Page 1

Engineer-to-Engineer Note EE-182

a

Technical notes on using Analog Devices DSPs, processors and development tools

Contact our technical support at dsp.support@analog.com and at dsptools.support@analog.com

Or vi sit our o n-li ne r esou rces htt p:/ /www.analog.com/ee-notes and http://www.analog.com/processors

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors

Contributed by Greg F. Rev 1 – February 3, 2004

Introduction

This EE-Note discusses thermal relief design

considerations for Analog Devices ADSPTS201S TigerSHARC® processors. This

document assists PCB and system designers by

providing thermal data as well as heat sink

recommendations to allow for proper design of

their thermal relief system.

The ADSP-TS201S processor is an ultra-highperformance, static superscalar, 32-bit processor

from the TigerSHARC family of Analog Devices

Inc. The processor core operates at a clock

frequency of 500 MHz, and is available in a flipchip ball grid array (BGA_ED) package.

Overview

This EE-Note discusses the following topics:

• Thermal overview

• Thermal calculations

• Heat sink basics

• Heat sinks: pin fins vs. rectangular-fins

• Heat sink recommendations

• Specification recommendations

• Heat sink attachment recommendations

• PCB design for thermal dissipation

• Thermal simulations

• Alternate thermal relief solutions

• Terminology

Thermal Overview

Proper thermal management is required to ensure

that the processor operates within the

temperature specifications provided in the

ADSP-TS201S data sheet [1]. Operating within

the specified temperature range ensures proper

processor operation and reliability.

The overall power estimation can also be used to

estimate a thermal relief budget for the

processor. Equation 1 gives a value for the total

average estimated power. Note that this equation

yields the total estimated average power

consumption for a single ADSP-TS201S in a

given system. Guard-banding this value is

recommended for a thermal relief design that will

allow the system to operate within specified

thermal parameters, even under worst-case

conditions.

P

Equation 1. Total Estimated Average Power

For more information on power consumption for

the ADSP-TS201, refer to the Engineer-toEngineer note EE-170, titled “Estimating Power

for ADSP-TS201S TigerSHARC Processors”

