AN-524

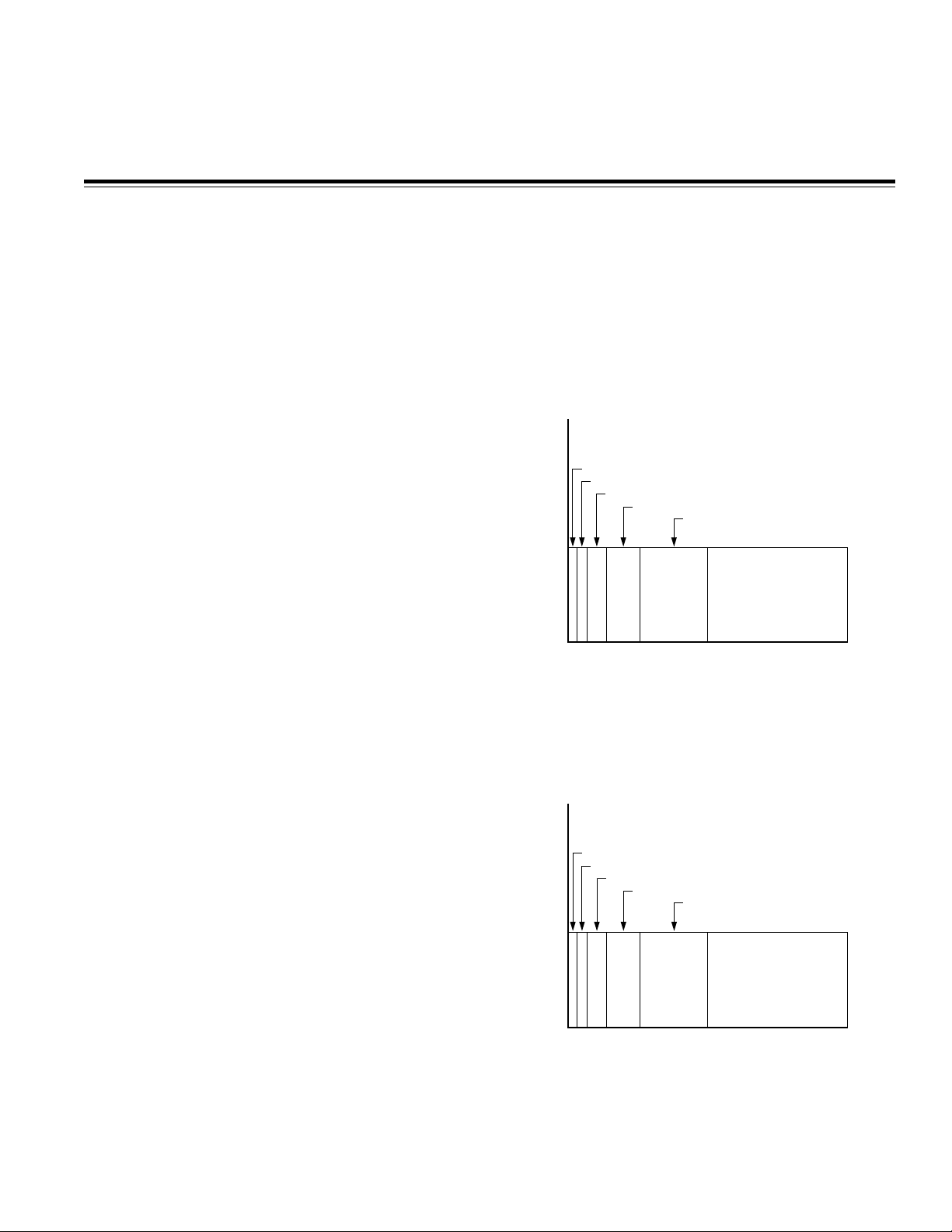

VIDEO FREQUENCY – MHz

0

0.1

3.37

LOW PASS SUB-BAND

LOWEST HIGH PASS BAND

SECOND HIGH PASS SUB-BAND

THIRD HIGH PASS SUB-BAND

FOURTH HIGH PASS SUB-BAND

FIFTH HIGH PASS SUB-BAND

0.21

0.42

0.84

1.68

a

ONE TECHNOLOGY WAY • P.O. BOX 9106

ADV601 Bin Width Calculation in ADSP-21xx DSP

INTRODUCTION

This application note is for hardware and software designers integrating an Analog Devices ADSP-21xx family Digital Signal Processor (DSP) into an ADV601

design. It describes software to control video compression in the ADV601 Video Codec chip via the auxiliary

serial port. Using this note and the information in the

ADV601 Video Codec data sheet you can do the following:

Design the DSP to ADV601 interface

Program the DSP

•

NORWOOD, MASSACHUSETTS 02062-9106

by David Starr

APPLICATION NOTE

781/329-4700

•

LOW PASS SUB-BAND

LOWEST HIGH PASS BAND

SECOND HIGH PASS SUB-BAND

THIRD HIGH PASS SUB-BAND

FOURTH HIGH PASS SUB-BAND

FIFTH HIGH PASS SUB-BAND

The design examples in this application note refer to the

ADV601-based Videolab demonstration board, but you

can apply the techniques used in these examples to any

ADV601-based design. The software source code and

hardware schematics mentioned in this note are available on the Analog Devices computer products FTP site,

whose Uniform Resource Locator (URL) is:

ftp://ftp.analog.com/pub/dsp/adv601/

WHAT IS A BIN WIDTH CALCULATOR?

The ADV601 Video Codec chip has two main parts, a

Wavelet Filter Bank and a run length/Huffman encoder.

