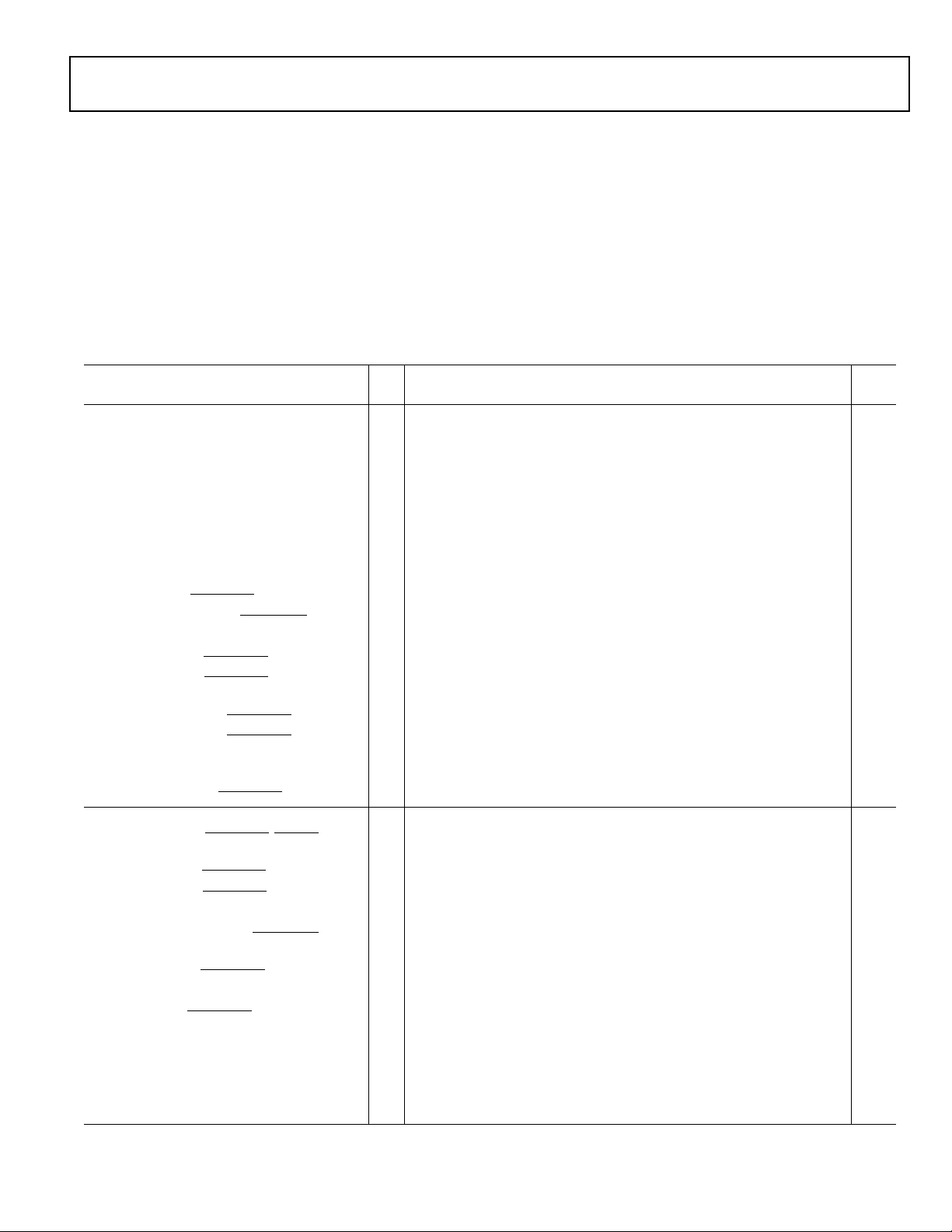

Blackfin

SPORT0

VOLTAGE REGULATOR INTERFACE

PORT F

JTAG TEST AND EMULATION

PERIPHERAL

ACCESS BUS

WATCHDOG TIMER

PPI

SPI0

SPI1

BOOT

ROM

DMA

ACCESS

BUS

INTERRUPT

CONTROLLER

DMA

CONTROLLER

L1 DATA

SRAM

L1 INSTRUCTION

SRAM

DCB

B

UART

DEB

TIMER2–0

L1 INSTRUCTION

ROM

GPIO

SPORT1

TWI

PORT G

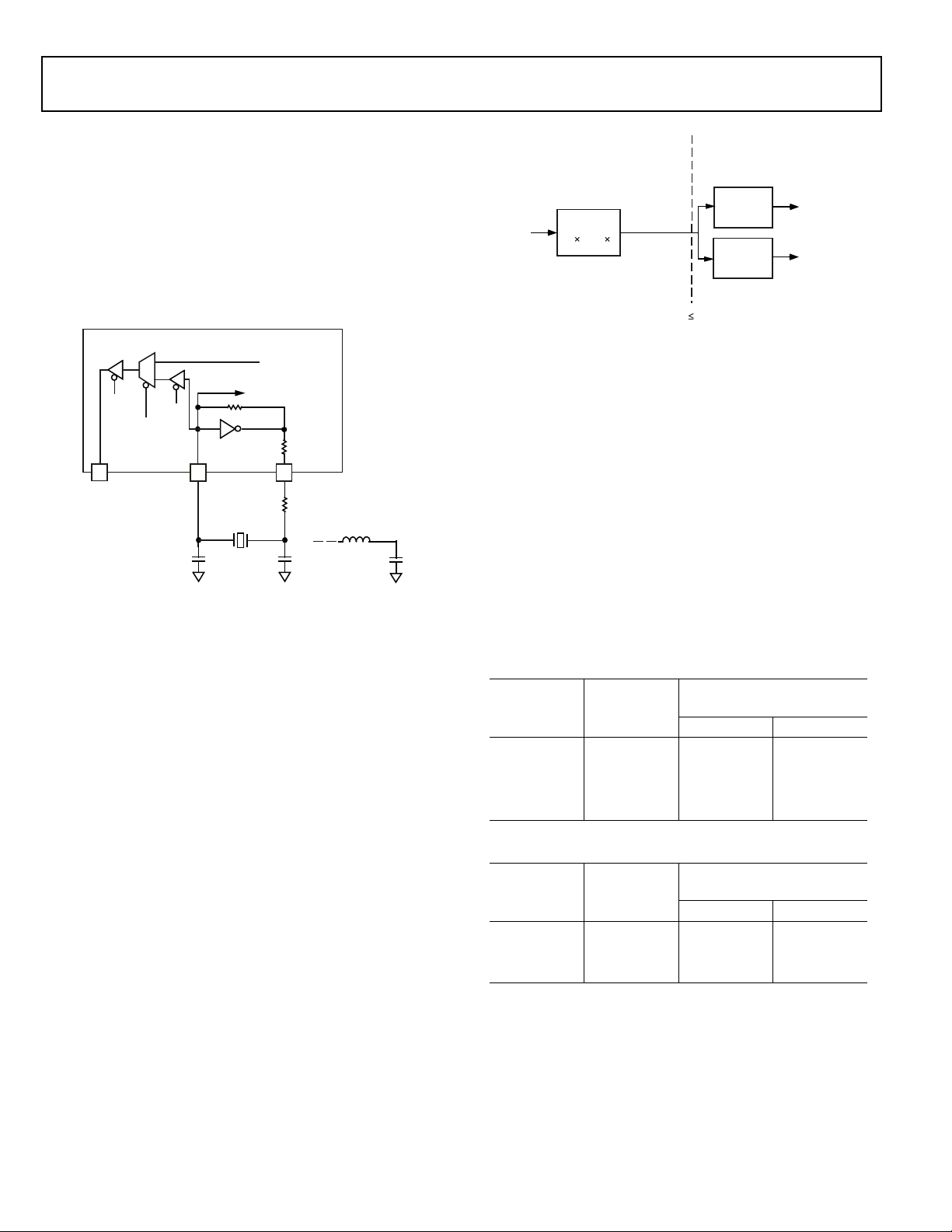

Embedded Processor

ADSP-BF592

FEATURES

Up to 400 MHz high performance Blackfin processor

Two 16-bit MACs, two 40-bit ALUs, four 8-bit video ALUs,

40-bit shifter

RISC-like register and instruction model for ease of

programming and compiler-friendly support

Advanced debug, trace, and performance monitoring

Accepts a wide range of supply voltages for internal and I/O

operations, see Operating Conditions on Page 15

Off-chip voltage regulator interface

64-lead (9 mm × 9 mm) LFCSP package

MEMORY

68K bytes of core-accessible memory

(See Table 1 on Page 3 for L1 and L3 memory size details)

64K byte L1 instruction ROM

Flexible booting options from internal L1 ROM and SPI mem-

ory or from host devices including SPI, PPI, and UART

Memory management unit providing memory protection

PERIPHERALS

Four 32-bit timers/counters, three with PWM support

2 dual-channel, full-duplex synchronous serial ports (SPORT),

supporting eight stereo I

2 serial peripheral interface (SPI) compatible ports

1 UART with IrDA support

Parallel peripheral interface (PPI), supporting ITU-R 656

video data formats

2-wire interface (TWI) controller

9 peripheral DMAs

2 memory-to-memory DMA channels

Event handler with 28 interrupt inputs

32 general-purpose I/Os (GPIOs), with programmable

hysteresis

Debug/JTAG interface

On-chip PLL capable of frequency multiplication

2

S channels

Blackfin and the Blackfin logo are registered trademarks of Analog Devices, Inc.