[2], which can be found on the Analog Devices

Web site, at

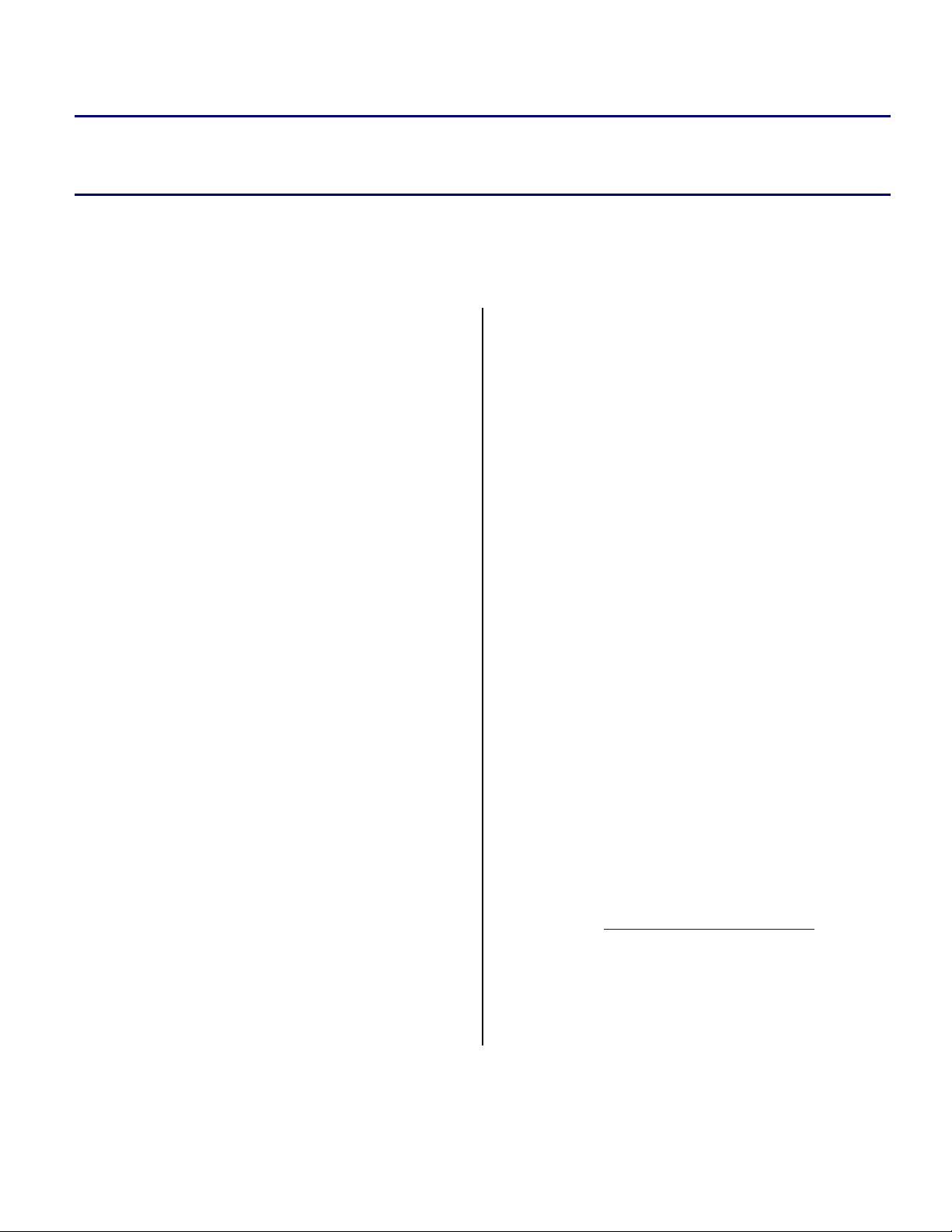

Figure 1 shows the top and side views of the

ADSP-TS201S processor package. This

TigerSHARC processor is available in a 25mm x

25mm BGA_ED package.

= PDD (avg.) + P

THERMAL

(avg.) + P

DD_IO

DD_DRAM

www.analog.com/tigersharc.)

(avg.)

Copyright 2004, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer product design or the use or application of

customers’ products or for any infringements of patents or rights of others which may result from Analog Devices assistance. All trademarks and logos are property

of their respective holders. Information furnished by Analog Devices Applications and Development Tools Engineers is believed to be accurate and reliable, however

no responsibility is assumed by Analog Devices regarding technical accuracy and topicality of the content provided in Analog Devices’ Engineer-to-Engineer Notes.

