Page 1

AN-525

a

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • 781/329-4700 • World Wide Web Site: http://www.analog.com

ADV601 Video Codec Design Considerations

by David Starr

OVERVIEW

This Applications note is for hardware and software designers starting an ADV601 design. Using this note and

the information in the ADV601 Video Codec data sheet

you can do the following:

Design ADV601-based video compression hardware.

Write software drivers and hardware diagnostic

programs.

Integrate your hardware into the PCI bus and your

software into Windows

The design examples in this application note refer to the

ADV601-based Videolab demonstration board, but you

can apply the techniques used in these examples to any

ADV601-based design. The software source code and

hardware schematics mentioned in this note are available on the Analog Devices computer products FTP site,

whose Uniform Resource Locator (URL) is:

ftp://ftp.analog.com/pub/dsp/adv601/

VCLK (VIDEO CLOCK) FREQUENCY FOR SQUARE AND

NONSQUARE PIXELS

The ADV601 uses the VCLK signal for internal processing,

DRAM timing and strobing in video data. The ADV601’s

internal PLL multiplies VCLK up to generate the DRAM

/CAS and /RAS timing. Use only the clock frequencies

listed on the data sheet under “Clock Pins,” even in

nonreal-time applications. You must set the mode control register bits P/N (PAL/NTSC) and SPE (Square Pixel

Enable) to match the selected VCLK frequency. For instance, if VCLK is 29.5 MHz, then set both P/N and SPE

equal to one for the ADV601 to function properly. If you

®

95.

intend to switch square pixel enable on and off, you must

also vary the clock frequency to match. Pulse-to-pulse jitter on VCLK should be less than 1 ns. The part is designed

to function with VCLK phase locked to the horizontal

sync. There is enough tolerance in the clock circuit to

track the horizontal timing variations caused by tape

speed variations (flutter and wow) on consumer grade

VHS video cassette recorders (VCRs).

COMPRESSED VIDEO DATA INTERFACE DESIGN ISSUES

The compressed video data bus must support a high

data rate. Raw video comes into the part at 12 to

14 Megapixels/sec. Video will come out of the part just

as fast at low compression ratios. The compression ratio

can vary from its programmed value, causing the video

data rate to increase (or decrease, but the increase

causes the difficulty). A slow compressed video bus will

cause the ADV601’s internal FIFO to underflow or overflow, resulting in lost frames on capture and torn frames

on playback. Difficulty may occur if the compressed

video bus is slower than 5 Megabytes/sec. The Analog

Devices evaluation board uses a Bus Master PCI bus interface capable of 16 Megabytes/sec.

Many applications capture and play back video to/from

hard disk. In this case the disk is the limiting factor in system throughput. However, if the disk and the ADV601 reside on the same bus (for example, a PCI bus system),