On compression (encoding) the video is transformed

into the Wavelet domain and then run length/Huffman

encoded. The Wavelet transform is analogous to the

Fourier transform. The Fourier transform is reversible

and can be, but seldom is, realized as a bank of bandpass filters. The output of each Fourier filter is often

called a “bin.” After Fourier transformation the signal is

said to be in the frequency domain. Like the Fourier

transform, the Wavelet transform is reversible. Unlike

Fourier, it is realized as a bank of band pass filters that

divides the input signal into “sub-bands.” The sub-band

width is logarithmic in frequency. The highest sub-band

contains the top half of the input signal frequency. The

next sub-band contains the middle quarter, and so on.

0

0.21

0.84

0.42

1.68

VIDEO FREQUENCY – MHz

3.37

6.75

Figure 1. ADV601 Luma Sub-Band Frequency Limits

Since Chroma is sampled at one-half the rate of Luma,

the frequency range of the chroma sub-bands is half that

of the corresponding Luma sub-bands.

Figure 2. Chroma Sub-Band Frequency Limits

AN-524

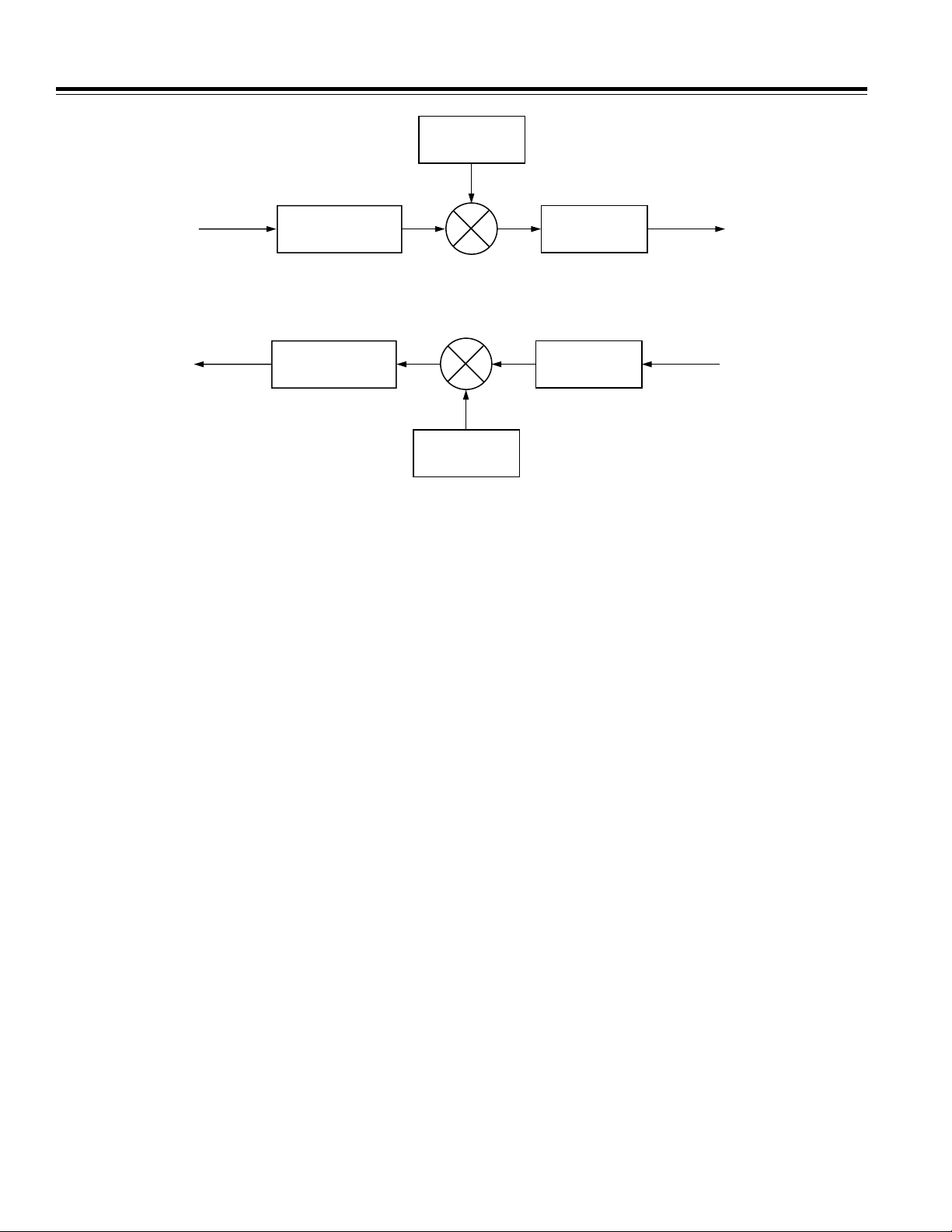

42 RECIPROCAL BIN

WIDTH REGISTERS

RAW VIDEO IN

WAVELET TRANSFORM

ADAPTIVE QUANTIZER

Figure 3. Block Diagram Encoding

RAW VIDEO

OUT

WAVELET TRANSFORM

ADAPTIVE QUANTIZER

Figure 4. Block Diagram Decoding

To reverse the Wavelet transform and recover the original signal, simply add all the sub-bands back together. If

all the bits in all the sub-bands are preserved, there is a

loss less transformation and the original signal is recovered intact. This gives about 3:1 loss less compression,

which is not really enough for many applications. The

signal in the highest frequency sub-band will contain

small amplitude wiggles that are mostly high frequency

noise and a few high amplitude spikes that represent

sharp edges in the picture.

