Page 1

AN-613

a

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

Programming the Automatic Fan Speed Control Loop

By Mary Burke

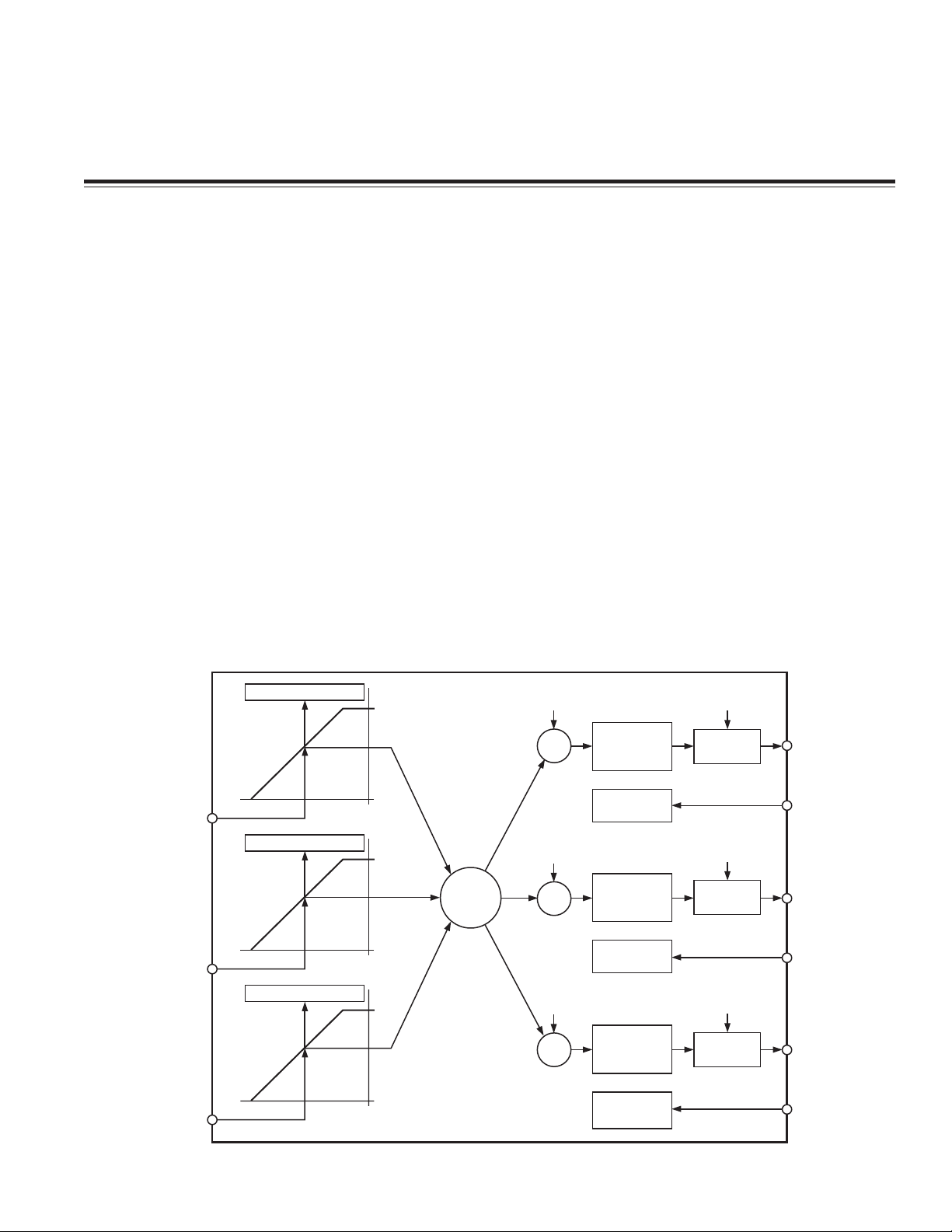

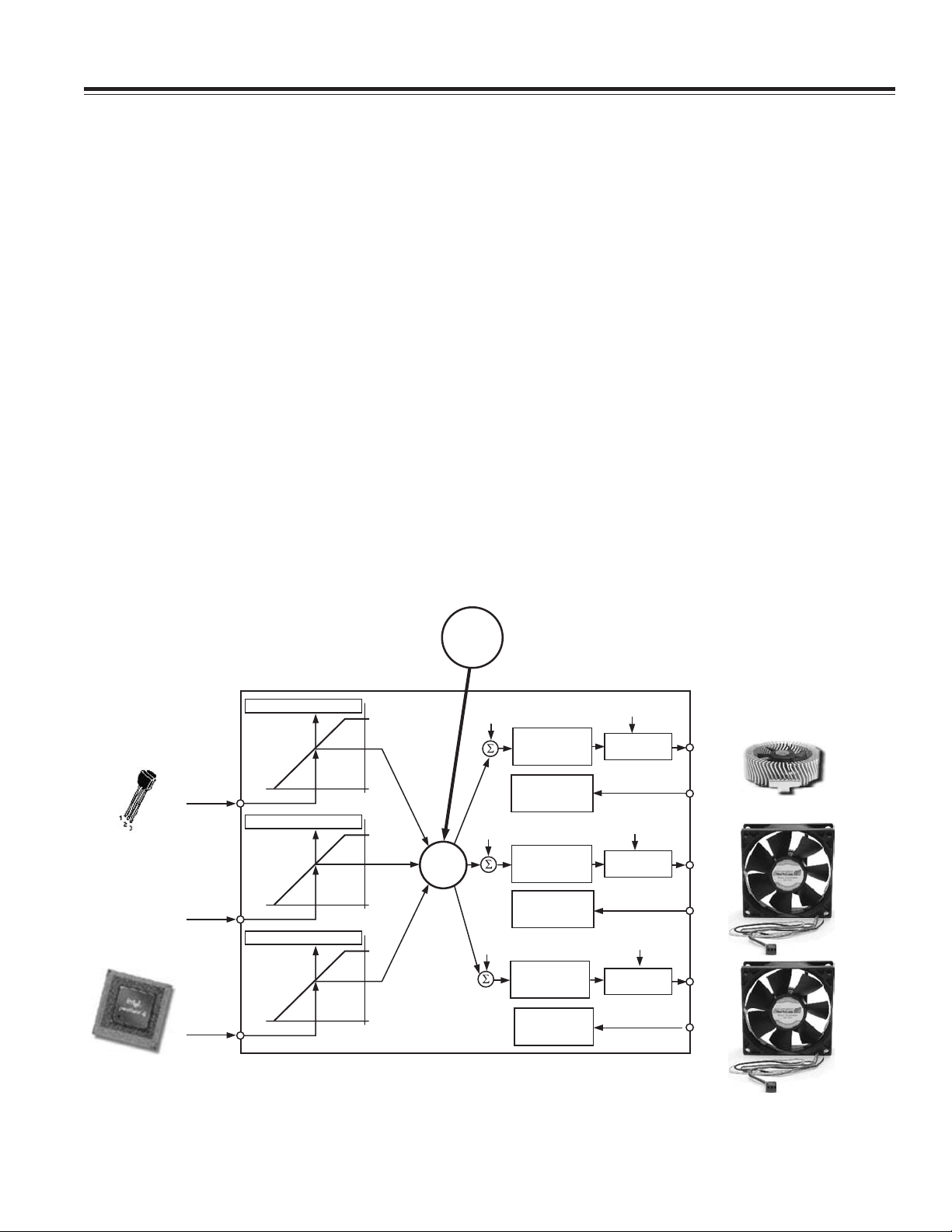

AUTOMATIC FAN SPEED CONTROL

The ADT7460/ADT7463 have a local temperature sensor

and two remote temperature channels that may be connected to an on-chip diode-connected transistor on a

CPU. These three temperature channels may be used as

the basis for automatic fan speed control to drive fans

using pulsewidth modulation (PWM). In general, the

greater the number of fans in a system, the better the

cooling, but this is to the detriment of system acoustics.

Automatic fan speed control reduces acoustic noise

by optimizing fan speed according to measured temperature. Reducing fan speed can also decrease system

current consumption. The automatic fan speed control

mode is very flexible owing to the number of programmable parameters, including T

discussed in detail later. The T

MIN

MIN

and T

and T

values for a

RANGE

RANGE

, as

temperature channel and thus for a given fan are critical

since these define the thermal characteristics of the system. The thermal validation of the system is one of the

most important steps of the design process, so these

values should be carefully selected.

AIM OF THIS SECTION

The aim of this application note is not only to provide

the system designer with an understanding of the automatic fan control loop, but to also provide step-by-step

guidance as to how to most effectively evaluate and

select the critical system parameters. To optimize the

system characteristics, the designer needs to give some

forethought to how the system will be configured, i.e.,

the number of fans, where they are located, and what

temperatures are being measured in the particular

REMOTE 1

TEMP

LOCAL

TEMP

REMOTE 2

TEMP

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

T

T

T

RANGE

RANGE

RANGE

100%

0%

100%

0%

100%

0%

MUX

PWM

MIN

PWM

MIN

PWM

MIN

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT

TACHOMETER 1

MEASUREMENT

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT

TACHOMETER 2

MEASUREMENT

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT

TACHOMETER 3

AND 4

MEASUREMENT

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

PWM2

PWM3

REV. 0

Figure 1. Automatic Fan Control Block Diagram

Page 2

AN-613

system. The mechanical or thermal engineer who is

tasked with the actual system evaluation should also be

involved at the beginning of the process.

AUTOMATIC FAN CONTROL OVERVIEW

Figure 1 gives a top-level overview of the automatic fan

control circuitry on the ADT7460/ADT7463. From a systems level perspective, up to three system temperatures

can be monitored and used to control three PWM outputs. The three PWM outputs can be used to control up

to four fans. The ADT7460/ADT7463 allow the speed of

four fans to be monitored. Each temperature channel

has a thermal calibration block. This allows the

designer to individually configure the thermal characteristics of each temperature channel. For example, one

may decide to run the CPU fan when CPU temperature

increases above 60°C, and a chassis fan when the local

temperature increases above 45°C. Note that at this

stage, you have not assigned these thermal calibration

settings to a particular fan drive (PWM) channel. The

right side of the Block Diagram (Figure 1) shows controls

that are fan-specific. The designer has individual control

over parameters such as minimum PWM duty cycle, fan

speed failure thresholds, and even ramp control of the

PWM outputs. This ultimately allows graceful fan speed

changes that are less perceptible to the system user.

STEP 1: DETERMINING THE HARDWARE CONFIGURATION

During system design, the motherboard sensing and

control capabilities should not be an afterthought, but

addressed early in the design stages. Decisions about

how these capabilities are used should involve the system thermal/mechanical engineer. Ask the following

questions:

1. What ADT7460/ADT7463 functionality will be used?

• PWM2 or SMBALERT?

• 2.5 V voltage monitoring or SMBALERT?

• 2.5 V voltage monitoring or processor power

monitoring?

• TACH4 fan speed measurement or over-

temperature THERM function?

• 5 V voltage monitoring or overtemperature

THERM function?

• 12 V voltage monitoring or VID5 input?

The ADT7460/ADT7463 offers multifunctional pins that

can be reconfigured to suit different system requirements and physical layouts. These multifunction pins

are software programmable. Various pinout options

are discussed in a separate application note.

2. How many fans will be supported in system, three or

four? This will influence the choice of whether to use

the TACH4 pin or to reconfigure it for the THERM

function.

3. Is the CPU fan to be controlled using the ADT7460/

ADT7463 or will it run at full speed 100% of the time?

If run at 100%, it will free up a PWM output, but the

system will be louder.

