12-Bit High Speed Multiplying

a

FEATURES

Differential Nonlinearity: 61/2 LSB

Nonlinearity: 0.05%

Fast Settling Time: 250 ns

High Compliance: –5 V to +10 V

Differential Outputs: 0 to 4 mA

Guaranteed Monotonicity: 12 Bits

Low Full-Scale Tempco: 10 ppm/8C

Circuit Interface to TTL, CMOS, ECL, PMOS/NMOS

Low Power Consumption: 225 mW

Industry Standard AM6012 Pinout

Available In Die Form

GENERAL DESCRIPTION

The DAC312 series of 12-bit multiplying digital-to-analog converters provide high speed with guaranteed performance to

0.012% differential nonlinearity over the full commercial operating temperature range.

The DAC312 combines a 9-bit master D/A converter with a

3-bit (MSBs) segment generator to form an accurate 12-bit D/A

converter at low cost. This technique guarantees a very uniform

step size (up to ±1/2 LSB from the ideal), monotonicity to

12-bits and integral nonlinearity to 0.05% at its differential current outputs. In order to provide the same performance with a

12-bit R-2R ladder design, an integral nonlinearity over temperature of 1/2 LSB (0.012%) would be required.

The 250 ns settling time with low glitch energy and low power

consumption are achieved by careful attention to the circuit design and stringent process controls. Direct interface with all

popular logic families is achieved through the logic threshold

terminal.

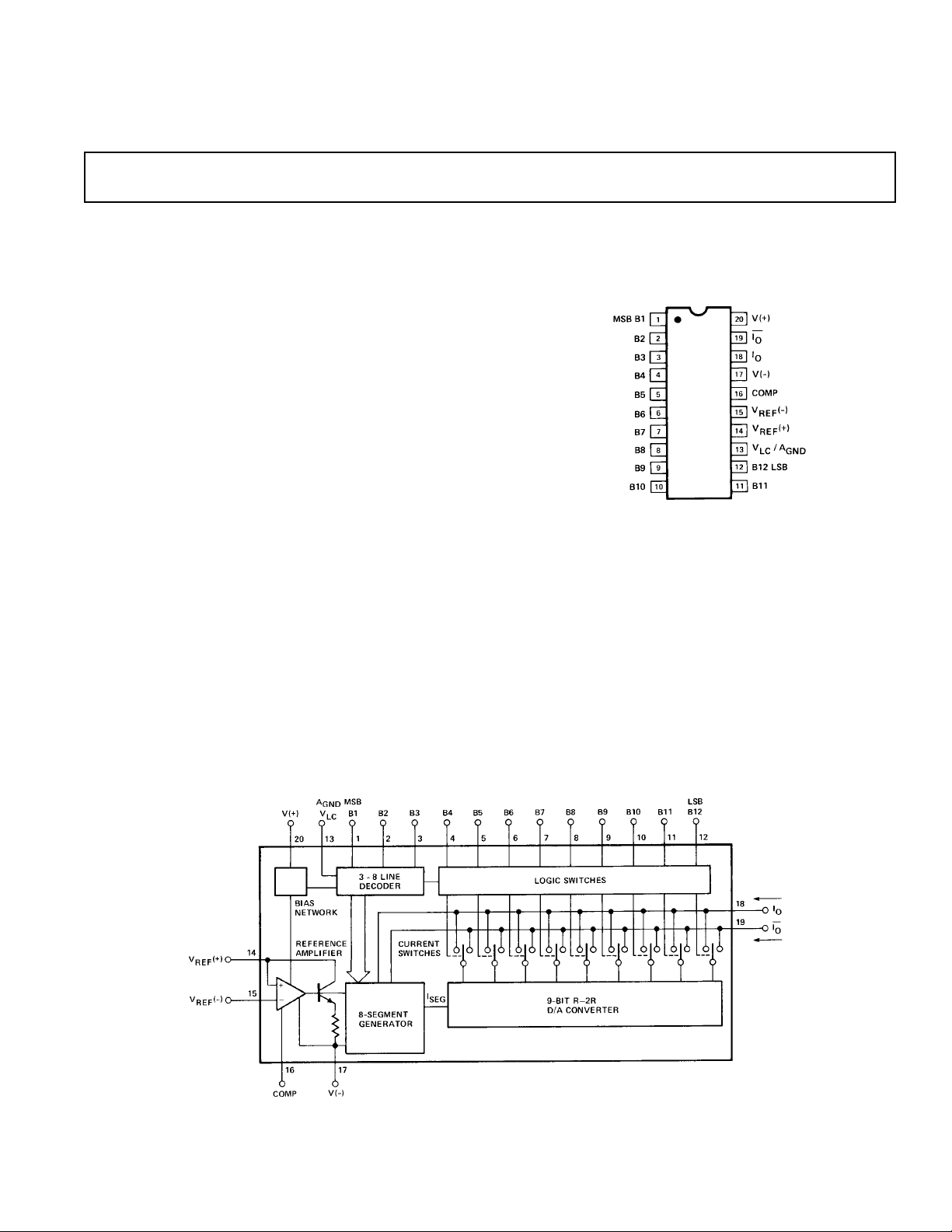

FUNCTIONAL BLOCK DIAGRAM

D/A Converter

DAC312

PIN CONNECTIONS

20-Pin Hermetic DIP (R-Suffix),

20-Pin Plastic DIP (P-Suffix),

20-Pin SOL (S-Suffix)

High compliance and low drift characteristics (as low as

10 ppm/°C) are also features of the DAC312 along with an excellent power supply rejection ratio of ± .001% FS/%∆V. Operating over a power supply range of +5/–11 V to ± 18 V the

device consumes 225 mW at the lower supply voltages with an

absolute maximum dissipation of 375 mW at the higher supply

levels.

