ANALOG DEVICES ADXRS453 Service Manual

High Performance,

V

Data Sheet

FEATURES

Complete rate gyroscope on a single chip

±300°/sec angular rate sensing

Ultrahigh vibration rejection: 0.01°/sec/g

Excellent 16°/hour null bias stability

Internal temperature compensation

2000 g powered shock survivability

SPI digital output with 16-bit data-word

Low noise and low power

3.3 V to 5 V operation

−40°C to +105°C operation

Ultrasmall, light, and RoHS compliant

Two package options

Low cost SOIC_CAV package for yaw rate (z-axis) response

Innovative ceramic vertical mount package (LCC_V) for

pitch and roll response

APPLICATIONS

Rotation sensing in high vibration environments

Rotation sensing for industrial and instrumentation

applications

High performance platform stabilization

Digital Output Gyroscope

ADXRS453

GENERAL DESCRIPTION

The ADXRS453 is an angular rate sensor (gyroscope) intended

for industrial, instrumentation, and stabilization applications in

high vibration environments. An advanced, differential, quad

sensor design rejects the influence of linear acceleration, enabling

the ADXRS453 to offer high accuracy rate sensing in harsh

environments where shock and vibration are present.

The ADXRS453 uses an internal, continuous self-test architecture. The integrity of the electromechanical system is checked by

applying a high frequency electrostatic force to the sense structure

to generate a rate signal that can be differentiated from the baseband rate data and internally analyzed.

The ADXRS453 is capable of sensing an angular rate of up to

±300°/sec. Angular rate data is presented as a 16-bit word that

is part of a 32-bit SPI message.

The ADXRS453 is available in a 16-lead plastic cavity SOIC

(SOIC_CAV) and an SMT-compatible vertical mount package

(LCC_V), and is capable of operating across a wide voltage

range (3.3 V to 5 V).

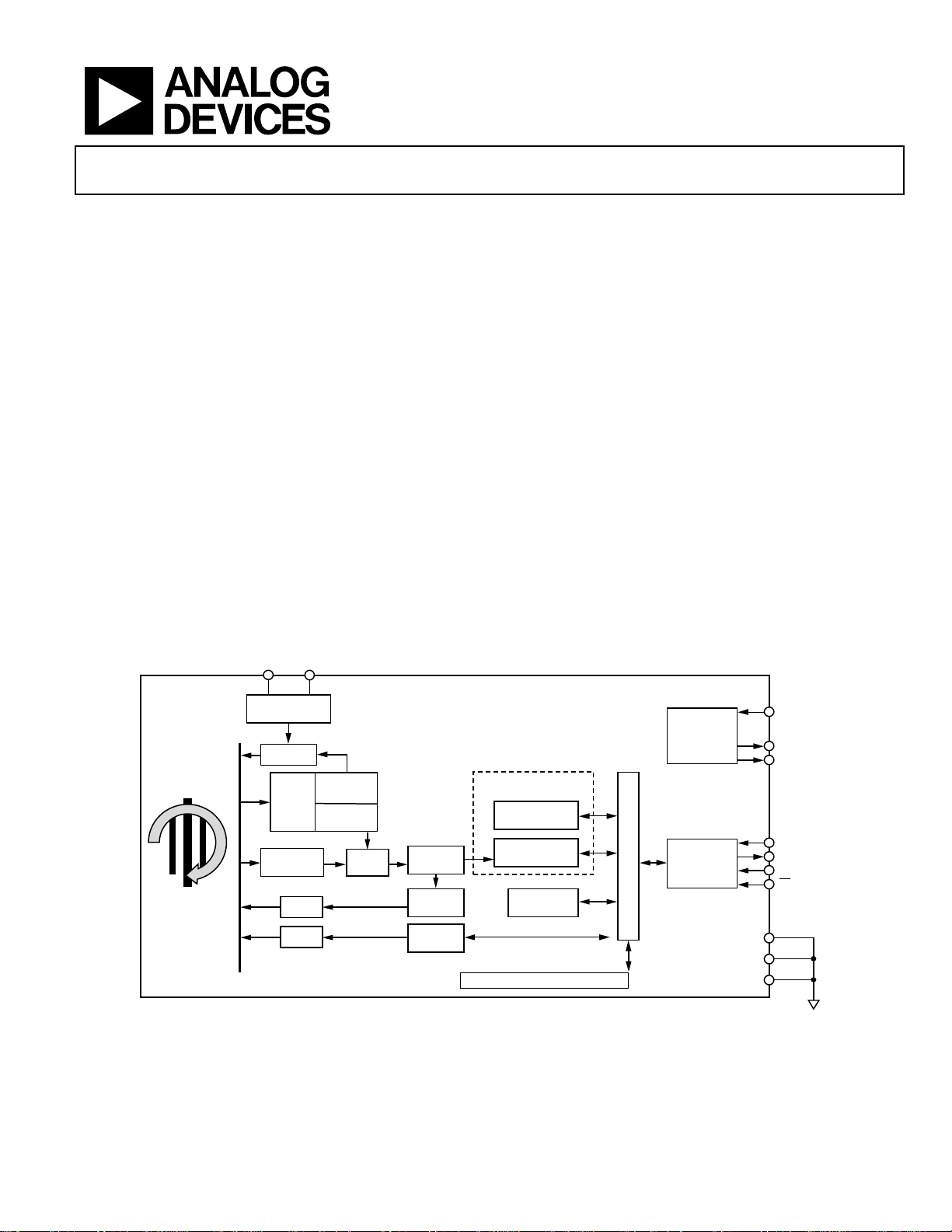

FUNCTIONAL BLOCK DIAGRAM

CP5

HIGH VO LTAG E

GENERATION

Z-AXIS ANGULAR

RATE SENSOR

HV DRIVE

PHASE-

LOCKED

LOOP

BAND-PASS

FILTER

Q DAQ

P DAQ

X

CLOCK

DIVIDER

AMPLITUDE

DETECT

12-BIT

ADC

DEMOD

Q FILTER

SELF-TEST

CONTROL

ADXRS453

ARITHMETIC

LOGIC UNIT

DECIMATION

TEMPERATURE

CALIBRATIO N

Figure 1.

FILTER

FAULT

DETECT ION

EEPROM

REGISTERS/MEMORY

LDO

REGULATOR

SPI

INTERFACE

P

DD

DV

DD

AV

DD

MOSI

MISO

SCLK

CS

DV

SS

P

SS

AV

SS

09155-001

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2011 Analog Devices, Inc. All rights reserved.

