ANALOG DEVICES ADXL346 Service Manual

3-Axis, ±2 g/±4 g/±8 g/±16 g

VSV

Ultralow Power Digital Accelerometer

FEATURES

Ultralow power: as low as 23 μA in measurement mode and

0.2 μA in standby mode at V

Power consumption scales automatically with bandwidth

User-selectable resolution

Fixed 10-bit resolution

Full resolution, where resolution increases with g range,

up to 13-bit resolution at ±16 g (maintaining 4 mg/LSB

scale factor in all g ranges)

Patent pending, embedded memory management system

with FIFO technology minimizes host processor load

Single-tap/double-tap detection

Activity/inactivity monitoring

Free-fall detection

Concurrent four- and six-position orientation detection

Supply and I/O voltage range: 1.7 V to 2.75 V

SPI (3- and 4-wire) and I

Flexible interrupt modes mappable to either interrupt pin

Measurement ranges selectable via serial command

Bandwidth selectable via serial command

Wide temperature range (−40°C to +85°C)

10,000 g shock survival

Pb free/RoHS compliant

Small and thin: 3 mm × 3 mm × 0.95 mm LGA package

APPLICATIONS

Handsets

Medical instrumentation

Gaming and pointing devices

Industrial instrumentation

Personal navigation devices

Hard disk drive (HDD) protection

= 2.6 V (typical)

S

2

C digital interfaces

ADXL346

GENERAL DESCRIPTION

The ADXL346 is a small, thin, ultralow power, 3-axis accelerometer

with high resolution (13-bit) measurement at up to ±16 g. Digital

output data is formatted as 16-bit twos complement and is accessible through either an SPI (3- or 4-wire) or I

The ADXL346 is well suited for mobile device applications. It

measures the static acceleration of gravity in tilt-sensing applications, as well as dynamic acceleration resulting from motion

or shock. Its high resolution (4 mg/LSB) enables measurement

of inclination changes of less than 1.0°.

Several special sensing functions are provided. Activity and

inactivity sensing detect the presence or lack of motion by

comparing the acceleration on any axis with user-set thresholds.

Tap sensing detects single and double taps in any direction. Freefall sensing detects if the device is falling. Orientation detection

is capable of concurrent four- and six-position sensing and a

user-selectable interrupt on orientation change for 2D or 3D

applications. These functions can be mapped individually to

either of two interrupt output pins. An integrated, patent pending

memory management system with 32-level first in, first out (FIFO)

buffer can be used to store data to minimize host processor activity

and lower overall system power consumption.

Low power modes enable intelligent motion-based power

management with threshold sensing and active acceleration

measurement at extremely low power dissipation.

The ADXL346 is supplied in a small, thin, 3 mm × 3 mm ×

0.95 mm, 16-lead, plastic package.

2

C® digital interface.