To obtain more compression we discard low order bits

in the high frequency sub-bands. This gives longer runs

of zeros that the run length encoder converts into a very

short code. Multiplying every data point in each subband by a fraction, called the reciprocal bin width, discards the low order bits. This is the adaptive quantizer

located in between the Wavelet filter bank and the run

length/Huffman encoder. There are 42 different subbands and each one has a reciprocal bin width register,

permitting independent quantization of each sub-band.

On decode, we restore the quantized signal to its proper

amplitude by multiplying each data point by a factor

called the bin width. Again there are 42 bin width registers. The duty of the “Bin Width Calculator” program is

to set all 42 bin width and 42 reciprocal bin width register with the proper fraction to achieve the desired compression ratio.

DESIRABLE FEATURES IN A BIN WIDTH CALCULATOR

Bit Rate Depends On Video Signal

Simple video (e.g., a shot of a cloudless blue sky) has

very little high frequency detail. Every pixel is the same

(blue). The high pass sub-bands will all be zero. The run

42 BIN WIDTH

REGISTERS

COMPRESSED

RUN LENGTH &

HUFFMAN ENCODER

RUN LENGTH &

HUFFMAN ENCODER

VIDEO OUT

COMPRESSED

VIDEO IN

length encoder will efficiently convert the long runs of

zeros into a single short code group, and the image will

compress tremendously. Other video (e.g., an actor

wearing a plaid shirt) has significant high frequency detail. When the TV broadcaster cuts from simple video to

complex video, or even from one scene to another, or to

a commercial, the bit rate will change substantially unless something is done. That "something" is handled by

the Bin Width Calculator, which must respond to the

video change by altering the bin-width register settings

to achieve the desired bit rate.

Constant Bit Rate

A constant bit rate Bin Width Calculator is needed when

video must go through a fixed bit rate communications

link. If the video bit rate from the ADV601 exceeds the

communication link bit rate, video will be lost. If the bit

rate from the ADV601 is less than the communications

link can handle, the viewer at the far end of the link is not

receiving the best possible picture. A better picture

would be obtained if more bits were sent. The constant

bit rate Bin Width Calculator adjusts the bin width registers on every frame to achieve the programmed target

bit rate as closely as possible.

Constant Quality

It is also possible to create a constant quality Bin Width

Calculator. If the objective is to maximize the amount of

video stored on a hard disk, the problem is a bit less demanding. Plain and simple video that compresses well

can be allowed to do so and only the busy and complex

video needs be trimmed down to size. The savings in

disk space are worthwhile, and might permit a longer

video capture before the hard drive is filled.

–2–

AN-524

0.9

0.8

0.7

0.6

SERIES 1

SERIES 2

41

35 29 23 17 11 5 –1

SUB-BAND NUMBER

0.5

0.4

0.3

RECIPROCAL BIN WIDTH

0.2

0.1

0

Figure 5. Sub-Band Quantization vs. Frequency

The Quantizing Curve

For reasonable compression, all the wavelet sub-bands

must be quantized to some degree. Given a fixed budget

of bits to encode a field, the Bin Width Calculator must

allocate the bits to produce a pleasing picture upon reconstruction. This Bin Width Calculator favors the low

frequency sub-bands. It always increases the quantization (discards more low order bits) as the frequency increases. The eye is most critical of the low frequency

information and does not really miss the higher frequencies. Stored in the Bin Width Calculator is a set of bin

widths that preserves a maximum number of bits and

creates a high quality minimum compression image.

Also stored is a second set of bin widths that discards

most of the bits to achieve maximum compression. The

program varies the actual bit rate by interpolating an intermediate curve that lies somewhere between the two

extremes. The max and min curves used by the program

could be modified to make various trade-offs of picture

quality versus bit rate. For instance, the highest frequency Luma sub-bands contain information in the

3.37 to 6.75 Megahertz band. If the video source is

known to roll off at say 3.58 Megahertz, then signal energy in the highest frequency bin is likely to be noise. In

such a case, better performance might be obtained by

multiplying the highest frequency sub-bands by zero to

discard ALL the bits in the bin. In this way, the limited bit

budget is directed toward encoding real picture rather

than video noise (snow or on color TV, confetti) Some

experimentation with the quantizing curves may yield

worthwhile performance improvements.

DSP-Based vs. Host-Based Bin Width Calculators

The bin width calculation problem remains the same

whether the calculator is interfaced to the ADV601

through the DSP serial port or through the Host parallel

port. From the host port, a processor can access all the

registers in the ADV601. From the DSP port a processor

can only read the statistics registers and write the bin

width registers. This is a subset of all the registers in the

ADV601. This program was tested on a system with a

Pentium

®

-based PC interfaced to the host port and a

ADSP-21xx DSP interfaced to the DSP port. The DSP performed only the bin width calculation and the host did

everything else. In a stand-alone design or embedded

system, the DSP could be interfaced through the host

port and thus have access to all the other registers in the

ADV601. In a stand-alone design, the DSP must be able

to read and write to the ADV601 mode control register,

among others.

Advantages of DSP Bin Width Computation

Speed

This DSP program takes a time critical computation out

of the host. The DSP can compute new bin widths within

the 1.2 milliseconds vertical retrace time, so the bin

width settings are right up to date. This can be difficult

to achieve in the host because Windows

®

is not a realtime operating system. It makes no guarantees of response time to anything. Tasks can hog the CPU and

prevent a host-based Bin Width Calculator from running

in a timely fashion. Windows 95 interrupt handlers are

not permitted to use the hardware floating point unit.

