversion

efficiency can be as high as 92%.

Load Disconnect

Driving EN to ground places the APW7212 in shutdown

mode. When in shutdown, the internal power MOSFET

turns off, all internal circuitry shuts down and the quiescent supply current reduces to 1µA maximum.

A special circuit is applied to disconnect the load from the

input during shutdown the converter. In conventional synchronous rectifier circuits, the back-gate diode of the highside P-FET is forward biased in shutdown and allows

current flowing from the battery to the output. However,

this device uses a special circuit, which takes the cathode of the back-gate diode of the high-side P-FET and

disconnects it from the source when the regulator is

shutdown. The benefit of this feature for the system design engineer is that the battery is not depleted during

shutdown of the converter. No additional components

must be added to the design to make sure that the battery is disconnected from the output of the converter.

Current-Limit Protection

The APW7212 monitors the inductor current, flowing

through the N-FET, and limits the current peak at currentlimit level to prevent loads and the APW7212 from damages during overload conditions.

Over-Temperature Protection (OTP)

The over-temperature circuit limits the junction temperature of the APW7212. When the junction temperature exceeds 150oC, a thermal sensor turns off the both N-FET

and P-FET, allowing the devices to cool. The thermal

sensor allows the converters to start a soft-start process

and regulate the output voltage again after the junction

temperature cools by 30oC. The OTP is designed with a

30oC hysteresis to lower the average Junction Temperature (TJ) during continuous thermal overload conditions,

increasing the lifetime of the device.

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

www.anpec.com.tw9

APW7212

(

)

Application Information

Input Capacitor Selection

The input capacitor (CIN) reduces the current peaks drawn

from the input supply and reduces noise injection into

the IC. The reflected ripple voltage will be smaller with

larger CIN. For reliable operation, it is recommended to

select the capacitor voltage rating at least 1.2 times higher

than the maximum input voltage. The capacitors should

be placed close to the VIN and GND.

Inductor Selection

For high efficiencies, the inductor should have a low DC

resistance to minimize conduction losses. Especially at

high-switching frequencies the core material has a higher

impact on efficiency. When using small chip inductors,

the efficiency is reduced mainly due to higher inductor

core losses. This needs to be considered when selecting the appropriate inductor. The inductor value determines the inductor ripple current. The larger the inductor

value, the smaller the inductor ripple current and the lower

the conduction losses of the converter. Conversely, larger

inductor values cause a slower load transient response.

A reasonable starting point for setting ripple current, ∆IL,

is 30% to 50% of the average inductor current. The recommended inductor value can be calculated as below:

2

V

IN

≥

L

V

OUT

−

⋅

VV

⋅

IF

η

INOUT

⋅

∆

)MAX(OUTSW

I

L

I

( )

AVGL

where

VIN = input voltage

V

= output voltage

OUT

FSW = switching frequency in MHz

I

= maximum output current in amp.

OUT

η = Efficiency

∆IL /I

= (0.3 to 0.5 typical)

L(AVG)

The peak inductor current is calculated as below:

VVV

1

II

I

V

I

IN

IN

C

IN

I

L

I

SW

I

D

L

)MAX(INPEAK

2

N-FET

⋅+=

LX

−⋅

INOUTIN

FLV

⋅⋅

SWOUT

I

D1

I

SW

I

PEAK

I

IN

OUT

ESR

C

OUT

V

OUT

I

LIM

∆I

L

I

OUT

Output Capacitor Selection

The current-mode c ontrol scheme of the APW7212 allows the use of tiny ceramic capacitors . The higher capacitor value provides the good load transients response.

Ceramic capacitors with low ESR values have the lowest

output voltage ripple and are recommended. If required,

tantalum capacitors may be used as well. The output ripple

is the sum of the voltages across the ESR and the ideal

output capacitor.

To avoid saturation of the inductor, the inductor should be

rated at least for the maximum input current of the con-

V

COUT

I

OUT

⋅≅∆

C

OUT

−

VV

INOUT

⋅

FV

SWOUT

verter plus the inductor ripple current. The maximum in-

ΔV

= ΔV

put current is calculated as below:

⋅

VI

=

I

)MAX(IN

OUT)MAX(OUT

η⋅

V

IN

OUT

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

RIV ⋅≅∆

ESR

ESRPEAKESR

+ ΔV

COUT

www.anpec.com.tw10

APW7212

Application Information (Cont.)