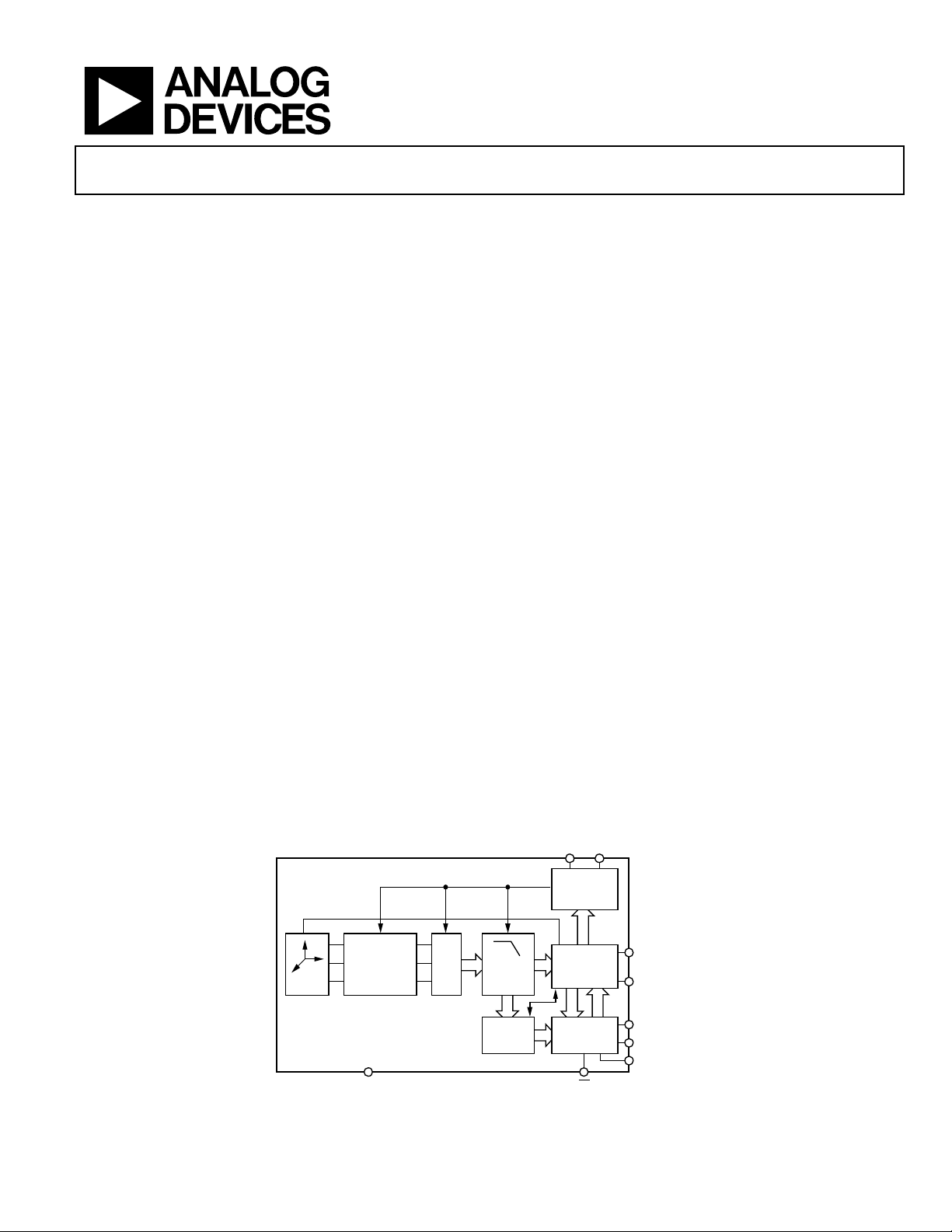

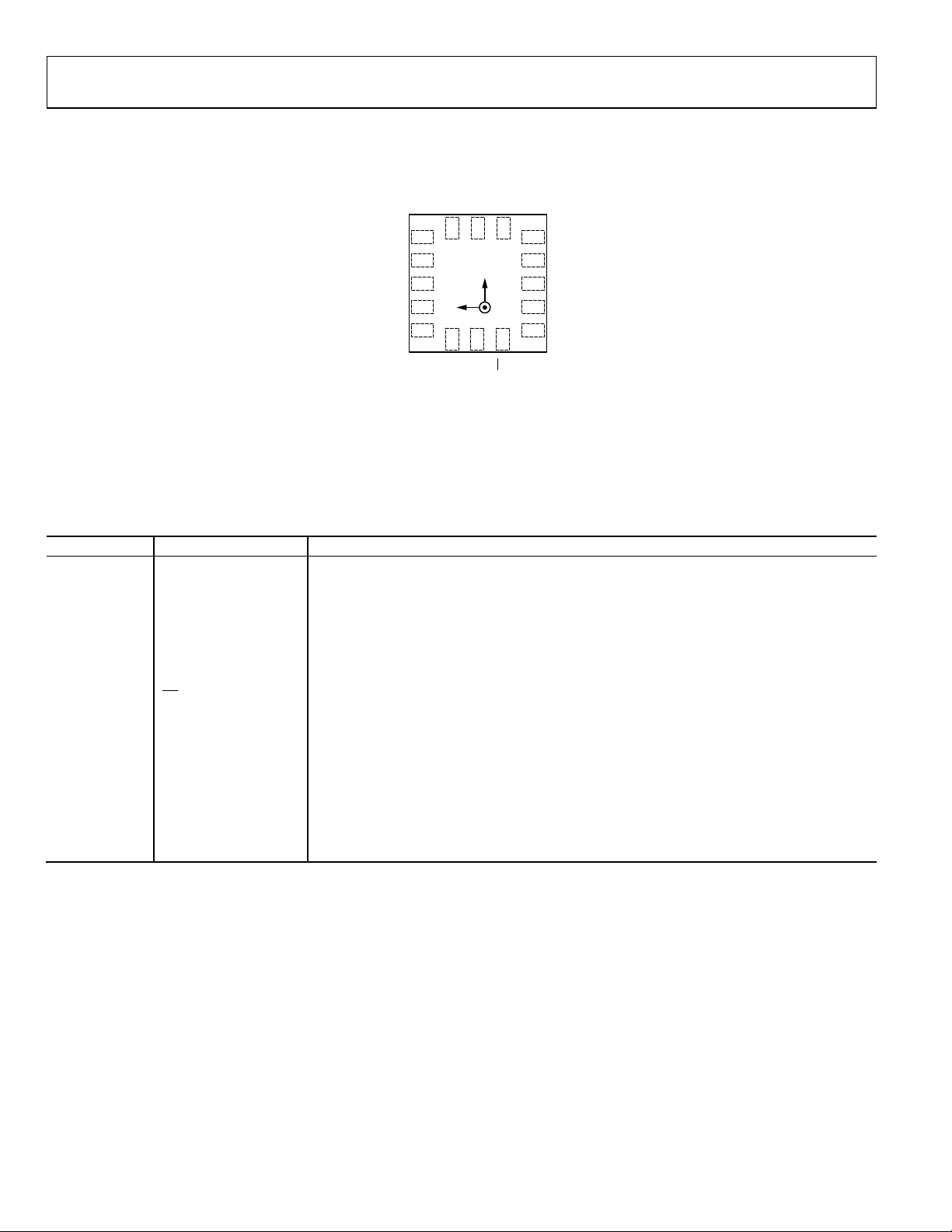

FUNCTIONAL BLOCK DIAGRAM

DD I/O

ADXL346

SENSE

3-AXIS

SENSOR

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

ELECTRONICS

GND

ADC

DIGITAL

FILTER

32-LEVEL

FIFO

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010 Analog Devices, Inc. All rights reserved.

POWER

MANAGEMENT

CONTROL

AND

INTERRUPT

LOGIC

SERIAL I/O

CS

INT1

INT2

SDA/SDI/SDIO

SDO/ALT

ADDRESS

SCL/SCLK

08167-001

ADXL346

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 5

Thermal Resistance ...................................................................... 5

Package Information .................................................................... 5

ESD Caution .................................................................................. 5

Pin Configuration and Function Descriptions ............................. 6

Typical Performance Characteristics ............................................. 7

Theory of Operation ...................................................................... 12

Power Sequencing ...................................................................... 12

Power Savings ............................................................................. 13

Serial Communications ................................................................. 14

SPI ................................................................................................. 14

I2C ................................................................................................. 17

Interrupts ..................................................................................... 19

FIFO ............................................................................................. 20

Self-Test ........................................................................................ 21

Register Map .................................................................................... 22

Register Definitions ................................................................... 23

Applications Information .............................................................. 29

Power Supply Decoupling ......................................................... 29

Mechanical Considerations for Mounting .............................. 29

Tap Detection .............................................................................. 29

Improved Tap Detection ............................................................ 30

Tap Sign ....................................................................................... 30

Threshold .................................................................................... 31

Link Mode ................................................................................... 31