With their guaranteed specifications, single chip reliability and

low cost, the DAC312 device makes excellent building blocks

for A/D converters, data acquisition systems, video display drivers, programmable test equipment and other applications where

low power consumption and complete input/output versatility

are required.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

© Analog Devices, Inc., 1996

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

DAC312–SPECIFICA TIONS

(@ VS = 615 V, I

= 1.0 mA, 08C ≤ TA ≤ +708C for DAC312E and –408C ≤ TA ≤ +858C

REF

for DAC312F, DAC312H, unless otherwise noted. Output characteristics refer

ELECTRICAL CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Min Typ Max Min Typ Max Units

Resolution 12 12 12 Bits

Monotonicity 12 12 12 Bits

Differential Nonlinearity DNL Deviation from Ideal ±0.0125 ±0.0250 ±0.0250 %FS

Nonlinearity INL Deviation from Ideal ±0.05 ± 0.05 ± 0.05 %FS

Full-Scale Current I

Full-Scale Tempco TCI

FS

FS

2

Step Size

Straight Line

V

= 10 V

REF

= R

= 10 kΩ

R

14

15

1

to both I

2

and I

OUT

DAC312E DAC312F DAC312H

3.967 3.999 4.031 3.935 3.999 4.063 3.935 3.999 4.063 mA

± 5 ± 20 ±10 ±40 ±80 ppm/°C

± 0.005 ± 0.002 ±0.001 ± 0.004 ±0.008 %FS/°C

.)

OUT

±0.5 ±1 ±1 LSB

Output Voltage Compliance V

Full-Scale Symmetry I

Zero-Scale Current I

Settling Time t

Propagation Delay–All Bits t

Output Resistance R

Output Capacitance C

Logic Input

Levels “0” V

Levels “1” V

Logic Input Current I

Logic Input Swing V

Reference Bias Current I

Reference Input

Slew Rate dl/dt R

Power Supply Sensitivity PSSI

Power Supply Range V+ V

Power Supply Current I+ V+ = +5 V, V– = –15 V 3.3 7 3.3 7 3.3 7 mA

Power Dissipation P

OC

FSS

ZS

S

PLH

t

PHL

O

OUT

IL

IH

IN

IS

15

FS+

PSSI

FS–

V– V

I– V+ = +15 V, V– = –15 V –13.9 –18 –13.9 –18 –13 9 –18 mA

I+ V+ = +5 V, V– = –15 V 3.9 7 3.9 7 3.9 7 mA

I– V+ = +15 V, V– = –15 V –13.9 –18 –13.9 –18 –13.9 –18 mA

d

DNL Specification Guaranteed over Compliance Range –5 +10 –5 +10 –5 +10 V

|IFS|–|IFS| ± 0.4 ± 1 ±0.4 ±2 ± 0.4 ± 2 µA

To ± 1/2 LSB, All Bits

Switched ON or OFF

All Bits Switched 50% Point 25 50 25 50 25 50 ns

Logic Swing to 50% Point 25 50 25 50 25 50 ns

1

Output

V

= GND 0.8 0.8 0.8 V

LC

VLC = GND 2 2 2 V

VIN = –5 to +18 V 40 40 40 µA

= 800 Ω, CC = 0 pF14 8 48 48 mA/µs

14(eq)

V+ = +13.5 V to +16.5 V,

V– = –15 V ±0.0005 ±0.001 ±0.0005 ±0.001 ± 0.0005 ±0.001 %FS/%∆V

V– = –13.5 V to –16.5 V,

V+ = +15 V ±0.00025 ±0.001 ±0.00025 ±0.001 ±0.00025 ±0.001 %FS/%∆V

= 0 V 4.5 18 4.5 18 4.5 18 V

OUT

= 0 V –18 –10.8 –18 –10.8 –18 –10.8 V

OUT

V+ = +5 V, V– = –15 V 225 305 225 305 225 305 mW

V+ = +15 V, V– = –15 V 267 375 267 375 267 375 mW

1

250 500 250 500 250 500 ns

>10 >10 >10 MΩ

20 20 20 pF

–5 +18 –5 +18 –5 +18 V

0 –0.5 –2 0 –0.5 –2 0 –0.5 –2 µA

0.10 0.10 0.10 µA

TYPICAL ELECTRICAL CHARACTERISTICS

characteristics refer to both I

OUT

and I

OUT

.