ADXRS453 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 4

Thermal Resistance ...................................................................... 4

Rate Sensitive Axis ....................................................................... 4

ESD Caution .................................................................................. 4

Pin Configurations and Function Descriptions ........................... 5

Typical Performance Characteristics ............................................. 7

Theory of Operation ........................................................................ 9

Continuous Self-Test .................................................................... 9

Mechanical Performance ............................................................... 10

Noise Performance ......................................................................... 11

Applications Information .............................................................. 12

Calibrated Performance ............................................................. 12

Mechanical Considerations for Mounting .............................. 12

Application Circuits ................................................................... 12

ADXRS453 Signal Chain Timing ............................................. 13

SPI Communication Protocol ....................................................... 14

Command/Response ................................................................. 14

Device Data Latching ................................................................. 15

SPI Timing Characteristics ....................................................... 16

Command/Response Bit Definitions ....................................... 17

Fault Register Bit Definitions ................................................... 18

Recommended Start-Up Sequence with CHK Bit

Assertion ...................................................................................... 20

Rate Data Format ............................................................................ 21

Memory Map and Registers .......................................................... 22

Memory Map .............................................................................. 22

Memory Register Definitions ................................................... 23

Package Orientation and Layout Information ............................ 25

Solder Profile............................................................................... 26

Package Marking Codes ............................................................ 27

Outline Dimensions ....................................................................... 28

Ordering Guide .......................................................................... 29

REVISION HISTORY

12/11—Rev. A to Rev. B

Changes to Features Section............................................................ 1

Changes to Rate Sensitive Axis Section ......................................... 4

Deleted Endnote 1, Table 3 .............................................................. 4

Deleted Figure 5; Renumbered Sequentially ................................. 6

Changes to Figure 4 .......................................................................... 6

Changes to Figure 32 ...................................................................... 25

Deleted Figure 36 ............................................................................ 26

6/11—Rev. 0 to Rev. A

Changes to Bit 30 and Bit 31 in Table 9 ....................................... 14

Updated Outline Dimensions ....................................................... 29

Changes to Ordering Guide .......................................................... 30

1/11—Revision 0: Initial Version

Rev. B | Page 2 of 32

Data Sheet ADXRS453

SPECIFICATIONS

TA = T

Table 1.

Parameter Test Conditions/Comments Symbol Min Typ Max Unit

MEASUREMENT RANGE Full-scale range FSR ±300 ±400 °/sec

SENSITIVITY

NULL ACCURACY TA = 25°C ±0.4 °/sec

NOISE PERFORMANCE

T

LOW-PASS FILTER

SENSOR RESONANT FREQUENCY f0 13 15.5 19 kHz

SHOCK AND VIBRATION IMMUNITY

SELF-TEST

SPI COMMUNICATIONS

MEMORY REGISTERS

POWER SUPPLY

1

Maximum limit is guaranteed by Analog Devices, Inc., characterization.

2

Cross-axis sensitivity specification does not include effects due to device mounting on a printed circuit board (PCB).

3

Minimum and maximum limits are guaranteed by design.

MIN

to T

, PDD = 5 V, angular rate = 0°/sec, bandwidth = f0/200 (~77.5 Hz), ±1 g, continuous self-test on.

MAX

See

Figure 2

Nominal Sensitivity 80 LSB/°/sec

Sensitivity Tolerance TA = −40°C to +105°C −3 +3 %

Nonlinearity1 Best fit straight line 0.05 % FSR rms

Cross-Axis Sensitivity2 −3 +3 %

T

= −40°C to +105°C ±0.5 °/sec

A

Rate Noise Density TA = 25°C 0.015 °/sec/√Hz

= 105°C 0.023 °/sec/√Hz

A

Cutoff (−3 dB) Frequency f0/200 fLP 77.5 Hz

Group Delay3 f = 0 Hz tLP 3.25 4 4.75 ms

Sensitivity to Linear Acceleration DC to 5 kHz 0.01 °/sec/g

Vibration Rectification 0.0002 °/sec/g2

See the

Continuous Self-Test section

Magnitude 2559 LSB

Fault Register Threshold Compared to LOCSTx register data 2239 2879 LSB

Sensor Data Status Threshold Compared to LOCSTx register data 1279 3839 LSB

Frequency f0/32 fST 485 Hz

ST Low-Pass Filter

Cutoff (−3 dB) Frequency f0/8000 1.95 Hz

Group Delay3 52 64 76 ms

Clock Frequency 8.08 MHz

Voltage Input High

Voltage Input Low

MOSI,

MOSI,

CS

CS

, SCLK

, SCLK

0.85 × P

−0.3 P

PDD + 0.3 V

DD

× 0.15 V

DD

Voltage Output Low MISO, current = 3 mA 0.5 V

Voltage Output High MISO, current = −2 mA PDD − 0.5 V

Pull-Up Current

CS

, PDD = 3.3 V, CS = PDD × 0.15

CS

, PDD = 5 V, CS = PDD × 0.15

See the

Memory Register Definitions

60 200 μA

80 300 μA

section

Temperature Register

Value at 45°C 0 LSB

Scale Factor 5 LSB/°C

Quadrature, Self-Test, and Rate Registers

Scale Factor 80 LSB/°/sec

Supply Voltage PDD 3.15 5.25 V

Quiescent Supply Current IDD 6.0 8.0 mA

Turn-On Time Power-on to 0.5°/sec of final value 100 ms

Rev. B | Page 3 of 32

ADXRS453 Data Sheet

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Acceleration (Any Axis, 0.5 ms)

Unpowered 2000 g

Powered 2000 g

Supply Voltage (PDD) −0.3 V to +6.0 V

Output Short-Circuit Duration

Indefinite

(Any Pin to Ground)

Operating Temperature Range

LCC_V Package −55°C to +125°C

SOIC_CAV Package −40°C to +125°C

Storage Temperature Range

LCC_V Package −65°C to +150°C

SOIC_CAV Package −40°C to +150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, for a device

soldered in a printed circuit board (PCB) for surface-mount

packages.

