Engineer To Engineer Note EE-181

Technical Notes on using Analog Devices' DSP components and development tools

a

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF

Digital Camera "OV6630" over the External Memory Bus

Contributed by Thorsten Lorenzen April 17, 2003

Contact our technical support by phone: (800) ANALOG-D or e-mail: dsp.support@analog.com

Or vi sit ou r on-l ine re sourc es ht tp:// www.analog.com/dsp and http://www.analog.com/dsp/EZAnswer

s

1 Introduction

The purpose of this note is to describe how to

hook up video devices like a CIF (Common

Interface Format) Single–Chip Digital Camera to

the external bus of the ADSP-BF535 Blackfin®

Processor. Because of its architecture and video

processing capabilities, Blackfin Processors will

interface with video devices. The ADSP-BF535

as the first part of the Blackfin family is not

equipped with a standard interface that glueless

interact with video devices. This note is

dedicated to show how the Asynchronous

Interface can be used to receive video in CIF

sizes.

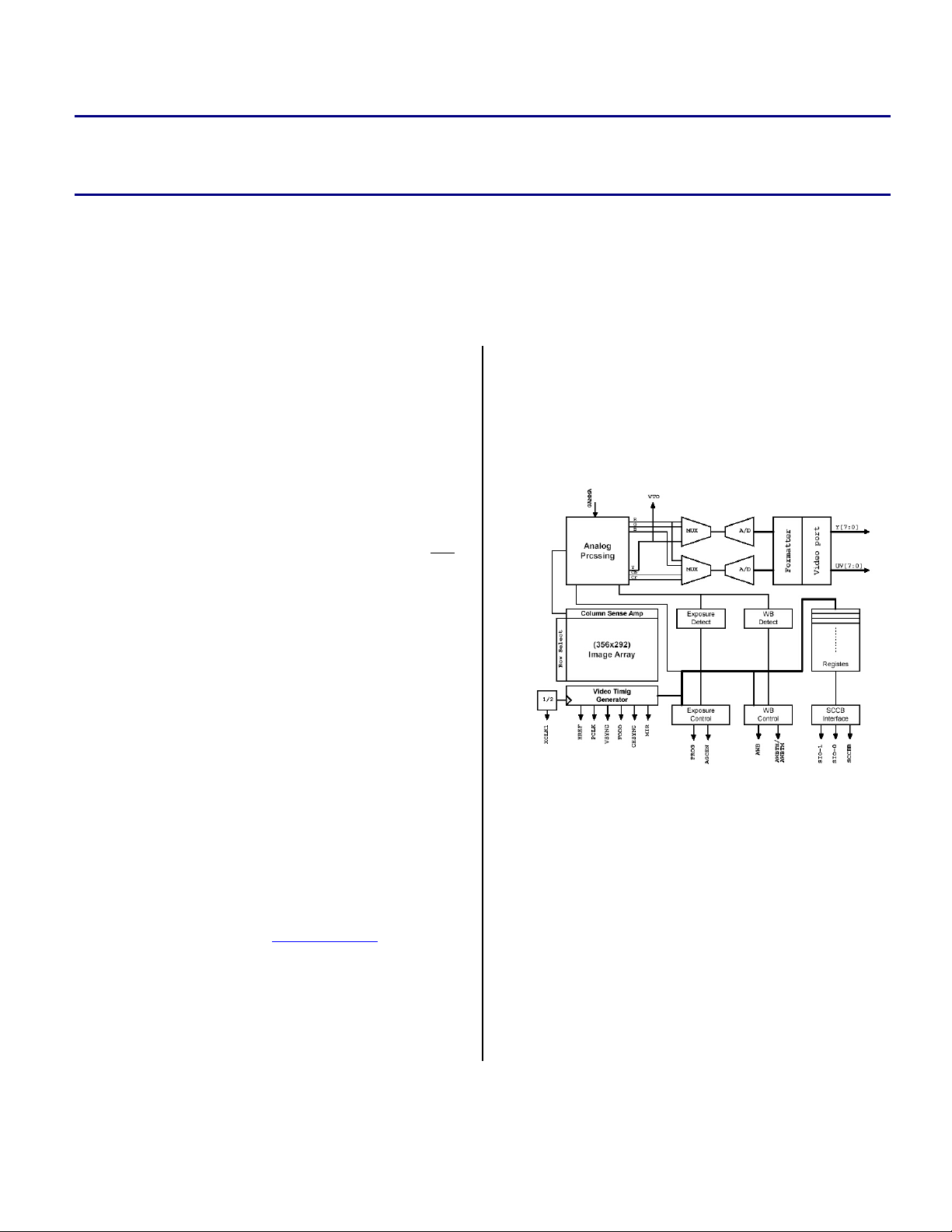

2 Output Format of the OV6630

The OV6630 is a CMOS Image sensor provided

as a single chip video/imaging camera device

designed to provide a high level functionality in

a single, small-footprint package. For more

details about the functionality it is referred to the

internet address below. In order to explain the

way been accessed by the ADSP-BF535

Processor see the schematic of the required

output pins in figure 2.1. The datasheet for the

OV6630 can be found at www.ovt.com

As it can be seen in figure 2.1 the pins Y[7:0]

and UV[7:0] are required to transfer data. The

PCLK represents the clock aligned to the data.

Each raising edge of the PCLK will indicate

valid data on the bus. These pins are necessary

and must be linked to the ADSP-BF535 for data

transfers. Additionally, some pins are required

for device control and configuration purposes.

The pin HREF asserted (polarity can be chosen)

indicates active video pixels (image data).

Figure 2.1

Because of the programmable sensor size as it is

discussed below HREF provides a way to

distinguish between active video pixels and

blank data. The blank data of the modified senor

field will also be transferred and is represented