A Windows 95 interrupt handler that relies upon Windows calls to schedule a Bin Width Calculator run as

soon as possible may find that Windows occasionally

schedules something other than the Bin Width Calculator to run next. In this case, the Bin Width Calculator

cannot compute the new bin widths before the next

frame begins.

Easier Program Development

The important Bin Width Calculator is one small program running in a dedicated CPU. If bit rate problems

are encountered, you know just where to look and the

code is small and self contained. Windows 95 device

driver and systems programming expertise is not required. Timing issues are easier to deal with because the

DSP does nothing but bin width calculation. Under Windows, if some other program has control of the machine, the Bin Width Calculator may be locked out and

unable to run in time.

Advantages of Host-Based Computations

Cost (No DSP to Buy)

Easier Program Development

Programmers may be more familiar with the host architecture and programming tools. Operating system expertise may be abundant and DSP experience may be

slim.

All trademarks are the property of their respective holders.

–3–

AN-524

ADV 601 TO DSP HARDWARE AND SOFTWARE INTERFACE

ONE FIELD TIME (16.66 MILLISECONDS)

DIRQ INTERRUPT

101

102

103

104

105

106

107

108

109

110

113

114

115

116

117

118

125

124

100

119

120

121

122

126

127

128

67

65

64

63

62

61

60

59

57

58

34

42

41

31

36

33

37

99

19

20

35

32

45

44

43

1

EBG/

EBR/

EINT/

ELIN

ELOUT

ECLK

EE

EMS/

ERESET/

RESET/

IRQ2/

IRQL1/

IRQL0/

IRQE/

PWDACK

PWD/

IAD15

IAD14

IAD13

IAD12

IAD11

IAD10

IAD9

IAD8

IAD7

IAD6

IAD5

IAD4

IAD3

IAD2

IAD1

IAD0

IACK/

IAL

IS/

IWR/

IRD/

XTAL

CLKIN

BMODE

MMAP

PF7

PF6

PF5

PF4

PF3

PF2

PF1

PF0

FL2

FL1

FL0

9

24

396987

VDDVDDVDDVDDVDDV

GND

GND

GND

GND

GND

8

21234054758688

GND

GND

111

DD

GND

DT0

TFS0

RFS0

DR0

SCLK0

DT1/F0

TFS1/IRQ1

RFS1/IRQ0

DR1/F1

SCLK1

CLKOUT

WR/

RD/

CMS/

IOMS/

BMS/

DMS/

PMS/

BR/

BGH/

BG/

A13

A12

A11

A10

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13

D12

D11

D10

GND

GND

GND

98

112

123

ADSP-2181

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

EZKIT U3

46

47

48

49

50

51

52

53

55

56

56

22

2

3

7

4

5

6

10

66

38

68

30

29

28

27

26

25

18

17

16

15

14

13

12

11

97

96

95

94

93

92

91

90

89

85

84

83

82

81

80

79

78

77

76

74

73

72

71

70

(CAN OCCUR ANYWHERE; DEPENDS ON HOW RAPIDLY HOST READS FIFO)

LAST CODE INTERRUPT

STATISTICS REGISTER DATA INTO DSP

BIN WIDTH REGISTER DATA OUT OF DSP

Figure 6. Field Timing Diagram

100

101

98

119

118

117

116

115

114

111

110

109

108

93

92

91

90

87

86

85

84

83

82

105

104

103

97

95

32

32

36

36

34

34

33

33

37

37

31

31

V

U?

14

QA

13

QB

12

QC

11

QD

15

RCO

ENP

ENT

CLK

LOAD

CLR

3

3

A

4

4

B

5

5

C

6

6

D

7

10

2

9

1

CC

74HC161

JP9-49

JP9-3

11

12

17

16

15

14

25

9

8

26

28

27

29

21

24

10

19

6

20

2230394651

DDVDDVDDVDDVDDVDD

V

XTAL

VCLK

VCLKO

VDATA0

VDATA1

VDATA2

VDATA3

VDATA4

VDATA5

VDATA6

VDATA7

VDATA8

VDATA9

VDATA10

VDATA11

VDATA12

VDATA13

VDATA14

VDATA15

VDATA16

VDATA17

VDATA18

VDATA19

VSYNC

HSYNC

FIELD

ENC/DEC

CREF

TXD

RXD

TCLK

TF

RF

DIRQ/

ADR1

ADR0

BE0/

BE1/

BE2/

BE3/

LCODE

WR/

RD/

FIFO_ERR

FIFO_SRQ

FIFO_STP

STATS_RDY

ACK/

HIRQ/

CS/

REST/

GND

GND

GND

GND

GND

GND

7

131823353847525658636874819689

57

596975

889499

107

125

113

VDDVDDVDDVDDVDDVDDVDDVDDVDDVDDVDDVDDVDDVDDV

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

102

106

112

120

126

GND

131

137

GND

136

GND

142

VIDEOLAB U9

146

156

144

DD

DADR8

DADR7

DADR6

DADR5

DADR4

DADR3

DADR2

DADR1

DADR0

DDAT0

DDAT1

DDAT2

DDAT3

DDAT4

DDAT5

DDAT6

DDAT7

DDAT8

DDAT9

DDAT10

DDAT11

DDAT12

DDAT13

DDAT14

DDAT15

RAS/

CAS/

WE/

DATA0

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

DATA8

DATA9

DATA10

DATA11

DATA12

DATA13

DATA14

DATA15

DATA16

DATA17

DATA18

DATA19

DATA20

DATA21

DATA22

DATA23

DATA24

DATA25

DATA26

DATA27

DATA28

DATA29

DATA30

DATA31

GND

GND

GND

GND

143

145

150

155

ADV601_PQFP

40

41

42

43

44

45

48

49

50

80

79

78

77

76

73

72

71

70

67

66

65

64

62

61

60

53

54

55

5

4

3

2

1

160

159

158

157

154

153

152

151

149

148

147

141

140

139

138

135

134

133

132

130

129

128

127

124

123

122

121

Figure 7. Electrical Schematic–ADSP-2181 to ADV601 Connections

–4–

AN-524

DSP Serial Port

DSP Interrupt Service Request (DIRQ) Interrupt

The ADV601 asserts the DIRQ interrupt when the Wavelet transform has completed and the statistics of this