bus bandwidth may also be a factor. If the video goes

from the ADV601 card to main memory, and then from

main memory to disk, bus traffic is double what it would

be if the video went directly from the ADV601 to the disk

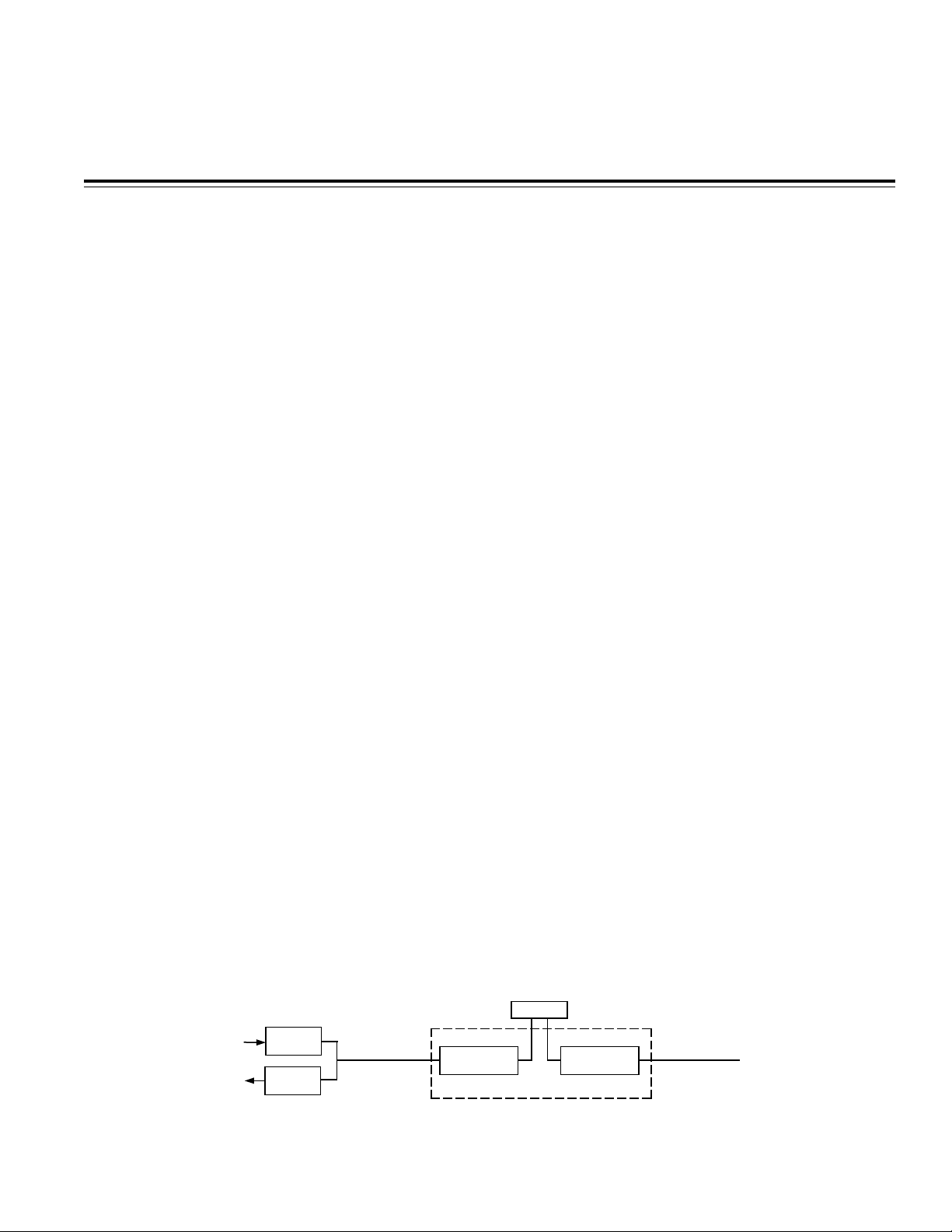

VIDEO

INPUT

VIDEO

OUTPUT

Windows is a registered trademark of Microsoft Corporation.

BIDIRECTIONAL

RAW VIDEO BUS

Figure 1. Video Signal Flow

WAVELET

TRANSFORM

DRAM

ADV601

HUFFMAN

CODER

BIDIRECTIONAL

COMPRESSED

VIDEO BUS

Page 2

AN-525

controller with no halfway stop in main memory. Burst

mode, where the hardware acquires the bus, asserts one

address and transfers a block of data, will give best performance. The bus hardware may not be fast enough if it

must acquire the bus and assert an address for each

word transfer.

FIFO STATUS SIGNALS FIFO_SRQ, FIFO_STP, FIFO_ERR,

FIFO_STP

FIFO_STP is a combined FULL and EMPTY pin. On encode it signals EMPTY, on decode it signals FULL. It

means stop moving data into or out of the FIFO.

FIFO_STP is asserted quite late and it can be difficult for

hardware to see the FIFO_STP signal in time to halt the

next FIFO transfer. In this case, an extra read will move

invalid data, and an extra write will trash a word already

inside the FIFO.

FIFO_SRQ

FIFO_SRQ is a combined NEARLY FULL and NEARLY

EMPTY bit. On Encode it signals NEARLY FULL, and

on DECODE is signals NEARLY EMPTY. NEARLY (the service request trigger point) is programmed by the FIFO

Control Register over the range 32 to 480 long words.

