Page 1

Assembly Instructions

SALES OFFICES:

1100 BURCH DRIVE

PO BOX 3477

EVANSVILLE, IN 47733 USA

EC 2616

Century Frame Tent

20’ and 30’ Hex

PHONE: 812-867-2421

FAX: 812-867-0547

1-800-544-4445

EMAIL: tents@anchorinc.com

www.anchorinc.com

PRODUCTION FACILITIES:

BRADENTON, FL

EVANSVILLE, IN

CFHEX 0508

Page 2

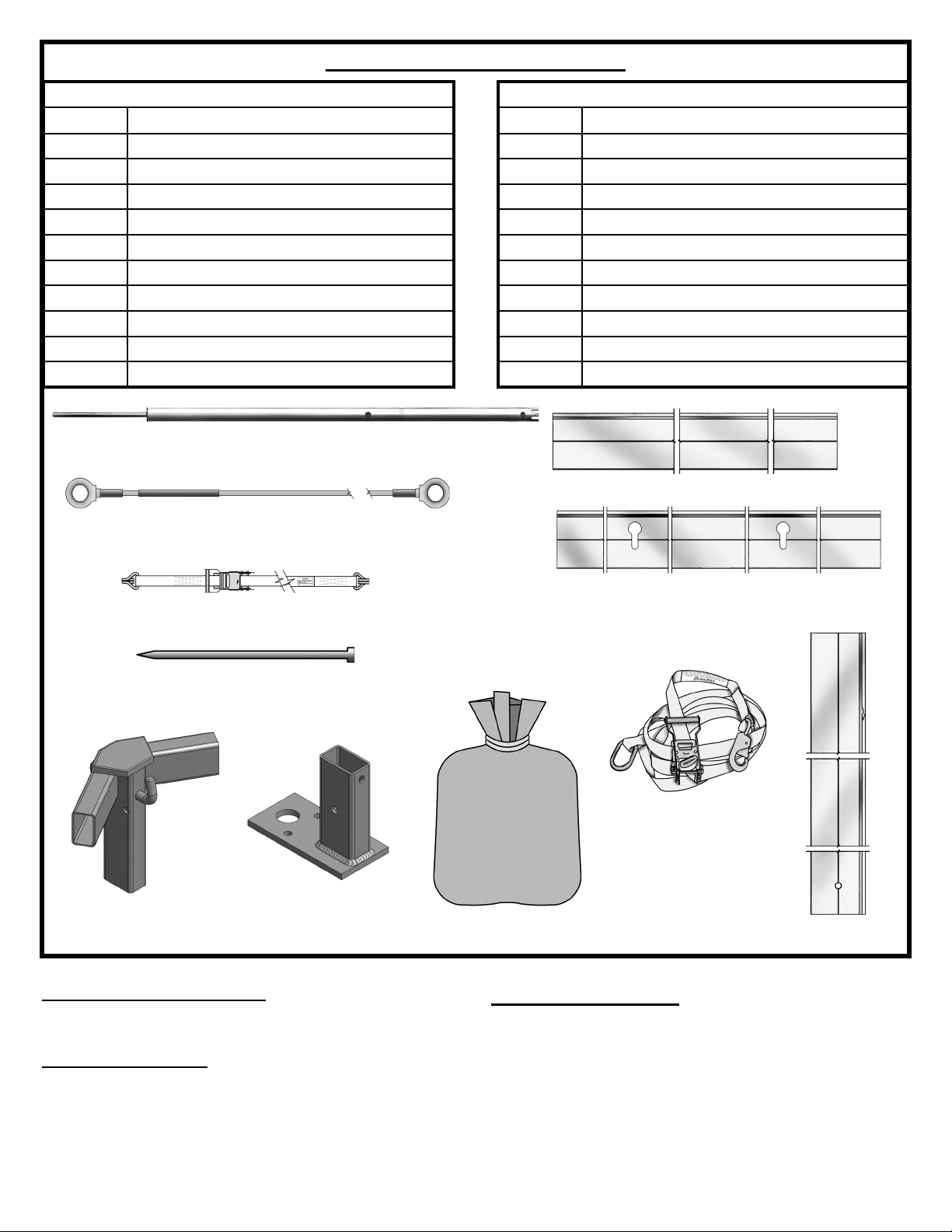

Parts Lists & Illustrations

20’ Hex Parts Table

Quantity Description

1 Center Pole

3 Cables

6 Tension Straps

6 10’ Eaves

6 Uprights

6 Base Plates

6 Guy Webs

1 Bag with Top

6 Corner Weldments

6 Walls (10’ - 2 pc. -- optional)

Center Pole

Cable

30’ Hex Parts Table

Quantity Description

1 Center Pole

3 Cables

6 Tension Straps

6 15’ Eaves

6 Uprights

6 Base Plates

6 Guy Webs

1 Bag with Top

6 Corner Weldments

6 Walls (15’ - 2 pc. -- optional)

10’ Eave

Tension Strap

Stake

Corner Weldment

Base Plate

Manpower Required

Three experienced installers should be able to assemble a

tent in less than forty-fi ve minutes.

