Page 1

AN-555

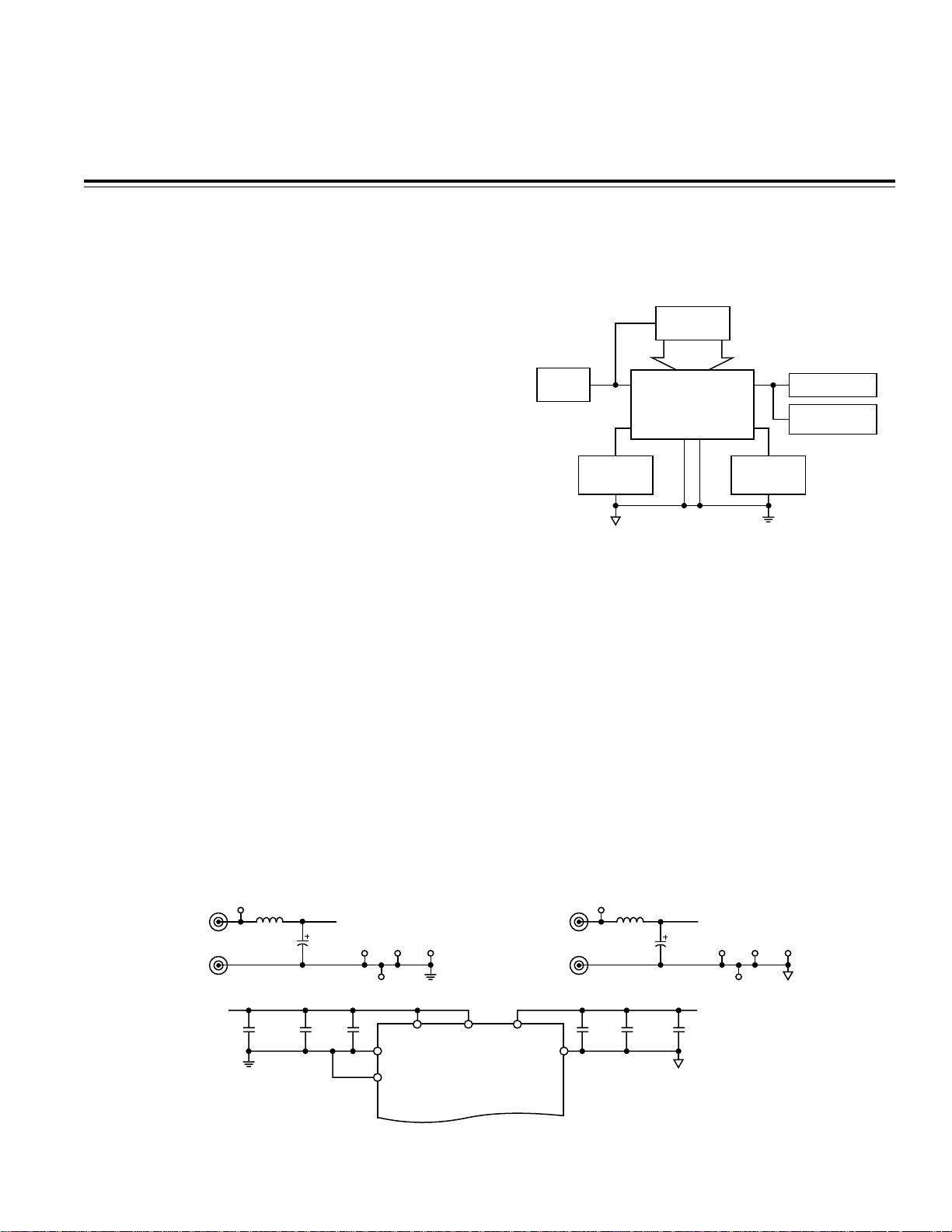

CLK

WORD

GENERATOR

DATA IN

DIGITAL

DATA BUS

DUAL DAC

EVALUATION

BOARD

AVDD DVDD

ANALOG

VDD

(3V TO 5V)

DIGITAL

VDD

(3V TO 5V)

ACOM DCOM

CLOCK

SOURCE

OSCILLOSCOPE

SPECTRUM

ANALYZER

DATA

OUT

a

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • 781/329-4700 • World Wide Web Site: http://www.analog.com

Using the AD9709, AD9763, AD9765, AD9767 Dual DAC Evaluation Board

By Steve Reine and Dawn Ostenberg

GENERAL DESCRIPTION

The AD9709, AD9763, AD9765 and AD9767 are highspeed, high-performance dual DACs (8-, 10-, 12-, 14bits) designed for I/Q transmit applications and for applications where board space is at a premium. The

evaluation board allows the user to take full advantage

of the various modes in which the AD976x can operate.

This includes operation as dual DACs with their own individual digital inputs, as well as interleaved DACs where

data is alternately written from digital input Port 1 to

either of the two DACs. Information on how to operate

the evaluation board is included in this application

note. However, for more detailed performance information, the reader should consult the individual data

sheets for the AD9709, AD9763, AD9765, and AD9767.

Figure 1. Typical Test Setup to Evaluate Performance

of AD976x Dual DAC Using Evaluation Board

The 8-, 10-, 12-, and 14-bit DACs in this family are all pinfor-pin-compatible and are MSB justified. Therefore, the

same evaluation board can be used to evaluate all

four parts.

EVALUATION SETUP

To evaluate the performance of the AD976x dual DAC

family, a small set of measurement and signal generation equipment is needed. Figure 1 shows a typical test

setup. Power supplies capable of driving from 3 V to 5 V

are needed for both analog and digital circuitry on the

evaluation board. A signal generator and digital word

generator are needed to provide the data and clock

inputs. On the output, an oscilloscope or spectrum

analyzer may be needed, depending on the type of performance being analyzed.

