AN-583

a

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

APPLICATION NOTE

Using the SSM2167 Evaluation Board

By Shawn Scarlett

SSM2167 EVALUATION BOARD

The evaluation board is a convenient means to evaluate

and understand the operation of the SSM2167. This

documentation provides a basic explanation of how the

board is set up and how to use it to evaluate the

SSM2167. This document is only a supplement and

makes several references to figures contained in the

product data sheet. The current data sheet is available

on-line at www.analog.com.

This document also contains the schematics and layout

for the evaluation board to allow easy modification and

experimentation. Applications support is available from

Analog Devices, Inc. on-line or in the United States at 1(800)

ANALOG D or 1(800) 262-5643.

Basic Connections and Setup

The board features simple, easy-to-use connections that

allow for a broad range of experimentation. The evaluation board is available only with the SSM2167-1.

Power and Ground

The SSM2167 is optimized for operation at 3 V;

however, it can operate from a wide range of supplies.

Please refer to the product data sheet for the maximum

limits. The SSM2167 board can be connected to a bench

power supply or two AA batteries. Power leads will need

to be soldered into place at JP3. Alternatively, a header

jack can be soldered to the board to allow easy disconnection. The power and ground connections are critical

to the performance of the board, so care should be taken

to ensure proper connection.

Shutdown Connection

Located at JP3, along with the power and ground, is the

low current shutdown connection. The board has a pull-up

resistor installed so that if no connection is made at that

point, the part will operate in active mode. To enable the

shutdown feature, simply connect the SHUTDOWN pin

on JP3 to ground. If an in-depth analysis is to be done on

the shutdown current, the pull-up resistor R5 may be

removed. The shutdown pin should not be left floating. If

R5 is removed, be sure to connect the SHUTDOWN pin

directly to the supply or ground.

Signal Connections, Input, and Output

Signal sources can be connected to the evaluation board

with standard 3.5 mm jacks or leads which can be

soldered directly to the board at JP2 and JP3. The board

uses 3.5 mm stereo sockets with the signal on the tip and

the sleeve connected to the board ground; the ring is left

floating. At both jumper connections, a ground point is

available to prevent noise.

The input jack is configured for maximum versatility. By

default, it is designed for use with an electret microphone or input source. It can be changed easily to

accommodate dynamic microphones.

Electret Microphones

The evaluation board is configured with a 2.2 kΩ resistor

(R4) to the supply for use as a biasing resistor. It is connected directly to the signal path so that both the jack

and the jumper (JP2) can be used as input connections.

Standard computer electret microphones can be used without modification because the ring and tip are connected

internally in the microphone. The input jack and JP2 are

decoupled from the input pin via a 0.1 µF capacitor (C1).

Dynamic Microphones

If the board is to be used with a dynamic or self-powered

microphone, R4 should be removed.

Output Signal

The output jack is decoupled from the circuit via a 10 µF

capacitor (C2). The connection can be made at either JP1

or the standard 3.5 mm jack, with the signal connection

to the tip of the plug. For listening tests, the output signal can be connected directly from the 3.5 mm jack to an

RCA input on a normal audio amplifier using a standard

stereo adapter cable. In this case, use the left (white or

black) RCA connection because it corresponds with the

tip of the 3.5 mm jack. The output of the SSM2167 is not

sufficient to drive headphones or other output transducers without external amplification.

