Page 1

Engineer-to-Engineer Note EE-219

a

Technical notes on using Analog Devices DSPs, processors and development tools

Contact our technical support at dsp.support@analog.com and at dsptools.support@analog.com

Or vi sit our o n-li ne r esou rces htt p:/ /www.analog.com/ee-notes and http://www.analog.com/processors

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs

Contributed by Brian M. Rev 1 – December 16, 2003

Introduction

This document contains example code and

hardware to interface an ADSP-21262 SHARC

DSP to a Hitachi HD44780-compatible character

LCD driver. The specific module used in this

example is an Optrex DMC-16128, which has a

16x1 character dot matrix LCD controlled by the

HD44780 driver.

A character LCD module interfaced to the DSP

can prove to be a very useful tool. In addition to

providing a user interface, the character device

can be used as a real-time debugging interface.

Using the character device to print the function

currently executing (or the state of buffers while

running) is a viable alternative to halting the

processor to check these states when using an

emulator.

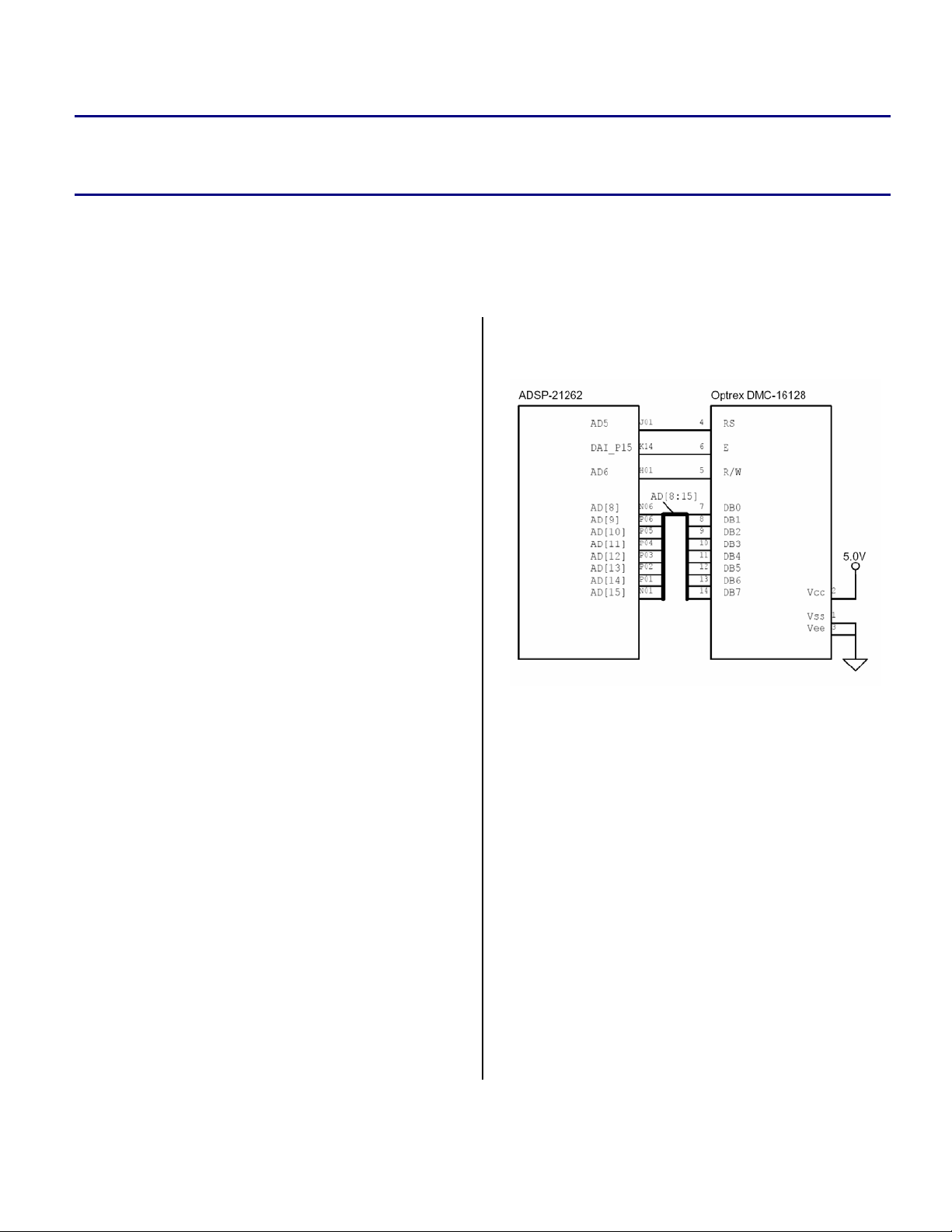

Hardware Interface

The critical control signals on the LCD driver are

constrained by timing specifications that are

slow. They are too slow to be used with the

Parallel Port. However, using software to control

general-purpose flags, it is possible to generate

the necessary waveforms. This method will work

for any DSP that provides at least 11 bidirectional programmable flags (in the SHARC®

family of DSPs, the ADSP-21065, ADSP-21161,

and ADSP-21262 provide enough programmable

flags to implement this interface). This will allow

both reading and writing capabilities with an 8bit interface. (The HD44780 compatible drivers

Copyright 2003, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer product design or the use or application of

customers’ products or for any infringements of patents or rights of others which may result from Analog Devices assistance. All trademarks and logos are property

of their respective holders. Information furnished by Analog Devices Applications and Development Tools Engineers is believed to be accurate and reliable, however

no responsibility is assumed by Analog Devices regarding technical accuracy and topicality of the content provided in Analog Devices’ Engineer-to-Engineer Notes.

can also operate with a 4-bit interface if fewer

general-purpose flag pins are available.)

Figure 1. Hardware Interface

On the ADSP-21262 SHARC DSP, the Parallel

Port pins are multiplexed with the generalpurpose flag pins. Therefore, any access to the