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

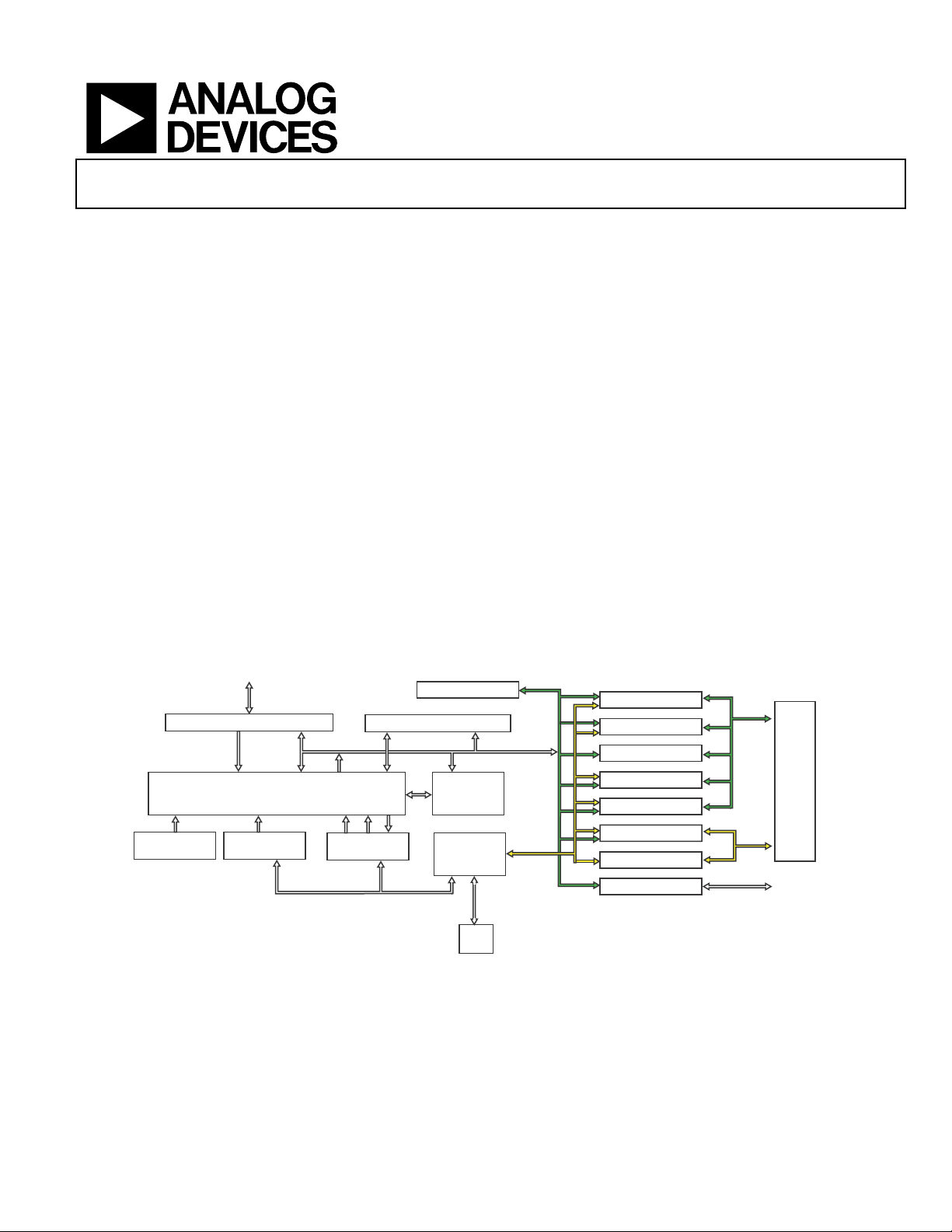

Figure 1. Processor Block Diagram

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106 U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 © 2011 Analog Devices, Inc. All rights reserved.

ADSP-BF592

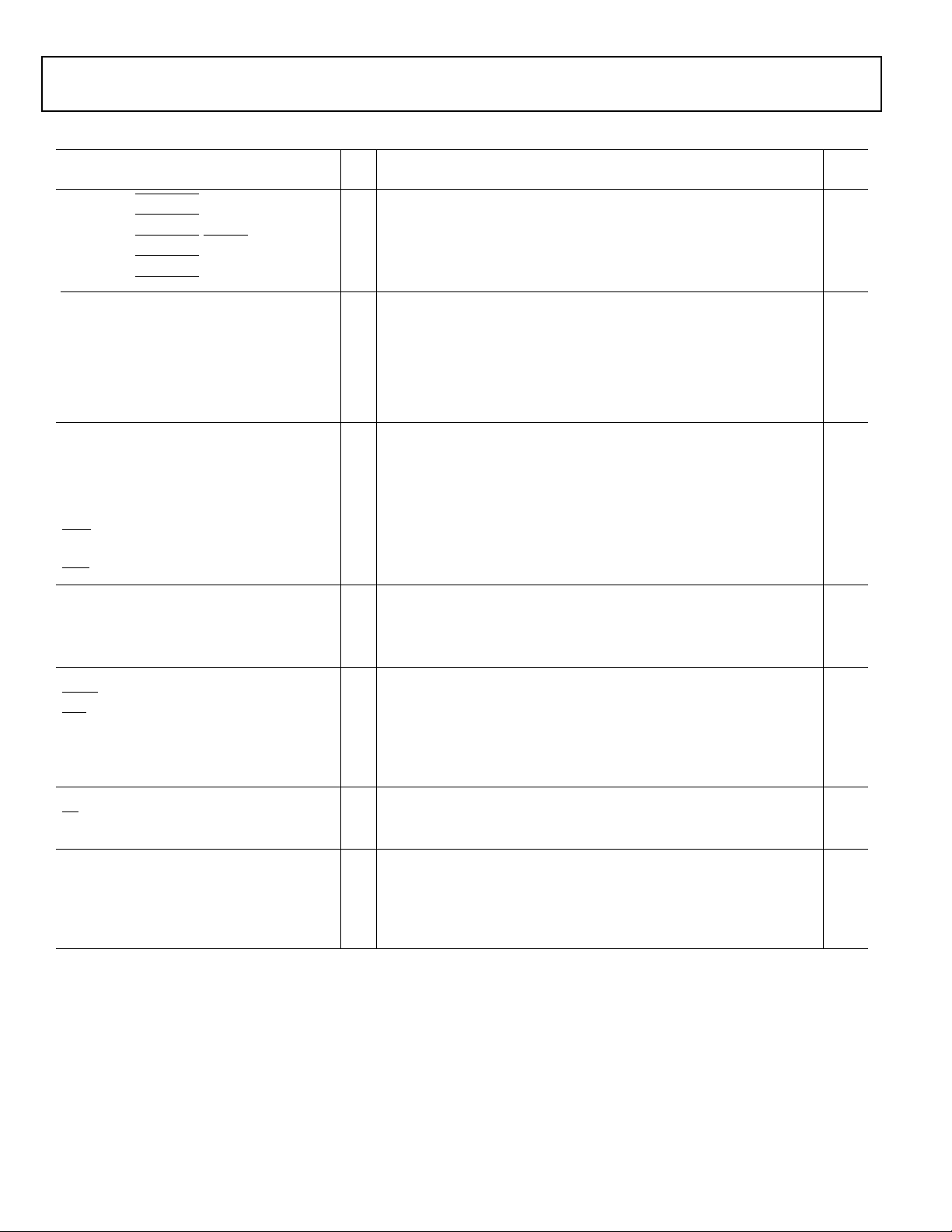

TABLE OF CONTENTS

Features ................................................................. 1

Memory ................................................................ 1

Peripherals ............................................................. 1

General Description ................................................. 3

Portable Low Power Architecture ............................. 3

System Integration ................................................ 3

Blackfin Processor Core .......................................... 3

Memory Architecture ............................................ 5

Event Handling .................................................... 5

DMA Controllers .................................................. 6

Processor Peripherals ............................................. 6

Dynamic Power Management .................................. 8

Voltage Regulation ................................................ 9

Clock Signals ....................................................... 9

Booting Modes ................................................... 11

Instruction Set Description ................................... 12

Development Tools ............................................. 12

Designing an Emulator-Compatible

Processor Board (Target) ................................... 12

Related Documents .............................................. 12

Related Signal Chains ........................................... 12

Signal Descriptions ................................................. 13

Specifications ........................................................ 15

Operating Conditions ........................................... 15

Electrical Characteristics ....................................... 17

Absolute Maximum Ratings ................................... 19

ESD Sensitivity ................................................... 19

Package Information ............................................ 20

Timing Specifications ........................................... 21

Output Drive Currents ......................................... 35

Test Conditions .................................................. 36

Environmental Conditions .................................... 39

64-Lead LFCSP Lead Assignment ............................... 40

Outline Dimensions ................................................ 42

Automotive Products .............................................. 42

Ordering Guide ..................................................... 42

REVISION HISTORY

Rev. 0 to Rev. A

Added 200 MHz model to Electrical Characteristics ....... 17

Added 200 MHz model to Ordering Guide ................... 43

Rev. A | Page 2 of 44 | August 2011

GENERAL DESCRIPTION

ADSP-BF592

The ADSP-BF592 processor is a member of the Blackfin® family

of products, incorporating the Analog Devices/Intel Micro

Signal Architecture (MSA). Blackfin processors combine a dualMAC state-of-the-art signal processing engine, the advantages

of a clean, orthogonal RISC-like microprocessor instruction set,

and single-instruction, multiple-data (SIMD) multimedia capabilities into a single instruction-set architecture.

The ADSP-BF592 processor is completely code compatible with

other Blackfin processors. The ADSP-BF592 processor offers

performance up to 400 MHz and reduced static power consumption. The processor features are shown in Table 1.

