Analog Devices ADSP-21992 Datasheet

a

Mixed Signal DSP Controller With CAN

ADSP-21992

KEY FEATURES

ADSP-219x, 16-Bit, Fixed Point DSP Core with up to

160 MIPS Sustained Performance

48K Words of On-Chip RAM, Configured as 32K Words

On-Chip 24-Bit Program RAM and 16K Words On-Chip

16-Bit Data RAM

External Memory Interface

Dedicated Memory DMA Controller for Data/Instruction

Transfer between Internal/External Memory

Programmable PLL and Flexible Clock Generation

Circuitry Enables Full-Speed Operation from Low-

Speed Input Clocks

IEEE JTAG Standard 1149.1 Test Access Port Supports

On-Chip Emulation and System Debugging

8-Channel, 14-Bit Analog-to-Digital Converter System,

with up to 20 MSPS Sampling Rate (at 160 MHz Core

Clock Rate)

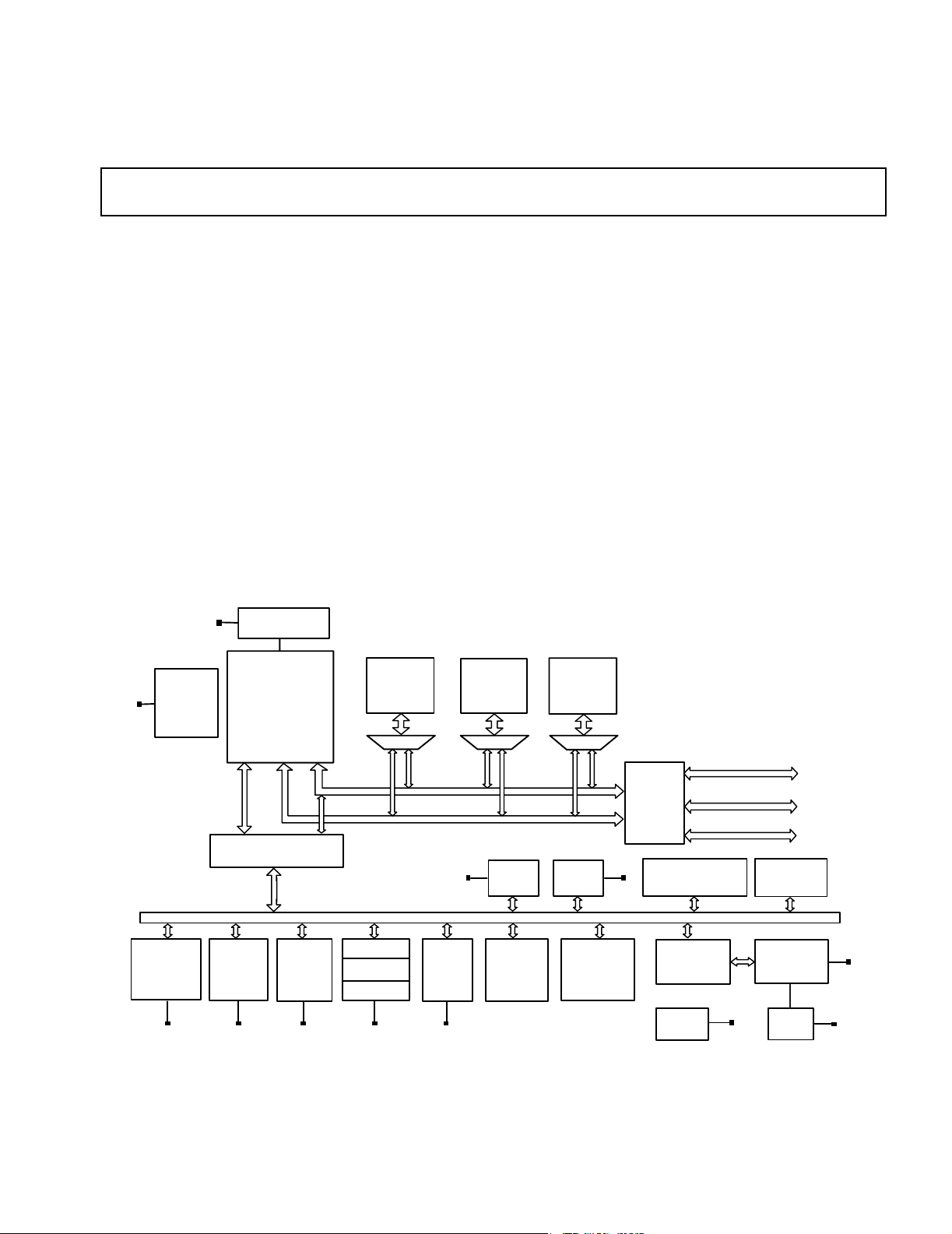

FUNCTIONAL BLOCK DIAGRAM

CLOCK

GENERATOR/PLL

JTAG

TEST AND

EMULATION

ADSP-219x

DSP CORE

32K ⴛ 24

PM RAM

Three Phase 16-Bit Center Based PWM Generation Unit

with 12.5 ns Resolution at 160 MHz Core Clock (CCLK)

Rate

Dedicated 32-Bit Encoder Interface Unit with

Companion Encoder Event Timer

Dual 16-Bit Auxiliary PWM Outputs

16 General-Purpose Flag I/O Pins

Three Programmable 32-Bit Interval Timers

SPI Communications Port with Master or Slave

Operation

Synchronous Serial Communications Port (SPORT)

Capable of Software UART Emulation

Controller Area Network (CAN) Module Fully Compliant

with V2.0B Standard

Integrated Watchdog Timer

Dedicated Peripheral Interrupt Controller with Software

Priority Control

Multiple Boot Modes

16K ⴛ 16

DM RAM

4K ⴛ 24

PM ROM

I/O

PWM

GENERATION

UNIT

BUS

I/O REGISTERS

ENCODER

INTERFACE

UNIT

(AND EET)

AUXILIARY

PWM

UNIT

PM ADDRESS/DATA

DM ADDRESS/DATA

TIMER 0

TIMER 1

TIMER 2

FLAG

I/O

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

ADDRESS

EXTERNAL

MEMORY

INTERFACE

(EMI)

SPI SPORT

WATCHDOG

TIMER

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel:781/329-4700 www.analog.com

Fax:781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

INTERRUPT

CONTROLLER

(ICNTL)

CONTROLLER AREA

NETWORK (CAN)

ADC

CONTROL

POR

DATA

CONTROL

MEMORY DMA

CONTROLLER

PIPELINE

FLASH ADC

VREF

ADSP-21992

KEY FEATURES (continued)

Precision 1.0 V Voltage Reference

Integrated Power-On-Reset (POR) Generator

Flexible Power Management with Selectable Power-

Down and Idle Modes

2.5 V Internal Operation with 3.3 V I/O

Operating Temperature Ranges of –40ºC to +85ºC and

–40ºC to +125ºC

196-Ball Mini-BGA Package

176-Lead LQFP Package

TARGET APPLICATIONS

Industrial Motor Drives

Uninterruptible Power Supplies

Optical Networking Control

Data Acquisition Systems

Test and Measurement Systems

Portable Instrumentation

TABLE OF CONTENTS

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . 2

DSP Core Architecture . . . . . . . . . . . . . . . . . . . . . . . 3

Memory Architecture . . . . . . . . . . . . . . . . . . . . . . . . 4

Internal (On-Chip) Memory . . . . . . . . . . . . . . . . . . 4

External (Off-chip) Memory . . . . . . . . . . . . . . . . . . 5

External Memory Space . . . . . . . . . . . . . . . . . . . . . 5

I/O Memory Space . . . . . . . . . . . . . . . . . . . . . . . . . 5

Boot Memory Space . . . . . . . . . . . . . . . . . . . . . . . . 6

Bus Request and Bus Grant . . . . . . . . . . . . . . . . . . . . 6

DMA Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DSP Peripherals Architecture . . . . . . . . . . . . . . . . . . 6

Serial Peripheral Interface (SPI) Port . . . . . . . . . . . . . 7

DSP Serial Port (SPORT) . . . . . . . . . . . . . . . . . . . . . 7

Controller Area Network (CAN) Module . . . . . . . . . 8

Analog-to-Digital Conversion System . . . . . . . . . . . . 8

Voltage Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PWM Generation Unit . . . . . . . . . . . . . . . . . . . . . . . 9

Auxiliary PWM Generation Unit . . . . . . . . . . . . . . . . 9

Encoder Interface Unit . . . . . . . . . . . . . . . . . . . . . . 10

Flag I/O (FIO) Peripheral Unit . . . . . . . . . . . . . . . . 10

Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General-Purpose Timers . . . . . . . . . . . . . . . . . . . . . 11

Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Peripheral Interrupt Controller . . . . . . . . . . . . . . . . 11

Low Power Operation . . . . . . . . . . . . . . . . . . . . . . . 12

Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power-Down Core Mode . . . . . . . . . . . . . . . . . . . 12

Power-Down Core/Peripherals Mode . . . . . . . . . . 12

Power-Down All Mode . . . . . . . . . . . . . . . . . . . . 12

Clock Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Reset and Power-On Reset (POR) . . . . . . . . . . . . . . 13

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Booting Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Instruction Set Description . . . . . . . . . . . . . . . . . . . 14

Development Tools . . . . . . . . . . . . . . . . . . . . . . . . . 14

Designing an Emulator-Compatible DSP Board . . . 15

Additional Information . . . . . . . . . . . . . . . . . . . . . . 15

PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . 15

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . 28

ESD SENSITIVITY . . . . . . . . . . . . . . . . . . . . . . . . 28

TIMING SPECIFICATIONS . . . . . . . . . . . . . . . . 28

Clock In and Clock Out Cycle Timing . . . . . . . . . 29

Programmable Flags Cycle Timing . . . . . . . . . . . 30

Timer PWM_OUT Cycle Timing . . . . . . . . . . . . 31

External Port Write Cycle Timing . . . . . . . . . . . . 32

External Port Read Cycle Timing . . . . . . . . . . . . 33

External Port Bus Request/Grant Cycle Timing . . 34

Serial Port Timing . . . . . . . . . . . . . . . . . . . . . . . . 35

Serial Peripheral Interface Port—Master Timing . 38

Serial Peripheral Interface Port—Slave Timing . . 39

JTAG Test And Emulation Port Timing . . . . . . . 40

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Output Disable Time . . . . . . . . . . . . . . . . . . . . . . 41

Output Enable Time . . . . . . . . . . . . . . . . . . . . . . 42

Example System Hold Time Calculation . . . . . . . 42

Pin Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 42

OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . 47

ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . 48

GENERAL DESCRIPTION

The ADSP-21992 is a mixed signal DSP controller based on the

ADSP-219x DSP Core, suitable for a variety of high performance

industrial motor control and signal processing applications that

require the combination of a high performance DSP and the

mixed signal integration of embedded control peripherals such

as analog-to-digital conversion with communications interfaces

such as CAN.

The ADSP-21992 integrates the fixed point ADSP-219x family

base architecture with a serial port, an SPI compatible port, a

DMA controller, three programmable timers, general-purpose

Programmable Flag pins, extensive interrupt capabilities, onchip program and data memory spaces, and a complete set of

embedded control peripherals that permits fast motor control

and signal processing in a highly integrated environment.