Sleep Mode vs. Low Power Mode............................................. 31

Offset Calibration ....................................................................... 31

Using Self-Test ............................................................................ 32

Orientation Sensing ................................................................... 32

Data Formatting of Upper Data Rates ..................................... 34

Noise Performance ..................................................................... 35

Operation at Voltages Other Than 2.6 V ................................ 35

Offset Performance at Lowest Data Rates ............................... 36

Axes of Acceleration Sensitivity ............................................... 37

Layout and Design Recommendations ................................... 38

Outline Dimensions ....................................................................... 39

Ordering Guide .......................................................................... 39

REVISION HISTORY

5/10—Revision 0: Initial Version

Rev. 0 | Page 2 of 40

ADXL346

SPECIFICATIONS

TA = 25°C, VS = 2.6 V, V

Table 1. Specifications

Parameter Test Conditions Min1 Typ2 Max1 Unit

SENSOR INPUT Each axis

Measurement Range User selectable ±2, ±4, ±8, ±16

Nonlinearity Percentage of full scale ±0.5 %

Inter-Axis Alignment Error ±0.1 Degrees

Cross-Axis Sensitivity3 ±1 %

OUTPUT RESOLUTION Each axis

All g Ranges 10-bit resolution 10 Bits

±2 g Range Full resolution 10 Bits

±4 g Range Full resolution 11 Bits

±8 g Range Full resolution 12 Bits

±16 g Range Full resolution 13 Bits

SENSITIVITY Each axis

Sensitivity at X

OUT

, Y

±2 g, 10-bit resolution 230 256 282 LSB/g

±4 g, 10-bit resolution 115 128 141 LSB/g

±8 g, 10-bit resolution 57 64 71 LSB/g

±16 g, 10-bit resolution 29 32 35 LSB/g

Sensitivity Deviation from Ideal All g ranges ±1.0 %

Scale Factor at X

OUT

±2 g, 10-bit resolution 3.5 3.9 4.3 mg/LSB

±4 g, 10-bit resolution 7.1 7.8 8.7 mg/LSB

±8 g, 10-bit resolution 14.1 15.6 17.5 mg/LSB

±16 g, 10-bit resolution 28.6 31.2 34.5 mg/LSB

Sensitivity Change Due to Temperature ±0.02 %/°C

0 g OFFSET Each axis

0 g Output for X

OUT

0 g Output Deviation from Ideal ±35 mg

0 g Offset vs. Temperature for X-, Y-Axes ±0.7 mg/°C

0 g Offset vs. Temperature for Z-Axis ±1.3 mg/°C

NOISE

X-, Y-Axes

Z-Axis

OUTPUT DATA RATE AND BANDWIDTH User selectable

Output Data Rate (ODR)

SELF-TEST7

Output Change in X-Axis 0.27 1.55

Output Change in Y-Axis −1.55 −0.27

Output Change in Z-Axis 0.40 1.95

POWER SUPPLY

Operating Voltage Range (VS) 1.7 2.6 2.75 V

Interface Voltage Range (V

Measurement Mode Supply Current ODR ≥ 100 Hz 140 μA

ODR < 10 Hz 30 μA

Standby Mode Supply Current 0.2 μA

Turn-On and Wake-Up Time8 ODR = 3200 Hz 1.4 ms

= 1.8 V, acceleration = 0 g, CS = 10 F tantalum, C

DD I/O

, Z

All g ranges, full resolution 230 256 282 LSB/g

OUT

OUT

, Y

, Z

All g ranges, full resolution 3.5 3.9 4.3 mg/LSB

OUT

OUT

, Y

, Z

−150 0 +150 mg

OUT

OUT

ODR = 100 Hz for ±2 g, 10-bit

resolution or all g ranges, full

resolution

ODR = 100 Hz for ±2 g, 10-bit

resolution or all g ranges, full

resolution

4, 5, 6

) 1.7 1.8 VS V

DD I/O

0.10 3200 Hz

Rev. 0 | Page 3 of 40

= 0.1 F, ODR = 800 Hz, unless otherwise noted.

I/O

g

1.1 LSB rms

1.5 LSB rms

g

g

g

ADXL346

Parameter Test Conditions Min1 Typ2 Max1 Unit

TEMPERATURE

Operating Temperature Range −40 +85 °C

WEIGHT

Device Weight 18 mg

1

All minimum and maximum specifications are guaranteed. Typical specifications are not guaranteed.

2

The typical specifications shown are for at least 68% of the population of parts and are based on the worst case of mean ±1 σ except for 0 g output and sensitivity,

which represents the target value. For 0 g offset and sensitivity, the deviation from the ideal describes the worst case of mean ±1 σ.

3

Cross-axis sensitivity is defined as coupling between any two axes.

4

Bandwidth is the −3 dB frequency and is half the output data rate bandwidth = ODR/2.

5

The output format for the 3200 Hz and 1600 Hz ODRs is different from the output format for the remaining ODRs. This difference is described in the Data Formatting of

Upper Data Rates section.

6

Output data rates below 6.25 Hz exhibit additional offset shift with increased temperature, depending on selected output data rate. Refer to the Offset Performance at

Lowest Data Rates section for details.

7

Self-test change is defined as the output (g) when the SELF_TEST bit = 1 (in the DATA_FORMAT register, Address 0x31) minus the output (g) when the SELF_TEST bit = 0.

Due to device filtering, the output reaches its final value after 4 × τ when enabling or disabling self-test, where τ = 1/(data rate). The part must be in normal power

operation (LOW_POWER bit = 0 in the BW_RATE register, Address 0x2C) for self-test to operate correctly.

8

Turn-on and wake-up times are determined by the user-defined bandwidth. At a 100 Hz data rate, the turn-on and wake-up times are each approximately 11.1 ms. For

other data rates, the turn-on and wake-up times are each approximately τ + 1.1 in milliseconds, where τ = 1/(data rate).