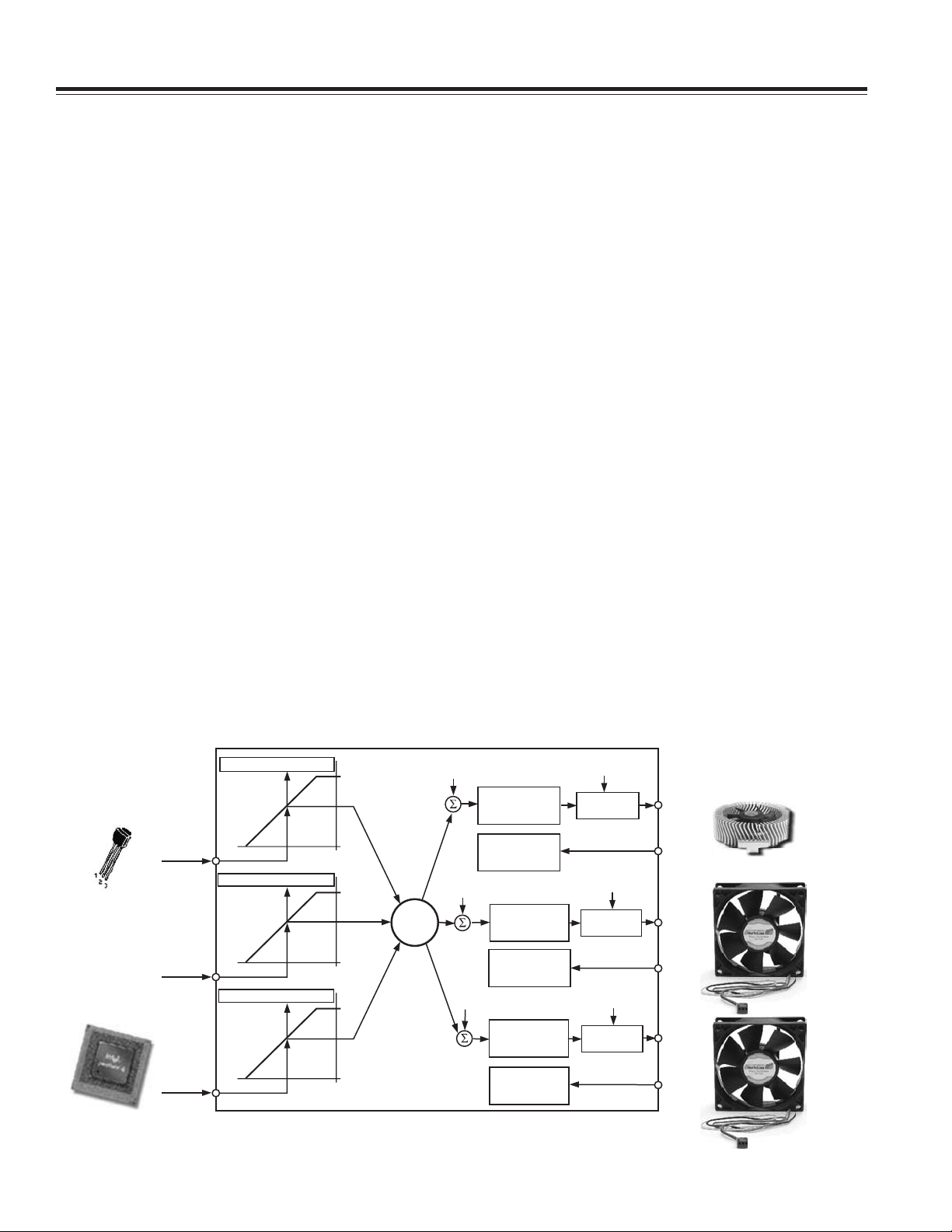

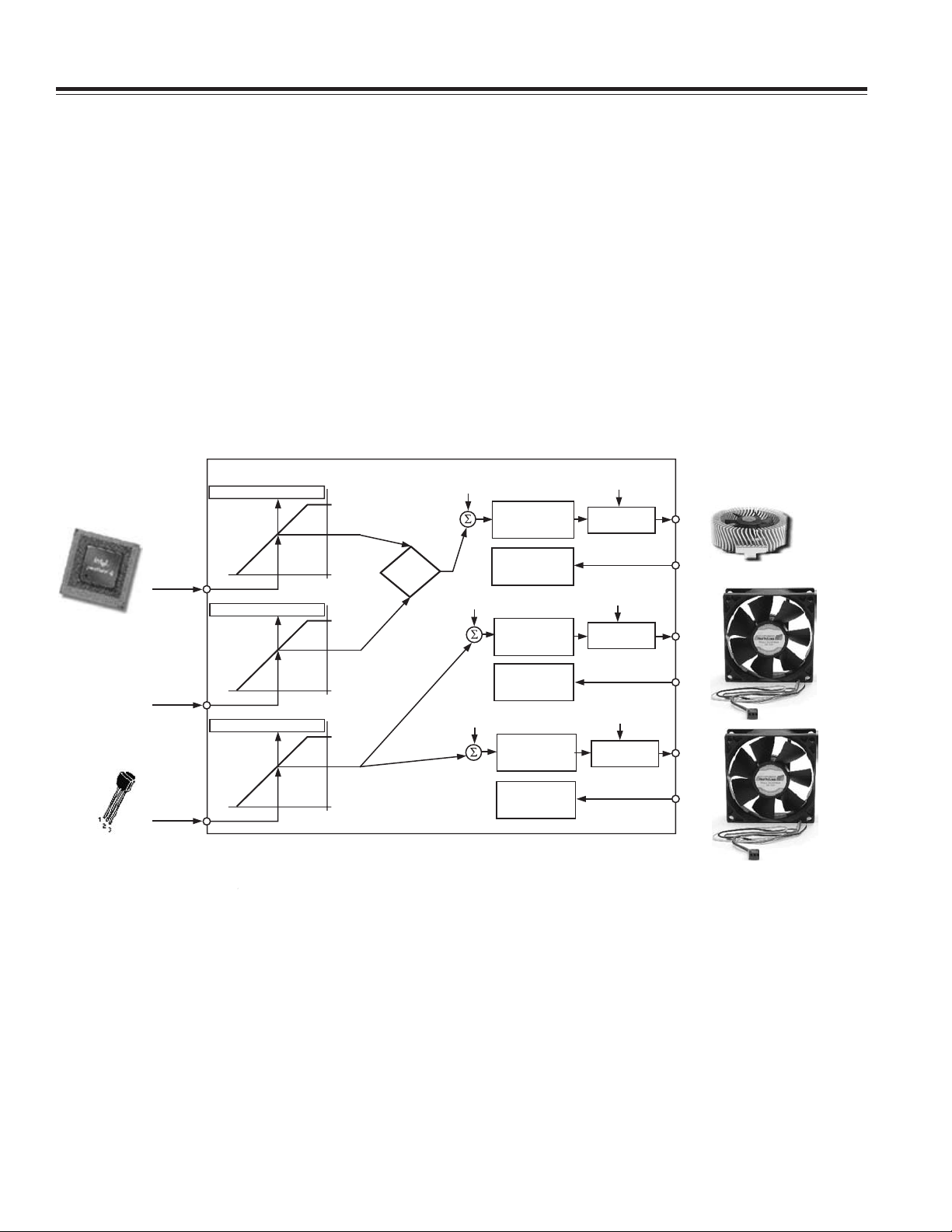

REMOTE 1 =

AMBIENT TEMP

LOCAL =

VRM TEMP

REMOTE 2 =

CPU TEMP

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

T

RANGE

T

RANGE

T

RANGE

Figure 2. Hardware Configuration Example

100%

0%

100%

0%

100%

0%

MUX

PWM

MIN

PWM

–2–

MIN

PWM

MIN

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 1

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 2

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 3

AND 4

MEASUREMENT

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

TACH1

PWM2

TACH2

PWM3

TACH3

CPU

FAN SINK

FRONT

CHASSIS

REAR

CHASSIS

REV. 0

Page 3

FRONT

CHASSIS

FAN

TACH2

AN-613

PWM1

TACH1

COMP

PWM3

TACH3

D1+

D1–

3.3VSB

5V

12V/VID5

CURRENT

V

CORE

REAR

CHASSIS

FAN

AMBIENT

TEMPERATURE

ADP316x

VRM

CONTROLLER

V

Figure 3. Recommended Implementation 1

4. Where will the ADT7460/ADT7463 be physically

located in the system?

This influences the assignment of the temperature

measurement channels to particular system thermal

zones. For example, locating the ADT7460/ADT7463

close to the VRM controller circuitry allows the VRM

temperature to be monitored using the local temperature channel.

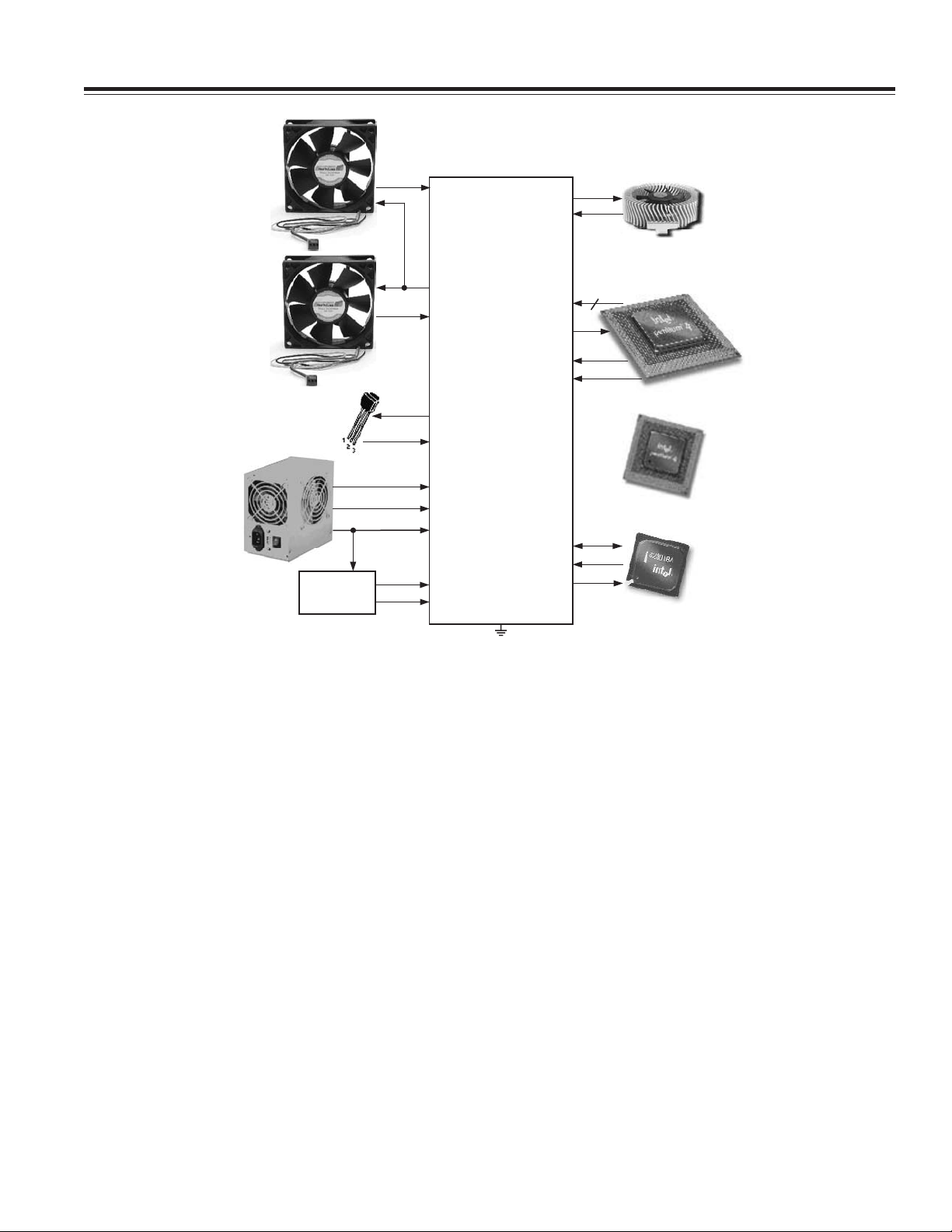

RECOMMENDED IMPLEMENTATION 1

Configuring the ADT7460/ADT7463 as in Figure 3 provides the systems designer with the following features:

1. Six VID Inputs (VID0 to VID5) for VRM10 Support.

2. Two PWM Outputs for Fan Control of up to Three

Fans. (The front and rear chassis fans are connected

in parallel.)

3. Three TACH Fan Speed Measurement Inputs.

4. V

5. CPU Core Voltage Measurement (V

Measured Internally through Pin 4.

CC

CORE

).

VID[0:4]/VID[0.5]

ADT7463

GND

5(VRM9)/6(VRM10)

D2+

D2–

THERM

SMBALERT

PROCHOT

SDA

SCL

6. 2.5 V Measurement Input Used to Monitor CPU Current (connected to V

output of ADP316x VRM

COMP

controller). This is used to determine CPU power

consumption.