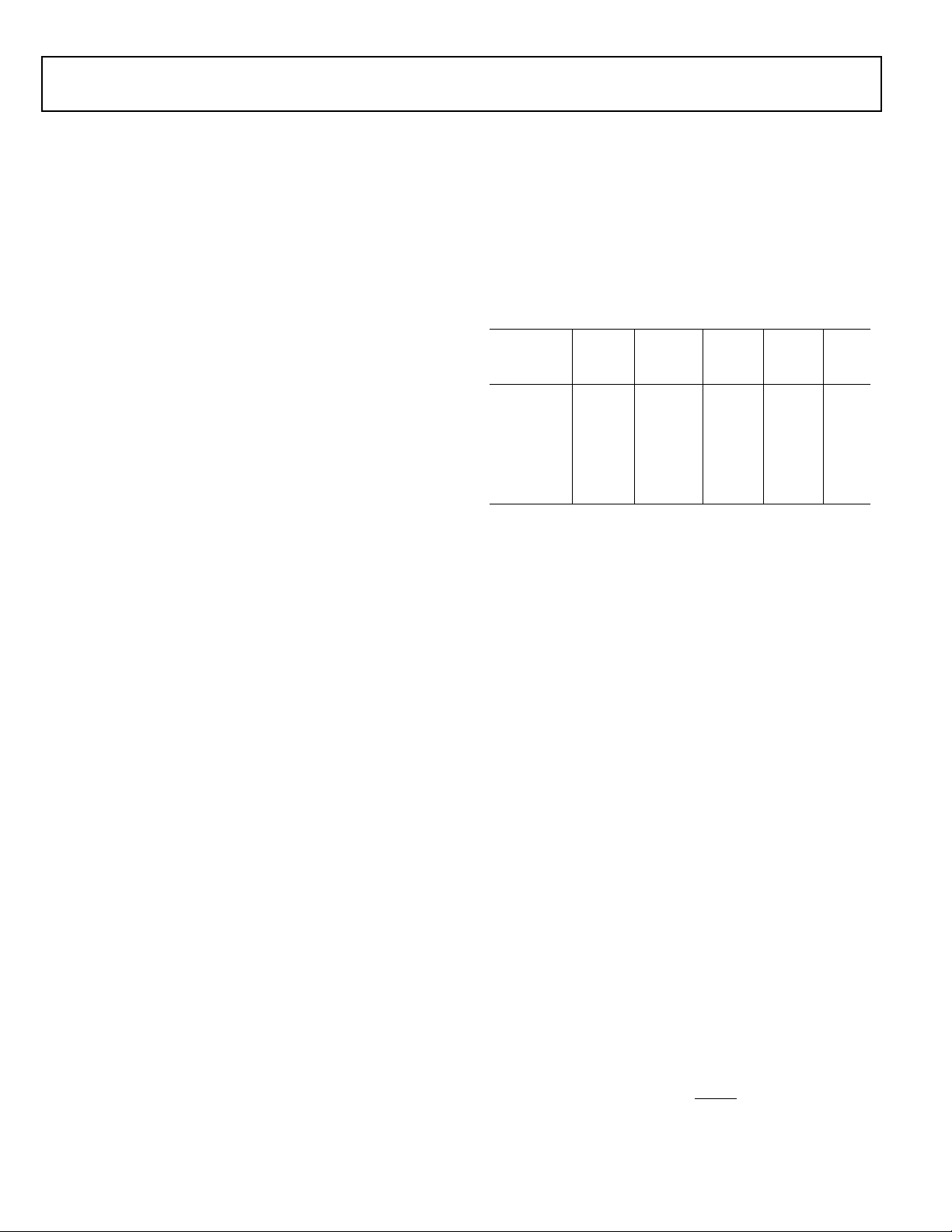

Table 1. Processor Features

Feature ADSP-BF592

Timer/Counters with PWM 3

SPORTs 2

SPIs 2

UART 1

Parallel Peripheral Interface 1

TWI 1

GPIOs 32

L1 Instruction SRAM 32K

L1 Instruction ROM 64K

L1 Data SRAM 32K

L1 Scratchpad SRAM 4K

Memory (bytes)

L3 Boot ROM 4K

Maximum Instruction Rate

Maximum System Clock Speed 100 MHz

Package Options 64-Lead LFCSP

1

Maximum instruction rate is not available with every possible SCLK selection.

1

400 MHz

By integrating a rich set of industry-leading system peripherals

and memory, Blackfin processors are the platform of choice for

next-generation applications that require RISC-like programmability, multimedia support, and leading-edge signal

processing in one integrated package.

PORTABLE LOW POWER ARCHITECTURE

Blackfin processors provide world-class power management

and performance. They are produced with a low power and low

voltage design methodology and feature on-chip dynamic

power management, which provides the ability to vary both the

voltage and frequency of operation to significantly lower overall

power consumption. This capability can result in a substantial

reduction in power consumption, compared with just varying

the frequency of operation. This allows longer battery life for

portable appliances.

head looping. The architecture is fully interlocked, meaning that

the programmer need not manage the pipeline when executing

SYSTEM INTEGRATION

The ADSP-BF592 processor is a highly integrated system-on-achip solution for the next generation of digital communication

and consumer multimedia applications. By combining industry

standard interfaces with a high performance signal processing

core, cost-effective applications can be developed quickly, without the need for costly external components. The system

peripherals include a watchdog timer; three 32-bit timers/counters with PWM support; two dual-channel, full-duplex

synchronous serial ports (SPORTs); two serial peripheral interface (SPI) compatible ports; one UART

®

with IrDA support; a

parallel peripheral interface (PPI); and a 2-wire interface (TWI)

controller.

BLACKFIN PROCESSOR CORE

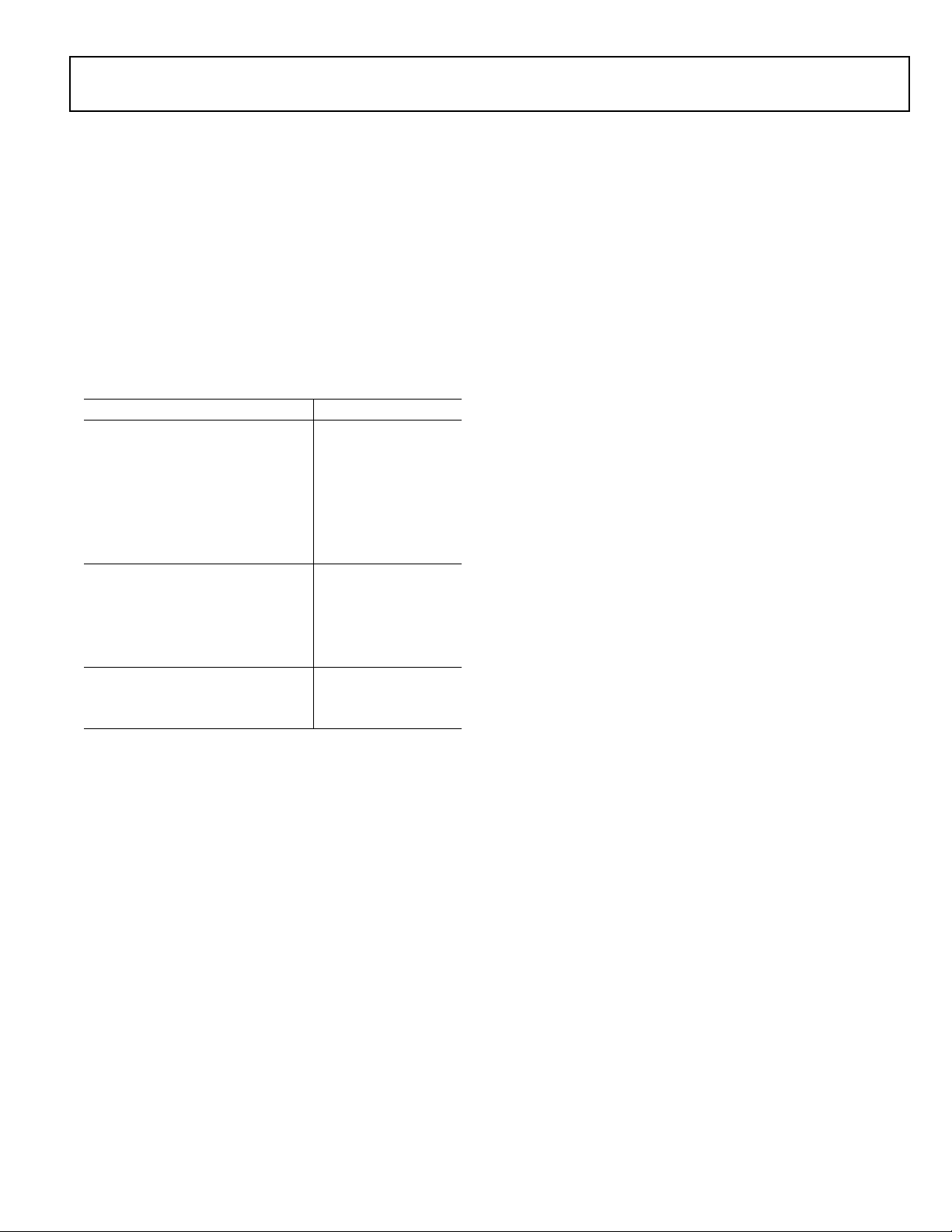

As shown in Figure 2, the Blackfin processor core contains two

16-bit multipliers, two 40-bit accumulators, two 40-bit ALUs,

four video ALUs, and a 40-bit shifter. The computation units

process 8-, 16-, or 32-bit data from the register file.

The compute register file contains eight 32-bit registers. When

performing compute operations on 16-bit operand data, the

register file operates as 16 independent 16-bit registers. All

operands for compute operations come from the multiported

register file and instruction constant fields.

Each MAC can perform a 16-bit by 16-bit multiply in each

cycle, accumulating the results into the 40-bit accumulators.

Signed and unsigned formats, rounding, and saturation

are supported.

The ALUs perform a traditional set of arithmetic and logical

operations on 16-bit or 32-bit data. In addition, many special

instructions are included to accelerate various signal processing

tasks. These include bit operations such as field extract and population count, modulo 2

and rounding, and sign/exponent detection. The set of video

instructions includes byte alignment and packing operations,

16-bit and 8-bit adds with clipping, 8-bit average operations,

and 8-bit subtract/absolute value/accumulate (SAA) operations.

The compare/select and vector search instructions are also

provided.

For certain instructions, two 16-bit ALU operations can be performed simultaneously on register pairs (a 16-bit high half and

16-bit low half of a compute register). If the second ALU is used,

quad 16-bit operations are possible.

The 40-bit shifter can perform shifts and rotates and is used to

support normalization, field extract, and field deposit

instructions.

The program sequencer controls the flow of instruction execution, including instruction alignment and decoding. For

program flow control, the sequencer supports PC relative and

indirect conditional jumps (with static branch prediction) and

subroutine calls. Hardware is provided to support zero over

instructions with data dependencies.

