APW7066

Dual Synchronous Buck PWM Controll ers and One Linear Controller

Features

• Two Synchronous Buck Converters and

a Linear Regulator

• VIN range up to 12V

• Input Power Supplies Require 12V and 5V or

use 12V to generate a Shunt Regulator 5.8V

• 0.6V Reference for VOUT1 and VOUT3

with 0.8% accurate

• 3.3V Reference for VOUT2 with 0.8% accurate

• Buffered VTT Reference Output

• Three Outputs have Independent Soft-Start

and Enable

• Internal 300kHz Oscillator and Programmable

Frequency range from 70 kHz to 800kHz

• Synchronous Switching Frequency

• DDR mode or Independent Mode Selection

• Phase Shift Selection

• Power Good Function

• Short-Circuit Protection for VOUT1 and VOUT2

• Thermally Enhanced TSSOP-24 and QFN-32

Package

• Lead Free Available (RoHS Compliant)

Applications

• Graphic Cards

• DDR memory Power Supplies

• Low-Voltage Distributed Power Supplies

General Description

The APW7066 has two synchronous buck PWM

controllers and one linear cont roller with high

pre cision internal references voltage to offer accurate

outputs. The PWM controllers are designed to drive

two N-channel MOSFETs in synchronous buck

topology, a nd the linear controller drives an external

N-chan nel MOSFET. The device requires 12V and 5V

power supplies, if the 5V supply is not available,

VCC12 ca n offer an optional shunt regulator 5.8V for

5V supply.

All outputs have independent soft-start and enable

functio ns by SS/EN pins to control. Connect a capacitor

from each SS/EN pin to the ground for setting the

soft-start ti me, and pulling the SS/EN pin below 1V to

disab le regulator. Pull the SS2/EN2 to VCC, enter the

DDR mode, the SS1/EN1 controls both VOUT1 and

VOUT2, and allows VOUT2 to track VOUT1. It also

off ers the phase shift function by REFOUT pin to

sele ct the phase shift between VOUT1 an d VOUT2 in

DDR mode or Independent mode. When all SS/EN

pins exceed 3. 3V and no faults are detected, the

PGOOD pin goes high to indicate the regulators are

ready. If any of t he SS/EN pins goes below 3.2V or

any of the outputs has a fault condition, the PGOOD

pin will be pulled low .

The inte rnal oscillator is nominally 300kHz (keep the

FS/SYN C pin open or short to GND), and it offers the

programmable frequency function from 70kHz t o

800kH z; connecting a resistor from FS/SYNC to VCC

to decrease the frequency, conversely, connect a

resistor fro m FS/SYNC to GND to increase th e frequency.

The IC also provides the synch ronous freque ncy fun ction.

Connect the LGATE signal of another converter to

FS/SYNC pin; forcing the switching frequency to follow

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and advise

customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw1

APW7066

Genera l Description (Cont.)

th e external clock. The possible synchronous frequency

is from 150kHz to 800kHz. There is no Rds(on)

sensing or under-voltage sensing on APW7066.

Howe ver, it provides a simple short-circuit protection

by monitoring the COMP1 a nd COMP2 for over-voltage.

When any of two pins exce eds their trip point and the

condition persists for 1-2 internal clock cycle (3-6us

at 300kHz), the n it will shut down all regulators.

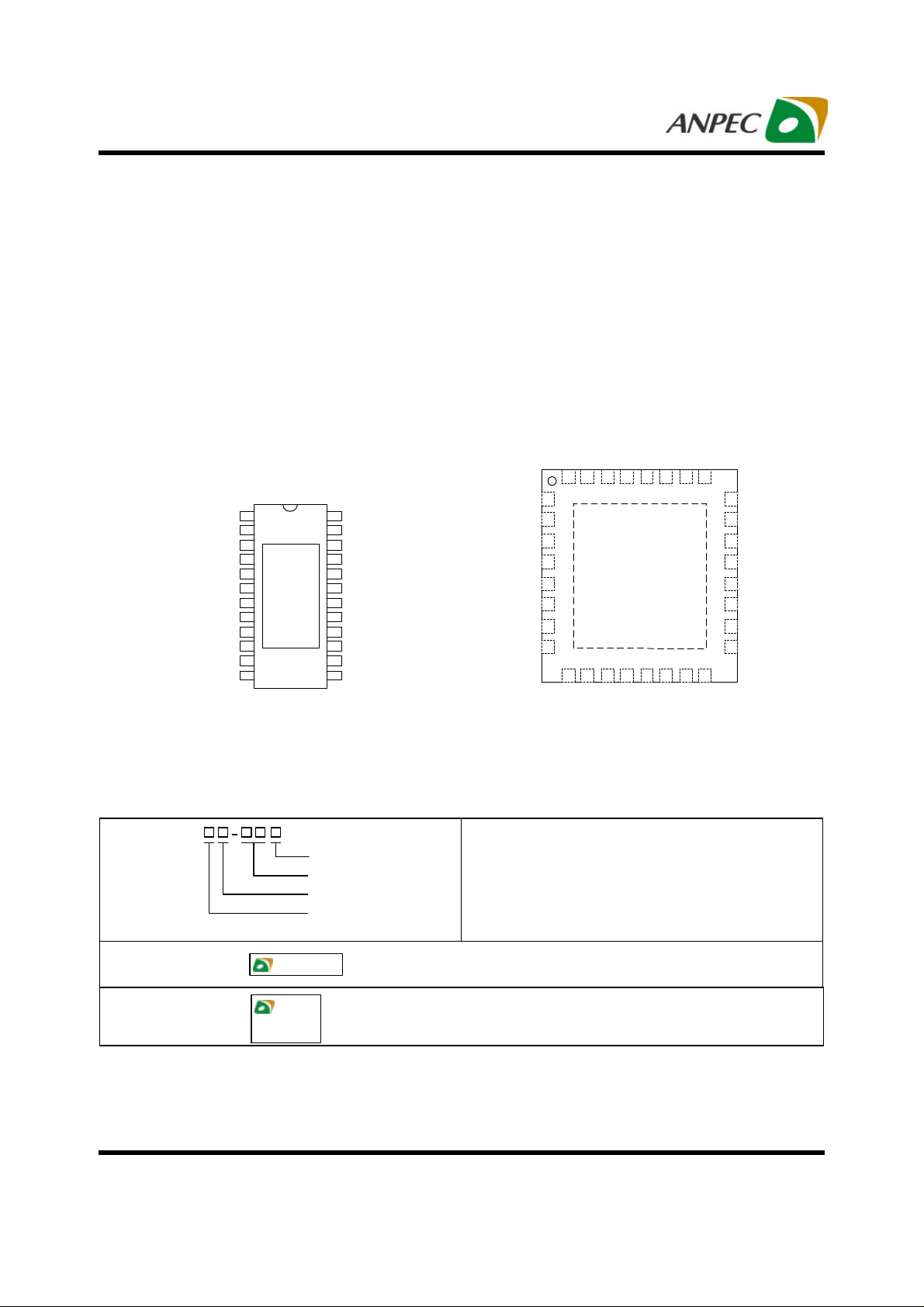

Pin Description

FB1

COMP1

COMP2

FB2

REFIN

REFOUT

SS1/EN1

SS2/EN2

SS3/EN3

VREF

DRIVE3

FB3

1

2

3

4

5

6

7

8

9

10

11

12

GND

BOTTOM

SIDE

PAD

TSSOP-24

TOP VIEW

24

23

22

21

20

19

18

17

16

15

14

13

VCC

BOOT1

UGATE1

VCC12

LGATE1

LGATE2

PGND

UGATE2

BOOT2

GND

PGOOD

FS/SYNC

REFIN

REFOUT

SS1/EN1

SS2/EN2

SS3/EN3

VREF

DRIVE3

Ord ering and Marking Information

APW7066

Lead Free Code

Handling Code

Temp. Range

Package Code

Package Code

R : TSSOP-P * QA : QFN-32

Operating Ambient Temp. Range

C : 0 to 70 C

Handling Code

TU : Tube TR : Tape & Reel

TY : Tray (for QFN only)

Lead Free Code

L : Lead Free Device Blank : Original Device

NC

32

FB2

COMP2

1

8

9

NC

FB3

32 LD 5x5 QFN32

°

FB1

COMP1

GND

BOTTOM

SIDE PAD

PGOOD

FS/SYNC

Top View

VCC

GND

NC

UGATE2

NC

NC

25

BOOT1

16

BOOT2

24

UGATE1

PGND_1

VCC12_1

LGATE1

LGATE2

VCC12_2

PGND_2

NC

17

APW7066 R :

APW7066 QA :

APW7066

XXXXX

APW7066

XXXXX

XXXXX - Date Code

XXXXX - Date Code

Note : ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate

termin ation finish; which are fully compliant with RoHS and compatible with both SnPb and lead-free soldiering

op erations. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J STD-020C

fo r MSL classification at lead-free peak reflow temperature.