7. 5 V Measurement Input.

8. VRM temperature uses local temperature sensor.

9. CPU Temperature Measured Using Remote 1 Temperature Channel.

10. Ambient Temperature Measured through Remote 2

Temperature Channel.

11. If not using VID5, this pin can be reconfigured as the

12 V monitoring input.

12. Bidirectional THERM Pin. Allows monitoring of

PROCHOT output from Intel

®

P4 processor, for

example, or can be used as an overtemperature

THERM output.

13. SMBALERT System Interrupt Output.

REV. 0

–3–

Page 4

AN-613

FRONT

CHASSIS

FAN

TACH2

PWM2

PWM1

TACH1

COMP

PWM3

TACH3

D1+

D1–

3.3VSB

5V

12V/VID5

CURRENT

V

CORE

REAR

CHASSIS

FAN

AMBIENT

TEMPERATURE

ADP316x

VRM

CONTROLLER

V

Figure 4. Recommended Implementation 2

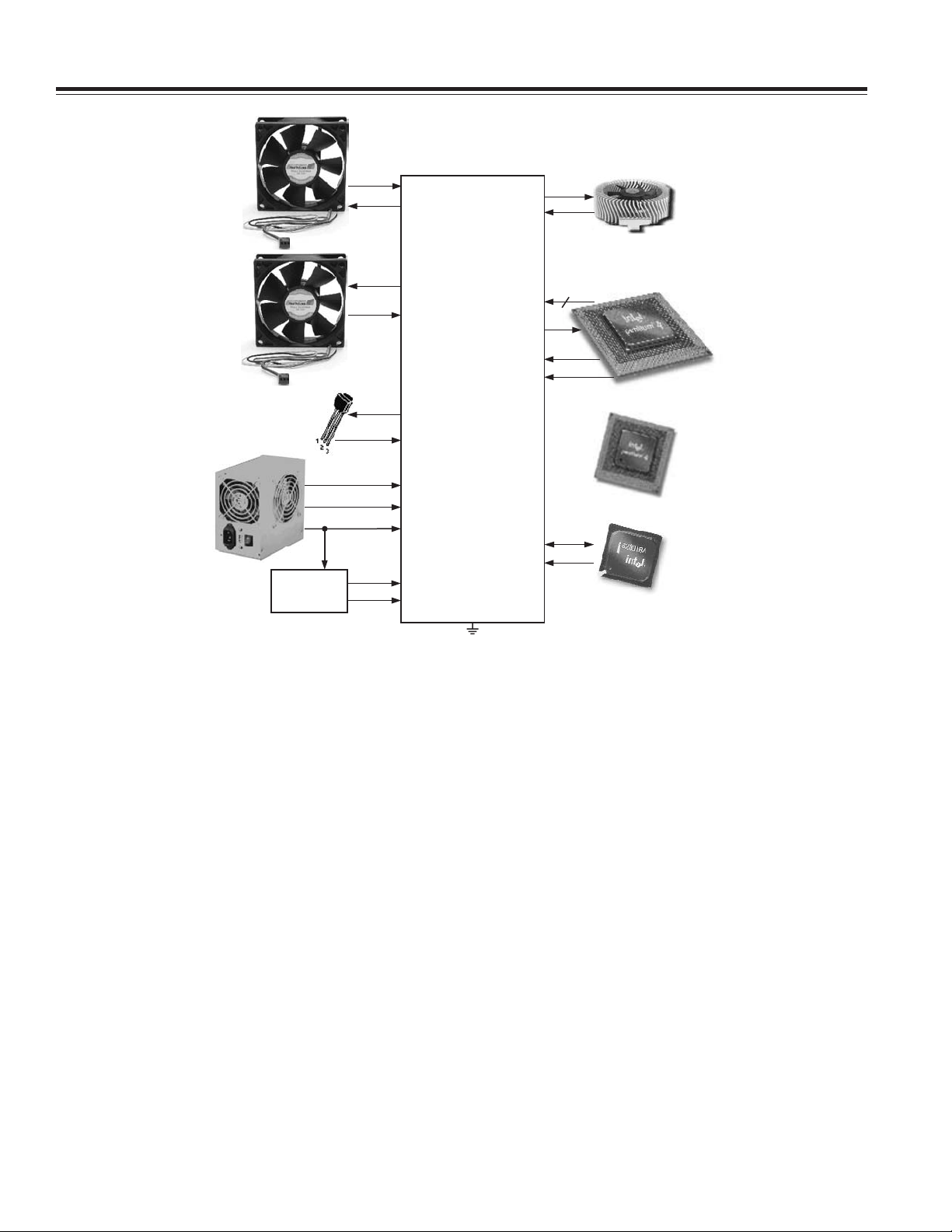

RECOMMENDED IMPLEMENTATION 2

Configuring the ADT7460/ADT7463 as in Figure 4 provides the systems designer with the following features:

1. Six VID Inputs (VID0 to VID5) for VRM10 Support.

2. Three PWM Outputs for Fan Control of up to Three

Fans. (All three fans can be individually controlled.)

3. Three TACH Fan Speed Measurement Inputs.

4. V

5. CPU Core Voltage Measurement (V

Measured Internally through Pin 4.

CC

CORE

).

6. 2.5 V Measurement Input Used to Monitor CPU Current (connected to V

output of ADP316x VRM

COMP

Controller). This is used to determine CPU power

consumption.

VID[0:4]/VID[0.5]

ADT7463

GND

5(VRM9)/6(VRM10)

D2+

D2–

THERM

PROCHOT

SDA

SCL

7. 5 V Measurement Input.

8. VRM Temperature Uses Local Temperature Sensor.

9. CPU Temperature Measured Using Remote 1 Temperature Channel.

10. Ambient Temperature Measured through Remote 2

Temperature Channel.

11. If not using VID5, this pin can be reconfigured as the

12 V monitoring input.

12. BIDIRECTIONAL THERM Pin. Allows monitoring

of PROCHOT output from Intel P4 processor, for

example, or can be used as an overtemperature

THERM output.

–4–

REV. 0

Page 5

AN-613

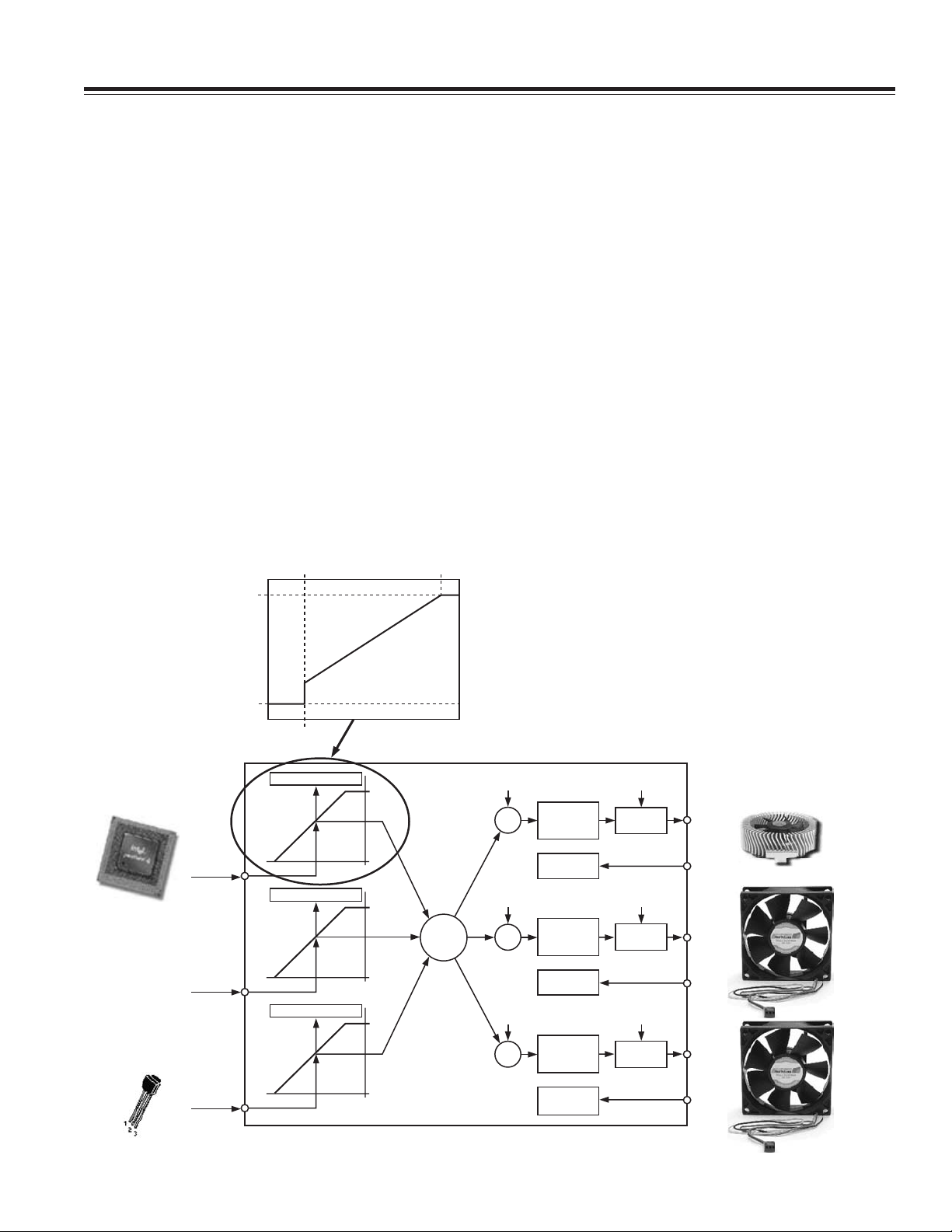

STEP 2: CONFIGURING THE MUX—WHICH TEMPERATURE CONTROLS WHICH FAN?

After the system hardware configuration is determined,

the fans can be assigned to particular temperature channels. Not only can fans be assigned to individual

channels, but the behavior of fans is also configurable.

For example, fans can be run under automatic fan control, can run manually (under software control), or can

run at the fastest speed calculated by multiple temperature channels. The MUX is the bridge between

temperature measurement channels and the three PWM

outputs.

Bits <7:5> (BHVR bits) of registers 0x5C, 0x5D, and 0x5E

(PWM configuration registers) control the behavior of

the fans connected to the PWM1, PWM2, and PWM3 outputs. The values selected for these bits determine how

the MUX connects a temperature measurement channel

to a PWM output.

AUTOMATIC FAN CONTROL MUX OPTIONS

<7:5> (BHVR) REGISTERS 0x5C, 0x5D, 0x5E

000 = Remote 1 Temp controls PWMx

001 = Local Temp controls PWMx

010 = Remote 2 Temp controls PWMx

101 = Fastest Speed calculated by Local and Remote 2

Temp controls PWMx

110 = Fastest Speed calculated by all three temperature

channels controls PWMx

The "Fastest Speed Calculated" options pertain to the

ability to control one PWM output based on multiple

temperature channels. The thermal characteristics of

the three temperature zones can be set to drive a

single fan. An example would be if the fan turns on

when Remote 1 temperature exceeds 60°C or if the local

temperature exceeds 45°C.

OTHER MUX OPTIONS

<7:5> (BHVR) REGISTERS 0x5C, 0x5D, 0x5E

011 = PWMx runs full speed (default)

100 = PWMx disabled

111 = Manual Mode. PWMx is run under software control.

In this mode, PWM duty cycle registers (registers 0x30 to

0x32) are writable and control the PWM outputs.

REMOTE 1 =

AMBIENT TEMP

LOCAL =

VRM TEMP

REMOTE 2 =

CPU TEMP

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

T

RANGE

T

RANGE

T

RANGE

100%

0%

100%

0%

100%

0%

MUX

MUX

PWM

MIN

PWM

MIN

PWM

MIN

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 1

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 2

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 3

AND 4

MEASUREMENT

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

TACH1

PWM2

TACH2

PWM3

TACH3

CPU

FAN SINK

FRONT

CHASSIS

REAR

CHASSIS

REV. 0

Figure 5. Assigning Temperature Channels to Fan Channels

–5–

Page 6

AN-613

MUX CONFIGURATION EXAMPLE

This is an example of how to configure the MUX in a

system using the ADT7460/ADT7463 to control three

fans. The CPU fan sink is controlled by PWM1, the front

chassis fan is controlled by PWM 2, and the rear chassis

fan is controlled by PWM3. The MUX is configured for

the following fan control behavior:

PWM1 (CPU fan sink) is controlled by the fastest speed

calculated by the Local (VRM Temp) and Remote 2 (processor) temperature. In this case, the CPU fan sink is

also being used to cool the VRM.

