Page 1

20 Meter

800-544-4445 • 812-867-2421

www.anchorinc.com

3M Uprights

Page 2

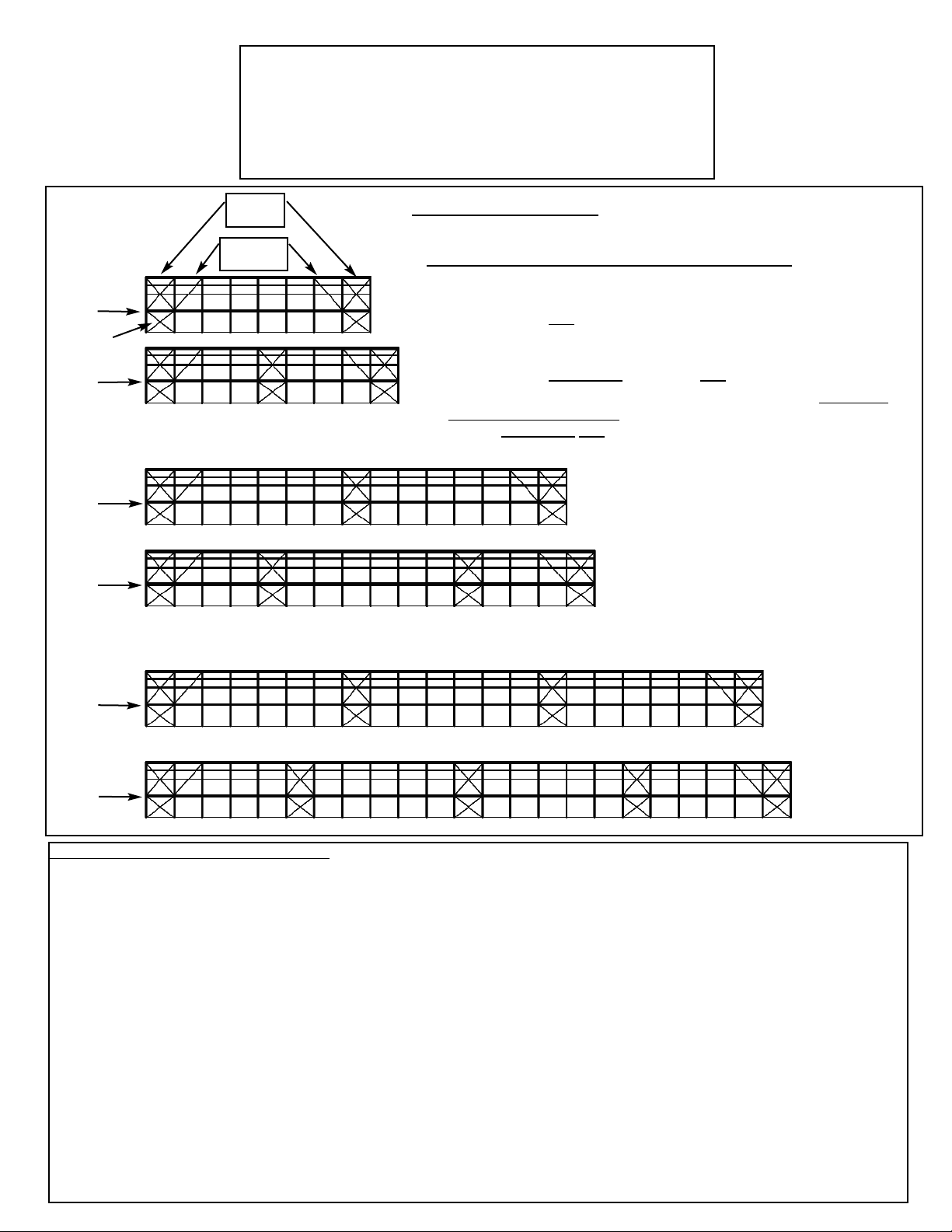

X-CABLING PATTERNS

For Anchor Structures

20m Span

(220 x 100 x 4mm Profile)

2-28-05

EAVE

EAVE

EAVE

EAVE

EAVE

EAVE

PRIMARY

ROOF

CABLES “X”

SIDE CABLES

1

6

5

432

321

3

21

Following the same (6) open bay rule...

The 16th bay must be x-cabled.

And, the 23rd, etc.

654

3

2

1

65432

1

43

2

1

6

5432

165

43

21

6

5

X-CABLING GENERAL INFORMATION:

NOTE: THIS INFORMATION IS CONSISTENT WITH CURRENT ENGINEERING DATA AND SUPERSEDES ANY

OTHER CABLING GUIDELINES DESCRIBED IN THIS INSTALLATION MANUAL.

For safety, X-cabling must be installed according to the above, engineered pattern. Unless it is properly cabled, the beam

system can fall in even moderate winds. It is the customer’s responsibility to follow the patterns shown above, which have

been approved by engineering analyses to ensure the safety of the structure. Secondary cables are added to the second

bay only and do not include side cables. The interior cabled bays may be positioned in any manner that avoids having (6)

consecutive side bays without cabling.

If the rafters of your 20m frame are spliced (keystoned) at 15m or 10m, the roof cables may be in two sections spliced endto-end. This 2-piece construction lets you remove the upper sections of the cables and use the lower sections on your 15m

or 10m frame. If your 20m frame is a reduction of a 25m frame, you can add 2.5m upper sections to the roof cables to

accomodate the full 25m span.

When installing x-cabling, it is best to attach all cables before tightening any of them. Then begin at ground level and tighten the cables in ascending order. The x-cabling should be used to establish a good vertical alignment of the beams either

by plumbing the beams or by using a careful visual sighting. Good alignment of the beams will improve the appearance of

the structure and make fabric installation easier.

SECONDARY

ROOF

CABLES “V”

SIDE VIEWS SHOWN

1. All 20m Structures require primary roof and side x-cabled end bays.

2. Structures with 6 or more total bays also require secondary x-cables in

the roof section only

of the second bays. Viewed from above, these form

a “V” shape. (Structures with 5 bays or less do not require secondary

cables in the second bay.)

3. No more than 6 consecutive

non-cabled side

bays are permitted.

4. After the 6th open side bay, an additional x-cabled bay with full primary

roof cables and side cables must be added to the interior, so that no more

than (6) consecutive side bays are non-cabled.

ENGINEERING RULES FOR PROPER X-CABLING

Page 3

BT 2000 240/300 570/627

Copyright: Without our written consent the disclosure, reprinting,

copying and reproduction of this publication, whether in full or in

part, are prohibited.

2

Spanning the world.

