Engineer-to-Engineer Note EE-249

a

Technical notes on using Analog Devices DSPs, processors and development tools

Contact our technical support at dsp.support@analog.com and at dsptools.support@analog.com

Or vi sit our o n-li ne r esou rces htt p:/ /www.analog.com/ee-notes and http://www.analog.com/processors

Implementing Software Overlays on ADSP-218x DSPs with VisualDSP++®

Contributed by Ramesh Babu and Aseem Vasudev Prabhugaonkar Rev 1 – October 4, 2004

Introduction

This EE-Note discusses the implementation of

software overlays on ADSP-218x DSPs. A

simple code example, demonstrating the software

overlay technique for ADSP-218x DSP, is

discussed later in this document.

Early versions of the VisualDSP® toolset used a

different scheme to support software overlays as

discussed in the legacy EE-Note Everything You

Always Wanted to know about Overlays - *But

were afraid to ask (EE-67). With VisualDSP++®

3.5 a new approach has been enabled.

What are Software Overlays?

Due to limited address space, many ADSP-218x

derivatives provide multiple memory pages,

called hardware overlays. The software overlay

technique is a completely different scheme to

populate the content of physical SRAM with

different data or code on demand.

“live address space”, and the memory address

where the program is executed in internal

memory is called “run address space”. The code

responsible for transferring the data / program

code from external memory to internal memory

at runtime is called an overlay manager. It

typically resides in a reserved space of the DSP’s

internal memory.

Software Overlays on ADSP-218x DSPs

Software overlays can be implemented using the

ADSP-218x DSP's external byte-wide memory

space. A byte-wide memory can be interfaced

through the processor's BDMA port. The overlay

code/data resides in the external byte-wide

memory. The overlay manager is responsible for

initializing byte DMA (BDMA) to transfer the

data/code from external memory into internal

memory when required.

VisualDSP++ Support

The software overlay technique is commonly

used when a processor is does not have sufficient

internal memory to hold all of the application's

data / program code. In these situations, part of

data / program code is loaded into internal

memory during the booting process and the

remaining part is placed in external memory.

When program code (or data) in external

memory has to be executed, it is loaded into

The VisualDSP++ linker automatically generates

overlay constants, which configure the BDMA

parameters in the overlay manager. Each overlay

has a word size, run-time address and live

address used by the overlay manager to

determine where the overlay resides and where it

is executed.

The linker-generated constants (where N is the

ID# of the overlay) are:

internal memory and executed.

The memory address range where the overlay

_ov_startaddress_N (live address space)

function resides in the external memory is called

Copyright 2004, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer product design or the use or application of

customers’ products or for any infringements of patents or rights of others which may result from Analog Devices assistance. All trademarks and logos are property

of their respective holders. Information furnished by Analog Devices applications and development tools engineers is believed to be accurate and reliable, however

no responsibility is assumed by Analog Devices regarding technical accuracy and topicality of the content provided in Analog Devices’ Engineer-to-Engineer Notes.

_ov_word_size_run_N

p

A

_ov_word_size_live_N

_ov_runtimestartaddress_N (run addr. space)

The linker is also responsible for resolving the

symbol addresses of overlay data and labels.

Example Program

This section shows a simple example program to

illustrate the software overlay implementation on

ADSP-218x DSPs. The assembly program

provided with this EE-Note toggles a flag pin at

two different speeds. This program uses two

software overlay functions which exist in the

external byte memory.