32

multiply, divide primitives, saturation

Rev. A | Page 3 of 44 | August 2011

ADSP-BF592

SEQUENCER

ALIGN

DECODE

LOOP BUFFER

16

16

8888

40 40

A0 A1

BARREL

SHIFTER

DATA ARITHMETIC UNIT

CONTROL

UNIT

R7.H

R6.H

R5.H

R4.H

R3.H

R2.H

R1.H

R0.H

R7.L

R6.L

R5.L

R4.L

R3.L

R2.L

R1.L

R0.L

AS TAT

40 40

32

32

32

32

32

32

32LD0

LD1

SD

DAG0

DAG1

ADDRESS ARITHMETIC UNIT

I3

I2

I1

I0

L3

L2

L1

L0

B3

B2

B1

B0

M3

M2

M1

M0

SP

FP

P5

P4

P3

P2

P1

P0

DA1

DA0

32

32

32

PREG

RAB

32

TO MEMORY

The address arithmetic unit provides two addresses for simultaneous dual fetches from memory. It contains a multiported

register file consisting of four sets of 32-bit index, modify,

length, and base registers (for circular buffering) and eight

additional 32-bit pointer registers (for C-style indexed stack

manipulation).

Blackfin processors support a modified Harvard architecture in

combination with a hierarchical memory structure. Level 1 (L1)

memories are those that typically operate at the full processor

speed with little or no latency. At the L1 level, the instruction

memory holds instructions only. Data memory holds data, and

a dedicated scratchpad data memory stores stack and local variable information.

Multiple L1 memory blocks are provided. The memory

management unit (MMU) provides memory protection for

individual tasks that may be operating on the core and can

protect system registers from unintended access.

The architecture provides three modes of operation: user mode,

supervisor mode, and emulation mode. User mode has

restricted access to certain system resources, thus providing a

protected software environment, while supervisor mode has

unrestricted access to the system and core resources.

The Blackfin processor instruction set has been optimized so

that 16-bit opcodes represent the most frequently used instructions, resulting in excellent compiled code density. Complex

DSP instructions are encoded into 32-bit opcodes, representing

fully featured multifunction instructions. Blackfin processors

support a limited multi-issue capability, where a 32-bit instruction can be issued in parallel with two 16-bit instructions,

allowing the programmer to use many of the core resources in a

single instruction cycle.

The Blackfin processor assembly language uses an algebraic syntax for ease of coding and readability. The architecture has been

optimized for use in conjunction with the C/C++ compiler,

resulting in fast and efficient software implementations.

Figure 2. Blackfin Processor Core

Rev. A | Page 4 of 44 | August 2011

ADSP-BF592

0x0000 0000

0xEF00 0000

0xFF80 0000

0xFF80 8000

0xFFA0 0000

0xFFA0 8000

0xFFA1 0000

0xFFA2 0000

0xFFB0 0000

0xFFB0 1000

0xFFC0 0000

0xFFE0 0000

BOOT ROM (4K BYTES)

RESERVED

L1 INSTRUCTION ROM (64K BYTES)

RESERVED

L1 SCRATCHPAD RAM (4K BYTES)

RESERVED

SYSTEM MEMORY MAPPED REGISTERS (2M BYTES)

CORE MEMORY MAPPED REGISTERS (2M BYTES)

RESERVED

DATA SRAM (32K BYTES)

RESERVED

L1 INSTRUCTION BANK B SRAM (16K BYTES)

RESERVED

0xEF00 1000

0xFFFF FFFF

L1 INSTRUCTION BANK A SRAM (16K BYTES)

0xFFA0 4000

MEMORY ARCHITECTURE

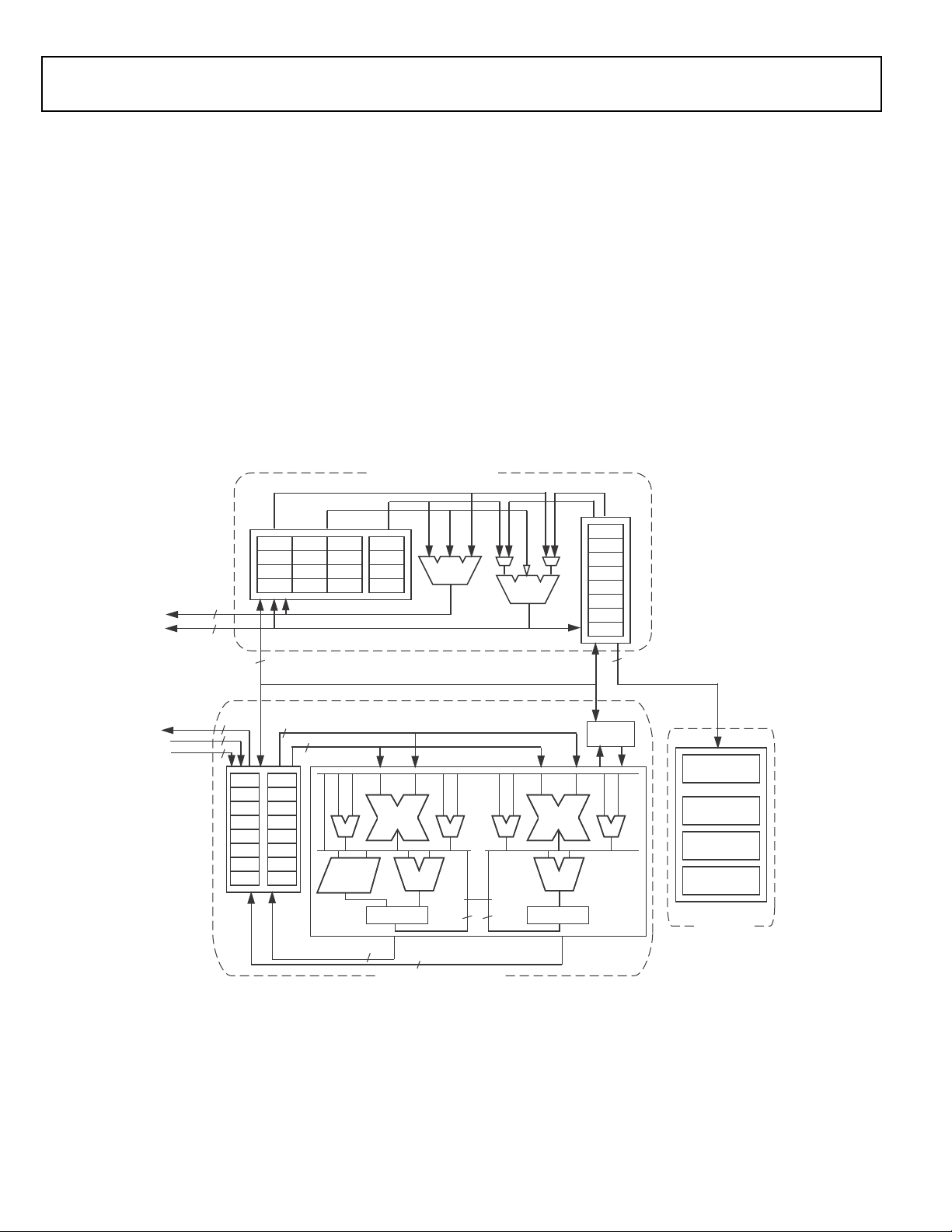

The Blackfin processor views memory as a single unified

4G byte address space, using 32-bit addresses. All resources,

including internal memory and I/O control registers, occupy

separate sections of this common address space. See Figure 3.

The core-accessible L1 memory system is high performance

internal memory that operates at the core clock frequency. The

external bus interface unit (EBIU) provides access to the boot

ROM.

The memory DMA controller provides high bandwidth datamovement capability. It can perform block transfers of code or

data between the L1 Instruction SRAM and L1 Data SRAM

memory spaces.

Custom ROM (Optional)

The on-chip L1 Instruction ROM on the ADSP-BF592 may be

customized to contain user code with the following features:

• 64K bytes of L1 Instruction ROM available for custom code

• Ability to restrict access to all or specific segments of the

on-chip ROM

Customers wishing to customize the on-chip ROM for their

own application needs should contact ADI sales for more information on terms and conditions and details on the technical

implementation.

I/O Memory Space

The processor does not define a separate I/O space. All

resources are mapped through the flat 32-bit address space.

On-chip I/O devices have their control registers mapped into

memory-mapped registers (MMRs) at addresses near the top of

the 4G byte address space. These are separated into two smaller

blocks, one which contains the control MMRs for all core functions, and the other which contains the registers needed for

setup and control of the on-chip peripherals outside of the core.

The MMRs are accessible only in supervisor mode and appear

as reserved space to on-chip peripherals.

Booting from ROM

The processor contains a small on-chip boot kernel, which configures the appropriate peripheral for booting. If the processor is

configured to boot from boot ROM memory space, the processor starts executing from the on-chip boot ROM. For more

information, see Booting Modes on Page 11.

Figure 3. Internal/External Memory Map

Internal (Core-Accessible) Memory

The processor has three blocks of core-accessible memory, providing high bandwidth access to the core.

The first block is the L1 instruction memory, consisting of

32K bytes SRAM. This memory is accessed at full processor

speed.

The second core-accessible memory block is the L1 data memory, consisting of 32K bytes. This memory block is accessed at

full processor speed.

The third memory block is a 4K byte L1 scratchpad SRAM,

which runs at the same speed as the other L1 memories.

L1 Utility ROM

The L1 instruction ROM contains utility ROM code. This

includes the TMK (VDK core), C run-time libraries, and DSP

libraries. See the VisualDSP++ documentation for more

information.

Rev. A | Page 5 of 44 | August 2011

EVENT HANDLING

The event controller on the processor handles all asynchronous

and synchronous events to the processor. The processor

provides event handling that supports both nesting and prioritization. Nesting allows multiple event service routines to be

active simultaneously. Prioritization ensures that servicing of a

higher-priority event takes precedence over servicing of a lowerpriority event. The controller provides support for five different

types of events:

• Emulation – An emulation event causes the processor to

enter emulation mode, allowing command and control of

the processor via the JTAG interface.

• RESET

• Nonmaskable Interrupt (NMI) – The NMI event can be

– This event resets the processor.

generated by the software watchdog timer or by the NMI

input signal to the processor. The NMI event is frequently

used as a power-down indicator to initiate an orderly shutdown of the system.