Page 4

BT 2000 240/300 570/627

Index

1 Introduction..............................................................................4

1.1 General notes ...................................................................................... 5

1.2 Construction tools ............................................................................... 7

2 Staightening of the tent any laying of the baseplates.................8

2.1 Laying of the baseplates ...................................................................... 8

3 Construction of the tent..........................................................13

3.1 Pre-assembly of the legs, beams and wind bracings .......................... 13

3.2 Mounting of the components ............................................................. 18

3.3 Mounting of the wind bracings .......................................................... 22

4 Erection of the tent .................................................................25

4.2 Mounting problems and their causes ................................................. 32

4.2.1 The corner- and middle legs do not fit to the baseplate receiver . 32

4.2.2 The baseplate pins cannot be fixed tight ..................................... 32

5 Mounting of tent’s covers .......................................................34

5.1 Pulling up the roof cover.................................................................... 34

5.2 Stretching of the roof cover (model with fixed tensioning) ................. 37

5.3 Stretching of the roof cover (model with rubber tensioning) .............. 39

5.4 Pulling in the gable covers (gable triangle)......................................... 40

5.5 Pulling in the sides- and gable walls.................................................. 40

5.6 Mounting of the ground rail (if provided) ........................................... 42

6 Dismantling ............................................................................43

7 Service notes ..........................................................................44

7.1 Construction of the tent..................................................................... 44

7.2 Bedding and transport ....................................................................... 44

7.3 Routine visual inspection ................................................................... 44

8 Ratings ...................................................................................45

8.1 Construction of the tent..................................................................... 45

8.2 Tent covers........................................................................................ 47

8.3 DIN ISO Normen................................................................................. 47

3

Spanning the world.

Page 5

BT 2000 240/300 570/627

1 Introduction

The following instructions describe in a methodical plan the construction and

erection of your RÖDER tent.

Follow always these instructions.

Work from point to point.

If it is necessary, there are extra points, in which you have to take care or pay

special attention.

Please pay attention to the appropriate safety regulations for

prevention of accidents.

Regarding the contents of this document:

The points 1-5 describe the construction of the tent. The points 6-8 repeat

additional technical informations, maintenance and dismantling’s instruction.

The drawings are made to show clearly the construction and dismantling

procedures and also for the identification of the separate building

components.

It has to be pointed out that the pictures, do not always correspond to the

real dimension and size. Explanations and/or notes have been added to

these pictures.

If you have any questions, please call

RÖDER Zelt- und Veranstaltungsservice GmbH in Germany on follow

numbers:

Phone ++49-6049-700 - 0 Fax ++49-6049-700 - 339

4

Spanning the world.

Page 6

BT 2000 240/300 570/627

1.1 General notes

Before starting construction you must read this documentation exactly. If the

points are clear and the building components are identified and ready, then

start construction and follow the instructions step by step.

Pay attention to the safety regulations for prevention of accidents.

The life of the helpers may be in danger due to the lack of knowledge and

poor observation of the given regulations.

Work on every point of the instructions chronologically.

For the construction of the tent there has to be a minimum of 6 people.

Notes on safety:

The joining of the ropes has to be stretched after mounting.

The taking out of the ropes is not allowed.

Use the supplied construction tools for the installation.

Pay attention to the pins, that they are fixed solid after mounting.

Pay attention to the purlins and to the intermediaite purlins to erect them

always correctly.

During mounting wear protective clothing according to your work to prevent

injuries.

Replaced used or damaged components with original new ones.

Pay attention to:

You have to keep the relevant safety appliances and standart specifications.

(Employer’s liability insurance association).

The construction helpers have to be instructed about the possible dangers

before construction begins.

The supervision and the responsibility has to be taken by an expert person

during the construction.

Expert is the person who knows about the operating cycle and the requisite

safety precautions.

5

Spanning the world.

Page 7

BT 2000 240/300 570/627

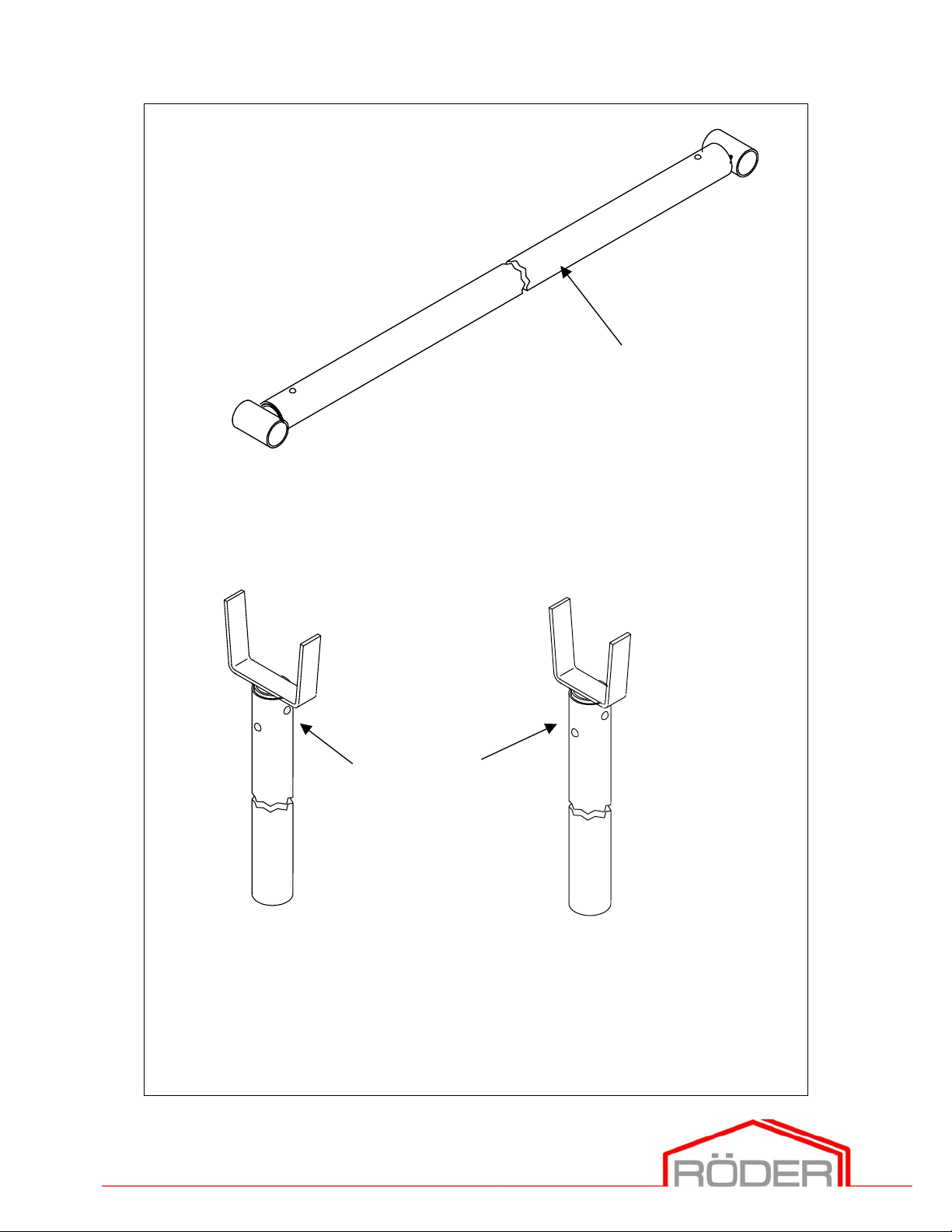

Measuring rod 5m

Fork 140mm

Mounting rods

Fork 80mm

Pic. 1

6

Spanning the world.