TP10

L1

DVDD

BEAD

C2

0.01mF

C9

10mF

25V

0.1mF

C3

TP37 TP38

TP43

DVDD1 DVDD2 AVDD

DCOM1

DCOM2

REV. 0

DVDDIN

BAN-JACK

BAN-JACK

DVDD

C1

0.001mF

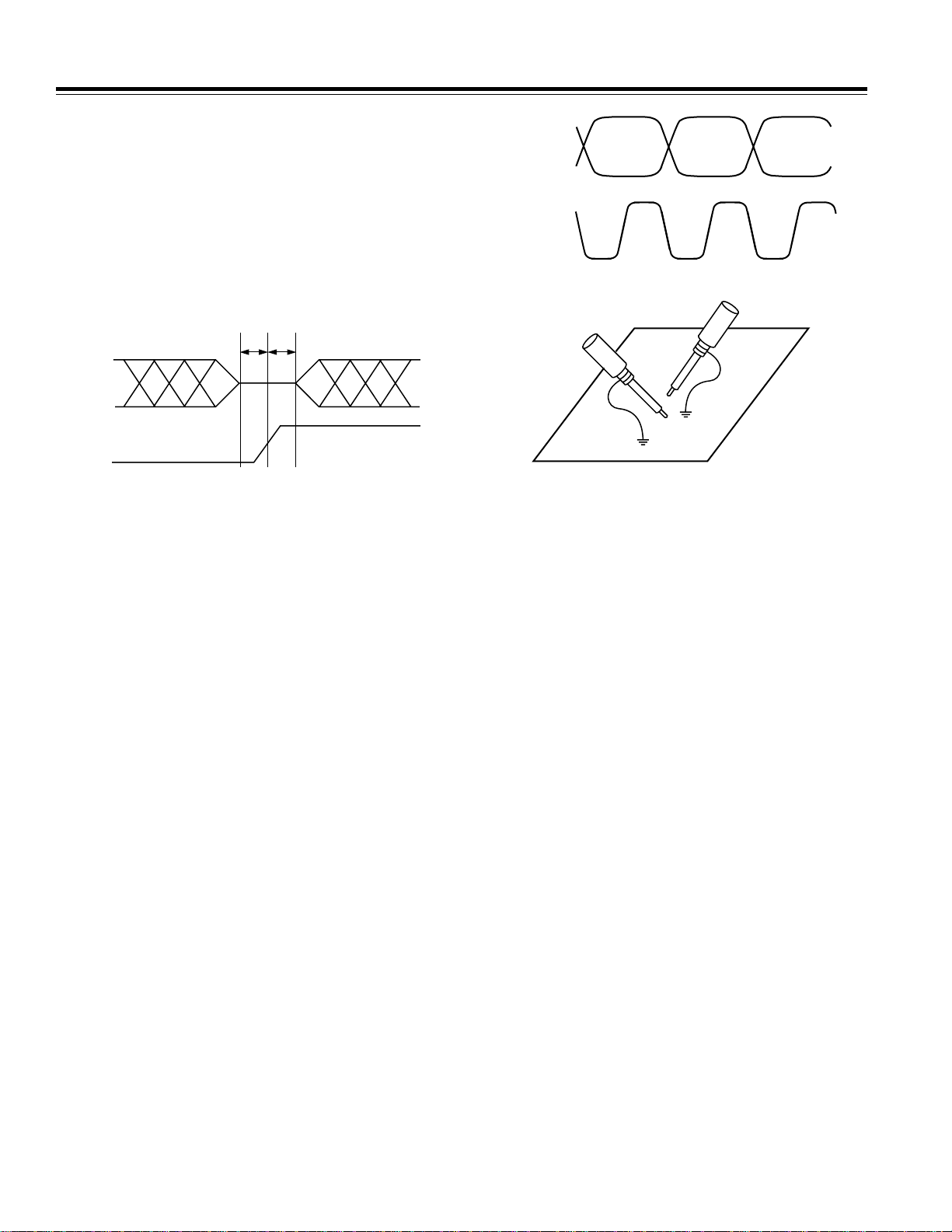

Figure 2. Analog and Digital Power Connections on Dual DAC Evaluation Board

TP39

DGND

DUAL DAC

AD9709

AD9763

AD9765

AD9767

POWER CONNECTIONS

The AD9709, AD9763, AD9765, AD9767 dual DACs all

have separate digital and analog power and ground

pins. Analog and digital power and ground have their own

banana-style connectors on the dual DAC evaluation

board. The best performance when using the evaluation

board is achieved when analog and digital power and

ground are connected to separate power supplies.

Figure 2 shows the power supply, grounding, and decoupling connections for the evaluation board and for the

DAC itself. Note that for best noise rejection on the

power supplies, the high value bulk capacitors are

placed at the external power connectors, while the

smaller value capacitors, needed for high frequency

rejection, are located close to the DAC.

TP11

L2

AVDDIN

ACOM

BAN-JACK

BAN-JACK

C13

0.1mF

BEAD

AVDD

C12

0.01mF

C10

10mF

25V

AVDD

TP40 TP41

C11

0.001mF

TP44

TP42

AGND

Page 2

AN-555

Analog and digital supplies can be run at either 3 V or

5 V, and do not have to run from the same supply voltage. Regardless of supply voltage, the digital input data

can be safely run from 3 V or 5 V logic levels, as long as

the proper resistor packs are placed in the digital input

data path (see Digital Inputs section).