PWM2 (front chassis fan) is controlled by the Remote 1

temperature (ambient).

PWM3 (rear chassis fan) is controlled by the Remote 1

temperature (ambient).

REMOTE 2 =

CPU TEMP

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

RANGE

100%

0%

100%

MUX

EXAMPLE MUX SETTINGS

<7:5> (BHVR) PWM1 CONFIGURATION REG 0x5C

101 = Fastest speed calculated by Local and Remote 2

Temp controls PWM1.

<7:5> (BHVR) PWM2 CONFIGURATION REG 0x5D

000 = Remote 1 Temp controls PWM2.

<7:5> (BHVR) PWM3 CONFIGURATION REG 0x5E

000 = Remote 1 Temp controls PWM3.

These settings configure the MUX, as shown in Figure 6.

PWM

MIN

PWM

MIN

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 1

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

TACH1

PWM2

CPU

FAN SINK

FRONT

CHASSIS

LOCAL =

VRM TEMP

REMOTE 1 =

AMBIENT TEMP

T

MIN

THERMAL CALIBRATION

T

MIN

T

RANGE

T

RANGE

TACHOMETER 2

PWM

MIN

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 3

AND 4

MEASUREMENT

0%

100%

0%

Figure 6. MUX Configuration Example

PWM

CONFIG

PWM

GENERATOR

TACH2

PWM3

TACH3

REAR

CHASSIS

–6–

REV. 0

Page 7

AN-613

STEP 3: DETERMINING T

SETTING FOR EACH

MIN

THERMAL CALIBRATION CHANNEL

T

is the temperature at which the fans will start to

MIN

turn on under automatic fan control. The speed at which

the fan runs at T

is programmed later. The T

MIN

MIN

values

chosen will be temperature channel specific, e.g., 25°C

for ambient channel, 30°C for VRM temperature, and

40°C for processor temperature.

T

is an 8-bit twos complement value that can be pro-

MIN

grammed in 1°C increments. There is a T

register

MIN

associated with each temperature measurement channel:

Remote 1, Local, and Remote 2 Temp. Once the T

MIN

value is exceeded, the fan turns on and runs at minimum

PWM duty cycle. The fan will turn off once temperature

has dropped below T

MIN

– T

(detailed later).

HYST

To overcome fan inertia, the fan is spun up until two

valid tach rising edges are counted. See the Fan Startup

Timeout section of the ADT7460/ADT7463 data sheet

for more details. In some cases, primarily for psychoacoustic reasons, it is desirable that the fan never

switches off below T

. Bits <7:5> of enhance acoustics

MIN

Register 1 (Reg. 0x62), when set, keeps the fans running

at PWM minimum duty cycle if the temperature should

fall below T

T

REGISTERS

MIN

Reg. 0x67 Remote 1 Temp T

Reg. 0x68 Local Temp T

Reg. 0x69 Remote 2 Temp T

MIN

.

= 0x5A (90°C default)

MIN

= 0x5A (90°C default)

MIN

= 0x5A (90°C default)

MIN

ENHANCE ACOUSTICS REG 1 (REG. 0x62)

Bit 7 (MIN3) = 0, PWM3 is OFF (0% PWM duty cycle)

when Temp is below T

MIN

– T

HYST

.

Bit 7 (MIN3) = 1, PWM3 runs at PWM3 minimum duty

cycle below T

MIN

– T

HYST

.

Bit 6 (MIN2) = 0, PWM2 is OFF (0% PWM duty cycle)

when Temp is below T

MIN

– T

HYST

.

Bit 6 (MIN2) = 1, PWM2 runs at PWM2 minimum duty

cycle below T

MIN

– T

HYST

.

Bit 5 (MIN1) = 0, PWM1 is OFF (0% PWM duty cycle)

when Temp is below T

MIN

– T

HYST

.

Bit 5 (MIN1) = 1, PWM1 runs at PWM1 minimum duty

cycle below T

MIN

– T

HYST

.

REMOTE 2 =

CPU TEMP

LOCAL =

VRM TEMP

REMOTE 1 =

AMBIENT TEMP

100%

PWM DUTY CYCLE

0%

T

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

MIN

T

RANGE

T

RANGE

T

RANGE

100%

0%

100%

0%

100%

0%

MUX

PWM

MIN

PWM

MIN

PWM

MIN

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT

TACHOMETER 1

MEASUREMENT

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT

TACHOMETER 2

MEASUREMENT

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT

TACHOMETER 3

AND 4

MEASUREMENT

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

TACH1

PWM2

TACH2

PWM3

TACH3

CPU

FAN SINK

FRONT

CHASSIS

REAR

CHASSIS

REV. 0

Figure 7. Understanding the T

–7–

Parameter

MIN

Page 8

AN-613

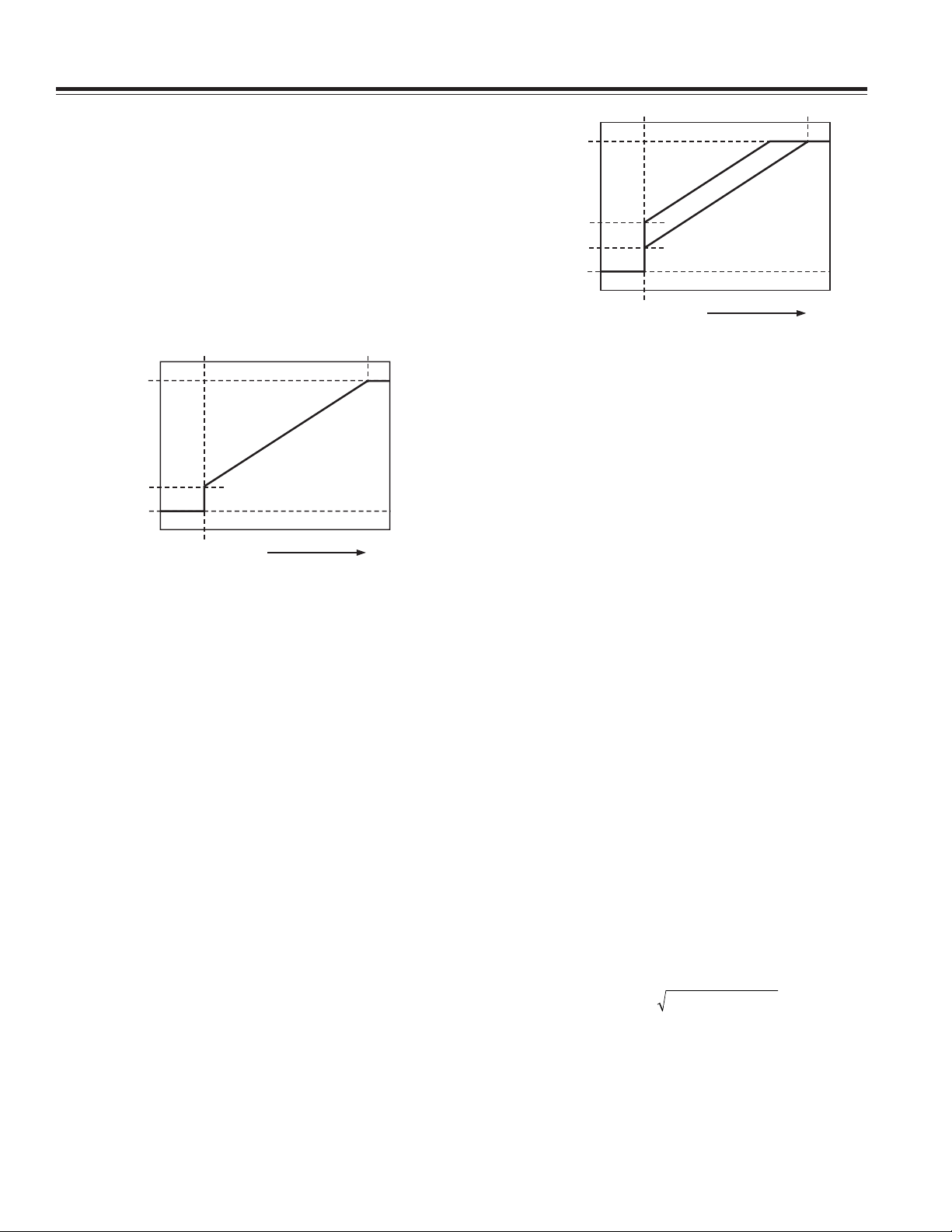

STEP 4: DETERMINING PWM

FOR EACH PWM (FAN)

MIN

OUTPUT

PWM

is the minimum PWM duty cycle at which each

MIN

fan in the system will run. It is also the “start” speed for

each fan under automatic fan control once the temperature rises above T

benefit, PWM

MIN

. For maximum system acoustic

MIN

should be as low as possible. Starting

the fans at higher speeds than necessary will merely

make the system louder than necessary. Depending on

the fan used, the PWM

setting should be in the 20% to

MIN

33% duty cycle range. This value can be found through

fan validation.

100%

PWM DUTY CYCLE

PWM

MIN

0%

TEMPERATURE

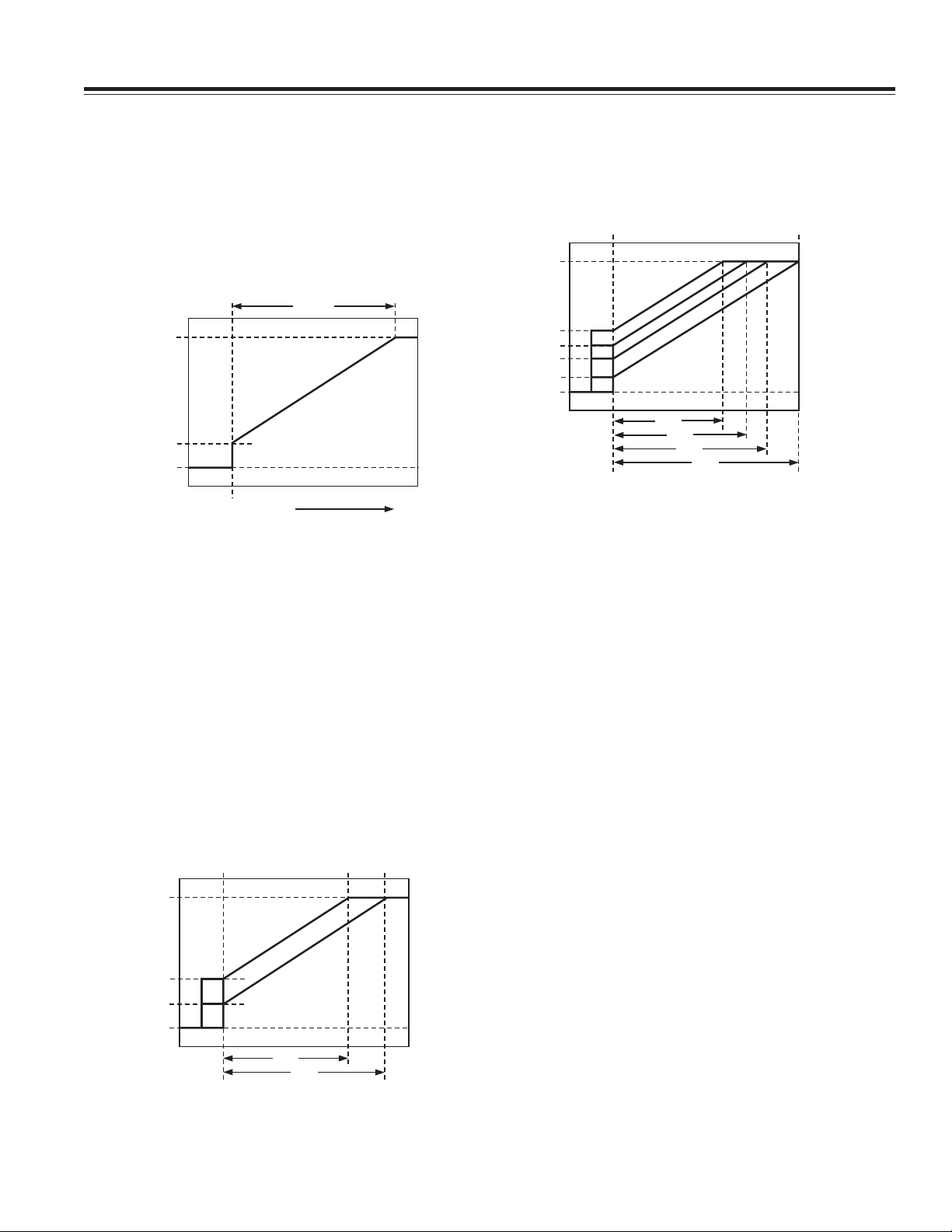

Figure 8. PWM

T

MIN

Determines Minimum PWM

MIN

Duty Cycle

It is important to note that more than one PWM

output can be controlled from a single temperature

measurement channel. For example, Remote 1 Temp

can control PWM1 and PWM2 outputs. If two different

fans are used on PWM and PWM2, then the fan characteristics can be set up differently. As a result, Fan 1

driven by PWM1 can have a different PWM

value than

MIN

that of Fan 2 connected to PWM2. Figure 9 illustrates

this as PWM1

duty cycle of 20%, whereas PWM2

(front fan) is turned on at a minimum

MIN

(rear fan) turns

MIN

on at a minimum of 40% duty cycle. Note, however,

that both fans turn on at exactly the same temperature, defined by T

MIN

.

