Page 1

AN-598

a

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

Temperature Compensation Techniques

for Low

Introduction

Analog Devices’ iMEMS accelerometers’ ability to sense

static acceleration make them uniquely suited for high

performance tilt measurement systems. However, the

0

g

stability over temperature performance of these sensors may, initially, lead one to believe that they would

be unusable over wide temperature ranges. This application note describes several techniques to compensate

for 0

g

drift over temperature.

Analyze the Application

Each temperature compensation strategy is suitable for

only certain applications. In order to find a practical temperature compensation technique, the first step must be an

evaluation of the application. The most effective technique will usually be one where the static acceleration

(dc) component can be ignored, and the accelerometer

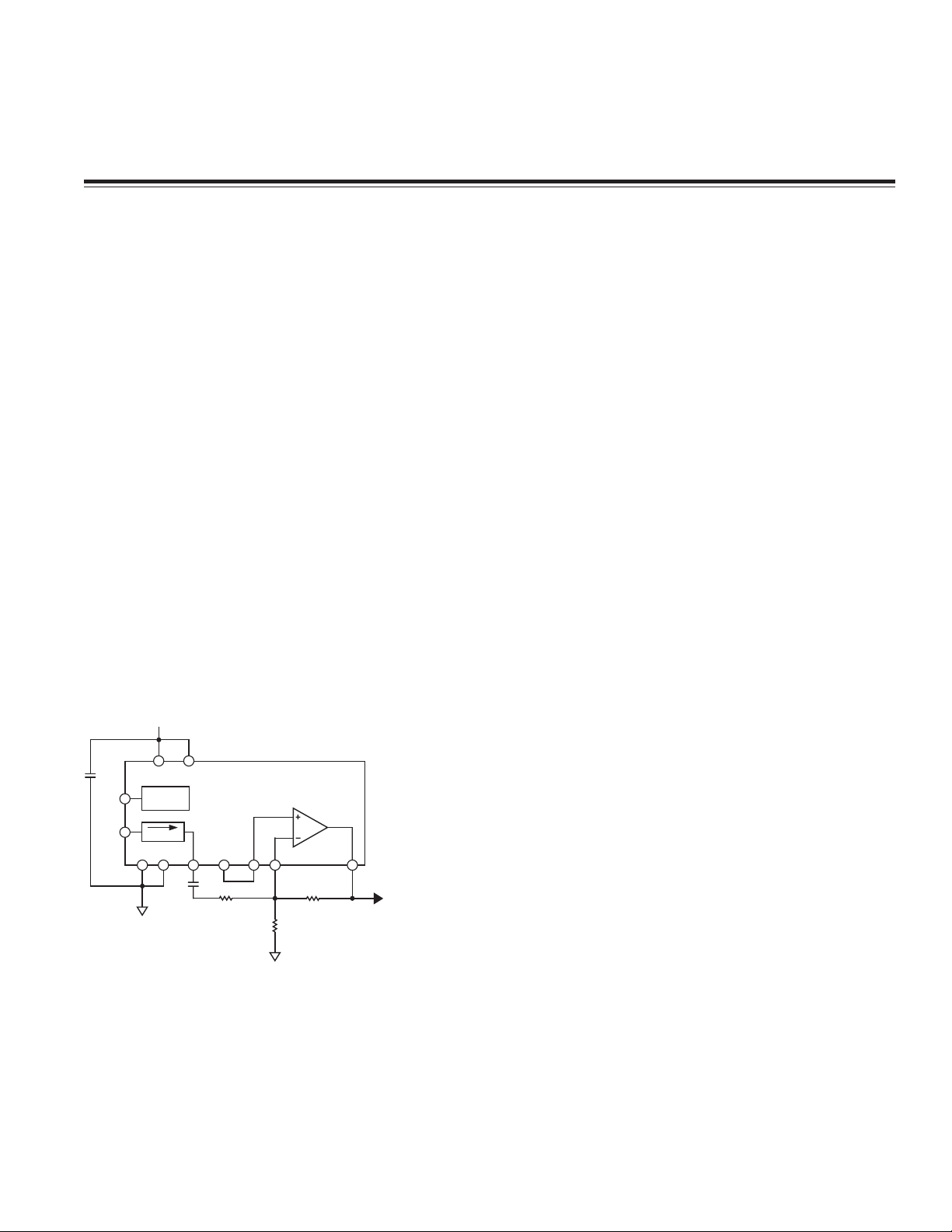

ac-coupled. The simplest manifestation of this is shown in

Figure 1.

g

iMEMS® Accelerometers

by Harvey Weinberg

Digital Trickery

Often, simple ac-coupling is not practical. In applications where the input stimulus frequency range is under

0.5 Hz, the coupling capacitor may become rather large.

Fortunately, similar results can be achieved by resorting

to a clever algorithm.