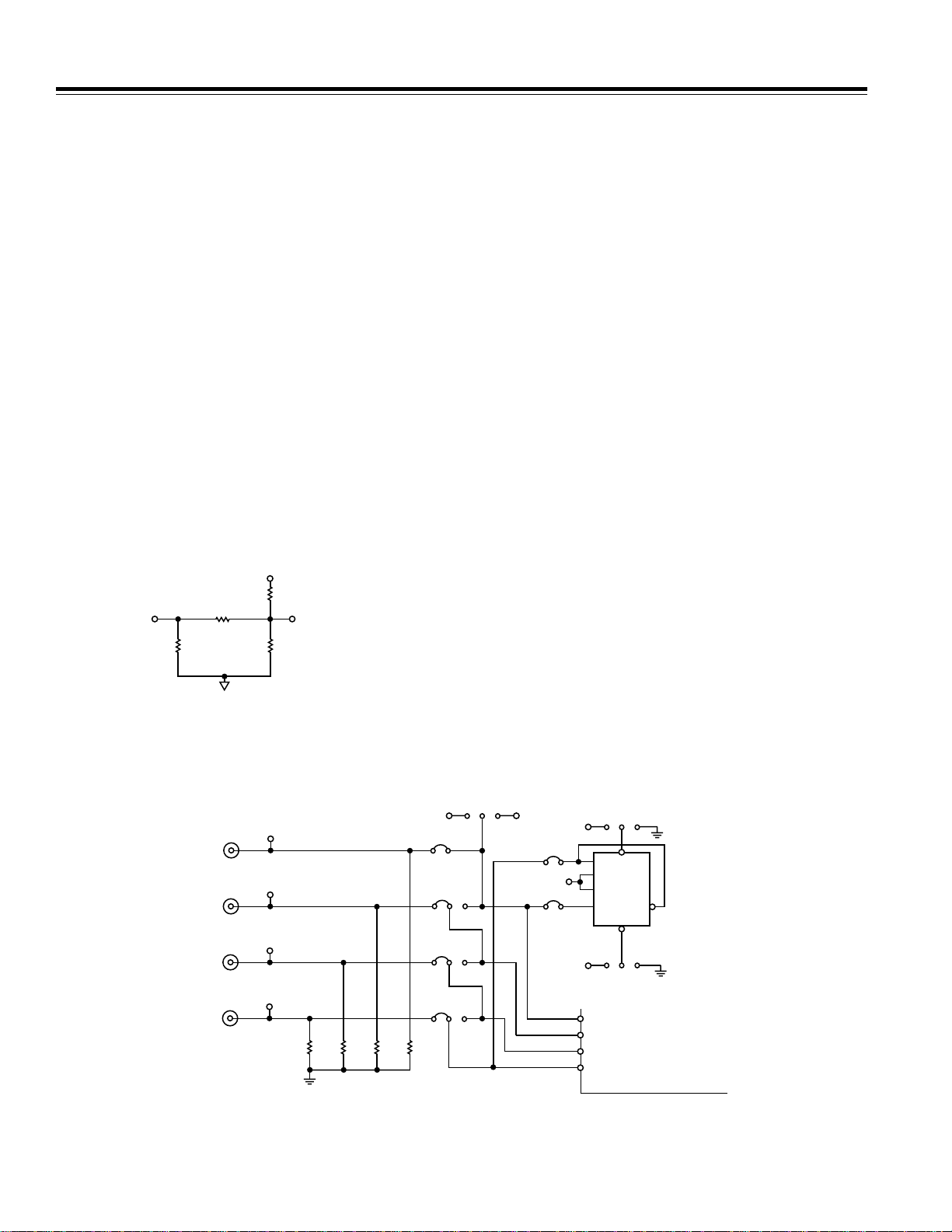

DIGITAL INPUTS

The digital inputs on the dual DAC evaluation board are

designed to accept inputs from any generic word generator. However, when running the DAC at high sample

rates, the quality of the digital data can have an impact

on the performance of the DAC. As an example, if the

edges of the digital information are slow, or the edges of

the various bits are skewed from each other in time,

specifications such as SNR and SINAD may be degraded.

The digital input path on the evaluation board includes

both pull-up and pull-down plug-in resistor packs. The

pull down resistors allow the user to apply digital logic

at 5 V levels when the DAC digital supply is operating at

3 V, and the pull-ups allow 3 V logic levels when the DAC

is run from a 5 V digital supply. The digital input signal

path is shown in Figure 3.

DVDD

NOT SUPPLIED WITH

DIGITAL DATA

INPUT

NOT SUPPLIED WITH

EVALUATION BOARD

22V

EVALUATION BOARD

DATA INPUT ON

AD9763/AD9765/AD9767

NOT SUPPLIED WITH

EVALUATION BOARD

CLOCK INPUTS

SMA connectors S1 to S4 are intended to be used as

clock and control lines for the AD976x, and are 50 Ω ter-

minated. The selection of JP9 also allows the user to

select a clock generated on the same digital data bus as

the input data.

Jumpers JP1 to JP7, JP9, and JP16 control the clock

inputs for the various clock modes in which the dual

DACs can operate. It is recommended that the clock

source be a square wave with minimal overshoot and

undershoot. Overshoot and undershoot beyond the supply rails can inject noise onto the clock, which may result

in jitter and reduced DAC performance. The dual DACs

can operate with a sine wave clock, but dynamic performance will be degraded. Figure 4 shows the clock input

section and jumper options for the dual DAC evaluation

board.

MODES OF OPERATION

The AD976x dual DAC family is designed to operate

either as two completely separate DACs in dual DAC

mode, or with a single digital input port in which the input

data is alternately sent to either of the two DACs (interleaving mode).

DGND

Figure 3. Input Structure of Digital Input Signal Path on

Dual DAC Evaluation Board

DCLKIN1 DCLKIN2

WRT1IN

IQWRT

CLK1IN

IQCLK

CLK2IN

RESET

WRT2IN

IQSEL

TP29

S1

TP30

S2

TP31

S3

TP32

S4

R1

50VR250VR350VR450V

Figure 4. Jumper Options for Clock Input Section on Dual DAC Evaluation Board

JP16

JP5

IC

JP4

IC

JP3

I

JP9

DVDD

JP2

DVDD

JP1

DVDD

C

JP6

LH

D

PRE

J

K

U1

CLK

Q

CLR

1

74HC112

JP7

DGND;8

HL

WRT1/IQWRT

CLK1/IQCLK

CLK2/IQRESET

WRT2/IQSEL

AD9709/AD9763/AD9765/AD9767

DVDD;16

–2–

REV. 0

Page 3

AN-555

DUAL DAC MODE

Jumper J8 controls the logic level of the MODE pin on

the AD976x dual DAC. With this jumper in the D position, the mode pin is pulled to a high logic level and the

AD976x is in dual DAC mode.