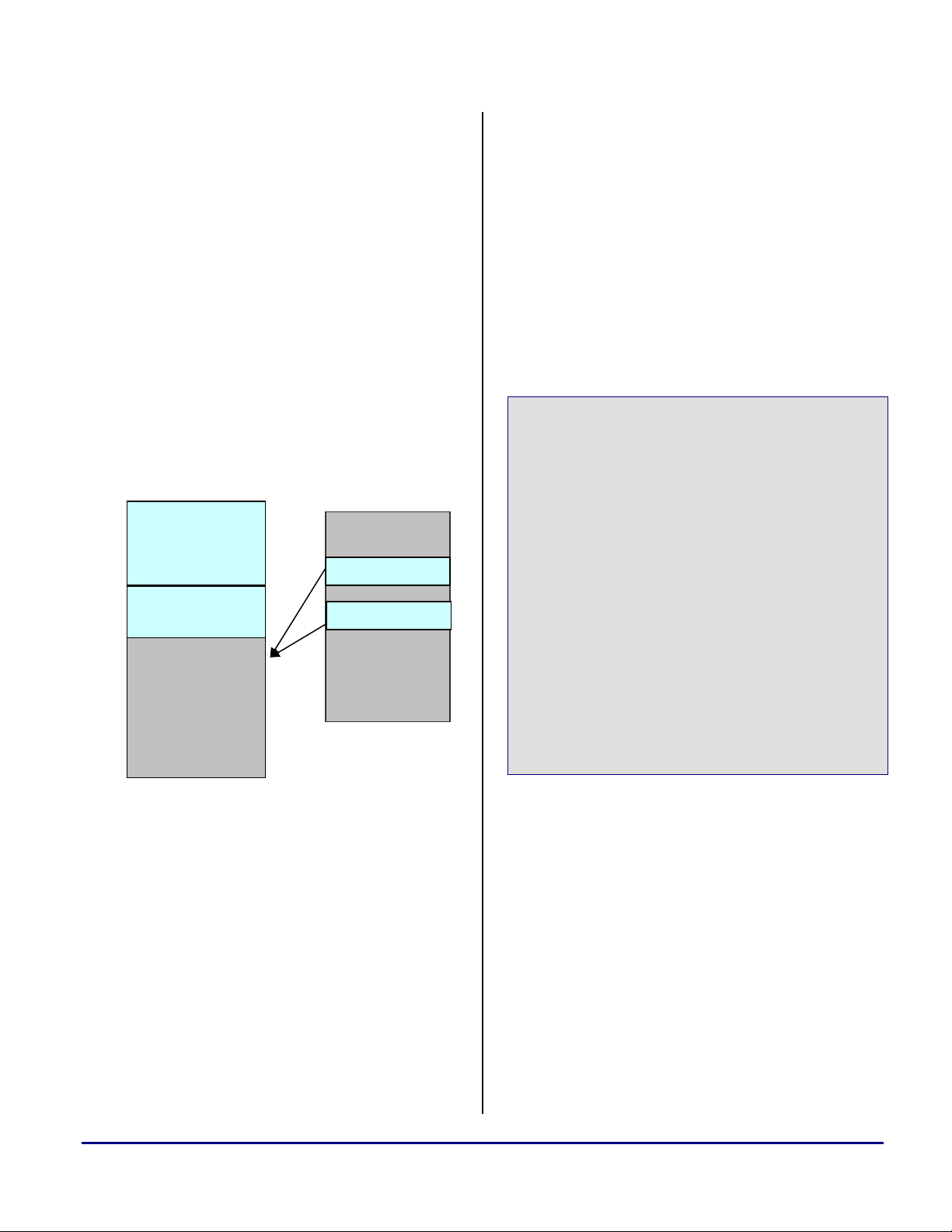

Internal PM

Memory

0x0000

Main ( )

Overlay_Manager ( )

0x2000

Figure 1. Simple Memory Overlay Example

0x1000

0x2000

ace

Run S

The main program calls the two software overlay

functions in an infinite loop. One of the software

overlay functions (

Fast-LED-Blink()) toggles

the LED at a faster rate; the other (

Blink()

) toggles the LED at a slower rate.

Figure 1 illustrates where the overlay functions,

overlay manager, and the main function are

stored.

The

main() and Overlay_Manager() functions

are loaded into the internal RAM of the ADSP218x during the booting process. The

Blink()

and Slow-LED-Blink() overlay

External Byte

Memory

Fast-LED-Blink ( )

Slow-LED-Blink ()

Slow-LED-

Fast-LED-

functions are saved in external byte memory.

During runtime, when an overlay functions is

called, the function is loaded into internal

memory and then executed. Accessing code

and/or data overlays dynamically provides

greater flexibility toward managing your DSP’s

internal memory.

Linker Definitions

Let's look into the declarations required in the

Linker Description File (.LDF) for the example

program explained above.

// "run" space for PMOVLAY pages

mem_pmovly {

TYPE(PM RAM)

START(0x002000)

END(0x003fff)

WIDTH(24)

}

// "live" space for PMOVLAY pages

mem_pmpage1 {

TYPE (BM RAM)

START(0x001000)

END(0x001fff)

Live Space

WIDTH(8)

}

mem_pmpage2 {

TYPE(BM RAM)

START(0x002000)

END(0x002fff)

WIDTH(8)

}

Listing 1. Run and Live Space Declaration in .LDF

The statements in Listing 1 in the MEMORY {}

section of the

(i.e., the run space and live space addresses of

the overlay program code).

Live space. which is specified in the byte

memory (BM), helps the linker generate the

overlay constants.

The statements in Listing 2, which are specified

in

code and data to the physical memory of a

processor in a DSP system. In Listing 2, the

commands

(e.g.,

.LDF file define the target memory

PROCESSOR { } section of the .LDF file, map

tell the linker that a specific section

pm_ovlay_1) from a specified input file

Implementing Software Overlays on ADSP-218x DSPs with VisualDSP++® (EE-249) Page 2 of 6

Loading...

Loading...