The ADSP-21992 architecture is code compatible with previous

ADSP-217x based ADMCxxx products. Although the architectures are compatible, the ADSP-21992, with ADSP-219x

architecture, has a number of enhancements over earlier architectures. The enhancements to computational units, data address

generators, and program sequencer make the ADSP-21992 more

flexible and easier to program than the previous ADSP-21xx

embedded DSPs.

Indirect addressing options provide addressing flexibility—

premodify with no update, pre- and post-modify by an immediate

8-bit, twos complement value and base address registers for easier

implementation of circular buffering.

The ADSP-21992 integrates 48K words of on-chip memory configured as 32K words (24-bit) of program RAM, and 16K words

(16-bit) of data RAM.

Fabricated in a high speed, low power, CMOS process, the

ADSP-21992 operates with a 6.25 ns instruction cycle time for

a 160 MHz CCLK, with a 6.67 ns instruction cycle time for a

–2– REV. 0

ADSP-21992

150 MHz CCLK, and with a 10.0 ns instruction cycle time for

a 100 MHz CCLK. All instructions, except two multiword

instructions, execute in a single DSP cycle.

The flexible architecture and comprehensive instruction set of

the ADSP-21992 support multiple operations in parallel. For

example, in one processor cycle, the ADSP-21992 can:

• Generate an address for the next instruction fetch.

• Fetch the next instruction.

• Perform one or two data moves.

• Update one or two data address pointers.

• Perform a computational operation.

These operations take place while the processor continues to:

• Receive and transmit data through the serial port.

• Receive or transmit data over the SPI port.

• Access external memory through the external memory

interface.

• Decrement the timers.

• Operate the embedded control peripherals (ADC, PWM,

EIU, etc.).

DSP Core Architecture

• 6.25 ns instruction cycle time (internal), for up to

160 MIPS sustained performance (6.67 ns instruction

cycle time for 150 MIPS sustained performance and

10.0 ns instruction cycle time for 100 MIPS sustained

performance)

• ADSP-218x family code compatible with the same easy

to use algebraic syntax

• Single cycle instruction execution

• Up to 1M words of addressable memory space with

twenty four bits of addressing width

• Dual purpose program memory for both instruction and

data storage

• Fully transparent instruction cache allows dual operand

fetches in every instruction cycle

• Unified memory space permits flexible address genera-

tion, using two independent DAG units

• Independent ALU, multiplier/accumulator, and barrel

shifter computational units with dual 40-bit accumulators

• Single cycle context switch between two sets of computa-

tional and DAG registers

• Parallel execution of computation and memory

instructions

• Pipelined architecture supports efficient code execution

at speeds up to 160 MIPS

• Register file computations with all nonconditional, non-

parallel computational instructions

• Powerful program sequencer provides zero overhead

looping and conditional instruction execution

• Architectural enhancements for compiled C code

efficiency

• Architecture enhancements beyond ADSP-218x family

are supported with instruction set extensions for added

registers, ports, and peripherals.

The clock generator module of the ADSP-21992 includes clock

control logic that allows the user to select and change the main

clock frequency. The module generates two output clocks: the

DSP core clock, CCLK; and the peripheral clock, HCLK.

CCLK can sustain clock values of up to 160 MHz, while HCLK

can be equal to CCLK or CCLK/2 for values up to a maximum

80MHz peripheral clock at the 160MHz CCLK rate.

The ADSP-21992 instruction set provides flexible data moves

and multifunction (one or two data moves with a computation)

instructions. Every single word instruction can be executed in a

single processor cycle. The ADSP-21992 assembly language uses

an algebraic syntax for ease of coding and readability. A compre-

hensive set of development tools supports program development.

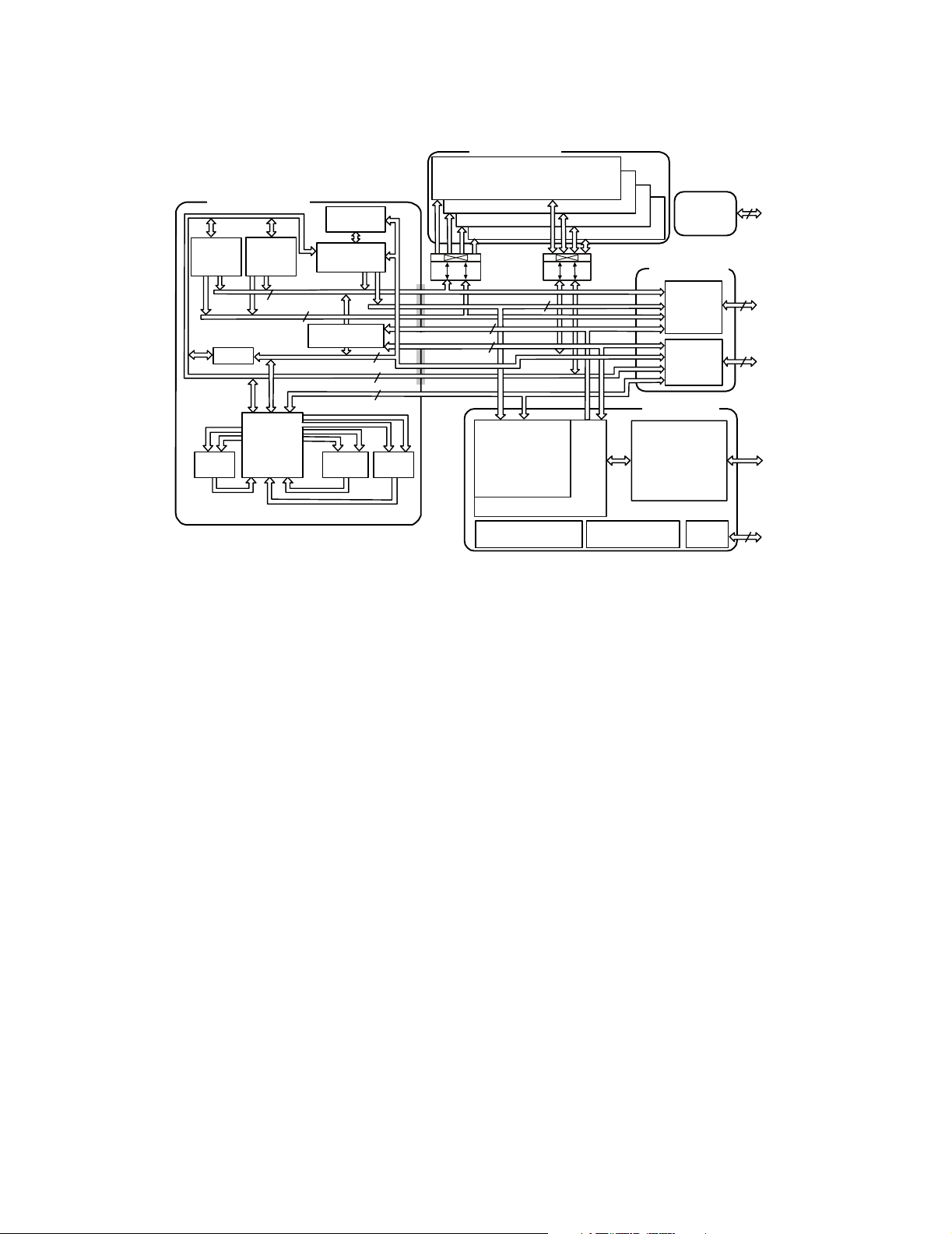

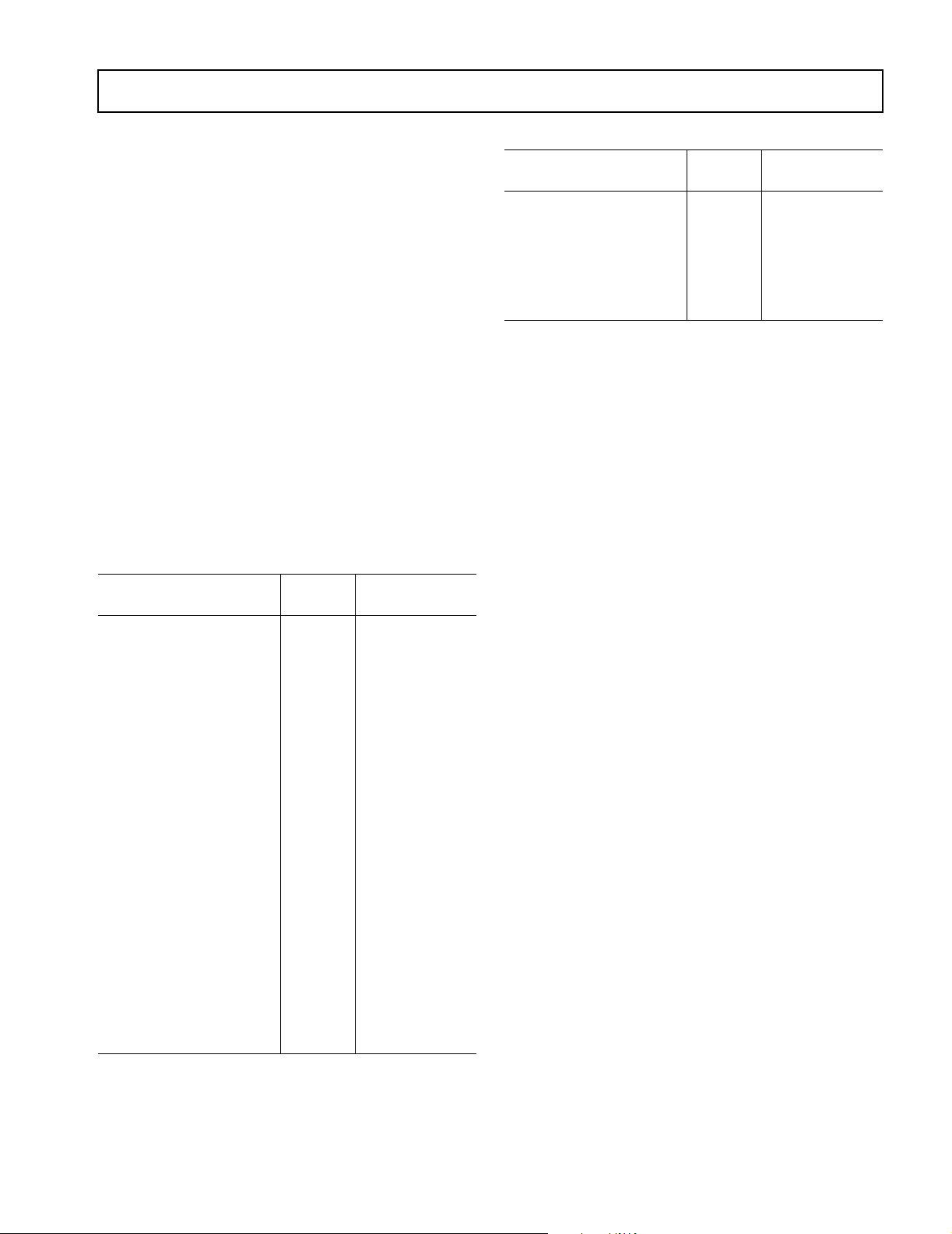

The block diagram Figure 1 shows the architecture of the

embedded ADSP-219x core. It contains three independent com-

putational units: the ALU, the multiplier/accumulator (MAC),

and the shifter. The computational units process 16-bit data from

the register file and have provisions to support multiprecision

computations. The ALU performs a standard set of arithmetic

and logic operations; division primitives are also supported. The

MAC performs single cycle multiply, multiply/add, and multi-

ply/subtract operations. The MAC has two 40-bit accumulators,

which help with overflow. The shifter performs logical and arith-

metic shifts, normalization, denormalization, and derive

exponent operations. The shifter can be used to efficiently

implement numeric format control, including multiword and

block floating point representations.

