Page 1

AN-529

a

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • 781/329-4700 • World Wide Web Site: http://www.analog.com

APPLICATION NOTE

5B Series Signal Conditioning Subsystems

in RFI/EMI Fields

The 5B Series Signal Conditioning Subsystem has been

tested and passed the stringent “heavy industrial” requirements of the European Union’s electromagnetic

compatibility (EMC) directive.

In order to comply with the European Standards in a

typical heavy industrial application we recommend the

following setup:

1. The modules must be mounted on a standard 5B

Series backplane.

2. The 5B backplane must be mounted inside a standard

metal cabinet that fully encloses the modules on all

sides. The cabinet must be earth grounded at a convenient point and good electrical contact between all

side panels must be assured.

3. All wiring must be routed through a metal conduit or

wire chase (flexible or rigid).

4. The conduit must be earth grounded and electrically

connected to the cabinet.

5. Due to the low input levels, it is recommended that all

input, output and power lines be shielded.

When used according to these installation directions,

any errors caused by EMI/RFI interference will be less

than 0.1% of the full-scale 5B measurement range (typical @ +25°C), for field strengths up to 10 V/m and frequencies up to 1 GHz.

CE CERTIFICATION TESTS

The 5B Series modules have been tested and certified

according to the rigorous electromagnetic constrains of

the EN50082-2 and EN50081-2 European Standards. A

description of each test is given below, followed by

Table I listing the standards for each test.

Test Descriptions

1. Radiated RF Immunity

The units were subject to an RF field using a log-periodic

antenna, maintained at 10 V/m by an amplifier placed

outside the RF chamber. The field was swept from a frequency of 80 MHz to 1 GHz, with a 1 kHz modulation. The

frequency increment size was 0.2% of the current frequency and the settling time at each frequency was two

seconds. The field strength was supervised by an RF

field monitor located next to the cabinet holding the

units. The amplifier was adjusted accordingly to maintain the 10 V/m field strength. The antenna was placed

exactly 1 m from the units. Readings were taken for both

horizontal and vertical polarizations. The outputs of the

units under test were acquired at every frequency

through a crosspoint matrix scanner and a precision

digital voltmeter. By subtracting the baseline reading

taken with no RF field, the change was obtained and

then expressed and stored as a percentage of span

change. This test simulated the effect of system operation in an environment that is exposed to strong (heavy

industrial) radiated electromagnetic waves.