Parallel Port also disturbs the LCD interface. To

avoid this problem, it is necessary to use one of

the DAI pins as a general-purpose flag, so that

the enable signal to the LCD will never be

changed unintentionally.

As shown in Figure 1, the final interface

implementation requires no glue logic. Each of

the 11 control pins for the HD44780 driver are

connected to a unique programmable flag pin

(when connecting to the ADSP-21262 SHARC

DSP, connect the E pin of the HD44780 to the

DAI pin being used a programmable flag, as

described above).

Page 2

a

For the power interface, SHARC EZ-KIT Lite™

development boards provide pins for both a 5V

and Ground, which can be connected to the Vdd

and Vss pins of the LCD module, respectively.

For the Vee connection, use a variable

potentiometer to control the contrast of the LCD,

or simply ground Vee for maximum contrast.

Since this device will handle characters and

strings, it is most useful to develop the code to

interface to the LCD module using the C

language. The code fragments contained in this

document are in C, and are compiled using the

VisualDSP++ development suite version 3.0

(service pack 1).

Code Listings 1 and 2 show the code necessary

Software

The most important step in developing the

software for this LCD controller is to emulate the

hold times necessary to communicate via the

interface. This can be done using “NOP” loops or

the timer. This example uses “NOP” loops. The

entirety of the code to access the LCD as

described in this document is included, along

with a VisualDSP++® project file.

to read from and write to the device. Note that in

most cases, it is necessary to wait for the device

to be ready before performing an actual read or

write. Part of the call to the read and write

function is a Boolean variable (bftest - Busy Flag

Test), indicating this requirement.

At the end of this document is a complete code

listing that contains the minor functions called

from the listings presented here.

//Read from the LCD

//Inputs passed - RegisterSelect = Indicates the desired state of the RS pin

// bftest = wait for the busy flag to clear before writing

//Outputs returned - the byte of data read from the LCD

int readFromLCD(int RegisterSelect, int bftest)

{

const int ReadWrite = 1;

int data,

busyflag = 1;

if(bftest)

{

while(busyflag)

{

busyflag = readFromLCD(LCDNORS,NOWAITFORBF);

busyflag = ((busyflag&0x80)>>7);

}

}

asm("bit clr flags 0x5400AAAA;");

asm("r0=flags; r0=r0 or %0; flags=r0;"::"d" (RegisterSelect<<26):"r0");

asm("r0=flags; r0=r0 or %0; flags=r0;"::"d" (ReadWrite<<28):"r0");

nanosec(1);