Table 3. Thermal Resistance

Package Type θJA θJC Unit

16-Lead SOIC_CAV (RG-16-1) 191.5 25 °C/W

14-Lead Ceramic LCC_V (EY-14-1) 185.5 23 °C/W

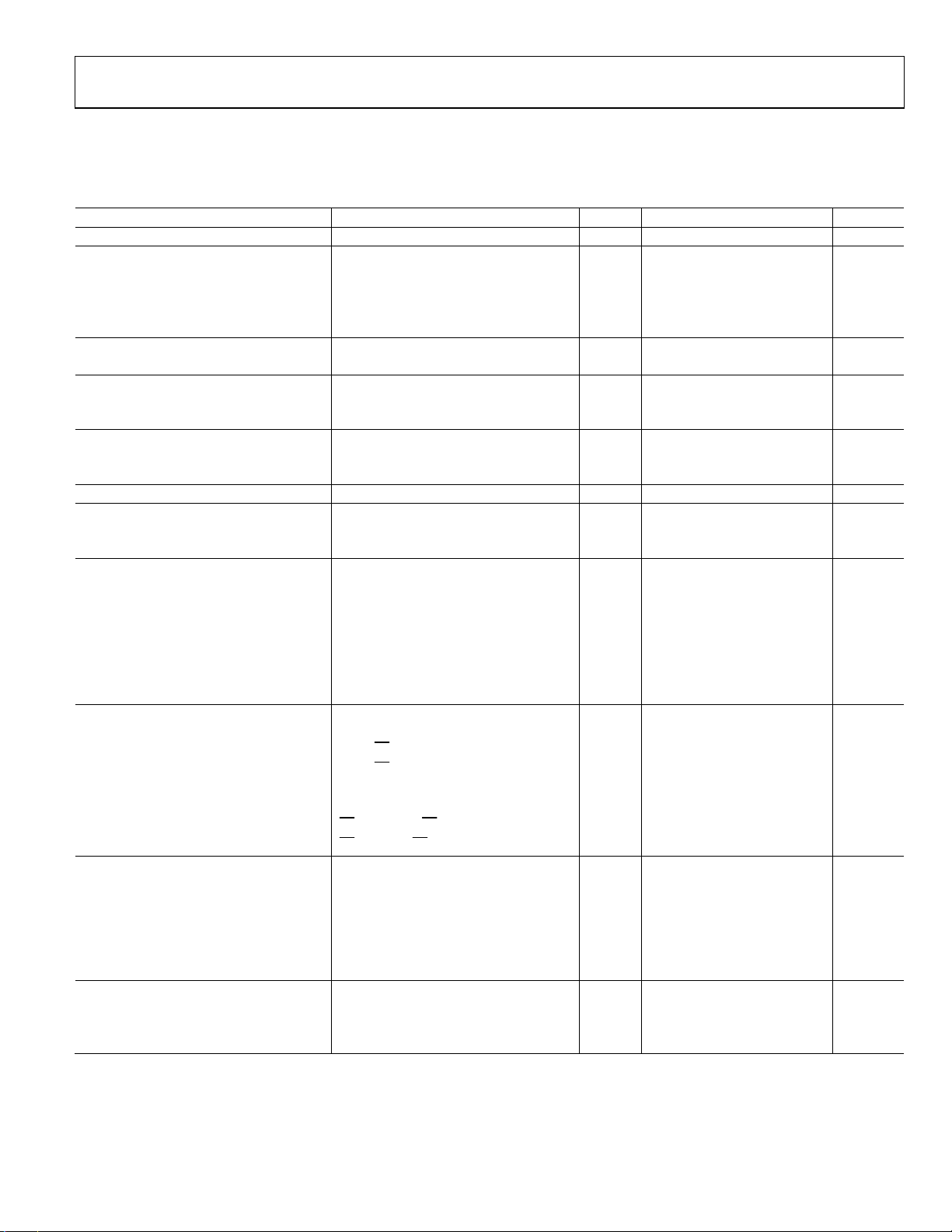

RATE SENSITIVE AXIS

The ADXRS453 is available in two package options.

The SOIC_CAV package is for applications that require

z-axis (yaw) rate sensing.

The LCC_V (vertical mount) package is for applications

that require x-axis or y-axis (pitch or roll) rate sensing.

The package has terminals on two faces. However, the terminals on the back are for internal evaluation only and should

not be used in the end application. The terminals on the

bottom of the package incorporate metallization bumps

that ensure a minimum solder thickness for improved solder

joint reliability. These bumps are not present on the back

terminals and, therefore, poor solder joint reliability can be

encountered if the back terminals are used in the end

application. For the outline dimensions of this package, see

Figure 38.