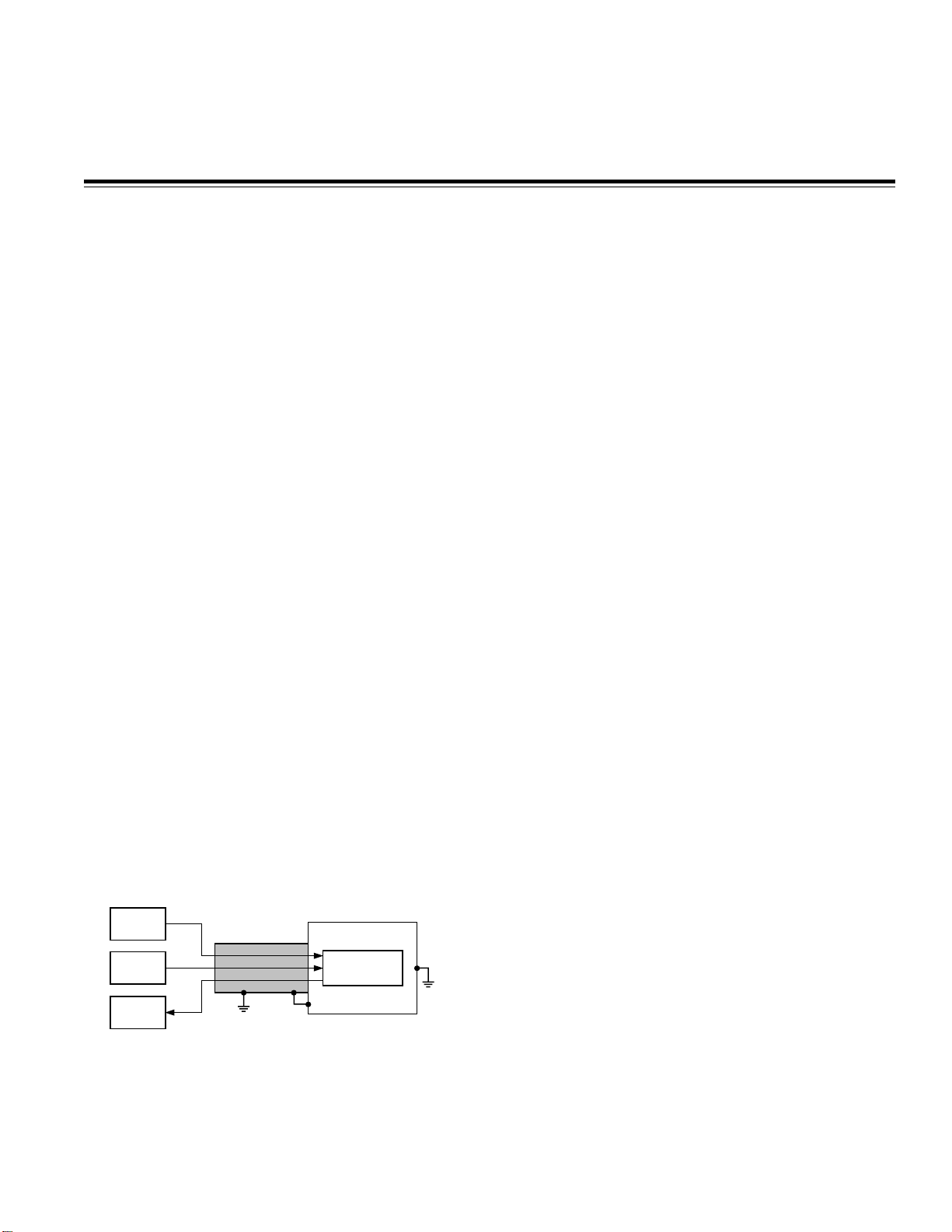

SENSORS

POWER

SUPPLY

CONTROL

SYSTEM

Figure 1. General Wiring Configuration

FLEXIBLE/RIGID

METAL CONDUIT

BACKPLANE

METAL CABINET

2. Conducted RF Immunity

The units were subject to conducted EMI via an RFgenerated signal resistively injected into the conductive

5B

layer of a standard flexible wire chase housing the wires

from the system backplane. The point of contact was approximately 20 cm from the units. The field was swept

from a frequency of 150 kHz to 80 MHz, with a 1 kHz

modulation. The frequency increment size was 1% of the

current frequency and the settling time at each frequency was two seconds. Ferrite beads were placed outside the RF chamber on the wires to ensure that the

disturbance was not reflected to the test measurement

instrumentation. As in the radiated RF immunity tests,

the outputs of the units were scanned in and the percentage of span change was stored.

Page 2

AN-529

3. Fast Transient Immunity

All field wires external to the system console are subjected to and must withstand transients occurring within

the normal environment of operation. The test configuration, routing field wires through a single wire chase,

requires transient testing be applied to the wire chase;

thus the conduit carrying the wires were placed in a

metal enclosure for testing. Positive and negative polarities of 0.5 kV, 1 kV and 2 kV with 5 ns/50 ns rise/fall times

were capacitively injected into the conduit. The outputs

were scanned before and after the transients and the

percent of span change was calculated and stored. (The

test instrumentation and supporting test equipment

were removed from the proximity of the wires during

the application of the transients to avoid damage to the

test equipment.)

4. Pulsed RF Immunity

The units were subjected to radiated RF at 900 MHz,

10 V/m, 100% square wave modulated at 200 Hz inside

the RF chamber using a log-periodic. About 180 readings were taken with a settling time of two seconds for

each reading. Both vertical and horizontal polarization

were tested. Once again, the percentage of span change

was calculated and stored.

5. Magnetic Field Immunity

The units were placed within two coils carrying current

to generate a magnetic field of 30 A/m @ 50 Hz. The field

strength was measured using a loop antenna and an oscilloscope. The units were placed in three configurations, X, Y and Z relative to the magnetic field. The

outputs of the units were scanned and the percentage of

change calculated. This tested the units’ behavior under

stray magnetic fields.

6. ESD—Contact

The units were subjected to the contact method following the human model by an ESD gun four times, using

positive and negative polarities at 4 kV. The ESD was

applied to the units’ cases, mounting screws and the DB25 connector backshell. After exposure, the units were

retested to ensure proper functionality.

7. ESD—Air

The units were subjected to the air discharge method

following the human model by an ESD gun eight times,

using positive and negative polarities at 2 kV, 4 kV, 6 kV

and 8 kV. The ESD was applied to the units’ cases,

mounting screws and the DB-25 connector backshell. After exposure, the units were retested to ensure proper

functionality.

8. Voltage Surges Immunity

Five positive and five negative 2 kV pulses with

1.2 µs/50 µs. Its rise/fall times, each lasting 1 minute,

were applied directly onto the shields at the input end of

the field wiring. A capacitor was connected from shield

to ground near the module end of the field wiring. When

a particular shield was under test, it was ensured that its

shield did not contact any other shields, forcing the

surge to enter the unit. The units were retested after

exposure to ensure proper functionality.

9. Emissions

The units were tested for radiated and conducted emissions. The units were biased at maximum output and

readings of field strength from 30 MHz to 1000 MHz in

both vertical and horizontal polarization were taken.

Readings from the ac main of the dc power supply from

50 kHz to 30 MHz were also taken.