by hex “10” on Y[7:0] and hex “80” UV[7:0].

Figure 2.2 shows a transfer of one pixel,

blanking and HREF indicating an active pixel.

Due to the configuration the sensor is set to

output over a 16 -bit bus in this note. One pixel

exists of one byte of luminance and one byte of

Copyright 2003, Analog Devices, Inc. All rights reserved. Analog Devices assumes no responsibility for customer product design or the use or application of

customers’ products or for any infringements of patents or rights of others which may result from Analog Devices assistance. All trademarks and logos are property

of their respective holders. Information furnished by Analog Devices Applications and Development Tools Engineers is believed to be accurate and reliable, however

no responsibility is assumed by Analog Devices regarding technical accuracy and topicality of the content provided in Analog Devices’ Engineer-to-Engineer Notes.

a

chrominance information that can be transferred

the same time.

Figure 2.2

The windowing feature of the OV6630 image

sensors allows user-definable window sizing as

required by the application. Window size setting

(in pixels) ranges from 2 x 2 to 356 x 292, and

can be positioned anywhere inside the 356 x 292

boundary.

Note that modifying window size and/or position

does not change frame or data rate. The OV6630

imager alters the assertion of the HREF signal to

be consistent with the programmed horizontal

and vertical region. The default output window is

352 x 288. Figure 2.3 shows it graphically.

the VSYNC pin on channel 1 and the HREF pin

on channel 4. It can be seen if the sensor is set to

transfer e.g. 200 lines the HREF will be asserted

200 times also. Each start of frame will be

indicated by VSYNC around 2 ms before HREF

asserts.

Figure 2.4

The video output port of the OV6630 image

sensor provides a number of output format /

standard options to suit many different

application requirements. These formats are user

programmable through Omnivision’s SCCB two

wire control interface.

The OV6630 imager supports both ITU-601 and

ITU-656 output formats in different

configurations.

In this note the sensor is set to provide

differential video signals (YUV) 4:2:2, 16-bit

wide and clocked at 8.867MHz (PCLK).