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw2

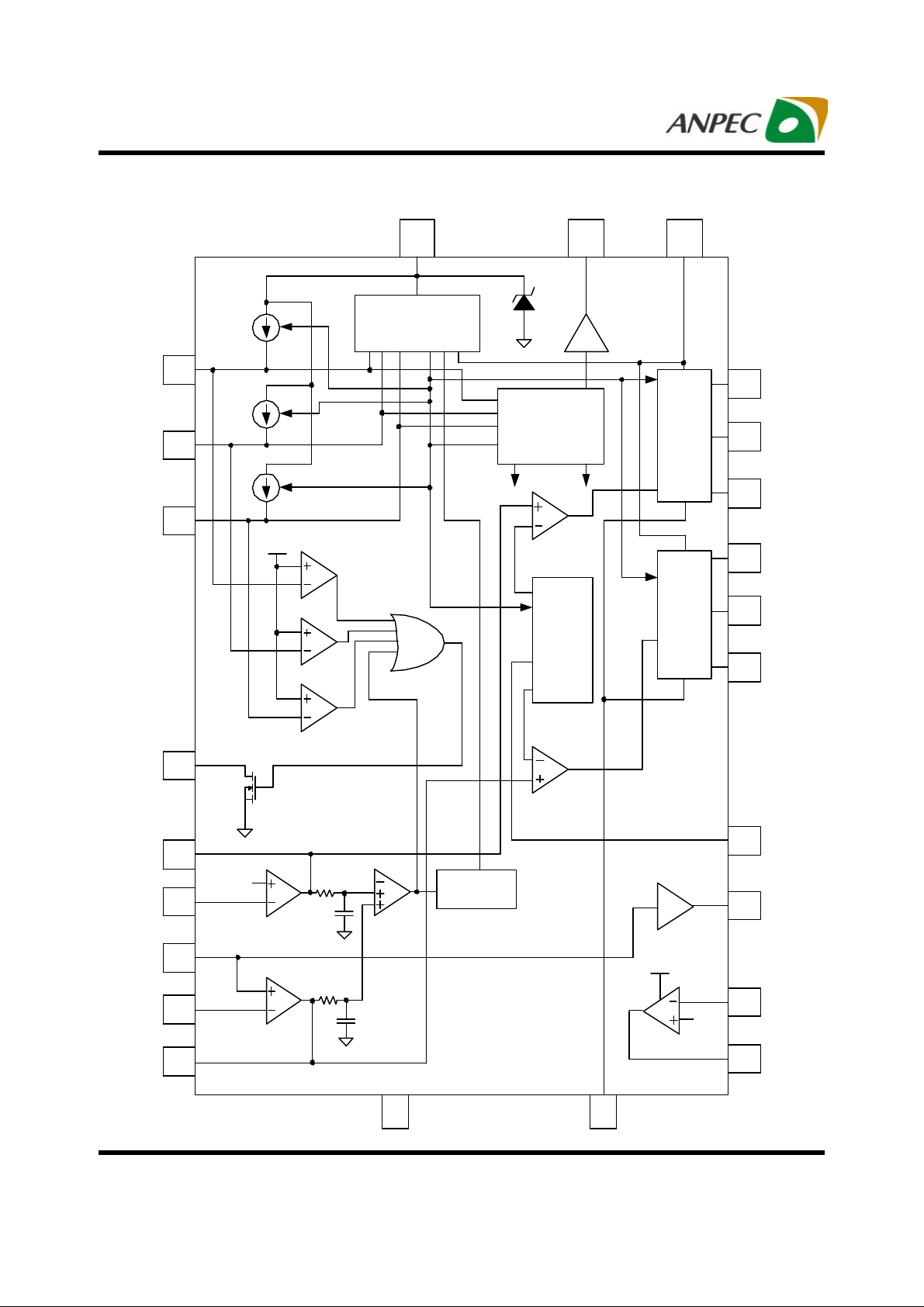

APW7066

Block Diag ram

SS1/EN1

SS2/EN2

SS3/EN3

3.3V

30uA

30uA

30uA

VCC VREF VCC12

5.8V

Power On Reset and

Control

Bias

Current

0.6V 3.3V

3.3V

Oscillator

Gate

Control

Logic 1

Gate

Control

Logic 2

BOOT1

UGATE1

LGATE1

BOOT2

UGATE2

LGATE2

PGOOD

Monitor COMP Pins

for Short Protection

COMP1

0.6V

FB1

REFIN

FB2

COMP2

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

3.3V

1-2 Clock

Cycle Filter

If short, Filter shut

down all outputs

GND PGND

FS/SYNC

REFOUT

VCC12

FB3

0.6V

DRIVE3

www.anpec.com.tw3

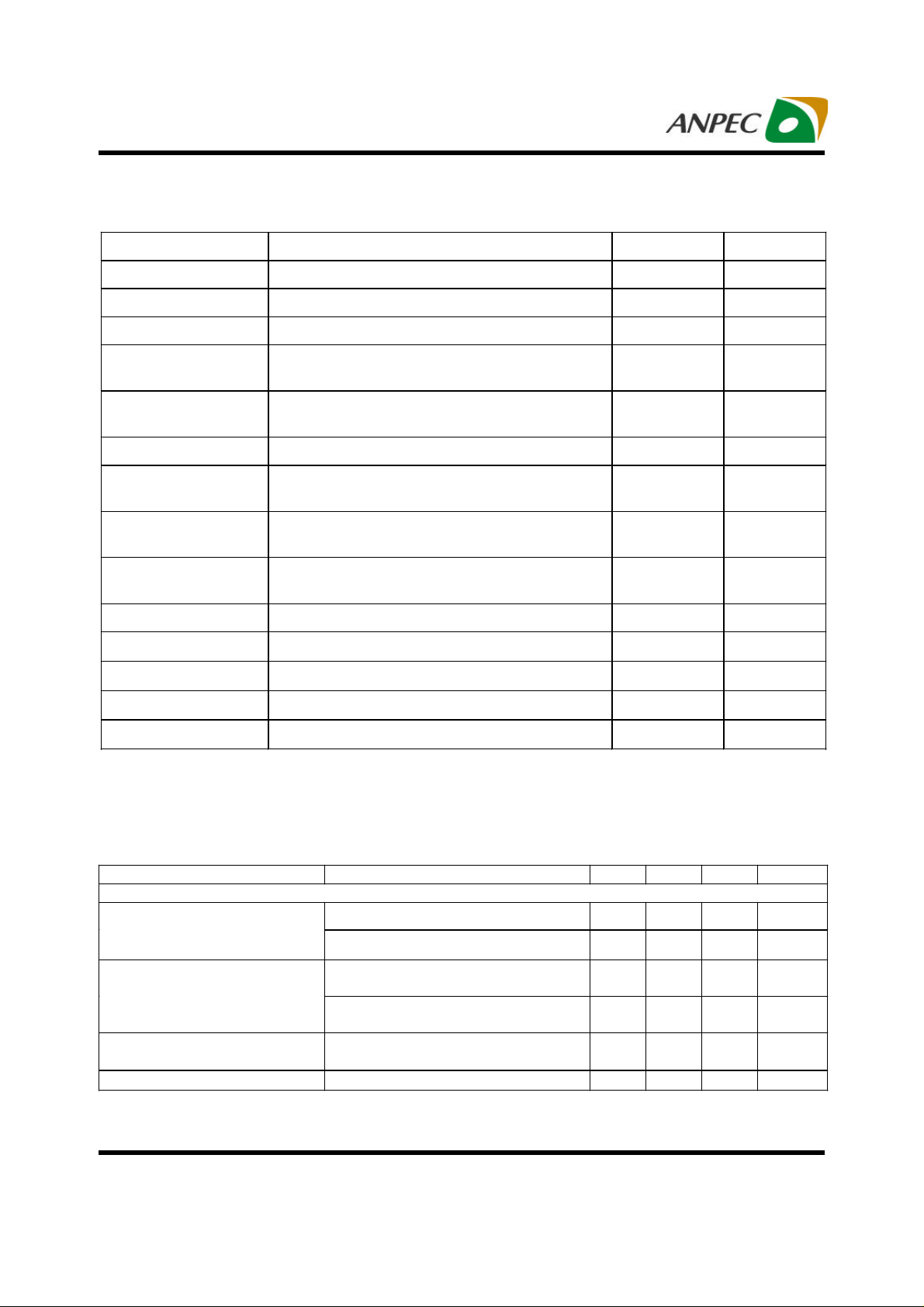

APW7066

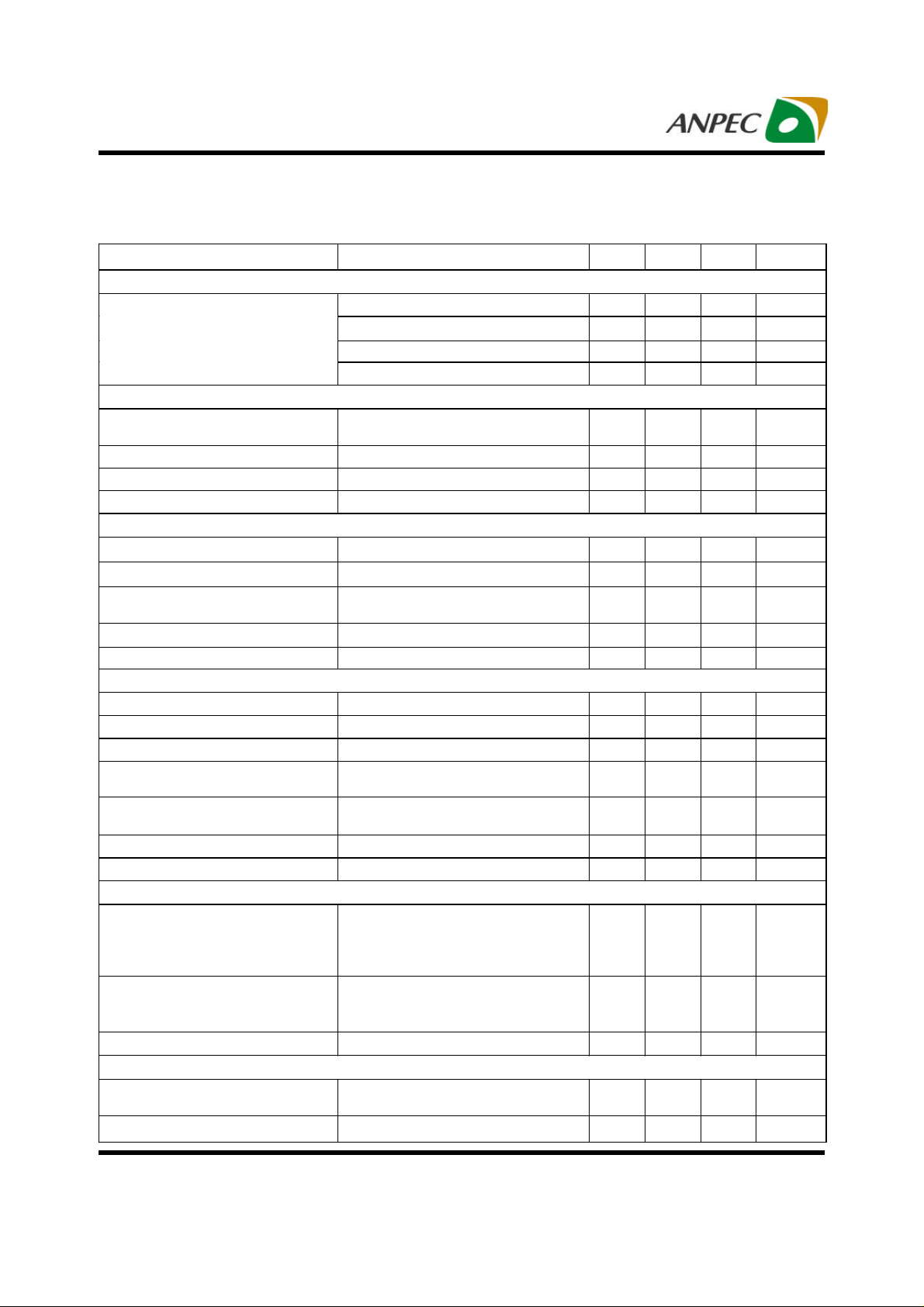

Ab solute Maximum Ratings

Symbol Parameter Rating Unit

VCC12 VCC12 to GND -0.3 to 15 V

VCC, separate supply VCC, separate supply -0.3 to 5.5 V

VCC, shunt regulator VCC, shunt regulator to GND -0.3 to 6 V

UGATE1, UGATE2,

BOOT1, BOOT2

LGATE1, LGATE2,

DRIVE3

FS/SYNC FS/SYNC to GND -0.3 to 15 V

REFIN, REFOUT,

PGOOD, VREF

FB1, COMP1, FB2,

COMP2, FB3

SS1/EN1, SS2/EN2,

SS3/EN3

PGND PGND to GND -0.3 to +0.3 V

TA Operating Temperature Range 0 to +70

TJ Maximum Junction Temperature +150

T

Storage Temperature Range -65 to +150

STG

TL Lead Temperature (Soldering, 10sec) 260

UGATE1, UGATE2, BOOT1, BOOT2 to GND -0.3 to 30 V

LGATE1, LGATE2, DRIVE3 to GND -0.3 to 15 V

REFIN, REFOUT, PGOOD, VREF to GND -0.3 to VCC V

FB1, COMP1, FB2, COMP2, FB3 to GND -0.3 to VCC V

SS1/EN, SS2/EN2, SS3/EN3 to GND -0.3 to VCC V

Ele ctrical Characteristics

°

C

°C

°C

°C

Operating Conditions: VCC = 5V, VCC12 = 12V, TA = 0 to 70°C, Unless Otherwise Specified.

Parameter Test Conditions Min. Typ. Max. Units

INPUT SUPPLY POWER

Input Supply Current

(Quiescent)

Input Supply Current (Dynamic)

Shunt Regulator Output Voltage

Shunt Regulator Current

VCC; outputs disabled

VCC12; outputs disabled

VCC12; UGATEs, LGATEs CL = 1nF,

300KHz

VCC; UGATEs, LGATEs CL = 1nF,

300KHz

20mA current; ~Equivalent to 300Ω

resistor VCC to 12V

300Ω resistor VCC to 12V

4 mA

6 mA

50 mA

7 mA

5.6 5.8 6.0 V

20 60 mA

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw4

APW7066

ND;