@ 258C; VS = 615 V, and I

= 1.0 mA, unless otherwise noted. Output

REF

DAC312N DAC312G

Parameter Symbol Conditions Typical Typical Units

Reference Input

Slew Rate dl/dt 8 8 mA/µs

Propagation Delay t

Settling Time t

PLH

S

, t

PHL

Any Bit 25 25 ns

To ±1/2 LSB, All

Bits Switched ON 250 250 ns

or OFF.

Full-Scale TC

IFS

±10 ±10 ppm/°C

–2–

REV. C

DAC312

ELECTRICAL CHARACTERISTICS

DAC312F, DAC312H, unless otherwise noted. Output characteristics refer to both I

@ VS = 615 V, I

= 1.0 mA, 08C ≤ TA ≤ 708C for DAC312E and –408C ≤ TA ≤ +858C for

REF

OUT

and I

.

Continued

OUT

DAC312E DAC312F DAC312H

Parameter Symbol Conditions Min Typ Max Min Typ Max Min Typ Max Units

Logic Input

Levels “0” V

IL

V

= GND 0.8 0.8 0.8 V

LC

Logic Input

Levels “1” V

IH

VLC = GND 2 2 2 V

Logic Input

Current I

IN

VIN = –5 V to +18 V 40 40 40 µA

Logic Input

Swing V

IS

–5 +18 –5 +18 –5 +18 V

Reference Bias

Current I

15

Reference Input dl/dt R

= 800 Ω 4 8 4 8 4 8 mA/µs

14(eq)

0 –0.5 –2 0 –0.5 –2 0 –0.5 –2 µA

Slew Rate CC = 0 pF (Note 1)

V+ = +13.5 V to +16.5 V, ±0.0005 ±0.001 ±0.0005 ± 0.001 ±0.0005 ±0.001 %FS/%∆V

Power Supply PSSI

Sensitivity PSSI

V– = –15 V

FS+

V– = –13.5 V to –16.5 V, ±0.00025 ±0.001 ±0.00025 ±0.001 ±0.00025 ±0.001 %FS/%∆V

FS–

V+ = +15 V

Power Supply V+ 4.5 18 4.5 18 4.5 18

Range V– V

= 0 V –18 –10.8 –18 –10.8 –18 –10.8 V

OUT

I+ 3.3 7 3.3 7 3.3 7

Power Supply I– V+ = +5 V, V– = –15 V –13.9 –18 –13.9 –18 –13.9 –18

Current I+ V+ = +15 V, V– = –15 V 3.9 7 3.9 7 3.9 7 mA

I– –13.9 –18 –13.9 –18 –13.9 –18

Power V+ = +5 V, V– = –15 V 225 305 225 305 225 305

Dissipation P

NOTES

1

Guaranteed by design.

2

TA = +25°C for DAC312H grade only.

Specifications subject to change without notice.

d

V+ = +15 V, V– = –15 V 267 375 267 375 267 375 mW

REV. C

–3–

DAC312

WAFER TEST LIMITS

@ VS = 615 V, I

= 1.0 mA, TA = 258C, unless otherwise noted. Output characteristics refer to both I

REF

OUT

and I

OUT

.

DAC312N DAC312G

Parameter Symbol Conditions Limit Limit Units

Resolution 12 12 Bits min

Monotonicity 12 12 Bits min

Nonlinearity ±0.05 ± 0.05 %FS max

Output Voltage Full-Scale Current +10 +10 V max

Compliance Voc Change <1/2 LSB –5 –5 V min

Full-Scale V

= 10.000 V 4.031 4.063 mA max

REF

Current R14, R15 = 10.000 kΩ 3.967 3.935 mA min

Full-Scale Symmetry I

Zero-Scale Current I

FSS

ZS

±1 ±2 µA max

0.1 0.1 µA max

Differential DNL Deviation from ±0.012 ±0.025 %FS max

Nonlinearity Ideal Step Size ±1/2 ±1 Bits (LSB) max

Logic Input Levels “0” V

Logic Input Levels “1” V

Logic Input Swing V

IL

IH

IS

VLC = GND 0.8 0.8 V max

VLC = GND 2 2 V min

+18 +18 V max

–5 –5 V min

Reference Bias

Current I

Power Supply PSSI

Sensitivity PSSI

Power Supply I+ V

Current I– I

Power V

Dissipation P

NOTE

Electrical tests are performed at wafer probe to the limits shown. Due to variations in assembly methods and normal yield loss, yield after packaging is not guaranteed

for standard product dice. Consult factory to negotiate specifications based on dice lot qualification through sample lot assembly and testing.