Page 8

BT 2000 240/300 570/627

1.2 Construction tools

The construction and dismantling has to be done with the respective

construction tools.

Special provided tools for the construction:

1.2.1 Measuring rod

1.2.2 Mounting rod 6m,

1.2.3 Mounting rod 4m,

1.2.4 Leading-in conductor for covers 2x

1.2.5 Bracing devices for tent‘s covers

More construction tools and working substance prepared for the structure:

At least 3x traction cable with carabine swivel (at least 250 daN carrying

force)

2x double ladder equivalent the height of tent’s side

1x spanner SW 17

2x spanner SW 24

1x handspike

2x aboutsledge

10x squared beam 80 x 80 x 400 mm

1x pincers

2x measuring tape 30 m

1x directional cord (at least double the length of the tent)

1x optional: peg puller (for dismantling recommended)

1x Crane or fork stacker with telescope jib with hoisting height 8-10m

mounting drawing cage.

7

Spanning the world.

Page 9

BT 2000 240/300 570/627

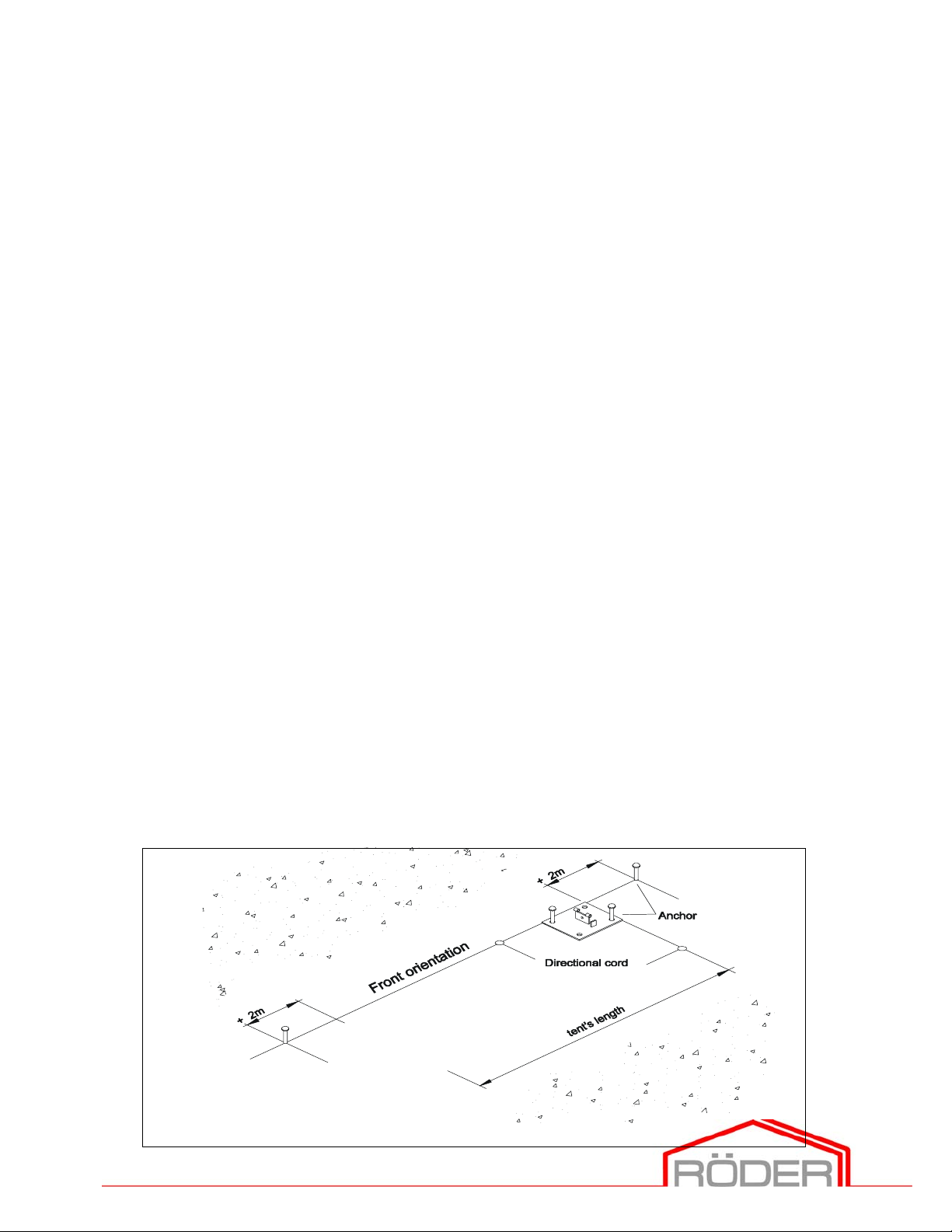

2 Straightening of the tent and laying of the baseplates

The main topology of the tent has to be straighten locally (e.g. road course,

front of houses etc.). It has to be carefully and exactly positioned, by lying

and straightening of the baseplates. The wrong placing of the baseplates will

incurr difficulties to the whole construction. Pay attention to the list of point

8.1, page 42. The borings of each baseplate for the given legs have to be

equivalent to the numbers of the earth anchors for placing.

Prepared assembling auxiliaries:

Construction tools: Building components:

Measuring rod All the provided baseplates 4-hole and 6-hole

Measuring tape For every baseplate equivalent number of earth-anchors

Directional cord For every baseplate a baseplate pin

Aboutsledge

2.1 Laying of the baseplates

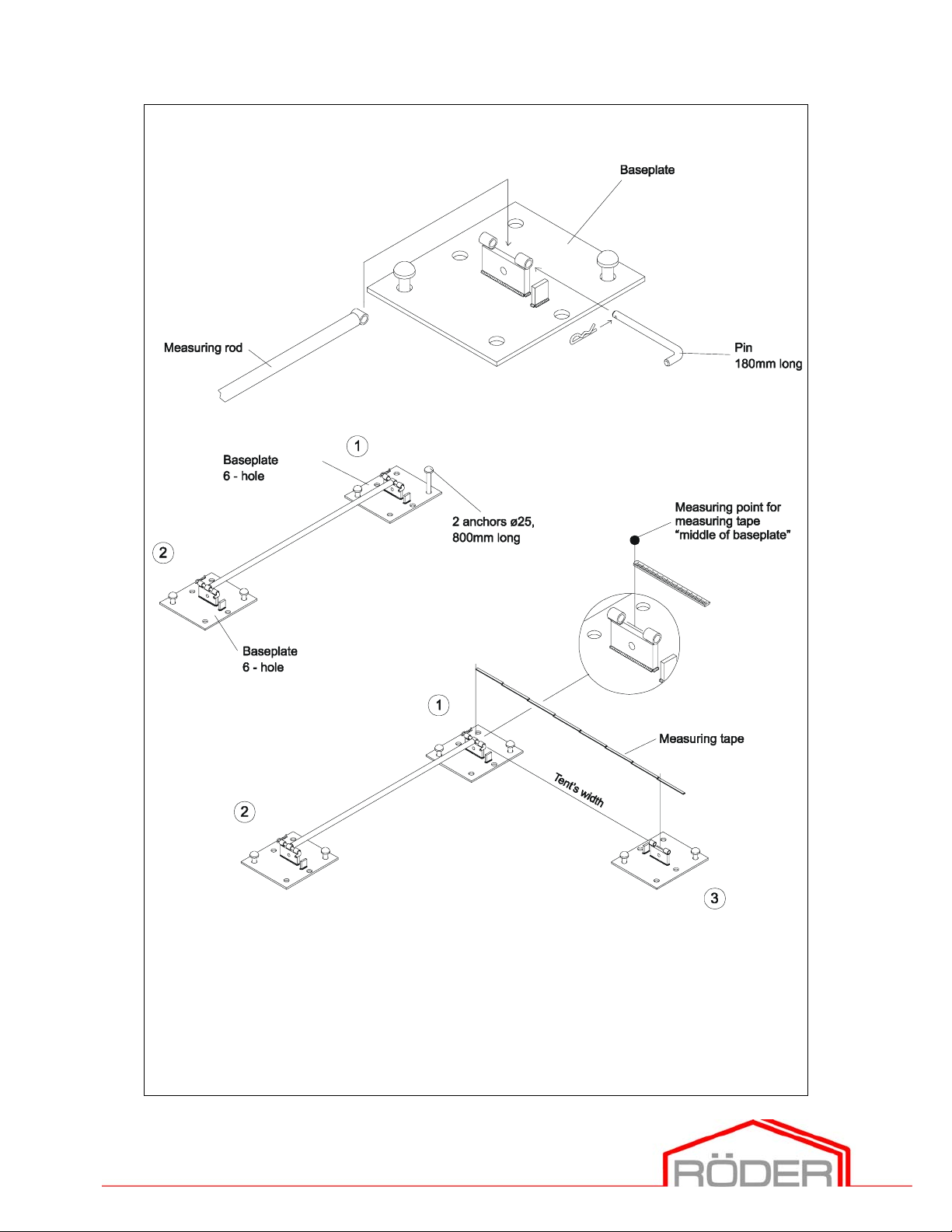

Indentify and assign the components according pic. 3.

Note: Do not beat the earth-anchors at all, leave about 5 cm

providing for adjustment.

The safety brackets of the baseplates are facing to the inside of the tent.

2.1.1 Choose a front orientation.

2.1.2 Stretch the directional cord (tent‘s length + 2m each side).

2.1.3 Adjust 1. baseplate parallel to the directional cord of the right angle

and fix it with the 2 earth-anchors (do not beat in the earth-anchors

`all the way).

Pic. 2

8

Spanning the world.

Page 10

BT 2000 240/300 570/627

Pic. 3

9

Spanning the world.

Page 11

BT 2000 240/300 570/627

.

Pic. 4

10

Spanning the world.

Page 12

BT 2000 240/300 570/627

2.1.4 Mount the measuring rod with baseplate pins to the baseplate

hole)

(pic. 3).

2

2.1.5 Mount the measuring rod to the baseplate

pin

(pic. 3).

(6-hole) with the flange

1

(6-

2.1.6 Adjust the baseplate

with 2 earth-anchors.

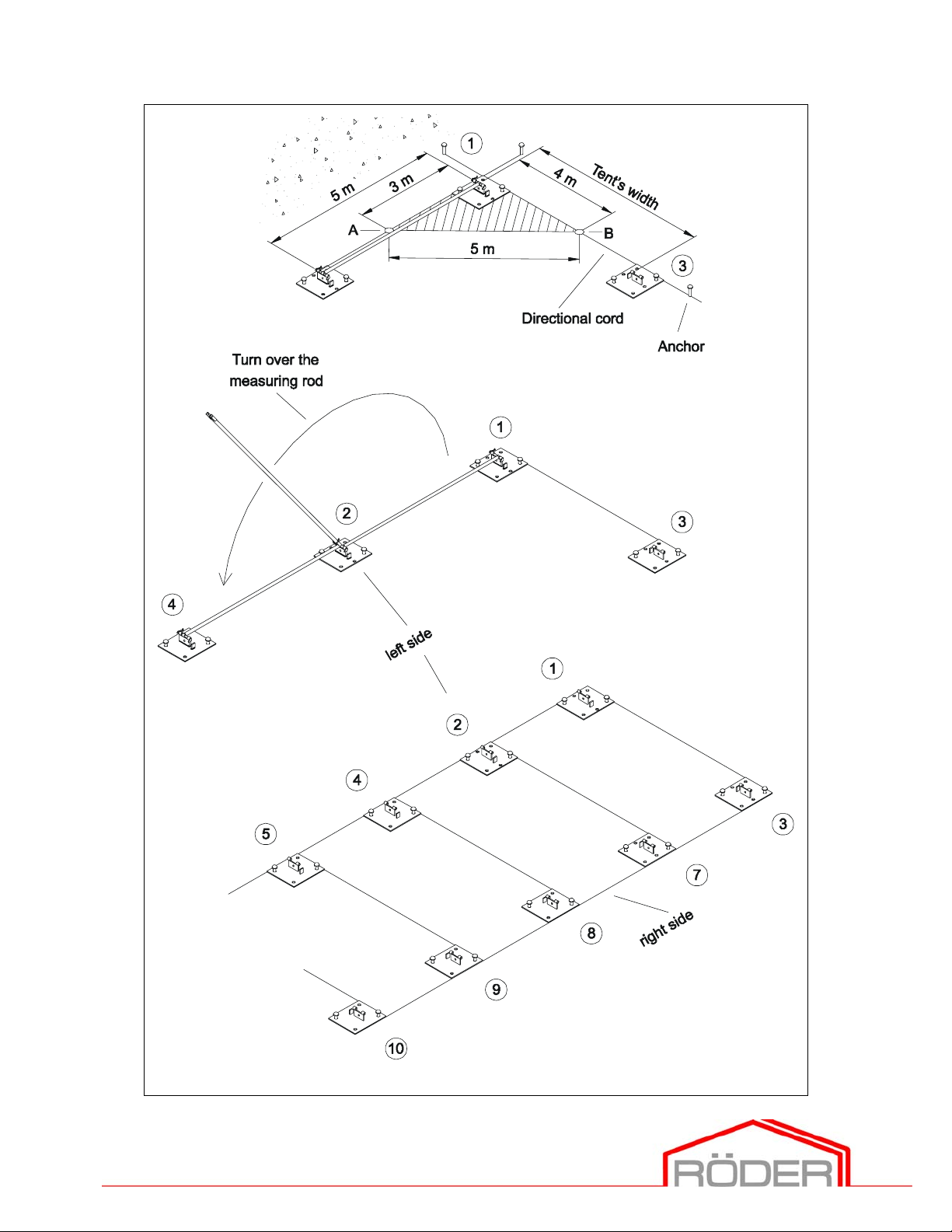

2.1.7 Stretch the directional cord across the tent’s width and adjust it by

estimating by sight right angle.

2.1.8 Measure the tent‘s width from the middle of the baseplate

middle of the baseplate

2.1.9 According to the picture measure to the mounted measuring rod

between baseplate

A). Take the measurements with the directional cord between the

1

baseplates

2.1.10 There ought to be a diagonal of 5,0m between the points A and B

(pic. 4). You have to place the directional cord in a way that between

the baseplates

and 3 exact 4,0m and mark it (point B) (pic. 4).