DRIVE3 to FB3; compare to internal

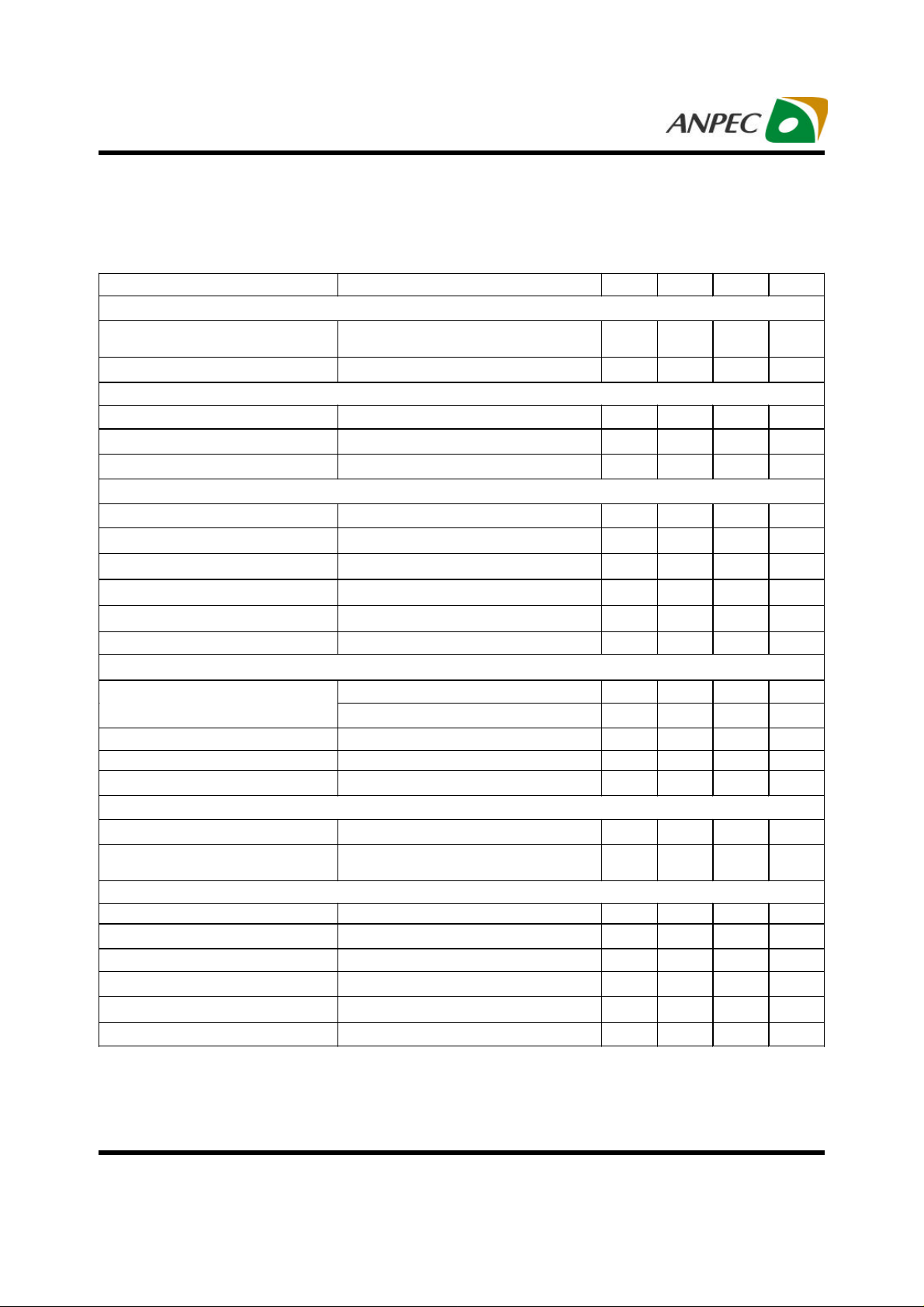

Ele ctrical Characteristics (Cont.)

Operating Conditions: VCC = 5V, VCC12 = 12V, TA = 0 to 70°C, Unless Otherwise Specified.

Parameter Test Conditions Min. Typ. Max. Units

INPUT SUPPLY POWER

VCC Rising 4.15 4.23 4.4 V

Power-On Reset Threshold

SYSTEM ACCURACY

Outputs 1 and 3 Reference

Voltage

Output 2 Reference Voltage 3.3V

Outputs 1 and 2 System Accuracy -0.8 0.8 %

Output 3 System Accuracy -0.8 0.8 %

OSCILLATOR

Accuracy -20 20 %

Frequency FS/SYNC pin open 240 300 360 KHz

Adjustment Range

Sawtooth Amplitude 2.1 V

Duty-Cycle Range 0 85 %

ERROR AMPLIFIER (OUT1 and OUT2)

Open-Loop Gain

Open-Loop Bandwidth

Slew Rate

EA Offset COMP1/2 to FB1/2; compare to

Maximum Output Voltage

Output High Source Current COMP1/2, VCOMP=2V

Output Low Sink Current COMP1/2, VCOMP=2V

PROTECTION AND MONITOR

Under-Voltage Threshold

(COMP1 and COMP2)

UV filter time

PGOOD Low Voltage IPGOOD = 2mA 0.1 0.3 V

LINEAR REGULATOR (OUT3)

VCC Falling 3.9 4.0 4.15

VCC12 Rising 7.55 7.8 8 V

VCC12 Falling 7.1 7.3 7.55

FS/SYNC pin: resistor to G

resistor to VCC12

RL = 10kΩ to ground

CL = 100pF, RL = 10kΩ to ground

CL = 100pF, RL = 10kΩ to ground

internal VREF/REFIN

RL = 10kΩ to ground; (may trip

short-circuit)

Causes PGOOD to go low; if there

for a filter time, implies the COMP

pin(s) is out-of-range, and shuts

down IC

Based on internal oscillator clock

frequency (nominal 300kHz = 3.3µs

clock period)

0.6 V

70 800 KHz

85 dB

15 MHz

4

2

VCC

-50 mA

45 mA

3.3

1 2

V

V

V/µs

mV

V

V

Clock

pulses

EA Offset

DRIVE3 High Output Voltage

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

VREF

2 mV

VCC12

www.anpec.com.tw5

APW7066

Ele ctrical Characteristics (Cont.)

Operating Conditions: VCC = 5V, VCC12 = 12V, TA = 0 to 70°C, Unless Otherwise Specified.

Parameter Test Conditions Min. Typ. Max. Units

LINEAR REGULATOR (OUT3)

DRIVE3 High Output Source

Current

DRIVE3 Low Output Sink Current

VREF

Output Voltage

Output Accuracy

Source Current

REFOUT (VTTREF)

Output Voltage Determined by REFIN voltage

Offset Voltage

Source Current

Sink Current

Output Capacitance

Output High Voltage Minimum To select 0 degree phase; see Table 1

ENABLE/SOFTSTART (SS/EN 1,2,3)

Enable Threshold

Soft-Start Current

Soft-Start High Voltage End of ramp

Output High Voltage To select DDR mod; see Table 1

FS/SYNC PLL

Frequency range of Lock-in

High Voltage

GATE DRIVERS

Output1 GATE Driver Source UGATE1, LGATE1=3V, BOOT=12V 1.8 A

Output2 GATE Driver Source UGATE2, LGATE2=3V, BOOT=12V 1 A

Output1 GATE Driver Sink UGATE1, LGATE1=3V, BOOT=12V 2.5

Output2 GATE Driver Sink UGATE2, UGATE2=3V, BOOT=12V 4

Output Voltage UGATE1, UGATE2 30 V

Output Voltage LGATE1, LGATE2 12 V

1.1µF max capacitance

EN Rising

EN falling

( from LG pin of another IC, for

example)

1.5 mA

2.5 mA

3.3 V

-0.8 +0.8

2.0 mA

0.6 3.3 V

-10 +10 mV

0.2 20 mA

0.48 mA

0.1 µ

3.8 VCC

1.05

0.95

-30

3.5 V

3.8 VCC

150 800 KHz

12 V

V

µ

%

F

V

A

V

Ω

Ω

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw6

APW7066

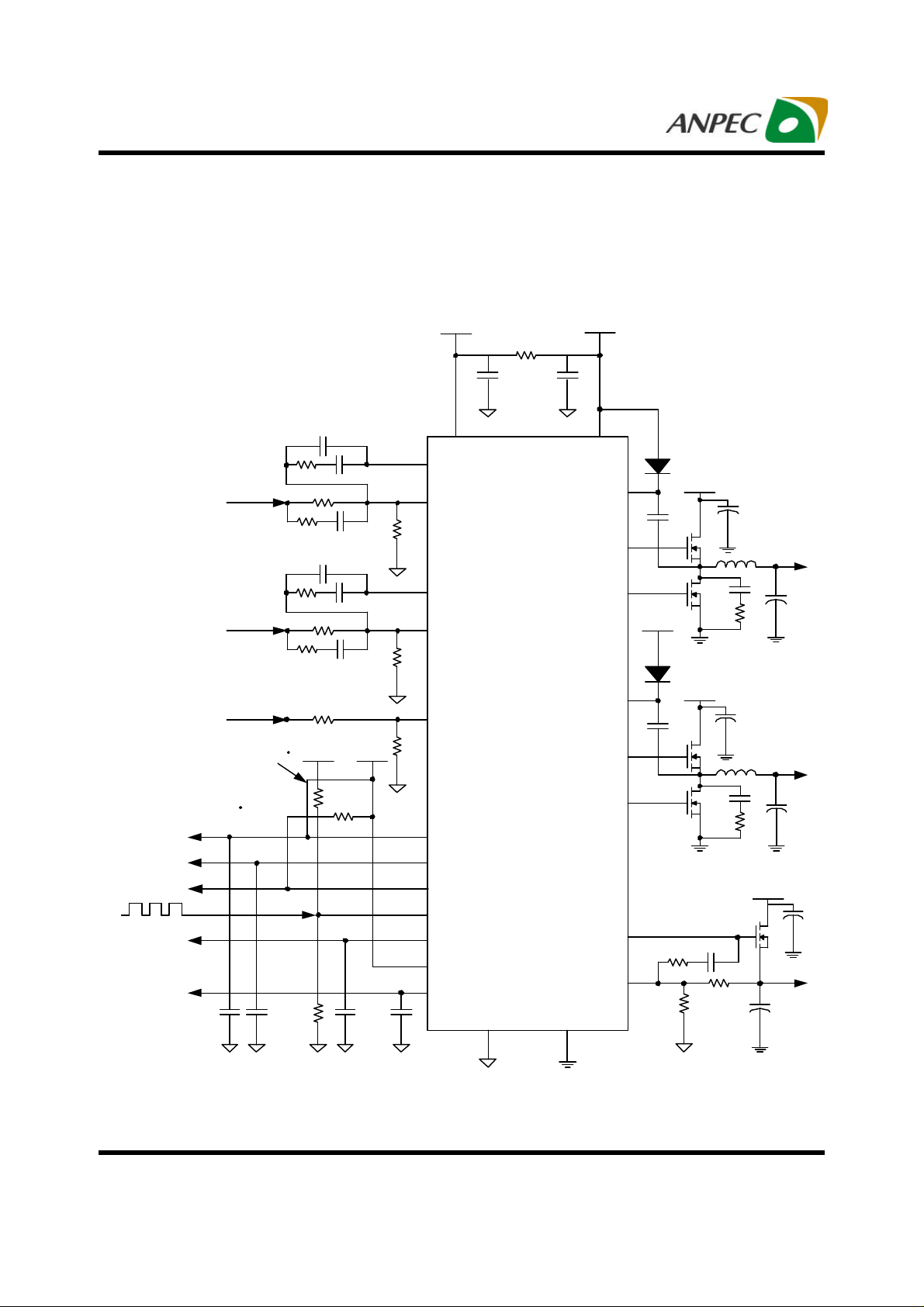

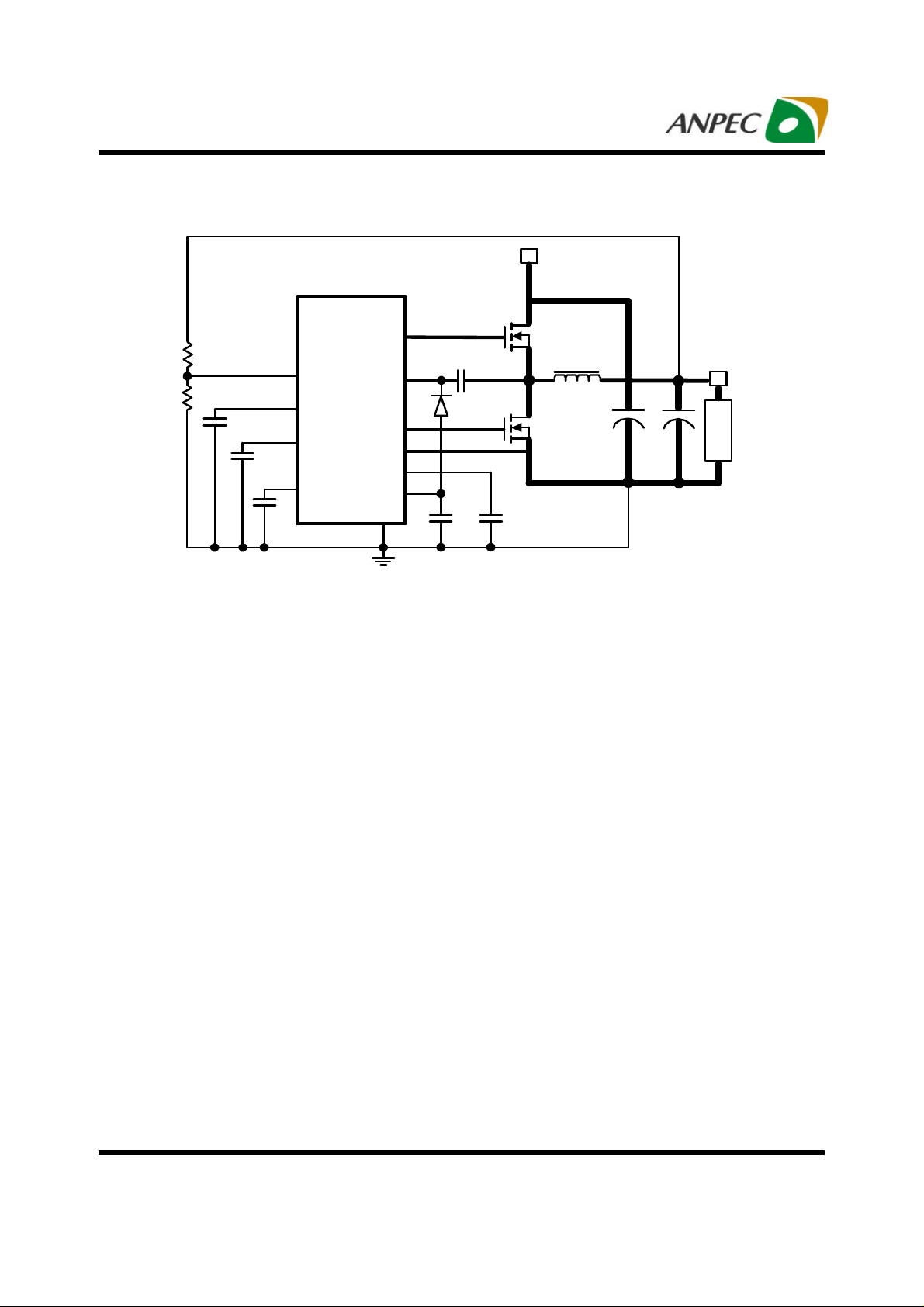

Typical Application Circuit

APW706 6

DDR MODE

VOUT1

VOUT2

VOUT1(DDR)

