AN-655

MICROCONVERTER

ADuC832

AUTO-ZERO

OP AMP

AD8628

AUTO-ZERO

OP AMP

AD8628

TEC

CONTROLLER

ADN8830

WAVELENGTH

MONITOR PD

TEC

THERMISTOR

8

TUNABLE LASER

CW LASER

AVERAGE POWER

CONTROLLER

ADN2830

POWER

MONITOR PD

ETALON

FILTER

2.5V

REFERENCE

ADR291

12-BIT

DAC

12-BIT

DAC

12-BIT

SER ADC

T/H

MUX

GPIO

i8051

CW

LASER

AD8565

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

Tunable Laser Reference Design for Designers with

the ADuC832/ADN8830/ADN2830

by Nobuhiro Matsuzoe

FEATURES

Single Board Solution for Tunable Lasers

8-Channel Selectable Wavelength Control

Wavelength Locking at 25 GHz/50 GHz Spacing

AutoPower Control (APC)

AutoTemperature Control (ATC)

AutoFrequency Control (AFC)

Laser Bias, Temperature Monitoring

EEPROM-Based Autorestoring

Serial Interfaces (SPI®/I2C®/RS-232) to Host System

Wavelength Stability < 2 pm (typ)

LD Temperature Stability < 0.01°C

APPLICATIONS

DWDM Transmission System

Optical Instrumentation

GENERAL DESCRIPTION

This tunable laser reference design offers a single board

solution with complete control requirements for DFB tunable laser subsystems. Designed to work from +3 V/–5 V

power supplies, it provides a low cost, low power tunable

laser solution designed for ease of use with standard

serial control interfaces.

A mixed-signal monolithic microprocessor, the ADuC832based wave locker feedback loop is designed to meet

the requirements of ITU-T grid spacing in a 50 GHz/25 GHz

system. An integrated 12-bit ADC with an 8- channel

multiplexer allows users to monitor laser bias current

and laser temperature via SPI, I2C, or RS -232C serial

interfaces. The ADN2830 laser bias controller can sink

up to 200 mA (single)/400 mA (dual) and its integrated

feedback control loop can maintain output optical power

constant over temperature changes during wave locking. The ADN8830 TEC controller enables excellent laser

temperature stability and precise wavelength control

with 1 pm resolution. A patented PWM/linear based TEC

drive architecture enables high efciency and minimizes

external ltering components.

REV. B

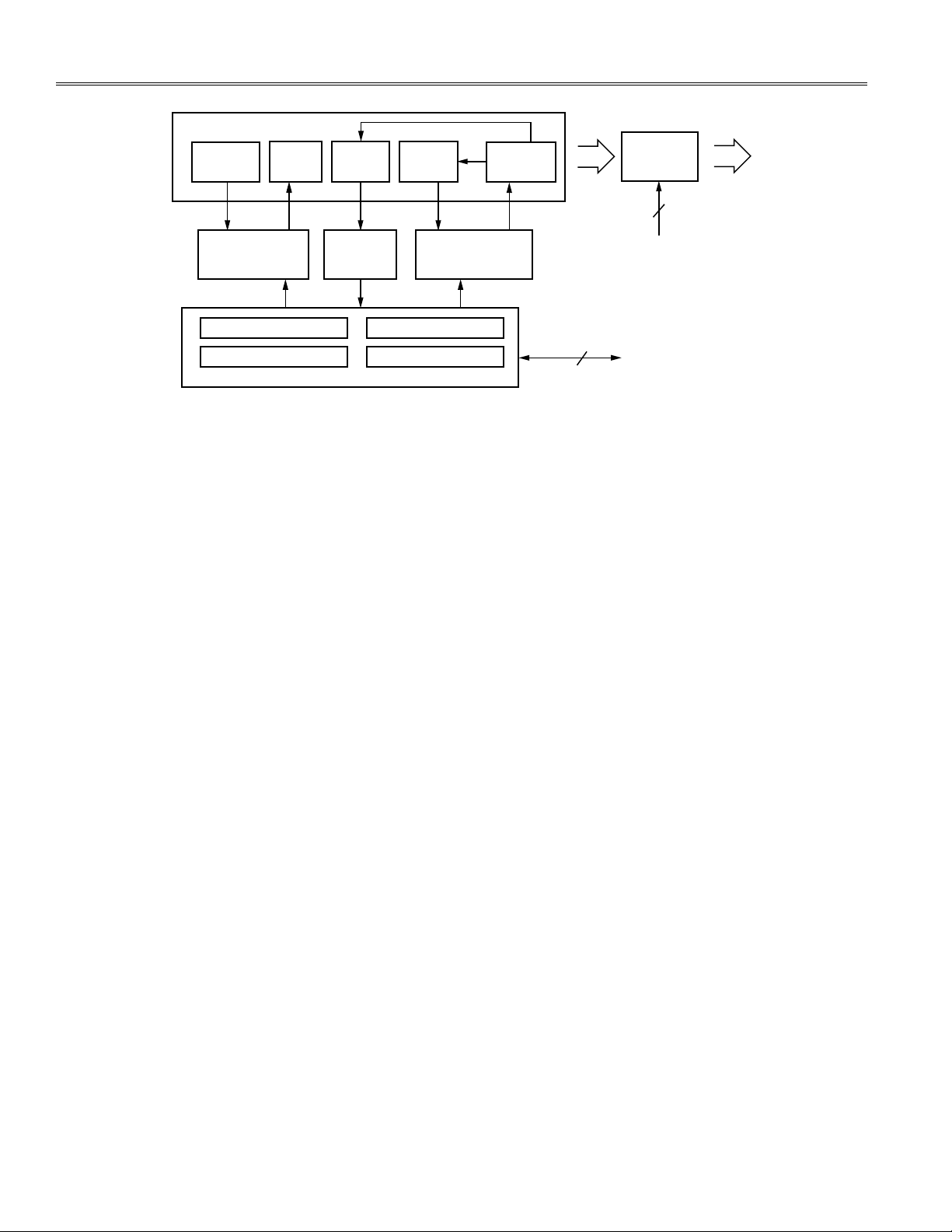

FUNCTIONAL BLOCK DIAGRAM

AN-655

–3–

AN-655

∆f F B

where:

F is the frequency slot

B is the bit rate.

S

S

<

(

)