Rev. 0 | Page 4 of 40

ADXL346

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Acceleration

Any Axis, Unpowered 10,000 g

Any Axis, Powered 10,000 g

VS −0.3 V to +3.0 V

V

−0.3 V to +3.0 V

DD I/O

Digital Pins

All Other Pins −0.3 V to +3.0 V

Output Short-Circuit Duration

(Any Pin to Ground)

Temperature Range

Powered −40°C to +105°C

Storage −40°C to +105°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

−0.3 V to V

3.0 V, whichever is less

Indefinite

DD I/O

+ 0.3 V or

THERMAL RESISTANCE

PACKAGE INFORMATION

The information in Figure 2 and Tabl e 4 provide details about

the package branding for ADXL346. For a complete listing of

product availability, see the Ordering Guide section.

Y2Z

vvvv

08167-047

Figure 2. Product Information on Package (Top View)

Table 4. Package Branding Information

Branding Key Field Description

Y2Z Part identifier for ADXL346

vvvv Factory lot code

ESD CAUTION

Table 3. Package Characteristics

Package Type θJA θ

16-Terminal LGA 150°C/W 85°C/W 18 mg

Device Weight

JC

Rev. 0 | Page 5 of 40

ADXL346

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

S

RESERVED

GND

16

DD I/O

NC

NC

NC

1

2

3

4

5

ADXL346

+Y

6

SDA/SDI/SDIO

TOP VIEW

(Not to Scale)

V

SCL/SCLK

NC = NO INTERNAL

CONNECTION

Figure 3. Pin Configuration (Top View)

Table 5. Pin Function Descriptions

Pin No. Mnemonic Description

1 V

Digital Interface Supply Voltage.

DD I/O

2 NC Not Internally Connected.

3 NC Not Internally Connected.

4 SCL/SCLK Serial Communications Clock.

5 NC Not Internally Connected.

6 SDA/SDI/SDIO Serial Data (I2C)/Serial Data Input (SPI 4-Wire)/Serial Data Input and Output (SPI 3-Wire).

7 SDO/ALT ADDRESS Serial Data Output (SPI 4-Wire)/Alternate I2C Address Select (I2C).

8

CS

Chip Select.

9 INT2 Interrupt 2 Output.

10 NC Not Internally Connected.

11 INT1 Interrupt 1 Output.

12 GND Must be connected to ground.

13 GND Must be connected to ground.

14 VS Supply Voltage.

15 RESERVED Reserved. This pin must be connected to VS.

16 GND Must be connected to ground.

V

14

15

+X

7

SDO/

13

GND

12

GND

11

INT1

10

+Z

8

ALT ADDRESS

NC

9

INT2

CS

08167-002

Rev. 0 | Page 6 of 40

ADXL346

A

A

A

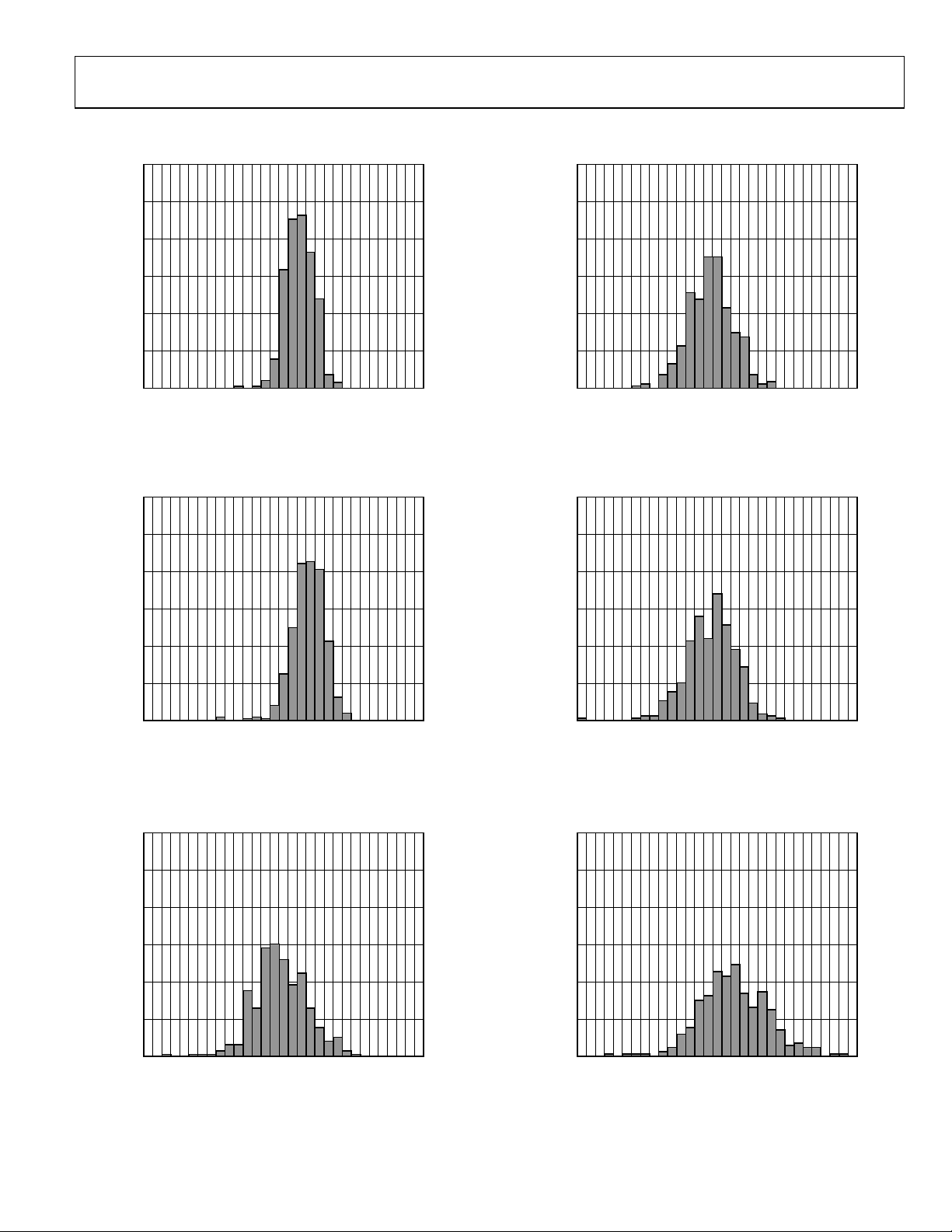

TYPICAL PERFORMANCE CHARACTERISTICS

30

30

25

20

15

10

PERCENT OF P OPULATION (%)