15

FS+

FS–

D

V+ = +13.5 V to +16.5 V, V– = –15 V ±0.001 ±0.001

V– = –13.5 V to –16.5 V, V+ = +15 V ±0.001 ±0.001 %/%max

= +15 V 7 7

S

≤ 1.0 mA –18 –18 mA max

REF

= +15 V

S

I

≤ 1.0 mA 375 375 mW max

REF

–2 –2 µA max

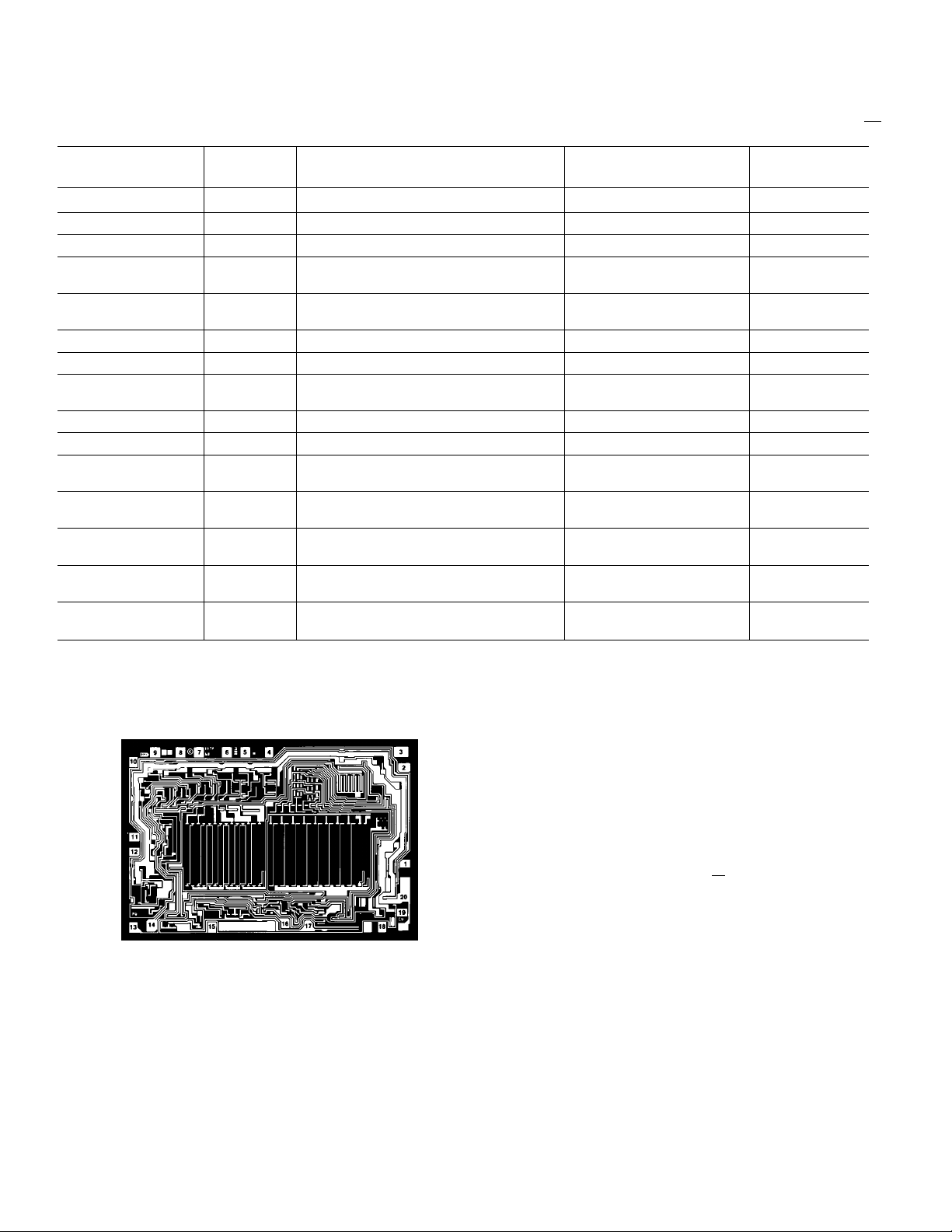

DICE CHARACTERISTICS

DIE SIZE 0.141 × 0.096 inch, 13,536 sq. mils (3.58 × 2.44 mm, 8.74 sq. mm)

1. B1 (MSB) 11. B11

2. B2 12. B12 (LSB)

3. B3 13. V

4. B4 14. V

5. B5 15. V

LC/AGND

(+)

REF

(–)

REF

6. B6 16. COMP

7. B7 17. V–

8. B8 18. I

9. B9 19. I

O

O

10. B10 20. V+

–4–

REV. C

DAC312

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

Operating Temperature

DAC312E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

DAC312F, DAC312H . . . . . . . . . . . . . . . . . . –40°C to +85°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Storage Temperature (Tj) . . . . . . . . . . . . . . . . . –65°C to +125°C

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . . . . .300°C

Power Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Logic Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –5 V to +18 V

Analog Current Outputs . . . . . . . . . . . . . . . . . . . . –8 V to +12 V

Reference Inputs V

, V15 . . . . . . . . . . . . . . . . . . . . . . . V– to V+

14

Reference Input Differential Voltage (V

Reference Input Current (I

) . . . . . . . . . . . . . . . . . . . . . 1.25 mA

14

Package Type u

1

Model DNL Range Description Option

DAC312ER2±1/2 LSB 0°C to +70°C Cerdip-20 Q-20

DAC312FR ±1 LSB –40°C to +85°C Cerdip-20 Q-20

DAC312BR/883 ± 1 LSB –55°C to +125°C Cerdip-20 Q-20

DAC312HP ± 1 LSB –40°C to +85°C Plastic DIP-20 N-20

DAC312HS ± 1 LSB –40°C to +85°C SOL-20 R-20

NOTES

1

, V15) . . . . . . . . . . ±18 V

14

2

JA

u

JC

Units

Burn-in is available on commercial and industrial temperature range parts in

cerdip, plastic DIP, and TO-can packages.