RATE

AXIS

+

16

RATE

SOIC PACKAGE

9

Figure 2. Rate Signal Increases with Clockwise Rotation

AXIS

Z-AXIS

+

LCC_V PACKAGE

09155-002

ESD CAUTION

Rev. B | Page 4 of 32

Data Sheet ADXRS453

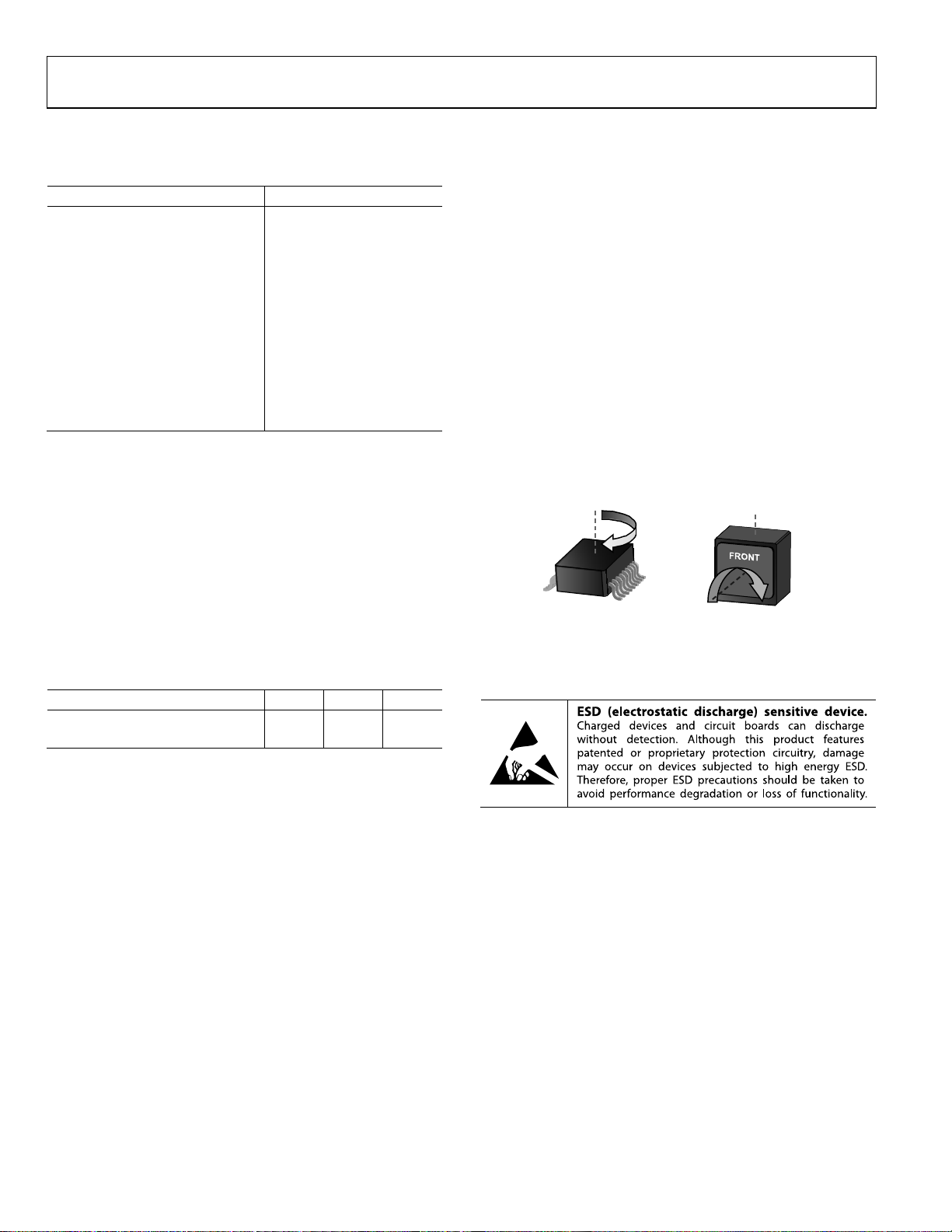

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

DV

RSVD

RSVD

CS

MISO

P

P

DD

DD

SS

V

X

1

2

3

ADXRS453

4

TOP VIEW

(Not to Scale)

5

6

7

8

16

SCLK

15

MOSI

14

AV

DD

13

DV

SS

12

RSVD

11

AV

SS

10

RSVD

9

CP5

09155-003

Figure 3. Pin Configuration, 16-Lead SOIC_CAV

Table 4. Pin Function Descriptions, 16-Lead SOIC_CAV

Pin No. Mnemonic Description

1 DVDD Digital Regulated Voltage. See Figure 25 for the application circuit diagram.

2 RSVD Reserved. This pin must be connected to DVSS.

3 RSVD Reserved. This pin must be connected to DVSS.

4

CS

Chip Select.