field are available. It starts transmitting the statistics

registers after the DIRQ interrupt, which serves as a

"heads-up" to the DSP. The DSP configures the serial

port to receive when it sees the DIRQ interrupt. In principle, the DIRQ interrupt signal is not absolutely necessary. The DSP could keep the serial port configured to

receive, and use the “data ready” interrupt from the serial port itself to indicate start of statistics register transmission. This example program uses the DIRQ interrupt

line to ensure DSP program activity in case a fault in the

DSP serial port programming kills the serial port’s “data

ready” interrupt.

Statistics Read

Following the DSP interrupt, the ADV601 will transmit

the Compression ratio register, the 42 sum of squares

registers, a Luma and two Chroma “sums” registers,

and finally the six Max and Min registers. The Compression ratio register lets the Host computer communicate

with the DSP. The communication is one-way (Host to

DSP) and contains whatever bits the host program cared

to write into compression ratio register via the host parallel port. This DSP program expects to find the desired

bits per pixel coded into the lower 8 bits of the compression ratio register. Possible values range from 16 bits

per pixel (coded as 0FF Hex) down to 1/16th bit per pixel

(coded as 1). This is purely a software convention, the

ADV601 just passes the bits from the host to the DSP. It

is mentioned here merely as an aid to understanding

operation of this particular program. Other coding

schemes could be readily devised.

Bin Width Register Write

The ADV601 has a simple state machine to operate the

DSP serial port. It transmits the statistics registers and

then receives the new bin width registers. The DSP must

wait until the last statistics register is read before it can

write the bin width and reciprocal bin width registers.

The ADV601 will become confused if this rule is not

obeyed. Bin width registers and reciprocal bin width

registers are interleaved with Register 0 being a reciprocal bin width register and Register 1 being its corresponding bin width register. Register order is given in

ADV601 data sheet Figure 9.

Field Size Measurement

This example program uses one DSP serial port to count

the number of ADV601 FIFO reads to give the DSP program the size of each compressed field. The FIFO/rd

strobe from the Videolab evaluation board is connected

to the clock line of the serial port. The serial port interrupts the DSP each time it thinks it has a word ready in

the serial port received data register, which happens

EZ-KIT is a registered trademark of Analog Devices, Inc.

every 16 FIFO reads. The DSP counts these interrupts to

determine field size. The DSP does not care about the

serial data, it does not even look at it, it just wants to

know how many FIFO read strobes occurred. There is a

limit on DSP serial port clocks of 13.824 MHz (see ADSP2100 Family User Manual Section 5.5). The PCI bus mastering interface on the Videolab card reads the FIFO

much faster than that. The 74HC161 counter was added

to reduce the frequency seen by the serial port clock input to less than the 13.824 MHz limit. In a real design a

PAL or an FPGA could easily be used.

Last Code Interrupt (LCODE)

The DSP uses the last code interrupt to start and stop the

FIFO read strobe count. Each time Last Code occurs, the

DSP resets its software FIFO read strobe counter, and

passes the finished count to the servo loop for processing. Last code is asserted when the host reads the nextto-last word from the FIFO and stays asserted until the

last word is read. This time can be quite short (10s of

nanoseconds) and the repetition rate is low (60 Hz) making the LCODE signal difficult to observe on an oscilloscope. Since LCODE occurs when the host gets around

to reading the FIFO, it can occur anywhere during the

field time and, as the host begins to fall behind writing

the disc, it will move farther and farther down the field

until eventually the host begins to drop data. The timing

diagram shows LCODE coming early, but it can be anywhere and move around from field to field.

PROGRAM THEORY OF OPERATION

PIDBWC.DSP

This is the main routine. It contains the interrupt vector

table, including the power-on reset vector. The initialization code configures SPORT1 as a serial port that disables the alternate functions (IRQ0 IRQ1 FlagIN and

FlagOut) of the SPORT1 pins. SPORT1 will be used to

count FIFO read strobes. The internal timer is set up to

give interrupts at the video frame rate (30 Hz). Programmable I/O pins PF1 through PF7 are programmed as output pins. Important routines toggle these pins so

program activity can be observed on an oscilloscope.

PF0 is set to input, and monitored to exit the program

and return control to the EZ-KIT

monitor permits display of program variables at the end

of a run, if you return to it. If you do not return, but reset

the EZ-KIT instead, the monitor power-on self-test overwrites all data memory with a test pattern.

The main loop does very little. It merely calls the

rite_reg routine to transmit the new bin width and reciprocal bin widths to the ADV601 after the statistics

read is done. Variable recvflg from the statistics read

routine in forms the main loop when statistics read is

done. The main loop does NOT call the bwcalc routine

to update the servo loop and compute a new bin width

curve. Bwcalc is called on the last code interrupt to

®

monitor. The EZ-KIT

–5–

AN-524

insure that the servo loop is updated just once each

time a new compressed field size becomes available.