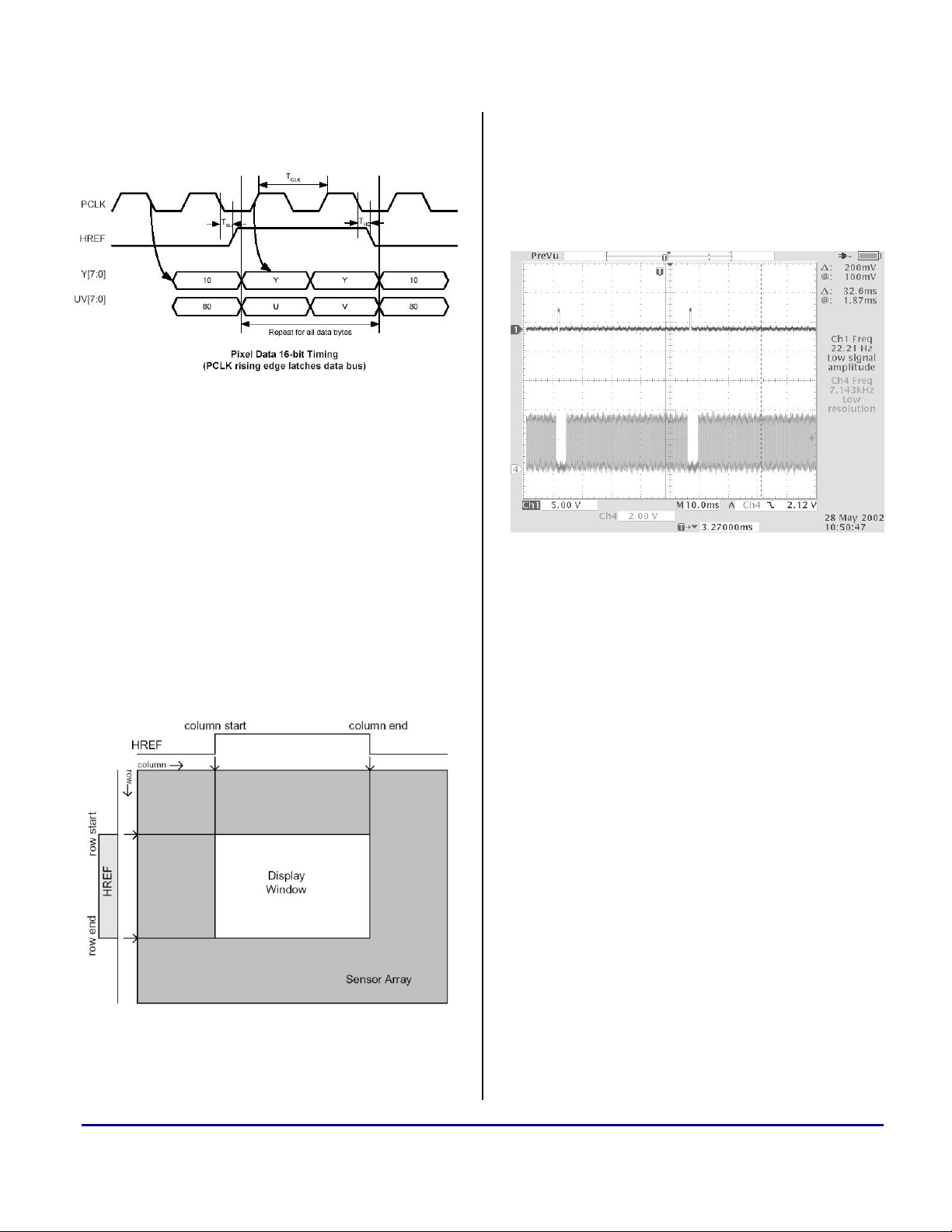

3 Asynchronize Interface of the ADSP-BF535 Blackfin Processor

The Processors asynchronous interface is used to

receive the video data. 32-bit data can be fetched

in a manner it is shown in figure 3.1.