The simplest method for operating the dual DAC evaluation board in the dual DAC mode is to select a common

clock for WRT1, WRT2, CLK1, and CLK2. An external

clock generator can be selected by inserting JP16, or a

clock from the word generator can be selected by inserting JP9. By inserting JP3, JP4, and JP5 all in the C position,

the selected clock can be applied to all four clock inputs.

Different combinations of JP3, JP4, and JP5 allow

multiple options if the user desires to drive the WRT

and CLK inputs from separate clocks.

In the dual mode, jumpers JP1 and JP2 should be

removed. The state of Jumpers JP6 and JP7 does not

matter in this mode.

Table I illustrates the jumper positions required to operate in the dual DAC mode of operation.

Table I. Jumper Options for Dual DAC Mode

Jumper Position Description

JP1, JP2,

JP6, JP7 Removed These are only used in

interleaved mode.

JP3, JP4,

JP5 C With these in the B posi-

tion, the evaluation board

can be run with one common clock.

detailed information on the functions of these inputs, as

well as the DAC input and output timing, see the

AD9709, AD9763, AD9765, and AD9767 data sheets.

Operation with a single clock can be achieved by selecting JP16 or JP9 for the clock source and inserting JP5 in

the C position, and removing JP3. JP4 can be used to

control IQRESET, but for most evaluations can simply be

tied low (Position I).

In interleaving mode, digital data present at input Port 1

is written into the Port 1 or Port 2 input buffers internal

to the DAC on the rising edge of IQWRT. The port into

which data is written depends on the state of IQSEL at the

time of the IQWRT rising edge. If IQSEL is high when the

rising edge occurs, data will be written to input Port 1. If

IQSEL is low at that time, data will be written to input

Port 2.

U1 on the evaluation board provides an alternating

IQSEL signal by toggling on every falling edge of

IQWRT. To enable this function, insert JP1 and JP2 and

remove JP3. JP6 and JP7 are used to synchronize the

input data stream with the IQSEL pin. To perform this

synchronization, power up the evaluation board with the

IQWRT and input data clocks disabled and at logic low. If

the first word in the digital data stream is meant for

Channel 1, preset U1 by inserting JP7 in the H position,

temporarily insert JP6 in the L position, then permanently

in the H position. If the first word in the data stream in

intended for Channel 2, reset U1 by inserting JP6 in the

H position, insert JP7 temporarily in the L position, then

permanently in the H position.

Table II illustrates the jumper positions required to operate in the dual DAC mode of operation.

JP8 D Enables Dual DAC Mode.

JP9 Optional Selects clock from word

generator. Remove JP9 if

clock source is from S1/JP16.

JP16 Optional Selects clock from connec-

tor S1. Remove JP16 if clock

source is from JP9/JP16/

DCLK1, DCLK2.

INTERLEAVING MODE

With jumper JP8 in the I position, the MODE pin on the

AD976x is pulled to a logic low level and the DAC is in

interleaving mode. In this mode, a single stream of digital data drives Port 1 on the DAC. This stream of data

contains alternating bits from two data channels. By

using the correct clock and control signals, data in the

two channels will be separated and sent to the correct

DAC outputs. This is typical of an I/Q application.

In interleaving mode, the definitions for the four clock

inputs change. WRT1, WRT2, CLK1, and CLK2 become

IQWRT, IQCLK, IQRESET, and IQSEL, respectively. For

REV. 0

Table II. Jumper Options for Interleaved Mode

Jumper Position Description

JP1, JP2 Inserted These enable U1 to generate the

alternating logic signal for IQSEL.

JP3 Remove If the IQSEL logic is to be gener-

ated by U1, this is not needed.

JP4 I Use to allow S3 control of

IQRESET pin.

JP5 C Allows IQWRT and IQCLK to be

driven by a common clock.

JP6, JP7 These are used to preset the

IQSEL pin before the data clock

is enabled. See text for descrip-

tion of use.

JP8 I Enables Interleaved Mode.

JP9 Optional Selects clock from word genera-

tor. Remove JP9 if clock source

is from S1/JP16.

JP16 Optional Selects clock from Connector S1.

Remove JP16 if clock source is

from JP9/DCLK1, DCLK2.