100%

PWM2

PWM2

MIN

PWM DUTY CYCLE

PWM1

MIN

0%

T

MIN

PWM1

TEMPERATURE

Figure 9. Operating Two Different Fans from a Single

Temperature Channel

PROGRAMMING THE PWM

The PWM

registers are 8-bit registers that allow the

MIN

REGISTERS

MIN

minimum PWM duty cycle for each output to be configured anywhere from 0% to 100%. This allows minimum

PWM duty cycle to be set in steps of 0.39%.

The value to be programmed into the PWM

register is

MIN

given by:

Value (decimal) = PWM

MIN

/0.39

Example 1: For a minimum PWM duty cycle of 50%,

Value (decimal) = 50/0.39 = 128 decimal

Value = 128 decimal or 80 hex

Example 2: For a minimum PWM duty cycle of 33%,

Value (decimal) = 33/0.39 = 85 decimal

Value = 85 decimal or 54 hex

PWM

REGISTERS

MIN

Reg. 0x64 PWM1 Min Duty Cycle = 0x80 (50% default)

Reg. 0x65 PWM2 Min Duty Cycle = 0x80 (50% default)

Reg. 0x66 PWM3 Min Duty Cycle = 0x80 (50% default)

FAN SPEED AND PWM DUTY CYCLE

It should be noted that PWM duty cycle does not

directly correlate to fan speed in RPM. Running a fan at

33% PWM duty cycle does not equate to running the fan

at 33% speed. Driving a fan at 33% PWM duty cycle

actually runs the fan at closer to 50% of its full speed.

This is because fan speed in %RPM relates to the square

root of PWM duty cycle. Given a PWM square wave as

the drive signal, fan speed in RPM equates to:

–8–

% fan speed PWM duty cycle 10=×

REV. 0

Page 9

AN-613

STEP 5: DETERMINING T

FOR EACH TEMPERATURE

RANGE

CHANNEL

T

is the range of temperature over which automatic

RANGE

fan control occurs once the programmed T

ture has been exceeded. T

is actually a temperature

RANGE

slope and not an arbitrary value, i.e., a T

only holds true for PWM

creased or decreased, the effective T

= 33%. If PWM

MIN

RANGE

tempera-

MIN

of 40°C

RANGE

is in-

MIN

is changed, as

described later.

T

RANGE

100%

PWM DUTY CYCLE

PWM

MIN

0%

TEMPERATURE

Figure 10. T

The T

RANGE

T

MIN

Parameter Affects Cooling Slope

RANGE

or fan control slope is determined by the fol-

lowing procedure:

1. Determine the maximum operating temperature for

that channel, e.g., 70°C.

2. Determine experimentally the fan speed (PWM duty

cycle value) that will not exceed the temperature at

the worst-case operating points, e.g., 70°C is reached

when the fans are running at 50% PWM duty cycle.

3. Determine the slope of the required control loop to

meet these requirements.

4. Use best fit approximation to determine the most

suitable T

value. ADT7460/ADT7463 evaluation

RANGE

software is available to calculate the best fit value.

Ask your local Analog Devices representative for

more details.

100%

50%

PWM DUTY CYCLE

33%

0%

30C

T

MIN

Figure 11. Adjusting PWM

40C

MIN

Affects T

RANGE

T

is implemented as a slope, which means as

RANGE

PWM

is changed, T

MIN

changes but the actual slope

RANGE

remains the same. The higher the PWM

smaller the effective T

will be, i.e., the fan will reach

RANGE

full speed (100%) at a lower temperature.

100%

50%

33%

25%

PWM DUTY CYCLE

10%

0%

30C

40C

45C

54C

T

MIN

Figure 12. Increasing PWM

T

RANGE

For a given T

value, the temperature at which the

RANGE

Changes Effective

MIN

fan will run at full speed for different PWM

easily be calculated:

T

=

T

+ ((

MAX

Max D. C. – Min D. C.

MIN

)

T

RANGE

where

T

= Temperature at which the fan runs full speed

MAX

T

= Temperature at which the fan will turn on

MIN

Max D. C.

Min D. C.

T

RANGE

Example: Calculate

40°C, and PWM

T

MAX

T

MAX

T

MAX

T

MAX

Example: Calculate

40°C, and PWM

T

MAX

T

MAX

T

MAX

T

MAX

Example: Calculate

40°C, and PWM

T

MAX

T

MAX

T

MAX

T

MAX

= Maximum duty cycle (100%) = 255 decimal

= PWM

MIN

= PWM duty cycle versus temperature slope

T

=

, given

MAX

= 10% duty cycle = 26 decimal

MIN

T

+ (

MIN

Max D. C.

–

Min D. C.

T

MIN

)

= 30°C,

T

RANGE

= 30°C + (100% – 10%) 40°C/170

= 30°C + (255 – 26) 40°C/170

= 84°C (

=

T

MIN

effective T

MIN

+ (

Max D. C.

= 54°C)

RANGE

T

MAX

, given

T

MIN

= 30°C,

= 25% duty cycle = 64 decimal

–

Min D. C.

)

T

RANGE

= 30°C + (100% – 25%) 40°C/170

= 30°C + (255 – 64) 40°C/170

= 75°C (

=

T

MIN

effective T

MIN

+ (

Max D. C.

= 45°C)

RANGE

T

MAX

, given

T

MIN

= 30°C,

= 33% duty cycle = 85 decimal

–

Min D. C.

)

T

RANGE

= 30°C + (100% – 33%) 40°C/170

= 30°C + (255 – 85) 40°C/170

= 70°C (

effective T

RANGE

= 40°C)

value, the

MIN

values can

MIN

/170

T

/170

T

/170

T

/170

RANGE

RANGE

RANGE

=

=

=

REV. 0

–9–

Page 10

AN-613

TEMPERATURE ABOVE T

MIN

020406080100 120

0

FAN SPEED – % OF MAX

10

20

30

40

50

60

70

80

90

100

2

C

80

C

53.3

C

40

C

32

C

26.6

C

20

C

16

C

13.3

C

10

C

8

C

6.67

C

5

C

4

C

3.33

C

2.5

C

TEMPERATURE ABOVE T

MIN

020406080100 120

0

PWM DUTY CYCLE – %

10

20

30

40

50

60

70

80

90

100

2

C

80

C

53.3

C

40

C

32

C

26.6

C

20

C

16

C

13.3

C

10

C

8

C

6.67

C

5

C

4

C

3.33

C

2.5

C

Example: Calculate

40°C, and PWM

T

=

T

+ (

MIN

= 30°C + (100% – 50%) 40°C/170

= 30°C + (255 – 128) 40°C/170

= 60°C (

effective T

T

T

T

MAX

MAX

MAX

MAX

SELECTING A T

The T

value can be selected for each temperature

RANGE

T

, given

MAX

= 50% duty cycle = 128 decimal

MIN

Max D. C.

RANGE

–

RANGE

SLOPE

Min D. C.

= 30°C)

channel: Remote 1, Local, and Remote 2 Temp. Bits

<7:4> (T

) of registers 0x5F to 0x61 define the T

RANGE

value for each temperature channel.

Table I. Selecting a T

Bits <7:4>* T

RANGE

0000 2°C

0001 2.5°C

0010 3.33°C

0011 4°C

0100 5°C

0101 6.67°C

0110 8°C

0111 10°C

1000 13.33°C

1001 16°C

1010 20°C

1011 26.67°C

1100 32°C (default)

1101 40°C

1110 53.33°C

1111 80°C

SUMMARY OF T

When using the automatic fan control function, the temperature at which the fan reaches full speed can be

calculated by

T

MAX

Equation 1 only holds true when PWM

duty cycle.

Increasing or decreasing PWM

tive T

same PWM duty cycle to temperature slope. The effective T

calculated using Equation 2.

T

MAX

where:

(

Max D. C.

value

* Register 0x5F configures Remote 1 T

Register 0x60 configures Local T

Register 0x61 configures Remote 2 T

FUNCTION

RANGE

=

T

+ T

MIN

RANGE

MIN

, although the fan control will still follow the

RANGE

for different PWM

RANGE

=

T

+ (

Max D. C.

MIN

–

Min D. C.

–

Min D. C.

)

T

RANGE

.

T

= 30°C,

MIN

)

T

Value

RANGE

RANGE

MIN

will change the effec-

values can be

MIN

)

T

/170 =

effective T

T

RANGE

/170

RANGE

RANGE

RANGE

= 33% PWM

/170 (2)

RANGE

RANGE

RANGE

=

(1)

–10–

Remember that %PWM duty cycle does not correspond

to %RPM. %RPM relates to the square root of the PWM

duty cycle.

% fan speed PWM duty cycle 10=×

Figure 13. T

vs. Actual Fan Speed Profile

RANGE

Figure 13 shows PWM duty cycle versus temperature for

each T

T

RANGE

setting. The lower graph shows how each

RANGE

setting affects fan speed versus temperature. As

can be seen from the graph, the effect on fan speed is

nonlinear. The graphs in Figure 13 assume that the fan

starts from 0% PWM duty cycle. Clearly, the minimum

PWM duty cycle, PWM

, needs to be factored in to see

MIN

how the loop actually performs in the system. Figure 14

shows how T

is affected when the PWM

RANGE

value is

MIN

set to 20%. It can be seen that the fan will actually run at

about 45% fan speed when the temperature exceeds T

MIN

REV. 0

.

Page 11

100

TEMPERATURE ABOVE T

MIN

010203040 10050 60 70 80 90

0

PWM DUTY CYCLE – %

10

20

30

40

50

60

70

80

90

100

TEMPERATURE ABOVE T

MIN

0

FAN SPEED – % MAX RPM

10

20

30

40

50

60

70

80

90

100

010203040 10050 60 70 80 90

90

80

70

60

50

40

30

PWM DUTY CYCLE – %

20

10

0

020406080100 120

TEMPERATURE ABOVE T

MIN

2

2.5

3.33

4

5

6.67

8

10

13.3

16

20

26.6

32

40

53.3

80

AN-613

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

This example uses the MUX configuration described

in Step 2, with the ADT7460/ADT7463 connected as

shown in Figure 6. Both CPU temperature and VRM temperature drive the CPU fan connected to PWM1.

Ambient temperature drives the front chassis fan and

rear chassis fan connected to PWM2 and PWM3.

The front chassis fan is configured to run at

PWM

at PWM

The CPU fan is configured to run at PWM

= 20%. The rear chassis fan is configured to run

MIN

= 30%.

MIN

= 10%.