Register usage rules influence placement of input and results

within the computational units. For most operations, the data

registers of the computational units act as a data register file,

permitting any input or result register to provide input to any unit

for a computation. For feedback operations, the computational

units let the output (result) of any unit be input to any unit on

the next cycle. For conditional or multifunction instructions,

there are restrictions on which data registers may provide inputs

or receive results from each computational unit. For more infor-

mation, see the

A powerful program sequencer controls the flow of instruction

execution. The sequencer supports conditional jumps, subrou-

tine calls, and low interrupt overhead. With internal loop

counters and loop stacks, the ADSP-21992 executes looped code

with zero overhead; no explicit jump instructions are required to

maintain loops.

Two data address generators (DAGs) provide addresses for

simultaneous dual operand fetches (from data memory and

program memory). Each DAG maintains and updates four 16-

bit address pointers. Whenever the pointer is used to access data

(indirect addressing), it is pre- or post-modified by the value of

one of four possible modify registers. A length value and base

address may be associated with each pointer to implement

automatic modulo addressing for circular buffers. Page registers

ADSP-219x DSP Instruction Set Reference

.

–3–REV. 0

ADSP-21992

ADSP-219x DSP CORE

DAG1

4 ⴛ 4 ⴛ 16

DM ADDRESS BUS

DATA

REGISTER

FILE

MULT

PX

DAG2

4 ⴛ 4 ⴛ 16

INPUT

REGIST ERS

RESULT

REGIST ERS

16 ⴛ 16-BIT

CACHE

64 ⴛ 24-BIT

PROGRAM

SEQUENCER

PM ADDRESS BUS

24

24

DMA CONNECT

PM DATA BUS

DM DATA BUS

I/O DATA

BARREL

SHIFTER

INTERNAL MEMORY

FOUR INDEPENDENT BLOCKS

24 BI T

ADDRESS

ADDRESS

ADDRESS

ADDRESS

I/O ADDRESS

24

16

16

DMA ADDRESS

DMA DATA

ALU

24

24

(MEMORY-MAPPED)

SYSTEM INTERRUPT

Figure 1. Block Diagram

24 BIT

I/O REGISTERS

CONTROL

BUFFERS

DMA CONTROLLER

CONTROLLER

DATA

16 BIT

16 B IT

18

STATUS

DATA

DATA

DATA

PROGRAMMABLE

0

K

1

C

K

O

2

C

L

K

B

O

L

C

B

O

L

B

EXTERNAL PORT

I/O PROCESSOR

PERIPHERALS

COMMUNICATIONS

FLAGS (16)

3

JTAG

K

TEST AND

C

O

EMULATION

L

B

ADDR BUS

MUX

DATA BUS

MUX

EMBEDDED

CONTROL

AND

PORTS

TIMERS

6

20

16

3

(3)

in the DAGs allow circular addressing within 64K word boundaries of each of the 256 memory pages, but these buffers may not

cross page boundaries. Secondary registers duplicate all the

primary registers in the DAGs; switching between primary and

secondary registers provides a fast context switch.

Efficient data transfer in the core is achieved with the use of

internal buses:

• Program Memory Address (PMA) Bus

• Program Memory Data (PMD) Bus

• Data Memory Address (DMA) Bus

• Data Memory Data (DMD) Bus

• Direct Memory Access Address Bus

• Direct Memory Access Data Bus

The two address buses (PMA and DMA) share a single external

address bus, allowing memory to be expanded off-chip, and the

two data buses (PMD and DMD) share a single external data

bus. Boot memory space and I/O memory space also share the

external buses.

Program memory can store both instructions and data, permitting the ADSP-21992 to fetch two operands in a single cycle, one

from program memory and one from data memory. The DSP

dual memory buses also let the embedded ADSP-219x core fetch

an operand from data memory and the next instruction from

program memory in a single cycle.

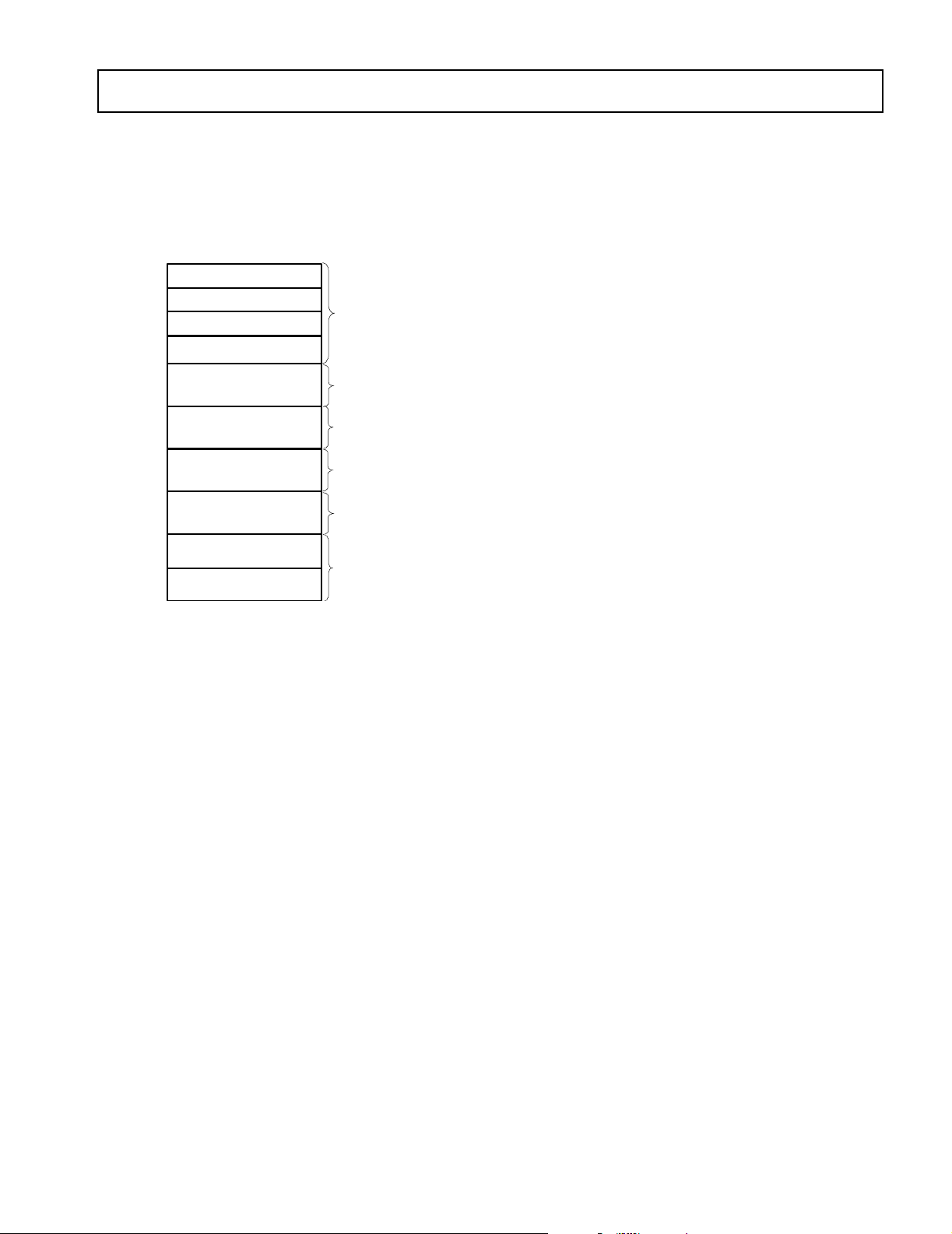

Memory Architecture

The ADSP-21992 provides 48K words of on-chip SRAM

memory. This memory is divided into three blocks: two

×

24-bit blocks (blocks 0 and 1) and one 16K × 16-bit block

16K

×

(block 2). In addition, the ADSP-21992 provides a 4K

24-bit

block of program memory boot ROM (that is reserved by ADI

for boot load routines). The memory map of the ADSP-21992

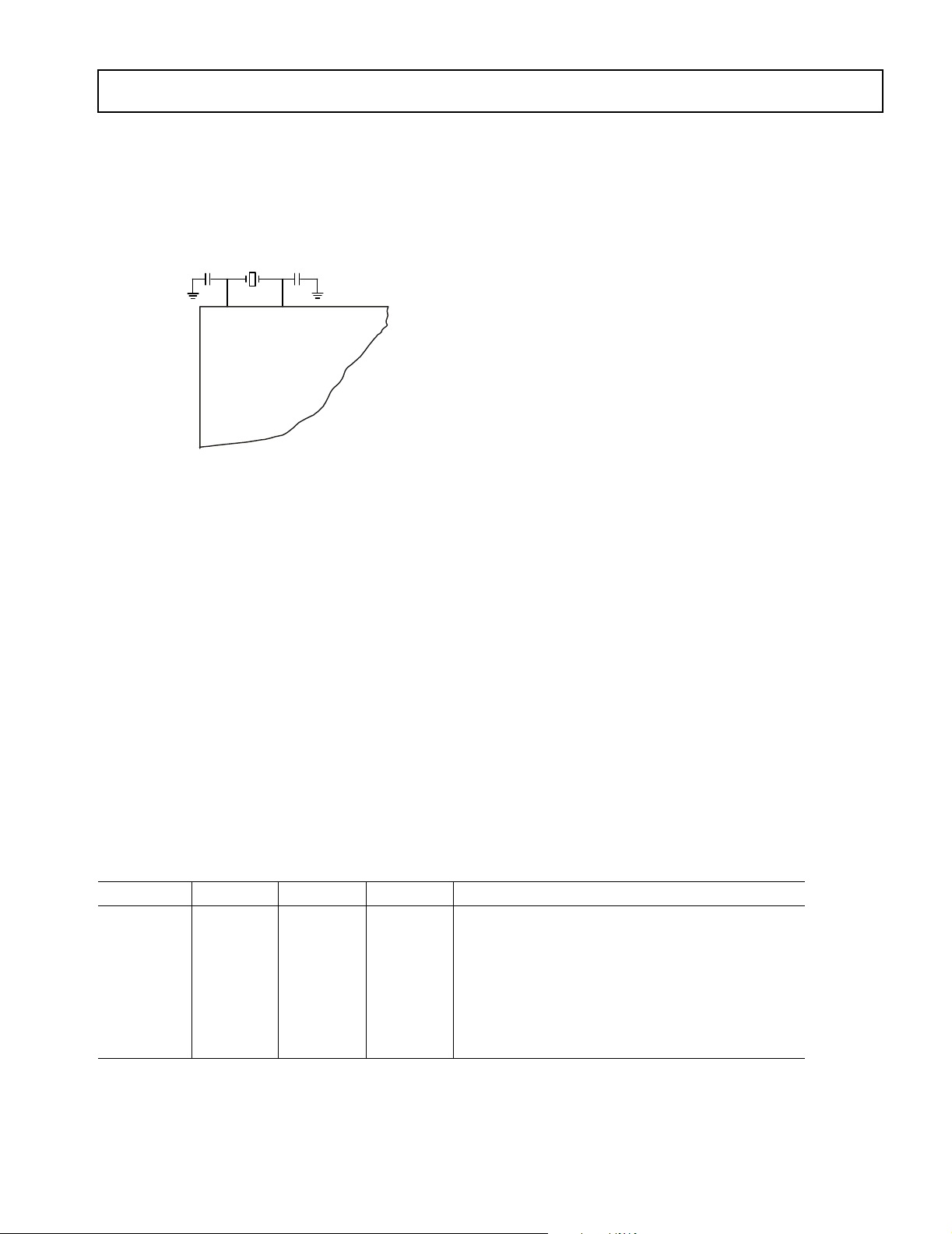

is illustrated in Figure 2.