5 MISO Master In/Slave Out.

6 PDD Supply Voltage.

7 PSS Switching Regulator Ground.

8 VX High Voltage Switching Node. See Figure 25 for the application circuit diagram.

9 CP5 High Voltage Supply. See Figure 25 for the application circuit diagram.

10 RSVD Reserved. This pin must be connected to DVSS.

11 AVSS Analog Ground.

12 RSVD Reserved. This pin must be connected to DVSS.

13 DVSS Digital Signal Ground.

14 AVDD Analog Regulated Voltage. See Figure 25 for the application circuit diagram.

15 MOSI Master Out/Slave In.

16 SCLK SPI Clock.

Rev. B | Page 5 of 32

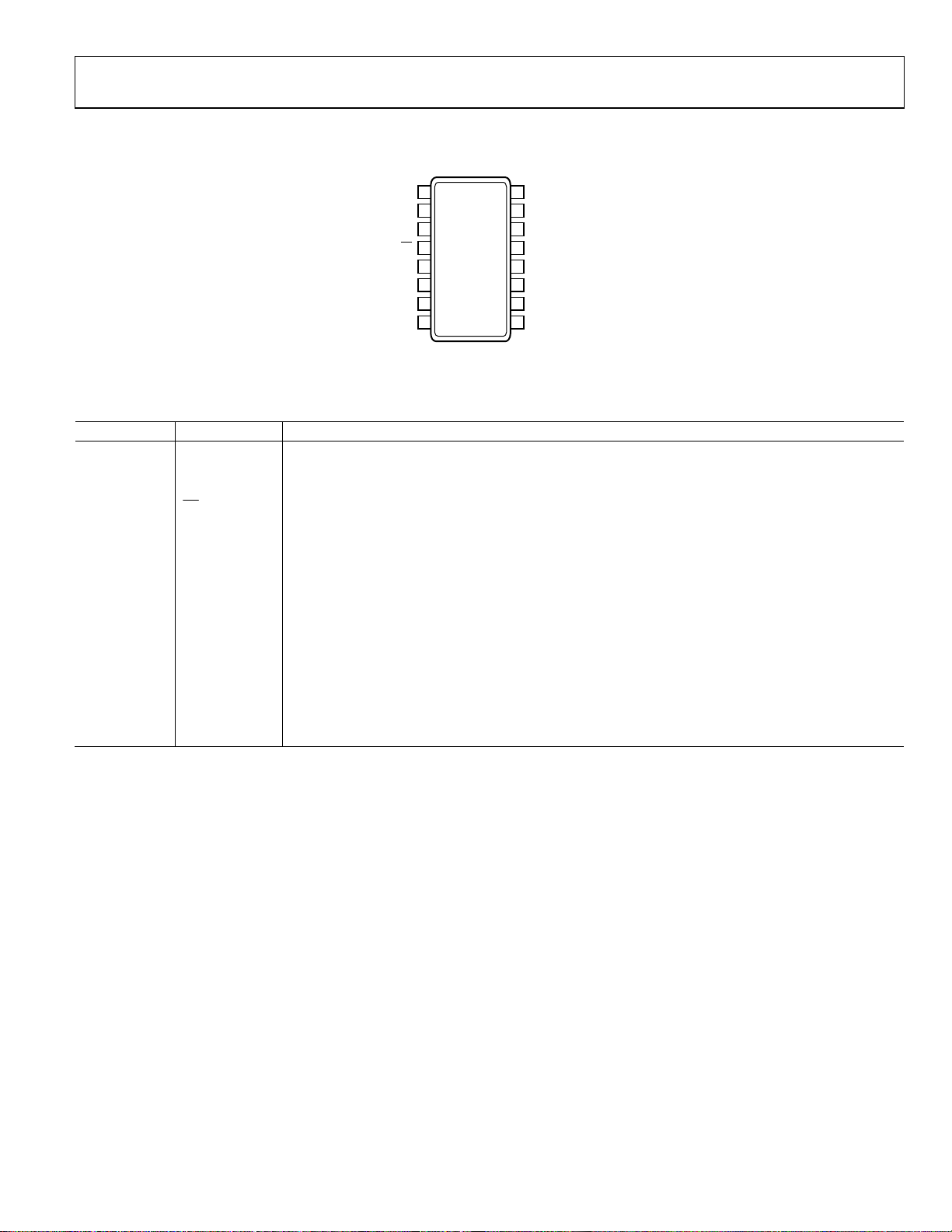

ADXRS453 Data Sheet

PDDPSSMOSI

14 13 12 11 10 9 8

1234567

SS

AV

NOTES

1. THE PACKAGE HAS T ERMINALS ON TWO FACES. HO WEVER, THE TERM INALS ON

THE BACK ARE FO R INTERNAL EVALUATI ON ONLY AND SHOULD NO T BE USED IN

THE END APPL ICATIO N. THE T ERMINALS ON THE BOT TOM O F THE PACKAG E

INCORPORAT E METAL LIZAT ION BUMPS THAT ENSURE A MINIMUM SOLDER

THICKNESS FOR IMPROVED SOLDER JOINT RELIABILITY. THESE BUMPS ARE

NOT PRESENT ON THE BACK TERMINAL S AND, THEREFORE, P OOR SOL DER

JOINT REL IABILI TY CAN BE ENCOUNT ERED IF TH E BACK TERMINALS ARE USED

IN THE END APPLICATI ON. FO R THE OUT LINE DI MENSIONS OF THI S PACKAGE,

SEE FIGURE 38.

DVSSCS

DD

DD

AV

MISO

DV

TOP VIEW

(Not to Scale)

SCLK

VXRSVD

CP5

RSVD

09155-004

Figure 4. Pin Configuration, 14-Terminal LCC_V

Table 5. Pin Function Descriptions, 14-Terminal LCC_V

Pin No. Mnemonic Description

1 AVSS Analog Ground.

2 AVDD Analog Regulated Voltage. See Figure 26 for the application circuit diagram.

3 MISO Master In/Slave Out.

4 DVDD Digital Regulated Voltage. See Figure 26 for the application circuit diagram.

5 SCLK SPI Clock.

6 CP5 High Voltage Supply. See Figure 26 for the application circuit diagram.

7 RSVD Reserved. This pin must be connected to DVSS.

8 RSVD Reserved. This pin must be connected to DVSS.

9 VX High Voltage Switching Node. See Figure 26 for the application circuit diagram.

10

CS

Chip Select.

11 DVSS Digital Signal Ground.

12 MOSI Master Out/Slave In.

13 PSS Switching Regulator Ground.

14 PDD Supply Voltage.

Rev. B | Page 6 of 32

Data Sheet ADXRS453

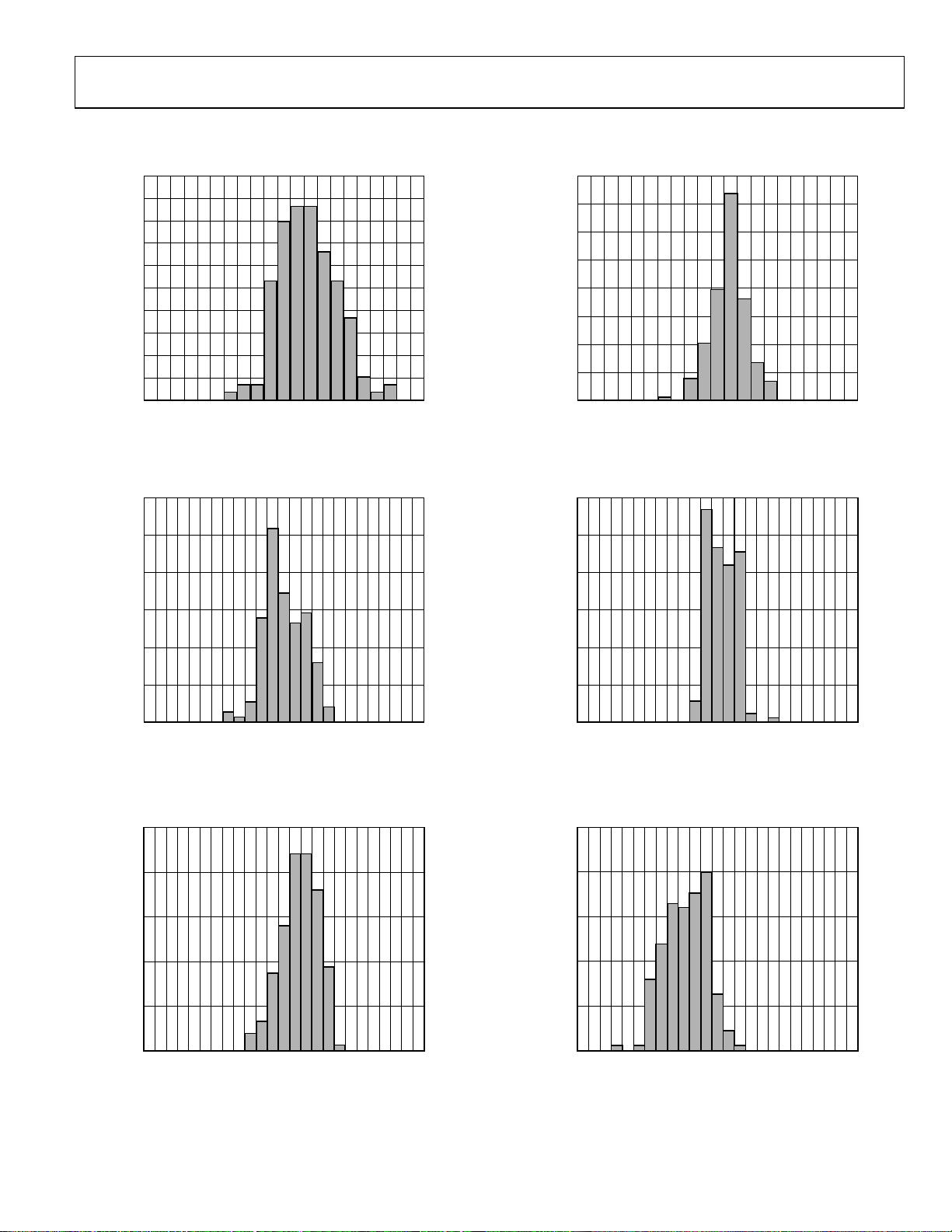

TYPICAL PERFORMANCE CHARACTERISTICS

20

18

16

14

12

10

8

6

4

PERCENT OF POPULATION (%)