Figure 2.3

In order to detect the first line of each frame the

signal VSYNC asserts before. Figure 2.4 shows

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 2 of 10

Figure 3.1

As mentioned in the ADSP-BF535 Blackfin

Hardware Reference Manual after a read cycle is

initiated the Async Memory Select line (/AMS) ,

Async Ouput Enable line (/AOE) and the Async

Read Enable line (/ARE) become asserted. After

a multicycle “Read Access” delay (Configured

by the Async Interface Bank Control Register),

the /ARE pin normally de-assert to complete the

read operation. But if the interface is configured

to extend the access, the /ARE pin remains low

until the ARDY pin has been sampled high. The

data will be fetched one cycle after this

happened.

a

Figure 3.2

Note also that each DMA transfer is split into

bursts of eight accesses (in this configuration,

four bursts per DMA execution). Understanding

this behavior is crucial for developing a proper

DMA interface. Figure 3.3 zooms into one of

these burst patterns to analyze how many cycles

are taken for each access.

Due to the architecture of the ADSP-BF535, a

DMA-controlled data download is somewhat

non-intuitive. Each data transfer is split into

bursts of eight read access. After the burst, a gap

appears because of internal bus activity. Figure

3.2 illustrates this.

As shown in the figure, the first DMA is set up to

read 32 data words (shown as Channel 2, the

/ARE signal). The large gap before the next

DMA is required for loading the next DMA

descriptor.

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 3 of 10

Figure 3.3

The peripheral clock “SCLK” is displayed in

channel 1 and channel 2 shows the /ARE pin.

After eight read strobes are done nine extra

cycles are taken to place the data into internal

memory.