1

2

parallel to the directional cord and mount it

3

(6-hole) and adjust the baseplate (pic. 3).

1

and baseplate 2 exact 3,0m and mark it (point

and 3 the dimension is 5,0m.

1

until the

3

2.1.11 Adjust the baseplate

Check once more the tent’s width between the baseplates

Mount the baseplate

2.1.12 Dismantle the baseplate pin of the baseplate

measuring rod on the baseplate

2.1.13 Adjust the baseplate

measuring rod. Fix the baseplate with earth-anchors.

again to the directional cord if necessary.

3

with 2 earth-anchors.

2

(pic. 4).

4

(6-hole) to the directional cord and mount the

11

1

and 3.

1

and turn down the

Spanning the world.

Page 13

BT 2000 240/300 570/627

2.1.14 Repeat the points 2.1.12 and 2.1.13 until all the baseplates of the

tent’s side have been fixed (use 6-hole baseplates to the corners).

3

2.1.15 Mount the measuring rod to the baseplate

baseplate (4-hole) and mount the measuring rod. Check the

dimension of the tent’s width between the baseplate

already mounted baseplate. Fix the baseplate with 2 earth-anchors.

2.1.16 Repeat the point 2.1.15 until all baseplates of the tent’s side haves

been fixed.

2.1.17 Finally check the tent’s dimensions among the middle of the 4 outer

baseplates.

. Adjust the followed

2

and the

12

Spanning the world.

Page 14

BT 2000 240/300 570/627

3 Construction of the tent

3.1 Pre-assembly of the legs, beams and wind bracings

Prepared assembling auxiliaries:

Construction tools: Building components:

Squared beams Endbeams

Crowbar Middlebeams

Legs

Ridge connectors

Safety stanchion for sliding eave connection

Pin Ø 20 with washer

Ridge pin Ø 16 with washer

Equivalent number of wind bracings (see 3.3)

Intermediaite purlins

Ridge purlins

Eave purlins

Gable supports

Gable eave rails

Mounting of the legs and beams

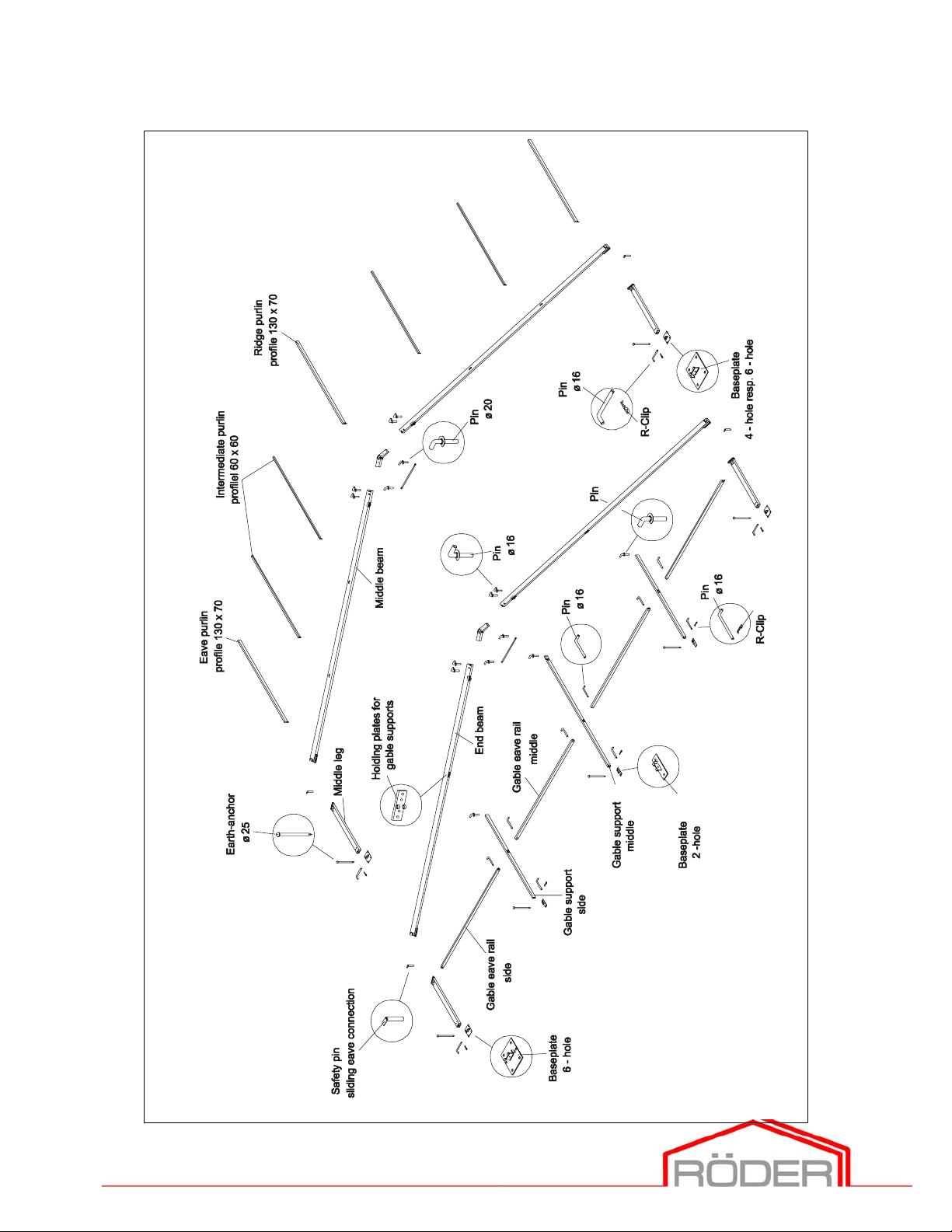

Identify and assign all the components according to the pic. 5, 6 and 7.

The components are according to the pictures. On placing proceed as

follows.

First mount only the two first bracings

3.1.1 Lay each of the corner- and middle legs between the baseplates.

3.1.2 Lay the end- and the middle beams between the baseplates.

3.1.3 Lay the ridge connector.

3.1.4 Lay and allocate the ridge struts.

3.1.5 Lay and allocate the respective mounting pins (pic. 5 - 7).

3.1.6 Lay and allocate to the endbay the gable supports and gable eave rails.

3.1.7 Lay and allocate the intermediate-, ridge- and eave purlins.

Ridge struts

.

13

Spanning the world.

Page 15

Building parts 20m-tent

BT 2000 240/300 570/627

Pic. 5

14

Spanning the world.

Page 16

Building parts 20m-tent

Endbay

BT 2000 240/300 570/627

15

Pic. 6

Spanning the world.

Page 17

Building parts 20m-tent

Normal- and bracing bay

BT 2000 240/300 570/627

16

Pic. 7

Spanning the world.

Page 18

Leg

g

Safety pin

Slidin

eave connection

BT 2000 240/300 570/627

Beam

Timber

Windbracing

Stopper

Sliding eave

Ring bolt

Pic. 8

17

Spanning the world.