2

0

–2.0 –1.6 –1.2 –0.8 –0.4 0 2.01.61.20.80.4

ERROR (°/sec)

Figure 5. SOIC_CAV Null Accuracy at 25°C

09155-006

40

35

30

25

20

15

10

PERCENT OF POPULATION (%)

5

0

–2.0 –1.6 –1.2 –0.8 –0.4 0 2.01.61.20.80.4

ERROR (°/sec)

Figure 8. LCC_V Null Accuracy at 25°C

09155-009

30

25

20

15

10

PERCENT OF POPUL ATION (%)

5

0

–2.5

–2.0

–3.0

–1.5

–1.0

–0.5

ERROR (°/sec)

0

Figure 6. SOIC_CAV Null Drift over Temperature

25

20

15

30

25

20

15

10

PERCENT OF POPUL ATION (%)

5

0

0.5

1.0

1.5

2.0

2.5

3.0

09155-007

–2.5

–2.0

–3.0

–1.5

–0.5

–1.0

ERROR (°/ sec)

0

1.5

1.0

0.5

3.0

2.5

2.0

09155-010

Figure 9. LCC_V Null Drift over Temperature

25

20

15

PERCENT OF POPULATION (%)

10

5

0

–0.030

–0.025

–0.020

–0.015

–0.010

–0.005

CHANGE IN SENSI TIVITY (%)

Figure 10. LCC_V Sensitivity Error at 25°C

0

0.030

0.025

0.020

0.015

0.010

0.005

09155-011

10

5

PERCENT OF POPULATIO N (%)

0

–3.0

–2.5

–2.0

–1.5

CHANGE IN SENSI TIVITY (%)

0

0.5

1.0

1.5

2.0

2.5

–1.0

–0.5

3.0

09155-008

Figure 7. SOIC_CAV Sensitivity Error at 25°C

Rev. B | Page 7 of 32

ADXRS453 Data Sheet

30

25

20

15

10

PERCENT OF POPULATION (%)

5

0

–3 –2 –1

0

ERROR (%)

Figure 11. SOIC_CAV Sensitivity Drift over Temperature

321

09155-012

45

40

35

30

25

20

15

10

PERCENT OF POPULAT ION (%)

5

0

–3 –2 –1

0

ERROR (%)

Figure 14. LCC_V Sensitivity Drift over Temperature

321

09155-015

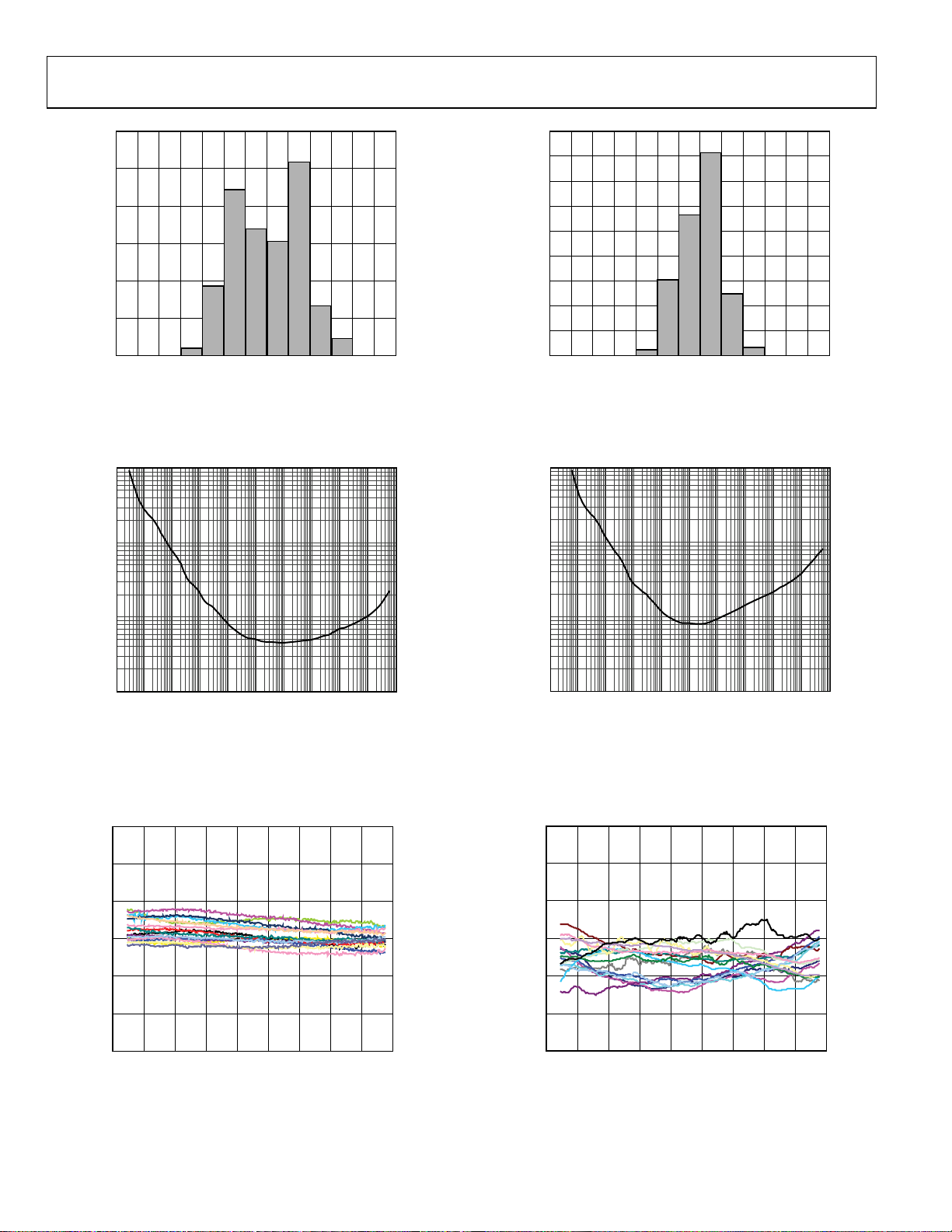

ROOT ALL AN VARIANCE (°/ sec)

0.001

1

0.1

0.01

0.01

0.001

0.0001

0.00001

0.0000001

0.000001

AVERAGING TIME (Hours)

Figure 12. Typical Root Allan Variance at 40°C

3

2

1

1

0.1

0.01

ROOT ALL AN VARIANCE (°/ sec)

1

0.1

10

100

1000

09155-013

0.001

0.0000001

0.01

0.001

0.0001

0.00001

0.000001

AVERAGING TIME (Hours)