5

0

–150 –100 –50 0 50 100 150

ZERO g OFFSET (mg)

08167-004

25

20

TION (%)

15

10

PERCENT OF P OPUL

5

0

–150 –100 –50 0 50 100 150

ZERO g OFFSET (mg)

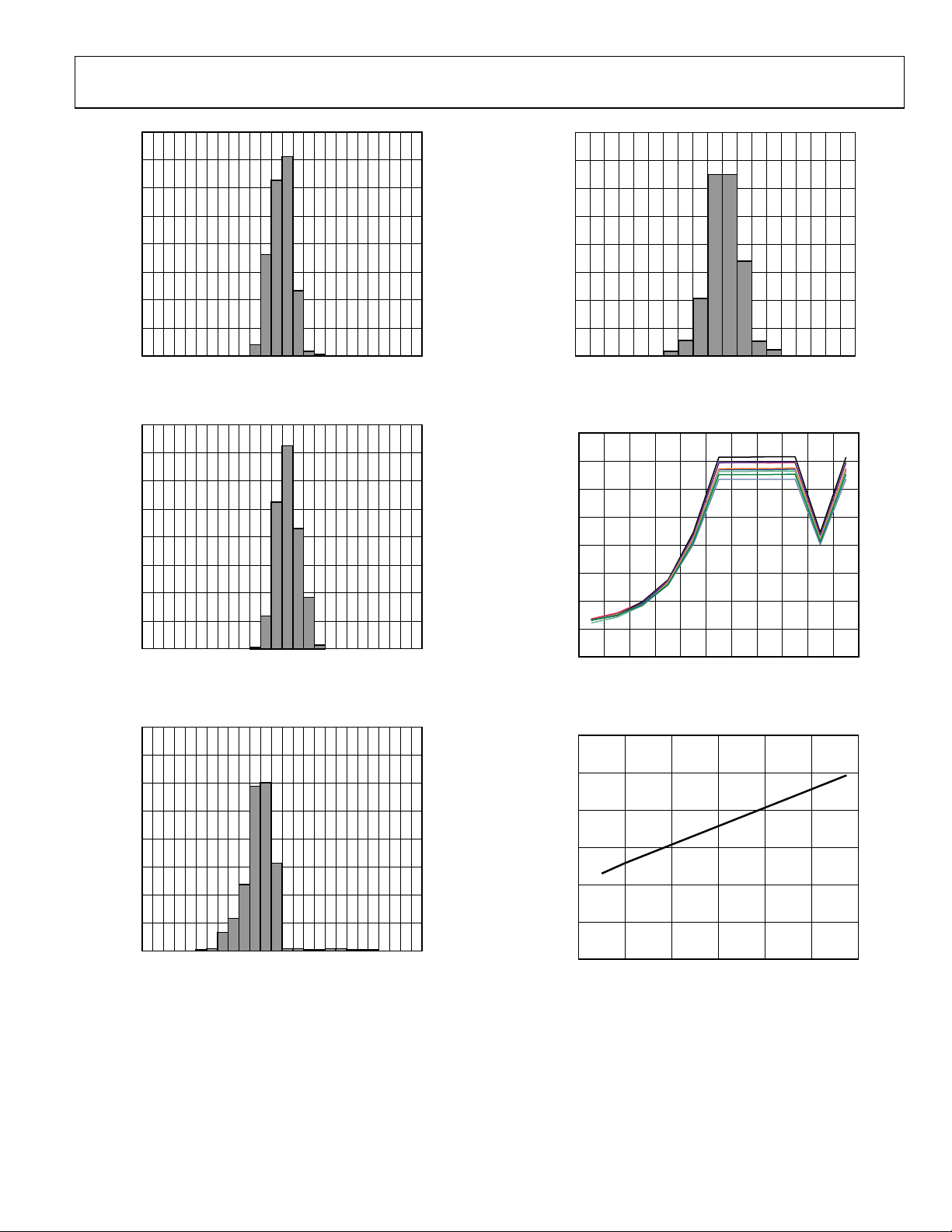

Figure 4. X-Axis Zero g Offset at 25°C, VS = 2.6 V Figure 7. X-Axis Zero g Offset at 25°C, VS = 1.8 V

30

25

20

15

10

30

25

20

TION (%)

15

10

08167-104

PERCENT OF P OPULATION (%)

5

0

–150 –100 –50 0 50 100 150

ZERO g OFFSET (mg)

08167-005

PERCENT OF P OPUL

5

0

–150 –100 –50 0 50 100 150

ZERO g OFFSET (mg)

Figure 5. Y-Axis Zero g Offset at 25°C, VS = 2.6 V Figure 8. Y-Axis Zero g Offset at 25°C, VS = 1.8 V

30

25

20

15

10

PERCENT OF P OPULATION (%)

5

0

–150 –100 –50 0 50 100 150

ZERO g OFFSET (mg)

Figure 6. Z-Axis Zero g Offset at 25°C, VS = 2.6 V

08167-006

30

25

20

TION (%)

15

10

PERCENT OF P OPUL

5

0

–150 –100 –50 0 50 100 150

ZERO g OFFSET (mg)