ADSP-BF592

• Exceptions – Events that occur synchronously to program

flow (in other words, the exception is taken before the

instruction is allowed to complete). Conditions such as

data alignment violations and undefined instructions cause

exceptions.

• Interrupts – Events that occur asynchronously to program

flow. They are caused by input signals, timers, and other

peripherals, as well as by an explicit software instruction.

Each event type has an associated register to hold the return

address and an associated return-from-event instruction. When

an event is triggered, the state of the processor is saved on the

supervisor stack.

The processor event controller consists of two stages: the core

event controller (CEC) and the system interrupt controller

(SIC). The core event controller works with the system interrupt

controller to prioritize and control all system events. Conceptually, interrupts from the peripherals enter into the SIC and are

then routed directly into the general-purpose interrupts of the

CEC.

Core Event Controller (CEC)

The CEC supports nine general-purpose interrupts (IVG15–7),

in addition to the dedicated interrupt and exception events. Of

these general-purpose interrupts, the two lowest priority

interrupts (IVG15–14) are recommended to be reserved for

software interrupt handlers, leaving seven prioritized interrupt

inputs to support the peripherals of the processor. The inputs to

the CEC, their names in the event vector table (EVT), and their

priorities are described in the ADSP-BF59x Blackfin Processor

Hardware Reference, “System Interrupts” chapter.

System Interrupt Controller (SIC)

The system interrupt controller provides the mapping and routing of events from the many peripheral interrupt sources to the

prioritized general-purpose interrupt inputs of the CEC.

Although the processor provides a default mapping, the user

can alter the mappings and priorities of interrupt events by writing the appropriate values into the interrupt assignment

registers (SIC_IARx). The inputs into the SIC and the default

mappings into the CEC are described in the ADSP-BF59x Black-

fin Processor Hardware Reference, “System Interrupts” chapter.

The SIC allows further control of event processing by providing

three pairs of 32-bit interrupt control and status registers. Each

register contains a bit, corresponding to each peripheral interrupt event. For more information, see the ADSP-BF59x Blackfin

Processor Hardware Reference, “System Interrupts” chapter.

DMA CONTROLLERS

The processor has multiple, independent DMA channels that

support automated data transfers with minimal overhead for

the processor core. DMA transfers can occur between the processor’s internal memories and any of its DMA-capable

peripherals. DMA-capable peripherals include the SPORTs, SPI

ports, UART, and PPI. Each individual DMA-capable peripheral has at least one dedicated DMA channel.

The processor DMA controller supports both one-dimensional

(1-D) and two-dimensional (2-D) DMA transfers. DMA transfer initialization can be implemented from registers or from sets

of parameters called descriptor blocks.

The 2-D DMA capability supports arbitrary row and column

sizes up to 64K elements by 64K elements, and arbitrary row

and column step sizes up to ±32K elements. Furthermore, the

column step size can be less than the row step size, allowing

implementation of interleaved data streams. This feature is

especially useful in video applications where data can be deinterleaved on the fly.

Examples of DMA types supported by the processor DMA controller include:

• A single, linear buffer that stops upon completion

• A circular, auto-refreshing buffer that interrupts on each

full or fractionally full buffer

• 1-D or 2-D DMA using a linked list of descriptors

• 2-D DMA using an array of descriptors, specifying only the

base DMA address within a common page

In addition to the dedicated peripheral DMA channels, there are

two memory DMA channels, which are provided for transfers

between the various memories of the processor system with

minimal processor intervention. Memory DMA transfers can be

controlled by a very flexible descriptor-based methodology or

by a standard register-based autobuffer mechanism.

PROCESSOR PERIPHERALS

The ADSP-BF592 processor contains a rich set of peripherals

connected to the core via several high bandwidth buses, providing flexibility in system configuration, as well as excellent

overall system performance (see Figure 1). The processor also

contains dedicated communication modules and high speed

serial and parallel ports, an interrupt controller for flexible management of interrupts from the on-chip peripherals or external

sources, and power management control functions to tailor the

performance and power characteristics of the processor and system to many application scenarios.

The SPORTs, SPIs, UART, and PPI peripherals are supported

by a flexible DMA structure. There are also separate memory

DMA channels dedicated to data transfers between the processor’s various memory spaces, including boot ROM. Multiple

on-chip buses running at up to 100 MHz provide enough bandwidth to keep the processor core running along with activity on

all of the on-chip and external peripherals.

The ADSP-BF592 processor includes an interface to an off-chip

voltage regulator in support of the processor’s dynamic power

management capability.

Watchdog Timer

The processor includes a 32-bit timer that can be used to implement a software watchdog function. A software watchdog can

improve system availability by forcing the processor to a known

state through generation of a hardware reset, nonmaskable

interrupt (NMI), or general-purpose interrupt, if the timer

expires before being reset by software. The programmer

Rev. A | Page 6 of 44 | August 2011

ADSP-BF592

initializes the count value of the timer, enables the appropriate

interrupt, then enables the timer. Thereafter, the software must

reload the counter before it counts to zero from the programmed value. This protects the system from remaining in an

unknown state where software, which would normally reset the

timer, has stopped running due to an external noise condition

or software error.

If configured to generate a hardware reset, the watchdog timer

resets both the core and the processor peripherals. After a reset,

software can determine whether the watchdog was the source of

the hardware reset by interrogating a status bit in the watchdog

timer control register.

The timer is clocked by the system clock (SCLK) at a maximum

frequency of f

SCLK

.

Timers

There are four general-purpose programmable timer units in

the processor. Three timers have an external pin that can be

configured either as a pulse width modulator (PWM) or timer

output, as an input to clock the timer, or as a mechanism for

measuring pulse widths and periods of external events. These

timers can be synchronized to an external clock input to the several other associated PF pins, to an external clock input to the

PPI_CLK input pin, or to the internal SCLK.

The timer units can be used in conjunction with the UART to

measure the width of the pulses in the data stream to provide a

software auto-baud detect function for the respective serial

channels.

The timers can generate interrupts to the processor core providing periodic events for synchronization, either to the system

clock or to a count of external signals.

In addition to the three general-purpose programmable timers,

a fourth timer is also provided. This extra timer is clocked by the

internal processor clock and is typically used as a system tick

clock for generation of operating system periodic interrupts.

Serial Ports

The ADSP-BF592 processor incorporates two dual-channel

synchronous serial ports (SPORT0 and SPORT1) for serial and

multiprocessor communications. The SPORTs support the following features:

Serial port data can be automatically transferred to and from

on-chip memory/external memory via dedicated DMA channels. Each of the serial ports can work in conjunction with

another serial port to provide TDM support. In this configuration, one SPORT provides two transmit signals while the other

SPORT provides the two receive signals. The frame sync and

clock are shared.

Serial ports operate in five modes:

• Standard DSP serial mode

• Multichannel (TDM) mode

2

S mode

•I

2

•Packed I

S mode

•Left-justified mode

Serial Peripheral Interface (SPI) Ports

The processor has two SPI-compatible ports that enable the

processor to communicate with multiple SPI-compatible

devices.

The SPI interface uses three pins for transferring data: two data

pins (Master Output-Slave Input, MOSI, and Master InputSlave Output, MISO) and a clock pin (serial clock, SCK). An SPI

chip select input pin (SPIx_SS

) lets other SPI devices select the

processor, and many SPI chip select output pins (SPIx_SEL7–1

let the processor select other SPI devices. The SPI select pins are

reconfigured general-purpose I/O pins. Using these pins, the

SPI port provides a full-duplex, synchronous serial interface,

which supports both master/slave modes and multimaster

environments.

UART Port

The ADSP-BF592 processor provides a full-duplex universal

asynchronous receiver/transmitter (UART) port, which is fully

compatible with PC-standard UARTs. The UART port provides

a simplified UART interface to other peripherals or hosts,

supporting full-duplex, DMA-supported, asynchronous transfers of serial data. The UART port includes support for five to

eight data bits, one or two stop bits, and none, even, or odd parity. The UART port supports two modes of operation:

• PIO (programmed I/O) – The processor sends or receives

data by writing or reading I/O mapped UART registers.

The data is double-buffered on both transmit and receive.

• DMA (direct memory access) – The DMA controller transfers both transmit and receive data. This reduces the

number and frequency of interrupts required to transfer

data to and from memory. The UART has two dedicated

DMA channels, one for transmit and one for receive. These

DMA channels have lower default priority than most DMA

channels because of their relatively low service rates.

Parallel Peripheral Interface (PPI)

The processor provides a parallel peripheral interface (PPI) that

can connect directly to parallel analog-to-digital and digital-toanalog converters, video encoders and decoders, and other general-purpose peripherals. The PPI consists of a dedicated input

clock pin, up to three frame synchronization pins, and up to 16

data pins. The input clock supports parallel data rates up to half

the system clock rate, and the synchronization signals can be

configured as either inputs or outputs.

The PPI supports a variety of general-purpose and ITU-R 656

modes of operation. In general-purpose mode, the PPI provides

half-duplex, bidirectional data transfer with up to 16 bits of

data. Up to three frame synchronization signals are also provided. In ITU-R 656 mode, the PPI provides half-duplex

bidirectional transfer of 8- or 10-bit video data. Additionally,

on-chip decode of embedded start-of-line (SOL) and start-offield (SOF) preamble packets is supported.

)

Rev. A | Page 7 of 44 | August 2011

ADSP-BF592

General-Purpose Mode Descriptions

The general-purpose modes of the PPI are intended to suit a

wide variety of data capture and transmission applications.

Three distinct submodes are supported:

• Input mode – Frame syncs and data are inputs into the PPI.

Input mode is intended for ADC applications, as well as

video communication with hardware signaling.

• Frame capture mode – Frame syncs are outputs from the

PPI, but data are inputs. This mode allows the video

source(s) to act as a slave (for frame capture for example).

• Output mode – Frame syncs and data are outputs from the

PPI. Output mode is used for transmitting video or other

data with up to three output frame syncs.

ITU-R 656 Mode Descriptions

The ITU-R 656 modes of the PPI are intended to suit a wide

variety of video capture, processing, and transmission applications. Three distinct submodes are supported:

• Active video only mode – Active video only mode is used

when only the active video portion of a field is of interest

and not any of the blanking intervals.