PHASE

SHIFT 0

VCC12

VCC

VCC

COMP1

FB1

COMP2

FB2

REFIN

Optional for

shunt regulator

APW7066

VCC12

BOOT1

UGATE1

LGATE1

BOOT2

UGATE2

VIN1

VOUT1

VCC12

VIN2=VOUT1(DDR)

VOUT2

PHASE

SHIFT 90

VTTREF

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

REFOUT

VREF

PGOOD

FS/SYNC

SS1/EN1

SS2/EN2

SS3/EN3

GND PGND

LGATE2

DRIVE3

FB3

VIN3

VOUT3

www.anpec.com.tw7

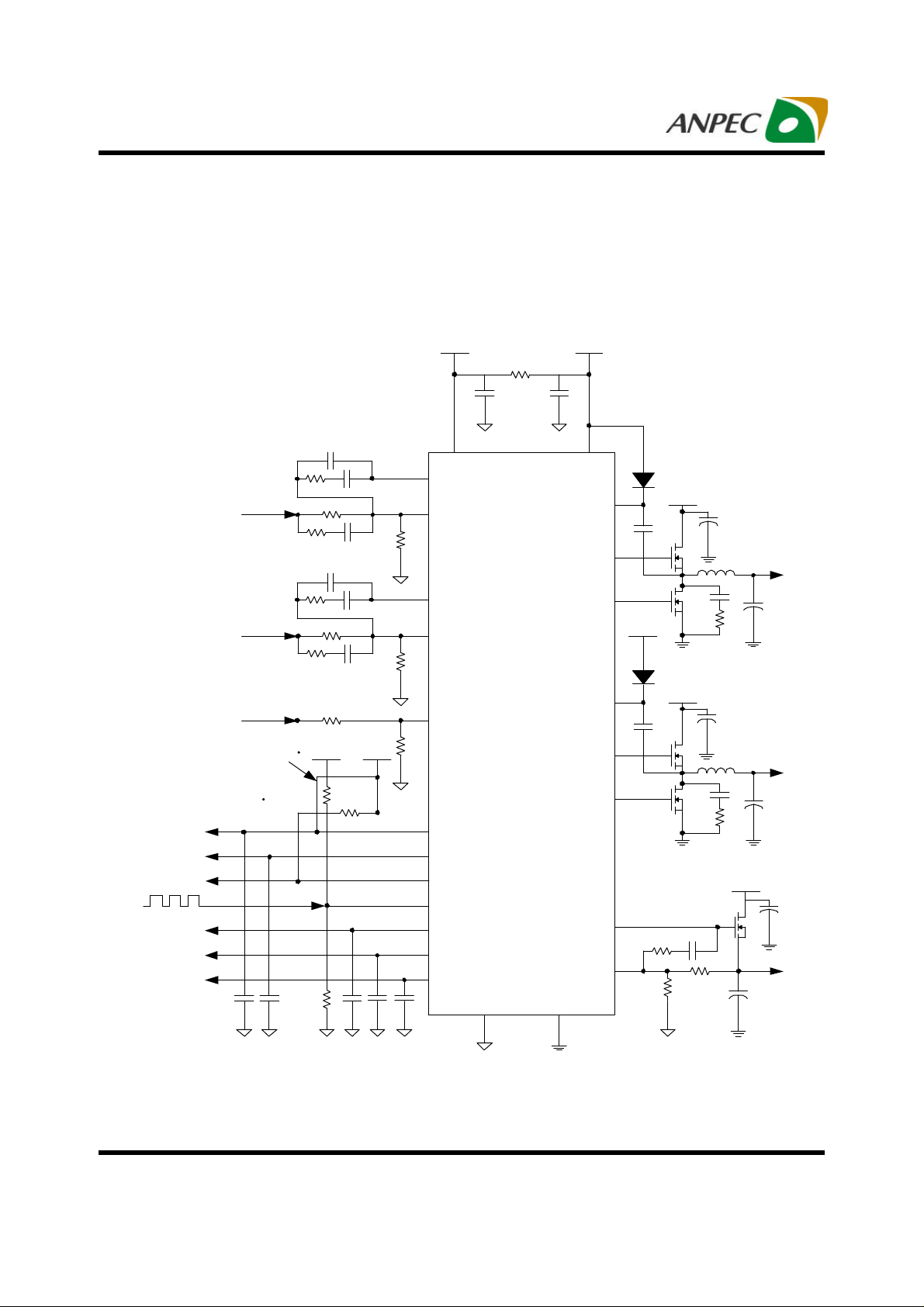

APW7066

Typ ical Application Circuit (Cont.)

APW706 6

IND EPENDENT MODE

PHASE

SHIFT 180

VTTREF

SYNCHRONOUS

FREQUENCY

VOUT1

VOUT2

VREF

PHASE

SHIFT 0

VCC12

VCC

VCC

COMP1

FB1

COMP2

FB2

REFIN

REFOUT

VREF

PGOOD

FS/SYNC

SS1/EN1

Optional for

shunt regulator

APW7066

VCC12

BOOT1

UGATE1

LGATE1

BOOT2

UGATE2

LGATE2

DRIVE3

VIN1

VOUT1

VCC12

VIN2

VOUT2

VIN3

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

SS2/EN2

SS3/EN3

GND PGND

FB3

VOUT3

www.anpec.com.tw8

APW7066

Function Pin De scriptions

VCC

Powe r supply input pin. Connect a nominal 5V power

supply to this pin for the control circuit, or connect a

resistor (nominally 300Ω) to VCC12 for a shunt

regulator function (typical 5.8V). It is recommended

that a de coupling capacitor (1 to 10uF) is connected

to the GND for noise decoupling.

GND

This pin is the signal ground pin. The metal thermal

pad und er the package is the IC substrate; connects

the GND pin and metal thermal pad together on the

board, and ties to the good GND p lane for electrical

and thermal con duction.

VC C12

Pow er supply input pin. Connect a no minal 12V power

su pply to this p in for the ga te driver. It is re commended

that a decoupling ca pacitor (1 to 10uF) is connected

to the GND for n oise decoupling.

PGND

This pin is the power grou nd pin for the gate driver a nd

linear driver circuit. It should be tied to the GND.

FB1, FB 2, FB3

These pins are th e inverting inputs of the error amplifiers of their respective regulators. They are used to

set the output voltage and the compensation

components.

SS1/EN1, SS2/EN2, SS3/EN3

These pins provide two functions. Connect a capacitor

to the GND fo r setting the soft-start time. Use an open

drain log ic signal to pull the SS/EN pin low to disable

the respective output, leave open to enable the respe ctive output.

COMP1 , COMP2

These pin s are the outputs of error amplifiers of their

respect ive regulators. They are used to set the

compensa tion components.

UGATE1, UGATE2

These pins provide t he gate driver for the upper

MOSFETs of VOUT1 a nd VOUT2.

LGATE1, LGATE2

These pins provide the gate driver for the lower

MOSFETs of VOUT1 and VOUT2.

BOOT1, BOOT2

These pins provide the bootstrap voltage to the gate

driver for driving the upper MOSFETs. It can be

connected to a power voltage directly, but the difference voltage between the BOOT a nd VIN must be high

enoug h to drive the upper MOSFETs.

REFIN

This pin is th e refere nce input voltag e of error amplifier

of the VOUT2. It also provides the volta ge into a buffe r,

which is ou t on the REFOUT pin.

REFOUT

This pin provides a buffed voltage, which is from REFIN

pin. In Independent mode, it can be used by other

ICs. In DDR mode, it is from th e VOUT1, and can be

use d as the VTT buffer.

This p in also uses to select th e phase shift (see table1 ).

When this pin pulls to VCC, the buffer is disabled and

the REFOUT is not available for use. It is reco mmended

that a 0.1u F capacitor is connected to the ground for

stability.

VR EF

This p in provides a 3.3V refe rence voltage, which can

be used by the REFIN pin or other ICs as a voltage

reference. It is recommended that a 1uF capacitor is

connected to ground for stability.

DRIVE3

This pin drives the gate of an external N-channel

MOSFET for line ar regulator.

PGOOD

This pin is an open drain device; connect a pull up

resistor to the VCC for PGOOD function.

FS/SYN C

This pin is used to adjust the switching frequency.

Con necting a resistor fro m FS/SYNC pin to the ground

increases the switching frequency. Conversely, connecting a resistor from this pin to the VCC12 reduces

the swit ching frequency. In addition, this pin also

provide s synchronous frequency function. An e xternal

clock can be fed into this pin, and force the switching

frequency to follow the external clock.

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw9

APW7066

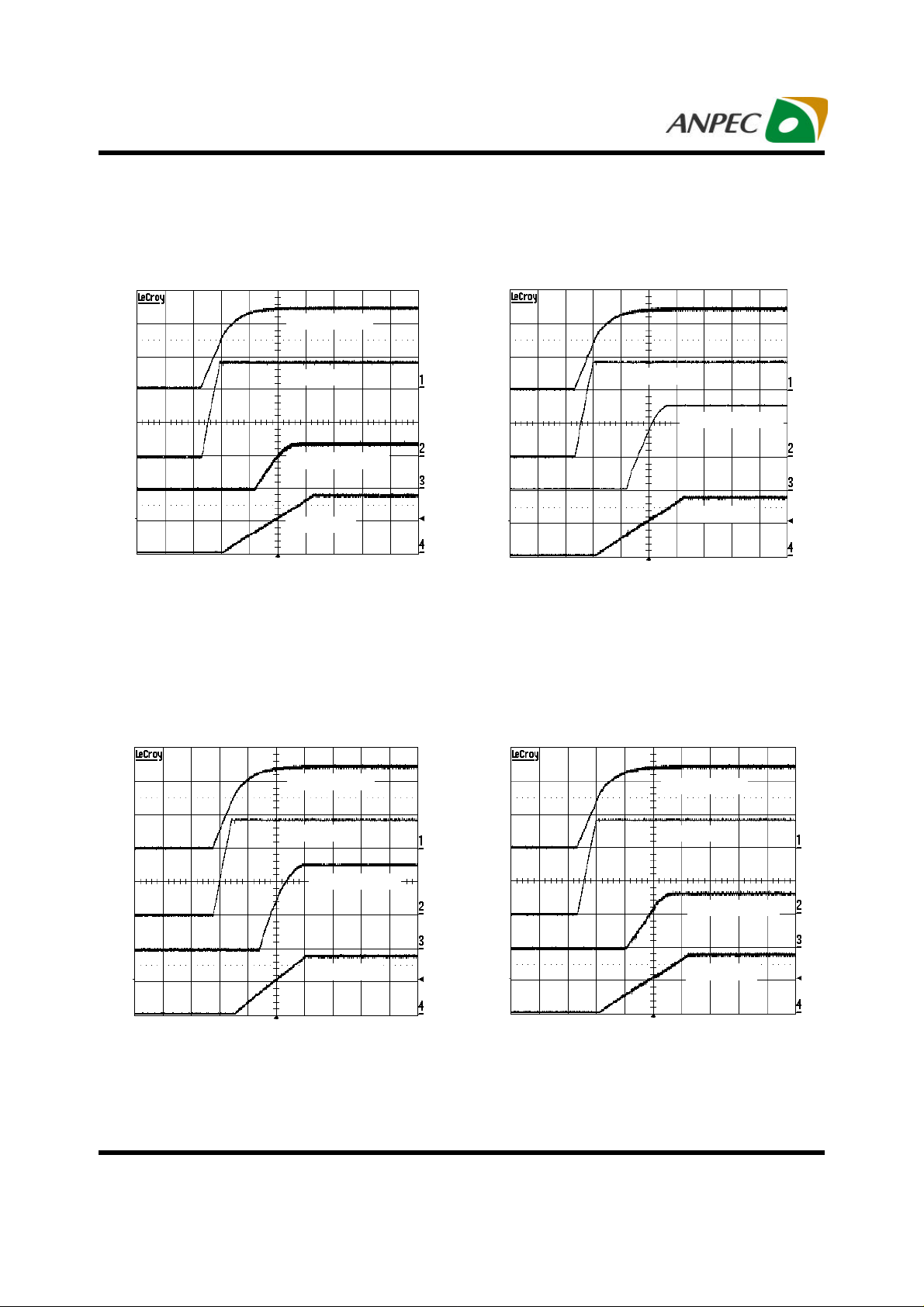

Typ ical Characteristics

VOUT1 Po wer Up

VCC12(5V/div)