Page 19

BT 2000 240/300 570/627

3.2 Mounting of the components

3.2.1 Connect together each of the left and right end- and middle beams

through pushing of the ridge connectors. The placing of timbers

makes the mounting easier. Place the pins (pins Ø 16 with washers) to

the equivalent borings. Pay attention that the pins fixed tightly (pic. 9).

3.2.2 Push the mounted beams into the receiver of the sliding eave

connection to the legs and push them until the limit stop. Place the

safety pin ∅ 14 to the equivalent boring through the open side of the

profile of beam (pic. 8).

3.2.3 Feed each ridge strut into the receivers and bolt them with pins (pins Ø

20 with washer). Fix the pins tight by screwing on behind the safety

bracket (pic. 10).

3.2.4 Place the legs of the bay (mounted beams and legs) into to the

baseplates. Bolt them with baseplate pins and fix the pins tight by

screwing on behind the safety bracket.

3.2.5 Mount the 2. bay according the instruction.

3.2.6 Mount the rest of the bays according to the points 3.2.1 and 3.2.2.

18

Spanning the world.

Page 20

Beam left

BT 2000 240/300 570/627

Ridge pin

Ridge

Timber

Beam right

Windbracing rope

Ring bolt

Ridge pin fixed

tight

19

Pic. 9

Spanning the world.

Page 21

Beam left

BT 2000 240/300 570/627

Stanchion pin Ø

Timber

Ridge strut

Beam right

Stanchion pin fixed

Pic. 10

20

Spanning the world.

Page 22

Tent’s length up to 40m

BT 2000 240/300 570/627

Windbracing

Free

Tent’s length over 40 m

Windbracing

Windbracing

Free fields

(max. 6)

Windbracing

Free

Windbracing 2

Pic. 11

21

Spanning the world.

Page 23

BT 2000 240/300 570/627

3.3 Mounting of the wind bracings

Mount the wind bracings (pic. 11).

Do not move them out.

Mount each of wind bracing to the first and to both last fields of the tent.

They must not be more than 6 free fields between the bracings.

If more than 6 free fields are built, then an additional wind bracing has to be

mounted.

See the picture 11 for the mounting of the brace fields.

In principle:

The wires of the wind bracings have to be mounted in the way that the

toggle-type fasteners are always set at the bottom part of the wire.

By the pre-assembly the roofing bonds have to be fastened only to a bay.

3.3.1 Prepare the wires of the wind bracings (accord. pic. 11) to the

equivalent fields.

3.3.2 Screw on the toggle-type fasteners of the side (do not screw them on

at all) Unhook the shackel.

3.3.3 Mount the ring bolts M16x120 of the roofing bonds to the ridge

connectors and fix them tight (pic. 9).

3.3.4 Feed from below the ring bolts into the endbay and screw the nut from

above, feed from above the ring bolt inside to the bay and screw it

from below with the nut. Hook the shackel (pic. 12).

3.3.5 Mount the side bonds to the corner- and middle legs according the

above instructions (pic. 8).

22

Spanning the world.

Page 24

BT 2000 240/300 570/627

Pic. 12

23

Spanning the world.

Page 25

BT 2000 240/300 570/627

Pic. 13

24

Spanning the world.

Page 26

BT 2000 240/300 570/627

4 Erection of the tent

You need a self-propelling crane or a fork stacker with telescope for the

putting of the tent (see also point 1.2).

Protect the dangerous spots during lifting.

Do not work under hanging load!

4.1.1 Put the legs of the mounted beams in to the already placed

baseplates types B. Adjust the boring, bolt the baseplate and the legs

of bay with the pin. Insert the pin from the inside of the tent to

outside. Fix tightly the pin with a R-clip.

4.1.2 Place the gable supports to their receivers of the end beams and if

provided place them the ridge connectors and bolt them. Fix them

tight by screwing down the safety bracket (pic. 18). After the

adjusting of the bay, the gable supports can be placed to the

baseplates.

4.1.3 Feed two load belts into the gravity center of bay (pic. 3) to the beams

and lift the bay with the aid of the crane or fork stacker. Place to both

sides the wires of the wind bracings. Now fix tightly to both sides the

bay with the wires after the setting upright.

4.1.4 Lift the bay slowly and take care that is not going to be twisted.

4.1.5 Place the bay vertical and fix it tight with the wires of the wind

bracings. The helpers are supporting the legs. Lay the wires of the

wind bracings to both sides and fix them tight by beating in the

anchors.

4.1.6 Disharge carefully the load belt and hung it off.

4.1.7 Follow the points 4.1.3 and 4.1.4 also for the 2. bay. After erecting

the 2. bay, leave them on the hooks.

4.1.8 Hang up the eave- and intermediate purlin. Hang up to the hooks

which are provided with the radius each of the below intermediate

25

Spanning the world.

Page 27

BT 2000 240/300 570/627

purlins of the right and left side of the tent into the endmeans of the

placed endbay. For tent types of the roof covers with expander

bracing pay attention to the bracing hooks of the eave purlins that

they are always facing insides of the tent. Hang up the purlins to the

2. bay with the aid of the mounting fork. Another person will hang the

4.1.9 Screw down the free wires of the wind bracing to each respective

4.1.10 position of 2. bay. Prestress the turn buckles.

4.1.11 Take out the wind bracings from anchor, which are for the safety of 1.

4.1.12 Mount the ridge purlin to the bay 1. and 2. (pic. 14).

4.1.13 Hang up the load belt to the 2. bay and place it to the 3. and 4. bay.

4.1.14 After the placing of the 3. and 4. bay, set the wind bracings and

4.1.15 Place the gable supports, which have been already set to the

purlins from the mounting drawing case (pic. 14 and 15).

bay and mount them also. Prestress the turn buckles.

prestress them. Mount the tension ropes of the side wind bracings to

the baseplates and prestress them loose. The ring bolt with the R-clip

has to be set to the boring of the corner baseplate in a way that the

boring for the R-clip is facing to the outside of the tent (pic. 16).

endbeams, to the baseplates and mount the baseplate pins. The

safety bracket of the baseplate is facing to the inside of the tent. Fix

tightly by screwing on the safety bracket

4.1.16 Hang up the gable eave rails and bolt them (pic. 17).

4.1.17 Beat in the earth-anchors to the baseplates of the supports (pic. 17).

4.1.18 The gable supports are provided with telescopes in order to level up

4.1.19 Mount the rest of the bays according the above instructions.

4.1.20 You can adjust the beams to the corner legs with the help of the

(pic. 17).

the differences of height. Remove the treaded bolts and place

accordinally the telescopes (pic. 17).

roofing bonds. Beams and corner legs have to be in alignment (pic.

16).

26

Spanning the world.

Page 28

BT 2000 240/300 570/627

Pic. 14

27

Spanning the world.

Page 29

BT 2000 240/300 570/627

Purlin

Angle

Mounting rod

28

Pic. 15

Spanning the world.

Page 30

BT 2000 240/300 570/627

Pic. 16

29

Spanning the world.