• Vertical blanking only mode – In this mode, the PPI only

transfers vertical blanking interval (VBI) data.

• Entire field mode – In this mode, the entire incoming bit

stream is read in through the PPI.

TWI Controller Interface

The processor includes a 2-wire interface (TWI) module for

providing a simple exchange method of control data between

multiple devices. The TWI is functionally compatible with the

widely used I

capabilities of simultaneous master and slave operation and

support for both 7-bit addressing and multimedia data arbitration. The TWI interface utilizes two pins for transferring clock

(SCL) and data (SDA) and supports the protocol at speeds up to

400K bits/sec.

The TWI module is compatible with serial camera control bus

(SCCB) functionality for easier control of various CMOS camera sensor devices.

2

C® bus standard. The TWI module offers the

Ports

The processor groups the many peripheral signals to two

ports—Port F and Port G. Most of the associated pins are shared

by multiple signals. The ports function as multiplexer controls.

General-Purpose I/O (GPIO)

The processor has 32 bidirectional, general-purpose I/O (GPIO)

pins allocated across two separate GPIO modules—PORTFIO

and PORTGIO, associated with Port F and Port G respectively.

Each GPIO-capable pin shares functionality with other processor peripherals via a multiplexing scheme; however, the GPIO

functionality is the default state of the device upon power-up.

Neither GPIO output nor input drivers are active by default.

Each general-purpose port pin can be individually controlled by

manipulation of the port control, status, and interrupt registers.

DYNAMIC POWER MANAGEMENT

The processor provides five operating modes, each with a different performance/power profile. In addition, dynamic power

management provides the control functions to dynamically alter

the processor core supply voltage, further reducing power dissipation. When configured for a 0 V core supply voltage, the

processor enters the hibernate state. Control of clocking to each

of the processor peripherals also reduces power consumption.

See Table 2 for a summary of the power settings for each mode.

Table 2. Power Settings

Core

PLL

Mode/State PLL

Full On Enabled No Enabled Enabled On

Active Enabled/

Disabled

Sleep Enabled — Disabled Enabled On

Deep Sleep Disabled — Disabled Disabled On

Hibernate Disabled — Disabled Disabled Off

Bypassed

Yes En ab le d En ab led O n

Clock

(CCLK)

Full-On Operating Mode—Maximum Performance

In the full-on mode, the PLL is enabled and is not bypassed,

providing capability for maximum operational frequency. This

is the power-up default execution state in which maximum performance can be achieved. The processor core and all enabled

peripherals run at full speed.

Active Operating Mode—Moderate Dynamic Power Savings

In the active mode, the PLL is enabled but bypassed. Because the

PLL is bypassed, the processor’s core clock (CCLK) and system

clock (SCLK) run at the input clock (CLKIN) frequency. DMA

access is available to appropriately configured L1 memories.

For more information about PLL controls, see the “Dynamic

Power Management” chapter in the ADSP-BF59x Blackfin Pro-

cessor Hardware Reference.

Sleep Operating Mode—High Dynamic Power Savings

The sleep mode reduces dynamic power dissipation by disabling

the clock to the processor core (CCLK). The PLL and system

clock (SCLK), however, continue to operate in this mode. Typically, an external event wakes up the processor.

System DMA access to L1 memory is not supported in

sleep mode.

Deep Sleep Operating Mode—Maximum Dynamic Power Savings

The deep sleep mode maximizes dynamic power savings by disabling the clocks to the processor core (CCLK) and to all

synchronous peripherals (SCLK). Asynchronous peripherals

may still be running but cannot access internal resources or

external memory. This powered-down mode can only be exited

by assertion of the reset interrupt (RESET

nous interrupt generated by a GPIO pin.

System

Clock

(SCLK)

) or by an asynchro-

Core

Power

Rev. A | Page 8 of 44 | August 2011

Note that when a GPIO pin is used to trigger wake from deep

Power Savings Factor

f

CCLKRED

f

CCLKNOM

--------------------

V

DDINTRED

V

DDINTNOM

------------------------

2

×

T

RED

T

NOM

------------

×

=

% Power Savings 1 Power Savings Factor–()100%×=

sleep, the programmed wake level must linger for at least 10ns

to guarantee detection.

Hibernate State—Maximum Static Power Savings

The hibernate state maximizes static power savings by disabling

clocks to the processor core (CCLK) and to all of the peripherals

(SCLK), as well as signaling an external voltage regulator that

V

can be shut off. Any critical information stored inter-

DDINT

nally (for example, memory contents, register contents, and

other information) must be written to a nonvolatile storage

device prior to removing power if the processor state is to be

preserved. Writing b#0 to the HIBERNATE

bit causes

EXT_WAKE to transition low, which can be used to signal an

external voltage regulator to shut down.

Since V

can still be supplied in this mode, all of the exter-

DDEXT

nal pins three-state, unless otherwise specified. This allows

other devices that may be connected to the processor to still

have power applied without drawing unwanted current.

As long as V

is applied, the VR_CTL register maintains its

DDEXT

state during hibernation. All other internal registers and memories, however, lose their content in the hibernate state.

Power Savings

As shown in Table 3, the processor supports two different

power domains, which maximizes flexibility while maintaining

compliance with industry standards and conventions. By isolating the internal logic of the processor into its own power

domain, separate from other I/O, the processor can take advantage of dynamic power management without affecting the other

I/O devices. There are no sequencing requirements for the

various power domains, but all domains must be powered

according to the appropriate Specifications table for processor

operating conditions, even if the feature/peripheral is not used.

Table 3. Power Domains

Power Domain VDD Range

All internal logic and memories V

All other I/O V

DDINT

DDEXT

The dynamic power management feature of the processor

allows both the processor’s input voltage (V

quency (f

) to be dynamically controlled.

CCLK

) and clock fre-

DDINT

The power dissipated by a processor is largely a function of its

clock frequency and the square of the operating voltage. For

example, reducing the clock frequency by 25% results in a 25%

reduction in dynamic power dissipation, while reducing the

voltage by 25% reduces dynamic power dissipation by more

than 40%. Further, these power savings are additive, in that if

the clock frequency and supply voltage are both reduced, the

power savings can be dramatic, as shown in the following

equations.

ADSP-BF592

where:

f

f

V

V

T

T

VOLTAGE REGULATION

The ADSP-BF592 processor requires an external voltage regulator to power the V

consumption, the external voltage regulator can be signaled

through EXT_WAKE to remove power from the processor core.

This signal is high-true for power-up and may be connected

directly to the low-true shut-down input of many common

regulators.

While in the hibernate state, the external supply, V

still be applied, eliminating the need for external buffers. The

external voltage regulator can be activated from this powerdown state by asserting the RESET

boot sequence. EXT_WAKE indicates a wakeup to the external

voltage regulator.

The power good (PG

only after the internal voltage has reached a chosen level. In this

way, the startup time of the external regulator is detected after

hibernation. For a complete description of the power-good

functionality, refer to the ADSP-BF59x Blackfin Processor Hard-

ware Reference.

CLOCK SIGNALS

The processor can be clocked by an external crystal, a sine wave

input, or a buffered, shaped clock derived from an external

clock oscillator.

If an external clock is used, it should be a TTL-compatible signal

and must not be halted, changed, or operated below the specified frequency during normal operation. This signal is

connected to the processor’s CLKIN pin. When an external

clock is used, the XTAL pin must be left unconnected.

Alternatively, because the processor includes an on-chip oscillator circuit, an external crystal may be used. For fundamental

frequency operation, use the circuit shown in Figure 4. A

parallel -resonant, fundamental frequency, microprocessorgrade crystal is connected across the CLKIN and XTAL pins.

The on-chip resistance between CLKIN and the XTAL pin is in

is the nominal core clock frequency

CCLKNOM

is the reduced core clock frequency

CCLKRED

DDINTNOM

DDINTRED

NOM

RED

is the nominal internal supply voltage

is the reduced internal supply voltage

is the duration running at f

is the duration running at f

domain. To reduce standby power

DDINT

) input signal allows the processor to start

CCLKNOM

CCLKRED

, can

DDEXT

pin, which then initiates a

Rev. A | Page 9 of 44 | August 2011

ADSP-BF592

CLKIN

CLKOUT (SCLK)

XTAL

SELECT

CLKBUF

TO PLL CIRCUITRY

FOR OVERTONE

OPERATION ONLY:

NOTE: VALUES MARKED WITH * MUST BE CUSTOMIZED, DEPENDING

ON THE CRYSTAL AND LAYOUT. PLEASE ANALYZE CAREFULLY. FOR

FREQUENCIES ABOVE 33 MHz, THE SUGGESTED CAPACITOR VALUE

OF 18 pF SHOULD BE TREATED AS A MAXIMUM, AND THE SUGGESTED

RESISTOR VALUE SHOULD BE REDUCED TO 0 ⍀.

18 pF *

EN

18 pF *

330 ⍀ *

BLACKFIN

560 ⍀

EXTCLK

EN

PLL

5u

to 64u

÷ 1 to 15

÷ 1, 2, 4, 8

VCO

CLKIN

“FINE” ADJUSTMENT

REQUIRES PLL SEQUENCING

“COARSE” ADJUSTMENT

ON-THE-FLY

CCLK

SCLK

SCLK d CCLK

the 500 kΩ range. Further parallel resistors are typically not recommended. The two capacitors and the series resistor shown in

Figure 4 fine tune phase and amplitude of the sine frequency.

The capacitor and resistor values shown in Figure 4 are typical

values only. The capacitor values are dependent upon the crystal

manufacturers’ load capacitance recommendations and the PCB

physical layout. The resistor value depends on the drive level

specified by the crystal manufacturer. The user should verify the

customized values based on careful investigations on multiple

devices over temperature range.

Figure 5. Frequency Modification Methods

All on-chip peripherals are clocked by the system clock (SCLK).