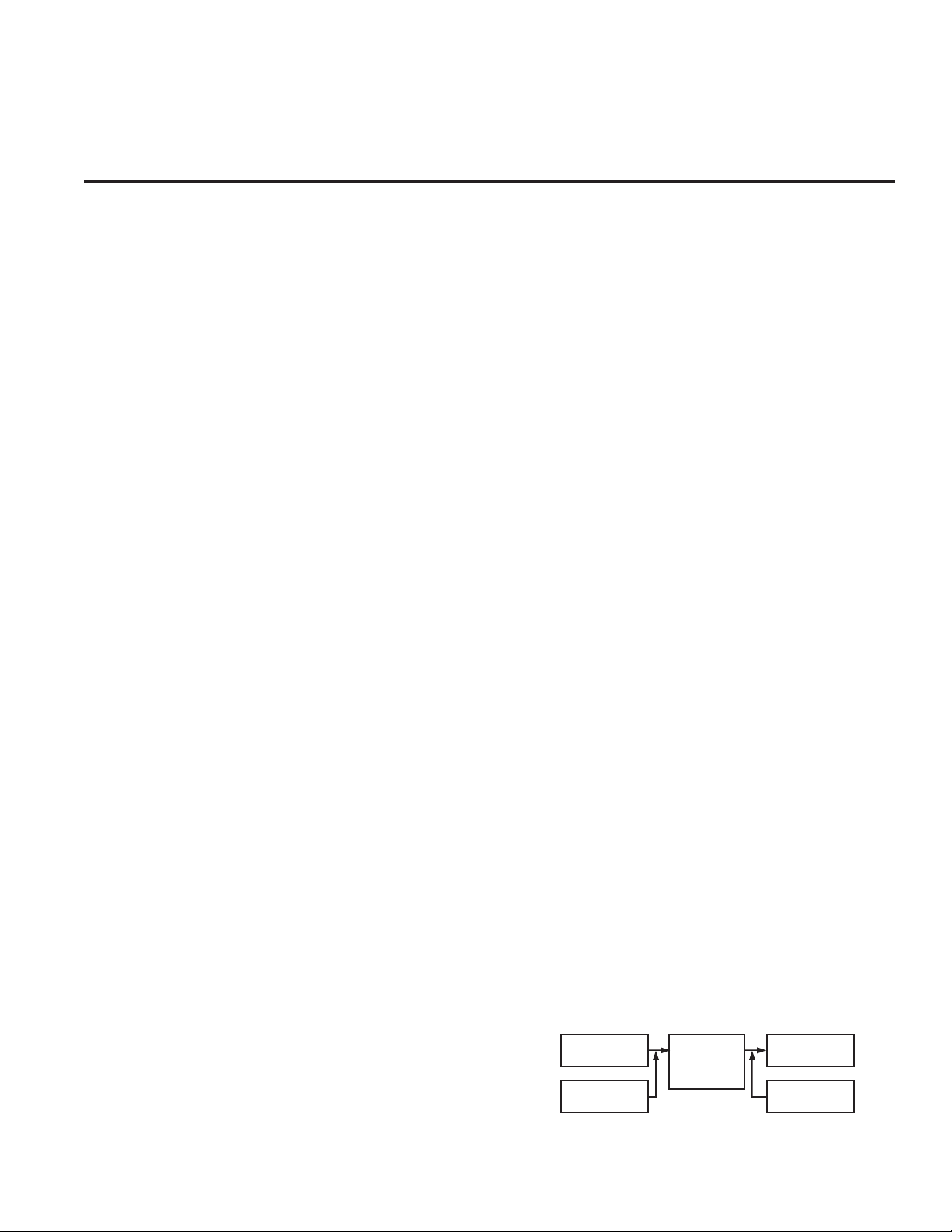

SIGNAL

GENERATOR

AC VOLTMETER

SSM2167

EVALUATION

BOARD

OSCILLOSCOPE

AC VOLTMETER

REV. A

Figure 1. Test Equipment Setup

© Analog Devices, Inc., 2003

AN-583

Test Equipment Setup

The recommended equipment and configuration is shown

in Figure 1. A low noise audio generator with a smooth

output adjustment range of 50 µV to 50 mV is a suitable

signal source. A 40 dB pad is useful to reduce the level of

most generators by 100´ to simulate microphone levels.

The input voltmeter can be connected before the pad

and need only go down to 10 mV. The output voltmeter

should go up to 2 V. The oscilloscope is used to verify

that the output is sinusoidal, that no clipping is occurring in the buffer, and that the noise-gating threshold

is set.

STEP 1. Connections

Connect power, ground, input, and output as discussed above.

STEP 2. Test Setup

To confirm the operation of the board and test setup,

first put JP4 in the 1:1 position and JP5 in the –55 dB

position. With power on, adjust the generator for an input

level of 15 mV, 1 kHz. The output meter should indicate

approximately 100 mV. If it does not, check the setup.

Substituting the SSM2167-2 will give an output of approximately 40 mV.

STEP 3. Listening

Connect a microphone to the SSM2167 and listen to the

results. Be sure to include the proper power for the microphone as discussed above. Experiment with the settings to

hear how the results change. Compression ratio will keep

the output steady over a range of source-to-microphone

distances, and the noise gate will keep the background

sounds subdued.

STEP 5. Adjusting the Compression Ratio

The evaluation board provides three different settings

for the compression ratio in the same manner as the

noise-gate threshold. Experiment with different compression ratios to determine what will sound best in a

given system; starting with a 2:1 ratio is recommended.

High compression ratios will exaggerate the effect of the

noise gate because compression ratio determines the

gain at the noise gate, as shown in Figure 4 of the data

sheet. Compression of 10:1 should be used only in systems where the noise floor is well below the noise gate.