VCC(2V/div)

VOUT1(1V/div)

SS1(2V/div)

Time(5ms/div)

VOUT2 Po wer Up

VCC12(5V/div)

VCC(2V/div)

VOUT2(2V/div)

SS2(2V/div)

Time(5ms/div)

VOUT3 Po wer Up VREF Power Up

VCC12(5V/div)

VCC(2V/div)

VOUT3(1V/div)

SS3(2V/div)

Time(5ms/div)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

VCC12(5V/div)

VCC(2V/div)

VREF(2V/div)

SS2(2V/div)

Time(5ms/div)

www.anpec.com.tw10

APW7066

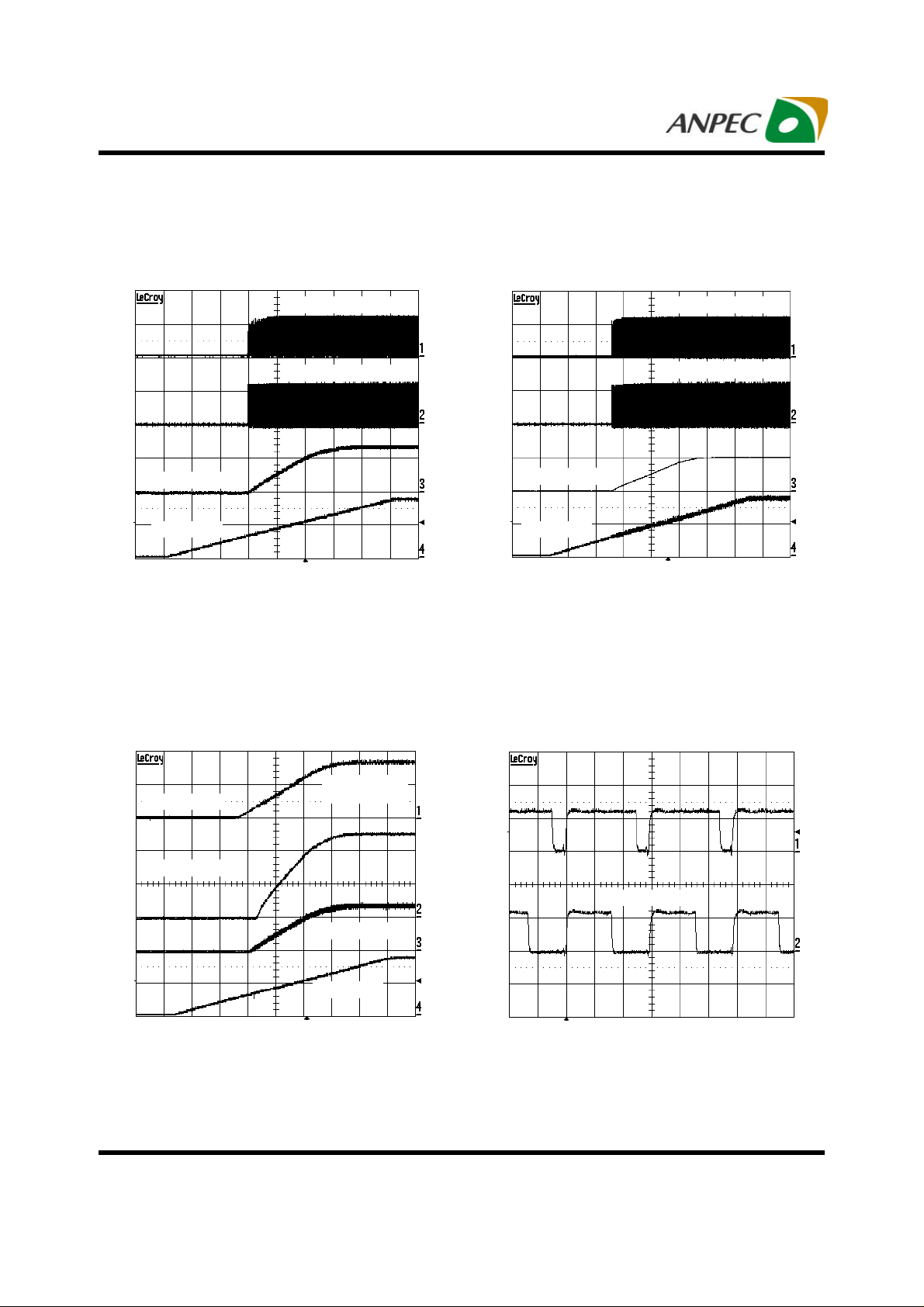

Typ ical Characteristics (Cont.)

VOUT1 Po wer Up

VOUT1(1V/div)

SS1(2V/div)

UGATE1(20V/div)

LGATE1(10V/div)

Time(2ms/div)

VOUT2 Po wer Up

UGATE2(20V/div)

LGATE2(10V/div)

VOUT2(5V/div)

SS2(2V/div)

Time(2ms/div)

DDR Mod e Power Up

VREF(2V/div)

VOUT2(2V/div)

VOUT1(1V/div)

SS1(2V/div)

Time(2ms/div)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

SS2=VCC

VOUT1= REFIN

Phase Shift 0 degrees

LG1(10V/div)

LG2(10V/div)

Time(1u s/div)

www.anpec.com.tw11

APW7066

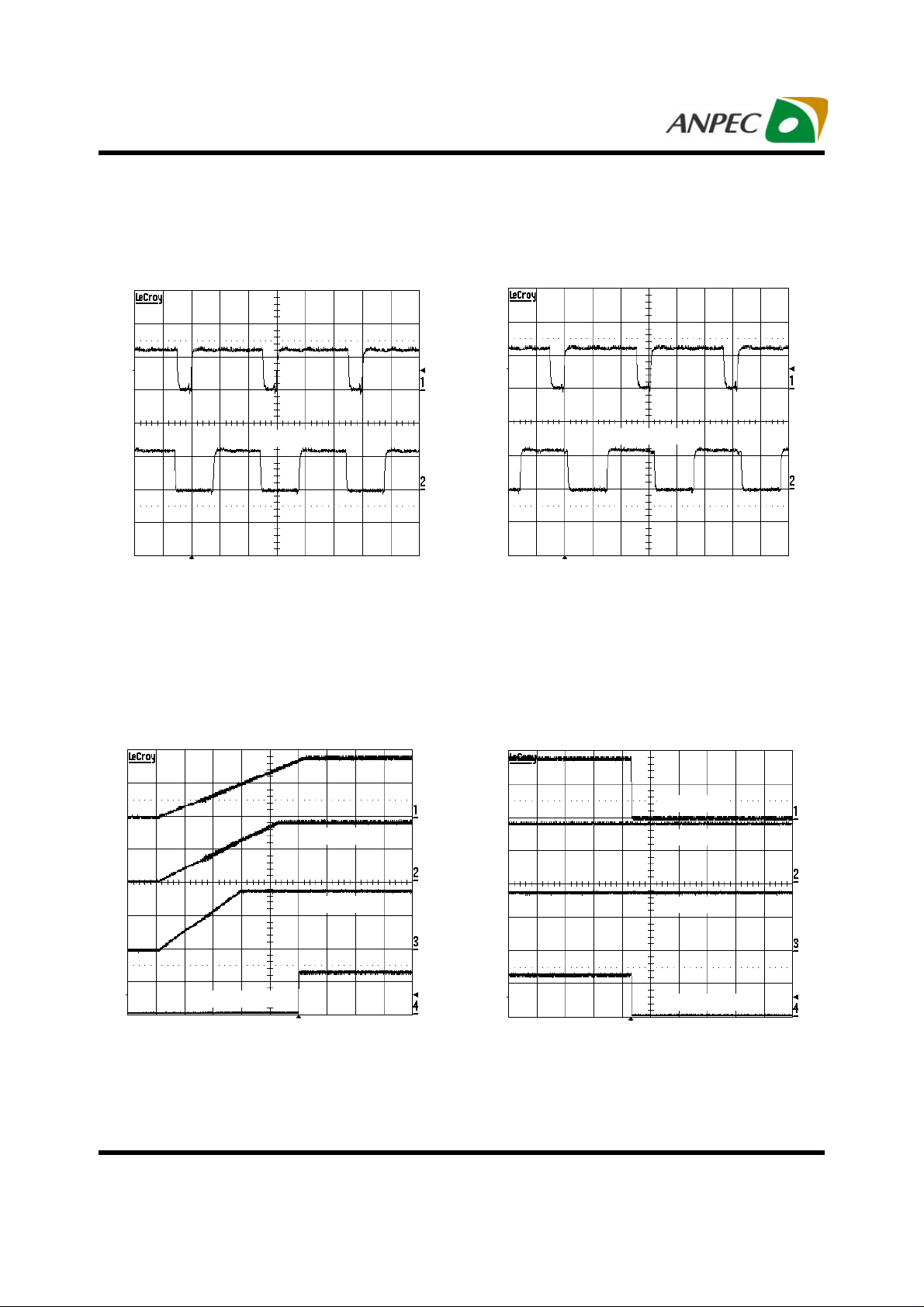

Typ ical Characteristics (Cont.)

Phase Shift 90 degrees

LG1(10V/div)

LG2(10V/div)

Time(1u s/div)

Phase Shift 180 degrees

LG1(10V/div)

LG2(10V/div)

Time(1u s/div)

PGOOD High PGOOD Low

SS1(2V/div)

SS2(2V/div)

SS3(2V/div)

PGOOD(5V/div)

Time(5ms/div)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

SS1(2V/div)

SS2(2V/div)

SS3(2V/div)

PGOOD(5V/div)