Page 2

a

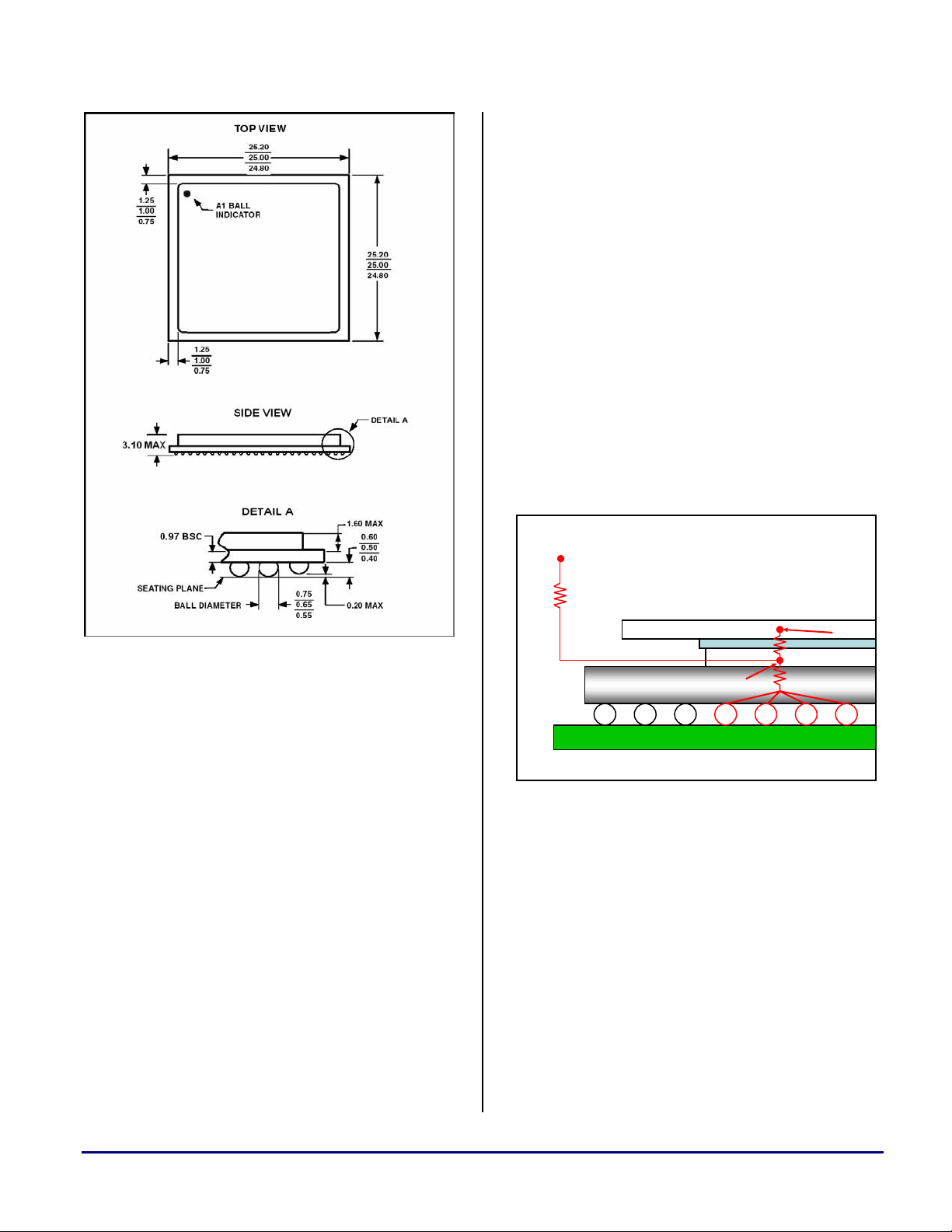

that there are two possible avenues for thermal

heat dissipation: the primary heat dissipation

path (i.e., the path with the least thermal

resistance) is via the “top” of the processor

package (through the thermal path denoted by

θ

), and the secondary heat dissipation path is

JC

through the “bottom” of the processor package,

via the package balls (through the thermal path

denoted by θ

The maximal thermal energy of the processor can

be transferred when the thermal resistance from

each component in the system is minimized.

Thus, the thermal energy generated by the

processor can be dissipated to the cooler ambient

air of the system (or through the PCB by the use

of thermal vias and an internal or external heat

sinking plane).

) to the PCB.

JB

Figure 1. ADSP-TS201S Outline Diagram

The BGA_ED package consists of the laminate

(with the attached ball-grid array on its bottom

surface), and a heat spreader, which is bonded to

the processor die via a thermally conductive

adhesive. The heat spreader aids in thermal

dissipation, since it attaches directly to the

processor die and provides a much larger surface

area than the die. (Increasing the surface area

decreases the overall thermal resistance for a

given surface.)

After thermal calculations have been completed,

if it is determined that a heat sink is necessary in

the system, use a heat sink with a minimum size

of 25mm square for thermal relief of the

processor.

Figure 2 is a simple model of a thermal system,

showings the components of the processor

package. This model shows all of the associated

components present in a thermal system. Note

T

AMB

θ

JA

HEAT SPREADER

LAMINATE

PCB

Figure 2. Thermal System Model Example

THERMAL ADHESIVE

T

JUNCTION

T

CASE

θ

JC

DIE

θ

JB

Note that θJA is a composite parameter that

encompasses all possible paths to the system’s

ambient air temperature based on the JEDEC

X-Y-Z spec. (The values for θ

, θJB, and θJC are

JA

provided in the “Thermal Characteristics”

section of the ADSP-TS201S data sheet.)

Thermal Calculations

To calculate the thermal performance of a

system, the first parameter that should be known

at the time of performing thermal calculations is

the maximum ambient air temperature, T

AMBIENT

of the system. The second parameter that should

,

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors (EE-182) Page 2 of 9

Page 3

a

be known is the value of the processor’s thermal

power consumption (P

THERMAL

). The third

parameter is the junction-to-ambient thermal

resistance, θ

. These three system parameters

JA

are required to calculate the maximum junction

temperature, as shown in Equation 2.