This leads to an interesting initialization problem. The

first DSP interrupt will occur BEFORE last code

(LCODE) occurs, since the Wavelet transform must

complete before the host can even start (let alone finish) reading the compressed field from the ADV601

FIFO. This program initializes the bin width/recip bin

width registers to a reasonable value. This initialization

is accomplished by the single call to bwcalc in the initialization code. All subsequent calls to bwcalc are

from the LCODE interrupt routine inside module

fldsiz.dsp.

The watch_dog routine gains control on timer tick with

initialization set for 30 Hz. Watch_dog is looking for

start and stop of incoming video. When the video

stops, watch_dog zeros out the servo loop error inte-

grator. This prevents a sizable error integral from one

video clip biasing the servo loop hard over at the beginning of the next clip. This is largely for convenience in

studying servo loop startup transients. You can stop

the video tape player, rewind and start over again and

have the servo start up the same way each time. Otherwise the startup on the second video clip depends upon

the previous video clip. Watch_dog detects video stop

by watching the field_cnt variable. When video

stops, the host stops reading the FIFO and the LCODE

interrupt stops occurring. This causes field_cnt to

stop changing. If field_cnt does not change after two

field times, watch_dog concludes that video has

stopped coming in.

fldsiz.dsp

The fldsiz module updates variable sportints,

which is proportional to compressed field size, on each

Last Code (LCODE) interrupt. Despite some obsolete

comments in early versions of the code, sportints is

unscaled. It is just the raw interrupt count and must be

scaled into bytes by the user routine. The other variables in fldsiz are either local scratch variables or a

debug “history buffer” like fieldsz, and are not used

outside the fldsiz module. If compressed field size is

measured by other means, software changes will be

confined to this module.

Serial Port 1 (SPORT1) is used by the EZ-KIT monitor to

load code and dump memory to the host, whereas the

Bin Width Calculator uses SPORT1 to count FIFO read

strobes. The fldsiz_start entry saves the settings of

all the SPORT1 control registers and the fldsiz_stop

routine restores them so the monitor will function after

a bin width calculation run and dump ram variables for

debug and test. For debugging in the software simulator, setting the ISCLK bit in the SPORT1 control register

causes simulated SPORT1 interrupts to occur. To function in real hardware the ISCLK bit (Internal Serial Port

Clock) must be clear, to allow the external FIFO read

strobes to clock the serial port. The fldsiz routine programs SPORT1 for 16-bit words, which means SPORT1

will generate the RX data ready interrupt after 16 SCLKS

(16 FIFO read strobes).

Routine cntpara services the SPORT1 RX data ready interrupt. It merely bumps variable intaccum on each entrance. The other code toggles a debug bit that can be

observed with an oscilloscope to show that the interrupt

is unmasked and active, and that FIFO reads are actually

being seen by the program.

Routine newfield services the LCODE interrupt. On

each interrupt it copies intaccum into sportints and

resets intaccum. Then it calls bwcalc to update the

servo loop. Newfield currently uses Data Address Generator (DAG) registers I2 and M2 to write the debug

buffer fieldsz. It does not save the register contents in

memory when it returns from interrupt. Should some

other code alter I2 it could cause trouble. A released version of sport0.dsp might want to disable the fieldsz

writes for safety’s sake.

Sportints needs proper scaling to yield field size in

pixels. Scaling must account for the 16:1 division done

in the serial port, the two pixels per 32-bit long word,

and the 4:1 hardware divider placed between the FIFO

read strobe and the serial port SCLK pin.

sport0.dsp

Sport0 handles reception of ADV601 statistics and transmission of bin width and reciprocal bin width register

data. As the name implies, it uses Serial Port 0 (SPORT0)

for the task. Sport0 writes recvflg and xmitflg to let

the rest of the system know when statistics read (receive) and bin width write (transmit) is active. The flags

are nonzero while transmit or receive is going on, and

zero when inactive. Pidbwc.dsp (main) uses recvflg to

start up transmission after the last statistics register is

read. Statistics are placed into array stats601 and bin

widths are transmitted out of array bw_recip_bw.

Routine sport0_start is the one-time initialization

routine. It loads the SPORT0 control registers, initializes

variables and handles the first field problem. The system does not know which compression ratio is required

until it can see the compression ratio register. The compression ratio register will not be available until the first

statistics read occurs. Therefore, sport_start initializes the compression ratio register to a reasonable number to avoid trouble that might occur should the system

try to process a random value of compression ratio.

Routine rite-reg is called by pidbwc.dsp (main) to

start up bin width register transmission. The advanced

“autobuffering” feature of ADSP-21xx family serial

ports is used to more input directly to data ram without

processor intervention. Rite_reg loads the Data

Address Generator (DAG) registers needed for autobuffering, turns on autobuffering, loads only the first

–6–

AN-524

word of the bw_recip_bw array into the transmit data

register and returns. The serial port hardware will push

the entire array out of the serial port with no more processor intervention and issue the TX data done interrupt

when done. The interrupt will transfer control to the

rite_reg_done routine. This code just turns off

autobuffering and clears the transmit flag.

Routine read_reg is the inverse of rite_reg. It uses

the same DAG registers to autobuffer receive the statistics.