–3–

Page 4

AN-555

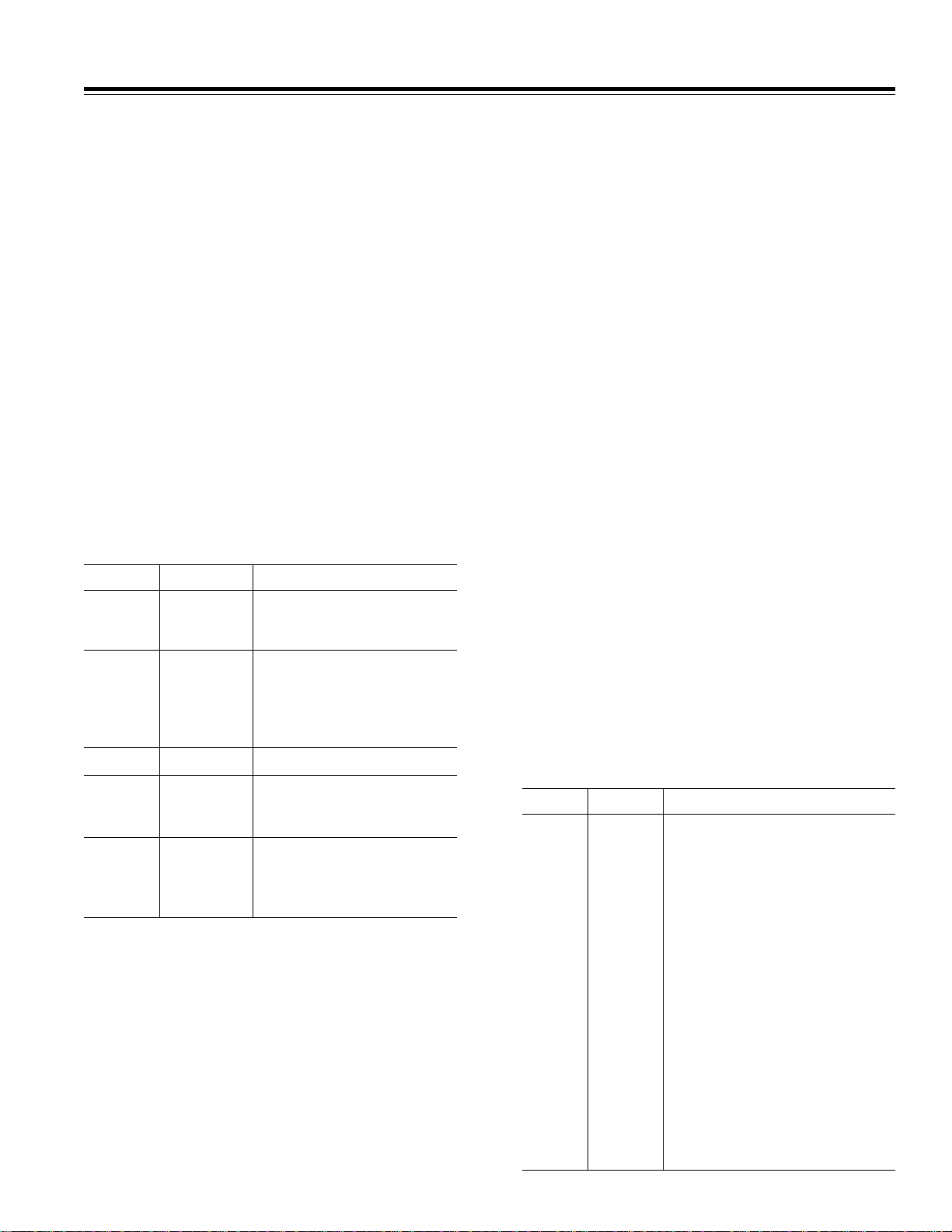

CLOCK TIMING/PERFORMANCE

To ensure that specified setup-and-hold times are met,

the digital data inputs should change state on the falling

edge of the clock. However, due to timing skews and

delays inherent in some circuits, this does not always

happen. If the timing of the data transition and the rising

edge of the clock violates the setup-and-hold times, SNR

performance will be seriously degraded. Figure 5 shows

the valid window during the clock cycle in which the

digital input data can transition with no degradation in

SNR performance.

tS t

H

DATA

CLOCK

DATA

CLOCK

CHANNEL 2

CHANNEL 1

Figure 5. Valid Window for Data Transition During

Clock Cycle

Correct timing can be verified by generating a word pattern that repeatedly toggles the LSBs between Logic 1

and Logic 0. The user will also need a digital oscilloscope with persistence capability.

Place one probe from the scope on the clock input of the

DAC. The sensitivity of this measurement is in the tenths

of nanoseconds, so the probe should be placed as close

as possible to the DAC itself. In addition, the scope

should be set to trigger from this channel. Place a second

probe from the oscilloscope on the LSB input of the

DAC, again as close as possible to the DAC itself. The

barrels of both probes should be grounded to the

evaluation board, as close to the measurement point as

possible. A convenient way of doing this is to wrap a

piece of bus wire around the barrel and then solder the

other end of the bus wire to the PCB. Figure 6 illustrates

a typical oscilloscope display for this test, as well as the

proper way to use the scope probes.

For the most accurate results, identical high input

impedance, low input capacitance probes should be

used. If possible, they should also be calibrated.

The data setup time can be measured by placing a variable delay between the clock generator and the clock

input of the word generator. This is most often done by

using a pulse generator. By adjusting the delay of the

digital data, place the data transition point on the falling

edge of the clock. At this point, SNR should be optimized. Increase the amount of delay for the digital data,

moving the transition point closer to the rising edge. As

the data transition gets close to the rising edge, SNR will

begin to degrade. At this point, on the oscilloscope,

measure the time difference between the data transition

and the midpoint of the rising edge. This is the measured data setup time.

Figure 6. Verifying Clock/Data Timing on Evaluation

Board, Proper Use of Scope Probes

To measure the input data hold time, perform the same

operation, but start with the data transition occurring at

the midpoint of the clock transition. SNR at this point

will be completely degraded. Increase the digital input

delay until the SNR is optimized. At this point, again

measure the time difference between the data transition

and the midpoint of the rising edge. This is the measured data hold time.

REFERENCE OPERATION

The AD9709, AD9763, AD9765, AD9767 contain a single

1.2 V reference that is shared by both of the DACs on the

chip. This reference drives two control amplifiers that

independently control the full-scale output currents in

each of the two DACs. Using the 1.2 V reference and the

control amplifier, reference currents are produced for

each DAC in an external resistor attached to FSADJ1

(DAC1) and to FSADJ2 (DAC2). The relationship between

the external resistor current and the full-scale output

current is:

I

FS

OUT

= 32 ×

Reference Current

Using the internal reference, this can also be expressed

as:

I

FS

OUT

= 38.4 ÷

R

EXT

On the evaluation board, R9 and R10 are the two external resistors that define the full-scale current.

An external reference can also be used simply by driving

the REFIO pin on the dual DAC (TP36) with an external

reference. The input impedance of the REFIO pin is very

high, minimizing any loading of the external reference.

However, because some references behave poorly

when driving capacitive loads, the bypass capacitor on

–4–

REV. 0

Page 5

AN-555

REFIO (C14) may need to be removed under these conditions. Figures 7 and 8 show the internal and external reference configurations for the AD9709, AD9763, AD9765,

and AD9767.

When using an external reference in this way, the fullscale output current for each DAC can be defined by;

I

FS

OUT

= 32 ×

V

REF/REXT

Note that in the internal reference configuration, any

additional load on the reference should be buffered with

an external amplifier. This external amplifier is not

included on the evaluation board.

For more detailed information on the operation of the

reference section of the DACs, see page 9 of the data

sheet.