Most systems require between 2:1 and 5:1 compression

for best results.

Listening Test

The final step in evaluating the SSM2167 should be a

listening test. The improvement in vocal clarity can be

heard by recording the SSM2167 output or listening to it

live. Ideally, the evaluation board should be connected

to an existing system. The impact of the compression is

demonstrated by shorting out RCOMP (R9 through R12).

When the RCOMP resistor is shorted, the VCA will revert

to the audible 1:1 compression setting. This will not

the noise-gate or limiting settings. The effect of turning

off the compression will be most noticeable when the

input signal is between –50 dBV and –40 dBV. Evaluating

the SSM2167 within the end application will also give

the best indication of how high the noise-gate threshold

should be set. The noise level of the system will be

greatly influenced by the design of the system, including

cooling fans, hard drives, handling, and other sources of

acoustic noise.

affect

STEP 4. Setting the Noise-Gate Threshold

The evaluation board provides three different preset values

of noise-gate threshold. Experiment with these values

by varying the gate. The board also provides landing

pads for a custom value that can be extrapolated from

the table given in the data sheet, or TPC 1 in the Typical

Performance Characteristics section of the data sheet.

Using above 5 kΩ is not recommended because

extremely low noise-gate thresholds may approach the

noise floor of the system.

The highest setting (–48 dB) is recommended to start an

evaluation. If the input signal is not sufficient to surpass

the threshold, lower the setting. In most applications, the

input signal will easily overcome this setting. If the gate

is set too low, the background noise will be amplified well

into the audible range. By examining the function

(Figure 1) in the data sheet, the maximum gain of the part

can be determined when the input signal is at the

noise-gate threshold. The dashed line on the transfer

function represents unity gain; the distance between the

dashed line and the solid line represents the VCA gain.

Listening tests are the most critical part of an evaluation.

Since test equipment and signal generators do not represent audio signals well, listening is the best way to

evaluate the benefits of the SSM2167. The evaluation

board makes it easy to implement the SSM2167 and to

pick appropriate application settings. The end result is a

noticeable improvement in signal clarity and a system

that is easy for customers to use.