It is hooked to the DSP interrupt and thus automatically

starts on every field. After starting up the autobuffered

receive, read_reg returns control. When the stats601

buffer is full (last statistic is read) SPORT0 will create the

RX data ready interrupt which is hooked to routine

read_reg_done. This code, like rite_reg_done, shuts

down autobuffering and clears recvflg to let main

know it can start up. To improve servo loop response,

read-reg-done will zero the servo loop error integrator

should the compression ratio change. Otherwise, a large

error built up over many fields might take an unreasonable length of time to respond to the new target compression ratio.

servo.dsp

This module does a textbook Proportional-Integral-Derivative (PID) servo loop. The Compression ratio register

gives the routine the target bits per pixel. This register is

written by the host through the ADV601 parallel host

port, and passed to the DSP via the serial link. Module

Sport0 receives the compression ratio register contents

and makes it available to servo.dsp in the first word of

array stats601. Variable sportints from fldsiz.dsp

tells servo.dsp how big the last compressed field really

was. Servo.dsp converts both the bits-per pixel compression ratio register and interrupt count into pixels

per field, scaled down by 8 (3-bit right shift) to avoid

overflow in 16-bit arithmetic. Symbol TGT SCALE defines size of this scaling shift.

After normalizing bit rate target and interrupt count into

a common scale, the bit rate error (variable err) is computed by subtracting actual field size from target field

size. If err is positive, the compressed field was too

small, if err is negative, the compressed field was too

big. After calculation of err, the module computes the

derivative of err by subtracting the previous value of

err from the new value of err and storing the result in

variable err_dir. It also computes the integral of err

by adding err to variable err_int. Hardware saturation in the ALU is required to prevent arithmetic overflow from wrapping around. If err, or especially

err_int, gets large, it is OK to peg out at full scale plus

or minus, but wrapping around from plus to minus is a

disaster that will cause sustained full-scale oscillation of

the bit rate.

The err, err_dir and err_int computation is a critical

section done with interrupts locked out. The error integral variable is a persistent long term history type state

variable. When the video changes, this history becomes

invalid, requiring an integrator reset to zero. This reset is

done from interrupt. Locking out interrupts prevents interrupt service routines from zeroing the variable in the

middle of the read-modify-write sequence which would

nullify the reset. A second reason for locking out interrupts is to prevent interrupt routines from unexpectedly

running with the ALU hardware saturation feature ON. I

believe that interrupt service routines will in fact function properly with ALU saturation ON or OFF, but it is

better to be safe than sorry.

Next output variable scrunch is computed from the following formula.

scrunch = loop_gain × err + int_gain × err_int + dir_gain

err_dir

Scrunch goes to the bin width curve generator. Full

scale positive will select a maximum bit rate, minimum

compression set of bin widths. Full-scale negative selects the opposite (min bit rate). Intermediate values of

scrunch cause the curve generator to interpolate intermediate compromise curves somewhere in-between the

max and min compression curves.

The three gain terms are scaled 16.8 (8 bits of integer,

8 bits of fraction). Unity is 256 (100 Hex). This permits

each of the three terms to either amplify or attenuate

their contribution to the final answer. The MAC is used

to do the multiply and accumulate the sum 32 bits wide.

After doing the three multiply accumulates, the 32-bit

MR register hardware saturation instruction (if MV sat

MR) is executed, but probably not needed. The program

now rescales the 32-bit answer into a 16-bit variable. It

does this by picking the middle 16 bits out of the 32-bit

MR register. The program does an 8-bit left shift and

takes the high order word. Overflow is checked by shifting the top nine bits of MR into the extension register

MR2. If they are not all the same (zero or one) then

scrunch has overflowed and must be saturated.

To aid debugging, servo saves (but never uses) a second

copy of the error integral called back_int. This can be

dumped after a video compression run to see the last

value of err_int. Fldsiz.dsp is constantly looking for

end of video to zero out err_int, meaning that

err_int will always read zero after a compression run.

The module also writes the values of err_int to circular buffer debug, to permit post compression of analysis

of servo loop transient response. Both features may be

deactivated to save space. The conditional SWEEP feature disables the entire feedback loop and sweeps

scrunch from minus full scale to plus full scale to check

the open loop response of the system.

(1)

×

–7–

AN-524

curve.dsp

Module curve.dsp has a pair of 42 element bin width

register curves (arrays max and min) stored as constants in program memory. For each of the 42 bin width

registers curve.dsp computes the value from Equation 2

in the DO interp loop.

bin width[i] = scrunch × min[i] + (1 - scrunch) × max(i)

(2)

This creates an output bin width curve that is a linear

interpolation between the two extremes. Then the reciprocal bin width values are computed with Equation 3 in

the DO recip loop.

Recip_bw[i] = 1 / bin width[i]

(3)

The results are placed in array bw_recip_bw for

sport0.dsp to transmit to the ADV601.