SRU(HIGH,DAI_PB15_I);

nanosec(3);

asm("r0=flags; r1=0x5555; %0=r0 and r1;":"=d" (data)::"r0","r1");

SRU(LOW,DAI_PB15_I);

nanosec(1);

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 2 of 11

Page 3

data = despreadData(data);

return data;

}

Listing 1. readFromLCD()

a

//Write to the LCD

//Inputs passed - RegisterSelect = Indicates the desired state of the RS pin

// data = the byte of data to write to the lcd

// bftest = wait for the busy flag to clear before writing

//Outputs returned - none

void writeToLCD(int RegisterSelect, int data, int bftest)

{

const int Enable = 30,

ReadWrite = 0;

int busyflag=1;

data=spreadData(data);

if(bftest)

{

while(busyflag)

{

busyflag = readFromLCD(LCDNORS,NOWAITFORBF);

busyflag = ((busyflag&0x80)>>7);

}

}

asm("bit set flags 0xAAAA;");

asm("bit clr flags 0x54005555;");

asm("r0=flags; r0=r0 or %0; flags=r0;"::"d" (RegisterSelect<<26):"r0");

asm("r0=flags; r0=r0 or %0; flags=r0;"::"d" (ReadWrite<<28):"r0");

asm("r0=flags; r0=r0 or %0; flags=r0;"::"d" (data):"r0");

nanosec(1);

SRU(HIGH,DAI_PB15_I);

nanosec(3);

SRU(LOW,DAI_PB15_I);

nanosec(1);

return;

}

Listing 2. writeToLCD()

Two functions, readFromLCD() and

writeToLCD(), are the basis for any other

function that will access the LCD. The functions

supplied in this example are:

lcdprintf() (Listings 4 and 5),

3),

lcdshiftright() (Listing 6), lcdshiftleft()

(Listing 7), and

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 3 of 11

lcdblink() (Listing 8).

lcdinit() (Listing

lcdInit() performs an initialization routine that

is outlined in both the Hitachi HD44780 data

sheet [2] and the Optrex LCD Module User’s

Manual [3]. Performing this initialization may

not always be necessary, but using it will

guarantee that the LCD is in its initial state

before any commands are set.

Page 4

a

lcdprintf() is a macro that parses a string in

the same manner as a standard printf. The

lcdprint() function is called by the

lcdprintf() macro to display the desired

characters, and the sprintf() function is called

by the macro to handle the arguments that are

passed. At this time, if no arguments are to be

passed, it is necessary to call the

lcdprint()

function directly, as the preprocessor cannot

handle a call without any arguments, and the

variable length argument functions in the C

runtime are not functioning.

The display for the 16x1 character LCD of the

DMC-16128 must be accessed as 2 lines, each

displaying 8 characters at a time. The first eight

characters are accessed by DD-RAM addresses

0x0 through 0x27, and the last eight characters

are accessed by addresses 0x40 through 0x67.

When reading or writing a string of more than

eight characters to the LCD, it is necessary to

write the first eight characters to the lower

addresses in succession, then change the DDRAM address to the upper address and write the

final characters.

The LCD driver has the ability to shift the

characters already in DD-RAM to the right or to

the left. However, these commands do not

automatically wrap the contents of the second

line to the first or vice versa. Therefore, it is

necessary to program the entire string into both

the upper and lower memory locations, with the

upper locations being shifted to the left by eight

locations.

This is exactly how the

lcdprint() function

operates. Specifically, it clears the display and

returns the cursor to home and writes the entire

string (up to 40 characters), beginning with the

first DD-RAM location. The DD-RAM location

is then changed to the second line, and the string

is written again beginning with the ninth

character at address 0x40. The rest of the string

is written, and then the first eight characters are

written beginning at address 0x60. This method

allows wrapping from the right half of the LCD

to the left, and vice versa.

The final three functions supplied are effects on

the display, and do not change the DD-RAM

contents. As their names suggest,

lcdshiftleft() and lcdshiftright() shift

the DD-RAM addresses currently displayed. The

function shifts the display a single character in

the specified direction the number of times

passed, repeated at the interval passed (in

hundreds of microseconds). Similarly,

lcdblink() turns the display off and on, the

number of times passed, at the interval passed (in

hundreds of microseconds).