Page 31

BT 2000 240/300 570/627

g

Gable support- middle

Gable eave

rail- holdin

Giebelstütze - Mitte Giebelstütze - Seite

Gable

Pin

Telescoping Connector

Gable support- side

Gable eave rail

Earthanchor

Telescoping Foot

Baseplate

R- clip

Baseplate

30

Spanning the world.

Page 32

BT 2000 240/300 570/627

Ridge connector

Beam

Pin

Safety bracket

Gable

Pic. 18

Beam

Gable eave

Leg

31

Spanning the world.

Page 33

BT 2000 240/300 570/627

4.2 Mounting problems and their causes

4.2.1 The corner- and middle legs do not fit to the baseplate’s receiver:

This is usually the result of the inaccurate working in point 2.

With the aid of the crowbar try to move the baseplate in the way that

the pins could be fixed. If this is not able, check the points from 2.1.2

until 2.1.17.

4.2.2 The baseplate pins cannot be fixed tight:

The baseplates are faung the wrong way.

Pull the earth-anchors, place the baseplates again and beat in the

earth-anchors again.

32

Spanning the world.

Page 34

BT 2000 240/300 570/627

Rope

Carabine swivel with the

opening upwards

Hanging of pull

back rope in

Leading-in conductor

keder

Buckles to the

outside

Running position

Keder

33

Pic. 19

Spanning the world.

Page 35

BT 2000 240/300 570/627

5 Mounting of tent’s covers

Before starting the mounting of the tent’s covers, all earth-anchors have to

be beaten in and the wind bracings tightened (compare point 4).

Use the leading-in conductor for covers. It makes mounting easier and helps

to avoid damages to the covers.

Do not try to pull in the cover with force. If there is any heavy resistance, pull

back another time and try again.

Prepared assembling auxiliares:

Construction tools: Building components:

3x traction cables with carabine All the roof covers

2x leading-in conductor for covers

mounting rod

5.1 Pulling up the roof cover

5.1.1 Set in right position the leading-in conductor to each of the open

ends in both of the beams to a tent’s longest side (pic. 19).

5.1.2 Throw a traction wire from left to right over the ridge of the first

brace field.

5.1.3 Pull with this wire two more traction wires over the ridge.

5.1.4 Place in the right position respective roof covers. (Buckles have to

show on the outside and right) (pic. 19).

5.1.5 Hang up both of the traction wire with the carabine hooks to both of

the outer

traction eyes of the roof cover. Hang up the 3. traction wire to a

traction eye

(pull back rope) (pic. 19).

34

Spanning the world.

Page 36

BT 2000 240/300 570/627

5.1.6 Lift the roof cover to the height of the leading-in conductor and feed

the right and left keder of the cover through the leading-in conductor

into the keder groove of the roof beam, through pulling of the

traction cables of the opposite tent’s side (pic. 19).

5.1.7 Pull the two of the traction wires at the same time the roof cover into

the roof

beam. Pull the cover slowly over the ridge.

5.1.8 After the setting of the cover into the roof beam, the traction wires

will be removed and hang up to the 3. traction wire, which has been

pulled in with the cover over the ridge. The traction wire will be

stretched back in a way that both of the other traction wires can be

placed again to the start position.

5.1.9 Repeat the points 5.1.1 until 5.1.8 for all the roof covers.

35

Spanning the world.

Page 37

Bracing pipe

g

p

Roof cover

BT 2000 240/300 570/627

Bracing pipe

side with

le

an

Pic. 20

connection

rofile

Pic. 21

Bracing pipe

ratchet

Clow hooks

Roof

Connection

Thread bracing

Pic. 23

36

Pic. 22

Spanning the world.

Page 38

BT 2000 240/300 570/627

5.2 Stretching of the roof cover (model with fixed tensioning)

There are 2 variations to distinguish among the roof covers:

a) With fixed bracing aa) –With stretch strap aaa) –With thread bracing

b) With rubber tensioning

If your tent has the model b) rubber tensioning, then skip this point and go

on with the mounting steps of point 5.3.

Prepared assembling auxiliaries:

Building components:

Bracing pipe with angle

Bracing pipe

Stretch strap with ratchet or thread bracing

Clow hooks

Connection profiles

5.2.1 Feed the 4 bracing pipes with the angles into the kits of the outer roof

covers. The angles have to show upwards and to the gable side of the

5.2.2 Feed the bracing pipes without angle into the kits of each roof cover.

5.2.3 Type stretch strap: set the connection profiles each on the bracing

5.2.4 Type stretch strap: pull the bracing device with the aid of the ratchet

5.2.5 Type thread bracing: set the tensioning devise to the free below keder

5.2.6 Type thread bracing: turn on the stretch bolt and stretch steady the

5.2.7 Repeat point 5.2.4 resp. 5.2.5 for all the roof covers.

5.2.8 Connect the tabs of the roof covers, with buckle straps or bands with

tent (pic. 20).

pipes between the covers and hang up the loop to the bracing device.

Hang up the mounting hooks of the bracing device to the boring of

the legs (pic. 21).

to stretch at the same time the roof cover in both of the sides.

groove of the roof beam and push it until the limit stop. Place the

connection profiles on the bracing pipes (pic. 22).

roof covers.

the equivalent opposite parts of the next roof cover (pic. 23).

37

Spanning the world.

Page 39

Eave purlin

with

BT 2000 240/300 570/627

Eave purlin

Inside

Roof cover

Rubber

tensioning

Pic. 24

Gable

cover

rubber

tensioning

Tensioning

hooks

Pic. 25

Pic. 26

38

Pic. 27

Spanning the world.

Page 40

BT 2000 240/300 570/627

5.3 Stretching of the roof cover (model with rubber tensioning)

There are 2 variations to distinguish among the roof covers:

a) With fixed bracing

b) With rubber tensioning

If your tent has the model a) fixed bracing, then skip this point and go on

with the mounting stepts of point 5.2

Work from the outside to the inside by hanging up the elastic chock cord.

5.3.1 Pull the elastic chock cord of the roof cover on one tent side around

the eave purlin and hang up into the hooks (pic. 24).

5.3.2 Hang up the elastic chock cord to the opposite of the roof cover

according the point 5.3.1.

5.3.3 Repeat the points 5.3.1 and 5.3.2 for all the roof covers.

5.3.4 After the stretching of the roof covers, check once more the elastic

chock cords of the separate covers and stretch them (pic. 25).

5.3.5 Connect the tabs of the roof covers, which have buckle straps or bur

band with the equivalent opposite parts of the next roof cover (pic.

23).

39

Spanning the world.

Page 41

BT 2000 240/300 570/627

5.4 Pulling in the gable covers (gable triangle)

The covers for the cover gable are each composed of 2 gable covers, an eyeand a loop side. The inside area of the tent is marked through the sewing of

the loops that turns down to the inside and bond resp. this is the overlapping

of the sides, which makes a right angle.

The outsides have been marked with the signboard RÖDER (if provided)

and/or with colour lines (if provided).

5.4.1 Feed with the keder the gable triangles into the above keder groove of

the endbeams. Hang up 1-2 wires into the traction eye. 1-2 mounting

helpers are pulling from the mounting drawing case or the movable

platform to the wires of the triangle covers until the ridge (pic. 26).