Tools Required

Sledge Hammer

4’ Step Ladder

(2) 9/16” Wrenches

(2) Fiesta Frame Lifts; optional but recommended.

15’ Eave

Guy Web

Bag with Top

Layout & Check

Utilize the parts list for a quick I.D. and a check list to

ensure that you have all the parts.

Upright

2

Page 3

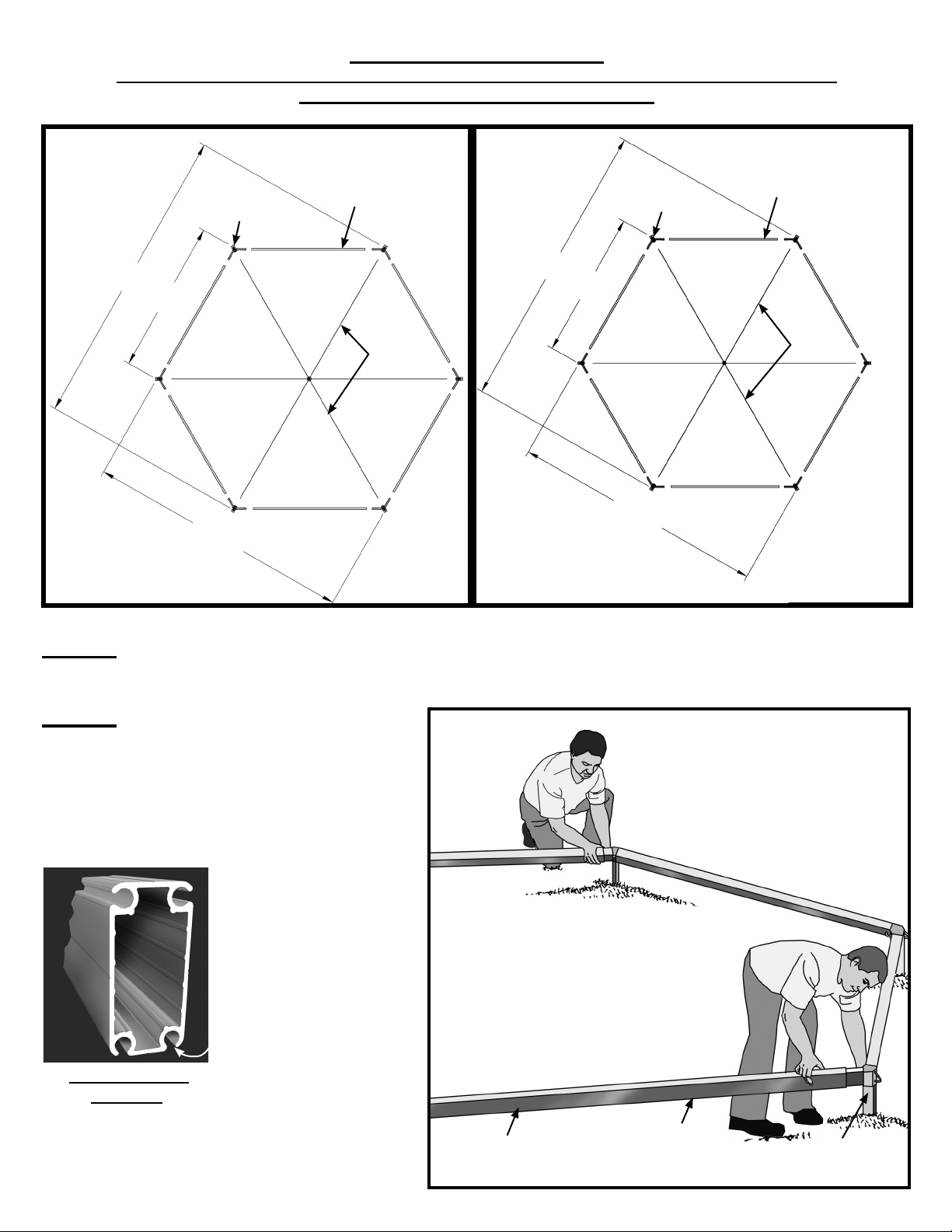

Caution! Inspect Site

Consult local Utility Company prior to installation. Prior to assembly be sure to look

around area for obstacles, pipes, wires, etc.