Figure 9. Z-Axis Zero g Offset at 25°C, V

= 1.8 V

S

08167-105

08167-106

Rev. 0 | Page 7 of 40

ADXL346

60

50

40

30

20

PERCENT OF POPULATION (%)

10

0

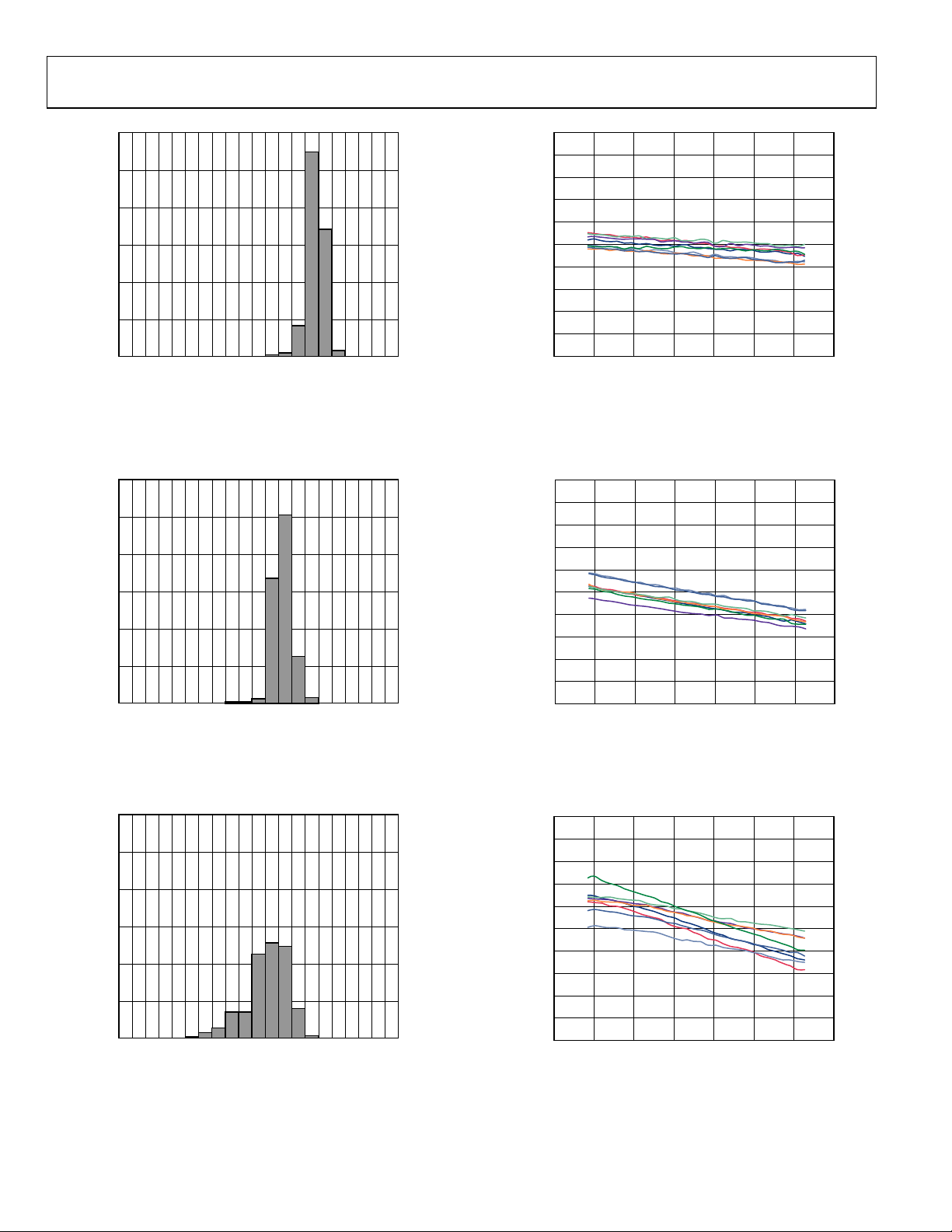

–3 –2 –1 0 1

ZERO g OFFSET TEMPERATURE COEFFICIENT (mg/°C)

Figure 10. X-Axis Zero g Offset Temperature Coefficient, VS = 2.6 V

250

200

150

100

50

0

–50

ZERO g OFFSET (mg)

–100

–150

–200

08167-010

–250

–40 –20 0 20 40 60 80 100

TEMPERATURE (° C)

08167-013

Figure 13. X-Axis Zero g Offset vs. Temperature—

Eight Parts Soldered to PCB, V

= 2.6 V

S

60

50

40

30

20

PERCENT OF POPULATION (%)

10

0

–3 –2 –1 0 1

ZERO g OFFSET TEMPERATURE COEFFICIENT (mg/°C)

Figure 11. Y-Axis Zero g Offset Temperature Coefficient, VS = 2.6 V

60

50

40

30

20

PERCENT OF POPULATION (%)

10

0

–3 –2 –1 0 1

ZERO g OFFSET TEMPERATURE COEFFICIENT (mg/°C)

Figure 12. Z-Axis Zero g Offset Temperature Coefficient, VS = 2.6 V

250

200

150

100

50

0

–50

ZERO g OFFSET (mg)

–100

–150

–200

08167-011

–250

–40 –20 0 20 40 60 80 100

TEMPERATURE (°C)

08167-014

Figure 14. Y-Axis Zero g Offset vs. Temperature—

Eight Parts Soldered to PCB, V

250

200

150

100

50

0

–50

ZERO g OFFSET (mg)

–100

–150

–200

08167-012

–250

–40 –20 0 20 40 60 80 100

TEMPERATURE (° C)