OPTIONAL

EXTERNAL

REFERENCE

BUFFER

ADDITIONAL

EXTERNAL

LOAD

I

REF

0.1mF

2kV

GAINCTRL

+1.2V REF

REFIO

FSADJ

DUAL DAC

REFERENCE

SECTION

AVDD

CURRENT

SOURCE

ARRAY

ACOM

Figure 7. Internal Reference Configuration

enabled. In this mode, a single R

resistor is connected

SET

to FSADJ1 and the resistor on FSADJ2 can be removed.

Note: Only parts with date code of 9930 or later have the

Master/Slave GAINCTRL function. For parts prior to this

date code, Pin 42 must be connected to AGND, and the

part will operate in the two resistor, independent gain

control mode.

OUTPUT CONFIGURATION

The AD9709, AD9763, AD9765, AD9767 have been

designed to achieve optimum performance with the

outputs used differentially. A transformer on the evaluation board (Mini-Circuits T1–1T) allows the conversion

of the differential outputs to a single-ended signal. The

bandwidth of this transformer allows low distortion

operation from 350 kHz to well past the Nyquist bandwidth

of the DAC when operating at its highest sampling rate.

Figure 9 shows a typical DAC output configuration. Both

outputs drive a 50 Ω resistor as well as a transformer.

The grounded centertap on the primary of the transformer causes the output of the DAC to swing around

ground, allowing for wider p-p swing while still remaining within the output voltage compliance range of the

DAC. On the evaluation board, these resistors are R5,

R6, R7, and R8. This provides a full-scale differential output voltage of 0.67 V p-p when operating with I

OUT

FS =

20 mA and the transformer terminated with 50 Ω.

AVDD

CURRENT

SOURCE

ARRAY

ACOM

AVDD

EXTERNAL

REFERENCE

I

REF

2kV

GAINCTRL

+1.2V REF

REFIO

FSADJ

DUAL DAC

REFERENCE

SECTION

Figure 8. External Reference Configuration

MASTER/SLAVE RESISTOR MODE, GAINCTRL

The AD9709, AD9763, AD9765, AD9767 all allow the gain

of each channel to be independently set by connecting

one R

resistor to FSADJ1 and another R

SET

resistor to

SET

FSADJ2. To add flexibility and reduce system cost, a

single R

resistor can be used to set the gain of both

SET

channels simultaneously.

When GAINCTRL is low (i.e., connected to AGND), the

independent channel gain control mode using two resistors is enabled. In this mode, individual R

resistors

SET

should be connected to FSADJ1 and FSADJ2. When

GAINCTRL is high (i.e., connected to AVDD), the master/

slave channel gain control mode using one resistor is

If the secondary of the transformer is terminated with

50 Ω, the DAC will then be capable of driving 0.5 dBm

into this load at full-scale out.

C4, C5, C6, and C15 (10 pF) on the evaluation board,

working together with the 50 Ω output resistors, form a

low-pass filter which gives some amount of image rejection at higher output frequencies. In applications where

an amplifier is used in place of the transformer, it is

important that the capacitor values be chosen to limit

the output slew rate of the DAC. If the output of the

amplifier becomes slew rate limited, severe distortion

can result.

AD9709

AD9763

AD9765

AD9767

IOUT

IOUT

10pF

50V 50V

50V

10pF

Figure 9. Typical DAC Output Configuration

REV. 0

–5–

Page 6

AN-555

TROUBLESHOOTING

The dual DAC evaluation board has been designed to

allow optimum performance from the AD9709, AD9763,

AD9765, AD9767. However, many factors can contribute

to suboptimal performance. The following is a list of

potential problems and their likely sources.

Problem—No signal or reduced signal on the output.

Is power applied correctly? Use an oscilloscope to verify

that the input data pins are switching and that the clock

is present on the input. Make sure that the output transformer is in place. Do the data input logic levels match

the DVDD being applied (3 V or 5 V)? Does the clock pass

through the input threshold, roughly one-half of DVDD?

If the internal reference is being used, make sure that

1.2 V is present at FSADJ1, FSADJ2 and REFIO. Make

sure that R9 and R10 are in place next to these test

points.

Problem—Signal and images appear at the DAC output

at twice or half the expected frequency.

The DAC is in the incorrect mode (Dual DAC or Interleaving). Make sure that the mode select jumper in the top

right corner of the eval board is set to the correct position. This jumper must be in one position or the other

and cannot be allowed to float.

Problem—Unusually high amount of noise on the output.

With an oscilloscope, verify the relative timing between

the data transition and the clock input as described in

the Clock Timing Performance section. Check to make

sure that the clock for the data source is synchronized

with the clock input to the DAC.

Problem—Can not match noise specifications from data sheet.

Is a low jitter clock being used? When generating a

single tone, does the spectrum analyzer show skirting

around the tone at the noise floor? This is a symptom of

clock jitter.

Problem—Can not match distortion spec.

Is the output signal from the DAC seeing 50 Ω? Is the

voltage on the output of the DAC within the compliance

range of ±1 V? Is the DAC output overdriving the spec-

trum analyzer input? Try increasing the spectrum analyzer input attenuation to see if the distortion products

drop. If they do, the analyzer is being overdriven.