Time(5ms/div)

www.anpec.com.tw12

APW7066

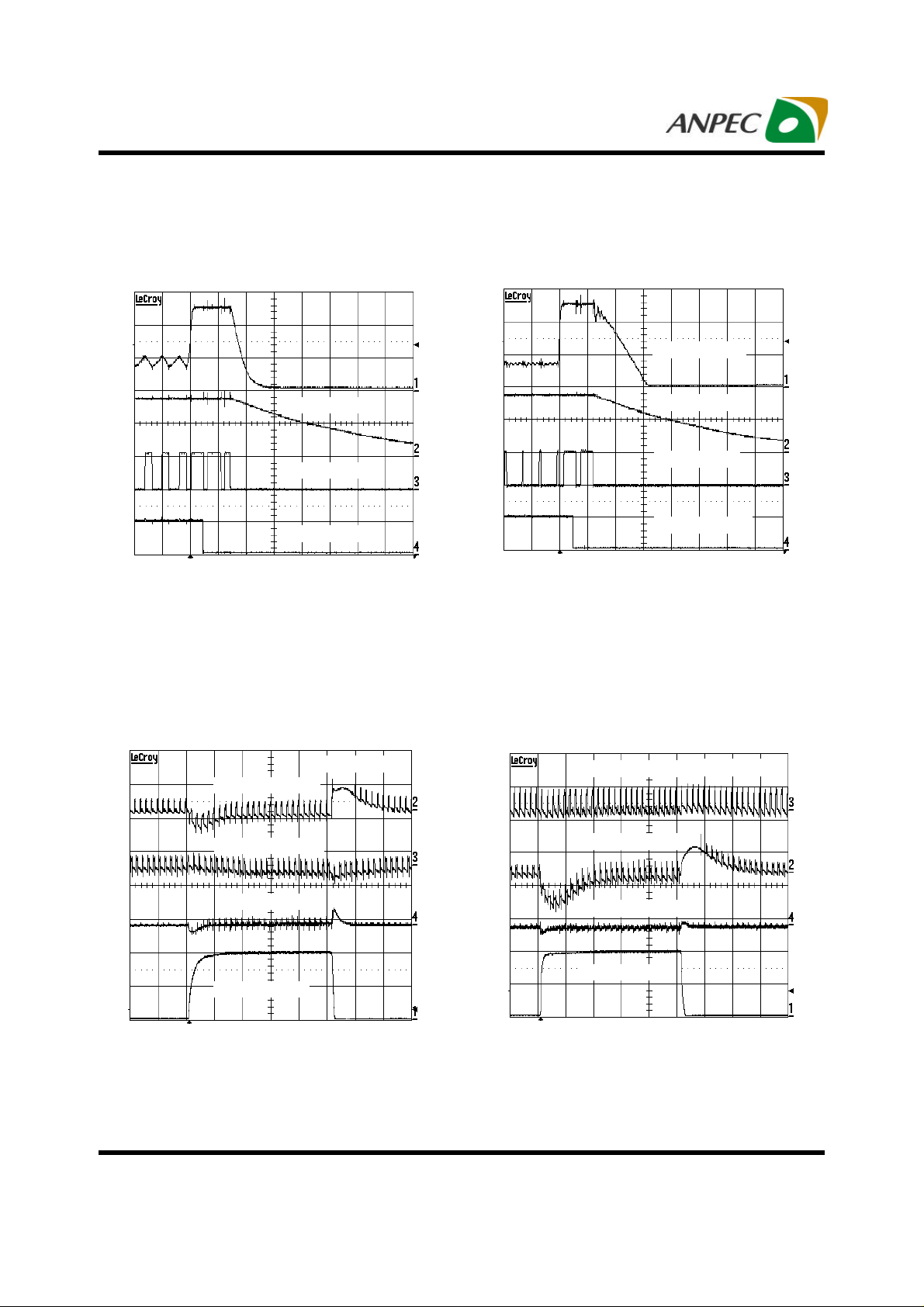

Typ ical Characteristics (Cont.)

VOUT2 Sho rt Circuit Protection

Comp2 (2V/div)

SS2 (2V/div)

UG2 (20V/div)

PGOOD (5V/div)

Time(5u s/div)

VOUT1 Sho rt Circuit Protection

Comp1 (2V/div)

SS1 (2V/div)

UG1 (20V/div)

PGOOD (5V/div)

Time(5u s/div)

VOUT1 Load Transient

VOUT1 (0.2V/div)

VOUT2 (0.1V/div)

VOUT3 (0.1V/div)

IOUT1 (10A/div)

Time(20 us/div)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

VOUT1=VIN3

VOUT2 Load Tran sient

VOUT1 (0.1V/div)

VOUT2 (0.1V/div)

VOUT3 (0.05V/div)

IOUT2 (5A/div)

VOUT1=VIN3

Time(20 us/div)

www.anpec.com.tw13

APW7066

Typ ical Characteristics (Cont.)

VOUT3 Load Transient UG1 Rising

VOUT1=VIN3

VOUT1 (0.1V/div)

VOUT2 (0.1V/div)

UG1 (10V/div)

Phase1 (10V/div)

VOUT3 (0.1V/div)

IOUT3 (2A/div)

Time(20 us/div)

UG1 Falling

UG1 (10V/div)

Phase1 (10V/div)

LG1 (10V/div)

Time(50 ns/div)

UG2 R ising

UG2 (10V/div)

Phase2 (10V/

LG1 (10V/div)

Time(50 ns/div)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

LG2 (10V/div)

Time(50 ns/div)

www.anpec.com.tw14

APW7066

Typ ical Characteristics (Cont.)

UG2 Falling

LG2 (10V/div)

Time(50 ns/div)

UG2 (10V/div)

Phas e2 (10V/div)

PGOOD Sink Curre nt vs. PGOOD Voltage

3

2.5

2

1.5

1

Sink Current (mA)

0.5

0

0 10 20 30 40

PGOOD Voltage (mV)

REFOUT Vo ltage vs. Source Current

3.35

3.34

3.33

3.32

3.31

3.3

3.29

3.28

3.27

REFOUT Voltage (V)

3.26

3.25

0 5 10 15 20

Source Current (mA)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

VREF Voltage vs. Source Current

3.32

3.31

3.3

3.29

VREF Voltage (V)

3.28

0 0.5 1 1.5 2

Source Current (mA)

www.anpec.com.tw15

APW7066

Typ ical Characteristics (Cont.)

UG1 Sink Current vs. Volta ge

2.4

2.2

2

1.8

1.6

1.4

1.2

1

0.8

Sink Current (A)

0.6

0.4

0.2

0

0 2 4 6 8 10 12

UG1 Volta ge (V)

UG1 Sou rce Current vs. Voltage

2.4

2.2

2

1.8

1.6

1.4

1.2

1

0.8

0.6

Source Current (A)

0.4

0.2

0

0 2 4 6 8 10 12

UG1 Volta ge (V)

LG1 Sink Current vs. Voltage

2.4

2.2

2

1.8

1.6

1.4

1.2

1

0.8

0.6

Sink Current (A)

0.4

0.2

0

0 2 4 6 8 10 12

LG1 Voltage (V)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

LG1 Sou rce Current vs. Voltage

2.4

2.2

2

1.8

1.6

1.4

1.2

1

0.8

0.6

Source Current (A)

0.4

0.2

0

0 2 4 6 8 10 12

LG1 Voltage (V)

www.anpec.com.tw16

APW7066

Typ ical Characteristics (Cont.)

UG2 Sink Current vs. Volta ge

1.6

1.4

1.2

1

0.8

0.6

0.4

Sink Current (A)

0.2

0

0 2 4 6 8 10 12

BOOT=12V

UG2 Volta ge (V)

UG2 Sou rce Current vs. Voltage

1.4

BOOT=12V

1.2

1

0.8

0.6

0.4

Source Current (A)

0.2

0

0 2 4 6 8 10 12

UG2 Voltage

LG2 Sink Current vs. Voltage

1.6

1.4

1.2

1

0.8

0.6

0.4

Sink Current (A)

0.2

0

0 2 4 6 8 10 12

LG2 Voltage (V)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

LG2 Sou rce Current vs. Voltage

1.4

1.2

1

0.8

0.6

0.4

Source Current (A)

0.2

0

0 2 4 6 8 10 12

LG2 Voltage (V)

www.anpec.com.tw17

APW7066

Typ ical Characteristics (Cont.)

DRIVE3 Sink Curre nt vs. Voltage DRIVE3 Source Current vs. Voltage

3.5

3

2

2.5

2

1.5

1

Sink Current (mA)

0.5

0

0 2 4 6 8 10 12

DRIVE3 Volta ge (V) DRIVE3 Volta ge (V)

FS Resistance vs. Switching Frequen cy

1000

FS to VCC12

900

800

700

600

500

400

300

200

FS Resistance (kΩ)

100

0

0 100 200 300 400 500 600 700 800

FS to GND

Switching Freq uency (kHz)

1.5

1

0.5

Source Current (mA)

0

0 2 4 6 8 10 12

Shunt Re gulator Sink Current vs. Voltage

60

50

40

30

20

Sink Current (mA)

10

0

3 3.5 4 4.5 5 5.5 6 6.5 7

Shunt Re gulator Voltage (V)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw18

APW7066

Typ ical Characteristics (Cont.)

Comp Sink Current vs. Volta ge

60

50

40

30

20

Sink Current (mA)

10

0

0 0.5 1 1.5 2 2.5 3

Comp Volta ge (V)

Comp Sou rce Current vs. Voltage

70

60

50

40

30

20

Source Current (mA)

10

0

0 1 2 3 4

Comp Volta ge (V)

FB Voltag e vs. Temperature

610

608

606

604

602

600

598

596

FB Voltage (V)

594

592

590

0 25 50 75 100 125 150

Temperature (°C)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

VREF Voltage vs. Temperature

3.35

3.34

3.33

3.32

3.31

3.3

3.29

3.28

VREF Voltage (V)

3.27

3.26

3.25

0 25 50 75 100 125 150

Temperature (°C)

www.anpec.com.tw19

APW7066

REFOUT

Function Descriptions

Operational Modes

The APW706 6 has two inde pendent synchronous buck

converters, and it also has DDR mode operation to

allow VOU T2 to track VOUT1.

In indepe ndent mode operation, connect a capacitor

from each SS/EN pin t o the ground to set each

regulator’s soft-start time. The 3.3V reference VREF

can be used directly, or divided by two resistors for

REFIN, since the VREF is controlled by the SS2/EN2.

DDR mode is chosen by conne cting the SS2/EN2 pin

to VCC(5V). In this mode, SS2/EN2 function w ill be

disabled, SS1/EN1 is used to control soft start and

enab le both VOUT1 and VOUT2. The VOUT1 is used

as the REFIN for the VOUT2, that makes VOUT2 to

track VOUT1.

VREF

REFIN

SS1/EN1

SS2/EN2

SS3/EN3

GND

Phase Shift

The APW7066 has phase shift function, use the

REFOUT pin to select the phase shift between

Independent mode and DDR mode. Connect the

REFOU T to VCC to get the 0 degrees in either mode.

In this case, the buffer of the REFOUT is disabled.

Lea ve the REFOUT open shifts the phase 90 degrees

in DDR mode, or 180 degree s in Independent mode,

REFOUT ca n be used in this case ( see Table 1.).

MODE SS2/EN2

DDR VCC VCC VOUT1 0 deg

DDR VCC Open VOUT1 90 deg

Independent SS2 cap VCC VREF

Independent SS2 cap Open VREF 180 deg

Table1.Mo de and Phase Se lection

REFIN PHASE SHIFT CH1/CH2

SS1/EN1 for CH1

and CH2

0 deg

SS1/EN1 for CH1

SS2/EN2 for CH2

The advanta ge of Phase shift is to avoid overlapping

the switching current spikes of the two channels, or

interaction betw een the channels; it also reduces the

RMS current of the input capacitors, allowing f ewer

caps to be employed. However, the phase shift

betwee n the rising edge of LGATE1 and L GATE2 (See

figure 3.), depending on the duty cycles, the falling

edges of the two channels might overlap; so the user

should check it.

Figure 1. Indep endent Mode Circuit

VOUT1

VCC

SS1/EN1

SS2/EN2

SS3/EN3

Figure 2.DDR Mode Circuit

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

REFIN

GND

LG1

LG2

(0deg)

LG2

(90deg)

LG2

(180deg)

0 90 180 0

Figure 3 . Phase of LG2 with respect

to rising edge of LG1

www.anpec.com.tw20

APW7066

I

Function De scriptions (Cont.)

Soft-Start/Enable

The three SS/EN pins control the soft-start and enable

or disable the controller. In Independent mode, the

three regulators all have independent soft-start and

enable functions. Co nnect a soft-start capacitor from

each SS/EN pin to the GND to set the soft-start

interval, and an open dra in logic signal for each SS/EN

pin w ill enable or disable the respective output.

Figu re 4. Show s the soft-start interval. Whe n both VCC

and VCC12 reach their Power-On-Reset threshold

4.23V and 7.8V, a 30uA current source starts to

charge the capacitor. When t he SS reaches the

enabled t hreshold about 1V, the internal 0.6V

reference starts to rise and follows the SS; the error

amplifier output (COMP) suddenly raises to 1.1V, which

is the valley of the oscillator’s triangle wave, leads the

VOUT to start up. Until the SS reaches about 3.0V,

the internal reference completes the soft-start interval

a nd reaches to 0.6V; then VOUT1 is in regu lation. The

SS1 still rises to 3.5V and then stops.