1

0.1

10

100

1000

09155-016

Figure 15. Typical Root Allan Variance at 105°C

3

2

1

0

–1

NULL OUTPUT (°/sec)

–2

–3

–50 –30 –10 10 30 50 70 90 110 130

TEMPERATURE (°C)

Figure 13. Null Output over Temperature, 16 Devices Soldered on PCB

09155-014

Rev. B | Page 8 of 32

0

ERROR (%)

–1

–2

–3

–50 –30 –10 10 30 50 70 90 110 130

TEMPERATURE (°C)

Figure 16. Sensitivity over Temperature, 16 Devices Soldered on PCB

09155-017

Data Sheet ADXRS453

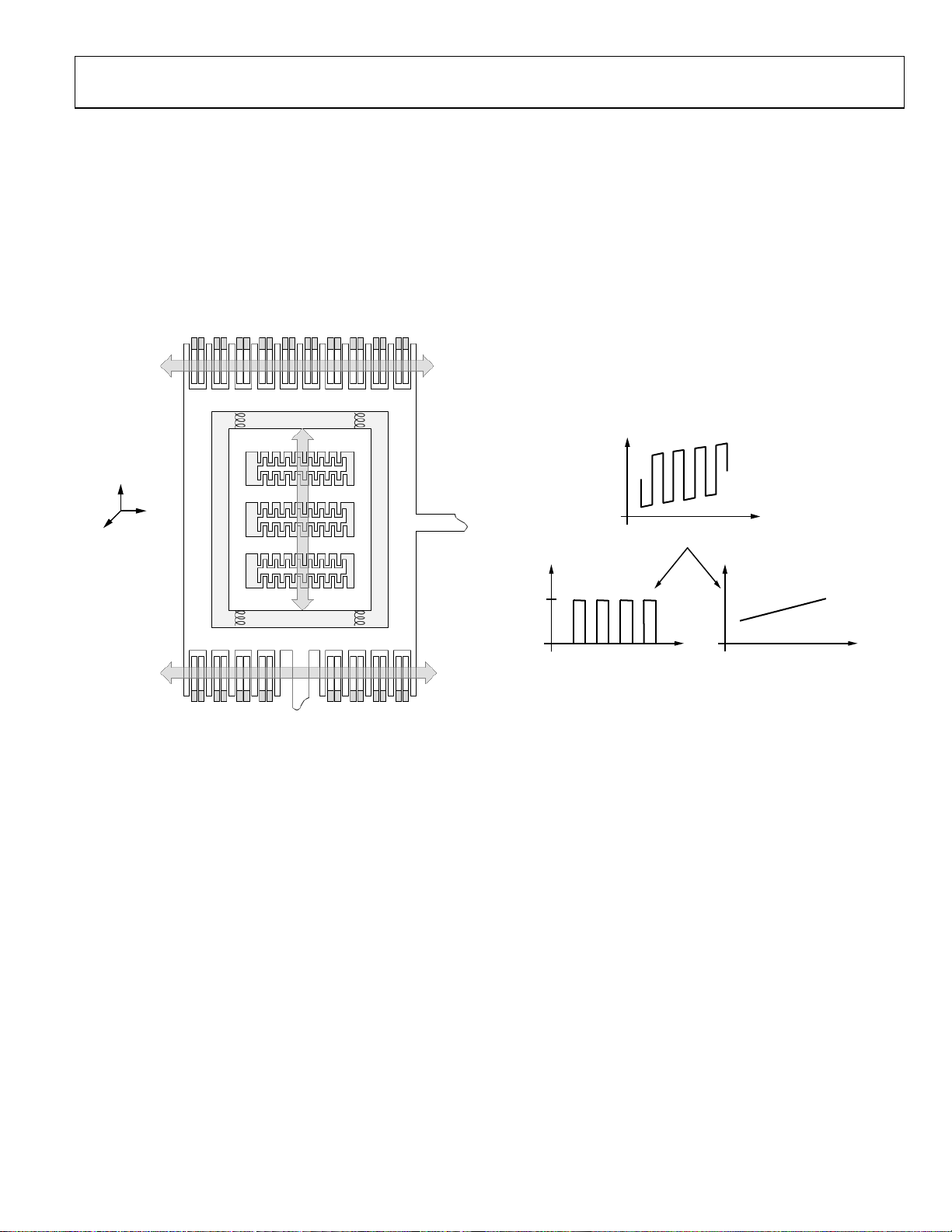

THEORY OF OPERATION

The ADXRS453 operates on the principle of a resonator gyroscope.

Figure 17 shows a simplified version of one of four polysilicon

sensing structures. Each sensing structure contains a dither frame

that is electrostatically driven to resonance. This produces the

necessary velocity element to produce a Coriolis force when the

device experiences angular rate. In the SOIC_CAV package, the

ADXRS453 is designed to sense a z-axis (yaw) angular rate; the

LCC_V vertical mount package orients the device such that it

can sense pitch or roll angular rate on the same PCB.

X

Y

Z

CONTINUOUS SELF-TEST

The ADXRS453 gyroscope implements a complete electromechanical self-test. An electrostatic force is applied to the

gyroscope frame, resulting in a deflection of the capacitive sense

fingers. This deflection is exactly equivalent to deflection that

occurs as a result of external rate input. The output from the

beam structure is processed by the same signal chain as a true

rate output signal, providing complete coverage of both the

electrical and mechanical components.

The electromechanical self-test is performed continuously

during operation at a rate higher than the output bandwidth of

the device. The self-test routine generates equivalent positive

and negative rate deflections. This information can then be

filtered with no overall effect on the demodulated rate output.

RATE SIGNAL WITH

CONTINUOUS SELF-T EST SIGNAL.

Figure 17. Simplified Gyroscope Sensing Structure

When the sensing structure is exposed to angular rate, the

resulting Coriolis force couples into an outer sense frame,

which contains movable fingers that are placed between fixed

pickoff fingers. This forms a capacitive pickoff structure that

senses Coriolis motion. The resulting signal is fed to a series of

gain and demodulation stages that produce the electrical rate

signal output. The quad sensor design rejects linear and angular

acceleration, including external g-forces and vibration. This is

achieved by mechanically coupling the four sensing structures

such that external g-forces appear as common-mode signals

that can be removed by the fully differential architecture

implemented in the ADXRS453.

The resonator requires 22.5 V (typical) for operation. Because

only 5 V is typically available in most applications, a switching

regulator is included on chip.

SELF-TEST AMPLITUDE.