The system clock frequency is programmable by means of the

SSEL3–0 bits of the PLL_DIV register. The values programmed

into the SSEL fields define a divide ratio between the PLL output

(VCO) and the system clock. SCLK divider values are 1 through

15. Table 4 illustrates typical system clock ratios.

Note that the divisor ratio must be chosen to limit the system

clock frequency to its maximum of f

. The SSEL value can be

SCLK

changed dynamically without any PLL lock latencies by writing

the appropriate values to the PLL divisor register (PLL_DIV).

The core clock (CCLK) frequency can also be dynamically

changed by means of the CSEL1–0 bits of the PLL_DIV register.

Supported CCLK divider ratios are 1, 2, 4, and 8, as shown in

Table 5. This programmable core clock capability is useful for

fast core frequency modifications.

Figure 4. External Crystal Connections

A third-overtone crystal can be used for frequencies above

25 MHz. The circuit is then modified to ensure crystal operation

only at the third overtone, by adding a tuned inductor circuit as

shown in Figure 4. A design procedure for third-overtone operation is discussed in detail in (EE-168) Using Third Overtone

Crystals with the ADSP-218x DSP on the Analog Devices website (www.analog.com)—use site search on “EE-168.”

The Blackfin core runs at a different clock rate than the on-chip

peripherals. As shown in Figure 5, the core clock (CCLK) and

system peripheral clock (SCLK) are derived from the input

clock (CLKIN) signal. An on-chip PLL is capable of multiplying

the CLKIN signal by a programmable 5× to 64× multiplication

factor (bounded by specified minimum and maximum VCO

frequencies). The default multiplier is 6×, but it can be modified

by a software instruction sequence.

On-the-fly frequency changes can be effected by simply writing

to the PLL_DIV register. The maximum allowed CCLK and

SCLK rates depend on the applied voltages V

the VCO is always permitted to run up to the frequency specified by the part’s instruction rate. The EXTCLK pin can be

configured to output either the SCLK frequency or the input

buffered CLKIN frequency, called CLKBUF. When configured

to output SCLK (CLKOUT), the EXTCLK pin acts as a reference signal in many timing specifications. While three-stated by

default, it can be enabled using the VRCTL register.

DDINT

Table 5. Core Clock Ratios

Signal Name

CSEL1–0

00 1:1 300 300

01 2:1 300 150

10 4:1 400 100

11 8:1 200 25

Table 4. Example System Clock Ratios

Signal Name

SSEL3–0

0010 2:1 100 50

0110 6:1 300 50

1010 10:1 400 40

and V

DDEXT

;

The maximum CCLK frequency both depends on the part’s

instruction rate (see Page Page 43) and depends on the applied

V

voltage. See Table 8 for details. The maximal system

DDINT

clock rate (SCLK) depends on the chip package and the applied

and V

V

DDINT

Rev. A | Page 10 of 44 | August 2011

Divider Ratio

VCO/CCLK

Divider Ratio

VCO/SCLK

voltages (see Table 10).

DDEXT

Example Frequency Ratios

(MHz)

VCO CCLK

Example Frequency Ratios

(MHz)

VCO SCLK

ADSP-BF592

BOOTING MODES

The processor has several mechanisms (listed in Table 6) for

automatically loading internal and external memory after a

reset. The boot mode is defined by the BMODE input pins dedicated to this purpose. There are two categories of boot modes.

In master boot modes, the processor actively loads data from

parallel or serial memories. In slave boot modes, the processor

receives data from external host devices.

Table 6. Booting Modes

BMODE2–0 Description

000 Idle/No Boot

001 Reserved

010 SPI1 master boot from Flash, using SPI1_SSEL5

011 SPI1 slave boot from external master

100 SPI0 master boot from Flash, using SPI0_SSEL2

101 Boot from PPI port

110 Boot from UART host device

111 Execute from Internal L1 ROM

The boot modes listed in Table 6 provide a number of mechanisms for automatically loading the processor’s internal and

external memories after a reset. By default, all boot modes use

the slowest meaningful configuration settings. Default settings

can be altered via the initialization code feature at boot time.

The BMODE pins of the reset configuration register, sampled

during power-on resets and software-initiated resets, implement the modes shown in Table 6.

• IDLE State/No Boot (BMODE - 0x0) — In this mode, the

boot kernel transitions the processor into Idle state. The

processor can then be controlled through JTAG for recovery, debug, or other functions.

• SPI1 master boot from flash (BMODE = 0x2) — In this

mode, SPI1 is configured to operate in master mode and to

connect to 8-, 16-, 24-, or 32-bit addressable devices. The

processor uses the PG11/SPI1_SSEL5

EEPROM/flash device, submits a read command and successive address bytes (0×00) until a valid 8-, 16-, 24-, or 32bit addressable device is detected, and begins clocking data

into the processor. Pull-up resistors are required on the

SSEL and MISO pins. By default, a value of 0×85 is written

to the SPI_BAUD register.

• SPI1 slave boot from external master (BMODE = 0x3) — In

this mode, SPI1 is configured to operate in slave mode and

to receive the bytes of the .LDR file from a SPI host (master) agent. To hold off the host device from transmitting

while the boot ROM is busy, the Blackfin processor asserts

a GPIO pin, called host wait (HWAIT), to signal to the host

device not to send any more bytes until the pin is deasserted. The host must interrogate the HWAIT signal,

available on PG4, before transmitting every data unit to the

processor. A pull-up resistor is required on the SPI1_SS

input. A pull-down on the serial clock may improve signal

quality and booting robustness.

to select a single SPI

on PG11

on PF8

• SPI0 master boot from flash (BMODE = 0x4) — In this

mode SPI0 is configured to operate in master mode and to

connect to 8-, 16-, 24-, or 32-bit addressable devices. The

processor uses the PF8/SPI0_SSEL2

EEPROM/flash device, submits a read command and successive address bytes (0×00) until a valid 8-, 16-, 24-, or 32bit addressable device is detected, and begins clocking data

into the processor. Pull-up resistors are required on the

SSEL and MISO pins. By default, a value of 0×85 is written

to the SPI_BAUD register.

• Boot from PPI host device (BMODE = 0x5) — The processor operates in PPI slave mode and is configured to receive

the bytes of the LDR file from a PPI host (master) agent.

• Boot from UART host device (BMODE = 0x6) — In this

mode UART0 is used as the booting source. Using an autobaud handshake sequence, a boot-stream formatted

program is downloaded by the host. The host selects a bit

rate within the UART clocking capabilities. When performing the autobaud, the UART expects a “@” (0×40)

character (eight bits data, one start bit, one stop bit, no parity bit) on the RXD pin to determine the bit rate. The

UART then replies with an acknowledgment which is composed of 4 bytes (0xBF—the value of UART_DLL) and

(0×00—the value of UART_DLH). The host can then

download the boot stream. To hold off the host the processor signals the host with the boot host wait (HWAIT)

signal. Therefore, the host must monitor the HWAIT, (on

PG4), before every transmitted byte.

• Execute from internal L1 ROM (BMODE = 0x7) — In this

mode the processor begins execution from the on-chip 64k

byte L1 instruction ROM starting at address 0xFFA1 0000.

For each of the boot modes (except Execute from internal L1

ROM), a 16 byte header is first brought in from an external

device. The header specifies the number of bytes to be transferred and the memory destination address. Multiple memory

blocks may be loaded by any boot sequence. Once all blocks are

loaded, program execution commences from the start of L1

instruction SRAM.

The boot kernel differentiates between a regular hardware reset

and a wakeup-from-hibernate event to speed up booting in the

latter case. Bits 7–4 in the system reset configuration (SYSCR)

register can be used to bypass the boot kernel or simulate a

wakeup-from-hibernate boot in case of a software reset.

The boot process can be further customized by “initialization

code.” This is a piece of code that is loaded and executed prior to

the regular application boot. Typically, this is used to speed up

booting by managing the PLL, clock frequencies, or serial bit

rates.

The boot ROM also features C-callable functions that can be

called by the user application at run time. This enables second

stage boot or boot management schemes to be implemented

with ease.

to select a single SPI

Rev. A | Page 11 of 44 | August 2011

ADSP-BF592

INSTRUCTION SET DESCRIPTION

The Blackfin processor family assembly language instruction set

employs an algebraic syntax designed for ease of coding and

readability. The instructions have been specifically tuned to provide a flexible, densely encoded instruction set that compiles to

a very small final memory size. The instruction set also provides

fully featured multifunction instructions that allow the programmer to use many of the processor core resources in a single

instruction. Coupled with many features more often seen on

microcontrollers, this instruction set is very efficient when compiling C and C++ source code. In addition, the architecture

supports both user (algorithm/application code) and supervisor

(O/S kernel, device drivers, debuggers, ISRs) modes of operation, allowing multiple levels of access to core

processor resources.

The assembly language, which takes advantage of the processor’s unique architecture, offers the following advantages:

• Seamlessly integrated DSP/MCU features are optimized for

both 8-bit and 16-bit operations.

• A multi-issue load/store modified-Harvard architecture,

which supports two 16-bit MAC or four 8-bit ALU + two

load/store + two pointer updates per cycle.

• All registers, I/O, and memory are mapped into a unified

4G byte memory space, providing a simplified programming model.

• Microcontroller features, such as arbitrary bit and bit-field

manipulation, insertion, and extraction; integer operations

on 8-, 16-, and 32-bit data-types; and separate user and

supervisor stack pointers.

• Code density enhancements, which include intermixing of

16-bit and 32-bit instructions (no mode switching, no code

segregation). Frequently used instructions are encoded

in 16 bits.

DEVELOPMENT TOOLS

The processor is supported with a complete set of

CROSSCORE® software and hardware development tools,

including Analog Devices emulators and VisualDSP++® development environment. The same emulator hardware that

supports other Blackfin processors also fully emulates the

ADSP-BF592 processor.

EZ-KIT Lite® Evaluation Board

For evaluation of the ADSP-BF592 processor, use the EZ-KIT

Lite boards soon to be available from Analog Devices. When

these evaluation kits are available, order using part number

ADZS-BF592-EZLITE. The boards come with on-chip emulation capabilities and are equipped to enable software

development. Multiple daughter cards will be available.