VOLTAGE

VSS

3V

VOUT

1V

t1 t2t0

Figure 4. Soft-Start Inte rval

C

SS

ttT

12Start-Soft ⋅=−=

2V

SS

Where :

CSS = external Soft-Start ca pacitor

ISS = Soft-Start current = 30µA

TIME

PGOOD

The PGOOD output is an open-drain device, when the

VCC is prese nt; the gate of open-drain device will be

high, forcing the PGOOD pin to go low. T he three

SS/EN pins and the SCP signals control the PGOOD

signal (see block diagram), after the t hree SS/EN

signals a re over threshold high 3.3V and three outputs

have no short -circuit, the PGOOD goes high to

indicate all regulators are re ady. If any of the SS/EN

pins goes below th reshold low 3.2V, the PGOOD will

go low. Also, if any of the outputs has a short, the

PGO OD pull low and if short-circuit condition

continues for 1-2 clock pulse s, all regulators will shut

down. If the short-circuit is not long enough to shut

down , it may still cause PGOOD to g o low momentarily.

Because the PGOOD is an open-drain device, the

typical range of the value to connect a pull high

resistor to VCC will be 1kΩ to 10kΩ; if PGOOD is not

used, leave it open.

Shunt Regulator

The APW7066 must have two power supplies VCC

(5V) a nd VCC12 (12V) to drive the IC; VCC (5V) is for

the control circu it and VCC12 (12V) is for the drivers

of output s. But it can also operate only VCC12,

because the shunt regulator 5.8V was designed for

VCC (5V); the range of the shunt regulator was design ed over the usual range 4.5V to 5.5V of typical 5V

power supplies.

Connect a resistor from VCC12 to VCC for shunt

regulator and for the su pply current. The input supply

current of VCC is 7mA; minimum shunt regulator

current is about 7mA, a nd therefore the 20mA shunt

regulator current is enough; thus, the typical value,

300Ω of the resistor is recommended. The relation

amon g minimun shunt regula tor current, requ ired shu nt

regulator current and supp ly current is:

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw21

APW7066

Switching Frequency (kHz)

FS Resistance (kO)

Function De scriptions (Cont.)

PGOOD (Cont.)

ISHUNT = ICC + ISHUNT(MIN)

Where :

ISHUNT = Re quired Shunt Regulator Current

ICC = Supp ly Current

ISHUNT(MIN) = Minimum Shu nt Regulator Current

VCC (5.8V)

OPTIONAL R

FOR SHUNT

REGULATOR

VCC12

Oscillator

The APW7066 provides the oscillator swit ching

f requency adjustment. Connect a resistor from

FS/SYNC pin to the ground, the nominally 300kHz

oscillator switching frequency is increased according

to the value of the re sistor. The adjustment range of

the switching freque ncy is 300kHz to 800kHz.

Converse ly, connecting a resistor from FS/SYNC pin

to the VCC12 reduces the switching frequency.The

adjustment ra nge of the switching frequency is 70kHz

to 30 0kHz.

1000

FS to VCC12

900

800

700

600

500

400

300

200

100

0

0 100 200 300 400 500 600 700 800

FS to GND

SYN C

The switching frequen cy also can be synchronized to

an external frequency. If there are two switching

converters on t he same board, taking the LGATE

sign al from another switching converter, go through a

10kΩ resistor, and conne cting to the FS/SYNC pin.

The APW7066 will read another converter’s freq uency

and after several milliseconds, the APW7066 will

change to new frequency. If ano ther converter’s signal

is lost, the APW7066 will return to internal oscillator.

This a llows the two switching converters for operating

at th e same frequency to avoid the interference from

the independent frequencies between them. The

a cceptable frequency is a range of 150kHz to 800kHz.

Short-Circuit Protection

The APW7066 has a simple short-circuit protection

to monitor COMP1 and COMP2 for VOUT1/2. When

output voltage has a short, the FB p in should start to

follow output, since it is a resistor divider from the

output. The FB is the inverting input of Error-Amp,

when FB pin is lower than the Error-Amp reference,

then the COMP will rise to increase the duty-cycle of

the up per MOSFET gate driver, this allows output to

get high er voltage. If the short-circuit condition is long

enou gh, the COMP pin will exceed the trip point 3.3V,

and the duty circle w ill hit the maximum. This means

that either Over-Cu rrent or Under-Voltage condition is

detected. If an y of the COMP1 and COMP2 exceeds

their trip po ints, and holds over a filter time (1-2 clock

cycle of switching frequency), then all regu lators will

shut down, and require a POR on either of VCC or

VCC12 to restart. Note that the linear regulator has

no short-circuit prote ction.

Figure 5. FS/SYNC Resistance vs. Frequen cy

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw22

APW7066

Applica tion Information

Output Voltage Setting

The output voltage can be adjusted with a resistive

divider, from ou tput voltage to FB pin to the ground.

Use 1% or better resistors for these resistor dividers

is recommended. The reference voltages of VOUT1

and VOUT3 are 0.6V, the reference voltage of VOUT2

is REFIN voltage. The VREF voltage is for REFIN in

independent mode. The following equations can be

used to calculate the outpu t voltage:

R1

R2

R1

R2

R1

R2

R3

0.6V x )

REFIN x )

0.6V x )

Mode) (DDR x VOUT1)

1(VOUT1 +=

1VOUT2 +=(

1VOUT3 += (

(1REFIN +=

R4

R3

(1REFIN +=

R4

Where :

R1 = re sistor from VOUT to FB

R2 = resistor from FB to GND

R3 = resistor from VREF or VOUT1 to REFIN

R4 = resistor from REFIN to GND

Note that the R1 is part of the compensation . It should

be conformed to the feedback compensation.

Line ar Regulator Input/Output MOSFET Selection

The maximum DR IVE3 voltage is determined by the

VCC12. Since this pin drives an external N-channel

MOSFET, therefore the maximum output voltage of

the linear regulator is depend ent upon the VGS.

VOUT3MAX = VCC12 - VG S

Another criteria is its efficiency of heat removal. The

power dissipated by the MOSFET is given by:

Pdiss = Iout x (VIN - VOUT3)

whe re Iout is the maximum load current VOUT3 is the

nominal output voltage

In some applications, heatsink might be required to

help mainta in the junctio n temperature of the MOSFET

below its maximum rating.

Linear Regulator Compensation Sele ction

The linear regulator is stable over all load current.

Mode) nt(Independe x VREF)

However, the transient response can be further

enhanced by connecting a RC network between the

FB3 and DRI VE3 pin. Depending on the output

capacitance and load current of the application, the

value of this RC network is then varied. A good starting

point for the resistor value is 6.8kΩ and 470pF for the

ca pacitor.

PWM Compensation

Linear Regulator Input/Output Capacitor Selection

The input capacitor is chosen based on its voltage

rating. Under load transient condition, the input

capacit or will momentarily supply the required

tran sient current. The output capacitor for the linear

regula tor is chosen to minimize any droop during load

tran sient condition. In addition, the capacitor is chosen

base d on its voltage rating.

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

Th e output LC filter of a step down converter introduces

a double pole, w hich contributes with –40dB/decade

gain slope and 180 degrees phase shift in the co ntrol

loop. A compensation network between COMP, FB

and VOUT should be added. The compensation

network is show n in Fig. 9.

The output LC filter consists of the output inductor

and o utput capacitors. The transfer function of the LC

filter is given b y:

C ESRs1

OUT

GAIN LC =

2

××+

1CESRsCLs

OUTOUT

+××+××

www.anpec.com.tw23

APW7066

V

App lication Information (Cont.)

PWM Com pensation (Cont.)

The poles and zero of this transfer function are:

FLC =

1

OUTCL2

××π×

1

FESR =

The FLC is the double po les of the LC filter, and FESR is

the zero introduced by the ESR of the output capacitor.

PHASE

Figure 6. The Ou tput LC Filter

OUTCESR ××π×2

L

COUT

ESR

FLC

-40dB/dec

FESR

Output

-20dB/dec

VIN

Driver

PWM

Comparator

VOSC

Output of

Error

Amplifier

Driver

Figure 8. The PWM Modulator

The compensation circuit is shown in Figure 9. It

provide a close loop tran sfer function with the highest

zero crossover freque ncy and sufficient phase margin.

The transfer function of error amplifier is given by:

1

+×

s

C2C1

××

C2C1R2

GAINAMP =

=

COMP

V

OUT

+

s

+

R3R1

×

××

C1R3R1

sC1

=

1

×

C2R2

+

+

s s

PHASE

+

R2 //

sC2

1

+

R3 // R1

sC3

1

( )

+×

s

1

×+

C3R3R1

1

×

C3R3

The poles an d zeros of the transfer function are:

Frequency

Figure 7. The LC Filter Gain & Frequen cy

The PWM modu lator is shown in Figure. 8. The input

is th e output of the error amplifier and the output is the

PHASE node. The transfer function of the PWM

modulator is given by:

GAIN PWM =

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

IN

OSC

VV∆

FZ1 =

FZ2 =

FP1 =

FP2 =

1

C2R2××π×2

1

( )

1

××π×

R22

1

C3R3 ××π×2

C3R3R1 ×+×π×2

×

C2C1

+

C2C1

www.anpec.com.tw24

APW7066

App lication Information (Cont.)

PWM Com pensation (Cont.)

C1

R3

C3

R2

C2

VOUT

R1

-

FB

+

VREF

Figure 9. Co mpensation Network

The closed loop gain of the converter can be written

as:

GAINLC x GAINPWM x

GAINAMP

Figure 10. shows the asymptotic plot of the closed

loop converter gain and the following guidelines w ill

help to design the compensation network. Using the

below guidelines should give a compensation similar

to the curve plotted. A stable closed loop has a -20dB/

decade slope and a phase margin greater than 45

deg ree.

1.Cho ose a value for R1, uaually between 1K and

5K.

2.Select the desired zero crossover frequ ency FO:

(1/5 ~ 1/1 0) x FS >FO>FESR

Use the following equa tion to calculate R2:

R2

V

OSC

∆

=

V

F

O

1R

××

F

IN

LC

3.Place th e first zero FZ1 before the output LC filter

double pole frequency FLC.

FZ1 = 0.75 x FLC

Calculate the C2 by the equation:

C2

=

1

0.75FR22

LC ×××π×

4.Set the pole at th e ESR zero frequency FESR:

FP1 = FESR

Calculate the C1 by the equation:

C1

=

2

C2

1FC2R2

ESR −×××π×

VCOMP

5.Set t he second pole FP2 at half the switching

frequency and also set the second zero FZ2 at the

outp ut LC filter double po le FLC. The compe nsation

gain should not exceed the error amplif ier open

loop gain, check the compensation gain at FP 2

with the capabilities of the error amplifier.

FP2 = 0.5xFO

FZ2 = FLC

Combine the two equ ations will get the following

component calculations:

Gain

0

R3

=

20log

(R2/R1)

R1

F

S

2xF

LC

FZ1=0.75FLC

FLC

1

−

FZ2=FLC

FESR

PWM & Filter

Gain

C3

Open Loop Error

FP1=FESR

=

Amp Gain

20log

(VIN/ VOSC)

1

××π

FP2=0.5FS

Frequency

SFR3

Compensation

Gain

FO

Converter

Gain

Figure 10. Converter Gain & Frequency

Output Inductor Sele ction

The inductor value determines the inductor ripple

current and affects the load transient response. Higher

indu ctor value redu ces the inductor’s ripple curre nt and

induce s lower output ripple voltage. The ripple current

and ripple voltage can be approximated by:

OUTIN

VV

RIPPLE

I ×

−

=

S

LF

×

OUT

V

IN

V

∆VOUT = IRIPPLE x ESR

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw25

APW7066

App lication Information (Cont.)

Output Inductor Selection (Cont.)

where Fs is the switching frequency o f the regulator.

Although increase the inductor value and frequency

reduce the ripple current and voltage, but there is a

tradeoff exists betw een the inductor’s ripple current

and the regulator load transient response time.

A smaller inductor will give the regulator a faste r load

transient response at the expense of higher ripple

current. Increasing the sw itching frequency (FS) also

reduces the ripple current and voltage, but it will

increa se the switching loss of the MOSFET and the

powe r dissipation of the converter. The maximum ripple

curre nt occurs at the maximum input voltage. A good

starting point is to choose the ripple current to be

a pproximately 30% of the maximum output current.

Once the inducta nce value has been chosen, select

an induct or that is capable of carrying the required

peak current without going into saturation. In some

types of inductors, especially core that is made of

ferrite, the ripple current w ill increase abruptly when it

saturates. This will result in a larger output ripple

voltag e.

Output Capacitor Selection

Higher Capacitor value and lower ESR reduce the

output ripple and the load transient drop. Therefore

select high p erformance low ESR capacitors that are

intended for switching regulator applications. In some

applica tions, multiple capacitors have to be parallel to

achieve the desired ESR value. A small decoupling

capacitor in parallel for bypassing the noise is also

recommended, and the voltage rating of the output

capacitors are also must be considered. If tantalum

capacitors are used, make sure they are surge tested

by th e manufactures. If in doubt, consult the capacitors

man ufacturer.