T

Equation 2. Processor Junction Temperature Calculation

JUNCTION

= (P

THERMAL

x θJA) + T

AMBIENT

From the result of Equation 2, we can then use

the calculated value for T

JUNCTION

to solve for the

calculated value for the processor's case

temperature, T

, using Equation 3. The result

CASE

of Equation 3 determines whether a heat sink is

required to allow the ADSP-TS201 to operate

within the thermal operating conditions specified

in the ADSP-TS201S data sheet. If the calculated

value for T

exceeds the maximum specified

CASE

case temperature for the device (from the ADSPTS201S data sheet), a heat sink will be required.

T

(max)= T

CASE

Equation 3. Heat Sink Requirement Equation

JUNCTION

– (P

THERMAL

x θJC)

If a heat sink is required for the processor, an

appropriate heat sink with the proper thermal

performance characteristics must be chosen. The

following two parameters for the heat sink must

be known: the sink-to-ambient (θ

) thermal

SA

resistance, and the thermal resistance of the

thermal interface material (θ

), which resides

CS

between the processor's case and the bottom

surface of the heat sink.

Knowing these two thermal resistance

parameters of the desired heat sink, we can now

calculate the case temperature (T

) of the

CASE

processor with the heat sink attached by using

Equation 4.

T

CASE (MAX)

Equation 4. Derived Heat Sink Requirement Equation

< T

AMBIENT

+ (P

THERMAL

x θSA) + (P

THERMAL

x θCS)

Equation 4 yields a conservative estimate for the

value for T

. This is because there are other

CASE

paths in the system to sink the thermal energy

(for example, through the PCB). A more

comprehensive model of the system to include

these additional paths can be used when

performing the thermal calculations for the

processor. (The value for θ

is provided in the

JB

data sheet of the ADSP-TS201S.)