– . /2 0 4

THERMISTOR TEC

WAVE

LOCKER

POWER

MONITOR

LASER

DIODE

MODULATOR

TEC CONTROLLER

ADN8830

I/V

AD8628

LASER CONTROLLER

ADN2830

ANALOG I/O

MICROPROCESSOR

DIGITAL I/O

SERIAL PORT

MICROCONVERTER ADuC832

I2C LINK TO HOST

2

CONTINUOUS

OPTICAL OUT

MODULATED

OPTICAL OUT

TRANSMIT DATA

2

TURNABLE LASER MODULE

REV. B

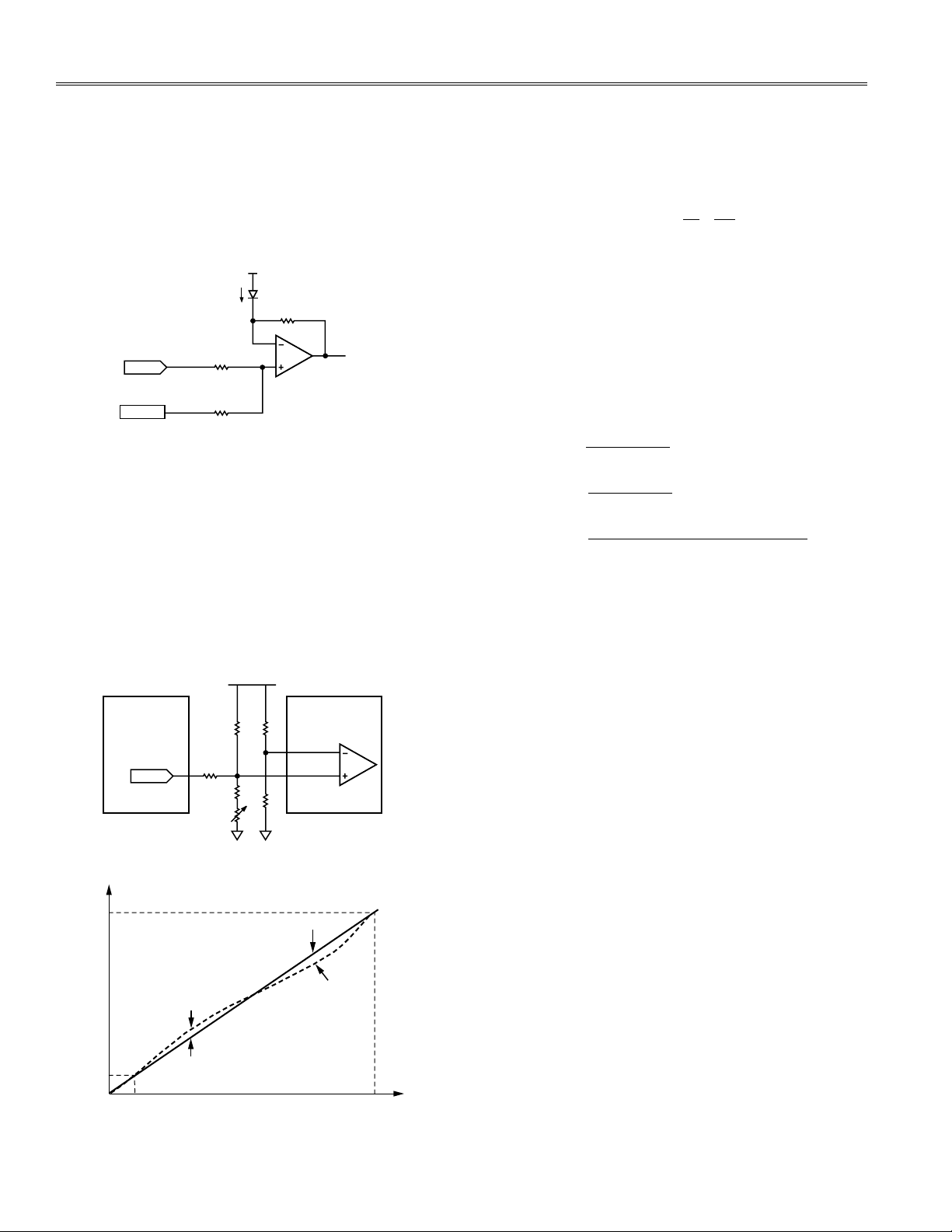

Figure 1. Typical Block Diagram of Optical

Transmitter with DFB Laser Module

WAVELENGTH TUNING

Because an optical transmitter requires a small formfactor design, use of the refractive index of a semiconductor laser is commonly used to alter the wavelength. As the

refractive index can be changed by both the temperature

and the density of carriers, transmitter designers can choose

from two different types of the wavelength-tunable laser

modules—distributed feedback (DFB) lasers and distributed Bragg reector (DBR) lasers. In general, the DBR

laser is capable of a fast tuning speed and a wide tuning

range. However, it requires multiple programmable current sources for wavelength control, which results in a

complex system design. In contrast, the DFB lasers can be

controlled by temperature of the laser chip, which results

in a lower system cost and higher reliability since the DFB

lasers are widely used today. The wavelength of the DFB

laser is related to temperature with a typical temperature

coefcient of 0.1 nm/K. By using a thermoelectric cooler

(TEC) and a thermistor with a built-in module, the laser

chip temperature can be adjusted, thus wavelength is

controlled. Figure 1 shows a simplied block diagram of

an optical transmitter designed with the DFB laser. The

wavelength tuning range of the DFB laser is limited by an

allowable operating temperature range. In fact, DFB lasers

provide a tuning range of a couple of nanometers which

is equivalent to 8 to 16 ITU-T grid channels depending on

the channel-to-channel spacing of the wavelength.

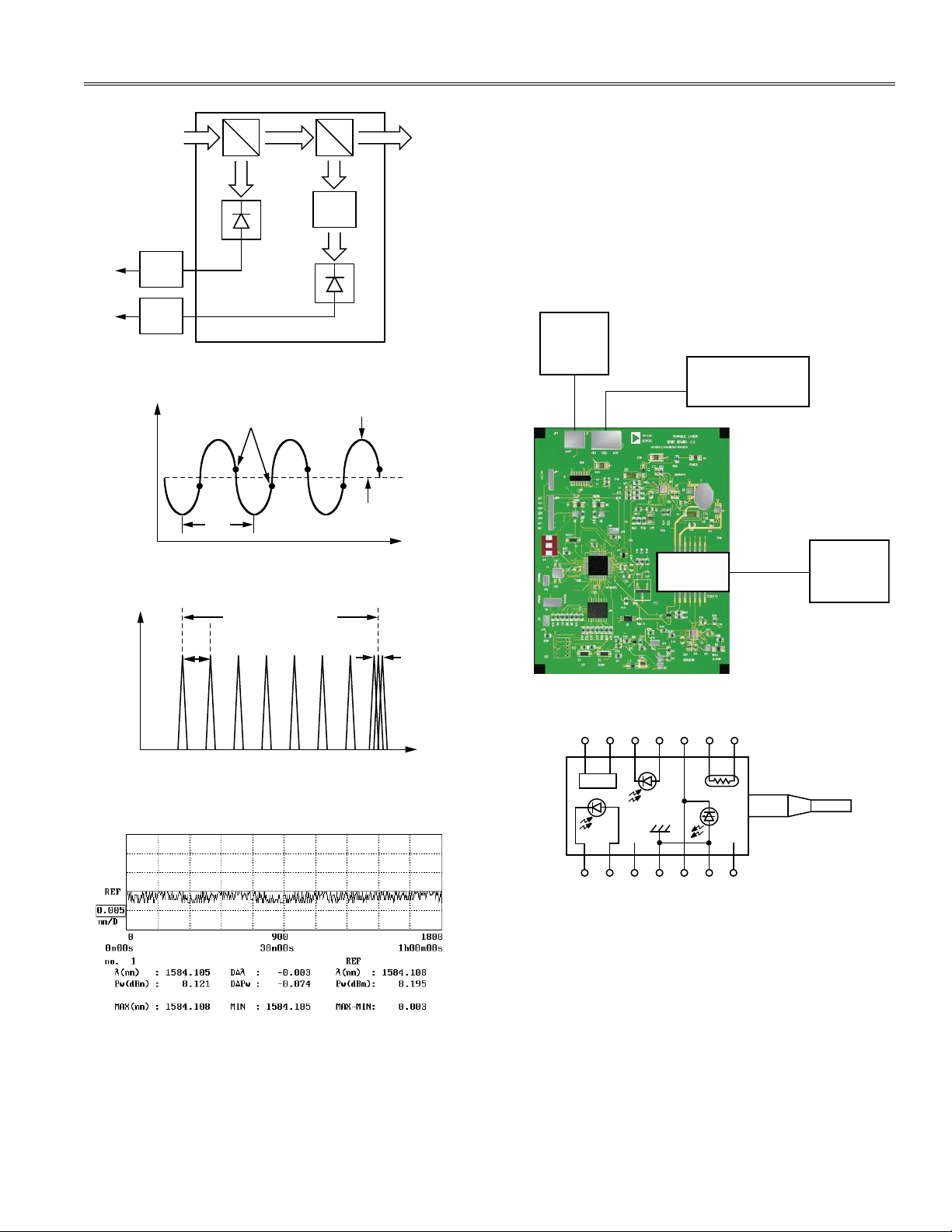

WAVELENGTH LOCKING

The internal or external wavelength locker generates

two monitor signals corresponding to the wavelength

and optical output power respectively. The wavelength

locker consists of the wavelength selective element and

the photodetector diode as shown in Figure 2a. The builtin Fabry Perot etalon works as a wavelength lter which

has a periodic characteristic similar to a comb lter. The

peak-to-peak range of the etalon lter, referred to as the

Free Spectral Range (FSR) cycle FS, is precalibrated by the

manufacturer to align with the ITU grid spacing as shown

in Figure 2b. Because the monitor signal has periodic

cycles, the algorithm of wavelength locking requires two

different tuning methods, coarse tuning, and ne tuning.