Input Capa citor Selection

The input capa citor is chosen based on the voltage

rating and t he RMS current rating. For reliable

operation , select the capacitor voltage rating to be at

least 1.3 times higher than the maximum input voltage.

The maximum RMS current rating requirement is

a pproximately IOUT/2, where IOUT is the load current.

During p ower up, the input capacitors have to handle

large amount of su rge current. If tantalum capacitors

are used, make sure they are surge tested by the

manuf actures. If in doubt, consult the capacitors

manuf acturer. For high frequency decoupling, a

ceramic capacito r 1uF can be connected between the

drain of upper MOSFET and the source of lower

MOSFET.

MOSFET Selection

The selection o f the N-channel power MOSFETs are

determin ed by the R

(C

) and maximum outp ut current requirement.The

RSS

, reverse transfer capacitance

DS(ON )

losses in the MOSFETs have t wo components:

conduction loss and transition loss. For the upper and

lower MOSFET, the losses are approximately given

by the follow ing :

P

= I

UPPER

P

LOWER

where I

(1+ TC )(R

out

= I

(1+ TC)(R

out

is the load current

OUT

TC is th e temperature dependency of R

DS(ON)

DS(ON)

)D + (0.5)(I

)(1-D )

)(VIN)(tsw)F

out

S

DS(ON)

FS is the switching frequency

t

is the switching interval

sw

D is the duty cycle

Note that b oth MOSFETs have conduction losses while

the upper MOSFET include an additional transition

loss.The switching internal, tsw, is a f unction of the

reverse transfer capacitance C

RSS

.

The (1+T C) term is to factor in the temperature

dependency of the R

the “R

vs Temperature” curve of the power

DS(O N)

an d can be extracted from

DS(ON)

MOSFET.

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw26

APW7066

App lication Information (Cont.)

Connecting One Input from Another Output

It can be conne cted one of the 3 outputs as the input

voltage to the 2nd. In these cases the output current

of the first output includ es its own load current and the

2n d output’s load current. Therefore, the components of

the first output must be designed and sized for the

both o utputs. The soft-start o f first ou tput must be faste r

than the 2nd output. If the first output is not pre sent

when the 2nd output tries to start up, th e 2nd output

cannot get smo oth and controlled output voltage rise,

even cause short-circuit protection .

Short Circuit Protection

The APW7066 provides a simple short circuit

protect ion function, and it is not easy to predict its

performa nce, since many factors can affect how well

it works. Therefore, the limitations and suggestions

of this me thod must be provid ed for users to understand

how to work it w ell.

• The short circuit protection was not designed to

work for the ou tput in initial short condition. In this

case, the short circuit protection may not work,

a nd damage the MOSFETs. If the circuit still works,

remove the short can cause an inductive kick on

the phase pin, and it may damage the IC and

MOSFETs.

• If the re sistance of the short is not low enough to

cause protection, t he regulator will work as the

load has increased, and continue to regulate up

until the MOSFETs is damaged. The resistance of

the short should include wiring, PCB traces,

conta ct resistances, and all of the return paths.

• The higher duty cycle will give a higher COMP

voltage level, and it is e asy to touch the trip point.

The compensation components also affect the

re sponse of COMP voltage; smaller caps may give

a faster response.

• The output cu rrent has faster rising time during

short; the COMP pin will have a sharp rise.

How ever, if the current rises too fast, it may cause

a false trip. The output capa citance and its ESR

can affect the rising time of the curre nt during short.

Layout Conside rations

In high power switching regulator, a correct layout is

important to ensu re proper operation of the regulator.

In general, interconnecting impedances should be

minimized b y using short, wide printed circuit traces.

Signal and power grounds are to be kept separate

and finally combin ed using ground plane construction

or single point grounding. Figure 10. illustrates the

layout, with bold lines indicating high current paths;

these traces must be short and wide. Components

along the bold lines should be p laced lose together.

Below is a checklist for your layout :

• The metal plate of the bottom of the packages

(TSSOP-24 a nd QFN-32) must be soldered to the

PCB and connected to the GND plane on the

ba ckside through several thermal vias.

• Keep the switching nodes (UGATE, LGATE a nd

PHASE) aw ay from sensitive small signal nodes

since these nodes are fast moving signals.

Therefore, keep tra ces to these nodes as short

a s possible.

• The traces from the gate drivers to the MOSFETs

(UG1, LG1 , UG2, LG2, DRIVE3) should be short

a nd wide.

• Deco upling capacitor, compensation component,

the resistor dividers, boot capacitors, and SS

ca pacitors should be close their pins.

• The inp ut capacitor should be near the drain of the

upper MOSFET ; the output capacitor should be

nea r the loads. The in put capacitor GND should be

close to the output capacitor GN D and the lower

MOSFET GND.

• The dra in of the MOSFETs (VIN a nd phase nodes)

should be a larg e plane for heat sinking.

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw27

APW7066

App lication Information (Cont.)

APW7066

UG

BOOT

C

C

REFOUT

C

VREF

FB

BOOT

REFOUT

VREF

PGND

VCC12SS

LG

VCC

Q1

Q2

V

IN

VOUT

L1

C

IN

OUT

C

L

O

A

D

C

SS

C

VCC12

CVCC

GND

Figure 11. Layout Guidelines

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw28

APW7066

Packa ging Information

TSSOP/ TSSOP-P (Refere nce JEDEC Registration MO-153)

e

N

2 x E / 2

E1 E

1 2

3

EXPOSED THERMAL

PAD ZONE

Dim

(THERMALLY ENHANCED VARIATIONDS ONLY)

Min. Max. Min. Max.

e/2

D1

E2

BOTTOM VIEW

Millimeters Inches

b

0.25

D

( 2)

S

( 3)

A 1.2 0.047

A1 0.00 0.15 0.000 0.006

A2 0.80 1.05 0.031 0.041

b 0.19 0.30 0.007 0.012

D

D1

6.4 (N=20PIN)

7.7 (N=24PIN)

9.6 (N=28PIN)

4.2 BSC (N=20PIN)

4.7 BSC (N=24PIN)

3.8 BSC (N=28PIN)

6.6 (N=20PIN)

7.9 (N=24PIN)

9.8 (N=28PIN)

0.252 (N=20PIN)

0.303 (N=24PIN)

0.378 (N=28PIN)

0.165 BSC (N=20PIN)

0.188 BSC (N=24PIN)

0.150 BSC (N=28PIN)

e 0.65 BSC 0.026 BSC

E 6.40 BSC 0.252 BSC

E1 4.30 4.50 0.169 0.177

E2

3.0 BSC (N=20PIN)

3.2 BSC (N=24PIN)

2.8 BSC (N=28PIN)

0.118 BSC (N=20PIN)

0.127 BSC (N=24PIN)

0.110 BSC (N=28PIN)

L 0.45 0.75 0.018 0.030

L1 1.0 REF 0.039REF

R 0.09 0.004

R1 0.09 0.004

S 0.2 0.008

φ

1 0° 8° 0° 8°

φ

2 12° REF 12° REF

φ

3 12° REF 12° REF

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

A2

A

A1

GAUGE

PLANE

L

(L1)

1

0.260 (N=20PIN)

0.311 (N=24PIN)

0.386 (N=28PIN)

www.anpec.com.tw29

APW7066

Packa ging Information

QFN-32

32 31 30 29 28 27 26 25

D

1

2

3

4

E

5

6

7

8

13 14 15 169 10 11 12

A

A1

D2

24

23

22

21

20

19

18

17

e

A3

3231

b

L

1

2

E2

Dim

A -

A1

Min. Max. Min.

0.00 0.04

Millimeters Inches

0.84

- 0.033

0.00 0.0015

A3 0.20 REF. 0.008 REF.

D

4.90 5.10

0.192 0.200

E 4.90 5.10 0.192 0.200

b 0.18 0.28 0.007 0.011

D2

E2

e

3.50 3.60

3.50 3.60

0.500 BSC

0.138 0.142

0.138 0.142

0.020 BSC

L 0.35 0.45 0.014 0.018

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

Max.

www.anpec.com.tw30

APW7066

Physica l Specifications

Terminal Material Solder-Plated Copper (Solder Material : 90/10 or 63/37 SnPb), 100%Sn

Lead Solderability Meets EIA Specification RSI86- 91, ANSI/J-STD-002 Category 3.

Reflow Condition (IR/Convection or VPR Reflow)

T

P

Ramp-up

T

L

Tsmax

Tsmin

Temperature

ts

Preheat

25

°

t 25 C to Peak

Classifica tion Reflow Profiles

tp

Ramp-down

Time

Critical Zone

TL to T

P

t

L

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Average ramp-up rate

(TL to TP)

Preheat

-

Temperature Min (Tsmin)

-

Temperature Max (Tsmax)

-

Time (min to max) (ts)

Time maintained above:

-

Temperature (TL)

-

Time (tL)

Peak/Classificatioon Temperature (Tp)

Time within 5°C of actual

Peak Temperature (tp)

Ramp-down Rate

Time 25°C to Peak Temperature

3°C/second max. 3°C/second max.

100°C

150°C

60-120 seconds

60-180 seconds

183°C

60-150 seconds

60-150 seconds

See table 1 See table 2

10-30 seconds 20-40 seconds

6°C/second max. 6°C/second max.

6 minutes max. 8 minutes max.

Notes: All temperatures refer to topside of the package .Measured on the body surface.

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

150°C

200°C

217°C

(mm)

www.anpec.com.tw31

APW7066

Classifica tion Reflow Profiles(Cont.)

Table 1. SnPb Entectic Process – Package Peak Reflow Temperature s

Package Thickness Volume mm

<350

<2.5 mm

240 +0/-5°C 225 +0/-5°C

3

Volume mm

3

≥350

≥2.5 mm 225 +0/-5°C 225 +0/-5°C

Table 2. Pb-free Process – Package Classification Reflow Temperatures

Package Thickness Volume mm3

<350

<1.6 mm

1.6 mm – 2.5 mm

260 +0°C* 260 +0°C* 260 +0°C*

260 +0°C* 250 +0°C* 245 +0°C*

Volume mm3

350-2000

Volume mm3

>2000

≥2.5 mm 250 +0°C* 245 +0°C* 245 +0° C*

*Tolerance: The device manufacturer/supplier shall assure process compatibility up to and

including the stated classification temperature (this means Peak reflow temperature +0°C.

For example 260°C+0 °C) at the rated MSL level.

Reliab ility Test Program

Test item Method Description

SOLDERABILITY MIL-STD-883D-2003

HOLT MIL-STD-883D-1005.7

PCT JESD-22-B,A102

TST MIL-STD-883D-1011.9

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JESD 78 10ms, 1tr > 100mA

245°C, 5 SEC

1000 Hrs Bias @125°C

168 Hrs, 100%RH, 121°C

-65°C~150°C, 200 Cycles

Carrie r Tape & Reel Dimensions

E

F

W

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

Po

P

P1

Ao

t

D

Bo

Ko

D1

www.anpec.com.tw32

APW7066

Application

ABCJT1T2WPE

TSSOP- 24

7.5 ±0.1

1.5 +0.1

1.5 min

4.0 ±0.1

2.0 ±0.1

6.9 ±0.1

8.3 ±0.1

1.5 ±0.1

0.3±0.05

Carrie r Tape & Reel Dimensions(Cont.)

J

C

A

330 ±1 100 ref 13 ±0.5 2 ±0.5 16.4 ±0.2 2 ±0.2 16 ±0.3 12 ±0.1 1.75±0.1

F D D1 Po P1 Ao Bo Ko t

T2

B

T1

5x5 Shipping T ray

(mm)

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw33

APW7066

5x5 Shipp ing Tray(Cont.)

Cov er Tape Dimensions

Application Carrier Width Cover Tape Width Devices Per Reel

TSSOP- 24 16 21.3 2000

Customer Service

Anpe c Electronics Corp.

Head Office :

5F, No . 2 Li-Hsin Road, SBIP,

Hsin-Ch u, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 88 6-3-5642050

Taip ei Branch :

7F, N o. 137, Lane 235, Pac Chiao Rd.,

Hsin Tien City, Taipei Hsien, Taiwan, R. O. C.

Tel : 886-2-89191368

Fax : 8 86-2-89191369

Copyright ANPEC Electronics Corp.

Rev. A.4 - Jun., 2005

www.anpec.com.tw34

Loading...

Loading...