a

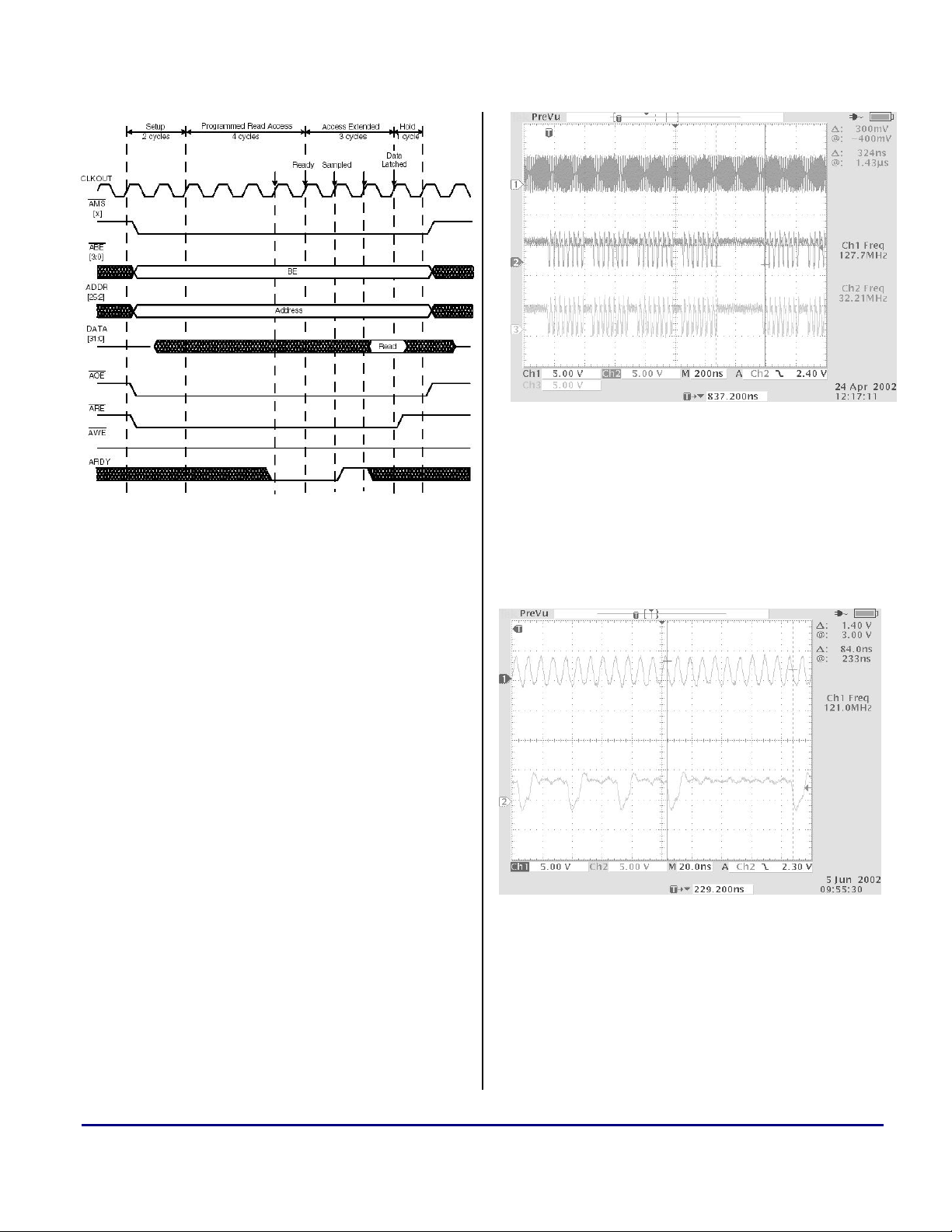

4 Interface the ADSP-BF535 Processor into the OV6630

The ADSP-BF535 is configured to make full use

of its 32-bit external memory interface, in order

to gain maximum throughput. Two 16-bit words

from the camera will be packed into one 32-bit

word before being read by the Blackfin

Processor.

To interface to the single-chip camera,

LVT16374 latches are used. These parts are able

to fetch the data received from the video device

and latch it until the Asynchronous Interface has

been read.

The 8.867 MHz PCLK of the OV6630 clocks a

74HC74 configured as a /2 divider. The 4.43

MHz output then clocks an LVT16374 to fetch

the data transmitted by Y[7:0] and UV[7:0] at the

rising edge. The data will be held in the

LVT16374 until the next rising edge of the

CLOCK “CK” appears.

When /OE asserts, the Processor reads the data

latched by the LVT16374.

The ADSP-BF535 provides 256kBytes of

internal L2 Memory. One frame of CIF video

contains 352 X 288 pixels. Each pixel can be

represented in two bytes under the 4:2:2 digital

component video representation. This equates to

202,752 bytes per frame. As shown in Figure 5.2,

storing the blanking data as well would

obviously cause the memory to overflow.

The use of the AND gate shown in Figure 4.1

stops the data transfer to avoid storing blanking

data to the internal memory. The AND gate is

controlled by the HREF signal of the camera.

HREF remains high during active video

transfers. The memory will be filled just with

active video data.

To detect the first line of each frame, the

VSYNC signal can be used as mentioned in

section 2. VSYNC is connected to a

programmable flag and generates an interrupt

before the start of a frame. This interrupt will

enable the DMA transfer.

Figure 5.1 shows how the timing requirements of

the camera and the Processor are met.

The ARDY pin is used to synchronize the video

data with the ADSP-BF535. As long as the

ARDY pin is low, the access is held off? This

way, the camera is able to control the

asynchronous memory interface.

By routing a GPIO pin to the PWDN pin of the

OV6630, the sensor can be turned off without the

lose of configurations done during setup time by

the SCCB bus.

By routing a GPIO pin to the PWDN pin of the

OV6630, the sensor can be turned off without the

lose of configurations done during setup time by

the SCCB bus.