During the rst phase, the laser temperature must settle

to the particular temperature corresponding to the target

wavelength, where the wavelength is assumed within

the capture range. In the case of Figure 2b, there are two

locking points on both slopes, positive slope and negative

slope, within a single FSR. Thus, the capture range must

be half of the SFR. Feedforward control with a look-up

table is used in this coarse tuning phase. After the wavelength settles within the capture range, the ne tuning

phase acquires the wave length errors between the target

wavelength and actual wavelength by monitoring the wave

locker signal. Then the wavelength errors will be fed back

to the temperature control circuit. The ne tuning phase

maintains the wavelength within an allowable wavelength

deviation range over ambient temperature changes. The

ITU-T recommendation species wavelength stability as

a frequency deviation in G.692. This deviation is dened

as the difference between the nominal central frequency

and the actual central frequency (Figure 2c). A maximum

frequency deviation is given by

In 10 Gbps transmit applications with 50 GHz Grid spacing, the frequency deviation f must be less than 7.5 GHz

which means wavelength deviation

67 pm. The test result of the wavelength deviation taken

must be less than

by the reference design is shown in Figure 2d.

–2–

REV. B

ETALON

FILTER

I/V

I/V

OPTICAL

INPUT

POWER

MPD

WA

VELENGTH MPD

WAVELENGTH LOCKER

OPTICAL

OUTPUT

TO

µC

TO

µC

Figure 2a. Wavelength Locker Block Diagram

WAVELENGTH

MONITOR PD

LOCK POINT

WAVELENGTH (nm

)

MONITOR CURRENT (A)

POWER

MONITOR PD

FSR

F

S

TUNABLE RANGE = 3nm

F

OPTICAL POWER (dB)

WAVELENGTH (THz)

NOTES

1. 1-HOUR WAVELENGTH STABILITY AT 25C, WAVE LOCKER ENABLED,

2 SEC INTERVAL.

2. F: LOCK POINT 1.5pm MAX TO MIN: 3pm.

3. LASER: FLD5F15CA, FUJITSU QUANTUM DEVICES LTD.

4. THE WAVELENGTH STABILITY IS MEASURED IN 3pm ACCURACY.

5. AFC STABILITY IS AFFECTED BY ACCUMULATIVE ERRORS OF APC AND

ATC CONTROL LOOP.

RS-232C

CABLE

FC-APC

(PANDA FIBER)

LASER

MODULE

COMPUTER

POWER SUPPLY

(+5V/–5V)

WAVELENGTH

METER

R

TH

PD1

PD2

7

6

5 4 3 2

1

8 9

10 11 12 13 14

TEC

AN-655

DEMONSTRATION BOARD

The tunable laser reference design board (demo board)

demonstrates autopower control (APC), autotemperature

control (ATC) and autofrequency control (AFC). Figure 3

shows simplied setup of the demo board. The demo board

has a mount space for a tunable DFB laser module in a 14-lead

buttery package. The demo board also provides a power

supply terminal, analog I/O ports, and a serial port. To mount

laser modules, a power photodetector must be oating within

the laser module package as seen in Figure 4.

Figure 2b. Wavelength Locker Characteristics

Figure 2c. Frequency Slots and Allowable

Frequency Deviation

Figure 3. Demo Board Setup

Figure 4. Laser Module Pin Assignment (reference: Fujitsu Quantum Devices, FLD5F6CA Data

Sheet)

REV. B

Figure 2d. AFC Typical Performance

–3–

AN-655

–5–

AN-655

V V R I V

where:

V V

R

LOCKPOINT REF m

REF

= ×

(

)

[ ]

=

[ ]

=

[ ]

–

.

46 2

46

2 50

2490 Ω

V G T V V

where:

T is target temperature of the thermistor in Celsius.

G =

V V

DAC LASER OFFSET

LASER

OFFSET

= ×

(

)

[ ]

=

[ ]

–

.

– .

0 0658

0 659

REV. B

GETTING STARTED

To ensure proper operation, follow the steps below.

1) Calculate the target voltages of the wavelength lock point according to the following equation:

The photo current Im2 needs to be solved at each lock point, because the Im2 may differ from lock point to lock point, laser

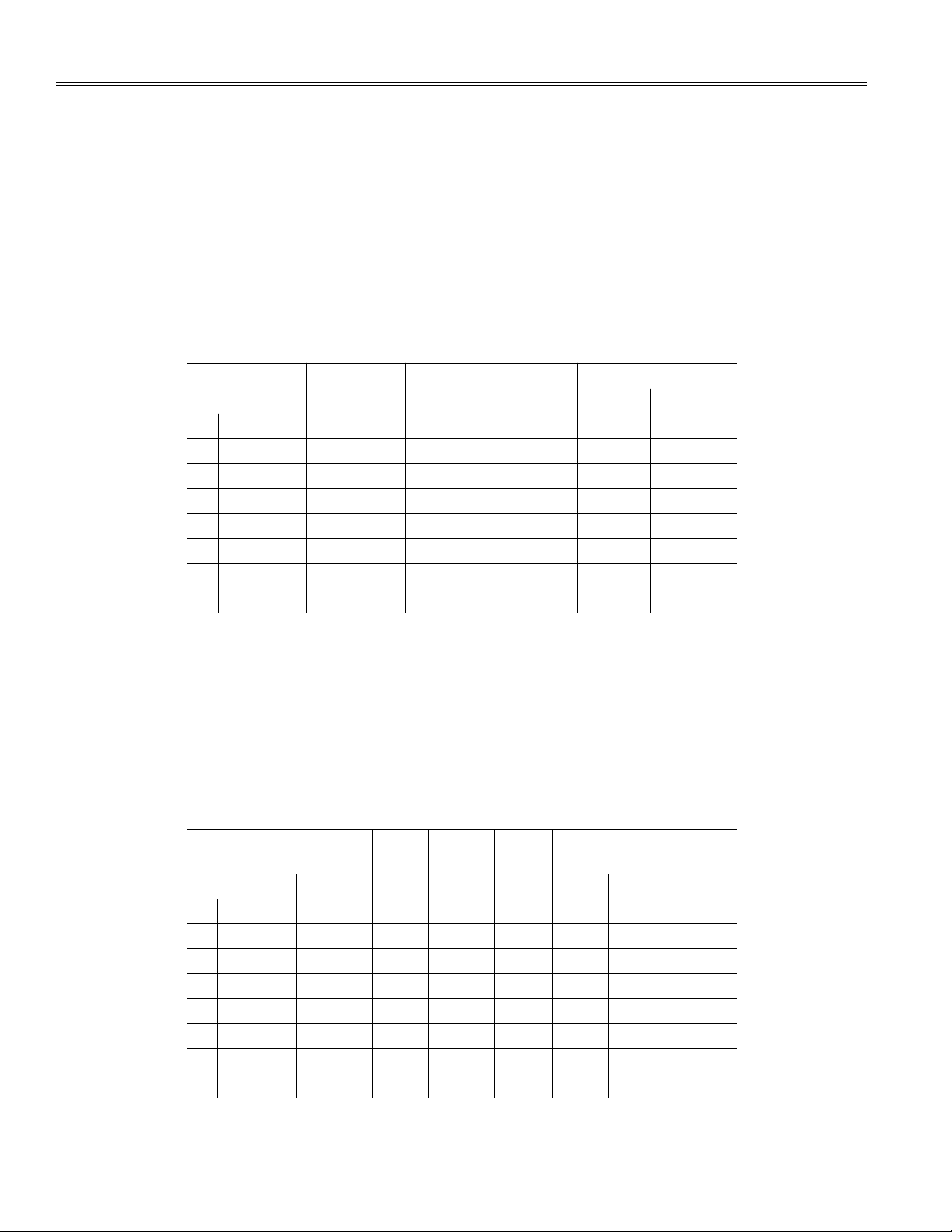

to laser. Table 1 is an example of the calculation result from the 8-channel wavelength tunable laser module.