As shown in Figure 2, the three internal memory RAM blocks

reside in memor y page 0. The entire DSP memory map consists

of 256 pages (pages 0 to 255), and each page is 64K words long.

External memory space consists of four memory banks

(banks3–0) and supports a wide variety of memory devices. Each

MS3–0

bank is selectable using unique memory select lines (

) and

has configurable page boundaries, wait states, and wait state

modes. The 4K words of on-chip boot ROM populates the top

of page 255, while the remaining 254 pages are addressable offchip. I/O memory pages differ from exte rna l m em or y in th at th ey

are 1K word long, and the external I/O pages have their own select

IOMS

pin (

). Pages 31–0 of I/O memory space reside on-chip and

contain the configuration registers for the peripherals. Both the

ADSP-219x core and DMA capable peripherals can access the

entire memory map of the DSP.

–4– REV. 0

ADSP-21992

NOTE: The physical external memory addresses are limited by

20 address lines, and are determined by the external data width

and packing of the external memory space. The Strobe signals

MS3-0

(

) can be programmed to allow the user to change starting

page addresses at run time.

0x00 0000

0x00 3FFF

0x00 4000

0x00 7FFF

0x00 8000

0x00 BFFF

0x00 C000

0x00 FFFF

0x01 0000

0x40 0000

0x80 0000

0xC0 0000

0xFF 0000

0xFF 0FFF

0xFF 1000

0xFF FFFF

BLOCK 0: 16K ⴛ 24-BIT PM RAM

BLOCK 1: 16K ⴛ 24-BIT PM RAM

BLOCK 2: 16K ⴛ 16-BIT DM RAM

RESERVED (16K)

EXTERNAL MEMORY

(4M–64K)

EXTERNAL MEMORY (4M)

EXTERNAL MEMORY (4M)

EXTERNAL MEMORY

(4M–64K)

BLOCK 3: 4K ⴛ 24-BIT

PM ROM

UNUSED ON-CHIP

MEMORY (60K)

PAGE 0 ( 64K) ON-CHIP

(0 WAIT STATE)

PAGES 1 TO 63 BANK 0

(OFF-CHIP) MS0

PAGES 64 TO 127 BANK 1

(OFF-CHIP)

PAGES 128 TO 191 BANK 2

(OFF-CHIP)

PAGES 192 TO 254 BANK 3

(OFF-CHIP)

PAGE 255

(INCLUDES ON-CHIP BOOT ROM)

MS1

MS2

MS3

Figure 2. Core Memory Map at Reset

Internal (On-Chip) Memory

The unified program and data memor y space of the ADSP-21992

consists of 16M locations that are accessible through two 24-bit

address buses, the PMA, and DMA buses. The DSP uses slightly

different mechanisms to generate a 24-bit address for each bus.

The DSP has three functions that support access to the full

memory map.

• The DAGs generate 24-bit addresses for data fetches from

the entire DSP memory address range. Because DAG

index (address) registers are 16 bits wide and hold the

lower 16 bits of the address, each of the DAGs has its own

8-bit page register (DMPGx) to hold the most significant

eight address bits. Before a DAG generates an address,

the program must set the DAG DMPGx register to the

appropriate memory page. The DMPG1 register is also

used as a page register when accessing external memory.

The program must set DMPG1 accordingly, when

accessing data variables in external memory. A “C”

program macro is provided for setting this register.

• The program sequencer generates the addresses for

instruction fetches. For relative addressing instructions,

the program sequencer bases addresses for relative jumps,

calls, and loops on the 24-bit program counter (PC). In

direct addressing instructions (two word instructions),

the instruction provides an immediate 24-bit address

value. The PC allows linear addressing of the full 24-bit

address range.

• For indirect jumps and calls that use a 16-bit DAG

address register for part of the branch address, the

Program Sequencer relies on an 8-bit Indirect Jump page

(IJPG) register to supply the most significant eight

address bits. Before a cross page jump or call, the program

must set the program sequencer IJPG register to the

appropriate memory page.

The ADSP-21992 has 4K word of on-chip ROM that holds boot

routines. The DSP starts executing instructions from the on-chip

boot ROM, which starts the boot process. See Booting Modes

on Page 13. The on-chip boot ROM is located on Page 255 in

the DSP memory space map, starting at address 0xFF0000.

External (Off-chip) Memory

Each of the off-chip memory spaces of the ADSP-21992 has a

separate control register, so applications can configure unique

access parameters for each space. The access parameters include

read and write wait counts, waitstate completion mode, I/O clock

divide ratio, write hold time extension, strobe polarity, and data

bus width. The core clock and peripheral clock ratios influence

the external memory access strobe widths. See Clock Signals on

Page 12. The off-chip memory spaces are:

• External memory space (MS3–0 pins)

• I/O memory space (IOMS pin)

• Boot memory space (BMS pin)

All of these off-chip memory spaces are accessible through the

External Port, which can be configured for 8-bit or 16-bit data

widths.

External Memory Space

External memory space consists of four memory banks. These

banks can contain a configurable number of 64K word pages. At

reset, the page boundaries for external memory have Bank0 containing pages 1 to 63, Bank1 containing pages 64 to 127, Bank2

containing pages 128 to 191, and Bank3 containing pages 192 to

MS3-0

254. The

memory bank pins select Banks 3-0, respectively. Both the ADSP-219x core and DMA capable peripherals

can access the DSP external memory space.

All accesses to external memory are managed by the External

Memory Interface Unit (EMI).

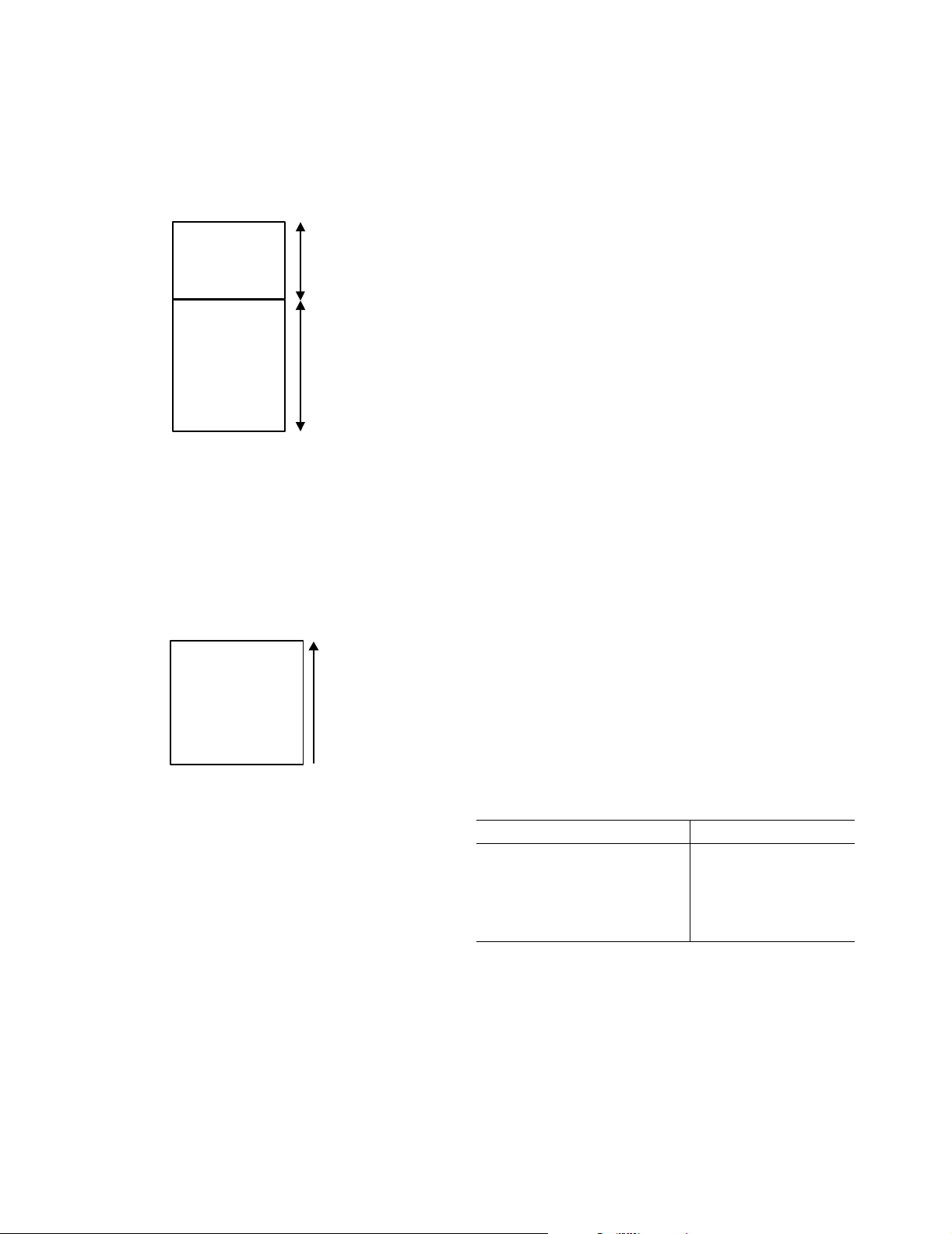

I/O Memory Space

The ADSP-21992 supports an additional external memory

called I/O memory space. The IO space consists of 256 pages,

each containing 1024 addresses. This space is designed to

support simple connections to peripherals (such as data converters and external registers) or to bus interface ASIC data registers.

The first 32K addresses (IO pages 0 to 31) are reserved for onchip peripherals. The upper 224K addresses (IO pages 32 to 255)

–5–REV. 0

ADSP-21992

are available for external peripheral devices. External I/O pages

IOMS

have their own select pin (

). The DSP instruction set

provides instructions for accessing I/O space.

0x00::0x000

ON-CHIP

PERIPHERALS

16-BITS

0x1F::0x3FF

0x20::0x000

OFF-CHIP

PERIPHERALS

16-BITS

0xFF::0x3FF

PAGES 0 TO 31

1024 WORDS/PAGE

2 PERIPHERALS/PAGE

PAGES 32 TO 255

1024 WORDS/PAGE

Figure 3. I/O Memory Map

Boot Memory Space

Boot memory space consists of one off-chip bank with 254 pages.

BMS

The

memory bank pin selects boot memory space. Both

the ADSP-219x core and DMA capable peripherals can access

the DSP off-chip boot memory space. After reset, the DSP always

starts executing instructions from the on-chip boot ROM.

0x01 0000

OFF-CHIP

BOOT MEMORY

16-BITS

0xFE 0000

PAGES 1 TO 254

64K WORDS/PAGE

two accesses. If an instruction requires an external memory read

and an external memory write access, the bus may be granted

between the two accesses. The external memory interface can be

configured so that the core will have exclusive use of the interface.

DMA and Bus Requests will be granted. When the external

BR

device releases

, the DSP releases BG and continues program

execution from the point at which it stopped.