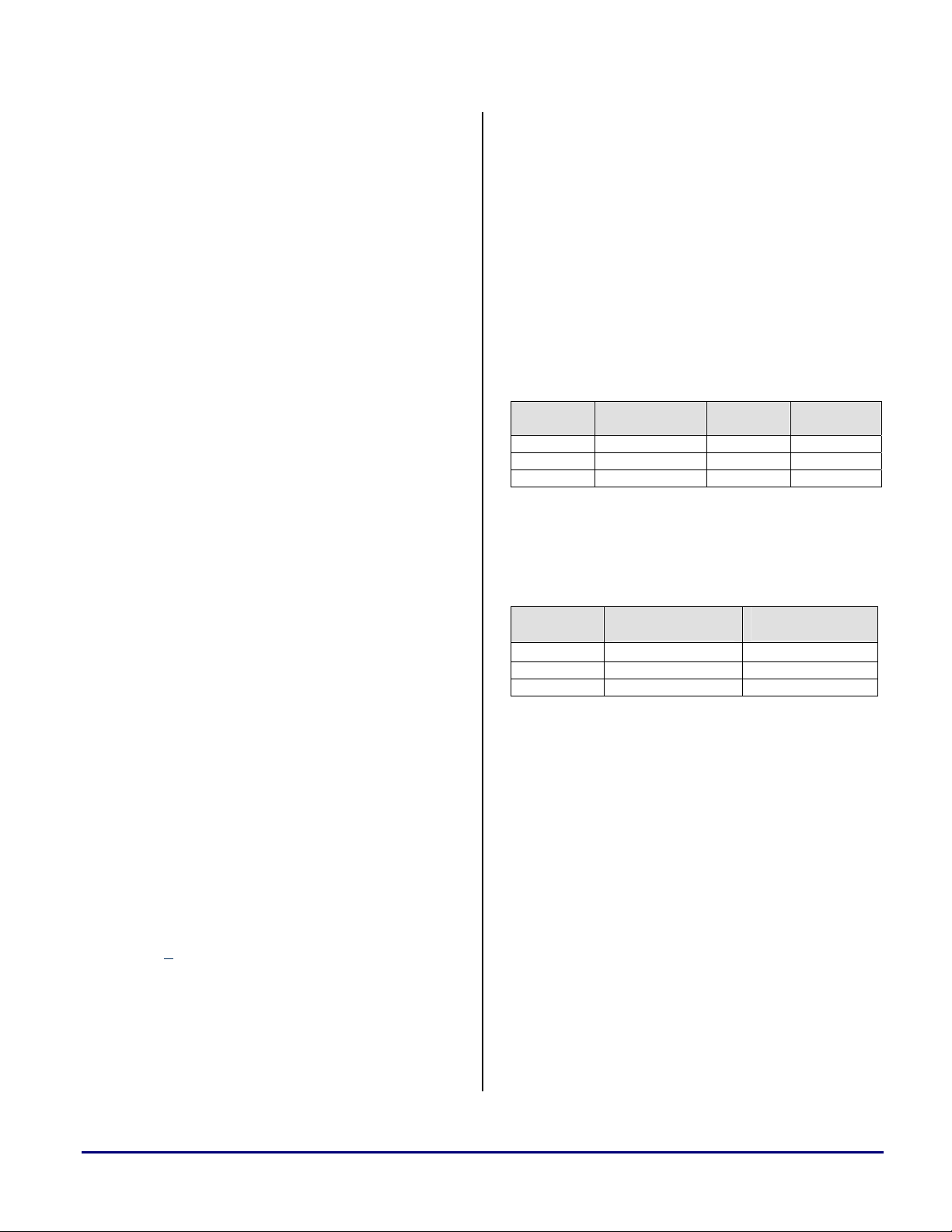

Table 2 shows the thermal resistance parameters

of the BGA_ED package of the processor based

on preliminary thermal parameters.

Air Velocity

(m/s)

0 19.6 8.3 0.7

1 15.4 8.3 0.7

2 13.7 8.3 0.7

Table 2. BGA_ED Thermal Resistance Parameters

θ

Without

JA

Heat Sink (°C/W)

θ

Nominal

JB

(°C/W)

θ

Nominal

JC

(°C/W)

Table 3 shows thermal resistance values for an

AAVID 374224B00032 heat sink. The values

shown in Table 3 are provided as an example.

Air Velocity

(m/s)

0 19.7 10.7

1 6.4 5.5

2 4.8 4.5

Table 3. Heat Sink Thermal Resistance Example

θ

Heat Sink

SA

Resistance (°C/W)

θ

With Heat Sink

JA

(°C/W)

For a specific application, the heat sink’s thermal

resistance values can be obtained from the

particular heat sink vendor.

Using Equation 4 and the data from Table 3, the

required minimal airflow over the heat sink can

be determined to allow for operating the

ADSP-TS201S within the maximum case

temperature specified in the processor's data

sheet. If this value is still insufficient, an active

thermal relief solution is required. See “Alternate

Thermal Relief Designs” later in this document.

If the resultant value from Equation 4 exceeds

the maximum value for T

CASE (MAX)

(from the

ADSP-TS201S data sheet), a heat sink with

better thermal characteristics will be required.

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors (EE-182) Page 3 of 9

Heat Sink Basics

A heat sink is characterized by its thermal

resistance, which describes the flow of heat from

Page 4

a

the heat sink to the ambient air for a given rise in

the heat sink temperature.

Thermal resistance is measured in units of °C/W.

Heat sink to local ambient thermal resistance

(θ

) is a measure of the thermal resistance from

SA

the bottom of the heat sink to the local ambient

air.

Thermal resistance is dependent upon the

following four parameters:

• Heat sink material

• Thermal conductivity of the heat sink

• Geometry of the heat sink

• Air velocity through the fins of the heat sink

Lowering the thermal resistance between the

processor and the ambient air increases the

thermal solution's efficiency.

Copper heat sinks are less thermally resistive

than aluminum, however, they are more

expensive typically. For copper, the value of

thermal resistivity (R) is 0.11; for aluminum the

thermal resistivity value is 0.23. The units for R

are given as °C-inches per Watt.

(See Figure 3.) The channel should be deep

enough and long enough to allow for the

thermocouple to sit at the center of the heat

spreader of the processor.

Place the thermocouple at the center of the heat

spreader. Secure it with a small, single bead of

thermally conductive epoxy. Clean the heat sink

and the heat spreader surfaces with isopropyl

alcohol (100%), and a lint-free cloth or swab

prior to attachment.