= 2.6 V

S

08167-015

Figure 15. Z-Axis Zero g Offset vs. Temperature—

Eight Parts Soldered to PCB, V

= 2.6 V

S

Rev. 0 | Page 8 of 40

ADXL346

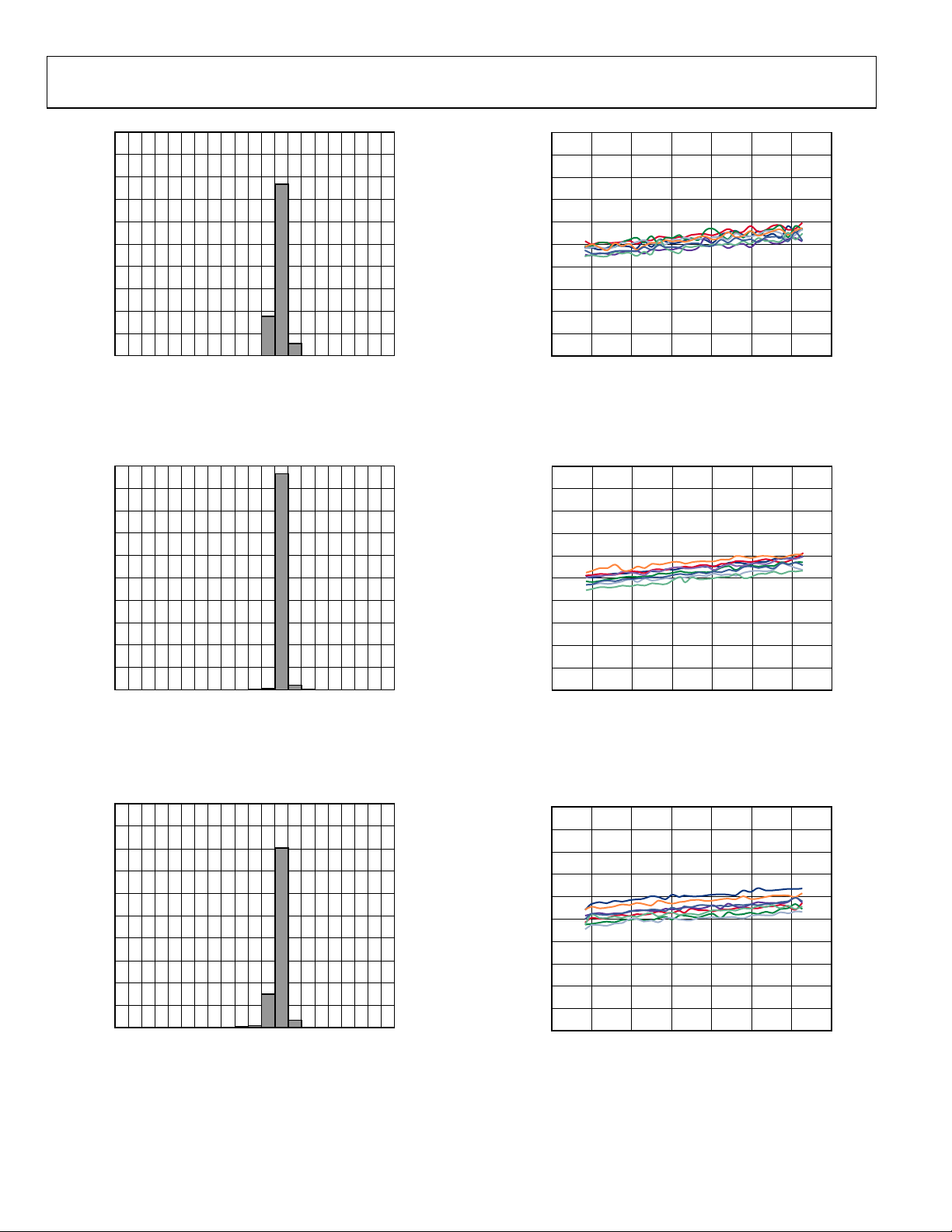

60

60

50

40

30

20

PERCENT OF POPUL AT I ON (%)

10

0

230 240 250 260 270 280

SENSITIVITY (LSB/g)

Figure 16. X-Axis Sensitivity at 25°C, VS = 2.6 V, Full Resolution

60

50

40

30

20

50

40

30

20

PERCENT OF POPUL AT I ON (%)

10

08167-016

0

230 240 250 260 270 280

SENSITIVITY (LSB/g)

08167-116

Figure 19. X-Axis Sensitivity at 25°C, VS = 1.8 V, Full Resolution

60

50

40

30

20

PERCENT OF POPUL AT I ON (%)

10

0

230 240 250 260 270 280

SENSITIVITY (LSB/g)

Figure 17. Y-Axis Sensitivity at 25°C, VS = 2.6 V, Full Resolution

60

50

40

30

20

PERCENT OF POPUL AT I ON (%)

10

0

230 240 250 260 270 280

SENSITIVITY (LSB/g)

Figure 18. Z-Axis Sensitivity at 25°C, VS = 2.6 V, Full Resolution

PERCENT OF POPUL AT I ON (%)

10

08167-017

0

230 240 250 260 270 280

SENSITIVITY (LSB/g)

08167-117

Figure 20. Y-Axis Sensitivity at 25°C, VS = 1.8 V, Full Resolution

60

50

40

30

20

PERCENT OF POPUL AT I ON (%)

10

08167-018

0

230 240 250 260 270 280

SENSITIVITY (LSB/g)

08167-118

Figure 21. Z-Axis Sensitivity at 25°C, VS = 1.8 V, Full Resolution

Rev. 0 | Page 9 of 40

ADXL346

100

90

80

70

60

50

40

30

20

PERCENT OF P OPULATION (%)

10

0

–0.10 –0.05 0 0.05 0.10

SENSITIV ITY TEMP E RATURE COEFFICIENT (%/°C)

Figure 22. X-Axis Sensitivity Temperature Coefficient, VS = 2.6 V

280

275

270

265

260

255

250

SENSITIVITY (LSB/g)

245

240

235

08167-022

230

–40 –20 0 20 40 60 80 100

TEMPERATURE (° C)