The bus request feature operates at all times, even while the DSP

is booting and

RESET

The ADSP-21992 asserts the

is active.

BGH

pin when it is ready to start

another external port access, but is held off because the bus was

previously granted. This mechanism can be extended to define

more complex arbitration protocols for implementing more

elaborate multimaster systems.

DMA Controller

The ADSP-21992 has a DMA controller that supports

automated data transfers with minimal overhead for the DSP

core. Cycle stealing DMA transfers can occur between the

ADSP-21992 internal memory and any of its DMA capable

peripherals. Additionally, DMA transfers can be accomplished

between any of the DMA capable peripherals and external

devices connected to the external memory interface. DMA

capable peripherals include the SPORT and SPI ports, and ADC

Control module. Each individual DMA capable peripheral has a

dedicated DMA channel. To describe each DMA sequence, the

DMA controller uses a set of parameters—called a DMA descriptor. When successive DMA sequences are needed, these DMA

descriptors can be linked or chained together, so the completion

of one DMA sequence auto initiates and starts the next sequence.

DMA sequences do not contend for bus access with the DSP

core, instead DMAs “steal” cycles to access memory.

All DMA transfers use the DMA bus shown in Figure 1 on

Page 4. Because all of the peripherals use the same bus, arbitra-

tion for DMA bus access is needed. The arbitration for DMA bus

access appears in Table 1.

Figure 4. Boot Memory Map

Bus Request and Bus Grant

The ADSP-21992 can relinquish control of the data and address

buses to an external device. When the external device requires

BR

access to the bus, it asserts the bus request (

) signal. The (BR)

signal is arbitrated with core and peripheral requests. External

Bus requests have the lowest priority. If no other internal request

is pending, the external bus request will be granted. Due to synchronizer and arbitration delays, bus grants will be provided with

a minimum of three peripheral clock delays. The ADSP-21992

will respond to the bus grant by:

• Three-stating the data and address buses and the MS3–0,

BMS, IOMS, RD, and WR output drivers.

• Asserting the bus grant (BG) signal.

The ADSP-21992 will halt program execution if the bus is

granted to an external device and an instruction fetch or data

read/write request is made to external general-purpose or peripheral memory spaces. If an instruction requires two external

memory read accesses, the bus will not be granted between the

Table 1. I/O Bus Arbitration Priority

DMA Bus Master Arbitration Priority

SPORT Receive DMA 0—Highest

SPORT Transmit DMA 1

ADC Control DMA 2

SPI Receive/Transmit DMA 3

Memory DMA 4—Lowest

DSP Peripherals Architecture

The ADSP-21992 contains a number of special purpose,

embedded control peripherals, which can be seen in the Functional Block Diagram on Page 1. The ADSP-21992 contains a

high performance, 8-channel, 14-bit ADC system with dual

channel simultaneous sampling ability across four pairs of inputs.

An internal precision voltage reference is also available as part of

the ADC system. In addition, a 3-phase, 16-bit, center based

PWM generation unit can be used to produce high accuracy

PWM signals with minimal processor overhead. The ADSP21992 also contains a flexible incremental encoder interface unit

–6– REV. 0

ADSP-21992

for position sensor feedback; two adjustable frequency auxiliary

PWM outputs, 16 lines of digital I/O; a 16-bit watchdog timer;

three general-purpose timers, and an interrupt controller that

manages all peripheral interrupts. Finally, the ADSP-21992

contains an integrated power-on-reset (POR) circuit that can be

used to generate the required reset signal for device power-on.

The ADSP-21992 has an external memory interface that is

shared by the DSP core, the DMA controller, and DMA capable

peripherals, which include the ADC, SPORT, and SPI communication ports. The external port consists of a 16-bit data bus, a

20-bit address bus, and control signals. The data bus is configurable to provide an 8- or 16-bit interface to external memory.

Support for word packing lets the DSP access 16- or 24-bit words

from external memory regardless of the external data bus width.

The memory DMA controller lets the ADSP-21992 move data

and instructions from between memory spaces: internal-toexternal, internal-to-inter nal, and external-to- external. On-chip

peripherals can also use this controller for DMA transfers.

The embedded ADSP-219x core can respond to up to seventeen

interrupts at any given time: three internal (stack, emulator

kernel, and power-down), two external (emulator and reset), and

twelve user defined (peripherals) interrupts. Programmer s assign

each of the 32 peripheral interrupt requests to one of the 12 user

defined interrupts. These assignments determine the priority of

each peripheral for interrupt service.

The following sections provide a functional overview of the

ADSP-21992 peripherals.

Serial Peripheral Interface (SPI) Port

The Serial Peripheral Interface (SPI) Port provides functionality

for a generic configurable serial port interface based on the SPI

standard, which enables the DSP to communicate with multiple

SPI compatible devices. Key features of the SPI port are:

• Interface to host microcontroller or serial EEPROM

• Master or slave operation (3-wire interface MISO, MOSI,

SCK)

• Data rates to HCLKⴜ4 (16-bit baud rate selector)

• 8- or 16-bit transfer

• Programmable clock phase and polarity

• Broadcast Mode – 1 master, multiple slaves

• DMA capability and dedicated interrupts

• PF0 can be used as Slave Select input line

• PF1–PF7 can be used as external Slave Select output

SPI is a 3 wire interface consisting of 2 data pins (MOSI and

MISO), one clock pin (SCK), and a single Slave Select input

SPISS

) that is multiplexed with the PF0 Flag IO line and seven

(

Slave Select outputs (SPISEL1 to SPISEL7) that are multiplexed

SPISS

with the PF1 to PF7 Flag IO lines. The

select the ADSP-21992 as a slave to an external master. The

SPISEL1 to SPISEL7 outputs can be used by the ADSP-21992

(acting as a master) to select/enable up to seven external slaves

in a multidevice SPI configuration. In a multimaster or a multidevice configuration, all MOSI pins are tied together, all MISO

pins are tied together, and all SCK pins are tied together.

input is used to

During transfers, the SPI port simultaneously transmits and

receives by serially shifting data in and out on the serial data line.

The serial clock line synchronizes the shifting and sampling of

data on the serial data line.

In master mode, the DSP core performs the following sequence

to set up and initiate SPI transfers:

1. Enables and configures the SPI port operation (data size,

and transfer format).

2. Selects the target SPI slave with the SPISELx output pin

(reconfigured Programmable Flag pin).

3. Defines one or more DMA descriptors in Page 0 of I/O

memory space (optional in DMA mode only).

4. Enables the SPI DMA engine and specifies transfer

direction (optional in DMA mode only).

5. In non DMA mode only, reads or writes the SPI port

receive or transmit data buffer.

The SCK line generates the programmed clock pulses for simultaneously shifting data out on MOSI and shifting data in on

MISO. In DMA mode only, transfers continue until the SPI

DMA word count transitions from 1 to 0.

In slave mode, the DSP core performs the following sequence to

set up the SPI port to receive data from a master transmitter:

1. Enables and configures the SPI slave port to match the

operation parameters set up on the master (data size and

transfer format) SPI transmitter.

2. Defines and generates a receive DMA descriptor in

Page 0 of memory space to interrupt at the end of the

data transfer (optional in DMA mode only).

3. Enables the SPI DMA engine for a receive access

(optional in DMA mode only).

4. Starts receiving the data on the appropriate SCK edges

after receiving an SPI chip select on the SPISS input pin

(reconfigured Programmable Flag pin) from a master

In DMA mode only, reception continues until the SPI DMA

word count transitions from 1 to 0. The DSP core could

continue, by queuing up the next DMA descriptor.

A slave mode transmit operation is similar, except the DSP core

specifies the data buffer in memory space from which to transmit

data, generates and relinquishes control of the transmit DMA

descriptor, and begins filling the SPI port data buffer. If the SPI

controller is not ready on time to transmit, it can transmit a “zero”

word.

DSP Serial Port (SPORT)

The ADSP-21992 incorporates a complete synchronous serial

port (SPORT) for serial and multiprocessor communications.

The SPORT supports the following features:

• Bidirectional: the SPORT has independent transmit and

receive sections.

• Double buffered: the SPORT section (both receive and

transmit) has a data register for transferring data words

to and from other parts of the processor and a register for

shifting data in or out. The double buffering provides

additional time to service the SPORT.

–7–REV. 0

ADSP-21992

• Clocking: the SPORT can use an external serial clock or

generate its own in a wide range of frequencies down to

0Hz.

• Word length: each SPORT section supports serial data

word lengths from three to sixteen bits that can be transferred either MSB first or LSB first.

• Framing: each SPORT section (receive and transmit) can

operate with or without frame synchronization signals for

each data-word; with internally generated or externally

generated frame signals; with active high or active low

frame signals; with either of two pulsewidths and frame

signal timing.

• Companding in hardware: each SPORT section can

perform A law and µ law companding according to

CCITT recommendation G.711.

• Direct Memory Access with single cycle overhead: using

the built-in DMA master, the SPORT can automatically

receive and/or transmit multiple memory buffers of data

with an overhead of only one DSP cycle per data-word.

The on-chip DSP, via a linked list of memory space

resident DMA descriptor blocks, can configure transfers

between the SPORT and memory space. This chained list

can be dynamically allocated and updated.

• Interrupts: each SPORT section (receive and transmit)

generates an interrupt upon completing a data-word

transfer, or after transferring an entire buffer or buffers if

DMA is used.

• Multichannel capability: The SPORT can receive and

transmit data selectively from channels of a serial bit

stream that is time division multiplexed into up to 128

channels. This is especially useful for T1 interfaces or as

a network communication scheme for multiple processors. The SPORTs also support T1 and E1 carrier

systems.

• Each SPORT channel (Tx and Rx) supports a DMA

buffer of up to eight, 16-bit transfers.

• The SPORT operates at a frequency of up to one-half the

clock frequency of the HCLK

• The SPORT is capable of UART software emulation.

Controller Area Network (CAN) Module

The ADSP-21992 contains a Controller Area Network (CAN)

Module. Key features of the CAN Module are:

• Conforms to the CAN V2.0B standard.

• Supports both standard (11-bit) and extended (29-bit)

Identifiers

• Supports Data Rates of up to 1Mbit/sec (and higher)

• 16 Configurable Mailboxes (All receive or transmit)

• Dedicated Acceptance Mask for each Mailbox

• Data Filtering (first 2 bytes) can be used for Acceptance

Filtering

• Error Status and Warning registers

• Transmit Priority by Identifier

• Universal Counter Module

• Readable Receive and Transmit Counters

The CAN Module is a low baud rate serial interface intended for

use in applications where baud rates are typically under 1 Mbit/

sec. The CAN protocol incorporates a data CRC check, message

error tracking and fault node confinement as means to improve

network reliability to the level required for control applications.

The CAN module architecture is based around a 16-entry

mailbox RAM. The mailbox is accessed sequentially by the CAN

serial interface or the host CPU. Each mailbox consists of eight

16-bit data words. The data is divided into fields, which includes

a message identifier, a time stamp, a byte count, up to 8 bytes of

data, and several control bits. Each node monitors the messages

being passed on the network. If the identifier in the transmitted

message matches an identifier in one of it's mailboxes, then the

module knows that the message was meant for it, passes the data

into it's appropriate mailbox, and signals the host of its arrival

with an interrupt.

The CAN network itself is a single, differential pair line. All nodes

continuously monitor this line. There is no clock wire. Messages

are passed in one of 4 standard message types or frames. Synchronization is achieved by an elaborate sync scheme performed

in each CAN receiver. Message arbitration is accomplished 1 bit

at a time. A dominant polarity is established for the network. All

nodes are allowed to start transmitting at the same time following

a frame sync pulse.