Corner

Weldment

20’

10’

Approximately

Approximately

Approximately

17’

20’ Hexagon Lay Out 30’ Hexagon Lay Out

10’ Eave

30’

15’

Approximately

Approximately

Cable

Approximately

Corner

Weldment

25’

15’ Eave

Cable

Step 1

Lay out parts for assembly as shown in the diagrams above.

Step 2

Join ends of eaves to corner weldments.

Wall Hangs in Bottom

Outside Channel.

Century Frame

Extrusion

Figure 2

Eave

Wall Channel on

Bottom outside of

beam.

Corner

Weldment

3

Page 4

Step 3 Attach Cables

Attach one eye end of cable to weldment

hook on a corner weldment. At the opposite corner, raise frame until cable loop

slips onto weldment hook, then lower to

ground. Repeat until all 3 cables are attached to frame.

Weldment hook.

Cable eye end.

Step 4 Put Top on Frame

Unfold top over eaves and cables. Pull

tabs at corners of top over corner weldments. Secure by placing slot in tabs

over ring on corner weldment.

Cable

Figure 3

Ring on Corner

Weldment

After tab is in place, fasten guy web snap to ring on

corner weldments. Attach base plates to uprights with

bolt and nut supplied.

Slot in

Ta b

Snap guy to ring

after tab is in place.

Step 5 Lift one Side

For 20’ hex frame: No frame lifts are required. Lift one

corner of frame and fi t upright onto weldment. As up-

rights are inserted, attach tension straps to keep uprights

attached to weldments. (See Step 6) Repeat at second

upright at an adjacent corner. Now stop to raise peak

(See Step 7)

Upright

20’ Hex Frame

Figure 4

Wind

Note: If wind is strong, drive in stakes through the guy

web ring and tie off loosely before lifting frame. (Reference step 10)

4

Figure 5a

Page 5

Step 5 (cont’d)

For 30’ hex frame: Two frame lifts

are required. Position the two lifts

on one eave as shown and attach

hooks to eave tube. Crank both

lifts at the same time. Stop when

uprights will fi t onto weldments.

Lower and remove frame lifts.

Note: If wind is strong, drive in

stakes through the guy web ring

and tie off loosely before lifting

frame. (Reference step 10)

Upright

30’ Hex Frame

Wind

Step 6 Attach Tension Straps

Place curtain web through triangle ring at end of corner tab

as shown in Figure 6. Fasten upper hook of tension strap to

curtain web. Insert lower hook into slot in upright.

Use ratchet to take up slack in web. This prevents uprights

from sliding off weldment when other side of tent is raised.

Do not tension at this time.

Repeat at other uprights in similar fashion.

Step 7 Adjust Center Pole

Center pole must be adjusted to the height shown in Figure 7a. Turn the

top of the center pole in the direction noted to meet the required dimension.

Frame Lifts

Ratchet

Figure 5b

Curtain Web

Tension Strap

Upright

Slot in Upright

Figure 6

Carefully position center pole pin through pole hole in top. Use caution

to prevent tearing of fabric. Raise top by pushing pole on the upper

cable. Slide pole along cable until at intersection of all cables. Place

lower cable in slot at bottom of pole and attach lock pin to secure. See

Figures 7b and 7c.

Caution:

Base of pole is on a roller for ease of installation. Be sure movement of

pole is controlled (fi rmly held) during installation and removal to prevent

base from moving too quickly.

Shorten Lengthen

20’ Hex

7’-4”

30’ Hex

12’-9”

Figure 7a

5

Page 6

Center Pole

Cables

Pole Pin

Center Pole

Lock Pin

Roller

Figure 7b

Step 8 Lift Other Side

Raise opposite side by repeating Step 5. Attach remaining uprights.

Plumb uprights.

Step 9 Installing Optional Walls

Determine proper mating of 2-piece walls with labels

on the inside. Slide tabs at top of walls into bottom

outside channel opening (see Century Frame extrusion drawing on Page 3).

Orient walls so that beading edges are adjacent to

uprights and the lace edges meet in the middle.

Figure 7c

Figure 9

Step 10 Attach Walls to Uprights

At each upright gather up wall and insert bottom of beading into

channel opening at top of upright. Feed all of beading into channel.