08167-025

Figure 25. X-Axis Sensitivity vs. Temperature—

Eight Parts Soldered to PCB, V

= 2.6 V, Full Resolution

S

100

90

80

70

60

50

40

30

20

PERCENT OF P OPULATION (%)

10

0

–0.10 –0.05 0 0.05 0.10

SENSITIV ITY TEMP E RATURE COEFFICIENT (%/°C)

Figure 23. Y-Axis Sensitivity Temperature Coefficient, VS = 2.6 V

100

90

80

70

60

50

40

30

20

PERCENT OF P OPULATION (%)

10

0

–0.10 –0.05 0 0.05 0.10

SENSITIV ITY TEMP E RATURE COEFFICIENT (%/°C)

Figure 24. Z-Axis Sensitivity Temperature Coefficient, VS = 2.6 V

280

275

270

265

260

255

250

SENSITIVITY (LSB/g)

245

240

235

08167-023

230

–40 –20 0 20 40 60 80 100

TEMPERATURE (°C)

08167-026

Figure 26. Y-Axis Sensitivity vs. Temperature—

Eight Parts Soldered to PCB, V

280

275

270

265

260

255

250

SENSITIVITY (LSB/g)

245

240

235

08167-024

230

–40 –20 0 20 40 60 80 100

TEMPERATURE (°C)

= 2.6 V, Full Resolution

S

08167-127

Figure 27. Z-Axis Sensitivity vs. Temperature—

Eight Parts Soldered to PCB, V

= 2.6 V, Full Resolution

S

Rev. 0 | Page 10 of 40

ADXL346

40

40

35

30

25

20

15

10

PERCENT OF POPULATION (%)

5

0

0.5 0.6 0.7 0.8 0.9 1.0

SELF-TEST SHIFT (

g)

Figure 28. X-Axis Self-Test Response at 25°C, VS = 2.6 V

40

35

30

25

20

15

10

PERCENT OF POPULATION (%)

5

0

–1.0 –0.9 –0.8 –0.7 –0.6 –0.5

SELF-TEST SHIFT (

Figure 29. Y-Axis Self-Test Response at 25°C, V

40

35

30

g)

= 2.6 V

S

35

30

25

20

15

10

PERCENT OF P OPULATION (%)

5

08167-007

0

90 100 120 140 160 180110 130 150 170

OUTPUT CURRENT ( µ A)

Figure 31. Supply Current at 25°C, 100 Hz Output Data Rate, V

160

140

120

100

80

60

SUPPLY CURRENT (µA)

40

20

08167-008

0

3.13 6.25 12.50 25 50 100 200 400 1600800 3200

OUTPUT DATA RATE (Hz)

Figure 32. Supply Current vs. Output Data Rate at 25°C—10 Parts, V

150

140

= 2.6 V

S

= 2.6 V

S

08167-019

08167-020

25

20

15

10

PERCENT OF POPULATION (%)

5

0

1.0 1.1 1.2 1.3 1.51.4

SELF-TEST SHIFT (

Figure 30. Z-Axis Self-Test Response at 25°C, V

08167-009

g)

= 2.6 V

S

130

120

110

100

SUPPLY CURRENT CO NSUMPTION ( µA)

90

1.6 1.8 2.0 2.2 2.4 2.6 2.8

SUPPLY VOLTAGE, VS (V)

Figure 33. Supply Current vs. Supply Voltage at 25°C

08167-021

Rev. 0 | Page 11 of 40

ADXL346

THEORY OF OPERATION

The ADXL346 is a complete 3-axis acceleration measurement

system with a selectable measurement range of ±2 g, ±4 g, ±8 g,

or ±16 g. It measures both dynamic acceleration resulting from

motion or shock and static acceleration, such as gravity, which

allows the device to be used as a tilt sensor.

The sensor is a polysilicon surface-micromachined structure

built on top of a silicon wafer. Polysilicon springs suspend the

structure over the surface of the wafer and provide a resistance

against forces due to applied acceleration.

Deflection of the structure is measured using differential capacitors

that consist of independent fixed plates and plates attached to the

moving mass. Acceleration deflects the proof mass and unbalances

the differential capacitor, resulting in a sensor output with an

amplitude proportional to acceleration. Phase-sensitive demodulation is used to determine the magnitude and polarity

of the acceleration.

POWER SEQUENCING

Power can be applied to VS or V

damaging the ADXL346. All possible power-on modes are

summarized in Tab le 6. The interface voltage level is set with

the interface supply voltage, V

ensure that the ADXL346 does not create a conflict on the

communication bus. For single-supply operation, V

the same as the main supply, V

however, V

can differ from VS to accommodate the desired

DD I/O

interface voltage, as long as V

is applied, the device enters standby mode, where power

After V

S

consumption is minimized and the device waits for V

applied and for the command to enter measurement mode to be

received. (This command can be initiated by setting the measure

bit (Bit D3) in the POWER_CTL register (Address 0x2D).) In

addition, any register can be written to or read from to configure

the part while the device is in standby mode. It is recommended

to configure the device in standby mode and then to enable

measurement mode. Clearing the measure bit returns the

device to the standby mode.

in any sequence without

DD I/O

, which must be present to

DD I/O

DD I/O

. In a dual-supply application,

S

is greater than or equal to V

S

DD I/O

can be

DD I/O

to be

.

Table 6. Power Sequencing

Condition VS V

Power Off Off Off

Bus Disabled On Off

Bus Enabled Off On

Standby or

Measurement Mode

On On

Description

DD I/O

The device is completely off, but there is a potential for a communication

bus conflict.

The device is on in standby mode, but communication is unavailable and will

create a conflict on the communication bus. The duration of this state should

be minimized during power-up to prevent a conflict.

No functions are available, but the device will not create a conflict on the

communication bus.

At power-up, the device is in standby mode, awaiting a command to enter

measurement mode, and all sensor functions are off. After the device is

instructed to enter measurement mode, all sensor functions are available.

Rev. 0 | Page 12 of 40

Loading...

Loading...