5 Data Structure and Improvements

As mentioned in section 2, the camera sends

active data plus blanking data sequentially.

Blanking data does fill the internal memory but

doesn’t contain any useful information.

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 4 of 10

a

Figure 4.1

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 5 of 10

a

f

f

f

f

A

At the raising edge

of PCLCK video

data can be taken

PCLCK = 8.867 MHz

OV6630

OV6630 Data Port

Y[7:0]

74HC74 [Q0] to

Top LVT16374 [CK]

74HC74 [Q0/] to

Bottom LVT16374 [CK]

ARDY

To half the frequency

each raising edge o

PCLCK will change the

state of the FlipFlops

output “74HC74”.

4.43 MHz

Each rising edge o

74HC74s Q & /Q will

fetch data to the certain

latch.

AOE/

Top LVT16374 Q[15:0]

To DSP D[15:0]

Each rising edge o

74HC74s Q & /Q will

put data to the output

/AOE remains low until

Figure 5.1

Each rising edge o

/AOE will fetch 32 bits

of data into the DS

P

ARDY is sampled high

fter each read burst one

access takes longer. That

does not affect the transfer

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 6 of 10

a

Figure 5.2

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 7 of 10

a

Conclusion:

The goal of this project is to show how video

sources can be connected to the ADSP-BF535

with less glue logic as possible. In fact, the

maximum resolution that can be achieved is

video in formats up to CIF (352 x 288). The

actual resolution is limited due to the limitation

of Blackfins external port timing, the DMA

structure and the internal memory.

The external port halts during the I/O processor

loads the next DMA descriptor when it has been

expired. That causes a large gap in the timing

(mentioned in chapter 3) and would not meet the

requirement set by the camera. A way out of this

problem is to set up the DMA downloading each

frame separately. So a DMA expires after

receiving each frame and will be reloaded during

the camera send blank data anyway (The camera

sends blank data between each line and each

frame).

The DMA Word Count Register is limited to the

maximum of 65,536 (2^16). A frame of CIF

format video in 4:2:2 standard is represented by

202,752 bytes (352*288 pixels * 2 bytes) . The

Processor accesses over a 32-bit interface results

in 50,688 words (202,752bytes /4 (bytes/word)).

That fits in the DMAs Word Count Register.

Resolutions higher than CIF could probably not

be served by the DMA on a frame by frame

basis. That causes the DMA to become reloaded

during active video pixel transfers and results in

data misses.

Building an interface like it is done in this note

the access to SDRAM or SRAM is not supported

anymore. Except the use of the PCI, SPORT, SPI

and USB data can just be stored in L1 or L2

memory. The ADSP-BF535 provides 52k of L1

memory and 256k bytes of L2 memory. L2

memory is be able to keep one frame of video in

CIF consisting of 202,752 bytes. Higher

resolutions does not fit in it.

A picture of the system is shown in figure C1.

Video transfers with higher resolutions

L

than CIF it is revered to the Note:

“Interfacing the ADSP-BF535 to

ADV7185/3 NTSC/PAL video decoder

over the External Memory Bus”.

This Note is available soon.

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 8 of 10

a

Figure C1

References:

-www.ovt.com

-OV6630 Datasheet

-OV7610MD Eva Board

-ADSP-BF535 Datasheet

-ADSP-BF535 Blackfin DSP Hardware Reference

-VisualDSP++™ 3.0

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 9 of 10

a

Document History

Version Description

April 17, 2003 Ported code example to VisualDSP++ 3.1

Changed according to new Blackfin naming convention.

January 23, 2003 Typos. Schematics, Gerber files and PDFs are attached to the web site

January 09, 2003 Initial release

August 06, 2002 Rev. 0.2

Interfacing the ADSP-BF535 Blackfin® Processor to Single-CHIP CIF Digital Camera "OV6630" over the External

Memory Bus (EE-181) Page 10 of 10

Loading...

Loading...