2

For devices processed in total compliance to MIL-STD-883, add/883 after part

number. Consult factory for 883 data sheet.

ORDERING GUIDE

Temperature Package Package

20-Pin Hermetic DIP (R) 76 11 °C/W

20-Pin Plastic DIP (P) 69 27 °C/W

20-Pin SOL (S) 88 25 °C/W

NOTES

1

Absolute maximum ratings apply to both DICE and packaged parts, unless

otherwise noted.

2

θJA is specified for worst case mounting conditions, i.e., θJA is specified for device

in socket for cerdip and P-DIP packages; θJA is specified for device soldered to

printed circuit board for SOL package.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the DAC312 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

1

REV. C

–5–

DAC312

TYPICAL PERFORMANCE CHARACTERISTICS

Output Current vs. Output Voltage

(Output Voltage Compliance)

Power Supply Current vs. Power

Supply Voltage

Reference Amplifier Common-Mode

Range

Power Supply Current vs.

Temperature

Output Compliance vs. Temperature

True and Complementary Output

Operation

Reference Amplifier Small-Signal

Frequency Response

Reference Amplifier Large-Signal

Frequency Response

–6–

Gain Accuracy vs. Reference Current

REV. C

BASIC CONNECTIONS

DAC312

Negative Low Impedance Output Operation

Accommodating Bipolar References

Positive Low Impedance Output Operation

Basic Negative Reference Operation

Recommended Full-Scale Adjustment Circuit

REV. C

Basic Positive Reference Operation

Pulsed Reference Operation

–7–

DAC312

BASIC CONNECTIONS

Interfacing with Various Logic Families

Bipolar Offset (True Zero)

MSB LSB I

Code Format Output Scale B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 (mA) (mA) V

Offset Binary; Positive Full-Scale 1 111111111 1 1 3.999 0.000 9.9951

True Zero Output. Positive Full-Scale –LSB 1 111111111 1 0 3.998 0.001 9.9902

+LSB 1 000000000 0 1 2.001 1.998 0.0049

Zero-Scale 1 000000000 0 0 2.000 1.999 0.000

–LSB 0 111111111 1 1 1.999 2.000 –0.0049

Negative Full-Scale +LSB 0 000000000 0 1 0.001 3.998 –9.9951

Negative Full-Scale 0 000000000 0 0 0.000 3.999 –10.000

2s Complement; Positive Full-Scale 0 111111111 1 1 3.999 0.000 9.9951

True Zero Output Positive Full-Scale –LSB 0 111111111 1 0 3.998 0.001 9.9902

MSB Complemented +1 LSB 0 000000000 0 1 2.001 1.998 0.0049

(Need Inverter at B1). Zero-Scale 0 000000000 0 0 2.000 1.999 0.000

–1 LSB 1 111111111 1 1 1.999 2.000 –0.0049

Negative Full-Scale +LSB 1 000000000 0 1 0.001 3.998 –9.9951

Negative Full-Scale 1 000000000 0 0 0.000 3.999 –10.000

–8–

I

O

O

OUT

REV. C

BASIC CONNECTIONS

DAC312

Basic Unipolar Operation

MSB LSB I

Code Format Output Scale B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 (mA) (mA) V

Straight Binary; Positive Full-Scale 1111111111 1 1 3.999 0.000 9.9976

Unipolar with True Positive Full-Scale –LSB 1111111111 1 0 3.998 0.001 9.9951

Input Code, True LSB 0000000000 0 1 0.001 3.998 0.0024

Zero Output. Zero-Scale 0000000000 0 0 0.000 3.999 0.0000

Complementary Binary; Positive Full-Scale 0000000000 0 0 0.000 3.999 9.9976

Unipolar with Positive full-Scale –LSB 0000000000 0 1 0.001 3.998 9.9951

Complementary Input LSB 1111111111 1 0 3.998 0.001 0.0024

Code, True Zero Output. Zero-Scale 1111111111 1 1 3.999 0.000 0.0000

I

O

O

OUT

Symmetrical Offset Operation

MSB LSB I

Code Format Output Scale B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12 (mA) (mA) V

Straight Offset Binary; Positive Full-Scale 1 1 1 1 1 1 1 1 1 1 1 1 3.999 0.00 9.9976

Symmetrical about Zero, Positive Full-Scale –LSB 1 1 1 1 1 1 1 1 1 1 1 0 3.998 0.001 9.9927