In applications where small, infrequent changes in inclination must be detected, the following technique is very

effective: maintain a long-term average (several minutes)

of the accelerometer output in memory and subtract the

actual accelerometer measurement from the long-term

average. As temperature changes rather slowly in the

real world (rarely faster than 1∞C per minute), the longterm average will slowly change as temperature causes

the accelerometer output to drift. The actual stimulus will

have a negligible effect on the long-term average as it

rarely occurs, compared to the large number of samples

taken to make the average.

+5V

TEMP

SENSOR

SENSOR

47

0.1F

1314

8

ADXL105

9

249k

1110

402k

634k

12

OUTPUT

2.5V 400mV/g

0.1F

1

6

Figure 1. AC-Coupling the ADXL105

Simple ac-coupling is most effective in applications

where one is most interested in sensing shock, vibration,

or fairly high speed changes in inclination (e.g., checking

if something has fallen over or been picked up).

Another method of measuring small changes in inclination while rejecting 0

for a certain acceleration rate of change (⌬ angle/⌬ time).

The apparent acceleration rate of change due to temperature drift will be very slow (less than 80 m

1∞C per minute rate of change of temperature) because

temperature is a slowly changing parameter, whereas

actual tilt angle changes are usually much faster. This

technique is commonly used in automobile tilt alarms

where two-degree inclination changes (35 m

detected in an environment where the temperature can

change as much as 50∞C in an hour. See the Car Alarm

Reference Design on the Analog Devices website at:

www.analog.com/technology/mems/markets/auto-

motive/ref_design.html for more information.

Brute Force Techniques

If none of the above-mentioned techniques is compatible

with the application, some form of hardware temperature compensation may be required.

g

drift due to temperature is to look

g

per second for a

g

) must be

REV. 0

Page 2

AN-598

Each accelerometer is “born” with a given temperature

characteristic that does not change over its life. Since

both the magnitude and sign of the temperature coefficient are variable from unit to unit, the temperature

compensation technique cannot simply consist of a temperature sensor in the feedback loop of an amplifier.

There are two basic techniques that can be used:

temperature mapping or ovenization. Temperature mapping is fairly straightforward in concept. A temperature

sensor is added to the circuit and the temperature is varied

while there is no stimulus (other than gravity) to the

accelerometer. The accelerometer output is read and used

to construct a compensation table or a formula that is

later used for temperature compensation. Since the

temperature characteristic of iMEMS accelerometers is

fairly linear, usually only two or three temperature points

are needed.

Normally the software used to construct the compensation table or formula is resident in the system

microcontroller and the temperature sweeps are performed during system level test or burn-in. In some

systems, there is even no need to perform a temperature

sweep, since the system can be made self-learning. For

example, an earthquake monitor can be built and then

warehoused in an unheated space for a few days. As the

temperature changes, the system learns how the temperature changes affect the acceleration signals. As long

as the systems do not experience any movement during

the “learn time,” the compensation table will be correct.

Ovenization solves the temperature drift problem by fixing

the temperature to some value at or higher than the maximum ambient temperature. This technique is most easily