Pin Fins versus Rectangular Fins

Pin-Fin

Heat Sink

Rectangular-Fin

Heat Sink

When performing processor case temperature

measurements, measure the case temperature,

T

, at the center of the heat spreader using a

CASE

thermocouple.

Heat Sink

(Bottom View)

Channel

Note:

Thermocouple

should be

located at the

exact center of

the heat

spreader.

Thermocouple

Figure 3. Thermocouple Placement and Heat Sink Channel

If a heat sink is to be used during the thermal

measurements, mill a channel in the heat sink to

facilitate the placement of the thermocouple.

Figure 4. Pin-Fin vs. Rectangular-Fin Heat Sink Example

Although rectangular-fin heat sinks have been

around longer, pin-fin heat sinks perform better

than rectangular-fin heat sinks, especially in

environments that provide little or no airflow in

the system. Due to the omni-directional structure

of pin-fin heat sinks, air can penetrate and exit

the heat sink at every possible angle, providing

more efficiency. The round shape of the

“pin-fins” creates turbulence within the heat

sink; this turbulence breaks the stagnant air

boundary layers around the pins, enhancing the

heat sink’s thermal performance. In addition, the

round pin structure exposes a large percentage of

the surface area to incoming airflow without

presenting an extreme pressure resistance to the

incoming airflow.

Heat sinks of many different sizes are available

from the listed manufacturers. Following is a list

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors (EE-182) Page 4 of 9

Page 5

a

of recommended heat sink manufacturers and

specific heat sinks that exhibit required thermal

relief performance. Visit the Web sites listed

below for more information.

Cool Shield Inc.,

www.coolshieldinc.com:

Figure 5. CSH0xx012 and CSH0xx021 Polymer Heat Sinks

Cool Innovations, www.coolinnovations.com:

4-101005U (pin-fin, copper)

4-101003U (pin-fin, copper)

3-101003U (pin-fin, aluminum)

3-101005M (pin-fin, aluminum)

AAVID Thermalloy, www.aavidthermalloy.com:

Figure 8. AAVID Thermalloy 374224B00032 Heat Sink

Figure 6. Cool Innovations “M” Series Pin-Fin Heat Sinks

Figure 7. Cool Innovations “U” Series Pin-Fin Heat Sinks

Figure 9. AAVID Thermalloy 374224B60023 Heat Sink

Specification Recommendations

The heat sink used to cool the ADSP-TS201S is

recommended to not exceed the weight and

dimension guidelines shown in Table 4. A

horizontal position for the assembled heat sink

and processor package is recommended.

Maximum Heat

Sink Dimension

(mm)

53 x 53 x 16.5 54 200 5

Table 4. Heat Sink Weight and Dimension Guidelines

Do not exceed the maximum lateral and vertical

forces when installing or removing the heat sink.

Analog Devices, Inc. recommends a heat sink

with length and width dimensions of 25mm. This

allows proper coverage of the heat spreader of

Maximum

Weight

(grams)

Minimum

Lateral (X-Y)

Shear Strength

(psi)

Maximum

Vertical (Z)

Force

(Kg)

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors (EE-182) Page 5 of 9

Page 6

a

the processor package. If a larger heat sink

(> 25mm square) is to be used, mechanical

support is necessary to avoid cantilevering of the

heat spreader.

Ensure that the heat sink is centered on the heat

spreader. When using a heat sink of 23mm x

23mm (which are the dimensions of the heat

spreader), used to ensure that the heat sink is

centered on the heat spreader to within 0.06”.

Heat Sink Attachment Recommendations

The thermal heat spreader is designed to increase

the thermal performance of the processor, and is

also the physical interface for attaching a heat

sink. Clear the thermal heat spreader and bottom

surface of the heat sink cleaned with Isopropyl

alcohol (100%) and a clean, lint-free swab before

mating the surfaces. Allow the isopropyl alcohol

to fully evaporate before dispensing the heat sink

adhesive.

Special care should be used when physically

handling the nickel-plated copper BGA_ED

package, since oil in the skin of the fingers can

contaminate the top surface of the thermal heat

spreader. Remove any finger oil, which

contaminates the thermal heat spreader, with

isopropyl alcohol before applying a heat sink or

thermal interface material to the processor.