//Initialize the LCD as described in the HD44780 Datasheet

//Inputs passed - none

//Outputs returned - none

void initLCD()

{

int readbyte,

dummybyte,

flagvalues;

//Handle the parallel port interrupt using ppInterruptVector

interrupt(SIG_PP, ppInterruptVector);

//Set up DAI pin 15 as an output that is low

SRU(LOW,DAI_PB15_I);

SRU(LOW,PBEN15_I);

//Set up the DSP to access the LCD

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 4 of 11

Page 5

setupForLCD(&flagvalues);

//Wait for 15 ms

microsec(150);

writeToLCD(LCDNORS,0x30,NOWAITFORBF);

//Wait for 4.1 ms

microsec( 41);

writeToLCD(LCDNORS,0x30,NOWAITFORBF);

//Wait for 100 us

microsec(1);

writeToLCD(LCDNORS,0x30,NOWAITFORBF);

writeToLCD(LCDNORS,0x38,NOWAITFORBF);

writeToLCD(LCDNORS,0x08,WAITFORBF);

writeToLCD(LCDNORS,0x01,WAITFORBF);

writeToLCD(LCDNORS,0x07,WAITFORBF);

writeToLCD(LCDNORS,0x0C,WAITFORBF);

finishedWithLCD(&flagvalues);

return;

}

Listing 3. initLCD()

a

//Print a string to the LCD

//Inputs passed - the string to be printed.

//Outputs returned - none

void lcdprint(char * display)

{

int i,flagvalues;

//Set up the DSP to access the LCD

setupForLCD(&flagvalues);

//Set up the interface

writeToLCD(LCDNORS,0x3C,WAITFORBF);

//Turn on the display with no cursor

writeToLCD(LCDNORS,0x0C,WAITFORBF);

//Set the mode to increment the address by one and shift to the right

writeToLCD(LCDNORS,0x06,WAITFORBF);

//If the string is too long for the display memory, say so

if(strlen(display)>40)

{

lcdprint("String too long");

return;

}

//Clear the display

writeToLCD(LCDNORS,0x01,WAITFORBF);

//Return the cursor to home

writeToLCD(LCDNORS,0x02,WAITFORBF);

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 5 of 11

Page 6

//For when the string is less than 8 characters

if(strlen(display)<=8)

{

for(i=0;i<strlen(display);i++)

{

writeToLCD(LCDRS,display[i],WAITFORBF);

}

//Shift the cursor to the last 8 chars

writeToLCD(LCDNORS,0xE0,WAITFORBF);

//Write the last 8 chars

for(i=0;i<strlen(display);i++)

{

writeToLCD(LCDRS,display[i],WAITFORBF);

}

}

//For all other cases

else

{

//Write first 8 chars

for(i=0;i<strlen(display);i++)

{

writeToLCD(LCDRS,display[i],WAITFORBF);

}

//Shift the cursor to the last 8 chars

writeToLCD(LCDNORS,0xC0,WAITFORBF);

//Write the last 8 chars

for(i=0;i<(strlen(display)-8);i++)

{

writeToLCD(LCDRS,display[(i+8)],WAITFORBF);

}

//Shift the cursor to the last 8 chars

writeToLCD(LCDNORS,0xE0,WAITFORBF);

//Write the last 8 chars

for(i=0;i<8;i++)

{

writeToLCD(LCDRS,display[i],WAITFORBF);

}

}

finishedWithLCD(&flagvalues);

return;

}

a

Listing 4. lcdprint()

#define lcdprintf(sting,...) sprintf(sting,sting,__VA_ARGS__);\

lcdprint(sting);

Listing 5. lcdprintf()

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 6 of 11

Page 7

//Shift the contents of the LCD to the left

//Inputs passed - number of times to repeat the shift

// - interval between the shifts

//Outputs returned - none

void lcdshiftleft(int number,int interval)

{

int i,flagvalues;

//Set up the DSP to access the LCD

setupForLCD(&flagvalues);

for(i=0;i<number;i++)

{

microsec(interval);

//Write the shift left command

writeToLCD(LCDNORS,0x18,WAITFORBF);

}

finishedWithLCD(&flagvalues);

return;

}

a

Listing 6. lcdshiftleft()

//Shift the contents of the LCD to the right

//Inputs passed - number of times to repeat the shift

// - interval between the shifts

//Outputs returned - none

void lcdshiftright(int number,int interval)