Table 1.

Wavelength Im2 V

[nm] [THz] [mA] [V] [Dec] [Hex]

0 1582.439 189.4496 521.4 1.202 1969 07B1

1 1582.851 189.4003 573.4 1.072 1757 06DD

2 1583.265 189.3508 511.4 1.227 2010 07DA

3 1583.692 189.2997 563.4 1.097 1798 0706

4 1584.110 189.2498 527.4 1.187 1944 0798

5 1584.529 189.1997 556.8 1.114 1824 0720

6 1584.942 189.1504 524.3 1.194 1957 07A5

7 1585.365 189.1000 553.3 1.122 1839 072F

LOCKPOINT

Lock Point ADC Code

2) Calculate the voltage setpoint for ADN8830 according to the following equation:

Table 2 is an example of the calculation result from the 8-channel wavelength tunable laser module.

Table 2.

Curve

Wavelength RTH T

[nm] [THz] [] [C] [V] [Dec] [Hex]

0 1582.439 189.4496 16810 12.191 0.144 236 00EC Positive

1 1582.851 189.4003 14370 15.941 0.390 639 027F Negative

2 1583.265 189.3508 12350 19.658 0.634 1040 0410 Positive

3 1583.692 189.2997 10630 23.433 0.883 1447 05A7 Negative

4 1584.110 189.2498 9220 27.106 1.125 1843 0733 Positive

5 1584.529 189.1997 8040 30.728 1.363 2233 08B9 Negative

6 1584.942 189.1504 7060 34.247 1.594 2612 0A34 Positive

7 1585.365 189.1000 6210 37.802 1.828 2996 0BB4 Negative

LASER

V

DAC Code Slope

DAC

–4–

REV. B

AN-655

Maximum TEC voltage V VLIM V= −

( )

×

[ ]

1 5 4.

3) Compile and download the software to the ADuC832. To select the download/debug mode, position the switch (S5) to

DEBUG, and then press the reset button (S3).This sets the ADuC832 to download mode. To select the normal mode, position the switch (S5) to NORMAL and press the reset button (S3). ADuC832 executes downloaded program after reset.

4) Mount the laser module to the mount pads labeled U13. The ADN2830 is capable of sinking a current up to 200 mA. The

maximum TEC voltage limit is set at 3.5 V ±5% by default. To change the TEC voltage limiter, change the value of R24 and

R25 which is congured as a voltage divider to set the voltage to the VLIM pin of ADN8830. Maximum TEC voltage can

be given by:

5) Set JP1 and JP2. To protect the laser module from accidental damage, it is recommended to close JP1 and JP2 if the

program has been changed. Shorting JP1 enables the ADN8830 to shut down mode regardless of control signals from

the ADuC832. Shorting JP2 enables the ADN2830 to ALS (Automatic Laser Shutdown) mode regard less of control signals

from ADuC832.

6) Apply +3 V and –5 V to the power supply terminal block (J1) located at the top of the demo board.

7) Leave JP2 open. ADN2830 starts to drive the laser diode.

8) Calibrate the optical output power by adjusting the multiturn potentiometer (R48).

9) Leave JP1 open. ADN8830 starts to control the laser temperature to the initial temperature setpoint selected by switch (S4).

10) Press S1 or S2 buttons to change the wavelength lock point. S1 increments and S2 decrements the wavelength point by 1.

11) To change the target wavelength lock point directly, congure the 3-bit DIP switch (S4) according to Table 3. This change

is effective only when the ADuC832 is powered up or after reset.

Table 3.

Ch# S4(1) S4(2) S4(3)

0 OFF OFF OFF

1 ON OFF OFF

2 OFF ON OFF

3 ON ON OFF

4 OFF OFF ON

5 ON OFF ON

6 OFF ON ON

7

12) 7-segment LED (DS1) displays the selected wavelength and DS1 blinks until the laser temperature is set. TEMPLOCK LED

(D1) is lit when the laser temperature is settled within the capture range. WL_LOCK LED (D2) is lit when the wavelength

is locked within ITU grid ±12pm.

ON ON ON

REV. B

–5–

AN-655

–7–

AN-655

V I V

im m2 2

2 5 2490= ×

(

)

[ ]

. –

NOT POPULATED

DAC1

2.5V REF

R57

0

R58

R46

249

I

m2

V

m2

A

VDO

DAC0

R1

TEMPSET

THERMIN

ADN8830

2.5V

ADuC832

R

TH

R3

R2

LINEARIZATION

ERROR < 0.5%

IDEAL

ACTUAL

2.5

0

CONTROL VOLTAGE (V)

THERMISTOR TEMPERATURE (C)

10 50

R = R exp B

1

T

–

1

T

where:

R

is thermistor resistance at 25 C.

B is thermistor constant

T

is temperature in K.

Typically, B = 3450 and R 10K

TH 25

x

25

25

25

25

×

°

=

R

R R

R R

R

R R

R R

R

R R R R – R R

R R

R

where:

R R R

R R

R

low high

low high

low high

low high

mid high mid low high low

high low mid

high high

low low

1

2

2

2

3

2

2

3

3

=

′ ′

′ ′

=

′ ′

′ +

′

=

+

+

′ =

+

′ =

+

–

–

REV. B

INTERFACING WAVELENGTH MONITOR PD

Figure 5 shows the current-to-voltage conversion circuit

on the demo board. The conversion gain is set by R46.

The input range of the wavelength monitor current Im2 is

up to 1.0 mA by default. The wavelength monitor voltage,

V

, is calculated by:

im2

Figure 5. I/V Conversion Circuit

INTERFACING 12-BIT DAC AND ADN8830

By using the interface circuit shown in Figure 6, the laser

temperature is controlled by DAC output voltage. This

scales the DAC voltage range from 0 V to 2.5 V for temperature range from 10°C to 50°C. The interface circuit

linearizes the thermistor transfer function. The TEMPSET

pin of ADN8830 is xed at 1.25 V. The THERMIN pin is

connected to the resistor network which includes the

thermistor. The characteristic of voltage-to-temperature

is shown in Figure 7.

Figure 6. Application Circuit Using DAC Control Voltage

Figure 7. V-to-Temperature Characteristic

To maintain optimal linearity over the required temperature

range, the value of the thermistor resistance should be

calculated at the lowest and the highest operating temperature according to the following equation:

R1, R2, and R3 are given by:

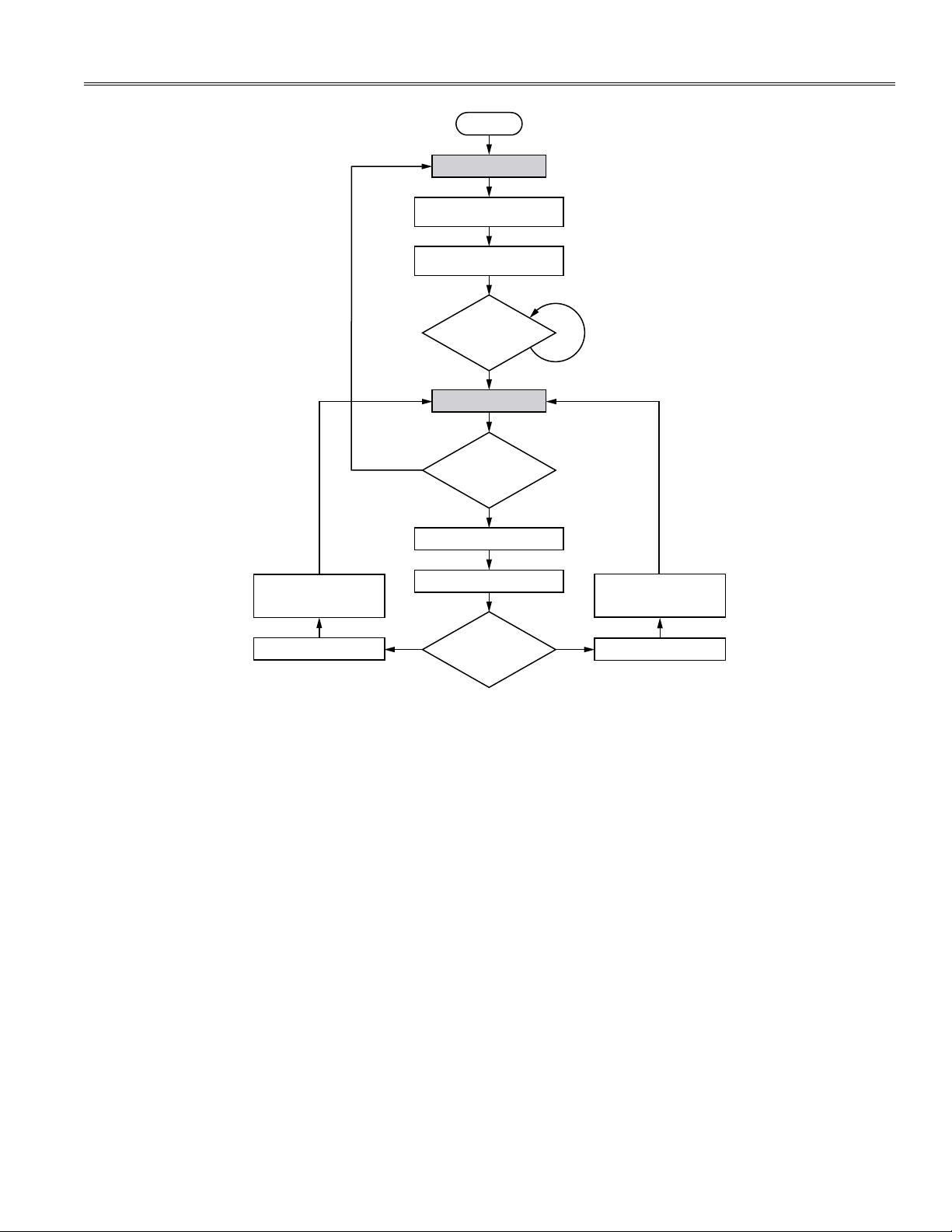

IMPLEMENTING THE WAVELENGTH LOCK

As the rst phase, the program executes the coarse tuning

with the ADN8830 TEC controller. The program reads S4

switch position, then generates the xed control voltage to

let the ADN8830 settle the laser temperature corresponding to the selected wavelength set by S4. Because the

ADN8830 has a local control loop for the temperature

control, the program waits for the temperature locked

signal from the ADN8830. After the laser temperature is

settled within the capture range of the wavelength lock,

the program starts the ne tuning. This phase uses the

monitor signal from the wavelength locker. The program

reads the actual wavelength and compares with the target

wavelength being stored in the memory. Then the program

adjusts the temperature control voltage, which corresponds

to the error amount between the target wavelength and

the monitored wavelength. Figure 8 shows the overview

of the program ow including the course and ne tuning.

Details of the course and ne tuning are shown in Figure 9

and Figure 10 respectively.

–6–

REV. B

AN-655

YES

NO

YES

NO

COMPARE

AC

QUIRED DATA WITH

TA

RGET DATA

TARGET CHANNEL

CHANGED?

START COARSE TUNE

MOVING AVERAGE FILTERING

START A/D CONVERSION

NEGATE LASER AND TEC

SHUTDOWN

LOAD AND SET AN INITIAL

TEMPERATURE

START FINE TUNE

START

SET LOOP GAIN

UPDATE D/A CONVERTER

TO

INCREMENT LASER

TEMP

SET LOOP GAIN

UPDATE D/A CONVERTER

TO

DECREMENT LASER

TEMP

LASER TEMP IN

CAPTURE RANGE OF

WA

VE LOCKER?

Figure 8. Overview of Program Flow Chart

REV. B

–7–

AN-655

–9–

AN-655

START COARSE TUNE

TEMPERATURE

LOCKED?

NO

TURN OFF

LASER/TEC

LOAD TARGET DATA

READ S4 SWITCH

ADC GAIN/OFFSET

CALIBRATION

LOCK POINT

CALIBRATION

SET LOCKING SLOPE

SET TARGET

TEMPERATURE

TURN ON

LASER/TEC

GO TO FINE TUNE

DELAY

REV. B

Figure 9. Coarse Tuning Flow Chart

–8–

REV. B

AN-655

START FINE TUNE

CHECK SLOPE

POLARITY

LP < ADC

FLAG = 0

GRID CHANNEL

CHANGED?

8 A/D

CONVERSIONS

AVR. FILTERING

LOCKPOINT–ADC

INCREMENT LASER

TEMPERATURE

DECREMENT LASER

TEMPERA

TURE

DELAY

ELSE

YES

POSITIVE SLOPE

BACK TO

COARSE TUNE

LP > ADC

FLAG = 1

GRID CHANNEL

CHANGED?

8 A/D

CONVERSIONS

AVR. FILTERING

LOCKPOINT–ADC

INCREMENT LASER

TEMPERATURE

DECREMENT LASER

TEMPERATURE

DELAY

ELSE

YES

NEGATIVE SLOPE

BACK TO

COARSE TUNE

NONO

Figure 10. Fine Tuning Flow Chart

ADuC832 SOFTWARE

The demo software is written in i8051 assembly that uses 1.2 kB out of 62 kB on-chip EE/Flash and 80 bytes out of 256 bytes

of on-chip RAM in ADuC832. The transaction time of the wavelength lock routine is approximately 0.3 ms at 4 MHz of the CPU

core clock setting. The essential part of the program is listed below. The rst control phase is labeled FF_Tune (Feed-Forward

Tuning), and second control phase is labeled L_Lock (Lambda Lock).

ORG 0060H ; MAIN PROGRAM

MAIN: ; ===cpu congure===

SETB ALS ; Shutdown laser driver, ADN2830 (ACTIVE HIGH)

CLR SD ; Shutdown TEC, ADN8830 (ACTIVE LOW)

MOV ADCCON1, #11001100b ; Select Ext. Vref, single conversion

MOV DACCON, #00011111b ; DAC0 On, 12bit, Asynchronous

MOV DAC0H, #007h ; DAC0 to 4th WL, Set TEMP =28.033degC

MOV DAC0L, #096h ;

MOV PLLCON, #00000000b ; Set core clock to 16MHz

SETB EA ; Enable Interrupt

MOV P0, #00101000b ; Turn on 7SEG display with ‘8’

CLR LLOCK_LED ; Turn off WL Lock LED

MOV CALN_L, #020h ; Lock point calib. value at neg. slope

MOV CALN_H, #000h ;

MOV CALP_L, #010h ; Lock point calib. value at pos. slope

MOV CALP_H, #000h ;

MOV CALDAC_L, #000h ; DAC initial value calib. low byte

MOV CALDAC_H, #000h ; DAC initial value calib. high byte

REV. B

–9–

AN-655

–11–

AN-655

REV. B

CALL DACDATA ; Load DAC data table to ram (30h to 3Fh)

CALL LP_DATA ; Load lock point data table to ram (40h to 4Fh)

CALL SW_DETECT ; Read 3-bit DIP SW position

CALL ADCCAL ; ADC Gain and Offset calib.