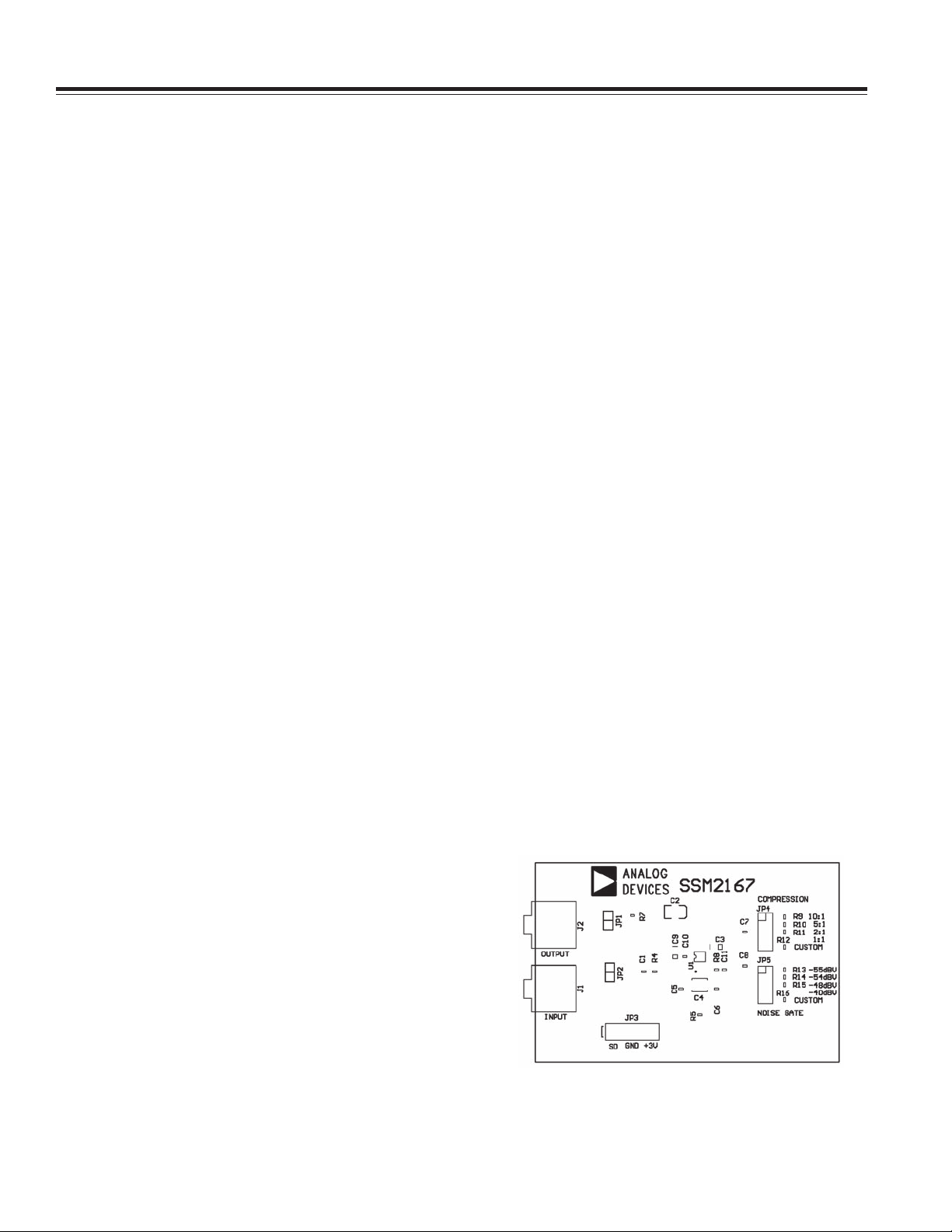

Figure 2. SSM2167 Evaluation Board; Top Layer

Including Component Identification and Placement

–2–

REV. A

AN-583

Figure 3. SSM2167 Evaluation Board; Top Layer

JP3

1

23

R5

5%

3.3V

C4

10F

10% 16V

SD

C1

0.1F

10%

1

2

4

3

R8

10k

5%

GND

VCA

IN

BUF

OUT

SHUTDOWN

C11

1000pF

10% 16V

SD

3.3V

MIC IN

J1

ST JACK

JP2

MIC IN

2mm 12mm SP

5

4

3

2

1

2

1

3.3V

C5

NS

C6

NS

500k

R4

2.2k

5%

3.3V

10

V

DD

SSM2167

INPUT

56

+

COMP RATIO

GATE THRS

AVG CAP

C3

+

TANT

10F

10% 10V

C9

TANT

10F

10% 10V

OUTPUT

Figure 4. SSM2167 Evaluation Board; Bottom Layer

LINE OUT

JP1

2

1

2mm 12mm SP

C2

9

8

7

C10

0.1F

10% 16V

3.3V

3.3V

C7

NS

C8

NS

TA N T

10F

10% 10V

+

100k

JP4

2

1

4

3

6

5

8

7

10

9

2mm 52mm SP

JP5

2

1

4

3

6

5

8

7

10

9

2mm 52mm SP

R7

5%

R9 175k 1%

R10 75k 1%

R11 15k 1%

R12 NS

R13 3k 1%

R14 2k 1%

R15 1k 1%

R16 NS

LINE OUT

J2

5

4

3

2

1

ST JACK

3.3V

10:1

5:1

2:1

1:1

CUSTOM

55dBV

54dBV

48dBV

40dBV

CUSTOM

REV. A

Figure 5. SSM2167 Evaluation Board Circuit Schematic

–3–

AN-583

Reference Part PCB Footprint Value Tolerance

U1 IC 10-Lead MSOP SSM2167

C1, C10 CAP 805 0.1 µF (X7R) 10%

C2, C3, C9 CAP CASE – A 10 µF (TANT) 10%

C4 CAP NP 1206 10 µF (X5R) 10%

J1, J2 ST JACK T.H. ST JACK

JP4, JP5 HEADER T.H. 2 mm ⫻ 52 mm SP

R5 RES 805 499 kΩ 1%

R8 RES 805 10 kΩ 5%

R4 RES 805 2.2 kΩ 5%

R7 RES 805 100 kΩ 5%

R9 RES 805 175 kΩ 5%

R10 RES 805 75 kΩ 5%

R11 RES 805 15 kΩ 5%

R13 RES 805 3 kΩ 5%

R14 RES 805 2 kΩ 5%

R15 RES 805 1 kΩ 5%

JP4 (7-8), JP5 (7-8) JUMPER 2 mm SHUNT

R12, R16 RES 805 NS

C5, C6, C7, C8 CAP 805 NS

C11 CAP 805 NS

JP1, JP2 HEADER 2 mm ⫻ 12 mm SP NS

JP3 HEADER 3 mm ⫻ 10.2 in SP NS

NS = Not Stuffed

Table I. Part List for SSM2167 Evaluation Board

E02728–0–10/03(A)

–4–

REV. A

Loading...

Loading...