MIN

100

90

80

70

60

50

40

30

FAN SPEED – % OF MAX

20

10

0

020406080100 120

Figure 14. T

PWM

EXAMPLE: DETERMINING T

TEMPERATURE CHANNEL

The following example is used to show how T

settings might be applied to three different thermal

zones. In this example, the following T

apply:

T

= 80°C for Ambient Temperature

RANGE

T

= 53.3°C for CPU Temperature

RANGE

T

= 40°C for VRM Temperature

RANGE

TEMPERATURE ABOVE T

RANGE

= 20%

MIN

, % Fan Speed Slopes with

FOR EACH

RANGE

MIN

MIN

RANGE

C

2

2.5

3.33

C

4

C

5

6.67

C

8

C

10

13.3

16

C

C

20

26.6

C

32

C

40

53.3

80

C

, T

RANGE

values

C

C

C

C

C

C

Figure 15. T

, % Fan Speed Slopes for VRM,

RANGE

Ambient, and CPU Temperature Channels

REV. 0

–11–

Page 12

AN-613

STEP 6: DETERMINING T

FOR EACH TEMPERATURE

THERM

CHANNEL

T

is the absolute maximum temperature allowed

THERM

on a temperature channel. Above this temperature, a

component such as the CPU or VRM may be operating

beyond its safe operating limit. When the temperature

measured exceeds T

, all fans are driven at 100% PWM

THERM

duty cycle (full speed) to provide critical system cooling.

The fans remain running 100% until the temperature drops

below T

– hysteresis. The hysteresis value is the

THERM

number programmed into hysteresis registers 0x6D and

0x6E. The default hysteresis value is 4°C.

The T

limit should be considered the maximum

THERM

worst-case operating temperature of the system. Since

exceeding any T

limit runs all fans at 100%, it has

THERM

very negative acoustic effects. Ultimately, this limit

should be set up as a failsafe, and one should ensure

that it is not exceeded under normal system operating

conditions.

T

RANGE

100%

Note that the T

limits are nonmaskable and affect

THERM

the fan speed no matter what automatic fan control settings are configured. This allows some flexibility since a

T

value can be selected based on its slope, while a

RANGE

“hard limit,” e.g., 70°C, can be programmed as T

MAX

(the

temperature at which the fan reaches full speed) by setting T

THERM

to 70°C.

THERM REGISTERS

Reg. 0x6A Remote 1 THERM limit = 0x64 (100°C default)

Reg. 0x6B Local Temp THERM limit = 0x64 (100°C

default)

Reg. 0x6C Remote 2 THERM limit = 0x64 (100°C default)

HYSTERESIS REGISTERS

Reg. 0x6D Remote 1, Local Hysteresis Register

<7:4> = Remote 1 Temp Hysteresis (4°C default)

<3:0> = Local Temp Hysteresis (4°C default)

Reg. 0x6E Remote 2 Temp Hysteresis Register

<7:4> = Remote 2 Temp Hysteresis (4°C default)

Since each hysteresis setting is four bits, hysteresis values

are programmable from 1°C to 15°C. It is not recommended that hysteresis values ever be programmed to

0°C, as this actually disables hysteresis. In effect, this

would cause the fans to cycle between normal speed and

100% speed, creating unsettling acoustic noise.

PWM DUTY CYCLE

0%

REMOTE 2 =

CPU TEMP

LOCAL =

VRM TEMP

REMOTE 1 =

AMBIENT TEMP

T

MIN

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

T

RANGE

T

RANGE

T

RANGE

T

THERM

100%

0%

100%

0%

100%

0%

MUX

PWM

MIN

PWM

PWM

MIN

MIN

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 1

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 2

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 3

AND 4

MEASUREMENT

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

TACH1

PWM2

TACH2

PWM3

TACH3

CPU

FAN SINK

FRONT

CHASSIS

REAR

CHASSIS

Figure 16. Understanding How T

Relates to Automatic Fan Control

THERM

–12–

REV. 0

Page 13

AN-613

STEP 7: DETERMINING T

FOR EACH TEMPERATURE

HYST

CHANNEL

T

is the amount of extra cooling a fan provides after

HYST

the temperature measured has dropped back below T

MIN

before the fan turns off. The premise for temperature

hysteresis (T

) is that without it, the fan would merely

HYST

“chatter,” or cycle on and off regularly, whenever temperature is hovering at about the T

The T

value chosen will determine the amount of

HYST

setting.

MIN

time needed for the system to cool down or heat up as

the fan is turning on and off. Values of hysteresis are

programmable in the range 1°C to 15°C. Larger values of

T

prevent the fans from chattering on and off as pre-

HYST

viously described. The T

100%

PWM DUTY CYCLE

0%

default value is set at 4°C.

HYST

T

RANGE

T

HYST

T

MIN

T

THERM

Note that the T

setting applies not only to the

HYST

temperature hysteresis for fan turn on/off, but the same

setting is used for the T

hysteresis value described

THERM

in Step 6. So programming registers 0x6D and 0x6E sets

the hysteresis for both fan on/off and the THERM function.

HYSTERESIS REGISTERS

Reg. 0x6D Remote 1, Local Hysteresis Register

<7:4> = Remote 1 Temp Hysteresis (4°C default)

<3:0> = Local Temp Hysteresis (4°C default)

Reg. 0x6E Remote 2 Temp Hysteresis Register

<7:4> = Remote 2 Temp Hysteresis (4°C default)

Note that in some applications, it is required that the

fans not turn off below T

PWM

. Bits <7:5> of Enhance Acoustics Register 1

MIN

but remain running at

MIN

(Reg. 0x62) allow the fans to be turned off, or to be kept

spinning below T

. If the fans are always on, the T

MIN

HYST

value has no effect on the fan when the temperature drops

below T

MIN

.

REMOTE 2 =

CPU TEMP

LOCAL =

VRM TEMP

REMOTE 1 =

AMBIENT TEMP

Figure 17. The T

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

HYST

T

RANGE

T

RANGE

T

RANGE

100%

0%

100%

0%

100%

0%

MUX

PWM

MIN

PWM

MIN

PWM

MIN

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 1

MEASUREMENT

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 2

MEASUREMENT

RAMP

CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 3

AND 4

MEASUREMENT

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

TACH1

PWM2

TACH2

PWM3

TACH3

Value Applies to Fan On/Off Hysteresis and THERM Hysteresis

CPU

FAN SINK

FRONT

CHASSIS

REAR

CHASSIS

REV. 0

–13–

Page 14

AN-613

ENHANCE ACOUSTICS REG 1 (REG. 0x62)

Bit 7 (MIN3) = 0, PWM3 is OFF (0% PWM duty cycle)

when Temp is below T

MIN

– T

HYST

.

Bit 7 (MIN3) = 1, PWM3 runs at PWM3 minimum duty

cycle below T

MIN

– T

HYST

.

Bit 6 (MIN2) = 0, PWM2 is OFF (0% PWM duty cycle)

when Temp is below T

MIN

– T

HYST

.

Bit 6 (MIN2) = 1, PWM2 runs at PWM2 minimum duty

cycle below T

MIN

– T

HYST

.

Bit 5 (MIN1) = 0, PWM1 is OFF (0% PWM duty cycle)

when Temp is below T

MIN

– T

HYST

.

Bit 5 (MIN1) = 1, PWM1 runs at PWM1 minimum duty

cycle below T

DYNAMIC T

– T

MIN

CONTROL MODE

MIN

HYST

.

In addition to the automatic fan speed control mode described in the previous section, the ADT7460/ADT7463

have a mode that extends the basic automatic fan speed

control loop. Dynamic T

control allows the

MIN

ADT7460/ADT7463 to intelligently adapt the system’s

cooling solution for best system performance or lowest

possible system acoustics, depending on user or design

requirements.

AIM OF THIS SECTION

This section has two primary goals:

1. To show how dynamic T

control alleviates the

MIN

need for designing for worst-case conditions.

2. To illustrate how the dynamic T

control function

MIN

significantly reduces system design and validation

time.

DESIGNING FOR WORST-CASE CONDITIONS

When designing a system, you always design for worstcase conditions. In PC design, the worst-case conditions

include, but are not limited to:

1. Worst-Case Altitude. A computer can be operated at

different altitudes. The altitude affects the relative air

density, which will alter the effectiveness of the fan

cooling solution. For example, comparing 40°C air

temperature at 10,000 ft to 20°C air temperature at

sea level, relative air density is increased by 40%. This

means that the fan can spin 40% slower, and make less

noise, at sea level than at 10,000 ft while keeping the

system at the same temperature at both locations.

2. Worst-Case Fan. Due to manufacturing tolerances,

fan speeds in RPM are normally quoted with a tolerance of ±20%. The designer needs to assume that the

fan RPM can be 20% below tolerance. This translates

to reduced system airflow and elevated system temperature. Note that fans 20% out of tolerance will

negatively impact system acoustics since they run

faster and generate more noise.

3. Worst-Case Chassis Airflow. The same motherboard

can be used in a number of different chassis configurations. The design of the chassis and physical

location of fans and components determine the system thermal characteristics. Moreover, for a given

chassis, the addition of add-in cards, cables, or other

system configuration options can alter the system

airflow and reduce the effectiveness of the system

cooling solution. The cooling solution can also be

inadvertently altered by the end user, e.g., placing a

computer against a wall can block the air ducts and

reduce system airflow.

VENTS

I/O CARDS

GOOD CPU AIRFLOW

FAN

VENTS

GOOD VENTING = GOOD AIR EXCHANGE POOR VENTING = POOR AIR EXCHANGE

FAN FAN

I/O CARDS

POOR CPU

AIRFLOW

POWER

SUPPLY

CPU

DRIVE

BAYS

VENTS

POWER

SUPPLY

CPU

DRIVE

BAYS

Figure 18. Chassis Airflow Issues

4. Worst-Case Processor Power Consumption. This is a

data sheet maximum that does not necessarily reflect

the true processor power consumption. Designing for

worst-case CPU power consumption results in that

the processor getting overcooled (generating excess

system noise).

5. Worst-Case Peripheral Power Consumptions. The

tendency is to design to data sheet maximums for

these components (again overcooling the system).

6. Worst-Case Assembly. Every system manufactured is

unique because of manufacturing variations. Heat

sinks may be loose fitting or slightly misaligned. Too

much or too little thermal grease may be used, or variations in application pressure for thermal interface

material can affect the efficiency of the thermal solution.

How can this be accounted for in every system? Again,

the system is designed for the worst case.

T

A

SA

TIMS

CTIM

TIMC

JTIM

T

S

T

TIM

T

C

T

TIM

T

CA

CS

JA

J

HEAT

THERMAL

INTERFACE

MATERIAL

INTEGRATED

HEAT

SPREADER

SINK

SUBSTRATE

THERMAL INTERFACE MATERIAL

PROCESSOR

EPOXY

Figure 19. Thermal Model

–14–

REV. 0

Page 15

AN-613

The design usually accounts for worst-case conditions

in all of these cases.

Note, however, that the actual system is almost never

operated at worst-case conditions.

The alternative to designing for the worst case is to use

the dynamic T

DYNAMIC T

Dynamic T

matic fan control loop by adjusting the T

control function.

MIN

CONTROL—OVERVIEW

MIN

Control mode builds upon the basic auto-

MIN

MIN

value based on system performance and measured temperature. Why is this important?

Instead of designing for the worst case, the system

thermals can be defined as “operating zones.” The

ADT7460/ADT7463 will self-adjust its fan control loop to

maintain an operating zone temperature or system target temperature. For example, you can specify that the

ambient temperature in a system should be maintained

at 50°C. If the temperature is below 50°C, the fans may not

need to run or may run very slowly. If the temperature is

higher than 50°C, the fans need to throttle up. How is this

different from the automatic fan control mode?

The challenge presented by any thermal design is finding the right settings to suit the system’s fan control

solution. This can involve designing for the worst case

(as previously outlined), followed by weeks of system

thermal characterization, and finally fan acoustic optimization (for psycho-acoustic reasons). Getting the most

benefit from the automatic fan control mode involves

characterizing the system to find the best T

T

settings for the control loop, and the best

RANGE

PWM

the ADT7460/ADT7463’s dynamic T

value for the quietest fan speed setting. Using

MIN

control mode

MIN

MIN

and

shortens the characterization time and alleviates tweaking the control loop settings because the device can

self-adjust during system operation.

DYNAMIC T

The dynamic T

CONTROL—THE SPECIFICS

MIN

control mode is operated by specify-

MIN

ing the “operating zone temperatures” required for the

system. Associated with this control mode are three

operating point registers, one for each temperature

channel. This allows the system thermal solution to be

broken down into distinct thermal zones, e.g., CPU operating temperature = 70°C, VRM operating temperature =

80°C, ambient operating temperature = 50°C. The

ADT7460/ADT7463 will dynamically alter the control

solution to maintain each zone temperature as closely

as possible to their target operating points.