Output Capacitor Selection (Cont.)

Where I

is the peak inductor current. For ceramic ca-

PEAK

pacitor application, the output voltage ripple is dominated

by the ∆V

. When choosing the input and output ce-

COUT

ramic capacitors, the X5R or X7R with their good temperature and voltage characteristics are recommended.

Output Voltage Setting

A resistive divider sets the output voltage. The external

resistive divider is connected to the output, allowing remote voltage sensing as shown in “Typical Application

Circuits”. A suggestion of the maximum value of R1 is

2MΩ and R2 is 600kΩ to keep the minimum current that

provides enough noise rejection ability through the resistor divider. The output voltage can be calculated as

below:

1R

+⋅=

1VV

REFOUT

2R

1R

+=

123.1

2R

Layout Consideration

For all switching power supplies, the layout is an important step in the design, especially at high peak currents

and switching frequencies. If the layout is not done

carefully, the regulator may show noise problems and

duty cycle jitter.

Layout Consideration

Via to VIN

1

VOUT

2

3

R1

APW7212 Layout Suggestion

V

IN

L1

SW

R2

Via To V

APW7212 Layout Suggestion

VIN

C1C2

C2

L1

PWM

PFM/PWM

Via To V

IN

V

EN

V

OUT

8

SW

7

GND

6

GND

54

PS

R2

C1

GND

FB

GND

R1

OUT

1. Since the VOUT supplies IC bias voltage, the output

capacitor should be placed close to the VOUT and

GND. Connecting the capacitor with VOUT and GND

pins by short and wide tracks without using any via

holes for good filtering and minimizing the voltage

ripple.

2. To minimize copper trace connections that can inject

noise into the system, the inductor should be placed

as close as possible to the SW pin to minimize the

noise coupling into other circuits.

3. Since the feedback pin and network is a high impedance circuit the feedback network should be routed

away from the inductor. The feedback pin and feedback network should be shielded with a ground plane

or trace to minimize noise coupling into this circuit.

4. A star ground connection or ground plane minimizes

ground shifts and noise is recommended.

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

www.anpec.com.tw11

APW7212

Pack age Information

TDFN2x2-8

D

D2

Pin 1 Corner

A

E

b

A1

A3

E2

K

S

Y

M

B

O

L

A

A1

A3

b

D

D2

E

E2

e

L

K 0.20

Note : 1. Followed from JEDEC MO-229 WCCD-3.

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

MIN. MAX.

0.70

0.00

0.18 0.30

1.90 2.10

1.00 1.60

1.90 2.10

0.60

0.30 0.45

L

e

TDFN2x2-8

MILLIMETERS

0.80

0.05

0.20 REF

1.00

0.50 BSC 0.020 BSC

INCHES

MIN. MAX.

0.028

0.000

0.008 REF

0.007 0.012

0.075 0.083

0.039 0.063

0.075 0.083

0.024

0.012 0.018

0.008

0.031

0.002

0.039

www.anpec.com.tw12

APW7212

Pack age Information

TSOT-23-6A

D

e

SEE VIEW A

E1

E

b

e1

A

A2A1

L

VIEW A

S

Y

M

B

O

L

A

A1

A2

b

c

D

E

E1

e

e1

θ

Note : Dimension D and E1 do not include mold flash, protrusions or gate

burrs. Mold flash, protrusion or gate burrs shall not exceed 10 mil

per side.

MILLIMETERS

MIN.

0.70

0.01

0.70

0.30

0.08

2.70 3.10

2.60 3.00

1.40 1.80

0.95 BSC

1.90 BSC

0.30L

0°

TSOT-23-6A

INCHES

MAX.

1.00

0.10

0.90

0.50

0.20

0.60

8° 0° 8°

MIN.

0.028

0.000

0.028

0.012

0.003

0.106 0.122

0.102 0.118

0.055 0.071

0.037 BSC

0.075 BSC

0.012

MAX.

0.039

0.004

0.035

0.020

0.008

0.024

c

0.25

GAUGE PLANE

SEATING PLANE

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

www.anpec.com.tw13

APW7212

Carrier Tape & R eel Dimensions

OD0

B0

P0

P2

P1

A

E1

F

W

Application

TDFN2x2-8

Application

TSOT-23-6A

K0

SECTION A-A

B

A

H

A0

SECTION B-B

OD1

B

T

A

d

T1

A H T1 C d D W E1 F

178.0±2.00 50 MIN.