For ADSP-TS201S processors, Analog Devices,

Inc. recommends three types of heat sink

attachment methods: tape anchor, solder anchor,

and adhesive.

The tape attachment method requires the use of a

thermally conductive adhesive tape that mates

the surfaces of the processor and the heat sink.

The tape serves a dual-purpose since it is also

used to compensate for any small surface

imperfections in either the processor or the heat

sink, which would work as an insulating air

barrier and would therefore increase the thermal

resistance in the system.

A solder anchor attachment method also requires

thermally conductive interface material between

the processor and the heat sink. This interface

material does not aid in attaching the heat sink to

the processor. The advantage to this method is

that a smaller amount of thermal interface

material is required; therefore, less thermal

resistance is introduced into the system. The

disadvantage is that additional board real estate

is required in order to facilitate the use of the

solder anchors on the top of the PCB.

GE Silicones “TSE 3281G” can be used to attach

a heat sink to the heat spreader of the

ADSP-TS201S package. (This material may be

purchased from General Electric Company, 960

Hudson River Road, Waterford, NY 12188 USA.

General Electric’s phone number is (800) 332-

5390.

Consider the adhesive's shelf life when selecting

the adhesive used to attach the heat sink to the

processor’s package. Dispense the adhesive in an

“X” pattern in the center of the nickel-plated heat

spreader; the adhesive is not allowed on the

bottom surface of the package laminate. A small

amount of adhesive is allowed to flow out to the

edge at the heat spreader and heat sink interface.

It is desired that no adhesive flows out of the

interface.

It is recommended that there is 0.45” clearance

on two opposite sides between the BGA_ED

body and the nearest component for heat sink

tool removal access.

The following information is presented for

reference purposes only. Verify any specific

applications needs.

• The adhesive thickness on the bonded surface

is nominally 0.004” (0.10mm) and must not

exceed 0.010” (0.25mm).

• The percentage of covered area of the bonded

surface shall not be less than 80% and must

not exceed 90% of the heat sink surface. The

adhesive must be centered about the heat

spreader’s surface within 0.06” (1.5mm).

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors (EE-182) Page 6 of 9

Page 7

a

• The surfaces to be bonded must be flat to

within 0.004” (0.10mm).

PCB Design for Thermal Dissipation

Figure 10, a thermal model of the BGA_ED

package, shows that more thermal energy will be

dissipated through the top of the package since

the die is upside-down in the package. Due to

design constraints, there may be situations where

sufficient clearance to install a heat sink on the

device may not be available (or there may be

enough room only for a smaller heat sink that

may not have sufficient heat dissipation

characteristics) to allow for thermal power

dissipation to escape through this interface.

T

AMB

T

θ

θ

PA

HEAT SPREADER

LAMINATE

THERMAL ADHESIVE

DIE

T

JUNCTION

θ

θ

SINK

SA

CS

T

CASE

θ

JC

JB

Performing thermal simulations on a given

system is one method of ensuring proper system

performance.

Correct processor performance is not guaranteed

if T

value for T

is exceeded; ensure that the operating

CASE

is within the range specified in

CASE

the ADSP-TS201S data sheet.

Below is a listing of vendors that provide thermal

simulation software. These companies can also

provide thermal simulation assistance.

• Maya (

• Flotherm (

http://www.mayahtt.com/home.asp)

http://www.flowtherm.com)

• ThermoAnalytics, Inc.

(

http://www.thermoanalytics.com)

• Harvard Thermal Inc.

(

http://www.harvardthermal.com)

Alternate Thermal Relief Designs

In some specific cases, a passive thermal relief

solution may not be sufficient for cooling the

processor to within its specified operating

temperature range. Alternate thermal relief

solutions that may be applicable to specific

system application include:

• Heat sink fans

PCB

T

PCB

Figure 10. ADSP-TS201S BGA-ED Thermal Model

In this situation, thermal energy can be dissipated

from the solder balls of the BGA_ED package to

a heat sinking plane of the PCB. Thermal vias in

the PCB can be used in conjunction with a heat

sinking plane (i.e., a copper layer or some other

type of thermally conductive material) of

• Heat pipes

• Forced airflow (ducting)

Heat Sink Fans

A heat sink and fan combination is probably the

simplest method in achieving better thermal

relief performance over a passive system. The

heat sink fan increases the flow of air across the

heat sink, which aids in decreasing the overall

thermal resistance of the heat sink.

sufficient area to allow thermal transfer to a heat

sink or some other means of thermal relief.