As each node transmits a bit, it checks to see if the bus is the same

state that it transmitted. If it is, it continues to transmit. If not,

then another node has transmitted a dominant bit so the first

node knows it has lost the arbitration and it stops transmitting.

The arbitration continues, bit by bit until only 1 node is left

transmitting.

The electrical characteristics of each network connection are very

stringent so the CAN interface is typically divided into 2 parts: a

controller and a transceiver. This allows a single controller to

support different drivers and CAN networks. The ADSP-21992

CAN module represents only the controller part of the interface.

This module's network I/O is a single transmit line and a single

receive line, which communicate to a line transceiver.

Analog-to-Digital Conversion System

The ADSP-21992 contains a fast, high accuracy, multiple input

analog-to-digital conversion system with simultaneous sampling

capabilities. This A/D conversion system permits the fast,

accurate conversion of analog signals needed in high performance

embedded systems. Key features of the ADC system are:

• 14-bit Pipeline (6-Stage Pipeline) Flash Analog-to-

Digital Converter.

• 8 dedicated analog inputs.

• Dual channel simultaneous sampling capability.

• Programmable ADC clock rate to maximum of

HCLKⴜ4.

• First channel ADC data valid approximately 375 ns after

CONVST (at 20 MSPS).

–8– REV. 0

ADSP-21992

• All 8 inputs converted in approximately 725 ns (at

20 MSPS).

• 2.0 V peak-to-peak input voltage range.

• Multiple convert start sources.

• Internal or external Voltage Reference.

• Out of range detection.

• DMA capable transfers from ADC to memory.

The ADC system is based on a pipeline flash converter core, and

contains dual input sample-and-hold amplifiers so that simultaneous sampling of two input signals is supported. The ADC

system provides an analog input voltage range of 2.0 Vp-p and

ⴜ

provides 14-bit performance with a clock rate of up to HCLK

The ADC system can be programmed to operate at a clock rate

⁄

that is programmable from HCLK

of 20 MHz (at 160MHz CCLK rate).

The ADC input structure supports 8 independent analog inputs;

four of which are multiplexed into one sample-and-hold amplifier

(A_SHA) and 4 of which are multiplexed into the other sampleand-hold amplifier (B_SHA).

At the 20 MHz sampling rate, the first data value is valid approximately 375 ns after the Convert Start command. All 8 channels

are converted in approximately 725 ns.

The core of the ADSP-21992 provides 14-bit data such that the

stored data values in the ADC data registers are 14 bits wide.

Voltage Reference

The ADSP-21992 contains an onboard band gap reference that

can be used to provide a precise 1.0 V output for use by the A/D

system and externally on the VREF pin for biasing and level

shifting functions. Additionally, the ADSP-21992 may be configured to operate with an external reference applied to the VREF

pin, if required.

PWM Generation Unit

Key features of the 3-phase PWM generation unit are:

• 16-bit, center based PWM generation unit

• Programmable PWM pulsewidth, with resolutions to

12.5 ns (at 80 MHz HCLK Rate)

• Single/double update modes

• Programmable dead time and switching frequency

• Twos complement implementation permits smooth tran-

sition into full ON and full OFF states

• Possibility to synchronize the PWM generation to an

external synchronization

• Special provisions for BDCM Operation (crossover and

output enable functions)

• Wide variety of special switched reluctance (SR)

operating modes

• Output polarity and clock gating control

• Dedicated asynchronous PWM shutdown signal

• Multiple shutdown sources, independently for each unit

4 to HCLK⁄30, to a maximum

4.

The ADSP-21992 integrates a flexible and programmable, 3phase PWM waveform generator that can be programmed to

generate the required switching patterns to drive a 3-phase

voltage source inverter for ac induction (ACIM) or permanent

magnet synchronous (PMSM) motor control. In addition, the

PWM block contains special functions that considerably simplify

the generation of the required PWM switching patterns for

control of the electronically commutated motor (ECM) or

brushless dc motor (BDCM). Tying a dedicated pin,

to GND, enables a special mode, for switched reluctance motors

(SRM).

The six PWM output signals consist of three high side drive pins

(AH, BH, and CH) and three low side drive signals pins (AL,

BL, and CL). The polarity of the generated PWM signals may

be set via hardware by the PWMPOL input pin, so that either

active HI or active LO PWM patterns can be produced.

The switching frequency of the generated PWM patterns is programmable using the 16-bit PWMTM register. The PWM

generator is capable of operating in two distinct modes, single

update mode or double update mode. In single update mode the

duty cycle values are programmable only once per PWM period,

so that the resultant PWM patterns are symmetrical about the

midpoint of the PWM period. In the double update mode, a

second updating of the PWM registers is implemented at the

midpoint of the PWM period. In this mode, it is possible to

produce asymmetrical PWM patterns that produce lower

harmonic distortion in 3-phase PWM inverters.

Auxiliary PWM Generation Unit

Key features of the auxiliary PWM generation unit are:

• 16-bit, programmable frequency, programmable duty

cycle PWM outputs

• Independent or offset operating modes

• Double buffered control of duty cycle and period registers

• Separate auxiliary PWM synchronization signal and asso-

ciated interrupt (can be used to trigger ADC Convert

Start).

• Separate auxiliary PWM shutdown signal (AUXTRIP).

The ADSP-21992 integrates a 2-channel, 16-bit, auxiliary PWM

output unit that can be programmed with variable frequency,

variable duty cycle values and may operate in two different

modes, independent mode or offset mode. In independent mode,

the two auxiliary PWM generators are completely independent

and separate switching frequencies and duty cycles may be programmed for each auxiliary PWM output. In offset mode the

switching frequency of the two signals on the AUX0 and AUX1

pins is identical. Bit 4 of the AUXCTRL register places the

auxiliary PWM channel pair in independent or offset mode.

The Auxiliary PWM generation unit provides two chip output

pins, AUX0 and AUX1 (on which the switching signals appear),

and one chip input pin,

down the switching signals—for example, in a fault condition.

AUXTRIP

, which can be used to shut

PWMSR

,

–9–REV. 0

ADSP-21992

Encoder Interface Unit

The ADSP-21992 incorporates a powerful encoder interface

block to incremental shaft encoders that are often used for

position feedback in high performance motion control systems.

• Quadrature rates to 53 MHz (at 80 MHz HCLK rate).

• Programmable filtering of all encoder input signals

• 32-bit encoder counter

• Variety of hardware and software reset modes

• Two registration inputs to latch EIU count value with

corresponding registration interrupt

• Status of A/B signals latched with reading of EIU count

value.

• Alternative frequency and direction mode

• Single north marker mode

• Count error monitor function with dedicated error

interrupt

• Dedicated 16-bit loop timer with dedicated interrupt

• Companion encoder event (1⁄T) timer unit.

The encoder interface unit (EIU) includes a 32-bit quadrature

up/down counter, programmable input noise filtering of the

encoder input signals and the zero markers, and has four

dedicated chip pins. The quadrature encoder signals are applied

at the EIA and EIB pins. Alternatively, a frequency and direction

set of inputs may be applied to the EIA and EIB pins. In addition,

two north marker/strobe inputs are provided on pins EIZ and

EIS. These inputs may be used to latch the contents of the

encoder quadrature counter into dedicated registers,

EIZLATCH and EISLATCH, on the occurrence of external

events at the EIZ and EIS pins. These events may be programmed

to be either rising edge only (latch event) or rising edge if the

encoder is moving in the forward direction and falling edge if the

encoder is moving in the reverse direction (software latched north

marker functionality).

The encoder interface unit incorporates programmable noise

filtering on the four encoder inputs to prevent spurious noise

pulses from adversely affecting the operation of the quadrature

counter. The encoder interface unit operates at a clock frequency

equal to the HCLK rate. The encoder interface unit operates

correctly with encoder signals at frequencies of up to 13.25 MHz,

at the 80 MHz HCLK rate, corresponding to a maximum

quadrature frequency of 53 MHz (assuming an ideal quadrature

relationship between the input EIA and EIB signals).

The EIU may be programmed to use the north marker on EIZ

to reset the quadrature encoder in hardware, if required.

Alternatively, the north marker can be ignored, and the encoder

quadrature counter is reset according to the contents of a

maximum count register, EIUMAXCNT. There is also a “single

north marker” mode available in which the encoder quadrature

counter is reset only on the first north marker pulse.

The encoder interface unit can also be made to implement some

error checking functions. If an encoder count error is detected

(due to a disconnected encoder line, for example), a status bit in

the EIUSTAT register is set, and an EIU count error interrupt is

generated.

The encoder interface unit of the ADSP-21992 contains a 16-bit

loop timer that consists of a timer register, period register and

scale register so that it can be programmed to time out and reload

at appropriate intervals. When this loop timer times out, an EIU

loop timer timeout interrupt is generated. This interrupt could

be used to control the timing of speed and position control loops

in high performance drives.

The encoder interface unit also includes a high performance

encoder event timer (EET) block that permits the accurate timing

of successive events of the encoder inputs. The EET can be programmed to time the duration between up to 255 encoder pulses

and can be used to enhance velocity estimation, particularly at

low speeds of rotation.

Flag I/O (FIO) Peripheral Unit

The FIO module is a generic parallel I/O interface that supports

sixteen bidirectional multifunction flags or general-purpose

digital I/O signals (PF15–PF0).

All sixteen FLAG bits can be individually configured as an input

or output based on the content of the direction (DIR) register,

and can also be used as an interrupt source for one of two FIO

interrupts. When configured as input, the input signal can be

programmed to set the FLAG on either a level (level sensitive

input/interrupt) or an edge (edge sensitive input/interrupt).

The FIO module can also be used to generate an asynchronous

unregistered wake-up signal FIO_WAKEUP for DSP core wake

up after power-down.

The FIO Lines, PF7–PF1 can also be configured as external slave

select outputs for the SPI communications port, while PF0 can

be configured to act as a slave select input.

The FIO Lines can be configured to act as a PWM shutdown

source for the 3-phase PWM generation unit of the

ADSP-21992.

Watchdog Timer

The ADSP-21992 integrates a watchdog timer that can be used

as a protection mechanism against unintentional software events.

It can be used to cause a complete DSP and peripheral reset in

such an event. The watchdog timer consists of a 16-bit timer that

is clocked at the external clock rate (CLKIN or crystal input

frequency).

In order to prevent an unwanted timeout or reset, it is necessary

to periodically write to the watchdog timer register. During

abnormal system operation, the watchdog count will eventually

decrement to 0 and a watchdog timeout will occur. In the system,

the watchdog timeout will cause a full reset of the DSP core and

peripherals.

–10– REV. 0

ADSP-21992

General-Purpose Timers

The ADSP-21992 contains a general-purpose timer unit that

contains three identical 32-bit timers. The three programmable

interval timers (Timer0, Timer1, and Timer2) generate periodic

interrupts. Each timer can be independently set to operate in one

of three modes:

• Pulse Waveform Generation (PWM_OUT) mode

• Pulsewidth Count/Capture (WDTH_CAP) mode

• External Event Watchdog (EXT_CLK) mode

Each Timer has one bidirectional chip pin, TMR2-TMR0. For

each timer, the associated pin is configured as an output pin in

PWM_OUT Mode and as an input pin in WDTH_CAP and

EXT_CLK Modes.