8.4+2.00

-0.00

13.0+0.50

-0.20

1.5 MIN. 20.2 MIN. 8.0±0.20 1.75±0.10 3.50±0.05

P0 P1 P2 D0 D1 T A0 B0 K0

4.0±0.10 4.0±0.10 2.0±0.05

1.5+0.10

-0.00

1.5 MIN.

0.6+0.00

-0.4

3.35 MIN 3.35 MIN 1.30±0.20

A H T1 C d D W E1 F

178.0±2.00 50 MIN.

8.4+2.00

-0.00

13.0+0.50

-0.20

1.5 MIN. 20.2 MIN. 8.0±0.30 1.75±0.10 3.5±0.05

P0 P1 P2 D0 D1 T A0 B0 K0

4.0±0.10 4.0±0.10 2.0±0.05

1.5+0.10

-0.00

1.0 MIN.

0.6+0.00

-0.40

3.20±0.20 3.10±0.20 1.50±0.20

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

(mm)

www.anpec.com.tw14

APW7212

Devices Per Unit

Package Type Unit Quantity

TDFN2x2-8

TSOT-23-6A

Taping Direction Information

TDFN2x2-8

Tape & Reel 3000

Tape & Reel 3000

USER DIRECTION OF FEED

TSOT-23-6

AAAX AAAX AAAX AAAX AAAX AAAX AAAX

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

USER DIRECTION OF FEED

www.anpec.com.tw15

APW7212

Classification Profile

Classification Reflow Profiles

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Preheat & Soak

Temperature min (T

Temperature max (T

Time (T

smin

to T

smax

smin

smax

) (ts)

)

)

Average ramp-up rate

(T

to TP)

smax

Liquidous temperature (TL)

Time at liquidous (tL)

Peak package body Temperature

(Tp)*

See Classification Temp in table 1 See Classification Temp in table 2

Time (tP)** within 5°C of the specified

classification temperature (Tc)

Average ramp-down rate (Tp to T

smax

)

Time 25°C to peak temperature

* Tolerance for peak profile Temperature (Tp) is defined as a supplier minimum and a user maximum.

** Tolerance for time at peak profile temperature (tp) is defined as a supplier minimum and a user maximum.

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

100 °C

150 °C

60-120 seconds

150 °C

200 °C

60-120 seconds

3 °C/second max. 3 °C/second max.

183 °C

60-150 seconds

217 °C

60-150 seconds

20** seconds 30** seconds

6 °C/second max. 6 °C/second max.

6 minutes max. 8 minutes max.

www.anpec.com.tw16

APW7212

Classification Reflow Profiles (Cont.)

Table 1. SnPb Eutectic Process – Classification Temperatures (Tc)

Package

Thickness

<2.5 mm

≥2.5 mm 220 °C 220 °C

Table 2. Pb-free Process – Classification Temperatures (Tc)

Package

Thickness

<1.6 mm

1.6 mm – 2.5 mm

≥2.5 mm 250 °C 245 °C 245 °C

Volume mm3

<350

260 °C 260 °C 260 °C

260 °C 250 °C 245 °C

Volume mm

<350

235 °C 220 °C

Reliability Test Program

Test item Method Description

SOLDERABILITY JESD-22, B102

HOLT JESD-22, A108

PCT JESD-22, A102

TCT JESD-22, A104

HBM MIL-STD-883-3015.7

MM JESD-22, A115

Latch-Up JESD 78

3

Volume mm3

350-2000

5 Sec, 245°C

1000 Hrs, Bias @ Tj=125°C

168 Hrs, 100%RH, 2atm, 121°C

500 Cycles, -65°C~150°C

VHBM≧2KV

VMM≧200V

10ms, 1tr≧100mA

Volume mm

≥350

Volume mm3

>2000

3

Customer Service

Anpec Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

2F, No. 11, Lane 218, Sec 2 Jhongsing Rd.,

Sindian City, Taipei County 23146, Taiwan

Tel : 886-2-2910-3838

Fax : 886-2-2917-3838

Copyright ANPEC Electronics Corp.

Rev. A.2 - Feb., 2011

www.anpec.com.tw17

Loading...

Loading...