OPERATING POINT REGISTERS

Reg. 0x33 Remote 1 Operating Point = 0x64 (100°C)

Reg. 0x34 Local Temp Operating Point = 0x64 (100°C)

Reg. 0x35 Remote 2 Operating Point = 0x64 (100°C)

PWM DUTY CYCLE

T

T

MIN

OPERATING

POINT

LOW

Figure 20. Dynamic T

T

HIGHTTHERMTRANGE

Control Loop

MIN

TEMPERATURE

Figure 20 shows an overview of the parameters that

affect the operation of the dynamic T

control loop. A

MIN

brief description of each parameter follows:

1. T

. If temperature drops below the T

LOW

limit, an

LOW

error flag is set in a status register and an SMBALERT

interrupt can be generated.

2. T

. If temperature exceeds the T

HIGH

limit, an error

HIGH

flag gets set in a status register and an SMBALERT

interrupt can be generated.

3. T

. This is the temperature at which the fan turns on

MIN

under automatic fan speed control.

4. Operating Point. This temperature defines the target

temperature or optimal operating point for a

particular temperature zone. The ADT7460/ADT7463

attempt to maintain system temperature at about the

operating point by adjusting the T

parameter of

MIN

the control loop.

5. T

. If temperature exceeds this critical limit, the

THERM

fans can be run at 100% for maximum cooling.

6. T

. This programs the PWM duty cycle versus

RANGE

temperature control slope.

DYNAMIC T

Since the dynamic T

CONTROL PROGRAMMING

MIN

control mode is a basic extension

MIN

of the automatic fan control mode, the automatic fan control mode parameters should be programmed first. Follow

the seven steps in the Automatic Fan Control section of the

ADT7460/ADT7463 data sheet before proceeding with

dynamic T

control mode programming.

MIN

REV. 0

–15–

Page 16

AN-613

STEP 8: DETERMINING THE OPERATING POINT FOR EACH TEMPERATURE CHANNEL

The operating point for each temperature channel is the

optimal temperature for that thermal zone. The hotter

each zone is allowed to be, the quieter the system since

the fans are not required to run at 100% all of the time.

The ADT7460/ADT7463 will increase/decrease fan

speeds as necessary to maintain operating point temperature. This allows for system-to-system variation

and removes the need for worst-case design. As long as

a sensible operating point value is chosen, any T

MIN

value can be selected in the system characterization. If

the T

value is too low, the fans will run sooner than

MIN

required, and the temperature will be below the operating point. In response, the ADT7460/ADT7463 will

increase T

to keep the fans off for longer and allow

MIN

OPERATING

0%

100%

0%

100%

0%

REMOTE 2 =

CPU TEMP

LOCAL =

VRM TEMP

REMOTE 1 =

AMBIENT TEMP

THERMAL CALIBRATION

T

THERMAL CALIBRATION

T

THERMAL CALIBRATION

T

MIN

MIN

MIN

T

RANGE

T

RANGE

T

RANGE

100%

POINT

MUX

PWM

MIN

PWM

MIN

PWM

MIN

the temperature zone to get closer to the operating

point. Likewise, too high a T

value will cause the

MIN

operating point to be exceeded, and in turn, the

ADT7460/ADT7463 will reduce T

to turn the fans on

MIN

earlier to cool the system.

PROGRAMMING OPERATING POINT REGISTERS

There are three operating point registers, one associated with each temperature channel. These 8-bit

registers allow the operating point temperatures to be

programmed with 1°C resolution.

OPERATING POINT REGISTERS

Reg. 0x33 Remote 1 Operating Point = 0x64 (100°C)

Reg. 0x34 Local Temp Operating Point = 0x64 (100°C)

Reg. 0x35 Remote 2 Operating Point = 0x64 (100°C)

PWM

CONFIG

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 1

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 2

MEASUREMENT

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 3

AND 4

MEASUREMENT

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

TACH1

PWM2

TACH2

PWM3

TACH3

CPU

FAN SINK

FRONT

CHASSIS

REAR

CHASSIS

Figure 21. Operating Point Value Dynamically Adjusts Automatic Fan Control Settings

–16–

REV. 0

Page 17

AN-613

STEP 9: DETERMINING THE HIGH AND LOW LIMITS FOR EACH TEMPERATURE CHANNEL

The low limit defines the temperature at which the T

value will start to be increased if temperature falls

below this value. This has the net effect of reducing the

fan speed, allowing the system to get hotter. An interrupt can be generated when the temperature drops

below the low limit.

The high limit defines the temperature at which the T

value will start to be reduced if temperature increases

above this value. This has the net effect of increasing fan

speed in order to cool down the system. An interrupt

can be generated when the temperature rises above the

high limit.

MIN

MIN

PROGRAMMING HIGH AND LOW LIMITS

There are six limit registers; a high limit and low limit

are associated with each temperature channel. These

8-bit registers allow the high and low limit temperatures

to be programmed with 1°C resolution.

TEMPERATURE LIMIT REGISTERS

Reg. 0x4E Remote 1 Temp Low Limit = 0x81

Reg. 0x4F Remote 1 Temp High Limit = 0x7F

Reg. 0x50 Local Temp Low Limit = 0x81

Reg. 0x51 Local Temp High Limit = 0x7F

Reg. 0x52 Remote 2 Temp Low Limit = 0x81

Reg. 0x53 Remote 2 Temp High Limit = 0x7F

REV. 0

Figure 22. Dynamic T

Control in Operation

MIN

–17–

Page 18

AN-613

HOW DOES DYNAMIC T

CONTROL WORK?

MIN

The basic premise is as follows:

1. Set the target temperature for the temperature zone,

which could be, for example, the Remote 1 thermal

diode. This value is programmed to the Remote 1

operating temperature register.

2. As the temperature in that zone (Remote 1 temperature)

rises toward and exceeds the operating point temperature, T

is reduced and the fan speed increases.

MIN

3. As the temperature drops below the operating point

temperature, T

is increased, reducing the fan speed.

MIN

The loop operation is not as simple as described above.

There are a number of conditions governing situations

in which T

can increase or decrease.

MIN

SHORT CYCLE AND LONG CYCLE

The ADT7460/ADT7463 implement two loops, a short

cycle and a long cycle. The short cycle takes place every

n monitoring cycles. The long cycle takes place every 2n

monitoring cycles. The value of n is programmable for

each temperature channel. The bits are located at the

following register locations:

Remote 1 = CYR1 = Bits <2:0> of Calibration Control

Register 2 (Addr = 0x37)

Local = CYL = Bits <5:3> of Calibration Control Register 2

(Addr = 0x37)

Remote 2 = CYR2 = Bits <7:6> of Calibration Control

Register 2 and Bit 0 of Calibration Control Register 1

(Addr = 0x36)

Table II. Cycle Bit Assignments

CODE Short Cycle Long Cycle

000 8 cycles (1 s) 16 cycles (2 s)

001 16 cycles (2 s) 32 cycles (4 s)

010 32 cycles (4 s) 64 cycles (8 s)

011 64 cycles (8 s) 128 cycles (16 s)

100 128 cycles (16 s) 256 cycles (32 s)

101 256 cycles (32 s) 512 cycles (64 s)

110 512 cycles (64 s) 1024 cycles (128 s)

111 1024 cycles (128 s) 2048 cycles (256 s)

Care should be taken in choosing the cycle time. A long

cycle time means that the T

is not updated very often;

MIN

if your system has very fast temperature transients, the

dynamic T

control loop will always be lagging. If you

MIN

choose a cycle time that is too fast, the full benefit of

changing T

may not have been realized and you

MIN

change again on the next cycle; in effect you would be

overshooting. It is necessary to carry out some calibration to identify the most suitable response time.

–18–

REV. 0

Page 19

SHORT CYCLE

Figure 23 displays the steps taken during the short cycle.

WAIT n

MONITORING

CYCLES

CURRENT

TEMPERATURE

MEASUREMENT

TEMPERATURE

TEMPERATURE

MEASUREMENT

T1(n)

OPERATING

POINT

OP1

PREVIOUS

T1 (n–1)

IS T1(n) >

(OP1 – HYS)

IS T1(n) – T1(n–1)

0.25 C

YES

NO

NO

YES

DO NOTHING

DO NOTHING

(i.e., SYSTEM IS

COOLING OFF

OR CONSTANT.)

AN-613

IS T1(n) – T1(n–1) = 0.5 – 0.75

IS T1(n) – T1(n–1) = 1.0 – 1.75

IS T1(n) – T1(n–1) > 2.0

Figure 23. Short Cycle

LONG CYCLE

Figure 24 displays the steps taken during the long cycle.

WAIT 2n

MONITORING

CYCLES

CURRENT

TEMPERATURE

MEASUREMENT

TEMPERATURE

T1(n)

OPERATING

POINT

OP1

IS T1(n)

IS T1(n) < LOW TEMP LIMIT

T

< HIGH TEMP LIMIT

MIN

T

MIN

T1(n) > T

AND

AND

< OP1

AND

NO

NO

OP1

MIN

C

C

C

YES

DECREASE T

DECREASE T

DECREASE T

DECREASE T

YES

MIN

MIN

MIN

by 1 C

INCREASE

T

by 1 C

MIN

DO NOT

CHANGE

by 1 C

by 2 C

by 4 C

MIN

REV. 0

Figure 24. Long Cycle

–19–

Page 20

AN-613

EXAMPLES

The following are examples of some circumstances that

may cause T

NORMAL OPERATION—NO T

to increase or decrease or stay the same.

MIN

ADJUSTMENT

MIN

1. If measured temperature never exceeds the programmed operating point–hysteresis temperature,

then T

is not adjusted, i.e., remains at its current

MIN

setting.

2. If measured temperature never drops below the low

temperature limit, then T

THERM LIMIT

HIGH TEMP

LIMIT

OPERATING

POINT

LOW TEMP

LIMIT

HYSTERESIS

ACTUAL

TEMP

T

MIN

is not adjusted.

MIN

Figure 25. Temperature between Operating Point and

Low Temperature Limit

Since neither the operating point–hysteresis temperature nor the low temperature limit has been

exceeded, the T

at a speed determined by the fixed T

value is not adjusted and the fan runs

MIN

and T

MIN

RANGE

val-

ues defined in the automatic fan speed control mode.

OPERATING POINT EXCEEDED—T

REDUCED

MIN

When the measured temperature is below the operating

point temperature less the hysteresis, T

remains

MIN

the same.

Once the temperature exceeds the operating temperature less the hysteresis (OP – Hys), the T

starts to

MIN

decrease. This occurs during the short cycle; see Figure 23.

The rate with which T

decreases depends on the pro-

MIN

grammed value of n. It also depends on how much the

temperature has increased between this monitoring

cycle and the last monitoring cycle, i.e., if the temperature has increased by 1°C, then T

Decreasing T

has the effect of increasing the fan

MIN

is reduced by 2°C.

MIN

speed, thus providing more cooling to the system.

If the temperature is only slowly increasing in the range

(OP – Hys), i.e., ≤ 0.25°C per short monitoring cycle, then

T

does not decrease. This allows small changes in

MIN

temperature in the desired operating zone without

changing T

. The long cycle makes no change to T

MIN

MIN

in the temperature range (OP – Hys) since the temperature has not exceeded the operating temperature.

Once the temperature exceeds the operating temperature, the long cycle will cause T

to reduce by 1°C

MIN

every long cycle while the temperature remains above

the operating temperature. This takes place in addition

to the decrease in T

that would occur due to the short

MIN

cycle. In Figure 26, since the temperature is only increasing at a rate less than or equal to 0.25°C per short cycle,

no reduction in T

takes place during the short cycle.

MIN

Once the temperature has fallen below the operating

temperature, T

ture starts to increase slowly, T

stays the same. Even when the tempera-

MIN

stays the same because

MIN

the temperature increases at a rate ≤ 0.25°C per cycle.