Interrupts

The interrupt controller lets the DSP respond to 17 interrupts

with minimum overhead. The DSP core implements an interrupt

priority scheme as shown in Table 2. Applications can use the

unassigned slots for software and peripheral interrupts. The

Peripheral Interrupt Controller is used to assign the various

peripheral interrupts to the 12 user assignable interrupts of the

DSP core.

Table 2. Interrupt Priorities/Addresses

IMASK/

Interrupt

Emulator (NMI)

—Highest Priority

Reset (NMI) 0 0x00 0000

Power-down (NMI) 1 0x00 0020

Loop and PC Stack 2 0x00 0040

Emulation Kernel 3 0x00 0060

User Assigned Interrupt

(USR0)

User Assigned Interrupt

(USR1)

User Assigned Interrupt

(USR2)

User Assigned Interrupt

(USR3)

User Assigned Interrupt

(USR4)

User Assigned Interrupt

(USR5)

User Assigned Interrupt

(USR6)

User Assigned Interrupt

(USR7)

User Assigned Interrupt

(USR8)

IRPTL Vector Address

NA NA

4 0x00 0080

5 0x00 00A0

6 0x00 00C0

7 0x00 00E0

8 0x00 0100

9 0x00 0120

10 0x00 0140

11 0x00 0160

12 0x00 0180

Table 2. Interrupt Priorities/Addresses

IMASK/

Interrupt

User Assigned Interrupt

(USR9)

User Assigned Interrupt

(USR10)

User Assigned Interrupt

(USR11)

—Lowest Priority

There is no assigned priority for the peripheral interrupts after

reset. To assign the peripheral interrupts a different priority,

applications write the new priority to their corresponding control

bits (determined by their ID) in the Interrupt Priority Control

register.

Interrupt routines can either be nested with higher priority interrupts taking precedence or processed sequentially. Interrupts can

be masked or unmasked with the IMASK register. Individual

interrupt requests are logically ANDed with the bits in IMASK;

the highest priority unmasked interrupt is then selected. The

emulation, power-down, and reset interrupts are nonmaskable

with the IMASK register, but software can use the DIS INT

instruction to mask the power-down interrupt.

The Interrupt Control (ICNTL) register controls interrupt

nesting and enables or disables interrupts globally.

The IRPTL register is used to force and clear interrupts. On-chip

stacks preserve the processor status and are automatically maintained during interrupt handling. To support inter rupt, loop, and

subroutine nesting, the PC stack is 33 levels deep, the loop stack

is 8 levels deep, and the status stack is 16 levels deep. To prevent

stack overflow, the PC stack can generate a stack level interrupt

if the PC stack falls below 3 locations full or rises above 28

locations full.

The following instructions globally enable or disable interrupt

servicing, regardless of the state of IMASK.

ENA INT;

DIS INT;

At reset, interrupt servicing is disabled.

For quick servicing of interrupts, a secondary set of DAG and

computational registers exist. Switching between the primary

and secondary registers lets programs quickly service interrupts,

while preserving the state of the DSP.

Peripheral Interrupt Controller

The Peripheral Interrupt Controller is a dedicated peripheral unit

of the ADSP-21992 (accessed via IO mapped registers). The

peripheral interrupt controller manages the connection of up to

32 peripheral interrupt requests to the DSP core.

For each peripheral interrupt source, there is a unique 4-bit code

that allows the user to assign the particular peripheral interrupt

to any one of the 12 user assignable interrupts of the embedded

ADSP-219x core. Therefore, the peripheral interrupt controller

IRPTL Vector Address

13 0x00 01A0

14 0x00 01C0

15 0x00 01E0

–11–REV. 0

ADSP-21992

of the ADSP-21992 contains eight, 16-bit Interrupt Priority

Registers (Interrupt Priority Register 0 (IPR0) to Interrupt

Priority Register 7 (IPR7)).

Each Interrupt Priority Register contains a four 4-bit codes; one

specifically assigned to each peripheral interrupt. The user may

write a value between 0x0 and 0xB to each 4-bit location in order

to effectively connect the particular interrupt source to the corresponding user assignable interrupt of the ADSP-219x core.

Writing a value of 0x0 connects the peripheral interrupt to the

USR0 user assignable interrupt of the ADSP-219x core while

writing a value of 0xB connects the peripheral interrupt to the

USR11 user assignable interrupt. The core interrupt USR0 is the

highest priority user interr upt, while USR11 is the lowest priority.

Writing a value between 0xC and 0xF effectively disables the

peripheral interrupt by not connecting it to any ADSP-219x core

interrupt input. The user may assign more than one peripheral

interrupt to any given ADSP-219x core interrupt. In that case,

the burden is on the user software in the interrupt vector table to

determine the exact interrupt source through reading status bits.

This scheme permits the user to assign the number of specific

interrupts that are unique to their application to the interrupt

scheme of the ADSP-219x core. The user can then use the

existing interrupt priority control scheme to dynamically control

the priorities of the 12 core interrupts.

Low Power Operation

The ADSP-21992 has four low power options that significantly

reduce the power dissipation when the device operates under

standby conditions. To enter any of these modes, the DSP

executes an IDLE instruction. The ADSP-21992 uses the configuration of the PD, STCK, and STALL bits in the PLLCTL

register to select between the low power modes as the DSP

executes the IDLE instruction. Depending on the mode, an

IDLE shuts off clocks to different parts of the DSP in the different

modes. The low power modes are:

• Idle

• Power-Down Core

• Power-Down Core/Peripherals

• Power-Down All

Idle Mode

When the ADSP-21992 is in Idle mode, the DSP core stops

executing instructions, retains the contents of the instruction

pipeline, and waits for an interrupt. The core clock and peripheral

clock continue running.

To enter Idle mode, the DSP can execute the IDLE instruction

anywhere in code. To exit Idle mode, the DSP responds to an

interrupt and (after two cycles of latency) resumes executing

instructions.

Power-Down Core Mode

When the ADSP-21992 is in Power-Down Core mode, the DSP

core clock is off, but the DSP retains the contents of the pipeline

and keeps the PLL running. The peripheral bus keeps running,

letting the peripherals receive data.

To exit Power-Down Core mode, the DSP responds to an

interrupt and (after two cycles of latency) resumes executing

instructions.

Power-Down Core/Peripherals Mode

When the ADSP-21992 is in Power-Down Core/Peripherals

mode, the DSP core clock and peripheral bus clock are off, but

the DSP keeps the PLL running. The DSP does not retain the

contents of the instruction pipeline. The peripheral bus is

stopped, so the peripherals cannot receive data.

To exit Power-Down Core/Peripherals mode, the DSP responds

to an interrupt and (after five to six cycles of latency) resumes

executing instructions.

Power-Down All Mode

When the ADSP-21992 is in Power-Down All mode, the DSP

core clock, the peripheral clock, and the PLL are all stopped. The

DSP does not retain the contents of the instruction pipeline. The

peripheral bus is stopped, so the peripherals cannot receive data.

To exit Power-Down Core/Peripherals mode, the DSP responds

to an interrupt and (after 500 cycles to re-stabilize the PLL)

resumes executing instructions.

Clock Signals

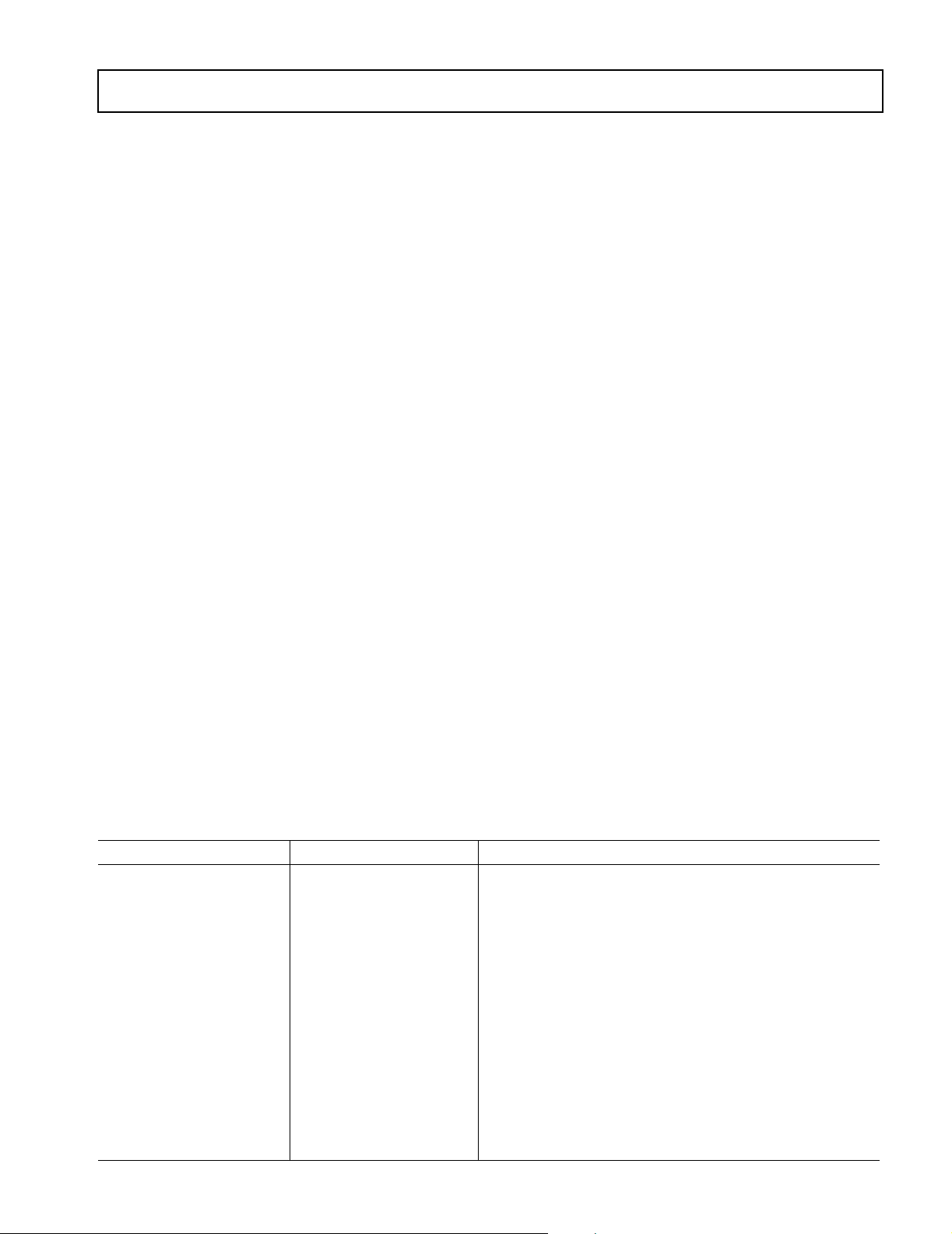

The ADSP-21992 can be clocked by a crystal oscillator or a

buffered, shaped clock derived from an external clock oscillator.

If a crystal oscillator is used, the crystal should be connected

across the CLKIN and XTAL pins, with two capacitors

connected as shown in Figure 5. Capacitor values are dependent

on crystal type and should be specified by the crystal manufacturer. A parallel resonant, fundamental frequency,

microprocessor grade crystal should be used for this

configuration.