DESIGNING AN EMULATOR-COMPATIBLE PROCESSOR BOARD (TARGET)

The Analog Devices family of emulators are tools that every system developer needs in order to test and debug hardware and

software systems. Analog Devices has supplied an IEEE 1149.1

JTAG Test Access Port (TAP) on each JTAG processor. The

emulator uses the TAP to access the internal features of the processor, allowing the developer to load code, set breakpoints,

observe variables, observe memory, and examine registers. The

processor must be halted to send data and commands, but once

an operation has been completed by the emulator, the processor

system is set running at full speed with no impact on

system timing.

To use these emulators, the target board must include a header

that connects the processor’s JTAG port to the emulator.

For details on target board design issues including mechanical

layout, single processor connections, multiprocessor scan

chains, signal buffering, signal termination, and emulator pod

logic, see (EE-68) Analog Devices JTAG Emulation Technical

Reference on the Analog Devices website (www.analog.com)—

use site search on “EE-68.” This document is updated regularly

to keep pace with improvements to emulator support.

RELATED DOCUMENTS

The following publications that describe the ADSP-BF592 processor (and related processors) can be ordered from any Analog

Devices sales office or accessed electronically on our website:

• Getting Started With Blackfin Processors

• ADSP-BF59x Blackfin Processor Hardware Reference

• Blackfin Processor Programming Reference

• ADSP-BF592 Blackfin Processor Anomaly List

RELATED SIGNAL CHAINS

A signal chain is a series of signal conditioning electronic com-

ponents that receive input (data acquired from sampling either

real-time phenomena or from stored data) in tandem, with the

output of one portion of the chain supplying input to the next.

Signal chains are often used in signal processing applications to

gather and process data or to apply system controls based on

analysis of real-time phenomena. For more information about

this term and related topics, see the “signal chain” entry in the

Glossary of EE Terms on the Analog Devices website.

Analog Devices eases signal processing system development by

providing signal processing components that are designed to

work together well. A tool for viewing relationships between

specific applications and related components is available on the

www.analog.com website.

The Circuits from the Lab

provides:

• Graphical circuit block diagram presentation of signal

chains for a variety of circuit types and applications

• Drill down links for components in each chain to selection

guides and application information

• Reference designs applying best practice design techniques

TM

site (www.analog.com\circuits)

Rev. A | Page 12 of 44 | August 2011

SIGNAL DESCRIPTIONS

ADSP-BF592

Signal definitions for the ADSP-BF592 processor are listed in

Table 7. In order to maintain maximum function and reduce

package size and pin count, some pins have dual, multiplexed

functions. In cases where pin function is reconfigurable, the

default state is shown in plain text, while the alternate function

is shown in italics.

All pins are three-stated during and immediately after reset,

All I/O pins have their input buffers disabled with the exception

of the pins that need pull-ups or pull-downs, as noted in

Table 7.

Adding a parallel termination to EXTCLK may prove useful in

further enhancing signal integrity. Be sure to verify overshoot/undershoot and signal integrity specifications on actual

hardware.

with the exception of EXTCLK, which toggles at the system

clock rate.

Table 7. Signal Descriptions

Driver

Signal Name Type Function

Port F: GPIO and Multiplexed Peripherals

PF0–GPIO/DR1SEC/PPI_D8/WAK EN1 I/O GPIO/SPORT1 Receive Data Secondary/PPI Data 8/Wake Ena ble 1 A

PF1–GPIO/DR1PRI/PPI_D9 I/O GPIO/SPORT1 Receive Data Primary/PPI Data 9 A

PF2–GPIO/RSCLK1/PPI_D10 I/O GPIO/SPORT1 Receive Serial Clock/PPI Data 10 A

PF3–GPIO/RFS1/PPI_D11 I/O GPIO/SPORT1 Receive Frame Sync/PPI Data 11 A

PF4–GPIO/DT1 SEC/PPI_D12 I/O GPIO/SPORT1 Transmit Data Secondary/PPI Data 12 A

PF5–GPIO/DT1 PRI/PPI_D13 I/O GPIO/SPORT1 Transmit Data Primary/PPI Data 13 A

PF6–GPIO/TSCLK1/PPI_D14 I/O GPIO/SPORT1 Transmit Serial Clock/PPI Data 14 A

PF7–GPIO/TFS1/PPI_D15 I/O GPIO/SPORT1 Transmit Frame Sync/PPI Data 15 A

PF8–GPIO/TMR2/SPI0_SSEL2

PF9–GPIO/TMR0/PPI_FS1/SPI0_SSEL3

PF10–GPIO/TMR1/PPI_FS2 I/O GPIO/Timer 1/PPI Frame Sync 2 A

PF11–GPIO/UA_TX/SPI0_SSEL4

PF12–GPIO/UA_RX/SPI0_SSEL7

PF13–GPIO/SPI0_MOSI/SPI1_SSEL3

PF14–GPIO/SPI0_MISO/SPI1_SSEL4

PF15–GPIO/SPI0_SCK/SPI1_SSEL5

Port G: GPIO and Multiplexed Peripherals

PG0–GPIO/DR0SEC/SPI0_SSEL1

PG1–GPIO/DR0PRI/SPI1_SSEL1/WAK EN3 I/O GPIO/SPORT0 Receive Data Primary/SPI1 Slave Select Enable 1/Wake Enable 3 A

PG2–GPIO/RSCLK0/SPI0_SSEL5

PG3–GPIO/RFS0/PPI_FS3 I/O GPIO/SPORT0 Receive Frame Sync/PPI Frame Sync 3 A

PG4–GPIO(HWAIT)/DT 0SEC/SPI0_SSEL6

PG5–GPIO/DT0PR I/SPI1_SSEL6

PG6–GPIO/TSCLK0 I/O GPIO/SPORT0 Transmit Serial Clock A

PG7–GPIO/TFS0/SPI1_SSEL7

PG8–GPIO/SPI1_SCK/PPI_D0 I/O GPIO/SPI1 Clock/PPI Data 0 A

PG9–GPIO/SPI1_MOSI/PPI_D1 I/O GPIO/SPI1 Master Out Slave In/PPI Data 1 A

PG10–GPIO/SPI1_MISO/PPI_D2 I/O GPIO/SPI1 Master In Slave Out/PPI Data 2

/WAK EN0 I/O GPIO/Timer 2/SPI0 Slave Select Enable 2/Wake Enable 0 A

I/O GPIO/Timer 0/PPI Frame Sync 1/SPI0 Slave Select Enable 3 A

I/O GPIO/UART Transmit/SPI0 Slave Select Enable 4 A

/TACI2–0 I/O GPIO/UART Receive/SPI0 Slave Select Enable 7/Timers 2–0 Alternate Input

Capture

I/O GPIO/SPI0 Master Out Slave In/SPI1 Slave Select Enable 3 A

I/O GPIO/SPI0 Master In Slave Out/SPI1 Slave Select Enable 4

(This pin should always be pulled high through a 4.7 k resistor,

if booting via the SPI port.)

I/O GPIO/SPI0 Clock/SPI1 Slave Select Enable 5 A

/SPI0_SS I/O GPIO/SPORT0 Receive Data Secondary/SPI0 Slave Select Enable 1/SPI0 Slave

Select Input

I/O GPIO/SPORT0 Receive Serial Clock/SPI0 Slave Select Enable 5 A

I/O GPIO (HWAIT output for Slave Boot Modes)/SPORT0 Transmit Data

Secondary/SPI0 Slave Select Enable 6

I/O GPIO/SPORT0 Transmit Data Primary/SPI1 Slave Select Enable 6 A

I/O GPIO/SPORT0 Transmit Frame Sync/SPI1 Slave Select Enable 7 A

(This pin should always be pulled high through a 4.7 k resistor if booting via

the SPI port.)

Typ e

A

A

A

A

A

Rev. A | Page 13 of 44 | August 2011

ADSP-BF592

Table 7. Signal Descriptions (Continued)

Signal Name Type Function

PG11–GPIO/SPI1_SSEL5/PPI_D3 I/O GPIO/SPI1 Slave Select Enable 5/PPI Data 3 A

PG12–GPIO/SPI1_SSEL2

PG13–GPIO/SPI1_SSEL1

PG14–GPIO/SPI1_SSEL4

PG15–GPIO/SPI1_SSEL6

TWI

SCL I/O TWI Serial Clock (This signal is an open-drain output and requires a pull-up

SDA I/O TWI Serial Data (This signal is an open-drain output and requires a pull-up

JTAG Port

TCK I JTAG CLK

TDO O JTAG Serial Data Out A

TDI I JTAG Serial Data In

TMS I JTAG Mode Select

TRST

EMU

Clock

CLKIN I CLK/Crystal In

XTAL O Crystal Output

EXTCLK O External Clock Output pin/System Clock Output C

Mode Controls

RESET

NMI

BMODE2–0 I Boot Mode Strap 2–0

PPI_CLK I PPI Clock Input

External Regulator Control

PG

EXT_WAKE O Wake up Indication A

Power Supplies ALL SUPPLIES MUST BE POWERED

V

DDEXT

V

DDINT

GND G Ground for All Supplies (Back Side of LFCSP Package.)

/PPI_D4/WAK EN2 I/O GPIO/SPI1 Slave Select Enable 2 Output/PPI Data 4/Wake E nabl e 2 A

/SPI1_SS/PPI_D5 I/O GPIO/SPI1 Slave Select Enable 1 Output/PPI Data 5/SPI1 Slave Select Input A

/PPI_D6/TACLK1 I/O GPIO/SPI1 Slave Select Enable 4/PPI Data 6/Timer 1 Auxiliary Clock Input A

/PPI_D7/TACLK2 I/O GPIO/SPI1 Slave Select Enable 6/PPI Data 7/Timer 2 Auxiliary Clock Input A

resistor. Consult version 2.1 of the I

2

C specification for the proper resistor

value.)

2

resistor. Consult version 2.1 of the I

C specification for the proper resistor

value.)

IJTAGReset

(This lead should be pulled low if the JTAG port is not used.)

O Emulation Output

I Reset

I Nonmaskable Interrupt

(Thisleadshouldbepulledhighwhennotused.)

I Power Good indication

See Operating Conditions on Page 15.

PI/OPowerSupply

P Internal Power Supply

Driver

Typ e

B

B

A

Rev. A | Page 14 of 44 | August 2011

Loading...

Loading...