THERM

LIMIT

HIGH TEMP

LIMIT

OPERATING

POINT

LOW TEMP

LIMIT

HYSTERESIS

T

MIN

DECREASE HERE DUE TO

SHORT CYCLE ONLY

T1(n) – T1 (n–1) = 0.5

OR 0.75

DECREASES BY 1 C

EVERY SHORT CYCLE

ACTUAL

TEMP

C = > T

MIN

NO CHANGE IN T

DUE TO ANY CYCLE SINCE

T1(n) – T1 (n–1) 0.25 C

AND T1(n) < OP = > T

STAYS THE SAME

DECREASE HERE DUE TO

C

LONG CYCLE ONLY

T1(n) – T1 (n–1)

AND T1(n) > OP = > T

DECREASES BY 1 C

EVERY LONG CYCLE

0.25 C

MIN

MIN

HERE

MIN

Figure 26. Effect of Exceeding Operating Point – Hysteresis Temperature

–20–

REV. 0

Page 21

AN-613

T

MIN

PREVENTED

FROM INCREASING

T

MIN

THERM

LIMIT

OPERATING

POINT

HIGH TEMP

LIMIT

LOW TEMP

LIMIT

ACTUAL

TEMP

HYSTERESIS

INCREASE T

MIN

CYCLE

When the temperature drops below the low temperature

limit, T

can increase in the long cycle. Increasing T

MIN

MIN

has the effect of running the fan slower and therefore

quieter. The long cycle diagram in Figure 24 shows the

conditions that need to be true for T

to increase. Here

MIN

is a quick summary of those conditions and the reasons

they need to be true.

T

can increase if

MIN

1. The measured temperature has fallen below the low

temperature limit. This means the user must choose

the low limit carefully. It should not be so low that the

temperature will never fall below it because T

MIN

would never increase and the fans would run faster

than necessary.

AND

2. T

is below the high temperature limit. T

MIN

is never

MIN

allowed to increase above the high temperature limit.

As a result, the high limit should be sensibly chosen

because it determines how high T

can go.

MIN

AND

3. T

is below the operating point temperature. T

MIN

MIN

should never be allowed to increase above the operating point temperature since the fans would not switch

on until the temperature rose above the operating point.

AND

4. The temperature is above T

control is turned off below T

. The dynamic T

MIN

.

MIN

MIN

Figure 27 shows how T

perature is above T

limit, and T

is below the high temperature limit and

MIN

increases when the current tem-

MIN

and below the low temperature

MIN

below the operating point. Once the temperature rises

above the low temperature limit, T

WHAT PREVENTS T

Since T

T

MIN

is dynamically adjusted, it is undesirable for

MIN

to reach full scale (127°C) because the fan would

FROM REACHING FULL SCALE?

MIN

never switch on. As a result, T

stays the same.

MIN

is allowed to vary only

MIN

within a specified range:

1. The lowest possible value to T

2. T

cannot exceed the high temperature limit.

MIN

3. If the temperature is below T

off or is running at minimum speed and dynamic T

is –127°C.

MIN

, the fan is switched

MIN

MIN

control is disabled.

Figure 28. T

Adjustments Limited by the High

MIN

Temperature Limit

THERM

LIMIT

HIGH TEMP

LIMIT

OPERATING

POINT

HYSTERESIS

ACTUAL

LOW TEMP

LIMIT

T

MIN

TEMP

Figure 27. Increasing T

REV. 0

for Quieter Operation

MIN

–21–

Page 22

AN-613

STEP 10: DETERMINING WHETHER TO MONITOR THERM

Using the operating point limit ensures that the dynamic

T

control mode is operating in the best possible

MIN

acoustic position while ensuring that the temperature

never exceeds the maximum operating temperature.

Using the operating point limit allows the T

MIN

to be

independent of system level issues because of its selfcorrective nature.

In PC design, the operating point for the chassis is usually the worst-case internal chassis temperature.

The optimal operating point for the processor is determined by monitoring the thermal monitor in the Intel

Pentium

®

4 processor. To do this, the PROCHOT output

of the Pentium 4 is connected to the THERM input of the

ADT7460/ADT7463.

The operating point for the processor can be determined

by allowing the current temperature to be copied to the

operating point register when the PROCHOT output

pulls the THERM input low on the ADT7460/ADT7463.

This gives the maximum temperature at which the

Pentium 4 can be run before clock modulation occurs.

ENABLING THERM TRIP POINT AS THE OPERATING POINT

Bits <4:2> of dynamic T

control Register 1 (Reg. 0x36)

MIN

enable/disable THERM monitoring to program the operating point.

DYNAMIC T

CONTROL REGISTER 1 (0x36)

MIN

<2> PHTR2 = 1 copies the Remote 2 current temperature

to the Remote 2 operating point register if THERM gets

asserted. The operating point will contain the temperature at which THERM is asserted. This allows the system

to run as quietly as possible without system performance being affected.

PHTR2 = 0 ignores any THERM assertions. The Remote 2

operating point register will reflect its programmed

value.

PHTL = 0 ignores any THERM assertions. The local tem-

perature operating point register will reflect its

programmed value.

<4> PHTR1 = 1 copies the Remote 1 current temperature

to the Remote 1 operating point register if THERM gets

asserted. The operating point will contain the temperature at which THERM is asserted. This allows the system

to run as quietly as possible without affecting system

performance.

PHTR1 = 0 ignores any THERM assertions. The Remote 1

operating point register will reflect its programmed

value.

ENABLING DYNAMIC T

Bits <7:5> of dynamic T

enable/disable dynamic T

CONTROL MODE

MIN

control Register 1 (Reg. 0x36)

MIN

control on the temperature

MIN

channels.

DYNAMIC T

<5> R2T = 1 enables dynamic T

temperature channel. The chosen T

CONTROL REGISTER 1 (0x36)

MIN

control on the Remote 2

MIN

value will be

MIN

dynamically adjusted based on the current temperature,

operating point, and high and low limits for this zone.

R2T = 0 disables dynamic T

control. The T

MIN

MIN

value

chosen will not be adjusted and the channel will behave

as described in the Automatic Fan Control section.

<6> LT = 1 enables dynamic T

temperature channel. The chosen T

control on the local

MIN

value will be

MIN

dynamically adjusted based on the current temperature,

operating point, and high and low limits for this zone.

LT = 0 disables dynamic T

control. The T

MIN

value cho-

MIN

sen will not be adjusted and the channel will behave as

described in the Automatic Fan Control section.

<7> R1T = 1 enables dynamic T

temperature channel. The chosen T

control on the Remote 1

MIN

value will be

MIN

dynamically adjusted based on the current temperature,

operating point, and high and low limits for this zone.

<3> PHTL = 1 copies the local current temperature to the

local temperature operating point register if THERM

gets asserted. The operating point will contain the temperature at which THERM is asserted. This allows the

system to run as quietly as possible without system performance being affected.

–22–

R1T = 0 disables dynamic T

control. The T

MIN

MIN

value

chosen will not be adjusted and the channel will behave

as described in the Automatic Fan Control section.

REV. 0

Page 23

AN-613

ENHANCING SYSTEM ACOUSTICS

Automatic fan speed control mode reacts instantaneously to changes in temperature, i.e., the PWM duty

cycle will respond immediately to temperature change.

Any impulses in temperature can cause an impulse in

fan noise. For psycho-acoustic reasons, the ADT7460/

ADT7463 can prevent the PWM output from reacting

instantaneously to temperature changes. Enhanced

acoustic mode will control the maximum change in

PWM duty cycle in a given time. The objective is to prevent the fan from cycling up and down and annoying the

system user.

ACOUSTIC ENHANCEMENT MODE OVERVIEW

Figure 29 gives a top-level overview of the automatic fan

control circuitry on the ADT7460/ADT7463 and where

acoustic enhancement fits in. Acoustic enhancement is

intended as a post-design “tweak” made by a system or

mechanical engineer evaluating best settings for the

system. Having determined the optimal settings for the

thermal solution, the engineer can adjust the system

acoustics. The goal is to implement a system that is

acoustically pleasing without causing user annoyance

due to fan cycling. It is important to realize that although

a system may pass an acoustic noise requirement spec,

(e.g., 36 dB), if the fan is annoying, it will fail the consumer test.

THE APPROACH

There are two different approaches to implementing

system acoustic enhancement. The first method is

temperature-centric. It involves “smoothing” transient

temperatures as they are measured by a temperature

source, e.g., Remote 1 temperature.

The temperature values used to calculate the PWM duty

cycle values would be smoothed, reducing fan speed

variation. However, this approach would cause an inherent delay in updating fan speed and would cause the

thermal characteristics of the system to change. It would

also cause the system fans to stay on longer than necessary, since the fan’s reaction is merely delayed. The user

would also have no control over noise from different

fans driven by the same temperature source. Consider

controlling a CPU cooler fan (on PWM1) and a chassis

fan (on PWM2) using Remote 1 temperature. Because

the Remote 1 temperature is smoothed, both fans would

be updated at exactly the same rate. If the chassis fan is

much louder than the CPU fan, there is no way to

improve its acoustics without changing the thermal solution of the CPU cooling fan.

The second approach is fan-centric. The idea is to control the PWM duty cycle driving the fan at a fixed rate,

e.g., 6%. Each time the PWM duty cycle is updated, it is

incremented by a fixed 6%. As a result, the fan ramps

REMOTE 2 =

CPU TEMP

LOCAL =

VRM TEMP

REMOTE 1 =

AMBIENT TEMP

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

THERMAL CALIBRATION

T

MIN

T

RANGE

T

RANGE

T

RANGE

100%

0%

100%

0%

100%

0%

MUX

ACOUSTIC

ENHANCEMENT

PWM

MIN

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 1

MEASUREMENT

PWM

MIN

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 2

MEASUREMENT

PWM

MIN

RAMP CONTROL

(ACOUSTIC

ENHANCEMENT)

TACHOMETER 3

MEASUREMENT

AND 4

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM

CONFIG

PWM

GENERATOR

PWM1

TACH1

PWM2

TACH2

PWM3

TACH3

CPU

FAN SINK

FRONT

CHASSIS

REAR

CHASSIS

REV. 0

Figure 29. Acoustic Enhancement Smooths Fan Speed Variations under Automatic Fan Speed Control

–23–

Page 24

AN-613

smoothly to its newly calculated speed. If the temperature starts to drop, the PWM duty cycle immediately

decreases by 6% every update. So the fan ramps

smoothly up or down without inherent system delay.

Consider controlling the same CPU cooler fan (on

PWM1) and chassis fan (on PWM2) using Remote 1 temperature. The T

MIN

and T

settings have already

RANGE

been defined in automatic fan speed control mode, i.e.,

thermal characterization of the control loop has been

optimized. Now the chassis fan is noisier than the CPU

cooling fan. So PWM2 can be placed into acoustic

enhancement mode independently of PWM1. The

acoustics of the chassis fan can therefore be adjusted

without affecting the acoustic behavior of the CPU cooling

fan, even though both fans are being controlled by

Remote 1 temperature. This is exactly how acoustic

enhancement works on the ADT7460/ADT7463.

ENABLING ACOUSTIC ENHANCEMENT FOR EACH PWM

OUTPUT

ENHANCE ACOUSTICS REGISTER 1 (Reg. 0x62)

<3> = 1 Enables acoustic enhancement on PWM1 output.

ENHANCE ACOUSTICS REGISTER 2 (Reg. 0x63)

<7> = 1 Enables acoustic enhancement on PWM2 output.

<3> = 1 Enables acoustic enhancement on PWM3 output.

EFFECT OF RAMP RATE ON ENHANCED ACOUSTICS MODE

The PWM signal driving the fan will have a period, T,

given by the PWM drive frequency, f, since T = 1/f. For a

given PWM period, T, the PWM period is subdivided into

255 equal time slots. One time slot corresponds to the

smallest possible increment in PWM duty cycle. A PWM

signal of 33% duty cycle will thus be high for 1/3 255

time slots and low for 2/3 255 time slots. Therefore,

33% PWM duty cycle corresponds to a signal that is high

for 85 time slots and low for 170 time slots.

PWM_OUT

33% DUTY

CYCLE

85

TIME SLOTS

PWM OUTPUT

(ONE PERIOD)

= 255 TIME SLOTS

170

TIME SLOTS

Figure 30. 33% PWM Duty Cycle Represented in

Time Slots

The ramp rates in the enhanced acoustics mode are

selectable from the values 1, 2, 3, 5, 8, 12, 24, and 48. The

ramp rates are actually discrete time slots. For example,

if the ramp rate = 8, then eight time slots will be added to

the PWM high duty cycle each time the PWM duty cycle

needs to be increased. If the PWM duty cycle value

needs to be decreased, it will be decreased by eight time

slots. Figure 31 shows how the enhanced acoustics