–6–

REV. 0

Page 7

DVDDIN

TP10

B1

BAN-JACK

B2

RED

L1

BEAD

POWER DECOUPLING AND INPUT CLOCKS

RED

TP11

B3

AVDDIN

BAN-JACK

B4

1

2

C9

10mF

25V

DVDD

TP37 TP38

BLKBLKBLK

TP39

L2

BEAD

1

2

C10

10mF

25V

AVDD

BLK BLK

TP40 TP41

BLK

TP42

AN-555

WRT1IN

IQWRT

CLK1IN

IQCLK

CLK2IN

RESET

WRT2IN

IQSEL

BAN-JACK

S1

S2

S3

S4

SLEEP

WHT

TP29

DGND;3,4,5

WHT

TP30

DGND;3,4,5

WHT

TP31

DGND;3,4,5

WHT

TP32

DGND;3,4,5

WHT

TP33

1

BAN-JACK

JP9

2

B

A

TP44

AGND

BLK

3

TP43

DGND

BLK

DCLKIN1 DCLKIN2

/2 CLOCK DIVIDER

JP6

2

3

1

JP16

DVDD

JP2

JP5

2

1

3

B

A

C

I

JP4

2

1

3

B

A

IC

JP3

2

1

3

B

A

I

1

1

1

R1

R2

50V

50V

2

2

1

R13

50V

2

TSSOP112

1

R3

50V

2

2

10

PRE

11

J

U1

13

CLK

12

K

CLR

14

DGND;8

DVDD;16

R4

50V

Q

Q

C

DVDD

9

7

1

C7

0.1mF

2

JP1

DVDD

TSSOP112

DVDD

1

C8

0.01mF

2

B

A

4

PRE

U1

CLR

A

JP7

15

DGND;8

DVDD;16

B

2

5

Q

6

Q

3

3

J

1

CLK

2

K

1

WRT1

CLK1

CLK2

WRT2

SLEEP

REV. 0

RP16

RCOM

22

1

R1 R9

3 4 5 6 7 8 92

INP1

INP2

INP3

INP4

INP5

INP6

INP7

10

INP8

RP9

RCOM

22

1

R1 R9

3 4 5 6 7 8 92

INP9

INP10

INP11

INP12

INP13

INP14

10

INCK1

RP10

RCOM

22

1

R1 R9

3 4 5 6 7 8 92

INP23

INP24

INP25

INP26

INP27

INP28

INP29

INP30

RP15

RCOM

22

10

Figure 10. Power Decoupling and Clocks on Dual DAC Evaluation Board

–7–

R1 R9

3 4 5 6 7 8 92

1

INP31

INP32

INP33

INP34

INP35

INP36

10

INCK2

Page 8

AN-555

2 P1

4 P1

6 P1

8 P1

10 P1

12 P1

14 P1

16 P1

18 P1

20 P1

22 P1

24 P1

26 P1

28 P1

30 P1

32 P1

34 P1

36 P1

38 P1

40 P1

2 P2

4 P2

6 P2

8 P2

10 P2

12 P2

14 P2

16 P2

18 P2

20 P2

22 P2

24 P2

26 P2

28 P2

30 P2

32 P2

34 P2

36 P2

38 P2

40 P2

P1 1

P1 3

P1 5

P1 7

P1 9

P1 11

P1 13

P1 15

P1 17

P1 19

P1 21

P1 23

P1 25

P1 27

P1 29

P1 31

P1 33

P1 35

P1 37

P1 39

P2 1

P2 3

P2 5

P2 7

P2 9

P2 11

P2 13

P2 15

P2 17

P2 19

P2 21

P2 23

P2 25

P2 27

P2 29

P2 31

P2 33

P2 35

P2 37

P2 39

INP1

INP2

INP3

INP4

INP5

INP6

INP7

INP8

INP9

INP10

INP11

INP12

INP13

INP14

INCK1

INP23

INP24

INP25

INP26

INP27

INP28

INP29

INP30

INP31

INP32

INP33

INP34

INP35

INP36

INCK2

RP5, 10V

116

RP5, 10V

314

RP5, 10V

512

RP5, 10V

710

RP6, 10V

116

RP6, 10V

314

RP6, 10V

512

RP7, 10V

116

RP7, 10V

314

RP7, 10V

512

RP7, 10V

710

RP8, 10V

116

RP8, 10V

314

RP8, 10V

512

RP3

RCOM

22

DVDD

RP5, 10V

215

RP5, 10V

4

RP5, 10V

6

RP5, 10V

8

RP6, 10V

2

RP6, 10V

4

RP6, 10V

6

11

RP6, 10V

89

RP4

RCOM

22

DVDD

RP7, 10V

215

RP7, 10V

4

RP7, 10V

6

RP7, 10V

8

RP8, 10V

2

RP8, 10V

4

RP8, 10V

6

RP8, 10V

89

R1

1

R9

1098765432

RP1

RCOM

R1

22

1

DVDD

13

11

9

15

13

R1

1

R9

1098765432

RP2

RCOM

R1

22

1

DVDD

13

11

9

15

13

11

DIGITAL INPUT SIGNAL CONDITIONING

R9

1098765432

RP13

RCOM

33

1

R1 R9

R1 R9

RP11

RCOM

33

1098765432

1

1098765432

DUTP1

DUTP2

DUTP3

DUTP4

DUTP5

DUTP6

DUTP7

DUTP8

DUTP9

DUTP10

DUTP11

DUTP12

DUTP13

DUTP14

DCLKIN1

R9

98765432

10

RP14

RCOM

33

1

R1 R9

R1 R9

RP12

RCOM

33

1098765432

1

1098765432

DUTP23

DUTP24

DUTP25

DUTP26

DUTP27

DUTP28

DUTP29

DUTP30

DUTP31

DUTP32

DUTP33

DUTP34

DUTP35

DUTP36

DCLKIN2

SPARES

RP5, 10V

710

RP8, 10V

710

Figure 11. Digital Input Signal Conditioning

–8–

REV. 0

Page 9

DUTP1

DUTP2

DUTP3

DUTP4

DUTP5

DUTP6

DUTP7

DUTP8

DUTP9

DUTP10

DUTP11

DUTP12

DUTP13

DUTP14

WRT1

CLK1

CLK2

WRT2

DUTP23

DUTP24

1

C1

VAL

2

1

DB13P1 (MSB)

2

DB12P1

3

DB11P1

4

DB10P1

5

DB9P1

6

DB8P1

7

DB7P1

8

DB6P1

9

DB5P1

10

DB4P1

11

DB3P1

12

DB2P1

13

DB1P1

14

DB0P1

15

DCOM1

16

DVDD1

17

WRT1

18

CLK1

19

CLK2

20

WRT2

21

DCOM2

22

DVDD2

23

DB13P2 (MSB)