No True Zero Output. (+) Zero-Scale 1 0 0 0 0 0 0 0 0 0 0 0 2.000 1.999 0.0024

1s Complement; Positive Full-Scale 0 1 1 1 1 1 1 1 1 1 1 1 3.999 0.000 9.9976

Symmetrical about Zero, Positive Full-Scale –LSB 0 1 1 1 1 1 1 1 1 1 1 0 3.998 0.001 9.9927

No True Zero Output. (+) Zero-Scale 0 0 0 0 0 0 0 0 0 0 0 0 2.000 1.999 0.0024

MSB Complemented (–) Zero-Scale 1 1 1 1 1 1 1 1 1 1 1 1 1.999 2.000 –0.0024

(Need Inverter at B1). Negative Full-Scale –LSB 1 0 0 0 0 0 0 0 0 0 0 1 0.001 3.998 –9.9927

REV. C

(–) Zero-Scale 0 1 1 1 1 1 1 1 1 1 1 1 1.999 2.000 –0.0024

Negative Full-Scale –LSB 0 0 0 0 0 0 0 0 0 0 0 1 0.001 3.998 –9.9927

Negative Full-Scale 0 0 0 0 0 0 0 0 0 0 0 0 0.000 3.999 –9.9976

Negative Full-Scale 1 0 0 0 0 0 0 0 0 0 0 0 0.000 3.999 –9.9976

–9–

I

O

O

OUT

DAC312

APPLICATIONS INFORMATION

REFERENCE AMPLIFIER SETUP

The DAC312 is a multiplying D/A converter in which the output current is the product of a digital number and the input reference current. The reference current may be fixed or may vary

from nearly zero to +1.0 mA. The full range output current is a

linear function of the reference current and is given by:

4095

IFR =

× 4 × (I

) = 3.999 I

REF

REF

,

4096

REF

= I

14

where I

In positive reference applications, an external positive reference

voltage forces current through R14 into the V

REF(+)

terminal

(pin 14) of the reference amplifier. Alternatively, a negative reference may be applied to V

flows from ground through R14 into V

at pin 15. Reference current

REF(–)

as in the positive

REF(+)

reference case. This negative reference connection has the advantage of a very high impedance presented at pin 15. The voltage at pin 14 is equal to and tracks the voltage at pin 15 due to

the high gain of the internal reference amplifier. R15 (nominally

equal to R14) is used to cancel bias current errors.

Bipolar references may be accommodated by offsetting V

REF

or

pin 15. The negative common-mode range of the reference amplifier is given by: V

= V– plus (I

CM–

× 3 kΩ) plus 1.23 V.

REF

The positive common-mode range is V+ less 1.8 V.

When a dc reference is used, a reference bypass capacitor is rec-

ommended. A 5.0 V TTL logic supply is not recommended as a

reference. If a regulated power supply is used as a reference,

R14 should be split into two resistors with the junction bypassed

to ground with a 0.1 µF capacitor.

For most applications the tight relationship between I

will eliminate the need for trimming I

. If required, full scale

REF

REF

and I

FS

trimming may be accomplished by adjusting the value of R14,

or by using a potentiometer for R14. An improved method of

full-scale trimming which eliminates potentiometer T.C. effects

is shown in the Recommended Full-Scale Adjustment circuit.

The reference amplifier must be compensated by using a capacitor from pin 16 to V–. For fixed reference operation, a 0.01 µF

capacitor is recommended. For variable reference applications,

see section entitled “Reference Amplifier Compensation for

Multiplying Applications.”

MULTIPLYING OPERATION

The DAC312 provides excellent multiplying performance with

an extremely linear relationship between I

and I

FS

REF

over a

range of 1 mA to 1 µA. Monotonic operation is maintained over

a typical range of I

from 100 µA to 1.0 mA. Although some

REF

degradation of gain accuracy will be realized at reduced values

of I

. (See Gain Accuracy vs. Reference Current).

REF

REFERENCE AMPLIFIER COMPENSATION FOR

MULTIPLYING APPLICATIONS

AC reference applications will require the reference amplifier to

be compensated using a capacitor from pin 16 to V–. The value

of this capacitor depends on the impedance presented to pin 14

for R14 values of 1.0 Ω, 2.5 Ω and 5.0 kΩ, minimum values of

C

are 5 pF, 10 pF, and 25 pF. Larger values of R14 require

C

proportionately increased values of C

for proper phase margin.

C

For fastest response to a pulse, low values of R14 enabling small

C

values should be used. If pin 14 is driven by a high imped-

C

ance such as a transistor current source, none of the above values will suffice and the amplifier must be heavily compensated

which will decrease overall bandwidth and slew rate. For R14 =

1 kΩ and C

enabling a transition from I

= 5 pF, the reference amplifier slews at 4 mA/µs

C

REF

= 0 to I

= 1 mA in 250 ns.