INTERNALL Y COMPARED

TO THE SPECIFICATION

09155-018

TABLE LI MITS.

Figure 18. Continuous Self-Test Demodulation

LOW FREQUENCY RATE

INFORMAT ION.

The difference amplitude between the positive and negative

self-test deflections is filtered to f

/8000 (~1.95 Hz) and is

0

continuously monitored and compared to hard-coded self-test

limits. If the measured amplitude exceeds these limits (listed in

Table 1), one of two error conditions is asserted, depending on

the magnitude of the self-test error.

For less severe self-test error magnitudes, the CST bit of the

fault register is asserted. However, the status bits (ST[1:0])

in the sensor data response remain set to 01 for valid

sensor data.

For more severe self-test errors, the CST bit of the fault

register is asserted and the status bits (ST[1:0]) in the

sensor data response are set to 00 for invalid sensor data.

Table 1 lists the thresholds for both of these failure conditions.

If desired, the user can access the self-test information by issuing

a read command to the self-test memory register (Address 0x04).

See the SPI Communication Protocol section for more information about error reporting.

09155-019

Rev. B | Page 9 of 32

ADXRS453 Data Sheet

(

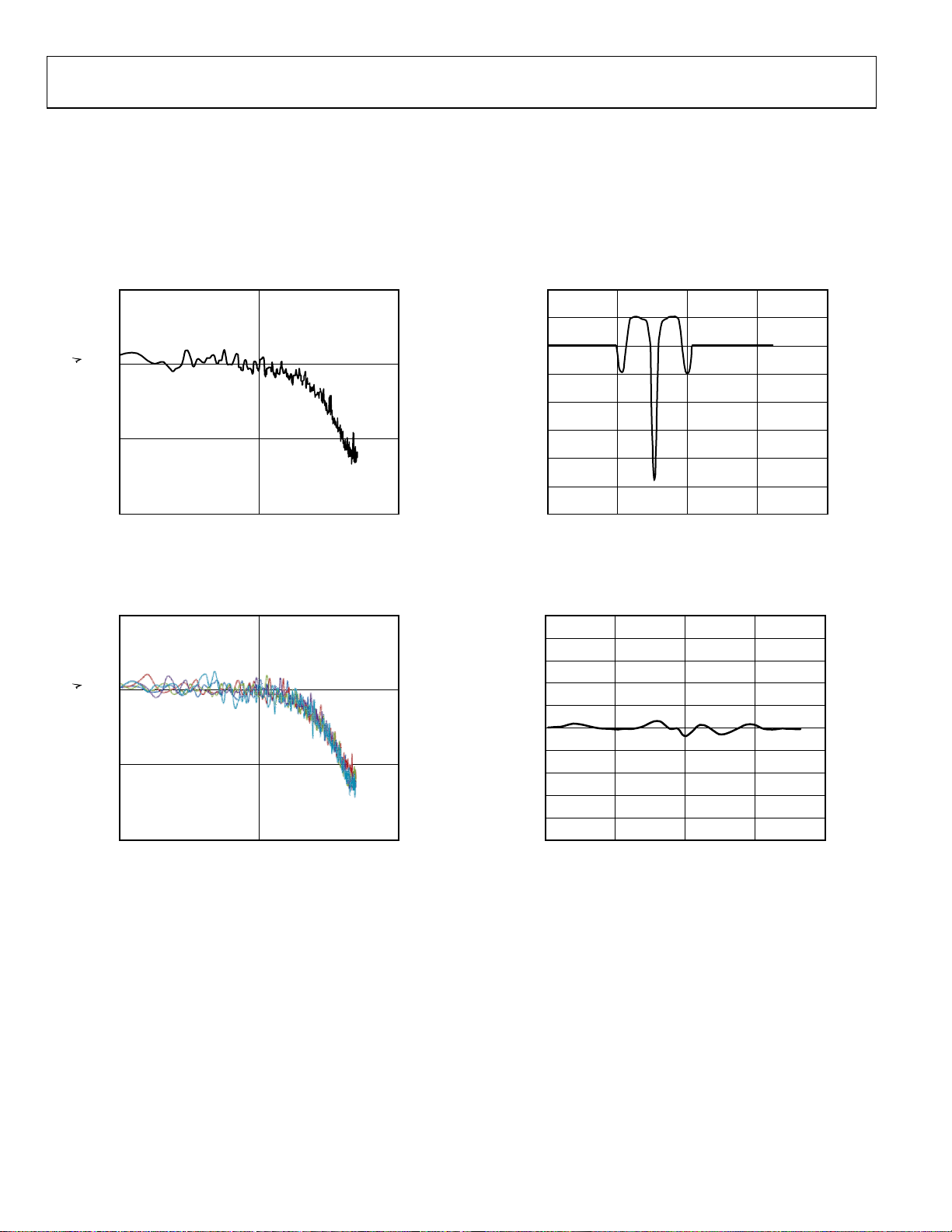

MECHANICAL PERFORMANCE

The ADXRS453 has excellent shock and vibration rejection.

Figure 19 shows the output noise response of the ADXRS453 in

a vibration free environment. Figure 20 shows the response of

the same device to 15 g rms random vibration (50 Hz to 5 kHz).

As shown in Figure 20, no frequencies are particularly sensitive

to vibration. Response to vibration in all axes is similar.

0.1

0.01

Shock response is also excellent, as shown in Figure 21 and

Figure 22. Figure 21 shows a 99 g input stimulus applied to

each axis, and Figure 22 shows the typical response to this

shock in each axis. Shock response of 0.01°/sec/g is apparent.

40

20

0

g)

–20

–40

0.001

GYRO OUTPUT (°/sec/ Hz)

0.0001

5 50 500

FREQUENCY (Hz)

Figure 19. ADXRS453 Output Noise Response with No Vibration Applied

0.1

0.01

0.001

GYRO OUTPUT (°/sec/ Hz)

0.0001

5 50 500

FREQUENCY (Hz)

Figure 20. ADXRS453 Output Noise Response with 15 g RMS Random

Vibration (50 Hz to 5 kHz) Applied

–60

INPUT STIMULUS

–80

–100

–120

00.100.05 0.15 0.20

09155-020

TIME (Seconds)

09155-022

Figure 21. 99 g Shock Input

10

8

6

4

2

0

–2

–4

GYRO OUTPUT (°/sec)

–6

–8

–10

00.100.05 0.15 0.20

09155-021

TIME (Seconds)

09155-023

Figure 22. Typical Output Response Due to 99 g Shock (see Figure 21)

Rev. B | Page 10 of 32

Loading...

Loading...