24

DB12P2

1

C2

0.01mF

2

U2

AD9763/

AD9765/

AD9767

1

C3

0.1mF

2

AVDD

MODE

AVDD

IA1

IB1

FSADJ1

REFIO

GAINCTRL

FSADJ2

IA2

IB2

ACOM

SLEEP

DB0P2

DB1P2

DB2P2

DB3P2

DB4P2

DB5P2

DB6P2

DB7P2

DB8P2

DB9P2

DB10P2

DB11P2

DVDD

MODE1

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

1

AVDD

JP8

2

AB

ACOM

1

AB

3

SLEEP

DUTP36

DUTP35

DUTP34

DUTP33

DUTP32

DUTP31

DUTP30

DUTP29

DUTP28

DUTP27

DUTP26

DUTP25

1

C11

VAL

2

JP15

AN-555

BL1

TP34

4

BL2

R15

256V

12

R14

256V

12

JP10

BL3

4

BL4

WHT

TP35

WHT

AGND;3,4,5

AGND;3,4,5

REFIO

TP36

WHT

1

2

S6

OUT1

C14

0.1mF

S11

OUT2

NC = 5

3

2

R11

TP45

WHT

TP46

WHT

VAL

R12

VAL

1.92kV

2

3

1

10pF

C15

10pF

C4

1

2

2

1

2

1

C12

0.01mF

2

1

2

R5

50V

10pF

10pF

R7

50V

C5

C6

1

2

2

1

2

1

C13

0.1mF

1

R6

50V

2

1

R8

50V

2

AVDD

1:1

16

T1

R9

2

1

C16

22nF

1

2

C17

22nF

1

2

12

R10

1.92kV

NC = 5

3

2

1:1

16

T2

DUT AND ANALOG OUTPUT SIGNAL CONDITIONING

REV. 0

Figure 12. Output Signal Conditioning

–9–

Page 10

AN-555

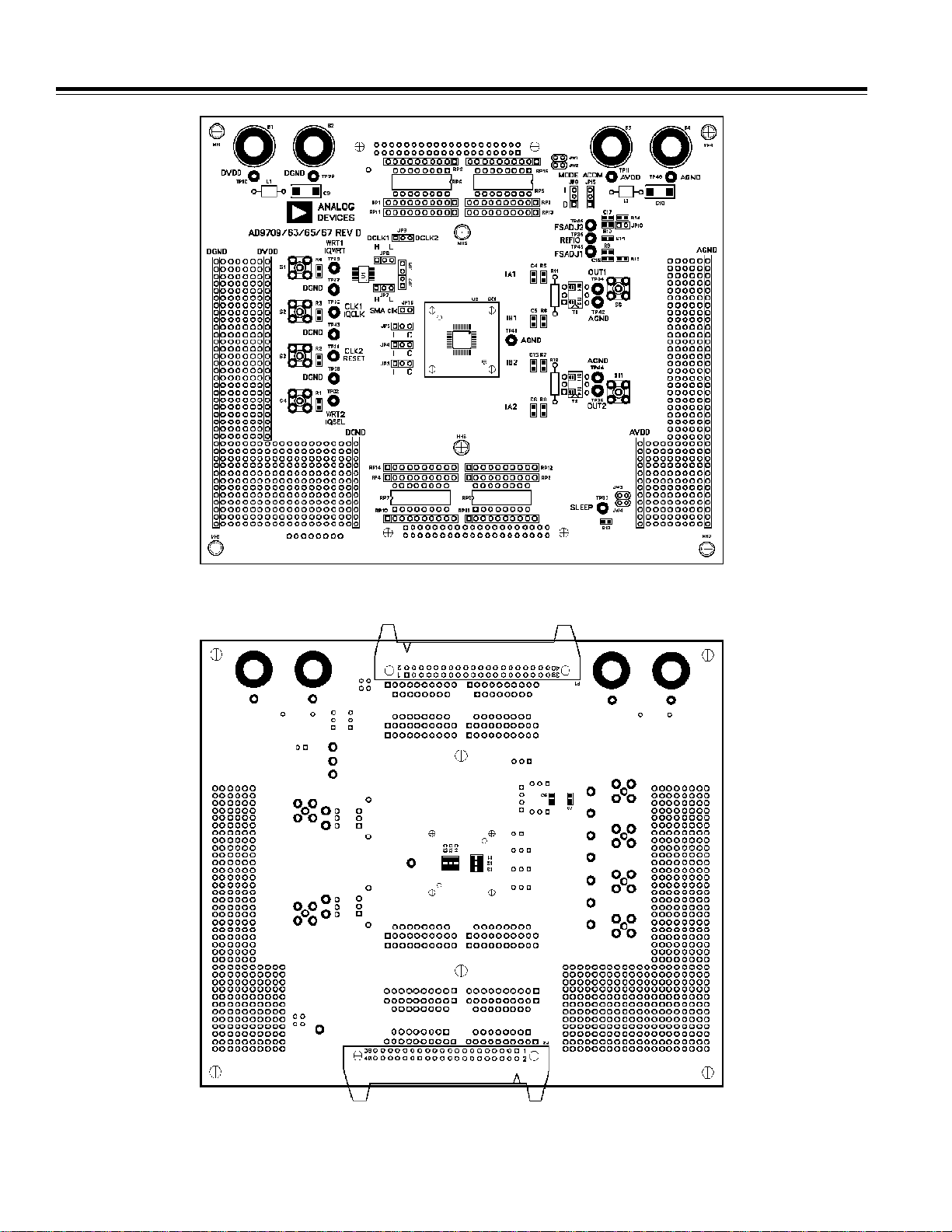

Figure 13. Assembly, Top Side

Figure 14. Assembly, Bottom Side

–10–

REV. 0

Page 11

AN-555

Figure 15. Layer 1, Top Side

REV. 0

Figure 16. Layer 2, Ground Plane

–11–

Page 12

AN-555

E3661–2–12/99 (rev. 0)

Figure 17. Layer 3, Power Plane

PRINTED IN U.S.A.

Figure 18. Layer 4, Bottom Side

–12–

REV. 0

Loading...

Loading...