REF

Operation with pulse inputs to the reference amplifier may be

accommodated by an alternate compensation scheme. This

technique provides lowest full-scale transition times. An internal

clamp allows quick recovery of the reference amplifier from a

cutoff (I

= 0) condition. Full-scale transition (0 mA to 1 mA)

REF

occurs in 62.5 ns when the equivalent impedance at pin 14 is

800 Ω and C

which is relatively independent of R

= 0. This yields a reference slew rate of 8 mA/µs

C

and VIN values.

IN

LOGIC INPUTS

The DAC312 design incorporates a unique logic input circuit

which enables direct interface to all popular logic families and

provides maximum noise immunity. This feature is made possible by the large input swing capability, 40 µA logic input cur-

rent, and completely adjustable logic threshold voltage. For V–

= –15 V, the logic inputs may swing between –5 V and +10 V.

This enables direct interface with +15 V CMOS logic, even

when the DAC312 is powered from a +5 V supply. Minimum

input logic swing and minimum logic threshold voltage are given

by: V– plus (I

× 3 kΩ) plus 1.8 V. The logic threshold may

REF

be adjusted over a wide range by placing an appropriate voltage

at the logic threshold control pin (pin 13, V

graph shows the relationship between V

temperature range, with V

nominally 1.4 above VLC. For

TH

). The appropriate

LC

and VTH over the

LC

TTL interface, simply ground pin 13. When interfacing ECL,

an I

≤ 1 mA is recommended. For interfacing other logic

REF

families, see block titled “Interfacing With Various Logic Families”. For general setup of the logic control circuit, it should be

noted that pin 13 will sink 7 mA typical; external circuitry

should be designed to accommodate this current.

–10–

REV. C

DAC312

ANALOG OUTPUT CURRENTS

Both true and complemented output sink currents are provided

where I

+ IO = IFR. Current appears at the true output when a

O

“1” is applied to each logic input. As the binary count increases,

the sink current at pin 18 increases proportionally, in the fashion of a “positive logic” D/A converter. When a “0” is applied to

any input bit, that current is turned off at pin 18 and turned on

at pin 19. A decreasing logic count increases I

as in a negative

O

or inverted logic D/A converter. Both outputs may be used simultaneously. If one of the outputs is not required it must still

be connected to ground or to a point capable of sourcing I

FR

; do

not leave an unused output pin open.

Both outputs have an extremely wide voltage compliance en-

abling fast direct current-to-voltage conversion through a resistor tied to ground or other voltage source. Positive compliance

is 25 V above V– and is independent of the positive supply.

Negative compliance is +10 V above V–.

The dual outputs enable double the usual peak-to-peak load

swing when driving loads in quasi-differential fashion. This feature is especially useful in cable driving, CRT deflection and in

other balanced applications such as driving center-tapped coils

and transformers.

POWER SUPPLIES

The DAC312 operates over a wide range of power supply voltages from a total supply of 20 V to 36 V. When operating with

V– supplies of –10 V or less, I

≤ 1 mA is recommended. Low

REF

reference current operation decreases power consumption and

increases negative compliance, reference amplifier negative

common-mode range, negative logic input range, and negative

logic threshold range; consult the various figures for guidance.

For example, operation at –9 V with I

= 1 mA is not recom-

REF

mended because negative output compliance would be reduced

to near zero. Operation from lower supplies is possible, however

at least 8 V total must be applied to insure turn-on of the internal bias network.

Symmetrical supplies are not required, as the DAC312 is quite

insensitive to variations in supply voltage. Battery operation is

feasible as no ground connection is required; however, an artificial ground may be used to insure logic swings, etc. remain between acceptable limits.

TEMPERATURE PERFORMANCE

The nonlinearity and monotonicity specifications of the

DAC312 are guaranteed to apply over the entire rated operating

temperature range. Full-scale output current drift is tight, typically ±10 ppm/°C, with zero-scale output current and drift essentially negligible compared to 1/2 LSB.

The temperature coefficient of the reference resistor R14 should

match and track that of the output resistor for minimum overall

full-scale drift. Settling times of the DAC312 decrease approximately 10% at –55°C; at +125°C an increase of about 15% is

typical.

SETTLING TIME

The DAC312 is capable of extremely fast settling times; typically 250 ns at I

= 1.0 mA. Judicious circuit design and care-

REF

ful board layout must be employed to obtain full performance

potential during testing and application. The logic switch design

enables propagation delays of only 25 ns for each of the 12 bits.

Settling time to within 1/2 LSB of the LSB is therefore 25 ns,

with each progressively larger bit taking successively longer. The

MSB settles in 250 ns, thus determining the overall settling time

of 250 ns. Settling to 10-bit accuracy requires about 90 ns to

130 ns. The output capacitance of the DAC312 including the

package is approximately 20 pF; therefore, the output RC time

constant dominates settling time if R

> 500 Ω.

L

Settling time and propagation delay are relatively insensitive to

logic input amplitude and rise and fall times, due to the high

gain of the logic switches. Settling time also remains essentially

constant for I

for lower I

values down to 0.5 mA, with gradual increases

REF

values lies in the ability to attain a given output

REF

level with lower load resistors, thus reducing the output RC

time constant.