If a buffered, shaped clock is used, this external clock connects

to the DSP CLKIN pin. CLKIN input cannot be halted,

changed, or operated below the specified frequency during

normal operation. This clock signal should be a TTL compatible

signal. When an external clock is used, the XTAL input must be

left unconnected.

ⴛ

The DSP provides a user programmable 1

tion of the input clock, including some fractional values, to

support 128 external to internal (DSP core) clock ratios. The

BYPASS pin, and MSEL6–0 and DF bits, in the PLL configuration register, decide the PLL multiplication factor at reset. At

run time, the multiplication factor can be controlled in software.

To support input clocks greater that 100 MHz, the PLL uses an

additional bit (DF). If the input clock is greater than 100 MHz,

DF must be set. If the input clock is less than 100 MHz, DF must

be cleared. For clock multiplier settings, see the

DSP Hardware Reference Manual

The peripheral clock is supplied to the CLKOUT pin.

All on-chip peripherals for the ADSP-21992 operate at the rate

set by the peripheral clock. The peripheral clock (HCLK) is

either equal to the core clock rate or one half the DSP core clock

rate (CCLK). This selection is controlled by the IOSEL bit in

the PLLCTL register. The maximum core clock is 160 MHz for

the ADSP-21992BST, 150 MHz for both the ADSP-21992BBC

.

to 32ⴛ multiplica-

ADSP-2199x

–12– REV. 0

ADSP-21992

and ADSP-21992YBC and 100 MHz for the ADSP-21992YST.

The maximum peripheral clock is 80 MHz for the ADSP21992BST, 75 MHz for both the ADSP-21992BBC and ADSP21992YBC and 50 MHz for the ADSP-21992YST—the combination of the input clock and core/peripheral clock ratios may not

exceed these limits.

CLKIN

Figure 5. External Crystal Connections

Reset and Power-On Reset (POR)

The

RESET

pin initiates a complete hardware reset of the ADSP-

21992 when pulled low. The

XTAL

ADSP-2199x

RESET

signal must be asserted

when the device is powered up to assure proper initialization. The

ADSP-21992 contains an integrated power-on reset (POR)

POR

circuit that provides an output reset signal,

, from the ADSP21992 on power-up and if the power supply voltage falls below

the threshold level. The ADSP-21992 may be reset from an

external source using the

RESET

signal, or alternatively, the

internal power-on reset circuit may be used by connecting the

POR

pin to the

RESET

pin. During power-up the

RESET

line

must be activated for long enough to allow the DSP core’s internal

clock to stabilize. The power-up sequence is defined as the total

time required for the crystal oscillator to stabilize after a valid

VDD is applied to the processor and for the internal phase-locked

loop (PLL) to lock onto the specific crystal frequency. A

minimum of 512 cycles will ensure that the PLL has locked (this

does not include the crystal oscillator start-up time).

RESET

The

used to generate the

input contains some hysteresis. If an RC circuit is

RESET

signal, the circuit should use an

external Schmitt trigger.

The master reset sets all internal stack pointers to the empty stack

condition, masks all interrupts, and resets all registers to their

RESET

default values (where applicable). When

is released, if

there is no pending bus request, program control jumps to the

location of the on-chip boot ROM (0xFF0000) and the booting

sequence is performed.

Power Supplies

The ADSP-21992 has separate power supply connections for the

internal (V

) and external (V

DDINT

) power supplies. The

DDEXT

internal supply must meet the 2.5 V requirement. The external

supply must be connected to a 3.3 V supply. All external supply

pins must be connected to the same supply. The ideal power-on

sequence for the DSP is to provide power-up of all supplies simultaneously. If there is going to be some delay in power-up between

the supplies, provide V

Booting Modes

first, then V

DD

DD_IO

.

The ADSP-21992 supports a number of different boot modes

that are controlled by the three dedicated hardware boot mode

control pins (BMODE2, BMODE1, and BMODE0). The use

of three boot mode control pins means that up to eight different

boot modes are possible. Of these only five modes are valid on

the ADSP-21992. The ADSP-21992 exposes the boot

mechanism to software control by providing a nonmaskable boot

interrupt that vectors to the start of the on-chip ROM memory

block (at address 0xFF0000). A boot interrupt is automatically

initiated following either a hardware initiated reset, via the

RESET

pin, or a software initiated reset, via writing to the

Software Reset register. Following either a hardware or a software

reset, execution always starts from the boot ROM at address

0xFF0000, irrespective of the settings of the BMODE2,

BMODE1, and BMODE0 pins. The dedicated BMODE2,

BMODE1, and BMODE0 pins are sampled at hardware reset.

The particular boot mode for the ADSP-21992 associated with

the settings of the BMODE2, BMODE1, BMODE0 pins is

defined in Table 3.

Table 3. Summary of Boot Modes

Boot Mode BMODE2 BMODE1 BMODE0 Function

0 0 0 0 Illegal – Reserved

1 0 0 1 Boot from External 8-bit Memory over EMI

2 0 1 0 Execute from External 8-bit Memory

3 0 1 1 Execute from External 16-bit Memory

4100Boot from SPI ≤ 4K bits

5101Boot from SPI > 4K bits

6 1 1 0 Illegal – Reserved

7 1 1 1 Illegal – Reserved

–13–REV. 0

ADSP-21992

Instruction Set Description

The ADSP-21992 assembly language instruction set has an

algebraic syntax that was designed for ease of coding and readability. The assembly language, which takes full advantage of the

unique architecture of the processor, offers the following benefits:

• ADSP-219x assembly language syntax is a superset of and

source code compatible (except for two data registers and

DAG base address registers) with ADSP-21xx family

syntax. It may be necessary to restructure ADSP-21xx

programs to accommodate the unified memory space of

the ADSP-21992 and to conform to its interrupt vector

map.

• The algebraic syntax eliminates the need to remember

cryptic assembler mnemonics. For example, a typical

arithmetic add instruction, such as AR = AX0 + AY0,

resembles a simple equation.

• Every instruction, but two, assembles into a single, 24-bit

word that can execute in a single instruction cycle. The

exceptions are two dual word instructions. One writes 16or 24-bit immediate data to memory, and the other is an

absolute jump/call with the 24-bit address specified in the

instruction.

• Multifunction instructions allow parallel execution of an

arithmetic, MAC, or shift instruction with up to two

fetches or one write to processor memory space during a

single instruction cycle.

• Program flow instructions support a wider variety of con-

ditional and unconditional jumps/calls and a larger set of

conditions on which to base execution of conditional

instructions.

Development Tools

The ADSP-21992 is supported with a complete set of

CROSSCORE™ software and hardware development tools,

including Analog Devices emulators and VisualDSP++™ development environment. The emulator hardware that supports

other ADSP-219x DSPs also fully emulates the ADSP-21992.

The VisualDSP++ project management environment lets programmers develop and debug an application. This environment

includes an easy to use assembler (which is based on an algebraic

syntax), an archiver (librarian/library builder), a linker, a loader,

a cycle-accurate instruction-level simulator, a C/C++ compiler,

and a C/C++ run-time library that includes DSP and mathematical functions. A key point for these tools is C/C++ code

efficiency. The compiler has been developed for efficient translation of C/C++ code to DSP assembly. The DSP has architectural

features that improve the efficiency of compiled C/C++ code.

The VisualDSP++ debugger has a number of important features.

Data visualization is enhanced by a plotting package that offers

a significant level of flexibility. This graphical representation of

user data enables the programmer to quickly determine the performance of an algorithm. As algorithms grow in complexity, this

capability can have a significant influence on the design development schedule by increasing productivity. Statistical profiling

enables the programmer to non intrusively poll the processor as

it is running the program. This feature, unique to VisualDSP++,

enables the software developer to passively gather important code

execution metrics without interrupting the realtime characteristics of the program. Essentially, the developer can identify

bottlenecks in software quickly and efficiently. By using the

profiler, the programmer can focus on those areas in the program

that impact performance and take corrective action.

Debugging both C/C++ and assembly programs with the

VisualDSP++ debugger, programmers can:

• View mixed C/C++ and assembly code (interleaved

source and object information)

• Insert breakpoints

• Set conditional breakpoints on registers, memory,

and stacks

• Trace instruction execution

• Perform linear or statistical profiling of program

execution

• Fill, dump, and graphically plot the contents of memory

• Perform source level debugging

• Create custom debugger windows

The VisualDSP++ IDDE lets programmers define and manage

DSP software development. Its dialog boxes and property pages

let programmers configure and manage all of the ADSP-219x

development tools, including the color syntax highlighting in the

VisualDSP++ editor. This capability permits programmers to:

• Control how the development tools process inputs and

generate outputs

• Maintain a one-to-one correspondence with the

command line switches of the tool

The VisualDSP++ Kernel (VDK) incorporates scheduling and

resource management tailored specifically to address the memory

and timing constraints of DSP programming. These capabilities

enable engineers to develop code more effectively, eliminating the

need to start from the very beginning, when developing new

application code. The VDK features include Threads, Critical

and Unscheduled regions, Semaphores, Events, and Device flags.

The VDK also supports Priority-based, Preemptive, Cooperative, and Time-Sliced scheduling approaches. In addition, the

VDK was designed to be scalable. If the application does not use

a specific feature, the support code for that feature is excluded

from the target system.

Because the VDK is a library, a developer can decide whether to

use it or not. The VDK is integrated into the VisualDSP++ development environment, but can also be used via standard

command line tools. When the VDK is used, the development

environment assists the developer with many error-prone tasks

and assists in managing system resources, automating the generation of various VDK based objects, and visualizing the system

state, when debugging an application that uses the VDK.

VCSE is Analog Devices technology for creating, using, and

reusing software components (independent modules of substantial functionality) to quickly and reliably assemble software

applications. Download components from the Web and drop

–14– REV. 0

ADSP-21992

them into the application. Publish component archives from

within VisualDSP++. VCSE supports component implementation in C/C++ or assembly language.

Use the Expert Linker to visually manipulate the placement of

code and data on the embedded system. View memory utilization

in a color-coded graphical form, easily move code and data to

different areas of the DSP or external memory with the drag of

the mouse, examine run-time stack and heap usage. The Expert

Linker is fully compatible with existing Linker Definition File

(LDF), allowing the developer to move between the graphical

and textual environments.

Analog Devices DSP emulators use the IEEE 1149.1 JTAG Test

Access Port of the ADSP-21992 processor to monitor and control

the target board processor during emulation. The emulator

provides full speed emulation, allowing inspection and modification of memory, registers, and processor stacks. Non intrusive incircuit emulation is assured by the use of the processor JTAG

interface—target system loading and timing are not affected by

the emulator.

In addition to the software and hardware development tools

available from Analog Devices, third parties provide a wide range

of tools supporting the ADSP-219x processor family. Hardware

tools include ADSP-219x DSP PC plug-in cards. Third party

software tools include DSP libraries, real-time operating systems,

and block diagram design tools.

Designing an Emulator-Compatible DSP Board

The Analog Devices family of emulators are tools that every DSP

developer needs to test and debug hardware and software

systems. Analog Devices has supplied an IEEE 1149.1 JTAG Tes t

Access Port (TAP) on each JTAG DSP. The emulator uses the

TAP to access the internal features of the DSP, allowing the

developer to load code, set breakpoints, observe variables,

observe memory, and examine registers. The DSP must be halted

to send data and commands, but once an operation has been

completed by the emulator, the DSP system is set running at full

speed with no impact on system timing.

To use these emulators, the target board must include a header

that connects the DSP JTAG port to the emulator.

For details on target board design issues including mechanical