E3279–5–3/98

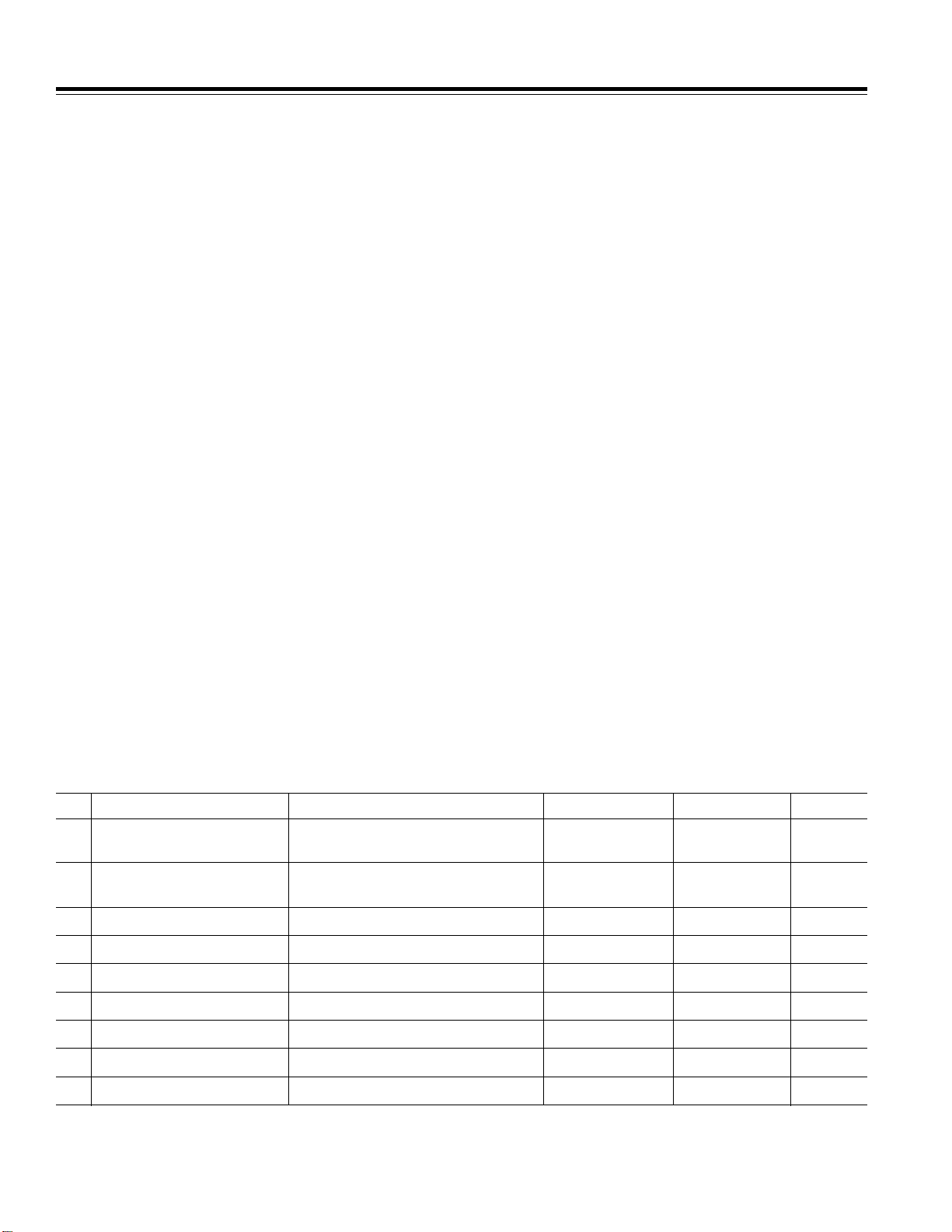

Table I. List of Test

No. Test Test Specification Basic Standard Test Setup Criteria

1 Radiated RF Immunity 800 MHz–1000 MHz, 10 V rms, ENV 50140 ENV 50140 A

Modulated, 1 kHz, 80%

2 Conducted RF Immunity 0.15 MHz to 80 MHz, 10 V rms ENV 50141 ENV 50141 A

80% Amplitude Modulated (1 kHz)

3 Fast Transient Immunity 1 kV, 2 kV IEC 801-4 IEC 801-4 B

4 Pulsed RF Immunity 900 MHz, 50% Duty Cycle , 200 Hz ENV 50140 ENV 50140 A

5 Magnetic Field Immunity 50 Hz, 30 A/m EN 61000-4-8 EN 61000-4-8 A

6 ESD Immunity Contact 4 Contact EN 61000-4-2 EN 61000-4-2 B

7 ESD Immunity Air 8 Air Discharge EN 61000-4-2 EN 61000-4-2 B

8 Voltage Surge Immunity 2 kV, 5 Positive, 5 Negative B

9 Emissions Radiated and Conducted

–2–

PRINTED IN U.S.A.

Loading...

Loading...