5.4.2 Cord up each of the both gable covers according to (pic. 30) from the

top to bottom and bind them on the tent inside. Bind the last loop

(pic. 27).

5.4.3 Repeat the points 5.4.1 and 5.4.2 for the opposite gable side.

5.5 Pulling in the sides- and gable walls

Every gable of the gable curtains is composed of wide and small roof covers

and each of them has been marked in a lower corner (GV = Gable wall).

The side walls will be fixed to the longest side of the tent and they have been

also marked (SV = Side wall).

Apply in the same way as the gable covers in setting through loops- and eye

sides.

5.5.1 Allocate the covers and lay them. The cranked hooks must be laying

upwards. The cranked hooks are facing to the outside of the tent by

the side walls, any by the gable walls are facing to the inside of the

tent (pic. 28).

5.5.2 Feed the keder upwards of the cover to the keder groove of the tent’s

legs and push it totally upwards.

40

Spanning the world.

Page 42

BT 2000 240/300 570/627

5.5.3 Feed the lower half of the cover and push it fully down.

5.5.4 Hook the cranked hooks into the groove insides of the gable eave rail

(eave purlin).

5.5.5 Mount according the points from 5.5.2 until 5.5.4 the respective 2.

cover

(eye-and loop side).

5.5.6 Cord up both of the covers according the point 5.4.2.

5.5.7 Repeat the points 5.5.2 until 5.5.6 for all the side-and gable walls.

Pic. 28

Hang up the

hooks inside

Fix the

hooks

41

Spanning the world.

Page 43

BT 2000 240/300 570/627

5.6 Mounting of the ground rail (if provided). The ground rails for the sides-

and gable walls are provided by RÖDER as an accessory.

5.6.1 Feed the ground rails into the ground rails kits of the side curtains (pic.

5.6.2 Push the ground rails on to the 180 mm long flange pin and secure

5.6.3 Feed the ground rail for the gable wall into the ground rail kit.

5.6.4 Hang up the ground rail to the bolt receiver of the ground rail holding

29).

them with a R-clip.

plate of the outer baseplate and fix it tight with a R-clip.

Ring bolt

for ground

Ground rail

-

Side cover

Pic. 29

Ground rail

outside

Gable cover

42

Wire for

Ground rail side

L=5090 mm

Spanning the world.

Page 44

BT 2000 240/300 570/627

6 Dismantling

For the dismantling of the tent you have to follow the instructions in reverse

to the construction.

The principle of dismantling:

All the covers of the tent ought to be dry before you start folding.

After dismantling you have to mark, sort and load all the building

components immediately.

The using of the peg puller, which is provided as an accessory part, makes

the removing of the earth anchors easier.

6.1 Dismantle the ground rails.

6.2 Undo, dismantle and lay on clean ground the sides- and the gable

walls and fold them together, resp. roll in pairs every accompanying

eye- and loop side.

6.3 Undo, dismantle and lay on a clean ground the gable covers and fold

them together, resp. roll in pairs every accompanying eye- and loop

side.

6.4 Unhook the roof cover bracing, resp. remove and dismantle it.

6.5 Remove from each other the buckle straps, resp. bur band of the roof

covers.

6.6 Remove the roof cover, place it on clean ground and fold it together,

resp. roll it.

6.7 Dismantle the gable supports and gable eave rails of the first gable.

6.8 Mount the setting rods to the first corner legs of one gable side and

fix the pin tightly.

6.9 Loosen the wind bracing to the first field.

6.10 Dismantle the wind bracings of the first field.

6.11 Dismantle all purlins of the first field.

6.12 4 people are fixing tightly the first bay.

6.13 Lay down the first bay carefully.

6.14 Dismantle the beams, legs and middle ridge connectors for all the

bays.

6.15 Repeat the points 6.7 and 6.14 for all the bays.

6.16 Pull the anchors.

43

Spanning the world.

Page 45

BT 2000 240/300 570/627

7 Service notes

7.1 Construction of the tent

7.1.1 The restretching of the wind bracings, treaded bolt connections and

roof racings is requisite:

- every 3 months (stand-by time)

- after hot periods

- after a strong gale

7.1.2 Pay attention to the earth-anchors, that is deep seated in a solid

position.

7.1.3 Check for deformation or damage.

7.1.4 If there are any damaged parts, then change them immediately with

new original spare parts.

7.2 Bedding and transport

To avoid damage to the aluminium profile you have to bed and to transport

all the aluminium profiles on a smooth area (e.g. RÖDER transport units) and

you have to pay attention to the profile, that stand out on the smaller profile

side.

7.3 Routine visual inspection

Periodically carry out a visual inspection after every use (e.g. after every event

day):

The inter- and eave purlins have to be hung up according to the rules.

The bolt- and pin connections have to be inspected.

Dirty covers have to be cleaned (the washing can take place in our own

RÖDER laundry).

44

Spanning the world.

Page 46

BT 2000 240/300 570/627

8 Ratings

8.1 Construction of the tent

All the dimensions have been given axial

Tent’s length: min. 10,0 m

Max. length: any enlarge in grid possible

Tent’s width: 20,0 m

Ridge height: 5,70 m / 6,27 m

Side height: 2,40 m / 3,00 m

Roof inclination: 18°

Bay distance middle: 5,0 m

Leg profile: 220 x 100 mm

Beam profile: 220 x 100 mm

Ridge purlin profile: 130 x 70 mm

Intermediate purlin profile: 60 x 60 mm

Eave purlin profile: 130 x 70 mm

Gable support profile: 130 x 70 mm

Gable eave rail profile: 130 x 70 mm

Material main construction: aluminium, anodic oxidation

Material connection parts: steel, zinced

Kind of connection (legs/beam): sliding eave connection

Requisite foundation pressure: > 0,2 MN/m² (see static)

Design load: (see static) wind load 100 km/h

0,5 kN/m²

Longest piece of part: 10,7 m

Anchorage: earth-anchor ∅ 25 mm x 1000 mm /

800 mm

45

Spanning the world.

Page 47

BT 2000 240/300 570/627

8.2 Tent covers

Check points unit actual value

Material PES

DIN 60001

Yarn notation linkage dtex 1100

DIN 53830 body dtex 1100

Set infabrics linkage Fd/cm 8,00

DIN 53853 body Fd/cm 8,00

Bond L1/1

Coating both sides PVC

Coating support g/m² 470

DIN 53358

GSM substance g/m² 650

DIN 53352

Tensile strength linkage N/5cm 2800

DIN 53354 body N/5cm 2500

Tear strength linkage N 300

DIN 53363 body N 300

Adherence N/5cm 100

DIN 53357

Weld adherence by 70°C N/5cm 2400

The quality B 101735 of DIN 4102 B1, M2, BS 3119/3120 proved that it is

flame retardent.

8.3 DIN ISO Normen

RÖDER tents have the following DIN ISO standard specifications:

DIN 1054 DIN 1055 DIN 1480 DIN 1808 DIN 3066 DIN 4112

DIN 4113 DIN 4114 DIN 4115 DIN 18800 DIN EN ISO 9004-1

47

Spanning the world.

Loading...

Loading...