CALL AUTO_DEMO ; Enable Auto demo if S1/S2 pushed

MOV ECON, #06H ; Erase all pages of data Flash/EE

CALL REV_WRITE ; Write board and rm revision to Flash/EE

FF_TUNE: ; ===Feed-forward tuning (coarse-tune)===

SETB ALS ; Turn off Laser, Active High

CLR SD ; Turn off TEC, Active LOW

CLR PBFLAG ; Clear PBFLAG

CLR P3.6 ; Turn off Temp lock LED

CALL CH_LOAD ; Load selected DAC initial value

CALL LP_LOAD ; Load selected Lock point value

CALL SLOPE_CHECK ; Check slope polarity

MOV P0, WL_SEL ; display selected wavelength ch# on 7seg

SETB LEDBI ; Turn on 7seg display

SETB LEDLE ; 7seg Latch enabled

CALL LP_CAL ; Lock point offset calibration

CALL DAC_CAL ; DAC initial value calibration

MOV DAC0H, DACINT_H ; Update DAC to target temp

MOV DAC0L, DACINT_L ; Update DAC to target temp

SETB SD ; Turn on TEC

CLR ALS ; Turn on Laser

CLR TMPLKFLAG ; Clear temp lock indicate ag

MOV R0, #00H ; SET Page Pointer ADDRESS

MOV R1, #03H ; SET Byte Location ADDRESS

MOV R2, WL_SEL ; SET 1byte Value to write

CALL EE_WRITE ; Call Flash/EE Write routine

CALL TEMP_LOCK ; Sit here until FF_Tune completion

L_LOCK: ; ===Lambda lock Loop (ne tune)===

SETB LEDBI ; Turn on 7seg display

MOV A, #07h ; Set delay time, A*12.5msec

CALL DELAY ; Call delay program, 100msec

JNB SLOPEFLAG, LL_POS ; Check slope polarity, positive or negative

LL_NEG: ; ==Lambda locking at Negative slope==

CALL PB_DETECT ; Detect push-button sw

JNB PBFLAG, LOOP_N ; Jump LOOP_N if PB is not pushed

JMP FF_TUNE ; if PBFLAG=1(PB detected), back to FF_TUNE

LOOP_N:

MOV A, #40d ; Set delay time, A * 12.5msec

–10–

REV. B

CLR P2.7 ; Test signal for cpu transaction monitoring

CALL DELAY ; Call delay program

SETB P2.7 ; Test signal for cpu transaction monitoring

CALL ADC ; Take 8 * samples

CALL AVR ; Averaging

CALL SUBTRACT ; Subtract (LOCKPOINT - ADCDATA)

CALL LOCK_INDICATE ; Turn LED on if result is in lock range

CALL GAIN_DECISION ; Check if error amount is <2LSB, <16LSB

CALL ADJUST_N ; Call dac update routine

CALL LD_BIAS_MONITOR ; Monitor Laser Bias on ADC1

CALL LD_TEMP_MONITOR ; Convert DAC0H/L code to temperature value

CALL CPU_TEMP_MONITOR ; Monitor on-chip temp sensor

JMP LL_NEG ; Back to loop top

LL_POS: ; ==Lambda locking at Positive slope==

CALL PB_DETECT ; Detect push-button sw

JNB PBFLAG, LOOP_P ; Jump LOOP_P if PB is not pushed

JMP FF_TUNE ; if PBFLAG=1(PB detected), back to FF_TUNE

LOOP_P:

MOV A, #40d ; Set delay time, A * 12.5msec

CLR P2.7 ; Test signal for cpu transaction monitoring

CALL DELAY ; Call delay program

SETB P2.7 ; Test signal for cpu transaction monitoring

CALL ADC ; Take 8 * samples

CALL AVR ; Averaging

CALL SUBTRACT ; Subtract (LOCKPOINT - ADCDATA)

CALL LOCK_INDICATE ; Turn LED on if result is in lock range

CALL GAIN_DECISION ; Check if error amount is <2LSB, <16LSB

CALL ADJUST_P ; Call dac update routine

CALL LD_BIAS_MONITOR ; Monitor Laser Bias on ADC1

CALL LD_TEMP_MONITOR ; Convert DAC0H/L code to temperature value

CALL CPU_TEMP_MONITOR ; Monitor on-chip temp sensor

JMP LL_POS ; Back to loop top

; END OF MAIN PROGRAM

AN-655

REV. B

–11–

AN-655

–13–

AN-655

REV. B

SOFTWARE MEMORY MAP

Table 4. Internal RAM, Lower 128 Bytes

Byte Address Byte Name Byte Description

00 to 1F – Reserved

20 Control Flags Detailed in Bit Memory Map

21 WL_SEL Wavelength select

22 CALDAC_L Offset calibration for DAC

23 CALDAC_H

24 CALP_H Offset calibration for positive locking points

25 CALP_L

26 CALN_H Offset calibration for positive locking points

27 CALN_L

28 DACINT_H DAC initial voltage

29 DACINT_L

2A LOCKPOINT_H Wave lock point being selected

2B LOCKPOINT_L

2C RES_H Errors between actual wavelength and target wavelength

2D RES_L

2E DACNEW_L Updated DAC output data

2F DACNEW_H

30 to 4F – Not used

50 AVR_H Averaged wave locker output value

51 AVR_L

52 SUM_H Accumulated wave locker output value

53 SUM_L

54 GAIN Temperature control gain

58 SMPL1_H ADC raw data #1

59 SMPL1_L

5A SMPL2_H ADC raw data #2

5B SMPL2_L

5C SMPL3_H ADC raw data #3

5D SMPL3_L

5E SMPL4_H ADC raw data #4

5F SMPL4_L

60 SMPL5_H ADC raw data #5

61 SMPL5_L

62 SMPL6_H ADC raw data #6

63 SMPL6_L

64 SMPL7_H ADC raw data #7

65 SMPL7_L

66 SMPL8_H ADC raw data #8

67 SMPL8_L

–12–

REV. B

Table 5. Internal RAM, Upper 128 Bytes

Byte Address Byte Name Byte description

80 MSB DAC initial data for channel 1

81 LSB

82 MSB DAC initial data for channel 2

83 LSB

84 MSB DAC initial data for channel 3

85 LSB

86 MSB DAC initial data for channel 4

87 LSB

88 MSB DAC initial data for channel 5

89 LSB

8A MSB DAC initial data for channel 6

8B LSB

8C MSB DAC initial data for channel 7

8D LSB

8E MSB DAC initial data for channel 8

8F LSB

90 MSB Wave lock point data for channel 1

91 LSB

92 MSB Wave lock point data for channel 2

93 LSB

94 MSB Wave lock point data for channel 3

95 LSB

96 MSB Wave lock point data for channel 4

97 LSB

98 MSB Wave lock point data for channel 5

99 LSB

9A MSB Wave lock point data for channel 6

9B LSB

9C MSB Wave lock point data for channel 7

9D LSB

9E MSB Wave lock point data for channel 8

9F LSB

AN-655

REV. B

–13–

AN-655

–15–

AN-655

REV. B

REV. B

Table 6. Internal RAM Bit Memory Map

Byte Bit Address Bit Name Bit Value Description

20h 00h SLOPEFLAG 1 Negative Lock curve

0 Positive Lock curve

01h RESFLAG 1 Lock Point < ADCDATA

0 Lock Point > ADCDATA

02h TEMPLKFLAG 1 Laser Temperature locked

0 Laser Temperature not locked

03h PBFLAG 1 Button is pushed

0 Button is not pushed

04h – Not used

05h – Not used

06h – Not used

07h – Not used

Table 7. Internal DATA Flash/EE ROM

Byte1 Byte2 Byte3 Byte4

Page 000 Board rev Farm rev Wavelength Grid

Page 001 Laser bias Laser bias Laser temp Laser temp

Page 002 CPU temp CPU temp

Page 003 Not used

:

Page 3FF

–14–

ADC0/P1.0/T2

ADC1/P1.1/T2EX

ADC2/P1.2

ADC3/P1.3

ADC4/P1.4

ADC5/P1.5/SS

ADC6/P1.6

ADC7/P1.7

CREF

VREF

DA

C0DAC1

RESET

P3.0/RxD

P3.1/TxD

P3.2/INT0

P3.3/INT1/M1SO/PWM1

P3.4/T0/PWMC/PWM0/EXTCLK

P3.5/T1/CONVST

P3.6/WR

P3.7/RD

SCLOCK

SDATA/MOSI

DVDD

DV

DD

DV

DD

AV

DD

AG

ND

DGND

DGND

DGND

P0.0

P0.1

P0.2

P0.3

P0.4

P0.5

P0.6

P0.7

XTAX2

XTAL1

ALE

PSEN

EA

P2.7/PWM1

P2.6/PWM0

P2.5

P2.4

P2.3

P2.2

P2.1

P2.0

C24

0.1F

34

20

48

5

AVDD

C21

0.1F

C22

0.1F

C23

0.1F

PVDD

6

35

47

21

ADuC834

43444546495051

52

3332424140

39383736313029

28

123

4

111213

14

789

10

15

16171819222324

25

26

27

LLOCK

U8

DAC0

1

5

4

3

2

AD8628ART

AVDD

DAC1

SW-PB

S3

R37

1k

PVDD

PVDD

JP4

123

4

HEADER 4 UART

JP7

123

4

HEADER 4 SPI/I

2

C

JP3

123

4

ANALOG AUX I/O

567

C26

0.1F

R44

0

C25

0.1F

VREF

1BMON

WLMON

S4

321

456

SW DIP-3

TEMPLOCK

SD

ALS

PVDD

R38

1k

R39

1k

1

3

2

S5

SW SPDT

JP5

HEADER 2 ICE

1

2

JP6

HEADER 2 PW

M

1

2

C27

15pF

C28

15pF

1

2 3

4

Y1

32.768kHz

SW-PBS1SW-PB

S2

R12

10k

R13

10k

PVDD

PVDD

PVDD

16

INA

INB

INC

INDLEBI

LT

VDD

SEG A

SEG B

SEG C

SEG D

SEG E

SEG F

SEG G

VSS

8

7126543

U9

1312111091514

CD4511BCWM

R49 287

R50 287

R51 287

R52 287

R53 287

R54 287

R55 287

R47 200

PVDD

abcdefg

dp

DPY

a

g

d

f

e

b

c

DS1

dp

ccom

cdp

DPY_7-SEG_DP

9

6

1108

54237

PVDD

R11 10k

R10 10k

R9 10k

R8 10k

R7 10k

R6 10k

PVDD

ALS: ACTIVE HIGH

SD: ACTIVE LOW

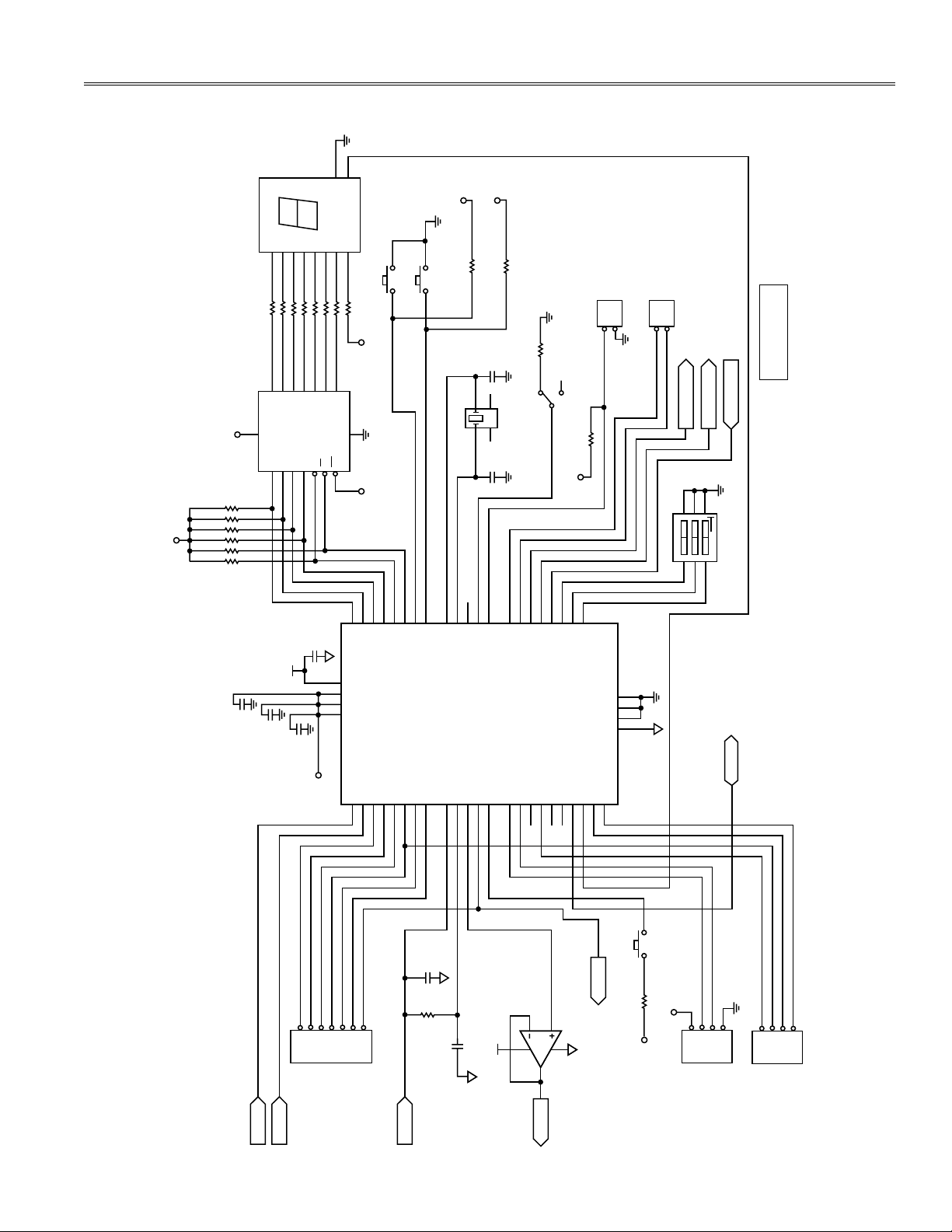

APPENDIX [A-1] SCHEMATIC–CPU

AN-655

REV. B

Figure 11. Schematic–CPU

–15–

AN-655

–17–

AN-655

TEMPOUTNCTHERMFAULT

THERMIN

TEMPSET

TEMPLOCKNCVREF

VLIM

VTEC

TEMPCTL

COMPFB

COMPOUT

PVDD

PGND

AV

DD

AG

ND

PHASE

SYNCOUT

SOFTSTART

FREQ

SYNCIN

OSC

OUTA

N1

P1

OUTB

N2

P2

SWIN

SWOUT

20

23

C2

0.1F

8

30

ADN8830

29282726252419

22

21910

11

18

17

31

32

12345

6

7

151612

13

14

LLOCK

C7

0.1F

JP1

JUMPER

1

2

R2

10k

PVDD

AVDD

C10

10nF

C9

1F

R26

1M

R27

205k

R28

100k

C14

330pF

C15

10F

R24

150k

R25

1k

PVDD

R21

10k

C5

0.1F

SD

SHORT JP1

SHUTDOWN TEC

[SD: ACTIVE LOW]

SD

A1B1Q2

CEXT2

RCEXT2

DGND

DV

CC

RCEXT1

CEXT1

Q1

Q2

B2

A2

CLR1

Q1

CLR2

U1

MM74HC123AM

PVDD PVDD

1234578

6

16

121110

9

141315

PVDD

1

2

3

4

5

U11

Y

B

A

NC7S32

NC

VINNCGND

NC

VO

UT

NC

NC

134

2

876

5

U2

ADR291GRU

AVDD

C1

0.1F

R20

10k

1%

R22

14.7k

R17

36.5k

R18

24k

R19

8.2k

TH

DAC0

TEMPLOCK

VREF

PVDD

R1

10k

C4

0.1F

R14

150

PVDD

1

2

3

Q1

FDV301N

R15

150

PVDD

1

2

32

Q2

FDV301N

D1

LED (G)

D2

LED (R)