and accurately realized with accelerometers that have an

on-chip temperature sensor such as the ADXL105. The

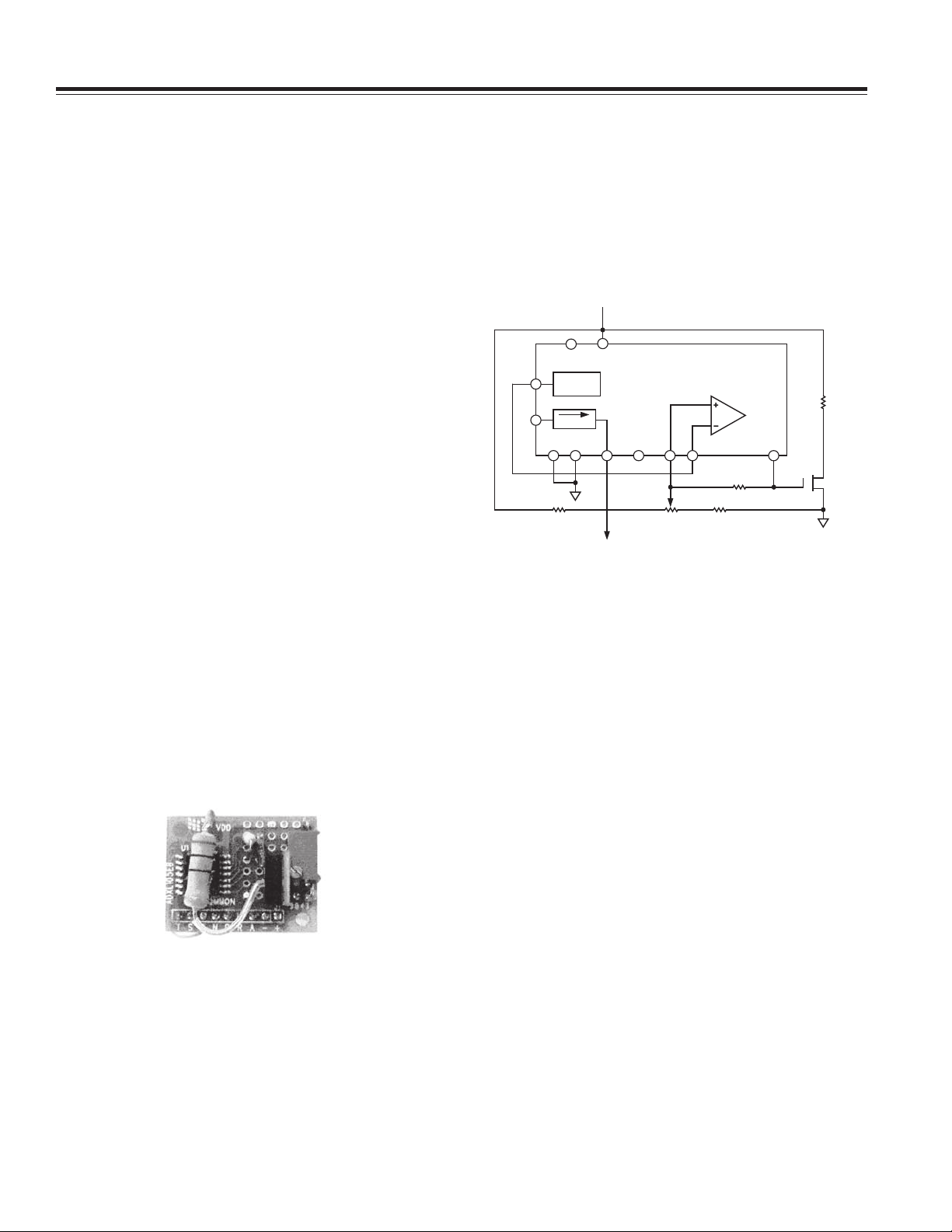

simplest manifestation is shown in Figure 2.

Here a power resistor is mounted on top of an ADXL105.

The on-chip temperature sensor is connected to the

inverting input of the ADXL105’s uncommitted op amp

while the noninverting input is connected to a fixed voltage chosen to correspond with the on-chip temperature

sensor’s output voltage at the desired temperature set

point. The uncommitted op amp output controls a small

MOSFET that switches power to the resistor. The schematic is shown in Figure 3.

+5V

13

14

8

OUTPUT

ADXL105

9

1k

TEMPERATURE

ADJUST

4

2W

HEATER

RESISTOR

1110

2k

750k

12

IRF530

1

6

TEMP

SENSOR

SENSOR

47

2k

ACCELERATION

Figure 3. Schematic for ADXL105 Ovenization Circuit

Using the values shown in Figure 3, the 0 g drift due to

temperature went from 216 m

g

to 44 mg over a 0∞C to

70∞C range (3.1 mg/∞C without ovenization to 0.44 mg/∞C

with ovenization).

The main disadvantage of ovenization is the relatively

high power consumption (approximately 6 W) which

makes it impractical for battery-powered systems.

Conclusion

There are a variety of methods that can be used for

temperature compensation. In order to choose one effectively, one must examine the application carefully and

capitalize on its particular requirements and possibilities.

The most effective methods of temperature compensation often use no hardware at all, only clever algorithms.

E03043–0–10/02(0)

Figure 2. Using a Power Resistor as a Heating Element

to Ovenize an ADXL105

©2002 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective companies.

–2–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...