Measurement of the settling time requires the ability to accurately resolve ±1/2 LSB of current, which is ±500 nA for 4 mA

FSR. In order to assure the measurement is of the actual settling

time and not the RC time of the output network, the resistive

termination on the output of the DAC must be 500 Ω or less.

This does, however, place certain limitations on the testing apparatus. At I

values of less than 0.5 mA, it is difficult to pre-

REF

vent RC damping of the output and maintain adequate

sensitivity. Because the DAC312 has 8 equal current sources for

the 3 most significant bits, the major carry occurs at the code

change of 000111111111 to 111000000000. The worst case settling time occurs at the zero to full-scale transition and it requires 9.2 time constants for the DAC output to settle to within

±1/2 LSB (0.0125%) of its final value.

The DAC312 switching transients or “glitches” are on the order

of 500 mV-ns. This is most evident when switching through the

major carry and may be further reduced by adding small capacitive loads at the output with a minor sacrifice in transition speeds.

Fastest operation can be obtained by using short leads, minimizing output capacitance and load resistor values, and by adequate

bypassing at the supply, reference, and V

terminals. Supplies

LC

do not require large electrolytic bypass capacitors as the supply

current drain is independent of input logic states; 0.1 µF capaci-

tors at the supply pins provide full transient protection.

REV. C

–11–

DAC312

DIFFERENTIAL VS. INTEGRAL NONLINEARITY

Integral nonlinearity, for the purposes of the discussion, refers

to the “straightness”of the line drawn through the individual response points of a data converter. Differential nonlinearity, on

the other hand, refers to the deviation of the spacing of the adjacent points from a 1 LSB ideal spacing. Both may be expressed

as either a percentage of full-scale output or as fractional LSBs

or both. The following figures define the manner in which these

parameters are specified. The left figure shows a portion of the

transfer curve of a DAC with 1/2 LSB INL and the (implied)

DNL spec of 1 LSB. Below this is a graphic representation of

the way this would appear on a CRT, for example, if the D/A

converter output were to be applied to the Y input of a CRT as

shown in the application schematic titled “CRT Display Drive.”

On the right is a portion of the transfer curve of a DAC specified for 2 LSB INL with 1/2 LSB DNL specified and the

graphic display below it.

DIFFERENTIAL LINEARITY COMPARISON

One of the characteristics of an R-2R DAC in standard form is

that any transition which causes a zero LSB change (i.e., the

same output for two different codes) will exhibit the same output each time that transition occurs. The same holds true for

transitions causing a 2 LSB change. These two problem transitions are allowable for the standard definition of monotonicity

and also allow the device to be specified very tightly for INL.

The major problem arising from this error type is in A/D converter implementations. Inputs producing the same output are

now represented by ambiguous output codes for an identical input. Also, 2 LSB gaps can cause large errors at those input levels (assuming 1/2 LSB quantizing levels). It can be seen from

the two figures that the DNL specified D/A converter will yield

much finer grained data than the INL specified part, thus improving the ability of the A/D to resolve changes in the analog

input.

D/A Converter with ±1/2 LSB INL, ±1 LSB DNL

Video Deflection by DACs

ENLARGED “POSITIONAL” OUTPUTS

D/A Converter with ±2 LSB INL, ±1/2 LSB DNL

Video Deflection by DACs

ENLARGED “POSITIONAL” OUTPUTS

–12–

REV. C

DESCRIPTION OF OPERATION

The DAC312 is divided into two major sections, an 8 segment

generator and a 9-bit master/slave D/A converter. In operation

the device performs as follows (see Simplified Schematic).

The three most significant bits (MSBs) are inputs to a 3-to-8

line decoder. The selected resistor (R5 in the figure) is connected to the master/slave 9-bit D/A converter. All lower order

resistors (R1 through R4) are summed into the I

higher order resistors (R6 through R8) are summed into the I

line, while all

O

O

line. The R5 current supplies 512 steps of current (0 mA to

0.499 mA for a 1 mA reference current) which are also summed

into the I

or IO lines depending on the bits selected. In the fig-

O

ure, the code selected is: 100 110000000. Therefore, 2 mA (4 ×

0.5 mA/segment) +0.375 mA (from master/slave D/A converter)

are summed into I

giving an IO of 2.375 mA. IO has a current

O

of 1.625 mA with this code. As the three MSB’s are incremented, each successively higher code adds 0.5 mA to I

tracts 0.5 mA from I

, with the selected resistor feeding its

O

and sub-

O

current to the master/slave D/A converter; thus each increment

of the 3 MSBs allows the current in the 9-bit D/A converter to

be added to a pedestal consisting of the sum of all lower order

currents from the segment generator. This configuration guarantees monotonicity.

DAC312

Expanded Transfer Characteristic Segment (001 010 011)

REV. C

Simplified Schematic

–13–

12-Bit Fast A/D Converter

Outline Dimensions

Dimension shown in inches and (mm).

20-Lead Plastic DIP (N-20)

20-Lead Cerdip (Q-20)

20-Lead Wide Body SOL (R-20)

000000000

–14–

PRINTED IN U.S.A.

Loading...

Loading...