FIFO_SRQ is easier to use for data transfer control than

FIFO_STP, because there is no penalty for moving one or

two words after FIFO_SRQ goes away. FIFO_SRQ will go

away at least 32 reads or writes before FULL or EMPTY

occurs. The size of each data transfer can be controlled

by programming NEARLY. Setting NEARLY to half full

(256 words) will cause the hardware to move at least 256

words for each service request. This can be advantageous if there is significant overhead required to set up

each bus transfer. Overhead might be arbitrating for the

bus, entering host interrupt service or asserting the data

address.

FIFO_SRQ can reoccur very rapidly. The host and the

ADV601 are racing each other through the FIFO. It is possible for the host to transfer a single word that clears the

FIFO service request and on the very next VCLK, the

ADV601 can transfer a word that sets the FIFO service

request again. FIFO_SRQ is asynchronous to the host

port. Take care not to violate setup and hold time

requirements of host port hardware.

FIFO_ERR

FIFO_ERR is a combined EMPTY and FULL pin. On

decode it signals EMPTY and on encode it signals FULL.

This is the reverse of FIFO_STP. When asserted, the host

is falling behind.

BIN WIDTH CALCULATION BASICS

Off-chip computation, either by the host or a dedicated

DSP, is required to control the compression ratio during

encode. The Wavelet transformer output is 16 bits wide.

To increase the compression ratio, some low order bits

must be discarded before the run length and Huffman

coders. This increases the length of the zero runs leading

to more data compression. The ADV601’s adaptive

quantizer discards low order bits by multiplying every

sample in the bin by a user-specified fraction, called the

reciprocal bin width. On playback, the sub-bands are

restored to proper size by multiplication by a userspecified coefficient called the bin width. Each of the 42

sub-bands has its own bin width and reciprocal Bin Width

Register. The bin widths are embedded in the compressed data stream during the encoding process. On

decode, the ADV601 extracts the bin widths from the

compressed data stream and multiplies each sample by

the bin width to bring it back up to proper size. Bin Width

Registers are of concern on encode only; nothing need be

put in the registers for decode.

Computation of a Bin Width Register is straightforward—

merely take the reciprocal of the corresponding reciprocal Bin Width Register. Remember that the reciprocal Bin

Width Registers are scaled 6.10 and the Bin Width Registers are scaled 8.8, and scale your reciprocal calculation

accordingly.

The number of bits required to encode an image varies

with the busyness of the image. A plain solid black field

will encode very compactly since there is no high frequency energy in the picture. The higher sub-bands are

all zero everywhere. On the other hand, something like a

close-up of a plaid shirt has a lot of high frequency energy and will call for more bits to encode. As the picture

gets busier, you need to use a smaller fraction in the reciprocal Bin Width Registers.

At the end of each field, the ADV601 supplies the bin

width computer with the sum of the squares of each subband as a measure of the busyness. These (and a few

other numbers) are referred to as “statistics.” As the sum

of the squares gets larger, the reciprocal bin widths need

to get smaller.

This bin width computation works best if done quickly.

The ADV601 will present the statistics just as vertical retrace is beginning. The bin width computer needs to read

all the statistics, compute 42 reciprocal bin widths and 42

bin widths, and write the new setting back into the

ADV601 before the next field starts. Next field starts in 20

horizontal line times or about 1.2 milliseconds. The computation needs to be repeated once per field, or

every 16 milliseconds. The computation load will be

about 1.2 milliseconds every 16 milliseconds or 7%. This

assumes that the bin width calculation is actually completed within the 1.2 millisecond deadline. If not, the

ADV601 will use the existing bin width setting on the new

field. Since one field is much like another field, no great

harm is done.

DIAGNOSTICS AND DEBUGGING STRATEGY

In testing out a new design it is important to get simple

things working before testing more complex features.

–2–

Page 3

AN-525

For instance, the host interface has to successfully write

the ADV601 mode control register before it is reasonable

to expect video data transfer to work. Listed below, in order, are the diagnostic tests used to bring up the Analog

Devices evaluation board.

16-Bit Data Interface (Bin Width Register) Test

First check the data interface into the part. If the data is not

getting into and out of the part reliably, almost anything

can go wrong. Data errors can cause the part’s internal registers to program with unexpected values, causing unexpected operation. For instance, failure to set the encode/

decode bit as intended will cause the part to drive an unexpected bus. Consider configuring the hardware for video

capture. The video A/D will drive the raw video bus. If a

data error causes the ADV601 to come up in decode mode

by mistake, it too will drive the raw video data bus, causing

both parts to get hot (or worse). The possibilities for unexpected behavior are broad, and defy analysis.