{

int i,flagvalues;

setupForLCD(&flagvalues);

for(i=0;i<number;i++)

{

microsec(interval);

//Write the shift right command

writeToLCD(LCDNORS,0x1C,WAITFORBF);

}

finishedWithLCD(&flagvalues);

return;

}

Listing 7. lcdshiftright()

//Blink the contents of the LCD

//Inputs passed - number of times to blink

// - Duration that the LCD is on/off

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 7 of 11

Page 8

//Outputs returned - none

void lcdblink(int number,int interval)

{

int i,flagvalues;

setupForLCD(&flagvalues);

for(i=0;i<number;i++)

{

microsec(interval);

//Turn the display off

writeToLCD(LCDNORS,0x08,WAITFORBF);

microsec(interval);

//Turn the display on

writeToLCD(LCDNORS,0x0C,WAITFORBF);

}

finishedWithLCD(&flagvalues);

return;

}

Listing 8. lcdblink()

a

The final code listings provide the rest of the

functions used in the code above. This code and

interface can be ported easily to be compatible

with either the ADSP-21161 or ADSP-21065

SHARC DSPs. Since these DSPs do not have

any multiplexing of their programmable flag

pins, it is not necessary to use a DAI pin for the

enable signal.

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 8 of 11

Page 9

a

Appendix

//Pause for a multiple of 100 us

//Inputs passed - duration in units of 100 us

//Outputs returned - none

void microsec(int duration)

{

int i;

for(i=0;i<duration;i++)

{

asm("lcntr=20000, do (pc,1) until lce; \

nop;");

}

return;

}

//Pause for a multiple of 100 ns

//Inputs passed - duration in units of 100 ns

//Outputs returned - none

void nanosec(int duration)

{

int i;

for(i=0;i<duration;i++)

{

asm("lcntr=20, do (pc,1) until lce; \

nop;");

}

return;

}

//Set up the DSP to access the LCD

//Inputs passed - Pointer to location to save the current value of the flags

register

//Outputs returned - none

void setupForLCD(int * flagvalues)

{

int dummy;

asm("%0=flags;":"=d" (*flagvalues));

asm("flags = 0xA8000000;");

asm("flags = 0xA8000000;");

REG(SYSCTL)|=PPFLGS;

SRU(LOW,DAI_PB15_I);

return;

}

//Restore the DSP to the state before accessing the LCD

//Inputs passed - Pointer to the location which contains the saved value of the

flags register

//Outputs returned - none

void finishedWithLCD(int * flagvalues)

{

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 9 of 11

Page 10

int dummy;

SRU(LOW,DAI_PB15_I);

SRU(LOW,PBEN15_I);

REG(SYSCTL)&=(0xFFFFFFFF-PPFLGS);

asm("flags=%0;"::"d" (*flagvalues));

asm("flags=%0;"::"d" (*flagvalues));

return;

}

//Spread a byte of data to match the FLAGS register

//Inputs passed - data = byte of data to spread

//Outputs returned - the 2-byte equivalent of the input

int spreadData(int data)

{

int i,

mask=0xff;

for(i=7;i>0;i--)

{

mask = mask >> 1;

data = (mask&data)|(((0xffffffff-mask)&data)<<1);

}

return data;

}

//Unspread a byte of data to match the FLAGS register

//Inputs passed - data = byte of data to unspread

//Outputs returned - the 2-byte equivalent of the input

int despreadData(int data)

{

int i,

newdata=0,

mask=1;

for(i=0;i<8;i++)

{

newdata |= (mask&data);

mask <<= 1;

data >>= 1;

}

return newdata;

}

a

Listing 9. Other useful functions.

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 10 of 11

Page 11

References

[1] How to Interface an LCD to the 21xx and 2106x Family DSP’s (EE-37). 09/97. Analog Devices Inc.

[2] Hitachi HD44780U (LCD-II) Datasheet. Rev. 0.0. 09/99. Hitachi, Ltd.

[3] Optrex Dot Matrix Character LCD Module User’s Manual. Optrex Corp.

Document History

Revision Description

a

Rev 1 – December 16, 2003

by Brian M.

Initial Version.

Connecting Character LCD Panels to ADSP-21262 SHARC® DSPs (EE-219) Page 11 of 11

Loading...

Loading...