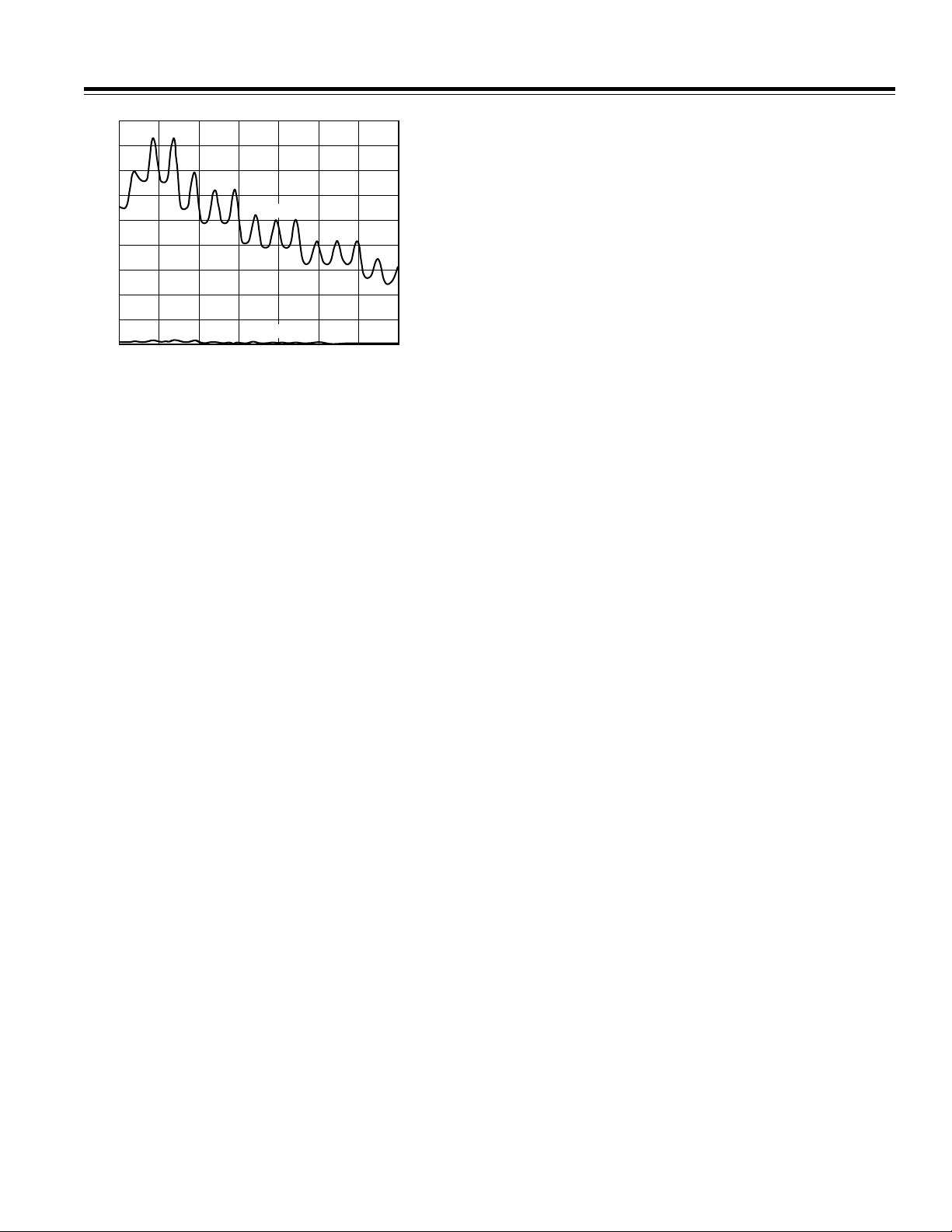

Testing and Tuning Plotting Performance

2

1.8

1.6

1.4

1.2

1

0.8

BITS PER PIXEL

0.6

0.4

0.2

0

1 3991571 1141 1711 2281 2851 3421

FIELD NUMBER

Figure 8. Beauty Video at 1 Bit per Pixel

The Raw2avi program can be used to measure the performance of the Bin Width Calculator. While doing its

primary job of converting raw ADV601 video into videofor-windows.avi files, the program finds the size of every field in the compressed video (.601) file. Raw2avi

records the field number, the field size, the compression

ratio and the number of bits per pixel of each field in a

side disk file named vid_siz.dat. The file is in ASCII,

and the following plot was generated from the side file

using a spread sheet. The target bit rate was 1 bit per

pixel. The input video was the Analog Devices

Beauty.601 file (distributed on the Videolab kit CDROM). Variable loop_gain was 8 (800 Hex after scaling). Int_gain and dir_gain were zero. Each scene

change causes an abrupt bit rate change. The narrow

spikes are only one field wide, corresponding to the one

field delay around the feedback loop.

Tune Proportional Gain First with No Integral and

Derivative Gain

PID servo loops are tuned by adjusting the loop gain for

best performance. Tune the gains one by one, proportional first. Set the integral gain and derivative gain to

zero. Increase the proportional gain until the system oscillates and then back off a reasonable amount. Then re

check for loop stability at high and low bit rates, and on

a variety of video material. Measure the peak and average bit rate errors over a representative video sample.

Then, attempt to improve the performance with integral

gain. Integral feedback will improve long-term accuracy

at the expense of transient response. Finally try derivative feedback to improve transient response. The

changes in loop performance are hard to observe by

eye, you really need a numerical figure of merit to guide

your tuning efforts.

FURTHER IMPROVEMENTS

After servo loop tuning, a smarter program might take

advantage of the statistical data to eliminate those one

field wide spikes that occur on scene change. One

scheme might maintain a running average of all the 42

sum of squares figures. Upon each statistics update

compare the new statistics with the running average of

prior statistics. A radical difference indicates a scene

change. Upon scene change the servo module might

just ask for heavy compression for the next field to avoid

data over run. Or the “statistics difference” signal just

developed might be fed into the servo module in place

of the computed err_dir signal. The statistics see a

scene change one field earlier, and thus allow the servo

module to anticipate a change in bit rate before it happens. The present computed err_dir signal is always

one field behind the video.

The program might compute the 42 differences between

this sum-of-squares and the last sum-of-squares. It

should then square or absolute value the 42 differences

(to prevent plus and minus differences from canceling

each other) and sum them to obtain a single measure of

image “change.” If this number is then divided by the

sum of all 42 bin width registers is will be normalized in

a useful fashion.

The present program changes the bin widths on every

field. The video might look better if field one and field

two were always quantized with the same bin width

numbers.

E3170–.5–2/98

PRINTED IN U.S.A.

–8–

Loading...

Loading...