Test the data interface by writing data into the part and

reading it back. Data read back shall match data written

in. The 16-bit wide bin width and reciprocal Bin Width

Registers are read/write, and hence testable, unlike other

registers such as the mode control register. The bin width

and reciprocal bin width registers, have addresses 100 to

153 (hex). The test should prove that each bit in each register can store both a one and a zero. It should prove that

all 84 registers are unique by storing a different test value

into each one and reading it back. The test should write

all 84 registers and then read all of them back. It must not

write one, read one and move to the next. It should take

advantage of the auto incrementing feature of the Indirect Address Register to write and read all 84 registers in

one swoop. Example code is in file wavetest.c (a part of

601test), and adv601.c (a part of 601cman). This code is

on the Videolab CD-ROM and on the ADV601 FTP site.

As soon the Bin Width Register test runs once, put the

program into a loop and test repeatedly. The new design

should run overnight with no errors before the data interface can be considered free of timing errors.

A successful Bin Width Register test verifies the indirect

address register, the indirect data register, the low 16 bits

of the data bus , and the following pins, byte enables BE0

and BE1, addresses ADR0 and ADR1, CS, WR, RD and

ACK. The ADV601 host interface handles all registers

identically, so Bin Width Register test success gives confidence that writes to other read only registers function

properly. Bin Width Register test failure suggests that

other registers may not read or write properly, which

throws doubt on the results of any other tests.

32-Bit Data Interface (FIFO) Test

A read/write test of the FIFO will verify all 32 bits of the

data bus since the FIFO port is 32 bits wide. Use the same

test data patterns as the Bin Width Register test uses, for

the same reasons. The procedure for writing test data

into the ADV601 FIFO is the same as for any video data.

Reset the part, initialize it in decode mode, and write the

FIFO data port until the FIFO is full. Write 512 long words

and read them back. Read back requires the chip be

placed into a special test mode. Do this by resetting the

chip, and putting it into encode mode. Set the 100 bit in

the FIFO control register. Example code is in 601 test

module wavetest.c Then just read the FIFO port. Resetting the chip merely zeroes the FIFO read and write pointers. Data in the FIFO is not altered. Again, after the test

runs once, by hand, loop it over night to detect intermittent errors. It took some time to resolve all the PCI bus

interface problems on the Analog Devices Videolab design. As above, failure of the FIFO test suggests that the

interface is dropping bits and corrupting the video. This

casts doubt on the results of any other tests. The FIFO

test will fail if the host cannot access the ADV601 control

registers which the Bin Width Register test checks out.

Color Ramp Test

Color Ramp tests video decoding, which is easier than

encoding. Color ramp is a simple ramp in both Luma and

Chroma. This special case encodes VERY compactly,

only 2440 bytes are required to encode a complete frame

of video. This is small enough to fit into the memory of

any microprocessor. Putting the test pattern into

memory sidesteps all problems of disk speed, disk latency, seek time, thermal recalibration time, disk fragmentation, and bus contention. Your test program

merely keeps loading the color ramp pattern into the

ADV601 FIFO whenever the part asserts FIFO Service Request. It has a whole frame time (33 milliseconds) to load

2440 bytes, for a very modest data rate of 74 Kilobytes

per second. The test passes when the color ramp pattern

appears on the video monitor. The color ramp test should

run forever (at least over night) to detect intermittent

problems. Color ramp exercises the complete video decode path through the ADV601, plus the video decoder, if

your design has one. If color ramp runs but captured

video does not, the problem is either speed (host can’t

load FIFO fast enough) or encode. The color ramp data

can be found in file c_ramp.c, a part of the 601test program available on the FTP site.

Bin Width and Reciprocal Bin Width Register Settings

To get the chip up and encoding initially, load the bin

width and reciprocal Bin Width Registers with one

“canned” set of values that will quantize each frame

heavily (high compression). The high compression will

reduce the data rate out the compressed data port (FIFO)

and avoid FIFO overrun if the host is slow for some reason. Successful video capture means the captured video

plays back properly. After successful capture, then it is

time to enable the statistics ready interrupt, read the statistics, and compute a new set of bin widths for each

frame. This interrupt service can be tricky to get right.