Pros: Better thermal relief performance is

achieved with the same heat sink.

Thermal Simulations

Cons: A fan requires additional system power. It

also consumes additional space in the system,

Due to the high-performance of modern DSPbased systems, proper thermal management is

regardless whether the fan is located on top of or

next to the heat sink.

critical for desired performance and operation.

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors (EE-182) Page 7 of 9

Page 8

a

Heat Pipe

A heat pipe can be used as a thermal relief

solution when there is insufficient height in a

system to allow placement of a heat sink, or the

height requirements limit the use of specific heat

sinks that exhibit insufficient thermal

characteristics. In this case, a heat pipe can

conduct thermal energy away from the processor

(via a cooling plate and a thermally conductive

pipe filled with a pressurized coolant) to a

remote heat sink and system fan to dissipate the

thermal energy to cooler air outside of the

system.

HEAT

PIPE

COOLING

COOLING

PLATE

FINS

Pros: The air duct (and fan combination) draw

cooler outside air into the enclosure and across

the processor’s heat sink. The air duct can be

designed to increase the speed of the air that

flows through it, increasing the cooling

characteristics of the system; a smaller fan can be

used in this case, decreasing overall system

noise. Lastly, air ducts can also isolate the

processor from the effects of system heating

(caused by other system components, such as a

linear regulator.)

Cons: Since air ducts are custom designed, they

can be expensive when compared to a heat sink.

Terminology

P

: The total power consumed on the VDD

DD

voltage domain by the TigerSHARC core. This is

an average value.

P

voltage domain by the Link Ports and Cluster

Bus of the TigerSHARC processor. This value is

system dependent, and is an average value.

: The total power consumed on the V

DD_IO

DD_IO

Figure 11. Heat Pipe Example

Pros: Heat pipes can be advantageous in systems

where a heat sink may be physically too large to

install.

Cons: Compared to a heat sink or fan sink

design, heat pipes are typically custom designed

and can be expensive.

Forced Airflow and Air Ducts

Forced airflow or ducting is another means to

achieve better cooling performance over a

passive design. Forced airflow is advantageous

in system designs with small enclosures that may

be so small that a fan of sufficient airflow

characteristics and size may not fit. A fan

external to the enclosure draws in or expels air

through an air duct, forcing air across the

processor heat sink.

P

DD_DRAM

: The total power consumed by the

internal DRAM of the processor. This is an

average value.

P

THERMAL

: Total power consumed by the

processor. This is an average value.

Heat transfer coefficient: theta (

θ

), given in

°C/W.

Thermal resistance: A measure of the flow of

heat from one medium to another.

Thermal equilibrium: System state when the

electrical power dissipated in the device is equal

to the heat flow out of the device.

T

AMBIENT

: The temperature of the local air

surrounding the processor in the system.

T

: The case temperature of the processor.

CASE

T

JUNCTION

T

SINK

: The processor junction temperature.

: The temperature of the heat sink.

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors (EE-182) Page 8 of 9

Page 9

a

θ

: The thermal resistance between the case of

CA

the processor and the ambient air.

θ

: The thermal resistance between the junction

JA

of the processor and the ambient air.

θ

: The thermal resistance between the junction

JB

and the balls of the package.

θ

: The thermal resistance between the junction

JC

and the case of the processor.

θ

: The thermal resistance between the heat sink

SA

and the ambient air. This is also sometimes

known as the thermal resistance of the thermal

interface material (applied between the heat sink

and the processor package), or θ

TIM

.

References

[1] ADSP-TS201S TigerSHARC Embedded Processor Preliminary Data Sheet. Rev PrH, January 2004.

Analog Devices, Inc.

[2] Estimating Power for ADSP-TS201S TigerSHARC Processors (EE-170)

. In preparation. Analog Devices, Inc.

Document History

Version Description

Rev 1 – February 3, 2004

by Greg F.

Public Release

Thermal Relief Design for ADSP-TS201S TigerSHARC® Processors (EE-182) Page 9 of 9

Loading...

Loading...