1

R23

150k

C3

0.1F

AVDD

FDW2520C

Q5

PVDD

C6

0.1F

765

8

1

234

L1

C8

22F

CDE ESRD

TEC–

4.7F

FDW2520C

Q6

PVDD

C11

10nF

765

8

1

234

L1

C13

3.3nF

TEC+

4.7F

C12

2.2nF

REV. B

APPENDIX [A-2] SCHEMATIC–TEC CONTROL

REV. B

–16–

Figure 12. Schematic–TBC Control

APPENDIX [A-3] SCHEMATIC–LASER CONTROL

TEC–

R57

0

WLMON

VREF

AVDD

U7

AD8628ART

2

1

5

4

3

R46

2.49k

0.1%

R58

0

DAC1

LD_C

LD_C

LD_A/GND

PD1_A

PD1_C

PD2_C

PD2_A

TEC–

TEC+

TH

TH

NC

NC

GND

3

12

13

458

9

7

6

1210

14

FLD5F15

U6

AVDD

TH

TEC+

R42

0

R43

0

R45

1k

VSS

R48

5k

R41

0

VSS

R40

1.24k

VSS

283154161533226

2

IBIAS

IBIAS

IMPD

PSET

NCNCNCNCNC

ASET

GND

GND

GND

GND

GND

GND

GND

V

CC

V

CC

V

CC

V

CC

V

CC

IMPDMON

IBMON

IBMON

PAVCAP

PAVCAP

ALS

MODENCFAIL

DEGRADE

ADN2830

VSS

30

26

27

7

22

14

1

8

11

12

21

25

6

23

249102017

131918

VSS

R36

1k

VSS

R36

1k

R32

100k

VSS

R16

150

D3

LED (R)

Q4

FDV301N

1

32

2

1

IMPDMON DISABLE: R42-SHORT, R43-OPEN, R41-SHORT

IMPDMON ENABLE: R42-OPEN, R43-SHORT, R41-OPEN

R31

100k

AVDD

AD8565AKS

2

1

5

4

3

U4

VSS

VSS

R30

100k

R29

100k

IBMON

VSS

C20

0.1F

R34

10k

JP2

HEADER 2

12

R4

10k

VSS

Q3

FDV301N

Q7

FDV304P

VSS

R5

10k

R33

3k

PVDD

R3

10k

PVDD

1

1

3

2

2

3

ALS

SHORT JP2 TO

SHUTDOWN LASER

[ALS: ACTIVE HIGH]

Q7 GATE HIGH: ALS ACTIVE

Q7 GATE LOW: ALS DISABLE

C16

10nF

C17

10nF

C18

10nF

C19

10nF

VSS

11

AN-655

REV. B

Figure 13. Schematic–Laser Control

–17–

AN-655

–19–

AN-655

J1

3

2

1

TERMINAL

BLOCK

D4

LED (G)

R56

150

C29

100F

C31

22F

AVDDPVDD

L2

10F

1

2

1

2

1

2

C30

100F

C32

22F

VSS

L3

10F

2

1

2

1

–5V

REV. B

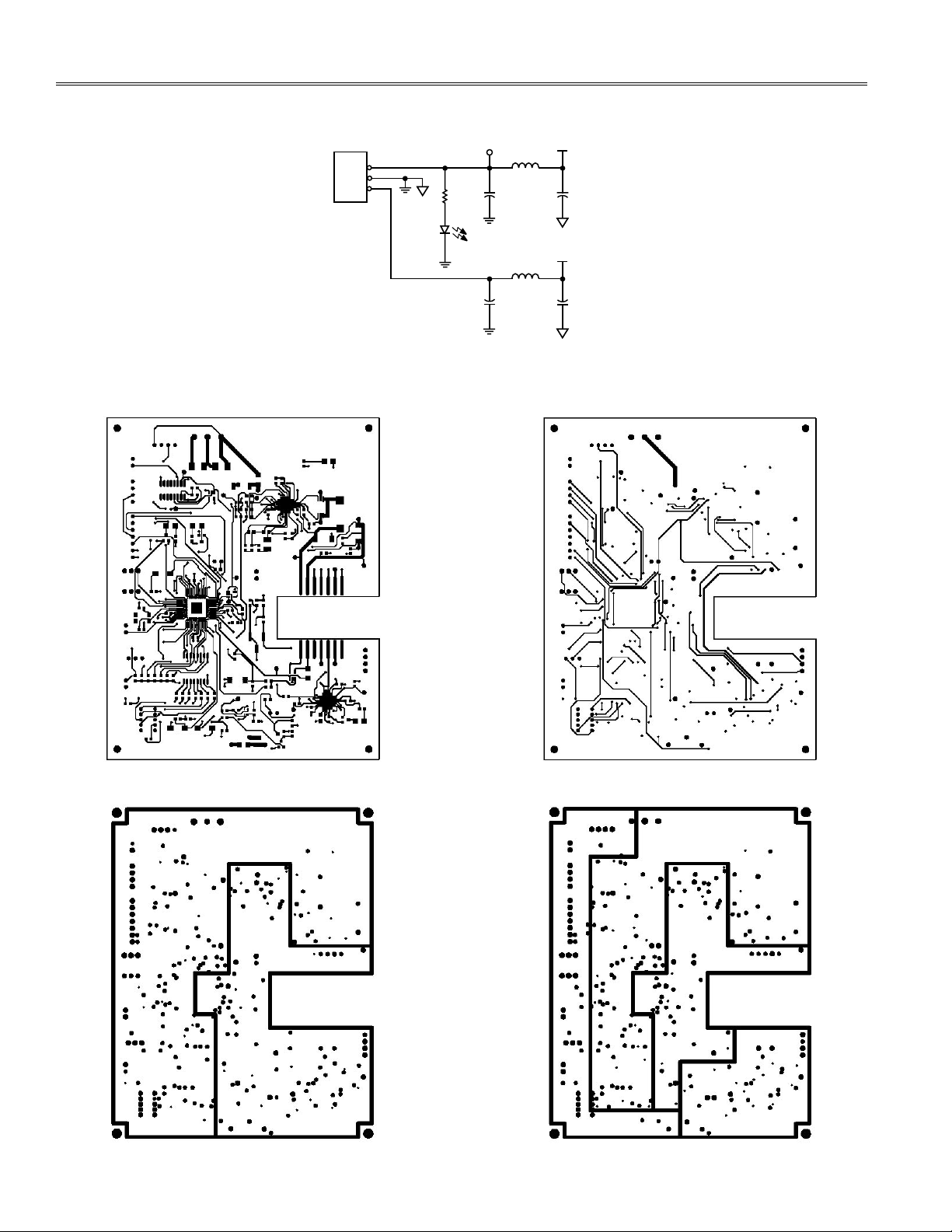

APPENDIX [A] SCHEMATIC–POWER SUPPLY

APPENDIX [B] PCB LAYOUT

Figure 14. Schematic–Power Supply

Figure 15. Top Layer

–18–

Figure 16. AGND/PGND Planes

Figure 17. Bottom Layer

Figure 18. AVDD/PVDD/VSS Planes

REV. B

Figure 19. Top Overlay

AN-655

APPENDIX [C] BILL OF MATERIALS

Provided as a software copy.

APPENDIX [D] SOFTWARE SOURCE CODE

Provided as a software copy.

REFERENCES

Analog Devices, ADuC832 Data Sheet

Analog Devices, ADN8830 Data Sheet

Analog Devices, ADN2830 Data Sheet

Fujitsu Quantum Devices, FLD5F6CA Data Sheet

Fujitsu Quantum Devices, FLD5F15CA Data Sheet

ITU-T G.692

REV. B

–19–

E03717–0–8/04(B)

Purchase of licensed I2C components of Analog Devices or one of its sublicensed Associated Companies conveys a license for the purchaser under the Philips

I2C Patent Rights to use these components in an I2C system, provided that the system conforms to the I2C Standard Specication as dened by Philips.

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

–20–

Loading...

Loading...