–3–

Page 4

AN-525

Errors can cause the part to output data furiously, causing a FIFO overrun. “Canned” bin width sets can be

found on the FTP site.

AVOID BUS FIGHTS

Both the raw and compressed video buses (VDATA and

DATA) are bidirectional buses, the ADV601 can either

read them or write them. The design must insure that two

chips do not drive the same bus at the same time, especially when coming out of reset or switching between

encode and decode. The ADV601 comes out of reset

reading the VDATA bus. If you rely upon software to initialize chips consider what will happen when the software fails. The ENC pin out of the ADV601 goes low when

the part is driving the VDATA bus, and can be used as

output enable for the other chips on the bus.

TEST POINTS AND LEDS

On a new design it will be necessary to observe each pin

of the ADV601 with a logic analyzer. The first Analog

Devices Videolab board had four 40-pin headers right on

the board. If headers won’t fit, Ironwood Electronics

makes a series of “chip extenders” that give logic analyzer access. Placing LEDs on the following pins can

greatly speed up hardware and software debug.

Pin Name LED Indication

FIELD Glows 1/2 bright when video is running.

FIFO_SRQ Activity when video is running.

HIRQ Activity when video is running. Full

bright after software crash.

ENC Verifies that software put the part into

encode mode at the right time.

RESET Signals unexpected reset.

FIFO_ERR Should never happen.

HARDWARE VS. SOFTWARE RESET

The ADV601 has both a hardware reset pin, and a reset

bit in the mode control register. Hardware reset must be

asserted once at power up. Driver software will be easier

to write if it too can assert hardware reset as a way of

placing the chip into a known initial state. The hardware

reset bit loads initial values into all the ADV601 registers

that have defined initial values. Asserting the software

reset bit in the mode control register makes the chip stop

processing video and permits changes to the mode control register. It does NOT load initial values into registers.

You must stop video processing with the software reset

bit before changing video processing via the mode control register. You should assert software reset, then change

the mode control register bits (and load all the other registers too) and then clear the software reset bit.

INTERRUPTS

The ADV601 asserts a single interrupt (HIRQ) to signal

many different things. The host program reads the interrupt mask/status register to determine why the ADV601

required attention. There are many reasons (six to be exact). Reading the interrupt mask/status register clears

and rearms all of the interrupts. In other words, reading

the register acknowledges the interrupt to the ADV601

saying, in effect, “I’ve seen you, now go away and interrupt me again the next time it happens.” This has two

side effects on host software. First, reading the register

clears the bits, so a second read of the register won’t return the same data. Second, if the condition causing the

interrupt reoccurs or another condition occurs, the chip

will interrupt again. An interrupt routine might do the following things:

Insure that it won’t be reentered if the interrupt stays

“hot” or is reasserted during interrupt service.

Read the interrupt status register once, and service all the

things that need service. For instance sooner or later both

statistics ready and FIFO service request will occur at the

same time.

When all servicing is done, read the interrupt status register one more time in case something came up during

service time. If so, service the new condition.

Avoid becoming stuck in interrupt service if the interrupt

stays “hot” no matter how much service the part is given.

CRUCIAL WIN 95 SETTINGS

You may be able to correct FIFO under runs or over runs

(FIFO_ERR bit gets set) by turning off CD-ROM auto insert

notification in Win 95. Go to “Settings” then “Control

Panel”. Click on “System” (a blue screen computer icon).

Click on the “Device Manager” tab. This will display all

the devices on the system. Click on the CD-ROM icon,

which should then expand one level. Go down and click

on “Properties.” Pick the “Settings” tab. Clear the check

mark in the “Auto Insert Notification” box.

It may also be necessary to remove the Win 95 “handicapped accessibility” option. While still on the “Control

Panel” click on “Add/Remove Programs.” Select the

“Windows Setup” tab. Remove the “Accessibility Options” (icon of a wheelchair). These two changes cured

FIFO overruns that occurred every ten seconds and

every five minutes.

E3171–.5–3/98

PRINTED IN U.S.A.

–4–

Loading...

Loading...