6

Figure 10

Page 7

Step 11 Secure Tent

Make certain that tent is positioned in the desired location. Drive

a 1” x 30” stake through each base plate.

Drive a 1” x 30” stake through the ring at bottom of web guy. See

Figure 9 for positioning of stake.

Tension web guy.

Proceed around tent until all web guys are tensioned. See guy

web operating instructions provided.

IMPORTANT NOTE: PLEASE REFER TO CAUTION AND

OTHER ANCHORING INFORMATION ON BACK PAGE.

Step 12 Tension Top

A firmly tensioned top is required for proper installation.

Pull fabric tightly and smoothly to minimize water pooling, wind damage, fabric shifting. Use ratchets on tension straps to tension the top (See Step 6).

Now tighten all eight of the fiesta straps spaced between

the uprights (See Step 10).

Step 13 Take Down

1. Remove guy webs and stakes.

2. Loosen tension straps.

3. Reverse installation steps.

IMPORTANT:

Check web guys and tension straps periodically for tight-

ness and good condition.

Store tent in a cool, dry area. Never store while wet or

damp.

Figure 9

Note:

The center of the fabric eaves should be

approximately 3” below the frame eaves

when properly tensioned.

3” Approximately

20’ Hex - 6’-8 Minimum

30’ Hex - 11’-5 Minimum

Eave Line

Note:

Tensioning of top can change from installation to installation. Cable stretch, fabric shrinkage or elongation and other

factors can require a different amount of tension to center pole.

7

Page 8

EVANSVILLE, INDIANA

PHONE NUMBER

812· 867· 2421

FAX NUMBER

812· 867· 0547

Anchor products are of superior design and operate best within the parameters of these instructions. It is imperative

that the instructions be carefully read and COMPLETELY FOLLOWED. Please read installation instructions before the

installation or removal of this product. Installation instructions are available online at www.anchorinc.com or by calling

1-800-544-4445.

CAUTION:

1. For each installation, the installer is solely responsible for evaluating the site and the proper securing method

determined. Some soils require different staking or securing than that provided with the tent. Due to this variety of

soil conditions, these are the manufacturer’s suggested sequence of installation procedures. Anchor’s responsibility

is limited to the manufacture of the tent parts and materials. We are not responsible for methods that installers may

choose to erect and secure the tent to the ground.

2. The number of stakes suggested in the installation instructions does not necessarily meet all or any relevant codes

on the site of the tent installation. The number of stakes suggested will, in many cases, keep the tent erected,

however, due to various soil conditions; these stakes will be insuf¿ cient to keep the tent secure in high winds.

It is the tent installer’s responsibility, not the manufacturer, to determine the appropriate number of stakes to meet

the necessary wind loads on the site. Regardless of the number of stakes we suggest, we make no representation

or warranty as to whether this speci¿ c number of stakes will meet the local tent code. Anchor does not, nor can

it make any suggestions, representation, or warranties about the adequate staking required at each speci¿ c

installation site. Staking information provided in the installation instructions is not a suggestion about what is

necessary to meet a site-speci¿ c load.

For additional assistance, consult: “The IFAI Procedural Handbook For the Safe Installation and

Maintenance of Tentage” and the IFAI Pocket Guide “Pullout Capacity of Tent Stakes”, both available from

the IFAI Tent Rental Division or on our website.

3. Inasmuch as the weather is unpredictable, good judgment and common sense must be incorporated within

installation guidelines. It is the responsibility of the tent installer/maintainer to determine the severity of the weather,

proper time and method of installation and/or erection and disassembly. Note: We recommend that snow and

ice be removed from the tent surface as soon as possible because accumulation will damage the tent

or fabric structure. Please consult with our Engineering Department about the maximum loads for each

product.

This product has been manufactured for use as a temporary structure. For the safety of all occupants, evacuation

is recommended if threatening weather occurs, or if there is any doubt concerning the safe use of this product.

4. Proper safety equipment should be used at all times to insure a safe installation and take down. We suggest a

careful evaluation be made to determine safety equipment needed, such as hard hats, steel-toe shoes, safety

glasses and other as required. It is our desire that all installations are safe. Please be aware of hidden dangers

both underground, i.e., gas lines, water lines, electrical lines, etc. and above the tent such as power lines and

telephone lines.

5. Anchor stands behind its products in accordance with its standard Terms and Conditions of sale. A copy of our

Terms and Conditions of Sale can be obtained by contacting Anchor at the telephone number and/or address on

this document.

28.2 04-29-08

Loading...

Loading...